Page 1

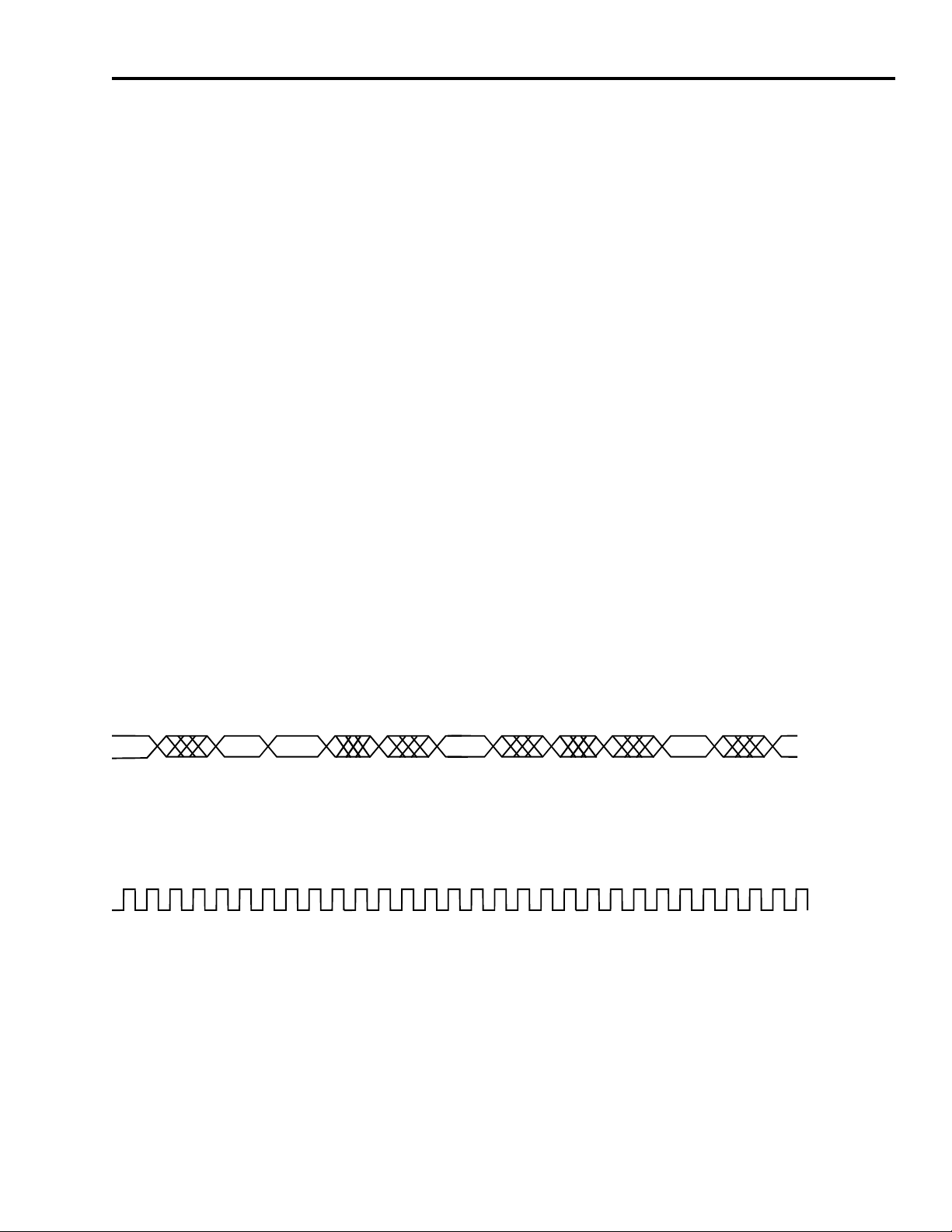

TO

E8

RED BIAS

VERTICAL

<21-B>

TO

E7

GRN BIAS

E5003

E5007

TP50

RED OUTPUT

194V

FOREWORD

This publication is intended to aid the technician in servicing the CTC195/197 television

chassis. It will explain the theory of operation, highlighting new and different circuits

associated with the digitally controlled chassis. The manual covers power supply,

horizontal and vertical deflection, video signal processing, and audio signal processing

theory of operation along with practical, proven troubleshooting methods. It is designed

to assist the technician to become more familiar with the chassis operation, increase

confidence and improve overall efficiency in servicing the product.

Note: This publication is intended to be used only as a training aid. It is not meant to

replace service data. Thomson Consumer Electronics Service Data for these instruments

contains specific information about parts, safety and alignment procedures and must be

consulted before performing any service. The information in this manual is as accurate

as possible at the time of publication. Circuit designs and drawings are subject to change

without notice.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Thomson Consumer Electronics Service

Data. All product safety requirements must be complied with prior to returning the

instrument to the consumer. Servicers who defeat safety features or fail to perform safety

checks may be liable for any resulting damages and may expose themselves and others to

possible injury.

All integrated circuits, all surface mounted devices, and many other

semiconductors are electrostatically sensitive and therefore require

special handling techniques.

Chipper Check® is a registered trademark of Thomson Consumer Electronics.

dbx® is a registered trademark of Carillon Electronics Corporation.

DSS® is a registered trademark of DirecTV, Inc., a unit of Hughes Electronics Corp.

TV Guide Plus+® is a registered trademark of Gemstar Development Corporation.

TV Guide® is a registered trademark of TV Guide Financial, Inc.

SRS®, the SRS symbol and Sound Retrieval System® are registered trademarks of

SRS Labs, Inc.

First Edition 9726 - First Printing

Copyright 1997 Thomson Consumer Electronics, Inc.

Trademark(s)® Registered Marca(s) Registrada(s)

Printed in U.S.A.

Prepared by

Thomson Consumer Electronics, Inc.

Technical Training Department

PO Box 1976

Indianapolis, Indiana 46206 U.S.A.

®

Page 2

Contents

General Features: ...............................................................................................................6

Technical Overview .......................................................................................................... 12

CTC195/197 “Main” Power Supply .............................................................................. 15

AC In and Degaussing ..........................................................................................................................15

Power Supply Operation .......................................................................................................................16

Secondary Supply Operation ................................................................................................................19

Troubleshooting ................................................................................................................ .................... 20

Auxiliary Power Supply Operation ............................................................................... 2 2

CTC195 Convergence Power Supply Overview ........................................................... 2 5

Power Supply Operation .......................................................................................................................26

Horizontal Deflection Overview..................................................................................... 30

Horizontal Circuits .......................................................................................................... 32

AFC and APC .......................................................................................................................................32

Horizontal Driver ..................................................................................................................................33

Horizontal Output .................................................................................................................................33

E/W Pin Correction & S-Correction (CTC197) ................................................................................... 35

E/W Pin Correction & S-Correction (CTC195) ................................................................................... 35

X-Ray Protection Circuit ......................................................................................................................36

Z-Axis Correction ................................................................................................................................. 37

Troubleshooting ................................................................................................................ .................... 38

Vertical Circuits................................................................................................................ 40

Half-Supply ........................................................................................................................................... 41

Troubleshooting ................................................................................................................ .................... 45

No Vertical Deflection .......................................................................................................................... 45

Scan Loss Detect & Shutdown Overview ............................................................................................46

Scan Loss Detect Operation.................................................................................................................. 47

System Control ................................................................................................................. 50

Overview ............................................................................................................................................... 50

Standby/AC Line Dropout Detector and Reset .................................................................................... 52

Reset, Recovery, Initialization and BrownOut ....................................................................................52

Software detection ................................................................................................................................ 52

+16V Standby........................................................................................................................................ 52

15 Second Timer ...................................................................................................................................53

POR ( Power Off Reset) .......................................................................................................................53

EEPROM and T4 Chip Power Control ............................................................................................... .54

Main Power Supply On/Off Control.....................................................................................................54

Power Down..........................................................................................................................................56

Batten Down the Hatches .....................................................................................................................56

Feature Auto Detection .........................................................................................................................58

Run Supply Detector............................................................................................................................. 58

Microprocessor Input Signals ...............................................................................................................59

Microprocessor Pin Assignments .........................................................................................................59

U13101 Pin Functions: .........................................................................................................................60

Page 3

IR Input.................................................................................................................................................. 66

OSD Circuit.......................................................................................................................................... 66

Service Menu ........................................................................................................................................67

Error Codes ...........................................................................................................................................68

Troubleshooting ................................................................................................................ .................... 70

I²C Bus................................................................................................................................................... 70

Main Tuner ....................................................................................................................... 7 5

Input Splitter.......................................................................................................................................... 76

Single Tuned Input Filtering................................................................................................................. 76

RF Amplifier .........................................................................................................................................76

RF Bandpass .......................................................................................................................................... 77

Mixer/Oscillator ....................................................................................................................................77

IF Bandpass ...........................................................................................................................................77

PLL / Frequency Synthesizer ................................................................................................................ 77

Bandswitching....................................................................................................................................... 78

Tuning ................................................................................................................................................... 78

Channel Selection .................................................................................................................................79

Software Control ................................................................................................................................... 80

EEPROM Requirements .......................................................................................................................81

