Page 1

K51A

A-PDF MERGER DEMO

MAR/01

TV

Basic Service Data

General Information/Safety Precautions ......................................................................... 1-2

Disassembly ................................................................................................................... 2-1

Alignments ...................................................................................................................... 3-1

Troubleshooting Guides ................................................................................................. 4-1

Trouble Aids (Waveforms, Voltage, Timing Charts) ...................................................... 5-1

Replacement Partslist ..................................................................................................... 6-1

Exploded Views .............................................................................................................. 7-1

Block Diagrams ............................................................................................................... 8-1

Schematic Diagrams ........................................................................................................ 9-1

Circuit Boards ................................................................................................................. 10-1

K51A

Latin America After Sales

Indianapolis, IN 46290 U.S.A.

SERVICE DATA INDEX

Page

Number

CAUTION: Modification or repair of this unit by unauthorized persons is a direct violation of FCC Rules Part 68.216 and could

result in risk of electric shock. You are urged to contact a qualified factory authorized service facility for repairs.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a ( ) on schematics and on the parts list in this Service Data and its bulletins.

Before servicing this instrument, it is important that the service technician read and follow the "Safety Precautions" in the Basic Service Data.

First Edition - First Printing

Copyright 2001 - Thomson Multimedia, Inc.

Printed in U.S.A. - Trademark(s)

®

Registered - Marca(s) Registrada(s)

K51A

Page 2

Alignment and Adjustments

3-1

3. Alignment and Adjustments

3-1 Preadjustment

1. Since there are no VRs in the K51A chassis, all

adjustments after parts replacement must be

done in the Service Mode.

2. The Factory Mode adjustments are necessary

when either the EEPROM (IC902) or the CRT

is replaced.

3. Do not tamper with the Ò AdjustmentÓ screen

of the Factory Mode menu. This screen is

intended only for factory use.

4. WHEN EEPROM (IC902) IS REPLACED

(1) When IC902 is replaced, all adjustment data

revert to their initial values. It is necessary to

re-program this data.

(2) After IC902 is replaced, warm up the TV for

10 seconds.

Make the following adjustments AFTER

setting up purity and convergence:

White Balance

Sub-Brightness

Vertical Center

Vertical Size

Horizontal Size (No use in 21Ó and 25Ó

models)

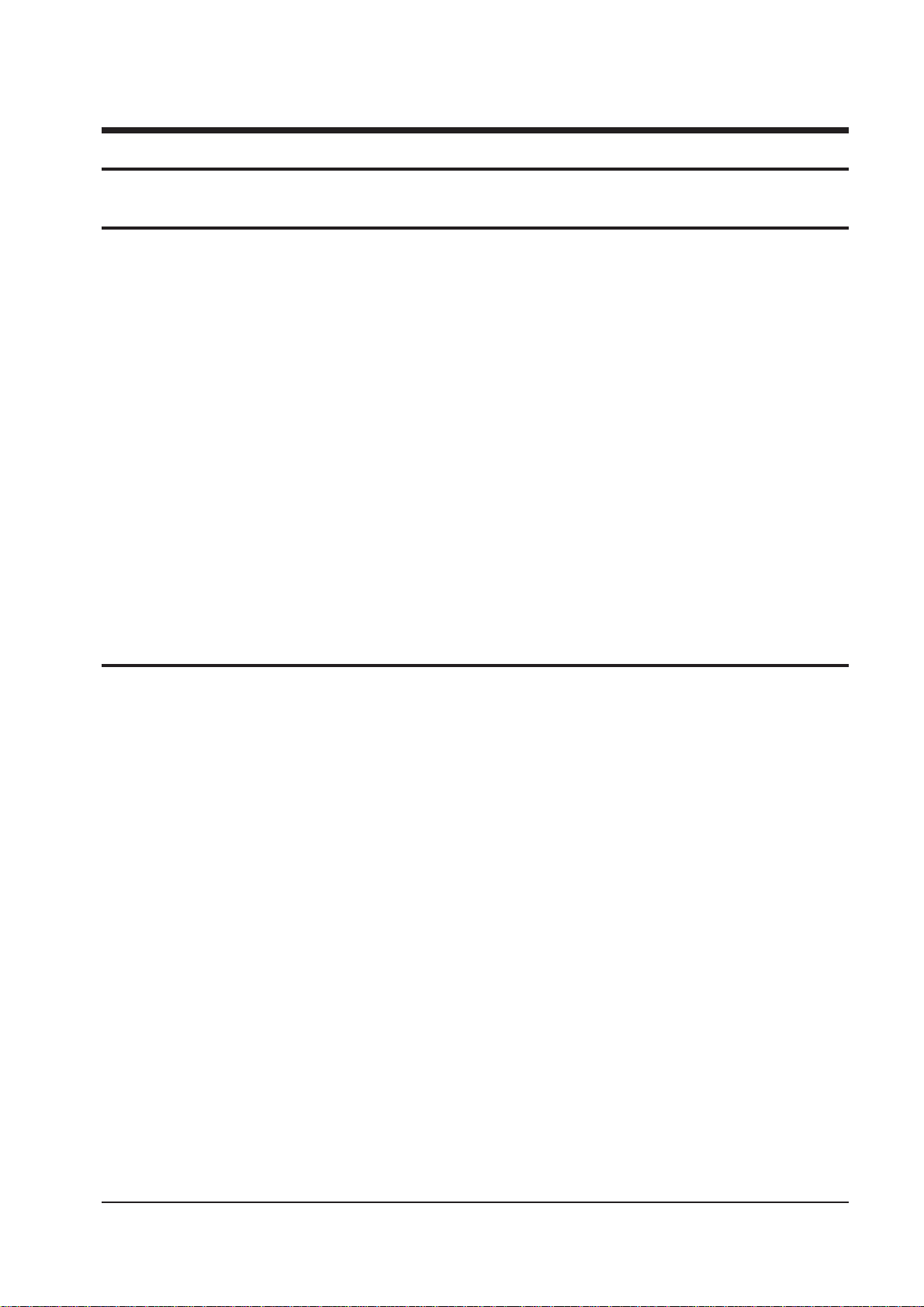

3-2 Factory (“SERVICE”) Mode

1. The set must be in Factory (ÒServiceÓ) Mode.

Selection sequence:

STAND-BY ® MUTE ® 1 ®8 ® 2 ® POWER ON

2. The Ò FACTORY MODEÓ message will be displayed. The Factory Mode

has four components : Adjustment, MPX, PIP, Option Byte and Factory

Reset.

3. Access the Adjustment Mode by pressing the ÒVOLUMEÓ keys ( , )

The adjustment parameters are listed in the accompanying table.

Select them by pressing the CHANNEL keys (▲,▼).

4. After completing the Factory Mode adjustments, turn the power switch

OFF.

▼

▼

Page 3

VSLN 30

VSN 32

VAN 32

HSN 45

EWAN 45

EWPN 33

EWCN 32

EWTN 38

*SERVICE*

¯

Press VOL

Press CH

Press VOL or

SBT 3

POWER OFF

Adjustment

MTS

PIP

Option

Reset

▼

AGC 15

VCO 62

SBT 7

SCT 11

SCR 8

STT 8

RG 32

GG 32

BG 32

SCO 20

PLA 5

¯

▼

¯

¯

▼

▼

VSLP 30

VSP 32

VAP 32

HSP 39

EWAP 46

EWPP 33

EWCP 32

EWPT 38

VSLN 30

VSN 32

VAN 32

HSN 45

EWAN 45

EWPN 33

EWCN 32

EWTN 38

AGC 15

VCO 62

SBT 7

SCT 11

SCR 8

STT 8

RG 32

GG 32

BG 32

SCO 20

PLA 5

VSLP 30

VSP 32

VAP 32

HSP 39

EWAP 46

EWPP 33

EWCP 32

EWPT 38

3-2-1 Adjustment

1. Selection sequence :

STAND-BY ® MUTE ® 1 ® 8 ® 2 ® POWER ON

2. Example : Sub-bright Adjustment

Alignment and Adjustments

3-2

SZM368ET2 (R4127)

Page 4

Alignment and Adjustments

3-3

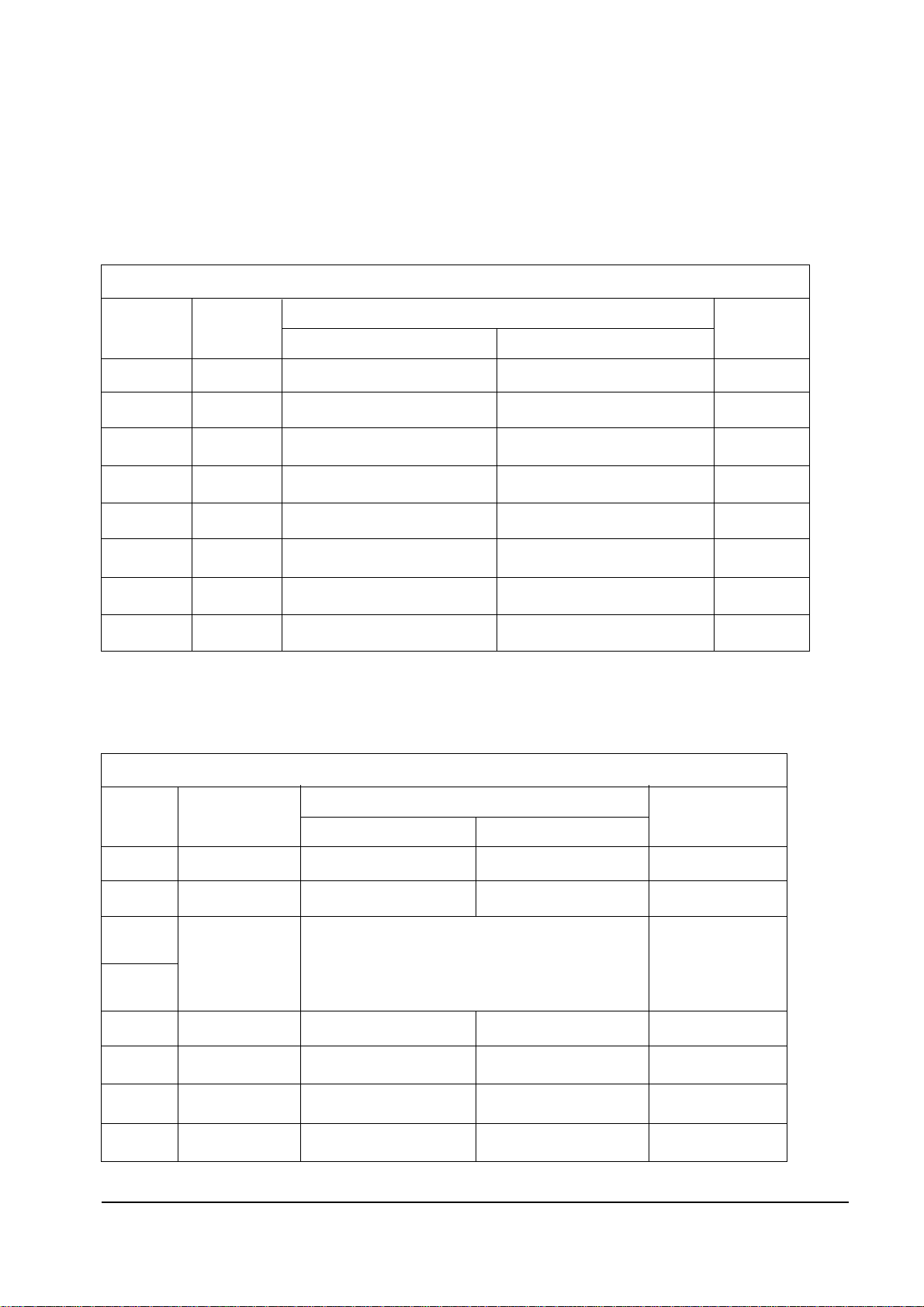

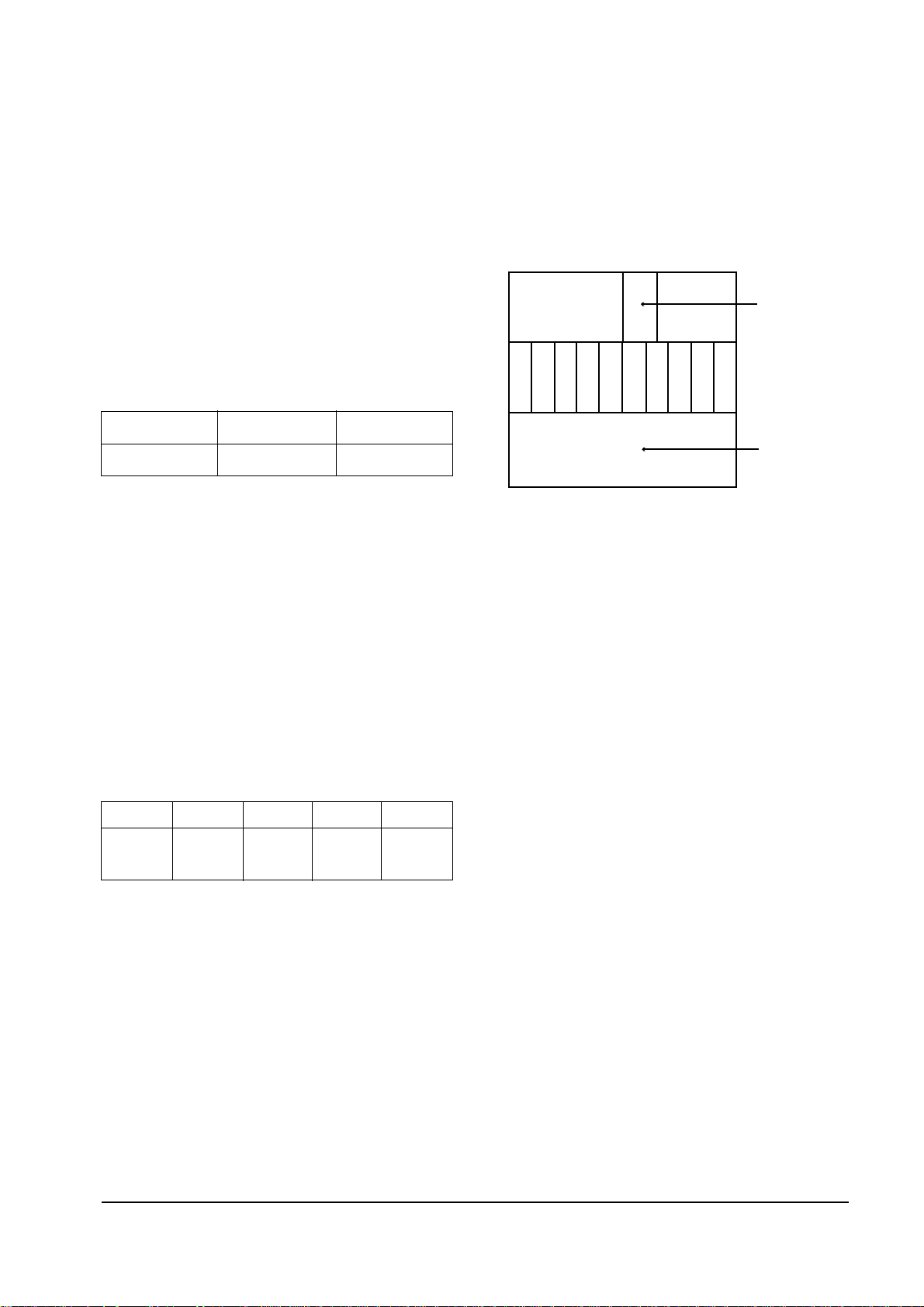

MEMORY SPECIFICATION

Table 3 - 1 Memory Specification

FUNCTION

A

D

J

U

S

T

M

E

N

T

OP

M

P

X

MODE

(OSD)

