Page 1

A-PDF MERGER DEMO

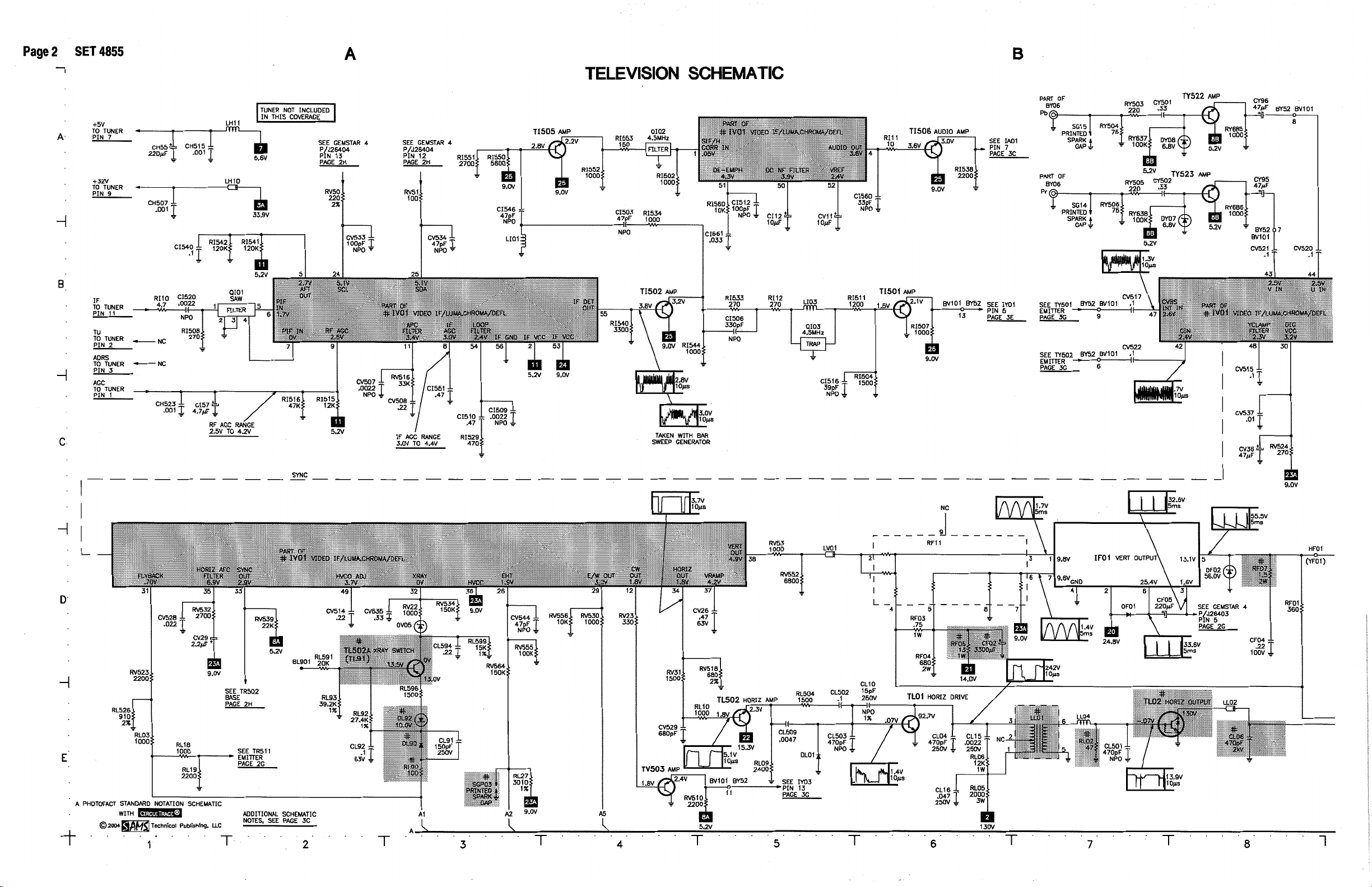

Page 2

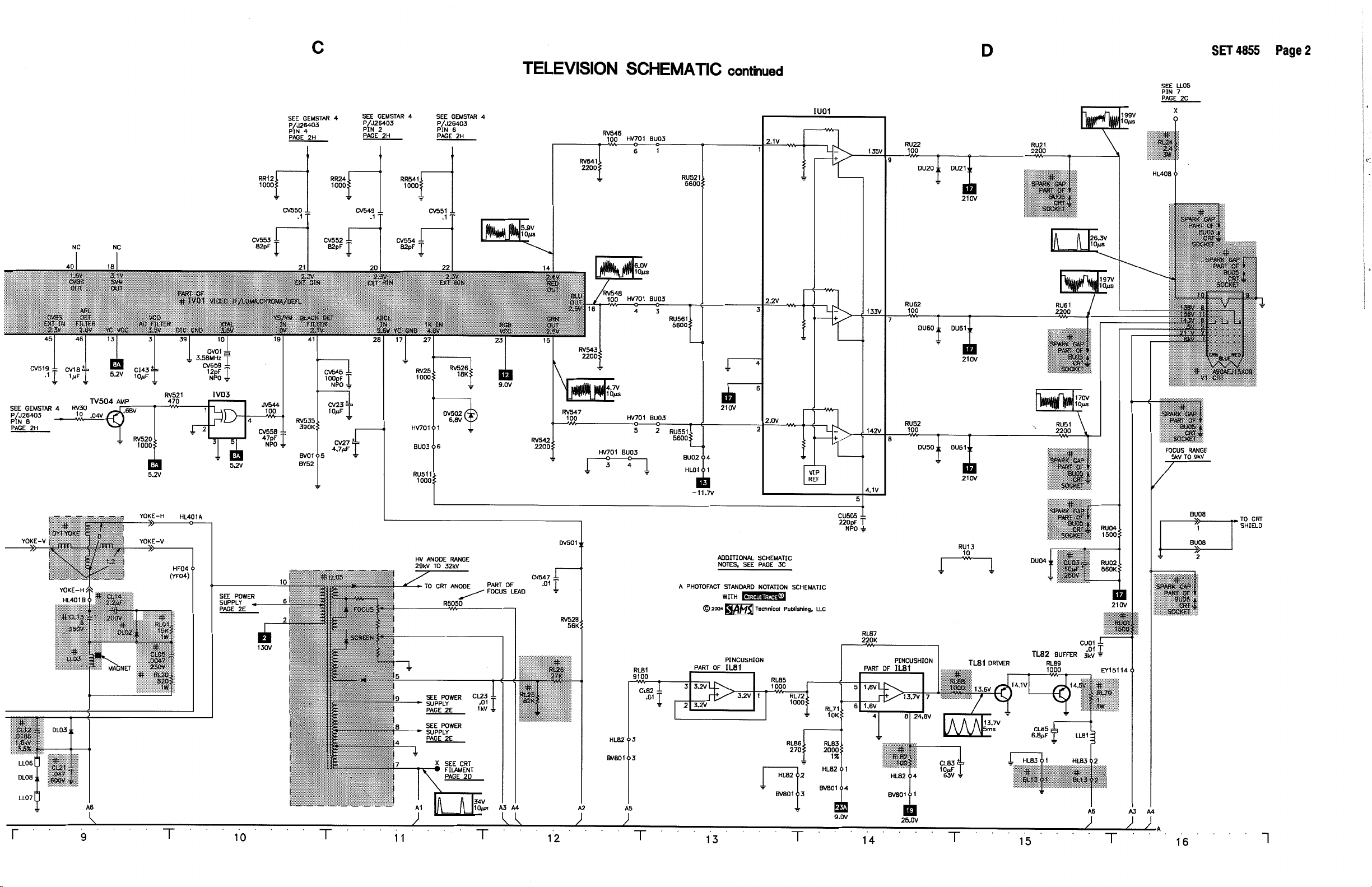

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

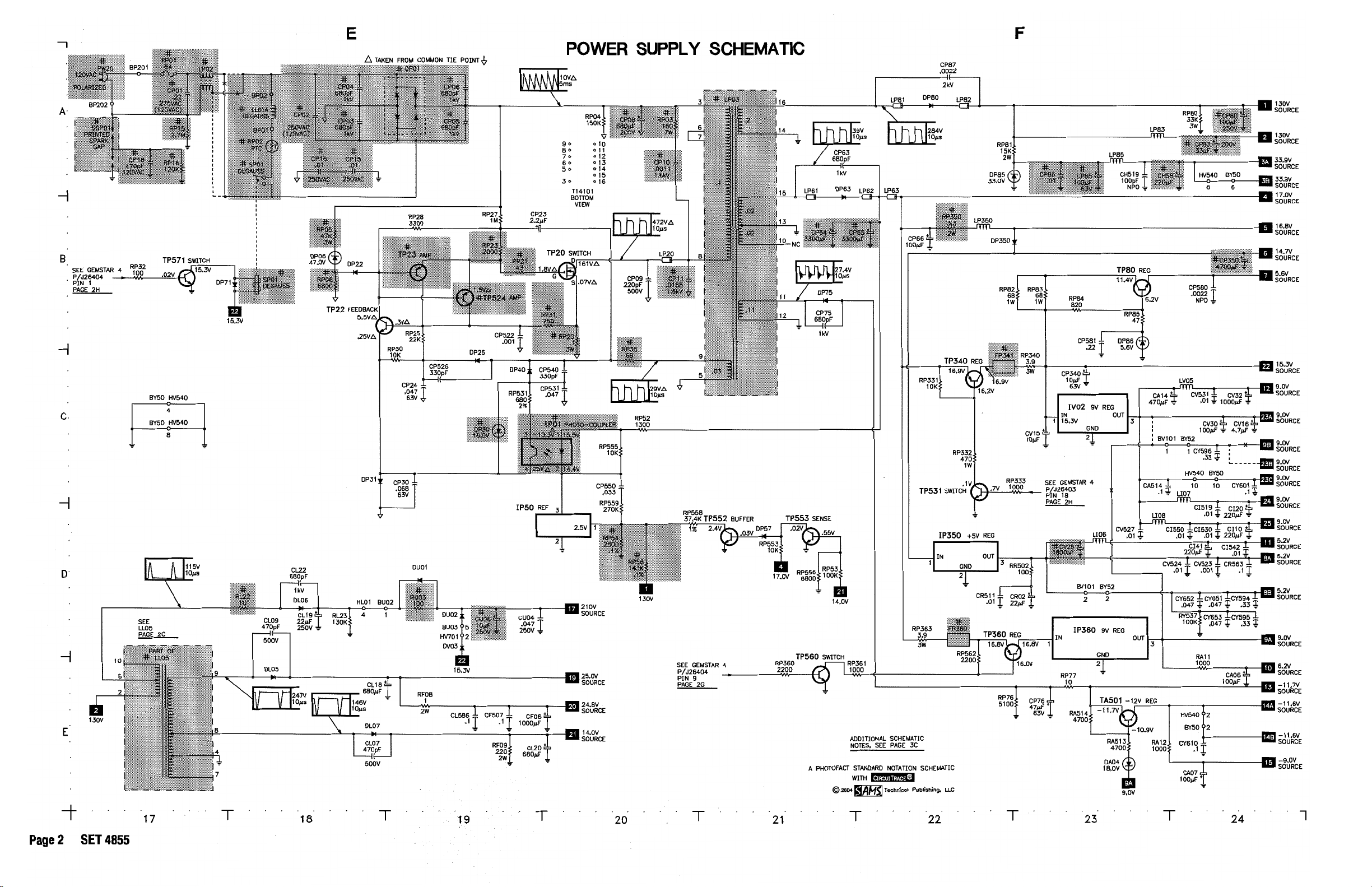

FP01

5A

120VAC

DP06

47V

RP06

LP02

To DeGauss

Circuit

RP05

DP22

TP22

RP28

TP23

RP25

RP30

2

DP01

4

3

CP24

1

RP27

RP23

RP21

RP31

DP26

CP23

Raw B+

156VDC

TP08

CP08

TP20

RP38

DP40

RP20

HOT COLD

LP03

3

8

9

5

16

14

15

13

10

11

12

DP80

CP80

NC

DP63

DP75

Reg B+UB

+33VE

DP85

+16VE

CP64

-12VE

CP76

DP31

DP30

16V

RP531

COLD

HOT COLD

IP01

13

3

2

2

1

RP54

4

HOT

IP50

Shunt

Reg

RP52

RP555

CP550

RP559

RP558

RP56

RP553

DP57

TP552

RegB+UB

Scan

Supply

RP53

TP553

RP556

ATC113 Power Supply

The standby supply is a high power, ZVS (Zero Voltage Switching) supply that minimizes

switching losses and radiated noise. ZVS refers to the ability of the supply causing the