IF Alignment ......................................................................................................................................... 81

IF DACS................................................................................................................................................81

Tuner Alignment ................................................................................................................................... 81

Troubleshooting ................................................................................................................ .................... 83

Electronic Alignment ............................................................................................................................ 83

RF Bandswitching.................................................................................................................................83

Channel Switching ................................................................................................................................85

No Tuning .............................................................................................................................................86

FPIP/2nd Tuner Overview .............................................................................................. 88

Video Input Switching .......................................................................................................................... 91

FPIP (U18100) Overview ..................................................................................................................... 92

FPIP Signal Switching .......................................................................................................................... 93

FPIP IC U18100 Pinout ........................................................................................................................ 96

Second Tuner (PIP) ............................................................................................................................... 98

PIP 2nd Tuner/IF.................................................................................................................................100

T4 Chip U16201.............................................................................................................. 101

T-Chip Overview ................................................................................................................................101

T4 Chip Bus Specifics ........................................................................................................................101

POR (Power-On Reset) Operation .....................................................................................................101

Bus Transceiver Reset.........................................................................................................................101

Transceiver Power Supply and Register Volatility............................................................................. 103

IF Processing .......................................................................................................................................103

Audio Detection ..................................................................................................................................103

CRT Management .............................................................................................................................. 103

Deflection Processing ......................................................................................................................... 103

Video Processing.................................................................................................................................103

Page 4

Video Processing ............................................................................................................. 104

Luma Processing .................................................................................................................................105

Chroma Processing ............................................................................................................................. 106

RGB Interface .....................................................................................................................................108

External RGB Input Processing..........................................................................................................108

RGB Output Section ...........................................................................................................................108

CRT Management ...............................................................................................................................109

Beam Current Limiting ....................................................................................................................... 109

CRT Drivers ........................................................................................................................................ 110

Automatic Kine Bias & Scan Velocity Modulation..................................................... 111

Scan Velocity Modulation................................................................................................................... 111

Automatic Kine Bias...........................................................................................................................112

AKB Operation ................................................................................................................................... 115

Start-up ................................................................................................................................................ 116

CTC195 AKB ..................................................................................................................................... 117

AKB and Color Temperature Alignment............................................................................................ 118

Audio Processing Overview .......................................................................................... 120

Audio Input/Switching Circuit............................................................................................................122

Balance Control ................................................................................................................................... 122

Volume Taper & Fletcher-Munson Network...................................................................................... 124

Audio Output Circuit ..........................................................................................................................125

AVR (Automatic Volume Reduction)................................................................................................ 127

SRS/Compressor Circuits.............................................................................................. 128

TV Guide Plus+ .............................................................................................................. 1 31

EPG Self-Diagnositcs ......................................................................................................................... 131

Menu’s ................................................................................................................................................. 132

Obtaining More Information...............................................................................................................132

Customizing The Channel Listing......................................................................................................132

One Touch Recording .........................................................................................................................132

Recording Options .............................................................................................................................. 132

Troubleshooting ................................................................................................................ .................. 132

Blank Screen .......................................................................................................................................132

No Sound, Picture Okay .....................................................................................................................133

Can’t Select Desired Channel .............................................................................................................133

Noisy Stereo Reception.......................................................................................................................133

No Picture, No Sound but TV is on.................................................................................................... 133

Sound Okay, Poor Picture ...................................................................................................................133

Black Box Appears on the Screen ......................................................................................................133

TV Guide Plus+ IR Controllers Not Working.................................................................................... 133

TV Guide Plus+ Cable Box Codes .....................................................................................................134

TV Guide Plus+ VCR Codes .............................................................................................................. 134

Page 5

PTV Digital Convergence Overview............................................................................ 13 6

Circuit Description..............................................................................................................................137

Digital Convergence Circuit ...............................................................................................................140

Convergence Yoke Drivers ....................................................................................................... .......... 142

Crosspoint Adjustments ......................................................................................................................144

Front Panel Service Mode..................................................................................................................145

Remote Control Service Functions............................................................................................... ...... 146

Convergence and Alignment Specifications ...................................................................................... 148

DigiCon Service .................................................................................................................................. 150

T-Chip Alignment ............................................................................................................................... 150

Banding ...............................................................................................................................................151

Digital Convergence Failure ...............................................................................................................152

CRT Replacement ...............................................................................................................................152

Digital Convergence IC ......................................................................................................................153

Convergence "Jumps" ......................................................................................................................... 153

Troubleshooting (General) .................................................................................................................. 154

Troubleshooting Geometry .................................................................................................................154

Troubleshooting Convergence............................................................................................................156

CRT Replacement ...............................................................................................................................156

EEPROM Replacement ...................................................................................................................... 161

Main EEPROM Replacement............................................................................................................. 161

DigiCon EEPROM Replacement ....................................................................................................... 161

DigiCon IC Replacement....................................................................................................................164

Red/Green/Blue CRT's........................................................................................................................ 165

Chipper Check Overview .............................................................................................. 166

Chipper Check Hardware.................................................................................................................... 167

Chipper Check Software .....................................................................................................................168

“Dead Set” Troubleshooting with Chipper Check ............................................................................. 169

Chipper Check Hookup ......................................................................................................................170

Chipper Check Operation ...................................................................................................................170

Diagnostic Function ............................................................................................................................170

Alignments Function ...........................................................................................................................171

Part Replaced Function ....................................................................................................................... 171

Page 6

6 Overview

General Features:

The CTC195/197 chassis is the latest in the Thomson Consumer Electronics line of

digitally controlled television receivers. It relies on microprocessor control to govern

the entire operation of the television, including consumer operation, system operation,

system monitoring and maintenance. The control circuits are not only responsible for

turning the set on and off, but also for aligning the different circuits such as deflection

and signal. Adjustments that were previously aligned with a potentiometer on other

chassis are now aligned digitally via the microprocessor with the values stored in the

EEPROM (Electrically Erasable Programmable Read Only Memory). The CTC197

will eventually replace a wide range of current TCE chassis', including the CTC169

and CTC176/177 series direct view chassis. Video and audio feature requirements

reflect a range of performance from previous core line products to midrange featured

sets. The basic feature package will include dBx stereo, 8 jack panel, and an on-screen

program guide.

Screen Sizes

The CTC197 covers direct view screen sizes from 27" to 35", measured diagonally.

The CTC195 will be used in PTV screen diagonal sizes from 46" to 61".

The projection television CTC195 chassis utilizes the CTC197 basic chassis plus

additional circuitry to adapt it for projection TV operation. The additional circuitry

consists of the "Digital Convergence" circuit board and it's own dedicated power

supply. The CTC195, unlike earlier PTV's that used analog convergence, uses the all

new "Digital Convergence" circuitry to provide near perfect convergence and linearity.

The CTC195 will replace previous PTV chassis CTC169, CTC178/188 and CTC187.

Video

The video performance of the CTC197 covers both low and mid levels. Models are

specified to include comb filter and S-VHS (where 600 LOR (Lines of Resolution) is

required) or non-comb filter without S-VHS (where 280 LOR is required). Auto

Color and AKB (Automatic Kine Bias) are basic for all chassis versions.

Tuning

CTC197 tuners incorporate the necessary specifications to follow normally accepted

cable TV tuning capabilities and will also meet the latest FCC "cable ready" requirments.

Channel tuning is also enhanced through a Fast Tune option.

Audio

CTC197 audio circuitry includes dBx stereo and is configured for both 1 watt and 5

watt output version. The CTC195 will add a 10 watt audio amplifier.

Page 7

The CTC197 contains a wide array of consumer selections and controls. Among them

are:

Sleep Timer

The sleep timer has four hour functionality and can be set in increments of fifteen

minutes. The OSD counts down time remaining when the sleep timer function is

enabled. The Sleep Time function also includes a descending audio taper automatically

implemented the last one minute of Sleep Timer operation.

On Screen Time and Channel Display

The On Screen Time and Channel features allows the current time and channel to be

displayed on screen. This feature can be programmed for continuous display through a

menu item (continuous display is not an option on PTV). This includes both AM and

PM selections. In cases where time has not been set, only the channel will be

displayed.

Factory Reset

Resets all consumer picture quality adjustments to one of three factory present conditions.

Auto Program

Overview 7

Automatically locates and enters into memory all active channels.

Commercial Skip

Commercial Skip is user implemented in thirty second increments up to four minutes

and then 60 second increments up to one hour. When CS times out, the programming

will return to the channel that was on screen when CS was initially entered. When CS

is enabled in two tuner PIP sets, the original channel will automatically appear in the

second tuner PIP. When CS times out, PIP is disabled.

Multilingual OSD

The CTC197 will support up to three customer-selectable OSD languages. Languages

will include: English, Spanish or Portuguese.

Alarm Timer

The Alarm Timer feature permits the user to set the TV to come on automatically at a

preset time every day. The TV will automatically turn off after two hours if no

other function is accessed by the consumer (i.e., volume, channel, etc.).

Parental Control

The parental control feature permits the user to engage a secondary scan list with more

limited channel choices. This may be used by parents to control the channel selection

capabilities of the set when they are not able to supervise program selection.