AGC

VCO

SBT

SCT

SCR

STT

RG

GG

BG

SCO

VSL

VS

VA

HS

EWA

EWP

EWC

EWT

PLA

SEP

TK2999ST

8

63

2

7

0

4

32

32

32

14

23

32

27

41

32

36

32

32

0

OFF

CD

50

13

46

32

290

300

40

290

300

1.4

2.4V

CR29805

8

63

2

7

0

4

32

32

32

14

23

32

27

41

32

36

32

32

0

OFF

8D

00

13

46

32

275

295

40

275

295

1.4

2.4V

UR29805

8

63

2

7

0

4

32

32

32

14

23

32

27

41

32

36

32

32

0

OFF

CD

50

13

46

32

290

300

40

290

283

300

2.4V

UR25805

8

63

2

7

0

4

32

32

32

14

23

32

27

41

32

36

32

32

0

OFF

CD

50

13

46

32

290

300

40

290

283

300

2.4V

RANGE

63

127

15

13

13

13

63

63

63

63

63

63

63

63

63

63

63

63

10

31

FF

FF

15

63

63

x

y

Y ± 5

x

y

Y ± 0.2

TK2599ST

8

63

2

7

0

4

32

32

32

14

23

32

27

41

32

36

32

32

0

OFF

C5

50

13

46

32

290

300

40

290

300

1.4

2.4V

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

BYTE 0

BYTE 1

ATT

SPECTRAL

WIDEBAND

HIGH - LIGHT

LOW - LIGHT

WHITE

BALANCE

ADJUSTMENT

MEASURING PULS ADJUSTMENT VOLTAGE

Page 5

VIDEO MUTE

AUDIO MUTE

NO ATS

NO V - CHIP

NO VIDEO MUTE

NO AUDIO MUTE

ATS

V-CHIP

USA

PAL M/N

Alignment and Adjustments

3-4

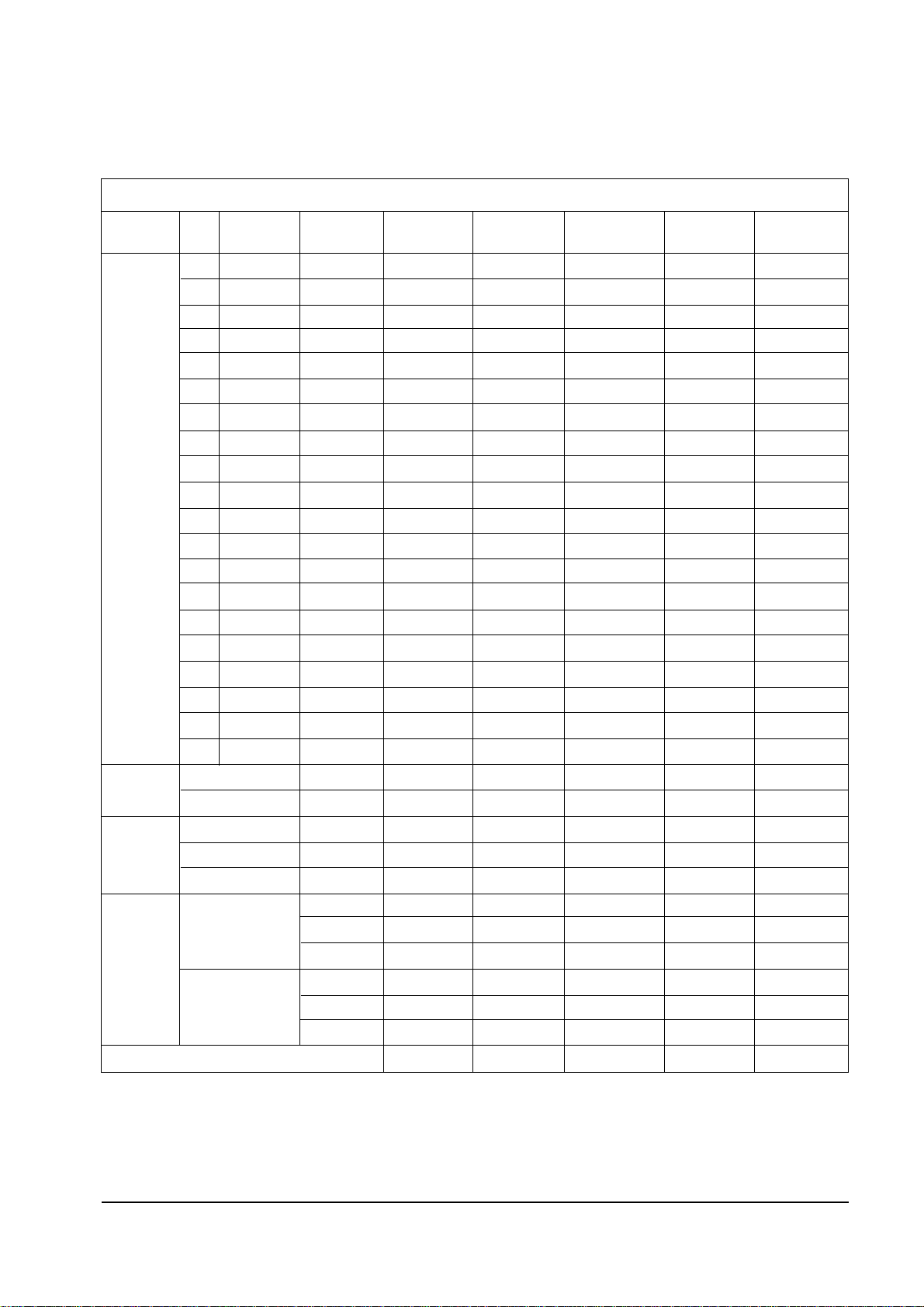

3-2-2 Option Table

NOTE : The Option Adjustment must be done in the Service Mode.

3-2-2 (A) OPTION BYTE 00

Table 3-2 Option Byte 00

NAME

V-SYNC

AUTO ON

PIP

CATV

S-VIDEO

TONE

CRT

MPX

NOT USED

NOT USED

NO PIP FUNCTION

AIR/STD/HRC/IRC

NOT USED

NO TONE CONTROL

4 : 3 CRT

NOT USED

USED ( NO V-SYNC, POWER OFF)

USED

PIP FUNCTION

AIR/STD/HRC/AFN

USED

TONE CONTROL

12.8 : 9 CRT

USED

REMARK

ARMY : 1

3-2-2 (B) OPTION BYTE 01

BYTE : 00

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

01

Table 3-3 Option Byte 01

NAME

AREA

LANGUAGE

NO VIDEO MUTE

NO AUDIO MUTE

ATS

V-CHIP

REMARK

SYSTEM/LANGUAGE

PAL

PAL

NT

NT

BYTE : 01

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

01

00 : ENGLISH

01 : SPANISH (SEDA)

02 : PORTUGUESE

11 : NOT USED

Page 6

Alignment and Adjustments

3-5

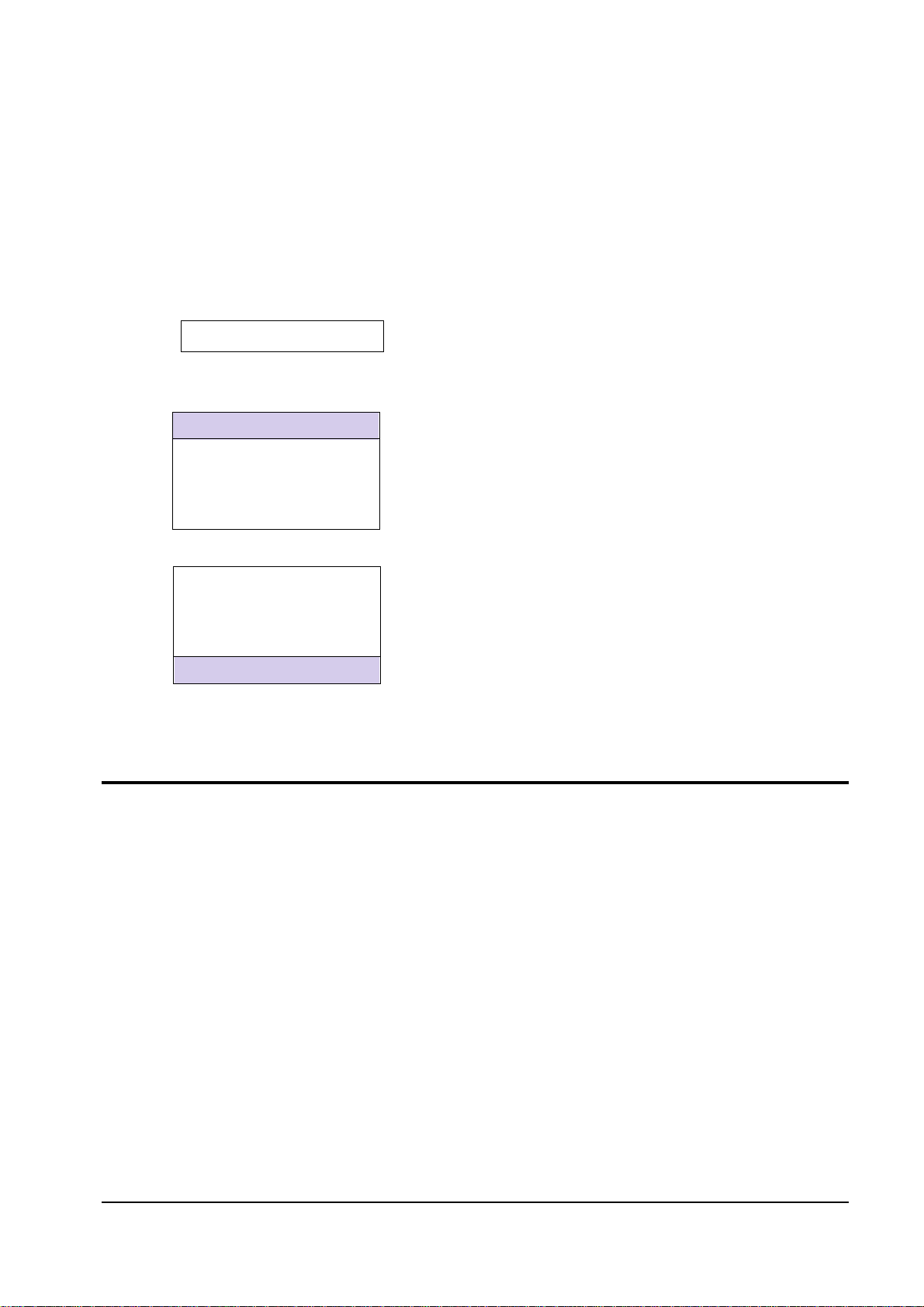

3-2-4 Factory Reset

When Ò Factory ResetÓ is selected, the User-Control data reverts to the initial values.

The User-Control data is available at MENU (picture, sound and the other functions).

Note : When Ò Factory ResetÓ is selected, the Factory Mode Data does not change.

Selection sequence :

Stand-By ® MUTE ® 1 ® 8 ® 2 ® POWER ON

* SERVICE *

Press VOL

Execute

Press CH

¯

▼

¯

▼

¯

Adjustment

MTS

PIP

Option

Reset

Adjustment

MTS

PIP

Option

Reset

3-3 Other Adjustments

3-3-1 General

1. Usually, a color TV needs only slight touch-up

adjustment upon installation. Check the basic

characteristics such as height, horizontal and

vertical sync and focus.

2. Observe the picture for good black and white

details. There should be no objectionable

color shading. If color shading is present,

perform the purity and convergence

adjustments described below.

3. Use the specified test equipment or its

equivalent.

4. Correct impedance matching is essential.

5. Avoid overload. Excessive signal from a

sweep generator might overload the front-end

of the TV. When inserting signal markers, do

not allow the marker generator to distort test

results.

6. Connect the TV only to an AC power source

with voltage and frequency as specified on the

backcover nameplate.

7. Do not attempt to connect or disconnect any

wires while the TV is turned on. Make sure

that the power cord is disconnected before

replacing any parts.

8. To protect against shock hazard, use an

isolation transformer.

SZM368ET2 (R4127)

Page 7

Alignment and Adjustments

3-6

3-3-2 Automatic Degaussing

A degaussing coil is mounted around the

picture tube, so external degaussing after

moving the TV should be unnecessary.

However, the receiver must be properly

degaussed upon installation.

The degaussing coil operates for about 1

second after the power is switched ON. If the

set has been moved or turned in a different

direction, disconnect its AC power for at least

10 Minutes.

If the chassis or parts of the cabinet become

magnetized, poor color purity will result. If

this happens, use an external degaussing coil.

Slowly move the degaussing coil around the

faceplate of the picture tube and the sides and

front of the receiver. Slowly withdraw the coil

to a distance of about 6 feet before removing

power.

3-3-3 High Voltage Check

CAUTION : There is no high voltage

adjustment on this chassis. The B+ power

supply must be set to either +135V or +125V

(for 20Ó screen). Conditions : Full color bar

input and normal picture level.

1. Connect a digital voltmeter to the second

anode of the picture tube.

2. Turn on the TV. Set the Brightness and

Contrast controls to minimum (zero beam

current).

3. The high voltage must not exceed 29.5KV.

4. Adjust the Brightness and Contrast controls to

both extremes. Ensure that the high voltage

does not exceed 29.5KV under any conditions.