voltage across the principal power output device, to reduce to near zero before the device

is switched on. Yet it has a slow enough time lag to allow the device to switch off

completely before any appreciable voltage is present across the device.

The MOSFET (TP20) begins conducting current when the gate voltage reaches the proper

turn on point. From that time, output current rises linearly due to the inductance of the

output transformer. However, once the gate voltage goes high, the drain voltage decreases

Page 9

Page 22

almost to zero volts. This eliminates much of the heat dissipation normally required of an

output device.

By reducing the switching losses to almost zero, the efficiency of the power supply is

greatly increased and the limiting of the switching voltages causes a substantial reduction

of switching noise.

Power Supply Operation

When AC is applied, DP01 converts the AC to approximately 156Vdc that is filtered by

CP08.

This “Raw B+” has two paths. First is through the transformer LP03 to the drain of TP20.

Second is through a series of resistors (RP27, 23, and 21) to the gate of TP20. As you

might guess this path is the start voltage for TP20.

With both drain and gate voltage TP20 conducts pulling the drain voltage to near zero,

collapsing the energy stored in LP03 winding pins 3, 8. This collapse causes voltage to be

induced into the secondary windings of LP03.

The winding on LP03 pins 9 and 5 is the secondary winding used for TP20 gate drive and

bias for TP22 and TP23. The pulse from this winding is sent to the anode and cathode of

DP26 and DP40 respectively. The positive bias is for the oscillator control circuit of TP22

and TP23. The negative bias is for IP01 and regulation. The un-rectified pulse provides

initial gate drive of TP20 via RP38, CP23, RP23, and RP21.

Oscillation occurs as TP20 turns on and off. TP22 and TP23 function as a latch circuit to

turn off TP20. As TP20 conducts, current is pulled through RP20. At some point the voltage

across RP20 increases till TP22 turns on. TP22 turns on pulling the base of TP23 lower

turning on TP23. With TP23 on, TP20 is turned off removing the voltage developed across

RP20 turning off TP22 and so on. The re-supply pulse and B+ through RP27 start the cycle

all over again.

Feedback is used to control the on time of TP20. The longer TP20 stays on, the more

current is developed in LP03. There are two feedback paths from the secondary side, the

+16V and the REG B+. Both voltages are required for proper regulation and run of the

power supply. IP50 shunt regulator controls the voltage across IP01 pins 1 and 2. As Reg

B+ goes up, IP50 becomes more resistive or open turning off IP01.

IP01 is used to couple the secondary to the primary. As the transistor in IP01 turns on

more, the less negative pin 4 becomes. This causes DP20’s emitter voltage to be more

positive. A more positive voltage on the emitter of TP22 means that the base voltage needs

to be more positive for it to turn on, there for TP20 stays on longer.