Page 8

8 Overview

Auto Tune (VCR/Cable/DSS Set-Up)

Auto select allows the user to select which channel or external input should automatically

be selected when the VCR1, VCR/LD or cable/DSS key is pressed on the remote.

Auto select set-up is accessible via on screen menu.

Channel Labeling

Channel labeling is permitted for no less than 28, four-character or 14, eight character

labels.

Channel Directory

The Channel Directory Feature permits up to 28 channels and their consumer input

labels to be displayed on-screen as an index. The channel directory presentation may

consist of more than one display screen.

TV Guide Plus+

Displays program title, length, elapsed time, program description, channel labeling and

EDS (Extended Data Service) broadcast early warning display in areas where the

system is broadcast. A menu item assisting in the selection of “Eastern Standard,

Central Western” standard time will be provided.

Closed Captioning

Field one and Field two of closed captioning are supported (CC1, CC2, CC3, CC4,

T1, T2, T3, T4). CCD enabling is through TV menu selection.

Color Temperature

A three position, user-selectable color temperature switch is available via the on screen

display system.

Interface

The CTC195/197 will support two levels of consumer feature operation. On select

chassis versions, the basic interface will be augmented with an ICON based "Fetch"

Menu. Highlighting and enabling a Fetch Icon automatically implements the set-up

menu of the feature or enables it. Fetch Menu items include: sleep timer, front panel

lockout, parental control, alarm timer, initial setup, and channel directory.

Mute

The Mute feature can be enabled via remote control or TV menu selection. Mute with

automatic CCD (Closed-Captioning) operation is consumer selectable via a menu

selection. When Mute and automatic CCD is selected the consumer CCD preference

will automatically be displayed. If no consumer preference has been noted, CC1 will

be selected. Text will not be permitted as an option.

Page 9

Front Panel Lock-Out

Front Panel Lock-Out disables the front TV access buttons. It can be enabled through

either the remote control or via menu option. Once enabled, the Front Panel

Lock-Out feature can be disabled through either remote command or by disconnecting

AC power to the set for more than sixty minutes.

Fast Track Tuning

The CTC197 will support, via the front panel or remote, a two speed tuning feature.

When the channel up/down key is depressed, the set will continuously select and tune

the next highest/lowest channel and displays it with OSD for 500 ms. If the channel up/

down key is held down for three or more seconds, the Fast Track Tuning feature is

enabled and the TV will select and tune the next highest/lowest channel at a more rapid

rate.

Cable Ready

Provides the channel capacity to provide the accepted “cable ready” standard.

FPIP

Overview 9

Basic Color PIP (FPIP) will be an optional feature on select chassis versions. PIP

features are similar to the CTC187 implementation including swap, and PIP continuous

move. Channel labeling will only be supported in the main picture. PIP can utilize Aux

1 (or S-VHS) as the second video source. Where a second source is not available,

both the big picture and small picture will be the same. Fast Track tuning is provided

for either small or large pix.

Two Tuner PIP

Two tuner PIP (T2FPIP) will be supported on select chassis versions. T2FPIP

features will be the same as those of FPIP but also include channel labeling of both

main and small PIP. Fast Track tuning is active for both small and large pix. The

CTC197 does not support separate main picture vs PIP color controls.

A/V Jack Panel

The jack panel will include two video inputs, one pair of left and right audio inputs and

an S-Video input jack. There will also be one pair of variable (hi-fi) left and right audio

outputs.

S-Video

Select CTC197 chassis will support S-Video with auto detection of the signal when

there is an active S-Video input. The S-Video input will replace Video Input 1.

Page 10

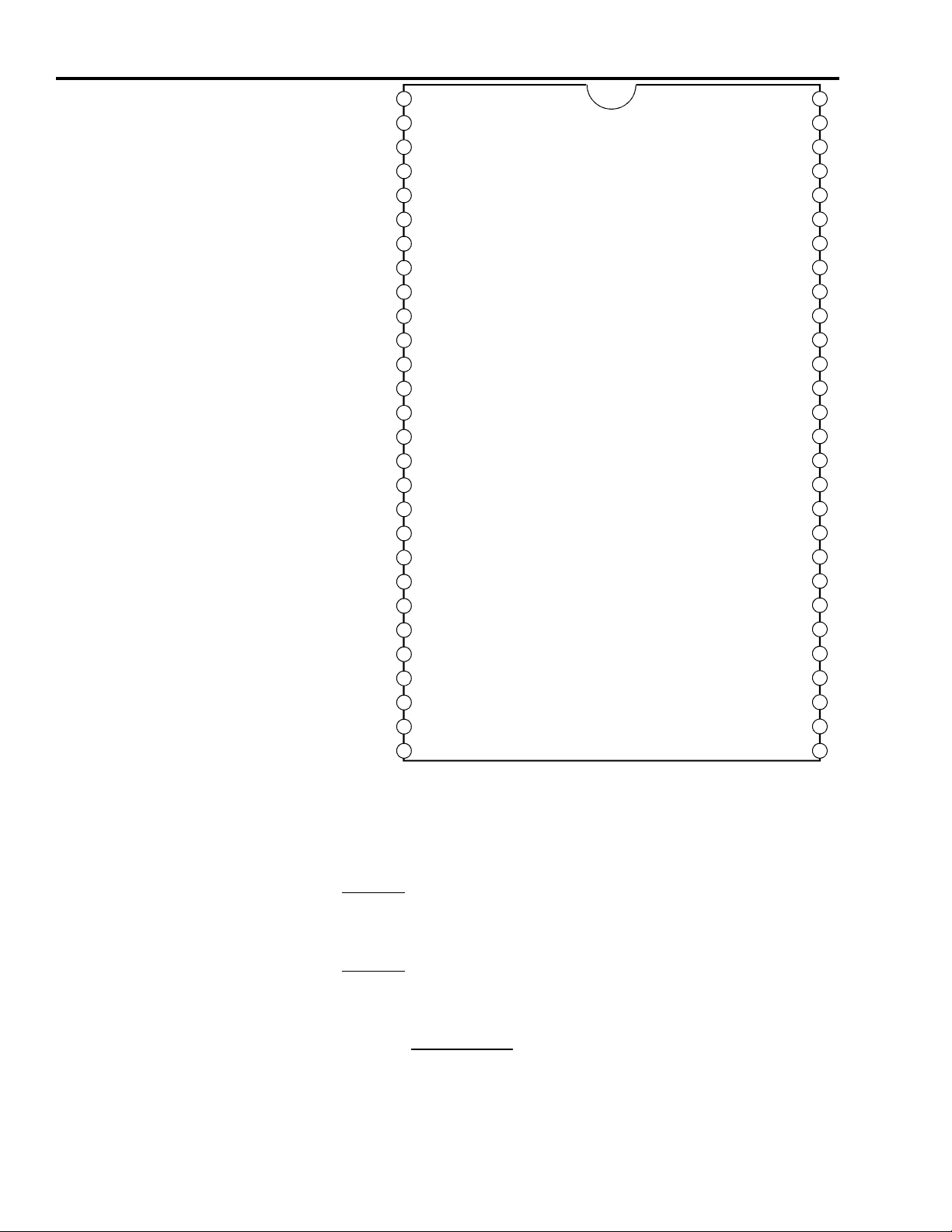

10 Overview

POWER

DVD

VCR1

VCR2

SAT

CABLE

AUDIO

TV

REVERSE

RECORD

INFO

VOL

MUTE

1

4

7

FAV INPUT

CLEAR

STOP

2

5

8

0

MENU

PLAY

CH+

CH-

SELECT

FORWARD

PAUSE

SKIP

VOL

GO BACK

3

6

9

ANTENNA

RESET

PIP

MOVE

SOUND

FETCH

CH CTRLSWAP

CRK70 Series Remote Control

Page 11

Comb Filter

A digital comb filter will be employed on select chassis versions. Comb filter versions

will also support consumer switchable video noise reduction.

No Signal Present

When the TV is placed in the S-Video or Video Input mode, and no signal is present, a

gray screen with the caption "No Signal Present" will be displayed.

dbx/SAP Audio

The CTC197 will support dbx/SAP. SAP (Separate Audio Programming) is a

selectable user feature that is specific to the channel selected. When Commercial Skip

is enabled while on a station broadcasting SAP programming, when the original channel

is retuned, SAP is re-enabled.

Audio Speaker Select

A menu option will permit the customer to turn internal speakers on or off.

Treble/Bass/Balance

Overview 11

The audio treble, bass and balance may be adjusted from the menu system.

SRS (Sound Retrieval System)

Basic SRS is supported via OSD. SRS audio is implemented through the internal

speakers. There is no external SRS speaker terminals.

Front Panel Controls

The front panel will provide Menu, Channel Up, Channel Down, Volume Up, Volume

Down and Power buttons.

Remote Use

The CTC197 uses the CRK70, CRK74, CRK83, & CRK84 remote controls.

Page 12

12 Overview

Technical Overview

The CTC197 was designed to provide a mid/high end replacement chassis for a broad

spectrum of TCE product line.

The CTC197 chassis begins with a bus controlled, tuner on board concept similar to

the CTC175/176/177 family and begins to expand on this base. The key developments

in the CTC197 are the T4 Chip, the FPIP IC, and a new Stereo IC.