3-3-4 FOCUS Adjustment

1. Input a black and white signal.

2. Adjust the tuning control for the clearest

picture.

3. Adjust the FOCUS control for well defined

scanning lines in the center area of the screen.

3-3-5 B+Line Check

There are 3 power modes :

1. ÒAÓ : When AC power supply is connected ;

Ò Stand-ByÓ mode.

2. ÒBÓ : When Ò Set Power-ONÓ button is

pressed.

3. ÒCÓ : Driven by FBT.

Each voltage is marked on its lead-in wire.

( )

25”

29.5KV

29”

29.5KV

SIZE

MAX

H-VOLTAGE

Page 8

Alignment and Adjustments

3-7

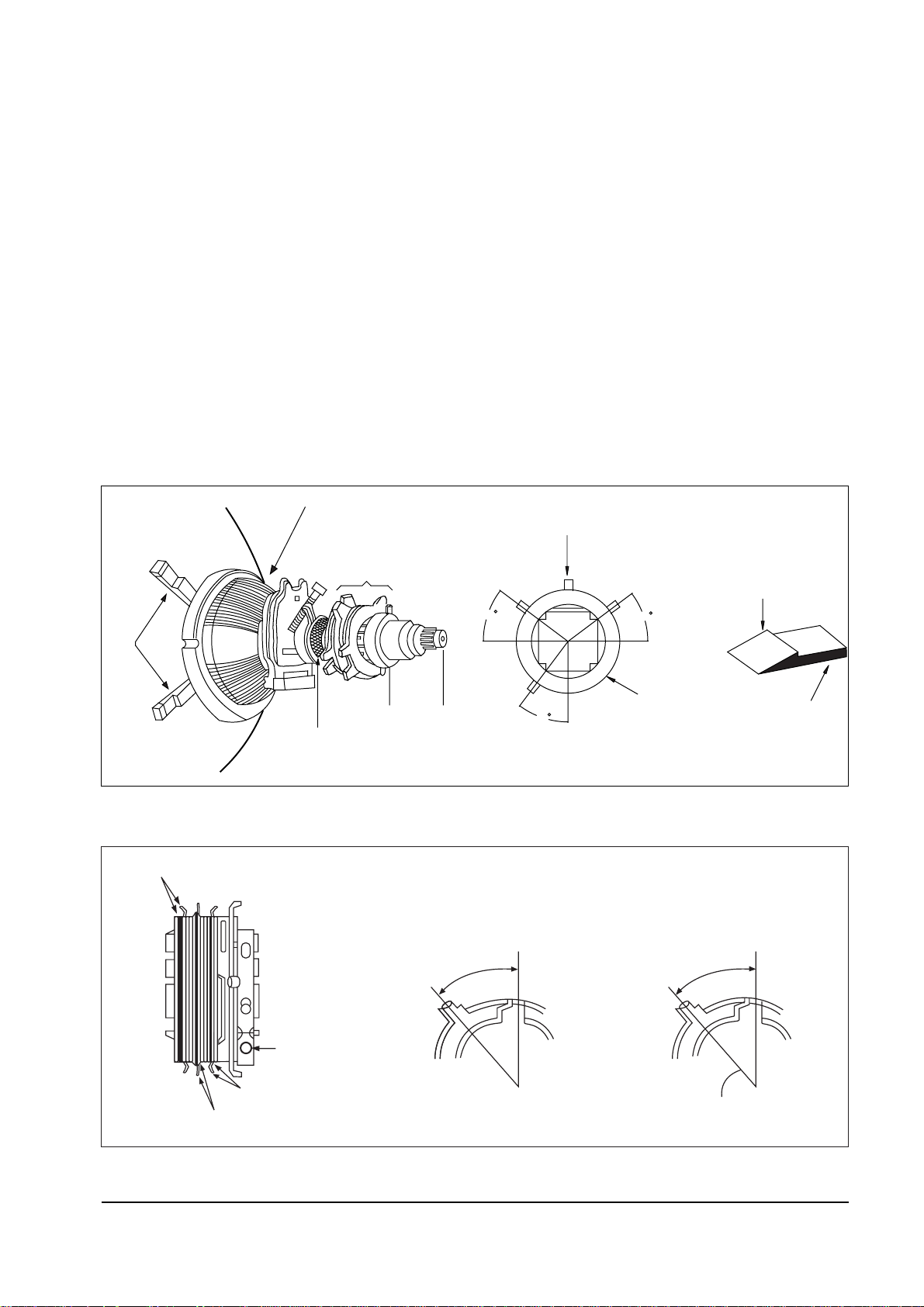

3-3-7 Color Purity Adjustment

1. Warm up the receiver. Operate it for 20

minutes, with the Brightness control set to

maximum.

2. Fully degauss the receiver. Use an external

degaussing coil.

3. Roughly adjust convergence by rotating the

Convergence Magnet.

4. Input a black and white signal.

5. Loosen the Deflection Yoke clamp screw, and

move the Deflection Yoke as close to the

purity magnet as possible.

6. Loosen the Purity Magnet clamp. Adjust the

purity magnet so that the vertical green raster

is precisely at the center of the screen. Then

tighten the clamp.

7. Slowly move the Deflection Yoke forward, and

adjust it for the best overall green screen.

8. Tighten the Deflection Yoke clamp screw.

Fig. 3-1 Tube Assembly

RUBBER WEDGES

30

30

LOCATION

DEFLECTION

YOKE

30

RUBBER WEDGE

ADHESIVE

RUBBER

WEDGES

KIT

RUBBER

WEDGES

PURITY AND

CONVERGENCE

MAGNET ASS'Y

CRT

DEFLECTION

YOKE

TAPE

CLOTH

GRASS

(1-3/16")

31 mm

Fig. 3-2 Purity and Convergence Magnets

2 POLE

PURITY

YOKE

CLAMP

SCREW

6 POLE

CONVERGENCE

4 POLE

CONVERGENCE

ADJUST THE ANGLE

(VERTICAL LINES)

FIXED

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

Page 9

Alignment and Adjustments

3-8

3-3-8 Center Convergence Adjustment

Note: Before attempting any convergence

adjustment, make sure that the receiver has

been powered ON for at least twenty minutes.

1. Input a crosshatch pattern from a color bar

generator.

2. Adjust the Brightness and Contrast controls

for a well defined pattern.

3. Adjust the two tabs of the 5-pole magnets.

Change the angle between the tabs, and

superimpose red and blue vertical lines in the

center area of the picture screen.

4. Next, turn both tabs at the same time. Keep

the angle between the tabs constant, and

superimpose the red and blue horizontal lines

at the center of the screen.

5. Adjust the two tabs of the 6-pole magnets.

Superimpose the red/blue lines on the green.

Adjusting the angle affects the horizontal

lines.

6. Repeat adjustments 3, 4 and 5. The dot

movement is complex because the 4-pole and

6-pole magnets interact.

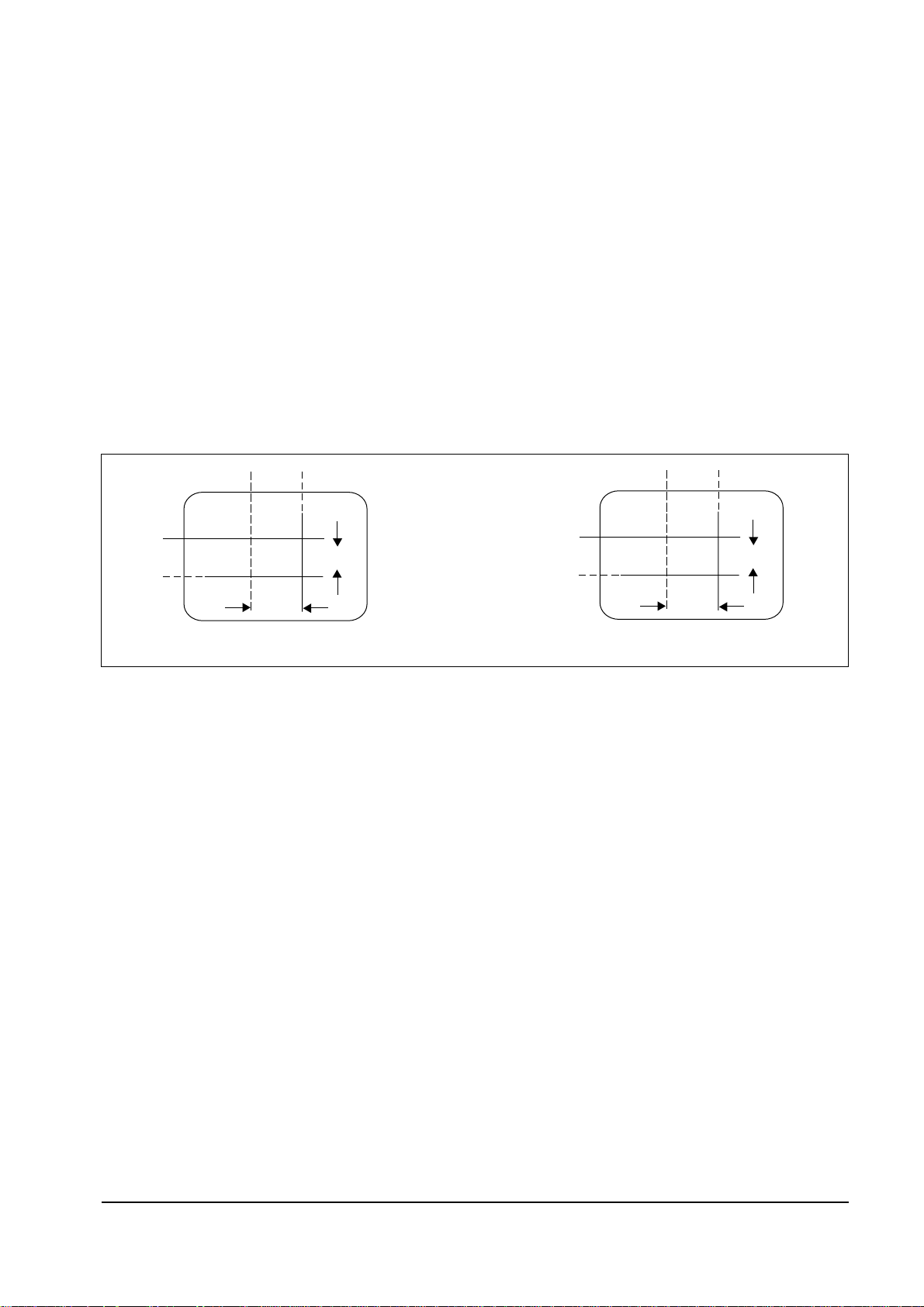

Fig. 3-3 Center Convergence Adjustment

RED

BLUE

BLUE

RED

4-Pole Magnet Movement

GREEN

RED/BLUE

RED/BLUE

GREEN

6-Pole Magnet Movement

3-3-9 AGC Adjustment

1. Input a COLOR-BAR pattern. (CH2)

2. Set the RF input signal to 70 dBmV.

3. Use Generator for PM5518 & PM5418.

4. Set AGC (in the Factory Mode) so that the DC level of IC TDA8377

Pin 53 is 3.0±0.05V.

3-3-10 AFT (VCO Adjustment)

1. Input an AGC adjustment signal.

2. Select Factory Mode VCO and press the MUTE key one time.

3. GEOMATRIX adjustments

VS EWA

VA EWP

VSL EWC

HS EWT

Page 10

Alignment and Adjustments

3-9

3-3-11 White Balance Adjustment

3-3-11 (A) SCREEN ADJUSTMENTS

1. Input a TOSHIBA pattern.

2. Check R506 ÒGÓ pin on the CRT PCB with an

oscilloscope.

3. Enter the Horizontal Line Mode.

4. Adjust the Screen Control on the FBT so that

the waveform of the 21st line is DC 2.0

(±0.5)V.

3-3-11 (B) HIGH-LIGHT ADJUSTMENT

1. NOTE : If a color analyzer is not available,

then approximate the following color

adjustments Òby eyeÓ.

2. Input a TOSHIBA pattern.

3. Set high-light to 290/300 (X,Y) with a color

analyzer.

4. Set low-light to 1.4F/L.

5. Adjust RG, BG and set GG to step 32.

3-3-11 (C) SUB-CONTRAST ADJUSTMENT

1. Set SCT so that the brightness level in highlight is 40 F/L (for a 29Ó SCREEN).

3-3-11 (D) SUB-BRIGHTNESS ADJUSTMENT

1. Input a TOSHIBA pattern.

2. Set SBT so that the brightness level in lowlight is 1.4 F/L.

3-3-11 (E) SUB-COLOR ADJUSTMENT

Set ÒSCRÓ in the Service Mode to step 0.

3-3-11 (F) SUB-TINT ADJUSTMENT

Set ÒSTTÓ in the Service Mode to step 4.

3-3-11 (G) VERTICAL SIZE ADJUSTMENT

1. Input a lion head pattern.

2. Set VS to 32 in the Factory Mode.

3. Set VA so that the top margin is 4.0. Adjust SL

so that the bottom margin is 4.0. If the top

and bottom margins are different, adjust VA so

that their sum is 8.0.

3-3-11 (H) HORIZONTAL SHIFT ADJUSTMENT

1. Input a lion head pattern.

2. Adjust ÒHSÓ in the Service Mode so that the

left and right margins of the lion head pattern

are 6.3 ± 0.5.