Page 10

Page 23

FP01

5A

120VAC

DP06

47V

RP06

LP02

To DeGauss

Circuit

RP05

DP22

TP22

21

RP28

TP23

RP25

RP30

DP01

4

3

CP24

RP27

RP23

RP21

RP31

DP26

CP23

Raw B+

156VDC

TP08

CP08

TP20

RP38

DP40

RP20

HOT COLD

LP03

3

8

9

5

16

14

15

13

10

11

12

DP80

CP80

NC

DP63

DP75

Reg B+UB

+33VE

DP85

+16VE

CP64

-12VE

CP76

HOT COLD

1

2

3

1

2

RP54

RP52

RP555

CP550

RP559

RP558

RP56

DP31

DP30

16V

RP531

IP01

3

4

HOT

COLD

IP50

Shunt

Reg

Key points about the ATC113 ZVS power supply:

• Stand-by operating frequency of 60 to 65KHz.

• RP20 over current protection.

• DP30 over voltage protection.

• TP552 and TP553 used for run mode current increase.

• If TP20 fails replace all active components on primary side.

• Run operating frequency of 40 to 50KHz.

Scan

Supply

RP553

RP53

DP57

TP553

RP556

TP552

RegB+UB

Page 11

Page 24

Power Supply Troubleshooting Tips

NOTE: Voltage readings taken at 90VAC input using a Vari-AC.

Regulation Problem:

IP01 (Photo-Coupler) can be by-passed by shorting pins 1 and 2 of IP01, and connecting a

10K potentiometer across pins 3 and 4. With the potentiometer set to 10K the Reg B+ is

aprox. +140Vdc. At 7.5K the Reg B+ was aprox. +100Vdc.

IP50 can also be checked with the same setup as in IP01. As the Reg B+ goes up IP50

conducts. Monitoring pin 3 of IP50 and with Reg B+ at +100Vdc pin 3 is aporx. +12.5Vdc.

As Reg B+ goes up IP50 will conduct and pin 3 will drop to +1.8Vdc. By using the 10K

potentiometer one can vary the Reg B+ and check all functions of feedback control.

Start-up Problem:

Unsolder the Drain of TP20 and turn on the Vari-AC. The gate voltage of TP20 should

measure +11.5Vdc. Anything less check for loads in the star-up circuit. Anything more

check for an open in OSC circuit and DP06 circuit.

Check for shorts on the secondary of LP03. Excessive load on the power supply will cause

it to shutdown and pulse.