The new T4 (U16201), used in part in the CTC185 chassis, allows more bus control of

adjustments and incorporates AKB (Automatic Kine Bias) and places the calculations

for AKB control with software.

The FPIP IC (U18100) is new to the CTC197 and allows bus control of PIP functions.

Although similar to the DPIP found in the CTC187, the FPIP also incorporates video

switching and a digital comb filter. A significant improvement over previous PIP IC

designs is that it requires no external memory. All RAM is internal to the IC.

The audio stereo decoder IC (U11600) allows bus control of the dBx decoder by the

I2C bus. The tone, volume and balance functions previously performed by a separate

IC, are now included in the stereo IC. In addition, two pairs of auxilliary line level

inputs are available. The IC also contains a "loop out/in" function to facilitate connection

of external processing circuitry such as SRS.

The SRS circuit used in the CTC197 was jointly developed by TCE and Hughes to

provide a lower cost version of the system used in the CTC169 and CTC179.

The tuner uses tuner-on-board technology. The design is very similar to the CTC179

with two exceptions. First, the tuner must meet new FCC Class B requirments. New

shielding was required to meet these specifications. Second, the main tuner uses the

combined PLL/DAC IC first used in the CTC185.

The PIP tuner is similar to the CTC179-2 chassis second tuner.

Signal processing will be familiar to the technician. IF/Video/Chroma processing is

again handled by the T-Chip and very similar to the CTC175/176/177 chassis. The T4

is the latest version. AFT changes from analog to I2C digital control. The 4.5 MHz trap

has been deleted from the IC. An external trap is now required.

The T4 also contains ACC (autoflesh/chroma autocolor control), black stretch, adaptive

coring and the low level AKB functions.

The microprocessor is an enhanced version of the ST9 series previously used in the

CTC187. New features include a new OSD to support the "Fetch" menu icons and an

EPG (Electronic Program Guide). The OSD is an anolog RGB system capable of 512

colors and 255 charactors. There also is increased ROM and RAM space.

The power supply is an isolating, variable frequency/variable pulse-width, switch mode

supply using a separate control IC and MOSFET switch. The design provides for

overcurrent and overvoltage protection. It can also be adapted over a wide range of

inputs (90-270 VAC).

Page 13

Overview 13

Ant

RF

Splitter

To CRT

Kine CBA

TP15105

TP15107

XRP

Protect

Q14901/

CR14901/

CR14902

IR

Pre-

Amp

Front

Panel

Key

Board

"Run" Reg

U14701

U27905

Main

EEPROM

U13102

Tuner

Aux-1 Vid In

Aux-2 Vid In

TP12704

YB/G/R

TP15103

30

R

31

G

B

32

XRP In

36

&

2nd

Main

Tuner

9

Y/C-Deflection

Beam

Sense

24

TP14901

IR In

5

System

6

Control

7

U13101

8

Std

by

19

3

5

D

5

6

AKB

10

AKB

T-Chip

U16201

28

"Run"

D

23

Aux-1 L In

Aux-1 R In

PIP IF

U27901

42

25

Vid

Out

E/W

Pin

17

34

V-In

Clk

D

SVM

D

13

3

TV Guide

Plus+

13

3

Video

Switch

8

U26901

Main

6

Vid In

D

2

44

D

H

V

Out

Out

15

22

4

3

49

To SVM

on Kine

CBA

10

PIP

Vid In

Clk

4

43

Clk

Aud

Decoder

Audio

(Aux-2)