SIZE

DC

29”

2.4

25”

2.4

HEIGHT

LIGHT

30”

33 ± 5

29”

37 ± 5

26”

45 ± 5

22”

45 ± 5

<TOSHIBA PATTERN>

High-Light

Low-Light

Page 11

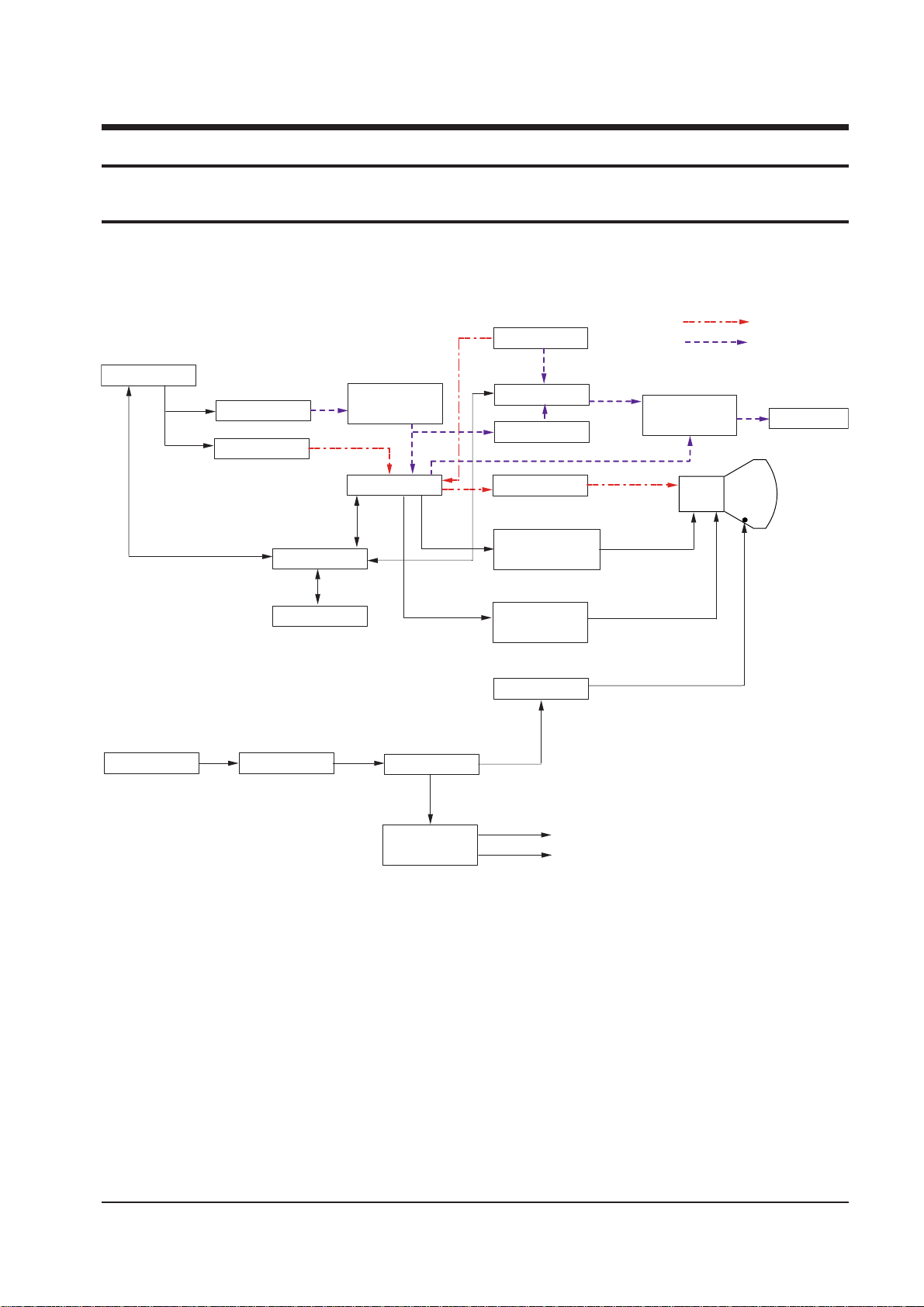

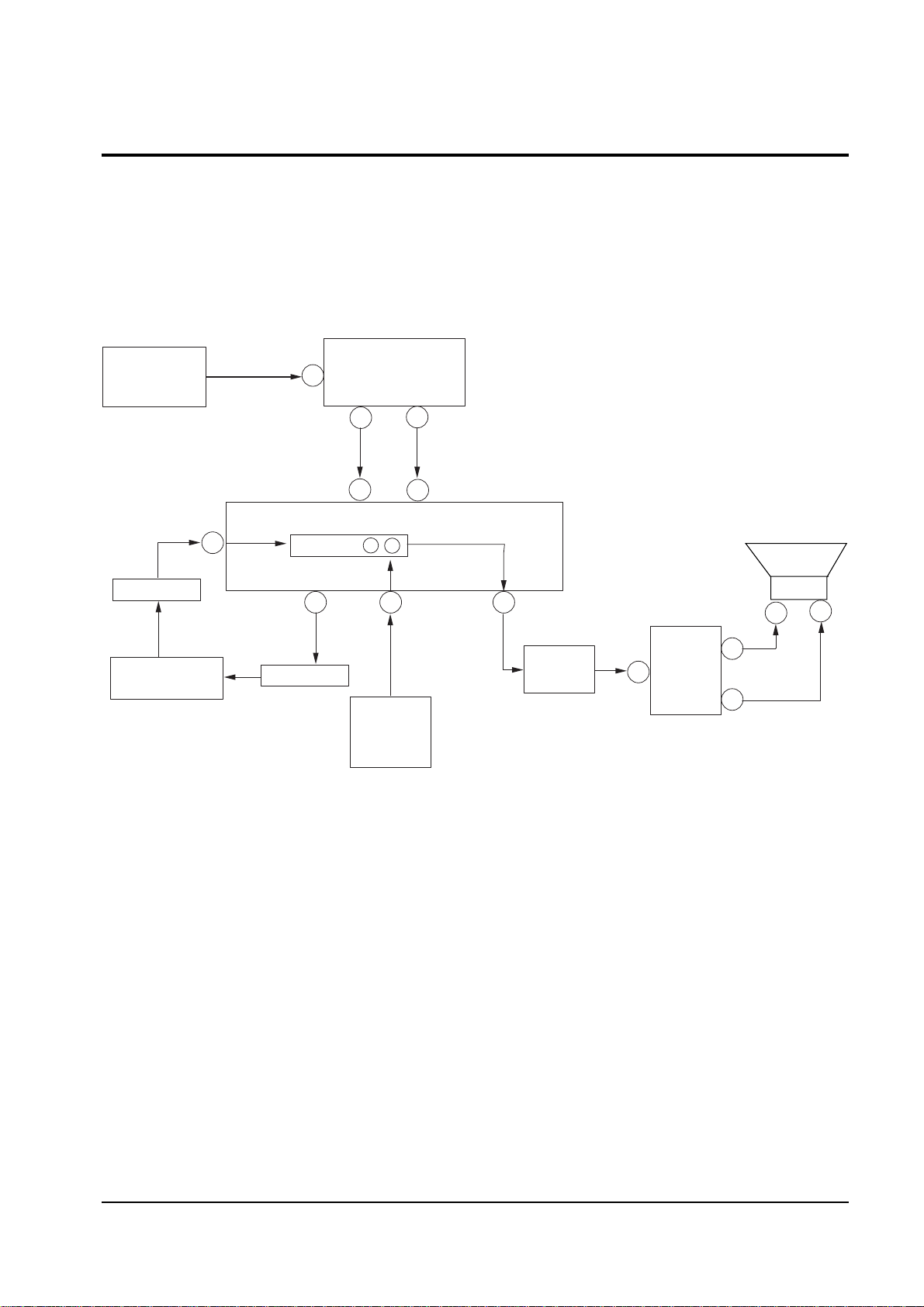

7. Block Diagrams

7-1 Main Block Diagram

Block Diagrams

8-1

JA701

EEPROM

TUNER

SIF

DETECTOR

CONTROL IC

MICOM

R/G/B AMP

DEFLECTION

HDRIZONTAL

DEFLECTION

VERTICAL

SAW

AC INPUT

TRANS

SAW

MULTI

REGULATOR

FBT

SPS

1-Chip

MTS

SOUND

AMP

JACK BLOCK

SPEAKER

TUO1

SF102

SF101

IC201

IC701

ICD01

IC201

IC501

Q401

IC301

T444

IC902

IC901

IC801

T801

IC853

5Volt

12Volt

130Volt

IC601

I2C

I

2

C

I2C

I

2

C

: video flow

: audio flow

CRT

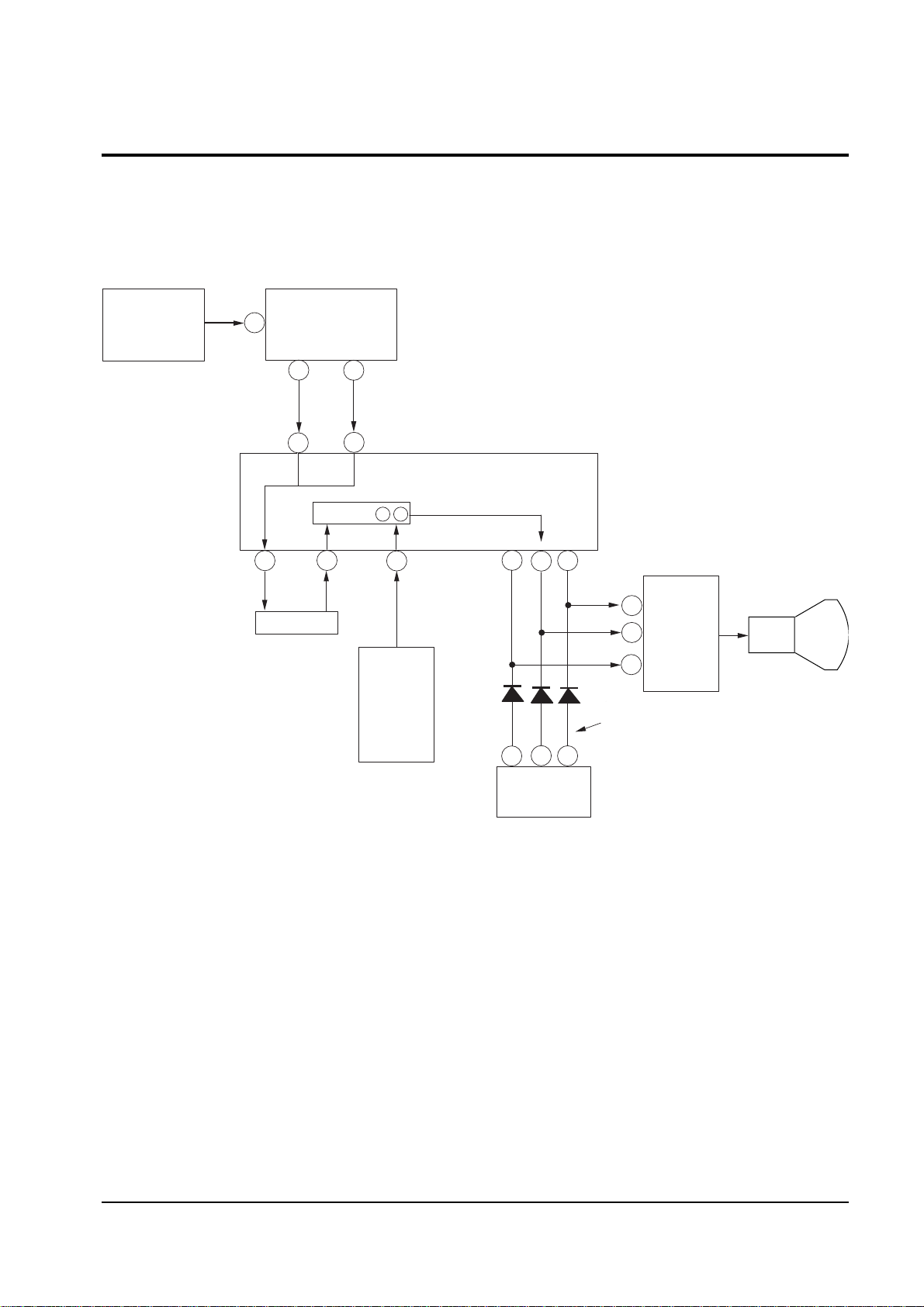

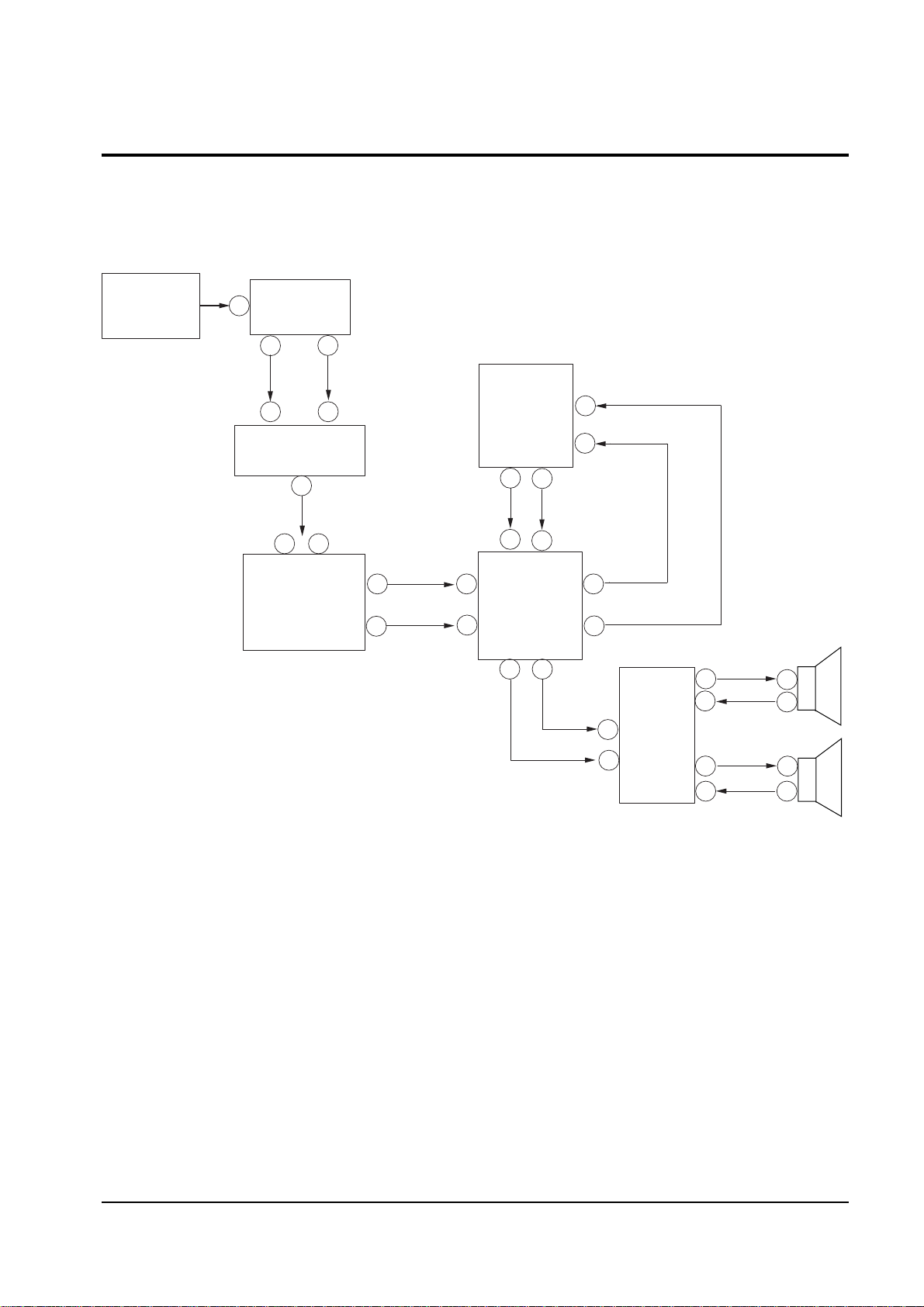

Page 12

Block Diagrams

8-2

7-2 VIDEO SIGNAL

SF101

MONO : M1963M

STEREO : M3951M

1

45

IC901

MICOM

IC501

TDA6108JF

(TDA6017Q)