Page 12

Page 25

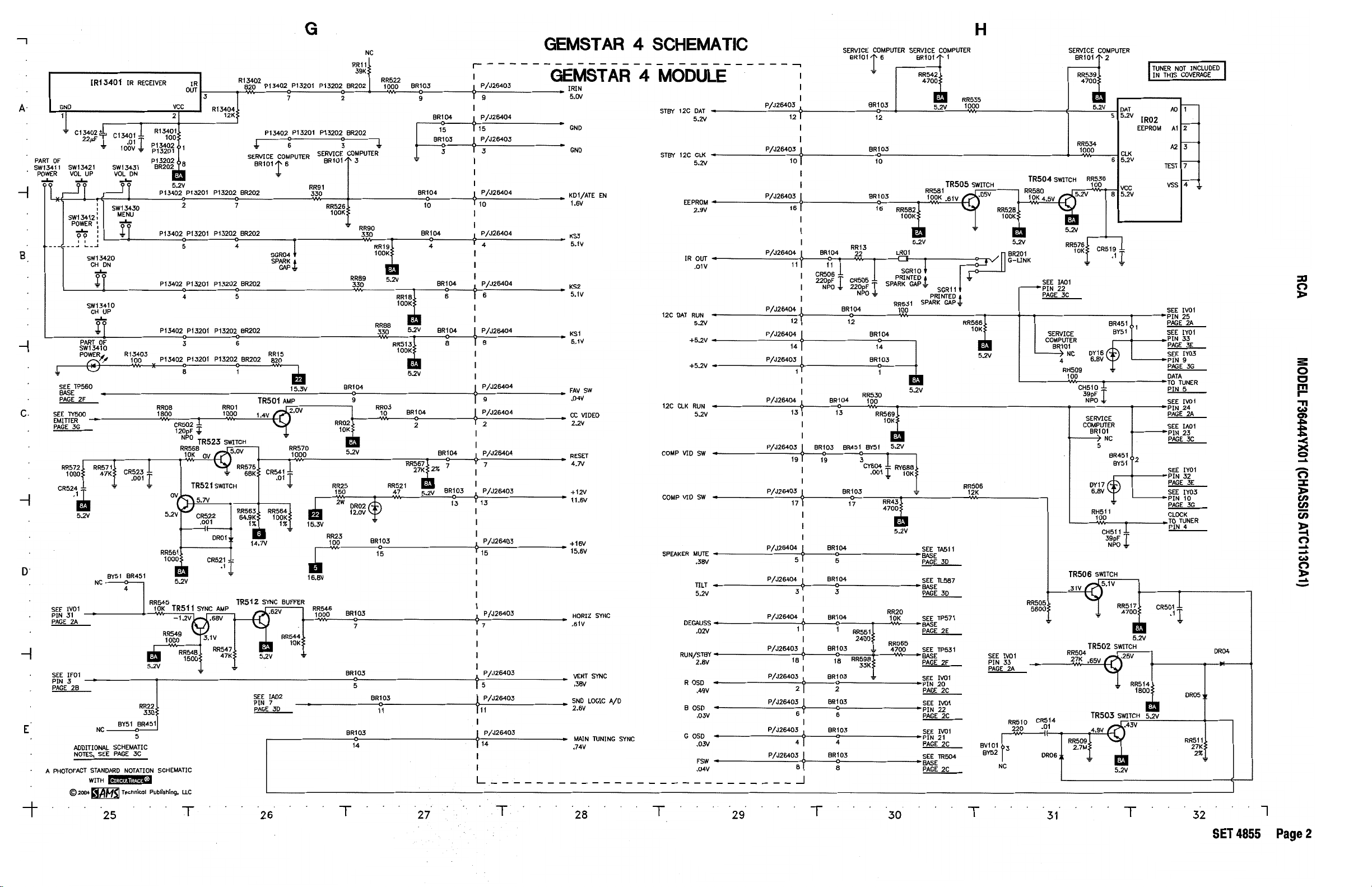

+5.2VE4

Gemstar 4

U26401

TR504

TR505

J26404

J26403

EEPROM Enable

8

5

IR02

6

4

Clock

I2C Stby

Data

BR103 BR104

ChipperCheck

Service Connector

BR101

BR202

Keyboard

1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 151 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

to

IR

2

4

5

6

7

KS3

KS2

KS1

KD1

2

I

C Run

Data

Clock

+5.2VE

IR Out

ECO

Gemstar 4 and System Control

The Gemstar module is used to generate the electronic program guide (EPG) and control

the chassis. The main processing IC, for the EPG, is U26401. U26401 has two main

functions; in standby U26401 processes information for the EPG and user input, in the run

mode U26401 controls the different functions of the chassis. The two flat ribbon cables

that connect the Gem4 module to the chassis are BR103 and BR104.

Power for the module comes from the +5.2VE via pin 14 of BR104. The standby I2C bus

provides communications to the EEPROM (IR02) and the Chipper Check interface via

BR103 pins 10 and 12. The Run I2C bus on pins 12 and 13 of BR104 provide

communication to the tuner, video processing (IV01), video switching and audio processing

(IA01) and switching IC’s. PIP functions are also controlled by the run clock and data.

User input is via remote or keyboard. BR103 pin 9 is the IR input to the Gem4 module and

keyboard input is on pins 4, 6, 8, and 10 of BR104. These signals are processed by the

system control and commands are sent to the chassis via I2C bus on BR104 pins 12 and

13.