36

35

13

14

38

Y

C

40

6

TP14101

Reg

B+

TP14303

L

W/B

R

Audio

17

TP14302

Pincushion

37

38

L

R

Stereo/SAP Decoder

U11600

Clk

D

9

10

27

D In

26

D Out

Main

51

Vid

PIP

1

Vid

Y

41

TP14502

U14501

Vert Out

1

V Pulse

3

H-Drive

Q14302/301

3

TP14301

U14801/

Q14802

C14805

3

8

5

13

10

+26V

TP14704

41

R

5

28

Clk

FPIP

Switch

U18100

C

39

S-Video

Out

T14301

6

42

L

39

40

R

L

6

Y

C

3

5

Ext

In

Q14401

Horz Out

6

T14401 IHVT

TP14703

C14504

H-Yoke

14

CRT V

L

Compressor

Data

Clk

From SysCtl

7

11

R

L

Audio Output

U11901

2

L

V-Yoke

5

TP14402

TP14501

21

9

TP14706

R

SRS/

CBA

Norm/En

U13101

4

+13V

SRS

R

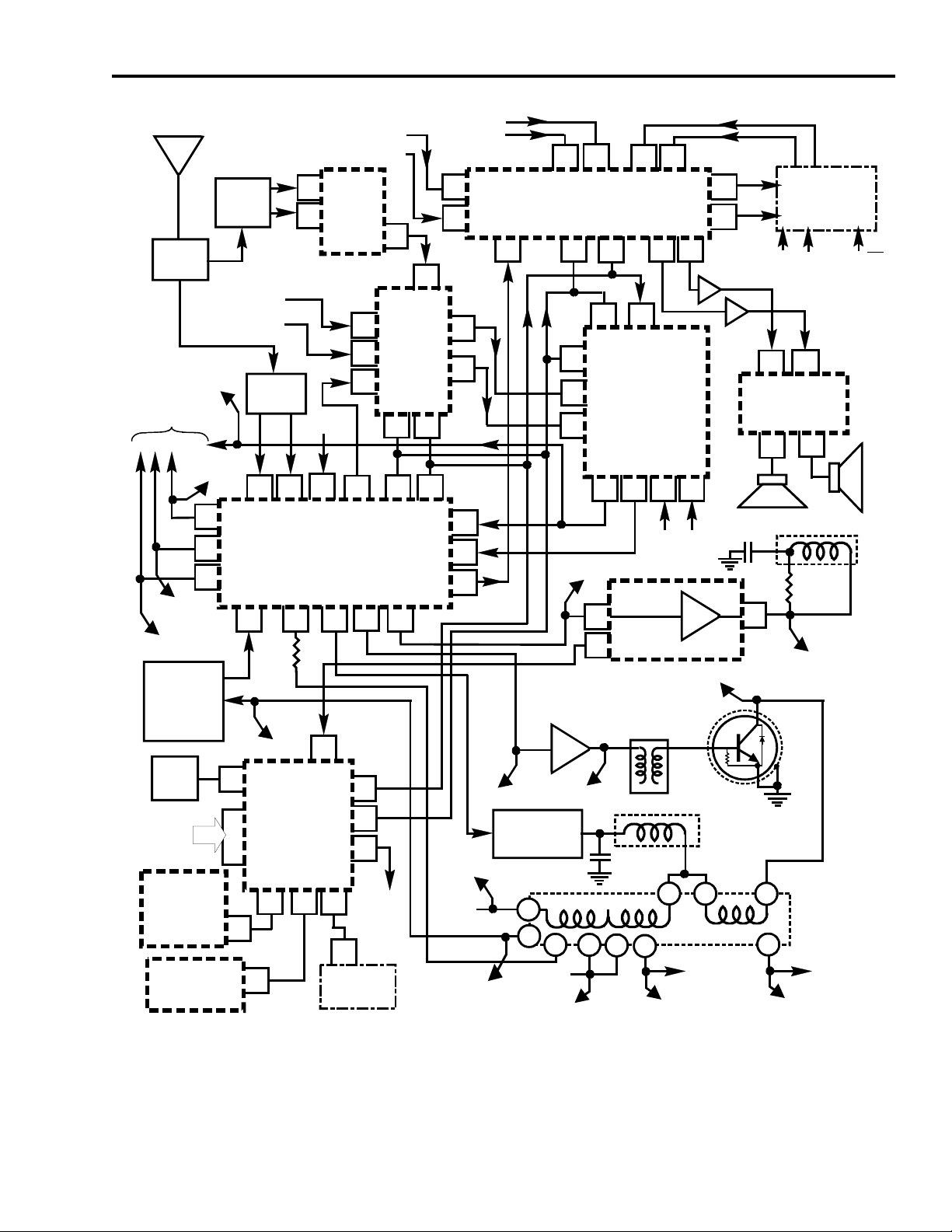

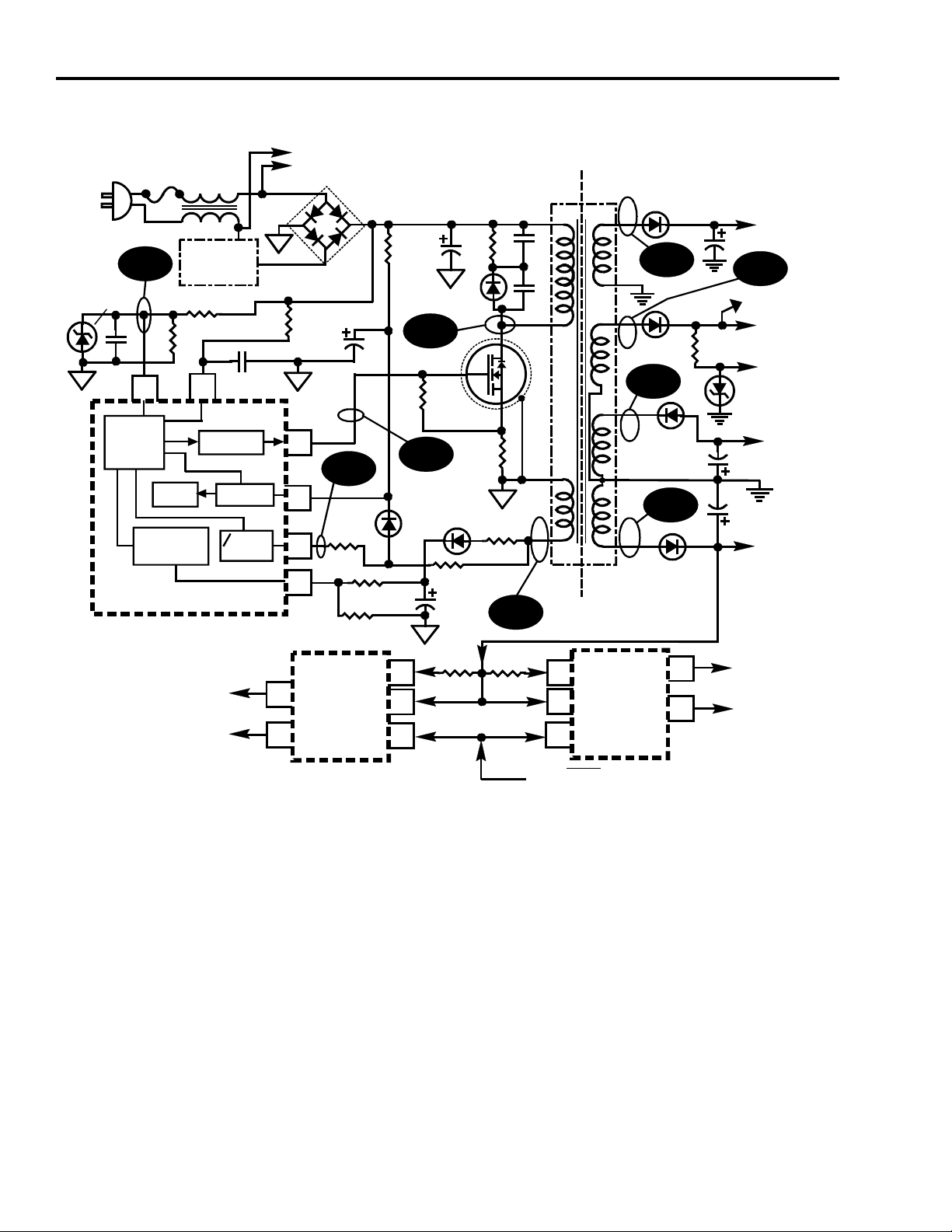