JA701

JACK

BLOCK

VIDEO INPUT

TU01

TECC1070PG26A

TECC1070PG31A

TECC1970PG26A

IC201

TDA8377A/N3

49

48

13

17

1

6

19

20

21

VIF

Q201

R

G

B

2

3

22

23

24

OSD-R/G/B

SWITCHING /

13

17

CRT

Page 13

Block Diagrams

8-3

7-3 AUDIO SIGNAL (MONO)

SF101

MONO:M1963M

STEREO : M3951M

1

45

JM08

JUMPER

49

48

6

2

6

15

1

VIF

Z601

+

3

L,C TRAP

(C222,C235,L217)

Q201

SPEAKER

-

8

SWITCHING /

IC201

TDA8377A/N3

JA701

JACK BLOCK

AUDIO INPUT

IC603

2

1

TU01

TECC1070PG26A

TECC1070PG31A

Page 14

Block Diagrams

8-4

7-4 AUDIO SIGNAL (STEREO)

1

1

2

IC 60 3

TDA7266S

JA701

JACK

BLOCK

STEREO:6P

ICD01

CXA2104S

12

6

5

4

2

9

2

SIF

+

IC701

TDA7449

-

1

LA7510

4

5

45

6

15

18

SIF

R-OUT

2

7

L-OUT

R-OUT

78

R

L

L-OUT

L-OUT

400mVrms

L

R

R-OUT

400mVrms

14

15

+

-

SPEAKER-R

SPEAKER-L

SF102

MONO : M9260M

IC202

TU01

TECC1070PG26A

TECC1070PG31A

TECC1970PG26A

Page 15

5-1 TK2599 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 TK2999ST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3 CR29805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-4 UR25805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-5 UR29805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

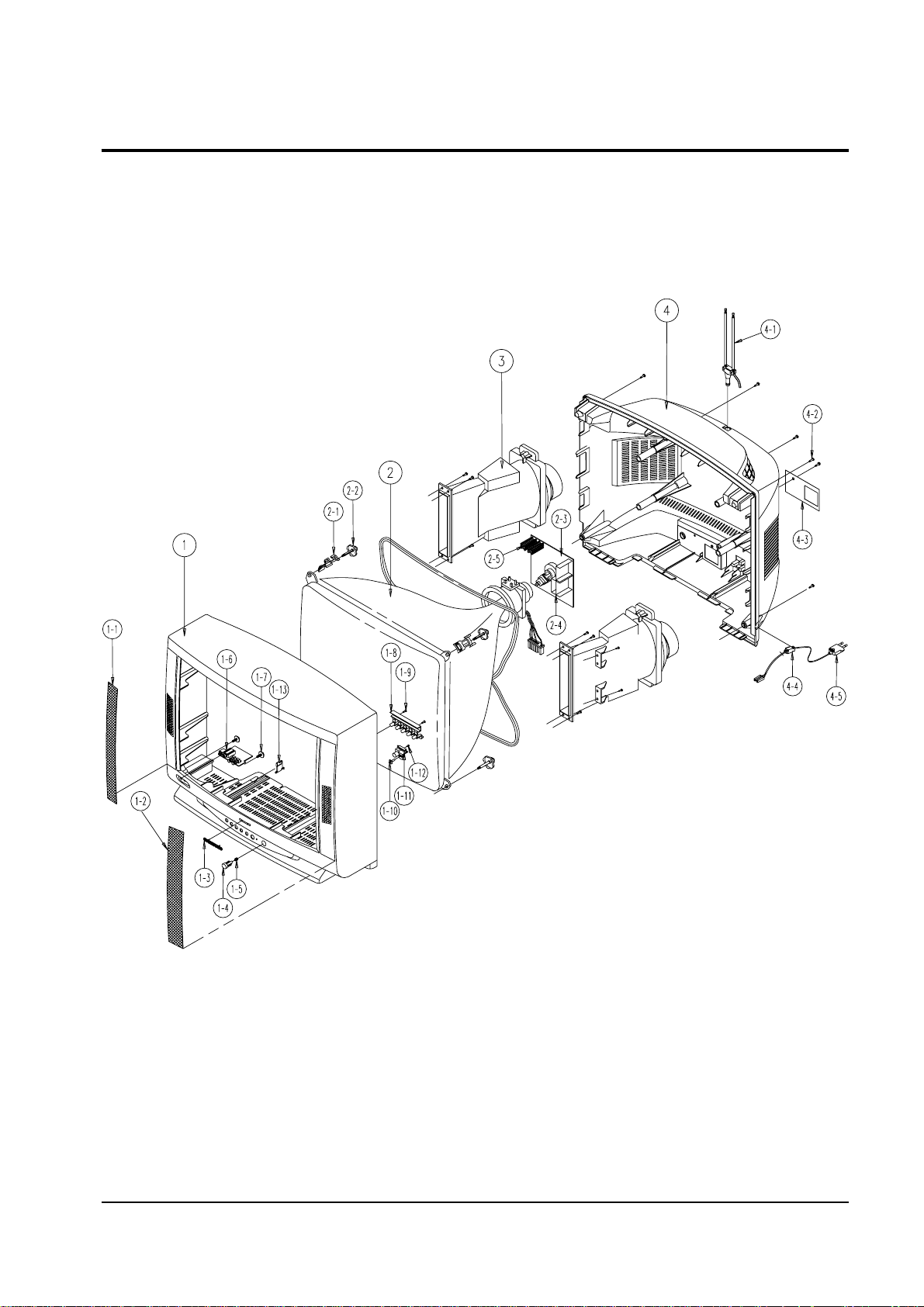

Exploded Views & Parts List

7-1

5. Exploded Views & Parts List

Page 16

Exploded Views & Parts List

7-2

5-5-1 TK2599ST

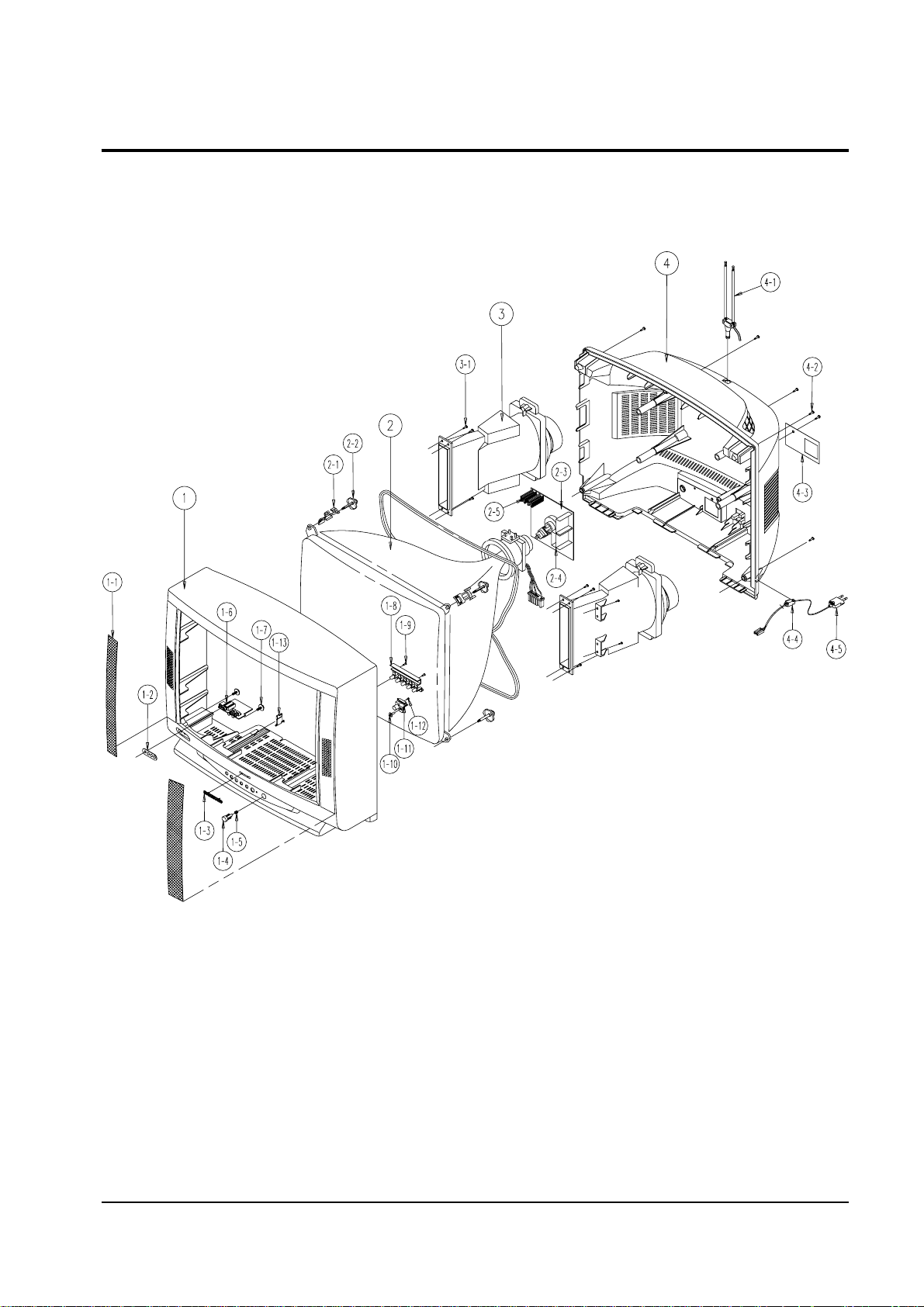

Page 17

Exploded Views & Parts List

7-3

5-5-2 TK2999ST

Page 18

Exploded Views & Parts List

7-4

5-5-5-3 CR29805

Page 19

Exploded Views & Parts List

7-5

5-4 UR25805

Page 20

Exploded Views & Parts List

7-6

5-5-5 UR29805

Page 21

10-1

PCB Layout

8. PCB Layout

MAIN (top)

D201 162 157

D202 129 155

D204 127 187

D205 132 187

D206 139 187

D207 147 145

D208 171 148

D210 124 207

D213 153 216

D301 129 47

D401 30 7

D402 132 109

D403 128 109

D404 20 15

D405 75 17

D406 176 153

D503 271 197

D511 319 218

D512 325 218

D513 322 218

D601 235 146

D801 230 79

D803 153 33

D804 228 42

D808 158 35

D809 160 67

D810 166 73

D811 161 12

D812 156 27

D814 248 36

D825 46 142

D901 258 136

D903 242 128

D908 159 99

D910 247 117

D951 309 87

D962 152 105

DB02 41 115

DE01 119 91

DP01 124 221

DU01 274 152

DU02 267 152

DU03 262 152

DX01 162 126

DZ101 25 164

DZ210 36 173

DZ211 36 170

DZ212 157 145

DZ217 106 204

DZ231 138 153

DZ243 47 185

DZ250 5 151

DZ302 117 44

DZ303 127 44

DZ304 133 51

DZ305 146 44

DZ306 146 47

DZ401 135 96

DZ402 251 131

DZ501 166 161

DZ505 321 238

DZ601 232 117

DZ612 242 215

DZ613 250 229

DZ621 250 218

DZ622 219 230

DZ707 188 238

DZ708 196 238

DZ801 281 9

DZ802 240 8

DZ803 240 32

DZ804 180 112

DZ805 228 18

DZ806 234 19

DZ807 161 114

DZ808 185 109

DZ809 128 27

DZ810 233 25

DZ811 186 13

DZ864 175 134

DZ901 287 106

DZ902 263 100

DZ905 306 131

DZ906 291 109

DZ907 288 109

DZ908 307 168

DZ910 320 82

DZX01 191 130

IC201 69 183

IC202 73 227

IC301 114 34

IC501 316 225

IC603 245 225

IC701 177 217

IC801 243 14

IC802 176 100

IC851 207 17

IC852 182 7

IC853 129 120

IC854 146 133

IC901 301 129

IC902 296 158

ICD01 205 167

ICE01 100 122

ICP01 163 172

Q101 46 199

Q201 109 221

Q204 201 134

Q401 31 92

Q402 17 156

Q403 17 156

Q601 152 207

Q604 238 132

Q801 121 28

Q901 248 132

Q902 139 192

Q903 142 65

Q951 294 94

QA01 50 164

QA02 57 164

QE01 79 143

QE02 113 115

QK201 147 207

QL01 130 165

QL02 130 161

QP01 154 186

QP02 150 186

QU03 285 166

QU05 267 157

QX01 192 134

Loc. No. X Y

DIODE

IC

Loc. No. X Y

TRANSISTOR

X

Y

Page 22

Preliminary Parts List 99 Sep 10

MODELS: TFK25806/TK2599ST (* in Sym column means not available as a repair part)

ASSY-PCB,MAIN

C101 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

C102 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C104 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C105 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C106 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C107 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C108 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C110 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C111 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C112 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C113 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C116 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C117 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C202 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C204 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

C205 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

C206 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C209 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C210 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C211 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C212 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C213 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C214 2202-000143 C-CERAMIC,MLC-AXIAL;10pF,5%,50V,NPO,TP,1.9x3.5,C217 2202-002055 C-CERAMIC,MLC-AXIAL;47nF,+80-20%,50V,Y5V,TP,2.2x3.