Page 6

Page 26

Troubleshooting the Gem4

1. With AC power applied to the set.

2. Check BR104-14 for +5.2VE

3. Voltage incorrect or missing, troubleshoot STBY power supply

4. Check BR103-10 and 12 (Clock & Data) for +5.0Vdc and 5Vp-p signal.

5. Signal present all the time troubleshoot main chassis and IR02.

6. Check BR104-4, 6, 8, and 10 for proper DC levels. Incorrect DC levels disconnect

BR202 and recheck.

7. Correct DC levels with BR202 disconnected troubleshoot keyboard.

8. Check for signal at BR104-12 and 13 when power button is pressed.

9. Clock and Data signal present when power is pressed troubleshoot the chassis.

10. Not present replace Gemstar module.

Start-up and Shutdown

3 Strikes and You’re Out Shutdown

The below error code table shows the different codes that can be thrown during the 3

strikes shutdown. The error codes can be viewed by accessing the service menu. Parameters 1, 2, and 3 are reserved for error codes. When viewing error codes for the first time it

is a good idea to reset all to zero and let the set go through the 3 strikes again. The new

error codes will indicate the first problem detected by the system control during start-up.

Error Code

(Dec)

00 No error code thrown

03 U26401 Gemstar Micro 12V Run fault

08

09

11

12

16

18

44

176

180

IV01 XRP event detected

IV01 Power on reset

IY03 F2PIP Power on reset

IA01 Stereo Decoder Power on reset

U26401 Gemstar Micro Run I2C clock or data clamped at logic state 0

U26401 Gemstar Micro Stand-by I2C clock or data clamped at logic state 0

IY03 F2PIP No acknowledge from device

IA01 Stereo Decoder No acknowledge from device

3-Line Comb No acknowledge from device

Device Condition

144

194

IY01 A/V Switch No acknowledge from device

Tuner No acknowledge from device

Page 7

Page 27

Y

Pr

Pb

XBox

Connector

BY51

XBox SW

3

1

BIAS

6

4

GND

5

BIAS

6

4

GND

5

VCC

Buffer

OUT

2

IY09

3

1

VCC

Buffer

OUT

2

IY07

3233

ClockData

16

Yin

IY01

Vcc

Yout

1

+5VE

Pb

BV101

40 +9VE

Pr

Pr

Pb

Y

Y

Chassis

CRT Board

R

14

G

15

IV01

43

16

44

47

IU01

B

BY52

7 41

I/O Board

Chassis

3

1

BIAS

6

4

GND

5

Buffer

VCC

IY08

OUT

2

IY03 PIP

BY50

ATC113 Y Pr Pb Path

The ATC113 is capable of two YPrPb inputs via conventional YPrPb cable and a special

cable connected to the V-Port (X-Box). Both inputs go three switch IC’s, IY09 for the Y

signal, IY07 for the Pr signal, and IY08 for the Pb signal. A voltage from the Gemstar

system control switches the three IC’s. BY51 pin 3 (XBOX SW) goes high approximately

3.1Vdc when the user selects V-Port input. When low, component input is selected. The Y

signal is further switched by IY01 (Audio / Video switch IC) and sent to the PIP processor or

comb filter. After PIP / Comb processing the Y signal along with Pr and Pb signals are sent

to connector BV101 and to the main chassis. All three signals are further processed by

IV01 and output as RGB to the CRT driver IU01.

I/O Module Troubleshooting

NOTE: Without the I/O module connected to the chassis the set will go through the 3-

strikes and you’re out shutdown.

The different I/O modules are board level troubleshooting. By checking the signals and

voltages to and from the I/O one can isolate down to board level. There are no set

procedures for this type of troubleshooting. Checking all signals and voltages on all

connectors is the only way to troubleshoot the I/O module. See service data for signal and

voltage requirements of each I/O.

Page 8

Loading...

Loading...