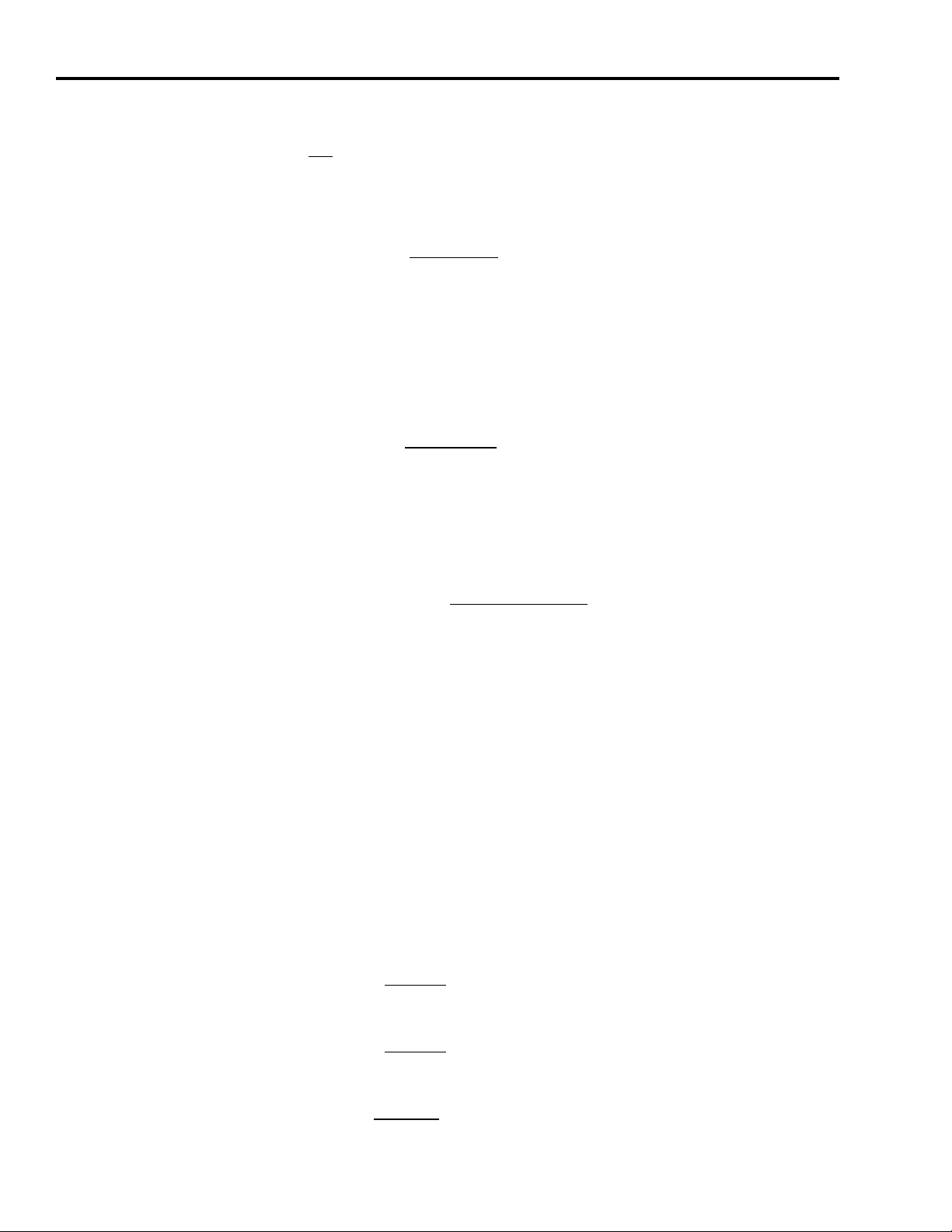

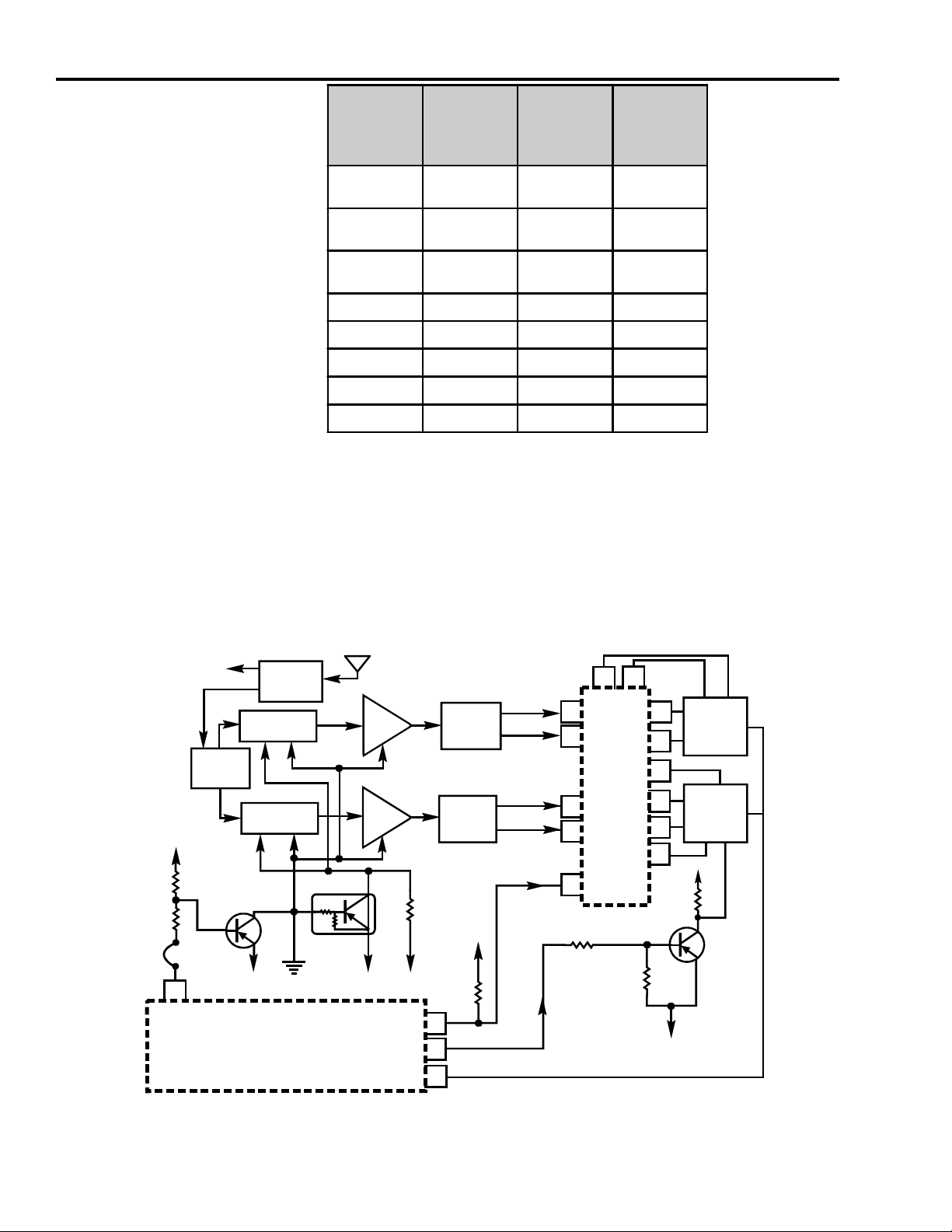

Fig. 1-1 CTC195/197 Block Diagram

Page 14

14 Main Power Supply (CTC195/197)

AC to PTV

F201

120VAC

WF51

CR108

3V

3

Control

Logic

Ref V

Ctl & Over

Load Amp

U14101

PWM Controller

L201

Degauss

Circuit

R145

R122

2

Output

C146

"V" Mon

0 Cross

Detect

Power Supply

CR210

R104

R146

C127

5

WF50

6

CR111

8

R105

1

R147

R149

C208

WF48

R111

WF49

CR102

Q101

R135

C147

R124

R148

WF52

"HOT!"

T101

Np

3

4

Nf

9

8

"HOT!"

"COLD!"

11

Ns1

13

Ns2

15

Ns3

16

12

10

Ns4

"COLD!"

WF56

WF54

CR113

WF53

CR116

CR106

CR107

+31V

(Stdby)

WF55

TP14101

+140V

(Stdby)

+33V

(Stdby)

CR133

33V

-12V

(Stdby)

+16V

(Stdby)

+5V

(Run)

+12V

(Run)