C223 2201-000258 C-CERAMIC,DISC;17pF,5%,50V,CH,TP,5x3,5

C224 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

C225 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C226 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C227 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C228 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

C229 2301-000342 C-FILM,PEF;2.2nF,5%,50V,TP,7.4x3.9x13mm,5

C230 2202-000162 C-CERAMIC,MLC-AXIAL;.015NF,5%,50V,SL,TP,3.5X1.9MM,C232 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

C233 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C234 2309-000138 C-FILM,PE-PPF;100nF,5%,50V,TP,20x16x8.5,7.5m

C235 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C237 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C239 2401-002229 C-AL;470nF,20%,50V,WT,TP,5x11,5

C240 2201-000379 C-CERAMIC,DISC;22nF,+80-20%,50V,Y5V,TP,8x4,5

C242 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C243 2201-000483 C-CERAMIC,DISC;33pF,5%,50V,CH,TP,5x3,5

C244 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C250 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C302 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C303 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5,5

C304 2305-000285 C-FILM,MPEF;220NF,5%,100V,TP,10.5X5.5X15MM,5

C305 2201-000259 C-CERAMIC,DISC;180pF,10%,500V,Y5P,TP,6x4,5

C306 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C308 2301-000254 C-FILM,PEF;39nF,5%,50V,TP,7.5x3.5x6.5mm,5

C401 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C402 2306-000322 C-FILM,MPPF;12nF,5%,1.6KV,TP,29x20.5x13,20

C404 2306-000235 C-FILM,MPPF;560nF,5%,400V,TP,26*22.5*14,20

C405 2301-000213 C-FILM,PEF;220nF,5%,250V,TP,21.5x11,7.5

C406 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C407 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

C408 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C409 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

Page 23

C410 2401-002268 C-AL;2.2uF,20%,250V,LZ,TP,8X11,5

C411 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C412 2401-000927 C-AL;22uF,20%,250V,GP,TP,13x20,5

C413 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C414 2201-000984 C-CERAMIC,DISC;680pF,10%,2KV,Y5P,TP,11x6,7.5m

C415 2303-000331 C-FILM,PPF;4.7nF,5%,630V,TP,19.5x12x7,7.5

C417 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C419 2306-000267 C-FILM,MPPF;8.2nF,5%,1.6KV,TP,28.5x18.5x12

C501 2305-000704 C-FILM,MPEF;100nF,5%,250V,TP,16.5x10.3x5.7

C503 2401-001232 C-AL;4.7uF,20%,250V,GP,TP,10x12.5,5

C504 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C505 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C506 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C510 2401-002264 C-AL;10uF,20%,350V,GP,TP,10x20mm,5m

C518 2201-002063 C-CERAMIC,DISC;10nF,+80-20%,3KV,Y5V,TP,16x5,7

C520 2202-000862 C-CERAMIC,MLC-AXIAL;390pF,10%,50V,Y5P,TP,3.5x1.9,C610 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

C627 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C628 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

C629 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C631 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C632 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

C634 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

C650 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V,TP,3.5x19

C651 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V,TP,3.5x19

C701 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C702 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C703 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C704 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C706 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C707 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C708 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C709 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C712 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5.7

C713 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C714 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C715 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5.7

C716 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

C717 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

C801 2401-003025 C-AL;330uF,20%,400V,GP,ST,30x40,10

C802 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,11x7,7

C803 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,11x7,7

C804 2303-000163 C-FILM,PPF;2.2nF,5%,800V,TP,15x13x8.5,7.5

C805 2201-000991 C-CERAMIC,DISC;560pF,10%,2KV,Y5P,TP,13x7,7.5

C806 2401-003026 C-AL;330uF,20%,200V,GP,ST,22x35,10

C807 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C808 2401-001571 C-AL;47uF,+20%-0%,50V,GP,TP,8x11.5,

C809 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C810 2401-000611 C-AL;1uF,20%,50V,WT,TP,5x11,5

C811 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C812 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C813 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C815 2401-000787 C-AL;220uF,20%,160V,GP,TP,16x31.5mm

C816 2401-000164 C-AL;1000uF,20%,25V,WT,TP,12.5x20,5

C817 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C820 2401-003141 C-AL;2200uF,20%,25V,WT,TP,13x25,5mm

C821 2201-002002 C-CERAMIC,DISC;4700pF,20%,400V,+20%~-55%,TP,2

C822 2201-000963 C-CERAMIC,DISC;1nF,20%,400V,Y5U,TP,11x8mm,10m

C823 2201-002002 C-CERAMIC,DISC;4700pF,20%,400V,+20%~-55%,TP,2

C824 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C825 2301-000310 C-FILM,PEF;68nF,5%,50V,TP,8.0X8.5X4.0X5,5

C827 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

C834 2401-002288 C-AL;470uF,20%,25V,WT,TP,10x20,5

Page 24

C855 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C861 2401-000287 C-AL;100uF,20%,16V,WT,TP,6.3x11,5

C862 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C870 2306-000350 C-FILM,MPPF;270NF,5%,400V,TP,26X18.5X10MM,20

C873 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C890 2201-000374 C-CERAMIC,DISC;220pF,5%,50V,CH,TP,12.5x3,5

C891 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C901 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C902 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3.5X1.9MM,C903 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C904 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3.5X1.9MM,C905 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C906 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C907 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C908 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0,5

C909 2201-000193 C-CERAMIC,DISC;10pF,0.3pF,50V,CH,TP,5x3,5

C910 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,8x3.5

C911 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C912 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C913 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C914 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C920 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

CB01 2306-000318 C-FILM,MPPF;220nF,20%,250V,TP,-,22.5mm

CB19 2301-001065 C-FILM,MPPF;47nF,5%,630V,TP,19x15.5x7,7.5

CD10 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

CD11 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CD12 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CD26 2401-001026 C-AL;3.3UF,20%,50V,GP,TP,5X11,5

CE01 2401-002597 C-AL;220uF,20%,35V,GP,TP,10x12.5,5

CE03 2401-001527 C-AL;47uF,20%,250V,HR,TP,13x25mm,5m

CE04 2305-000470 C-FILM,MPEF;68nF,5%,100V,TP,-,5mm

CL01 2201-000258 C-CERAMIC,DISC;17pF,5%,50V,CH,TP,5x3,5

CL02 2201-000247 C-CERAMIC,DISC;15pF,5%,50V,CH,TP,5x3,5

CN501B AA39-20604A LEAD CONNECTOR-ASSY;-,YBNH250-09,YBNH05/04,5/4P,50

CN601 3711-002643 CONNECTOR-HEADER;BOX,4P,1R,2.5mm,STRAIGHT,SN

CN602 3711-002644 CONNECTOR-HEADER;BOX,5P,1R,2.5mm,STRAIGHT,SN

CN701 3711-002648 CONNECTOR-HEADER;BOX,9P,1R,2.5mm,STRAIGHT,SN

CP01 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

CP02 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

CP03 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

CP04 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

CP05 2401-001496 C-AL;47uF,20%,16V,GP,TP,5x7,5

CU02 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU06 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CU11 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU12 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU13 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU33 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD06 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD08 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

CUD09 2301-000160 C-FILM,PEF;12nF,5%,50V,TP,11.0x6.0x9.0mm,

CUD15 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CUD18 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CUD20 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD21 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CUD23 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD24 2301-000204 C-FILM,PEF;2.7nF,5%,50V,TP,7.4x3.9x13mm,5

CUD25 2301-000356 C-FILM,PEF;47nF,5%,50V,TP,7.5x4.0x6.5,5mm

CUD28 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD29 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CUD30 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

D201 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D202 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

Page 25

D204 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D205 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D206 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D207 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D210 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D301 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D401 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D402 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D403 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D404 0402-000540 DIODE-RECTIFIER;RU20A,600V,1.5A,-,TP

D405 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D406 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D503 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D511 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D512 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D513 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D601 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D801 0402-001160 DIODE-BRIDGE;D5SB60,600V,2.8A,SIP-4,ST

D803 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D804 0402-001105 DIODE-RECTIFIER;ERB43-04SV1,400V,1.0A,-,TP

D809 0402-000564 DIODE-RECTIFIER;FML-G22S,200V,10A,TO-220

D812 0402-000231 DIODE-RECTIFIER;FMG-G26S,600V,4A,TO-220F,ST

D814 0402-000213 DIODE-RECTIFIER;ERB12-06,600V,1.0A,DO-41,TP

D825 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D903 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D908 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D910 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D951 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D962 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DB02 0402-001296 DIODE-RECTIFIER;FMP-3FU,1.5KV,5A,TO-3PF,ST

D-COIL AA27-20004J COIL-DEGAUSSING;

DE01 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

DU01 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DU02 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DU03 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DZ101 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,TP

DZ210 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ211 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ217 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ231 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ250 0403-000662 DIODE-ZENER;MTZ3.0B,3.0V,3.01-3.22V,500mW,

DZ302 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D

DZ303 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D

DZ304 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D

DZ305 0403-000494 DIODE-ZENER;MTZ39,39V,35.36-37.2V,500mW,DO

DZ306 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,TP

DZ401 0403-000300 DIODE-ZENER;MTZ8.2B,8.2V,7.78-8.19V,500mW,

DZ402 0403-000355 DIODE-ZENER;UZ5.1BSB,5.1V,4.97-5.18V,500mW

DZ505 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ601 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ612 0403-000656 DIODE-ZENER;MTZ15C,15V,14.35-15.09V,500mW,

DZ613 0403-000656 DIODE-ZENER;MTZ15C,15V,14.35-15.09V,500mW,

DZ621 0403-000656 DIODE-ZENER;MTZ15C,15V,14.35-15.09V,500mW,

DZ622 0403-000656 DIODE-ZENER;MTZ15C,15V,14.35-15.09V,500mW,

DZ707 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ708 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ801 1405-001036 VARISTOR;430V,2500A,14x8.5mm,TP

DZ802 1405-001036 VARISTOR;430V,2500A,14x8.5mm,TP

DZ803 0403-000300 DIODE-ZENER;MTZ8.2B,8.2V,7.78-8.19V,500mW,

DZ804 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500mW,

DZ805 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500mW,

DZ806 0403-000562 DIODE-ZENER;MTZ7.5B,7.5V,7.07-7.45V,500mW,

DZ807 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

Page 26

DZ808 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500mW,

DZ810 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DZ864 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500mW,

DZ901 0403-000355 DIODE-ZENER;UZ5.1BSB,5.1V,4.97-5.18V,500mW

DZ902 0403-000562 DIODE-ZENER;MTZ7.5B,7.5V,7.07-7.45V,500mW,

DZ905 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

DZ906 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

DZ907 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

DZ908 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

DZ910 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500mW,

F801 3601-001012 FUSE-FERRULE;250V,4A,SB,GLASS,5.2x20mm

F801A 3602-000114 FUSE-HOLDER;-,-,30mohm

F801B 3602-000114 FUSE-HOLDER;-,-,30mohm

GT102A AA39-20010B LEAD-CONNECTOR,ASSY;-,YFH800-01,S,1P,500,1617#22

IC201 1204-001193 IC-CHROMA;TDA8375,DIP,56P,-,PLASTIC,8V,9

IC202 1204-000506 IC-IF DETECTOR;LA7510,SIP,9P,-,PLASTIC,12V,-,

IC301 1204-000517 IC-VERTIVAL DEF.;LA7845,SIP,7P,-,PLASTIC,40V,11H/SINK

IC501 1201-001330 IC-VIDEO AMP;6108,ZSIP,9P,-,SINGLE,-,PLASTIH/SINK

IC603 1201-001308 IC-POWER AMP;7266,ZIP,15P,-,DUAL,26dB,PLASTH/SINK

IC701 1204-001455 IC-VOLUME/TONE CONT.;TDA7449,DIP,20P,300MIL,PLASTIC

IC801 1203-001482 IC-PWM CONTROLLER;3S1265R,TO-3P,5P,210,PLASTIC,6H/SINK

IC802 1203-000644 IC-POSI.FIXED REG.;7630,SIP,10P,-,PLASTIC,5.1/8V,H/SINK

IC851 0604-001038 PHOTO-COUPLER;TR,130-260%,200mW,DIP-4,ST

IC852 1203-001217 IC-POSI.ADJUST REG.;431,TO-92,3P,4.58MIL,PLASTIC,2

IC853 1203-001225 IC-POSI.FIXED REG.;78R09,TO-220,4P,-,PLASTIC,8.78

IC901 AA13-00017A IC-MCU;-,SZM-368ET2(R4127),16BIT,SDIP,CT28B2,42P,60

IC902 1103-001106 IC-EEPROM;24C080,1028x8BIT,DIP,8P,300MIL

ICD01 1209-001116 IC-ETC, LINEAR;CXA2104S,DIP,30P,-,PLASTIC,9V,

ICE01 1201-000191 IC-OP AMP;4558,DIP,8P,300MIL,DUAL,20V/mV

ICP01 1209-000214 IC-DELAY LINE;TDA4665,DIP,16P,300MIL,PLASTIC

J258 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

JA701 3722-001103 JACK-RCA;5P(9P),3.4mm,AG,BLK,#16-22

L102 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L103 2701-000207 INDUCTOR-AXIAL;56uH,5%,2.5x3.4mm

L104 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L201 2701-000127 INDUCTOR-AXIAL;15uH,10%,2.5x3.4mm

L202 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L203 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L204 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L205 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L206 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L207 2701-000207 INDUCTOR-AXIAL;56uH,5%,2.5x3.4mm

L237 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L401B AA27-30003G COIL-LINERITY;-,44uH,DR14x15,PI0.2x10,18x33,

L404 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L405 2701-000142 INDUCTOR-AXIAL;1uH,10%,2.5x3.4mm

L406 2901-000297 FILTER-EMI ON BOARD;-,3A,-,-,3.5x5,TP,L602 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L710 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L801 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L807 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L808 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L809 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L810 2701-001032 INDUCTOR-AXIAL;100UH,10%,5X14MM

L811 2901-000297 FILTER-EMI ON BOARD;-,3A,-,-,3.5x5,TP,L812 2901-000297 FILTER-EMI ON BOARD;-,3A,-,-,3.5x5,TP,L815 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L816 2701-001032 INDUCTOR-AXIAL;100UH,10%,5X14MM

L864 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

L901 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L902 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

L903 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

LB01 3301-000287 CORE-FERRITE BEAD;AA,3.5x1.0x6.0mm,1500,2400G

Page 27

LB02 AA27-40003A COIL-HORIZ,WIDTH;-,1mH,SB-5S 8x20,PI0.12,LD901 AA96-30001B ASSY-LED,GUIDE;-,AA61-50055A,DL-G5RGA,LE01 AA27-40003L COIL-HORIZ,WIDTH;-,1.0mH,DR14x20,2UEW0.45,ST

LK803 AA29-30002F FILTER-LINE NOISE;-,6mH,2.45A,-,LUD01 2701-000106 INDUCTOR-AXIAL;1.5uH,10%,2.8x7mm

NT801 1404-001045 THERMISTOR-NTC;4.7ohm,15%,2900K,35.0mW,TP

P801 1404-001087 THERMISTOR-PTC;7ohm,30%,220V,270V,19A,-,ST

Q101 0501-000436 TR-SMALL SIGNAL;KTC3197,NPN,625mW,TO-92,TP,20Q201 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,TP,120Q204 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,TP,120Q401 0502-001136 TR-POWER;KSD5703,NPN,70W,TO-3PF,ST,8-H/SINK

Q403 0502-001007 TR-POWER;KSC2073-H2,NPN,25W,TO-220,ST,6

Q601 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,TP,120Q604 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,TP,120Q901 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,TP

Q902 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,TP,120Q951 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1W,TO-92L,-,120QE01 0502-000298 TR-POWER;KSD73,NPN,30W,TO-220,-,120-240H/SINK

QE02 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,TP,120QL01 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,TP

QL02 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,TP

QP01 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,TP,120QP02 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,TP,120QU03 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,TP

QU05 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,TP,120R102 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R103 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R104 2001-000221 R-CARBON;1.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R107 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R108 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R109 2001-000938 R-CARBON;68OHM,5%,1/8W,AA,TP,1.8X3.2MM

R111 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3.2MM

R112 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R113 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R114 2001-000221 R-CARBON;1.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R120 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R200 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R202 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

R204 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

R205 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R206 2001-000534 R-CARBON;240OHM,5%,1/8W,AA,TP,1.8X3.2MM

R207 2001-000534 R-CARBON;240OHM,5%,1/8W,AA,TP,1.8X3.2MM

R209 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R210 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R211 2001-000864 R-CARBON;56KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R212 2001-000617 R-CARBON;3.9MOHM,5%,1/8W,AA,TP,1.8X3.2MM

R213 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R214 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R215 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R216 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R217 2001-000011 R-CARBON;75KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R219 2001-000864 R-CARBON;56KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R222 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

R223 2001-000252 R-CARBON;1.6KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R224 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R226 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R228 2004-001089 R-METAL;560Kohm,5%,1/8W,AA,TP,1.8x3.2m

R229 2001-000938 R-CARBON;68OHM,5%,1/8W,AA,TP,1.8X3.2MM

R230 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R231 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R232 2001-000016 R-CARBON(S);1OHM,5%,1/2W,AA,TP,2.4X6.4MM

R233 2001-000539 R-CARBON;24KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R234 2001-000008 R-CARBON;15KOHM,5%,1/8W,AA,TP,1.8X3.2MM

Page 28

R235 2001-000522 R-CARBON;22KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R237 2004-001914 R-METAL;39Kohm,2%,1/8W,AA,TP,1.8x3.5mm

R239 2001-000864 R-CARBON;56KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R245 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R250 2001-000066 R-CARBON(S);10KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R251 2001-000531 R-CARBON;240KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R252 2001-001062 R-CARBON(S);10MOHM,5%,1/2W,AA,TP,2.4X6.4MM

R253 2001-001411 R-CARBON;5.6MOHM,5%,1/8W,AA,TP,1.7X3.2MM

R260 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

R280 2001-000864 R-CARBON;56KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R301 2001-001044 R-CARBON(S);1.1KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R302 2001-001044 R-CARBON(S);1.1KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R303 2001-000016 R-CARBON(S);1OHM,5%,1/2W,AA,TP,2.4X6.4MM

R304 2003-002014 R-METAL OXIDE(S);0.6ohm,5%,2W,AF,TP,3.9x10mm

R306 2003-002069 R-METAL OXIDE;470ohm,5%,2W,AF,TP,3.9x10mm

R309 2003-002069 R-METAL OXIDE;470ohm,5%,2W,AF,TP,3.9x10mm

R311 2003-002069 R-METAL OXIDE;470ohm,5%,2W,AF,TP,3.9x10mm

R403 2001-001114 R-CARBON(S);270OHM,5%,1/2W,AA,TP,2.4X6.4MM

R405 2003-000540 R-METAL OXIDE(S);1Kohm,5%,2W,AF,TP,4x12mm

R406 2003-002008 R-METAL OXIDE(S);18Kohm,5%,2W,AF,TP,3.9x10mm

R407 2001-001153 R-CARBON(S);47OHM,5%,1/2W,AA,TP,2.4X6.4MM

R408 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

R409 2008-001011 R-FUSIBLE(S);0.18ohm,10%,2W,AF,TP,3.9x10mm

R410 2008-001011 R-FUSIBLE(S);0.18ohm,10%,2W,AF,TP,3.9x10mm

R411 2004-001408 R-METAL(S);91Kohm,1%,1/2W,AA,TP,2.4x6.4mm

R412 2004-001408 R-METAL(S);91Kohm,1%,1/2W,AA,TP,2.4x6.4mm

R413 2003-000458 R-METAL OXIDE(S);100ohm,5%,2W,AF,TP,4x12mm

R415 2003-002007 R-METAL OXIDE(S);4.7Kohm,5%,2W,AF,TP,3.9x10mm

R416 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R418 2008-000254 R-FUSIBLE(S);0.68ohm,5%,2W,AF,TP,3.9x10mm

R419 2008-000252 R-FUSIBLE(S);0.47ohm,10%,1/2W,AF,TP,2.5x6.5

R501 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R502 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R503 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R504 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R505 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R506 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R517 2002-001009 R-COMPOSITION;2.7Kohm,10%,1/2W,AA,TP,3.7X9.0

R518 2002-001009 R-COMPOSITION;2.7Kohm,10%,1/2W,AA,TP,3.7X9.0

R519 2002-001009 R-COMPOSITION;2.7Kohm,10%,1/2W,AA,TP,3.7X9.0

R520 2001-000096 R-CARBON(S);1MOHM,5%,1/2W,AA,TP,2.4X6.4MM

R523 2008-000299 R-FUSIBLE(S);47ohm,5%,2W,AF,TP,3.9x10mm

R524 2002-001006 R-COMPOSITION;4.7Kohm,5%,1/2W,AA,TP,3.7x9mm

R526 2008-000254 R-FUSIBLE(S);0.68ohm,5%,2W,AF,TP,3.9x10mm

R601 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R602 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R603 2004-000195 R-METAL;100Kohm,1%,1/8W,AA,TP,1.8x3.2m

R606 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R607 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R610 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R617 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R618 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R619 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R622 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R623 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R624 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R707 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R709 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R713 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R714 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R715 2001-001187 R-CARBON(S);75OHM,5%,1/2W,AA,TP,2.4X6.4MM

R719 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R720 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

Page 29

R802 2001-001150 R-CARBON(S);470KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R803 2003-000994 R-METAL OXIDE(S);33Kohm,5%,2W,AF,TP,3.9x10mm

R804 2003-000994 R-METAL OXIDE(S);33Kohm,5%,2W,AF,TP,3.9x10mm

R805 2002-001012 R-COMPOSITION;8.2Mohm,5%,1/2W,AA,TP,3.7x9mm

R806 2001-001071 R-CARBON(S);12KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R807 2001-001071 R-CARBON(S);12KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R808 2004-001889 R-METAL(S);127Kohm,1%,1/2W,AA,TP,2.5x6.5m

R810 2001-001150 R-CARBON(S);470KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R811 2001-001153 R-CARBON(S);47OHM,5%,1/2W,AA,TP,2.4X6.4MM

R814 2001-001050 R-CARBON(S);1.5KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R819 2001-001178 R-CARBON(S);680OHM,5%,1/2W,AA,TP,2.4X6.4MM

R820 2003-001047 R-METAL OXIDE(S);68ohm,5%,2W,AF,TP,3.9x10mm

R822 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R826 2001-001125 R-CARBON(S);300KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R827 2001-001093 R-CARBON(S);2.2KOHM,5%,1/2W,AA,TP,2.4X6.4MM

R828 2004-001983 R-METAL(S);2.49Kohm,1%,1/2W,AA,TP,2.4x6.4

R830 2008-001058 R-FUSIBLE;0.18ohm,5%,1W,AF,TP,3.9x10mm

R831 2008-001058 R-FUSIBLE;0.18ohm,5%,1W,AF,TP,3.9x10mm

R832 2003-000746 R-METAL OXIDE(S);56ohm,5%,2W,AF,TP,4x12mm

R833 2003-001035 R-METAL OXIDE(S);27ohm,5%,2W,AF,TP,3.9x10mm

R836 2008-000266 R-FUSIBLE(S);1ohm,5%,2W,AF,TP,3.9x10mm

R861 2008-001033 R-FUSIBLE(S);10ohm,5%,2W,AF,TP,3.9x10mm

R862 2008-001033 R-FUSIBLE(S);10ohm,5%,2W,AF,TP,3.9x10mm

R901 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3.2MM

R902 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R903 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R904 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R905 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R906 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R907 2001-000995 R-CARBON;820OHM,5%,1/8W,AA,TP,1.8X3.2MM

R908 2001-000232 R-CARBON;1.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R909 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R911 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R912 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

R914 2001-000490 R-CARBON;200OHM,5%,1/8W,AA,TP,1.8X3.2MM

R915 2001-000252 R-CARBON;1.6KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R918 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R920 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R921 2001-001062 R-CARBON(S);10MOHM,5%,1/2W,AA,TP,2.4X6.4MM

R922 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

R923 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

R924 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R925 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R926 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R927 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R928 2004-001234 R-METAL;75Kohm,5%,1/8W,AA,TP,1.8x3.2mm

R930 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

R931 2001-000010 R-CARBON;68KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R932 2001-001062 R-CARBON(S);10MOHM,5%,1/2W,AA,TP,2.4X6.4MM

R935 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

R951 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R952 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R953 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R956 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R957 2001-000117 R-CARBON(S);68OHM,5%,1/2W,AA,TP,2.4X6.4MM

R958 2001-000252 R-CARBON;1.6KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R959 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R961 2001-000766 R-CARBON;43KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R962 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R964 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

R965 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R966 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R967 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

Page 30

RA03 2003-002102 R-METAL OXIDE(S);68Kohm,5%,2W,AF,TP,4x12mm

RA04 2003-002102 R-METAL OXIDE(S);68Kohm,5%,2W,AF,TP,4x12mm

RE01 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE02 2001-000766 R-CARBON;43KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE03 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE04 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE05 2008-001018 R-FUSIBLE(S);0.47ohm,10%,2W,AF,TP,3.9x10mm

RE06 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

RE07 2003-002069 R-METAL OXIDE;470ohm,5%,2W,AF,TP,3.9x10mm

RE08 2001-001120 R-CARBON(S);3.3OHM,5%,1/2W,AA,TP,2.4X6.4MM

RE09 2001-000531 R-CARBON;240KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE10 2001-000531 R-CARBON;240KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RE11 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RJ01 2002-000326 R-COMPOSITION;1.8Mohm,10%,1/2W,AA,TP,3.5x9.5

RL01 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RL02 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RL801 3501-001040 RELAY-POWER;12VDC,500mW,10A,1FormA,15mS,5m

RM901 AA59-60001U MODULE-REMOCON;-,ORC-50VF/SR-12V,38KHz,940nm,

RP01 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RP04 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RP902 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

RS02 2001-001187 R-CARBON(S);75OHM,5%,1/2W,AA,TP,2.4X6.4MM

RS03 2001-001187 R-CARBON(S);75OHM,5%,1/2W,AA,TP,2.4X6.4MM

RU03 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU04 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU05 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU06 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU07 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU08 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU09 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU10 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU12 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU13 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU14 2004-001989 R-METAL;620ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU15 2004-001989 R-METAL;620ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU16 2004-001989 R-METAL;620ohm,5%,1/8W,AA,TP,1.8x3.2mm

RU17 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU18 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU19 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RU20 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD03 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD04 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD08 2001-000435 R-CARBON;1MOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD09 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD13 2004-001165 R-METAL;82Kohm,1%,1/8W,AA,TP,1.8x3.2mm

RUD24 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD25 2001-000007 R-CARBON;3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD30 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD40 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD41 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD42 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

RUD43 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2MM

SF101 2904-000287 FILTER-SAW AV;45.75MHz,SIP5P,ST,12.5dB,NTSCSF102 2904-000289 FILTER-SAW AV;45.75MHz,SIP5P,ST,14.4dB,NTSCSW901 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SPST

SW902 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SPST

SW903 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SPST

SW904 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SPST

SW905 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SPST

SWM01 3403-000179 SWITCH-PUSH;250V,5A,DPST,-,JPW-2104B

T201 AA26-10005E TRANS-IF;-,7MM,IF,0.136uH,7mm,5pF,82.5M

T401 AA26-50001R TRANS-HORIZ DRIVE;-,80MH,520UH,4UH,G11A EI19,ST

T444 AA26-30005Q TRANS-FLYBACK;-,FUH-29A001(S),29/25,130V

Page 31

T801 AA26-20007Z TRANS-SWITCHING;-,90~260,130/15.5/12/8V,UL/CSA

TU01 AA40-10005Y TUNER-F/S;TECC1970PG26A(S),NTSC/USA,TR,1

V999 3704-001105 SOCKET-CRT;11P,20PI,26.5PI,NI,X202 2801-003298 CRYSTAL-UNIT;3.579545MHz,30ppm,28-AAM,20pF,

X901 2801-003224 CRYSTAL-UNIT;32.768KHz,20ppm,28-AAY,12.5pF,

XL01 2801-003299 CRYSTAL-UNIT;3.582056MHz,30ppm,28-AAM,20pF,

XL02 2801-003300 CRYSTAL-UNIT;3.575611MHz,30ppm,28-AAM,20pF,

Z201 2903-001022 FILTER-CERAMIC;TR,4.5MHz,-,0.5dB,-,TP,Z601 2903-000135 FILTER-CERAMIC;BP,4.5MHz,+-60KHz,6dB,-,TP,-

ASSY-CRT

CRT AA03-10016K CRT-COLOR;-,A59KPR84X01(D),0mG,25,110DE

ASSY-ACCESSORY

BATT 4301-000120 BATTERY-MN;1.5V,-,AA,14.5x50mm,MACH/T AA26-90001C TRANS-MATCHING;-,300ohm/75ohm,PAL,40-890MHz

RCA/CA AA39-40001B CABLE-RCA;-,RCA,1500mm,0.12/10,RED/WHT/Y

I/B AA68-00419A MANUAL-USERS;K51A,W/P100(G),-,SPA,B5,40PAGE, ,ALL1,

ASSY-PCB,A/V FRONT

* AA97-00286A ASSY-PCB,A/V FRONT;-,TFK29806,K51A,NTSC,-,CE60 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CE61 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CN602B AA39-20069A LEAD-CONNECTOR,ASSY;-,YBNH025-05,67096-005,5P,500,