7

6

U14701

Main

Reg

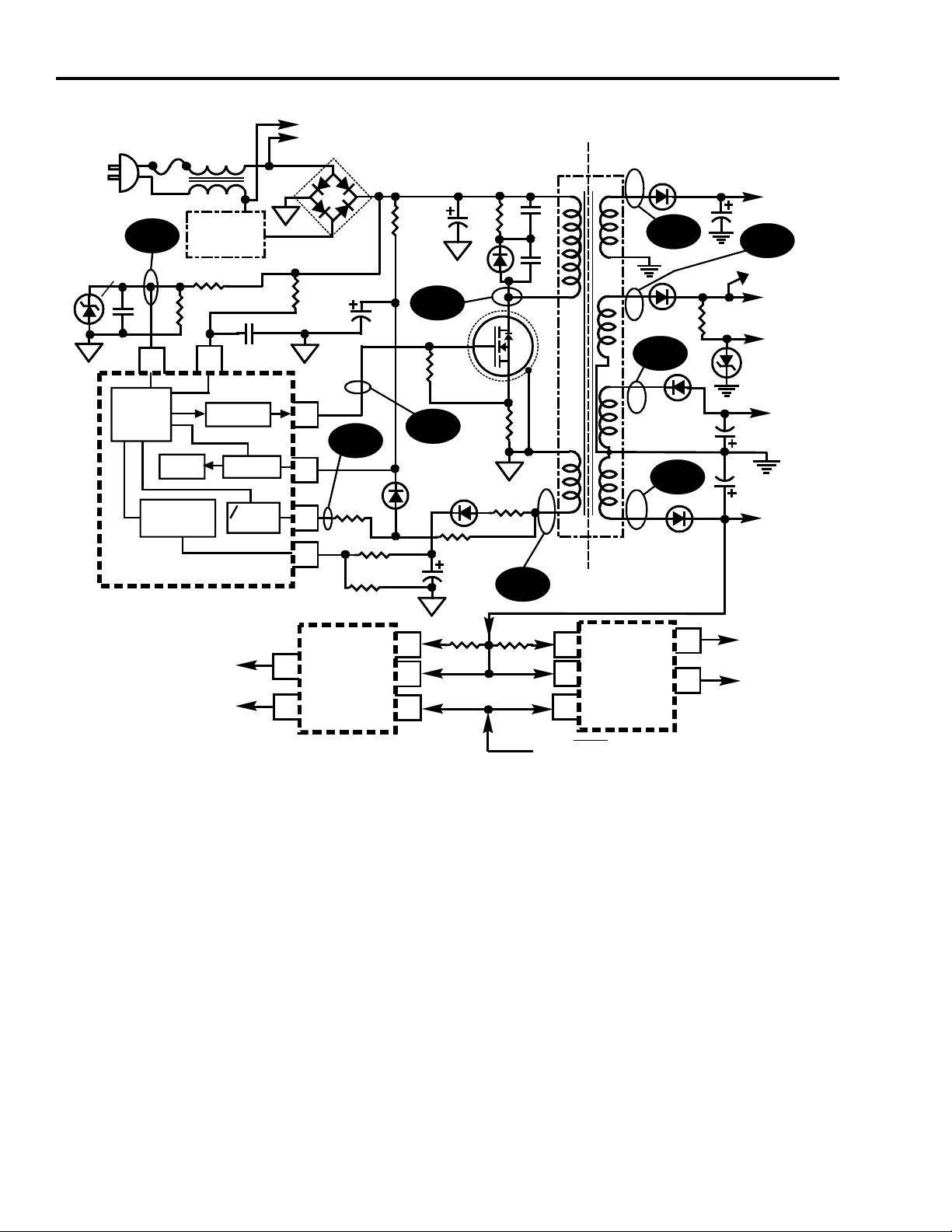

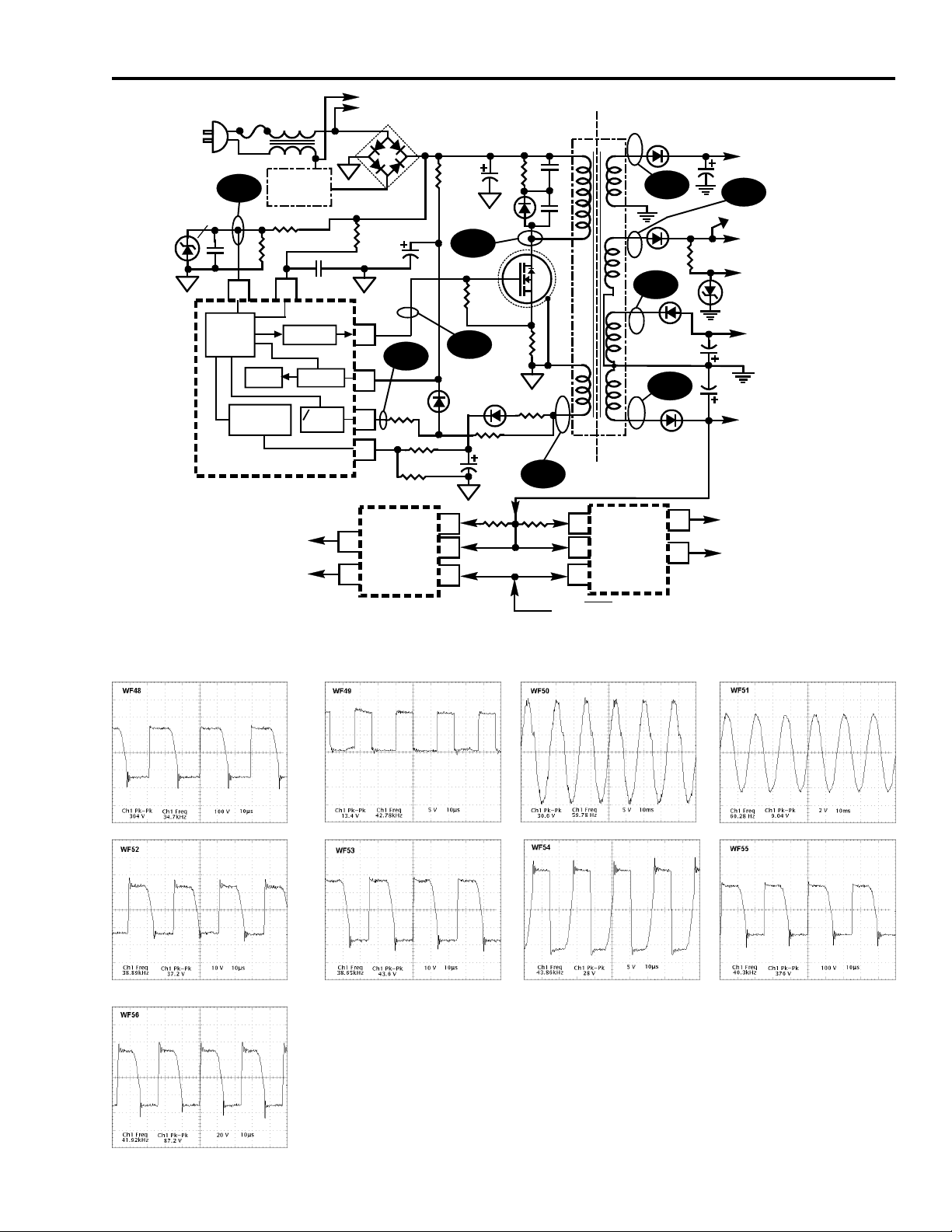

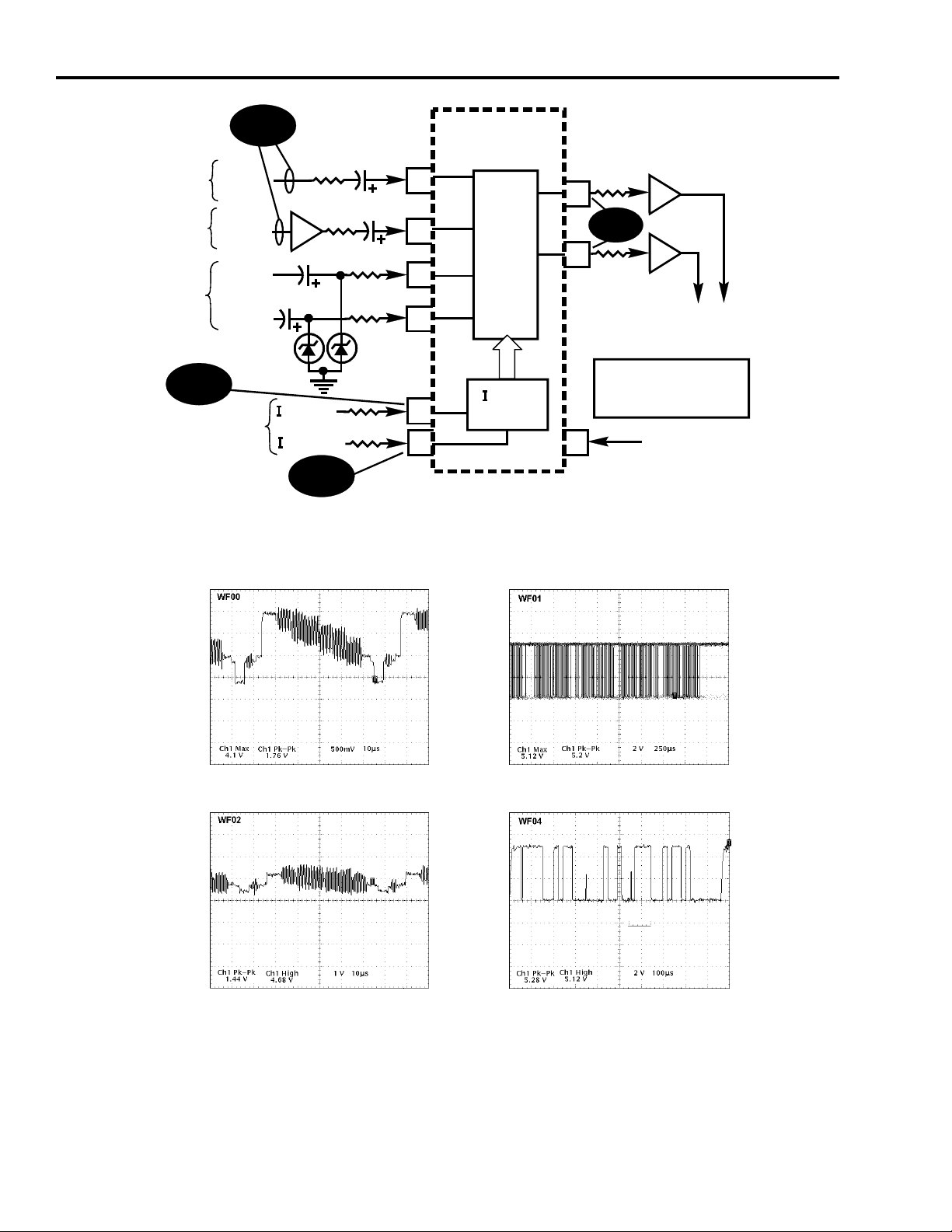

Fig. 2-1 Main Power Supply

See Waveforms Page 21.

2

1

3

2

U27905

1

3

RUN/STBY

FPIP

Reg

(from Sys Ctl U13101-19)

7

6

+5V

(Run)

+12V

(Run)

Page 15

Main Power Supply (CTC195/197) 15

CTC195/197 “Main” Power Supply

The CTC195 and CTC197 main power supply is a variable frequency/variable

pulse width switch mode power supply (refer to Fig. 2-1). It uses a power supply

controller IC (U14101) that drives the power MOSFET, Q101. The CTC195 &

CTC197 are “cold” chassis and the electrical isolation between the power supply

and chassis is achieved using the ferrite core transformer, T101. Energy is stored

in the transformers primary winding during the power MOSFETS On time and is

transferred to the secondary windings when the MOSFET switches off (flyback

period). The transformer (T101) must expend all it’s stored energy before the

start of the next “On” period of the MOSFET. The power supply is self oscillating

and the frequency is dependent on the load and the AC line voltage. The

frequency can vary between 25kHz and 90 kHz. This supply uses “hot side”

regulation which means that there is no actual physical sampling of the secondary

voltages. The feedback winding (Nf) on the hot side of the transformer is tightly

coupled to the Reg B+ windings on the secondary. Voltage variations in Reg B+

are reflected back into the feedback winding (Nf). The regulator IC U14101 has

its own internal reference voltage. The power supply operates whenever it is

connected to the AC line and supplies current on demand up to its current output

limit. The maximum input power to the supply is 180 watts. A diagram of the

power supply is shown in Figure 2-1.

AC In and Degaussing

The AC input to the supply is passed through fuse F201 and then choke L201. It

then enters the bridge diode, CR210. C208 is the Raw B+ filter capacitor and the

unregulated voltage at this point is approximately 150VDC at 120VAC input.

The degaussing circuit is connected in the line via thermistor RT201 and degauss

relay K201. Power for the relay comes from the +12V RUN2 supply. The +12V

RUN2 supply is only present when the instrument is turned on. The relay K201 is

closed and current flows through the degauss coil and thermister RT201. This

heats the thermistor and reduces the current through the degauss coil. After

approximately 1.5 seconds the current through the thermistor falls enough that the

relay de-energizes allowing the relay to open, ending the degauss cycle.

Page 16

16 Main Power Supply (CTC195/197)

Power Supply Operation

When the instrument is first plugged into an AC source, approximately 150VDC

Raw B+ is developed by the bridge rectifier diodes and the Raw B+ filter

capacitor C208. This is coupled through the primary winding (Np) of T101 (pin

3) and to the drain of the power MOSFET (Q101) via pin 4 of the transformer.

The source of the MOSFET is connected to ground through R124 (.22 ohm/2

watt). At the instant that the instrument is plugged in, the power supply is not

operating and IC U14101 needs a source of power to turn on Q101 the first time.

IC U14101 pin 6 (Vcc) receives B+ via resistor R104 which is connected to raw

B+.

With B+ applied to pin 6 of the regulator, U14101 outputs a voltage at pin 5 that

is applied to the gate of Q101. This turns the MOSFET (Q101) on for the first

time and results in a current flow through the primary (Np) of T101 and Q101.

The IC senses this current indirectly using a circuit consisting of C146 and R146.

One side of R146 is connected to Raw B+ while the other side is connected to

C146 to form a simple RC network. This network is connected to pin 2 of

U14101. This is the primary current sensing input. The capacitor is held in a

discharged state by pin 2 of IC U14101 until the gate of the MOSFET is turned on

at which time C146 is allowed to start charging. With the MOSFET turned on, the

current increases through it and the voltage on pin 2 of the IC also starts to

increase. When the voltage at pin 2 reaches approximately 3 volts, the IC shuts

off the drive to the MOSFET. At this point, the energy stored in the primary of

transformer (Np) is transferred to the secondary windings. At the same time, the

energy transfer is also coupled back into the feedback winding (Nf) between pins

8 and 9. The voltage developed at pin 8 of T101 is rectified by CR111 and filtered

by C127. This voltage is applied to pin 6 (Vcc) of U14101 and now serves as the

Run Vcc instead of the voltage across R104. The voltage across R104 is only

used during initial start-up. After all of the energy is depleted in the secondary

windings, the voltage at pin 8 of T101 starts to decay down to zero. This

decreasing voltage is applied to pin 8 of the IC through R105. This is the zero

crossing input to the IC. When this waveform goes through zero, it signals the

start of another cycle and the IC turns the power MOSFET back on. Current will

again start increasing through Q101 and the voltage on pin 2 of the IC starts

increasing again.

Once the power supply is operating, a method is needed to regulate the output

voltages. This is accomplished by the feedback input at pin 1 of IC U14101. The

winding on pins 8 and 9 of T101 serves three functions. As already explained, it

serves to power the IC and also serves as the zero crossing input to the IC. Its

third function is to provide voltage feedback information from the secondaries

back to the IC. The physical construction of the transformer is such that the

feedback winding is tightly coupled to the Reg B+ winding on the secondary. For

this reason, the voltage across the winding Nf closely follows the voltage

fluctuations on the secondary. This voltage is rectified by CR102 and filtered by

C147 where it is applied to a precision voltage divider. This divider is formed by

R147 and R149. The output of the divider is connected to pin 1 of the IC U14101.