CN701B AA39-20112D LEAD-CONNECTOR,ASSY;-,YBNH025-09,67096-009,9P,500,

JB01 3722-001031 JACK-RCA;3P,3.6mm,#18,AU

JE60 3722-000143 JACK-PHONE;1P(VER),3.4mm,AG,BLK,NO

RE60 2001-001077 R-CARBON(S);150OHM,5%,1/2W,AA,TP,2.4X6.4MM

RE61 2001-001077 R-CARBON(S);150OHM,5%,1/2W,AA,TP,2.4X6.4MM

REMOCON

* AA59-10111C REMOCON;-,TM59,SZM368ET2,25,L/GRAY,TELEFUNKEN,EX,-,

ASSY-HOLDER,SPK

* AA91-60222A ASSY-HOLDER,SPK;DP,-,-,-,AA91-60003C,7202

ASSY-POWER,CORD

* AA96-00172A ASSY-POWER,CORD;-,KJP173N,EP2/YES,-,ARGENTINA,P-CORD AA39-10005Q POWER-CORD;-,KKP-560N,H03VVH2-F,2.4m,3P,C

HOLDER AA61-20070A HOLDER-CORD;-,-,PP,V0,BLK,KE-0002

ASSY-CABINET

* AA92-30177B ASSY-CABINET,FRONT;TFK25806C/TCE(2552)

SPK+CF 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWRCH18

SP+CF 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWRCH18

KC+CF 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWRCH18

WR+CF 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWRCH18

PA+CF AA60-10002A SCREW-TAPPING;RH,+,M4,L12,ZPC(YEL),-,OD14

CRT+CF AA60-10050Q SCREW-ASSY;WC,HH,+,M5,L26.5,SWRCH18A,ZPC(

CB+CF AA60-10050T SCREW-TAPPING;RH,+,2S,M4,L20,ZPC(BLK),SWRCH1

CB+RCA AA60-10050T SCREW-TAPPING;RH,+,2S,M4,L20,ZPC(BLK),SWRCH1

BOSS-C AA61-40018A BOSS-CABINET;-,HIPS,HB,NTR,-,SOPP AA61-40113A STOPPER-PCB;501H,HIPS,NTR,HB,-,STOPP AA61-40007A STOPPER-PCB;5038.5368,ABS HB,NTR,-,-,SPRING AA61-60004M SPRING-ES;-,SUS304,0.5,OD8,H15,N6,-,-,GRI/S AA63-50258B GRILLE-SHEET;-,CT-2951N,PA130 PI0.5,PS,T0.4

CABBAC AA63-60001Q SPACER-FELT;FELT,T0.35,BLK,150X8,-,SPACER AA63-60108A SPACER-SWITCH;PS,T0.4,BLK,-,2551,-

Page 32

BADGE AA64-00475A BADGE-BRAND;AL,TELEFUNKEN,GOLD,50(25),-,TFK25860,KNOPOW AA64-10568C KNOB-POWER;-,6251,MASTER,ABS,HB,BLK

KNOCON AA64-10569A KNOB-CONTROL;-,6251,-,ABS,HB,BLK

FRONT AA64-30822Y CABINET-FRONT;-,6252,BK708P EG TELEFUNKE,HIPS,HB,BLK,-,BACK AA64-30823F CABINET-BACK;DP,-,2551,-,,BLK,V2

INDLED AA64-40368A INDICATOR-LED;-,6251,-,ACRYL,-,CLEAR,WIN/RE AA64-40369B WINDOW-REMOCON;-,6251,-,PC,V0,VIOLET,IN-AV AA64-60441Y INLAY-AV;K51A NT,TELEFUNKEN,PS SHEET,T0.3,BLK,-,IN-BA AA64-60052X INLAY-BACK;29D4,K51A 5PIN,PS,-,BLK,-,C-CORD AA65-30008A CLAMP-CORD;PE,HB,BLK,-,-,C-D,CO AA65-30017A CLAMP-D,COIL;NYLON-66,V0,NTR,DADH300,25 20'

C-WIRE AA65-30105A CLAMP-WIRE;NYLON 66,V2,NTR,15MM,ALL MODEL

ASSY-SPEAKER

* AA96-00173A ASSY-SPEAKER;-,5W ,8OHM,3001-001071,AA39-20505B,SPK 3001-001071 SPEAKER;5W,8ohm,90dB,180Hz

LEAD/C AA39-20505B LEAD CONNECTOR-ASSY;-,YSH025-04,REC,4P,600.800,100

C-D,CO AA65-30113A CLAMP-D,COIL;NYLON 66,V2,BLK,TVI 25~29,-,-

Page 33

Preliminary Parts List 99 Sep 10

MODELS: TFK29806/TK2999ST (* in Sym column means not available as a repair part)

ASSY-PCB,MAIN

C101 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

C102 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C104 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C105 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C106 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C107 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C108 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C110 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C111 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C112 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C113 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C116 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C117 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C202 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C204 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

C205 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

C206 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C209 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C210 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C211 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C212 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C213 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C214 2202-000143 C-CERAMIC,MLC-AXIAL;10pF,5%,50V,NPO,TP,1.9x3.5,C217 2202-002055 C-CERAMIC,MLC-AXIAL;47nF,+80-20%,50V,Y5V,TP,2.2x3.

C223 2201-000258 C-CERAMIC,DISC;17pF,5%,50V,CH,TP,5x3,5

C224 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

C225 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C226 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C227 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C228 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

C229 2301-000342 C-FILM,PEF;2.2nF,5%,50V,TP,7.4x3.9x13mm,5

C230 2202-000162 C-CERAMIC,MLC-AXIAL;.015NF,5%,50V,SL,TP,3.5X1.9MM,C232 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

C233 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C234 2309-000138 C-FILM,PE-PPF;100nF,5%,50V,TP,20x16x8.5,7.5m

C235 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C237 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C239 2401-002229 C-AL;470nF,20%,50V,WT,TP,5x11,5

C240 2201-000379 C-CERAMIC,DISC;22nF,+80-20%,50V,Y5V,TP,8x4,5

C242 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C243 2201-000483 C-CERAMIC,DISC;33pF,5%,50V,CH,TP,5x3,5

C244 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C250 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C302 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C303 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5,5

C304 2305-000285 C-FILM,MPEF;220NF,5%,100V,TP,10.5X5.5X15MM,5

C305 2201-000259 C-CERAMIC,DISC;180pF,10%,500V,Y5P,TP,6x4,5

C306 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C308 2301-000254 C-FILM,PEF;39nF,5%,50V,TP,7.5x3.5x6.5mm,5

C401 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C402 2306-000322 C-FILM,MPPF;12nF,5%,1.6KV,TP,29x20.5x13,20

C404 2306-000235 C-FILM,MPPF;560nF,5%,400V,TP,26*22.5*14,20

C405 2301-000213 C-FILM,PEF;220nF,5%,250V,TP,21.5x11,7.5

C406 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C407 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

C408 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C409 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

Page 34

C410 2401-002268 C-AL;2.2uF,20%,250V,LZ,TP,8X11,5

C411 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4,5

C412 2401-000927 C-AL;22uF,20%,250V,GP,TP,13x20,5

C413 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C414 2201-000984 C-CERAMIC,DISC;680pF,10%,2KV,Y5P,TP,11x6,7.5m

C415 2303-000331 C-FILM,PPF;4.7nF,5%,630V,TP,19.5x12x7,7.5

C417 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C419 2306-000329 C-FILM,MPPF;7nF,3%,1.6KV,TP,28.5x18.5x11mm

C501 2305-000704 C-FILM,MPEF;100nF,5%,250V,TP,16.5x10.3x5.7

C503 2401-001232 C-AL;4.7uF,20%,250V,GP,TP,10x12.5,5

C504 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C505 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C506 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C510 2401-002264 C-AL;10uF,20%,350V,GP,TP,10x20mm,5m

C518 2201-002063 C-CERAMIC,DISC;10nF,+80-20%,3KV,Y5V,TP,16x5,7

C520 2202-000862 C-CERAMIC,MLC-AXIAL;390pF,10%,50V,Y5P,TP,3.5x1.9,C610 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

C627 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C628 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

C629 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C631 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C632 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

C634 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

C650 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V,TP,3.5x19

C651 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V,TP,3.5x19

C701 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C702 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C703 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C704 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C706 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C707 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C708 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C709 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C712 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5.7

C713 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C714 2305-000355 C-FILM,MPEF;330nF,5%,63V,TP,-,5mm

C715 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5.7

C716 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

C717 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

C801 2401-003025 C-AL;330uF,20%,400V,GP,ST,30x40,10

C802 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,11x7,7

C803 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,11x7,7

C804 2303-000163 C-FILM,PPF;2.2nF,5%,800V,TP,15x13x8.5,7.5

C805 2201-000991 C-CERAMIC,DISC;560pF,10%,2KV,Y5P,TP,13x7,7.5

C806 2401-003026 C-AL;330uF,20%,200V,GP,ST,22x35,10

C807 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C808 2401-001571 C-AL;47uF,+20%-0%,50V,GP,TP,8x11.5,

C809 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C810 2401-000611 C-AL;1uF,20%,50V,WT,TP,5x11,5

C811 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C812 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C813 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C815 2401-000787 C-AL;220uF,20%,160V,GP,TP,16x31.5mm

C816 2401-000164 C-AL;1000uF,20%,25V,WT,TP,12.5x20,5

C817 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

C820 2401-003141 C-AL;2200uF,20%,25V,WT,TP,13x25,5mm

C821 2201-002002 C-CERAMIC,DISC;4700pF,20%,400V,+20%~-55%,TP,2

C822 2201-000963 C-CERAMIC,DISC;1nF,20%,400V,Y5U,TP,11x8mm,10m

C823 2201-002002 C-CERAMIC,DISC;4700pF,20%,400V,+20%~-55%,TP,2

C824 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

C825 2301-000310 C-FILM,PEF;68nF,5%,50V,TP,8.0X8.5X4.0X5,5

C827 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

C834 2401-002288 C-AL;470uF,20%,25V,WT,TP,10x20,5

Page 35

C855 2201-000599 C-CERAMIC,DISC;560pF,10%,500V,Y5P,TP,7x4,5

C861 2401-000287 C-AL;100uF,20%,16V,WT,TP,6.3x11,5

C862 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C870 2306-000350 C-FILM,MPPF;270NF,5%,400V,TP,26X18.5X10MM,20

C873 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C890 2201-000374 C-CERAMIC,DISC;220pF,5%,50V,CH,TP,12.5x3,5

C891 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C901 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C902 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3.5X1.9MM,C903 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C904 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3.5X1.9MM,C905 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

C906 2202-000121 C-CERAMIC,MLC-AXIAL;100pF,10%,50V,Y5P,TP,1.9x3.5,C907 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C908 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0,5

C909 2201-000193 C-CERAMIC,DISC;10pF,0.3pF,50V,CH,TP,5x3,5

C910 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,8x3.5

C911 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5

C912 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

C913 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

C914 2202-000286 C-CERAMIC,MLC-AXIAL;56pF,5%,50V,SL,TP,1.9x3.5,C920 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V,TP,-,7.5

CB01 2306-000318 C-FILM,MPPF;220nF,20%,250V,TP,-,22.5mm

CB19 2301-001258 C-FILM,PPF;39nF,5%,400V,TP,19.5x9x15,7.5

CD10 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

CD11 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CD12 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CD26 2401-001026 C-AL;3.3UF,20%,50V,GP,TP,5X11,5

CE01 2401-002597 C-AL;220uF,20%,35V,GP,TP,10x12.5,5

CE03 2401-001527 C-AL;47uF,20%,250V,HR,TP,13x25mm,5m

CE04 2305-000470 C-FILM,MPEF;68nF,5%,100V,TP,-,5mm

CL01 2201-000258 C-CERAMIC,DISC;17pF,5%,50V,CH,TP,5x3,5

CL02 2201-000247 C-CERAMIC,DISC;15pF,5%,50V,CH,TP,5x3,5

CN501B AA39-20604A LEAD CONNECTOR-ASSY;-,YBNH250-09,YBNH05/04,5/4P,50

CN601 3711-002643 CONNECTOR-HEADER;BOX,4P,1R,2.5mm,STRAIGHT,SN

CN602 3711-002644 CONNECTOR-HEADER;BOX,5P,1R,2.5mm,STRAIGHT,SN

CN701 3711-002648 CONNECTOR-HEADER;BOX,9P,1R,2.5mm,STRAIGHT,SN

CP01 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

CP02 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5m

CP03 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

CP04 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0mm,

CP05 2401-001496 C-AL;47uF,20%,16V,GP,TP,5x7,5

CU02 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU06 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CU11 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU12 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU13 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V,TP,2.2x3.

CU33 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD06 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD08 2301-000289 C-FILM,PEF;5.6nF,5%,50V,TP,7x6x3,5

CUD09 2301-000160 C-FILM,PEF;12nF,5%,50V,TP,11.0x6.0x9.0mm,

CUD15 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CUD18 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

CUD20 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD21 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

CUD23 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD24 2301-000204 C-FILM,PEF;2.7nF,5%,50V,TP,7.4x3.9x13mm,5

CUD25 2301-000356 C-FILM,PEF;47nF,5%,50V,TP,7.5x4.0x6.5,5mm

CUD28 2401-001989 C-AL;4.7uF,20%,50V,BP,TP,5x11,5

CUD29 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CUD30 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

D201 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D202 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

Page 36

D204 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D205 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D206 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D207 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D210 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D301 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D401 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D402 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D403 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D404 0402-000540 DIODE-RECTIFIER;RU20A,600V,1.5A,-,TP

D405 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D406 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D503 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D511 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D512 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D513 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

D601 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D801 0402-001160 DIODE-BRIDGE;D5SB60,600V,2.8A,SIP-4,ST

D803 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D804 0402-001105 DIODE-RECTIFIER;ERB43-04SV1,400V,1.0A,-,TP

D809 0402-000564 DIODE-RECTIFIER;FML-G22S,200V,10A,TO-220

D812 0402-000231 DIODE-RECTIFIER;FMG-G26S,600V,4A,TO-220F,ST

D814 0402-000213 DIODE-RECTIFIER;ERB12-06,600V,1.0A,DO-41,TP

D825 0402-000493 DIODE-RECTIFIER;1R5GU41,400V,1.5A,DO-15L,TP

D903 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D908 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D910 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

D951 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D962 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DB02 0402-001296 DIODE-RECTIFIER;FMP-3FU,1.5KV,5A,TO-3PF,ST

D-COIL AA27-20004H COIL-DEGAUSSING;

DE01 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,TP

DU01 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DU02 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DU03 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,TP

DZ101 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,TP

DZ210 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ211 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ217 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ231 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500mW,

DZ250 0403-000662 DIODE-ZENER;MTZ3.0B,3.0V,3.01-3.22V,500mW,

DZ302 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D

DZ303 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D

DZ304 0403-000660 DIODE-ZENER;MTZ22A,22V,20.15-21.2V,500mW,D