If this voltage exceeds 400 mV, the IC terminates the drive signal to the MOSFET.

Page 17

F201

120VAC

WF51

CR108

3V

3

Control

Logic

Ref V

Ctl & Over

Load Amp

U14101

PWM Controller

L201

Degauss

Circuit

R145

R122

2

Output

C146

"V" Mon

0 Cross

Detect

AC to PTV

Power Supply

CR210

R146

C127

5

WF50

6

CR111

8

R105

1

R147

R149

R104

C208

WF48

WF49

R111

Q101

CR102

R135

C147

Main Power Supply (CTC195/197) 17

"HOT!"

T101

R124

8

R148

WF52

"COLD!"

CR116

Ns1

Ns2

Ns3

11

13

15

WF54

16

12

WF56

CR106

CR113

+31V

(Stdby)

WF55

TP14101

+140V

(Stdby)

+33V

(Stdby)

CR133

33V

-12V

(Stdby)

Np

3

4

Nf

9

WF53

Ns4

"COLD!""HOT!"

10

CR107

+16V

(Stdby)

+5V

(Run)

+12V

(Run)

2

U27905

1

3

RUN/STBY

FPIP

Reg

(from Sys Ctl U13101-19)

7

6

U14701

Main

Reg

2

1

3

Fig. 2-1 (Repeated) Main Power Supply

See Waveforms Page 21.

7

6

+5V

(Run)

+12V

(Run)

Page 18

18 Main Power Supply (CTC195/197)

AC to PTV

F201

120VAC

WF51

CR108

3V

3

Control

Logic

Ref V

Ctl & Over

Load Amp

U14101

PWM Controller

L201

Degauss

Circuit

R145

R122

2

Output

C146

"V" Mon

0 Cross

Detect

Power Supply

CR210

R104

R146

C127

5

WF50

6

CR111

8

R105

1

R147

R149

C208

WF48

R111

WF49

CR102

Q101

R124

R135

C147

R148

WF52

"HOT!"

T101

Np

3

4

Nf

9

8

"HOT!"

"COLD!"

11

Ns1

13

Ns2

15

Ns3

16

12

10

Ns4

"COLD!"

WF56

WF54

CR113

WF53

CR116

CR106

CR107

+31V

(Stdby)

WF55

TP14101

+140V

(Stdby)

+33V

(Stdby)

CR133

33V

-12V

(Stdby)

+16V

(Stdby)

+5V

(Run)

+12V

(Run)

7

6

U14701

Main

Reg

Fig. 2-1 (Repeated) Main Power Supply

See Waveforms Page 21.

2

1

3

2

U27905

1

3

RUN/STBY

FPIP

Reg

(from Sys Ctl U13101-19)

7

6

+5V

(Run)

+12V

(Run)

Page 19

Main Power Supply (CTC195/197) 19

In this way the output drive signal from pin 5 of the IC is regulated so that 400mV

is maintained at pin 1 of the IC. The voltage divider is adjusted so that this

corresponds to the required Reg B+ (»140VDC).

There are two ways of turning off the MOSFET. First, by exceeding 400mV on

pin 1. Second, the voltage on pin 2 (primary current sense) exceeds 3 volts. Pin

1 senses the output voltage while pin 2 limits the maximum output current. If the

output load increases, then more energy must be stored in the primary of the

transformer. This requires the MOSFET be turned on longer. If it is on too long,

C146 on pin 2 charges above 3 volts and shuts off the drive to the MOSFET,

acting as overcurrent protection.

Now let’s take a look at some of the other components in the power supply. R145

and R122 form a voltage divider from raw B+. This voltage is applied to pin 3 on

the IC and forms a “Voltage In” monitor. If the voltage on pin 3 falls below

approximately 1.0 volt the supply shuts down. This is to protect against “Low

Line” voltages. The R/C/Diode network across pins 3 and 4 of T101 form a

snubber network to help dampen any ringing when Q101 turns on and off.

Secondary Supply Operation

The output voltages on the secondary side of the supply are +140, +16, -12, and

the audio supply which varies depending on which audio system in the unit. The

secondary supplies are operational as long as AC power is applied to the instrument.

Each of these voltages are provided by an individual winding on the transformer

with a single rectifier/filter combination.

A 33 volt low power supply for the tuner is derived from the +140V supply. This

supply is composed of a 33 volt zener diode and filter capacitors. A switchable

+12 and +5 volts are provided by regulator U14701. These are both derived from

the +16 volts. Pin 1 is the +16V input while pin 2 is the input for the +5V. The

+16V at pin 2 is passed through a resistor which drops the +16 down to a lower

value reducing the amount of dissipation in the IC. The outputs are filtered before

being sent to the respective circuits. A unique feature of the IC is that their

outputs are switchable (on or off) by a TTL control signal from the system control

circuit. The outputs of regulator IC can be turned off by pulling pin 3 low. IC

U27905 is the same type of regulator as U14701 but provides the supplies for the

FPIP module.

Page 20

20 Main Power Supply (CTC195/197)

Troubleshooting

Many of the malfunctions in the power supply can be quickly resolved with

simple resistance and voltage measurements. However step-by-step check lists

for some of the more common problems are provided below. One item in particular

deserves special attention. If the main supply is not running, first check for

presence of Raw B+. This can be checked at the +/- terminals of the Raw B+

capacitor C208. There should be approximately 150VDC at this point. If Raw

B+ is present, connect an oscilloscope to pin 6 of U14101. If you see a oscillating

or varying waveform of approximately 4.5 volts to 12 volts, then the IC is not

getting enough Vcc voltage to run. As C127 charges through R104, the voltage

on pin 6 of U14101 will rise, then fall when IC U14101 attempts to turn on.

At this point, it will begin to output pulses on pin 5 of the IC to turn on Q101. If

the supply does not start the voltage on pin 6 starts to decay and the IC turns off.

This process then repeats itself. The result is an oscillation on pin 6. The most

likely cause is an open CR111. If CR111 is shorted, the voltage on pin 6 would

be very low and there would be no oscillation. In any case, if the voltage is

oscillating on pin 6 then the supply is not starting or is trying to start but not

getting enough Vcc from pin 8 of the transformer to pin 6 on the IC.

Another important area that needs to be addressed is what happens to the power

supply during a heavy load or a short on one of the outputs. During heavy load the

voltage ramp on pin 2 of U14101 exceeds 3 volts and the supply shuts down in the

current limit mode. At this point the power supply then tries to restart and if the

load (or short) is still present, it shuts down again. This sequence repeats itself at

an interval of approximately 1/2 second. A large amount of current will be

flowing through the primary of the transformer as the supply tries to restart which

results in an audible “chirp”. If you hear this, suspect a short on one of the

secondaries such as a shorted horizontal output transistor, etc.

Symptom: Fuse Opens

Check for shorted Q101. If shorted, replace Q101 and check R124. If Q101 not

shorted, check CR210 (bridge rectifier) for short.

If fuse opens again, suspect U14101 and varify Q101.

Symptom: No Raw B+

Check fuse F14201. If open, replace and check Raw B+. If fuse OK, check for

output from bridge diodes (CR14210). If bridge OK, check surge resistor R14203.

Symptom: No Secondary Supplies

Check Raw B+. If Raw B+ not present, go to No Raw B+ check above.

If Raw B+ OK, use scope and check U14101-6 for oscillation. If oscillation

present check for open CR111 or R135. If oscillation not present go to step 3.

Is power supply “Chirping”? If yes, check for shorts on the secondary side of

supply. If no, check for shorted CR111 or shorted R135.

Page 21

F201

120VAC

WF51

CR108

3V

3

Control

Logic

Ref V

Ctl & Over

Load Amp

U14101

PWM Controller

L201

Degauss

Circuit

R145

R122

2

Output

C146

"V" Mon

0 Cross

Detect

AC to PTV

Power Supply

CR210

R146

C127

5

WF50

6

CR111

8

R105

1

R147

R149

R104

C208

WF48

WF49

R111

Q101

CR102

R135

C147

Main Power Supply (CTC195/197) 21

"HOT!"

"COLD!"

R124

R148

WF52

T101

Np

3

4

Nf

9

8

Ns1

Ns2

Ns3

Ns4

"COLD!""HOT!"

11

13

15

16

12

10

WF56

WF54

CR113

WF53

CR116

CR106

CR107

+31V

(Stdby)

WF55

TP14101

+140V

(Stdby)

+33V

(Stdby)

CR133

33V

-12V

(Stdby)

+16V

(Stdby)

2

1

3

RUN/STBY

U27905

FPIP

Reg

(from Sys Ctl U13101-19)

+5V

(Run)

+12V

(Run)

7

6

U14701

Main

Reg

2

1

3

Fig. 2-1 (Repeated) Main Power Supply

+5V

7

6

(Run)

+12V

(Run)

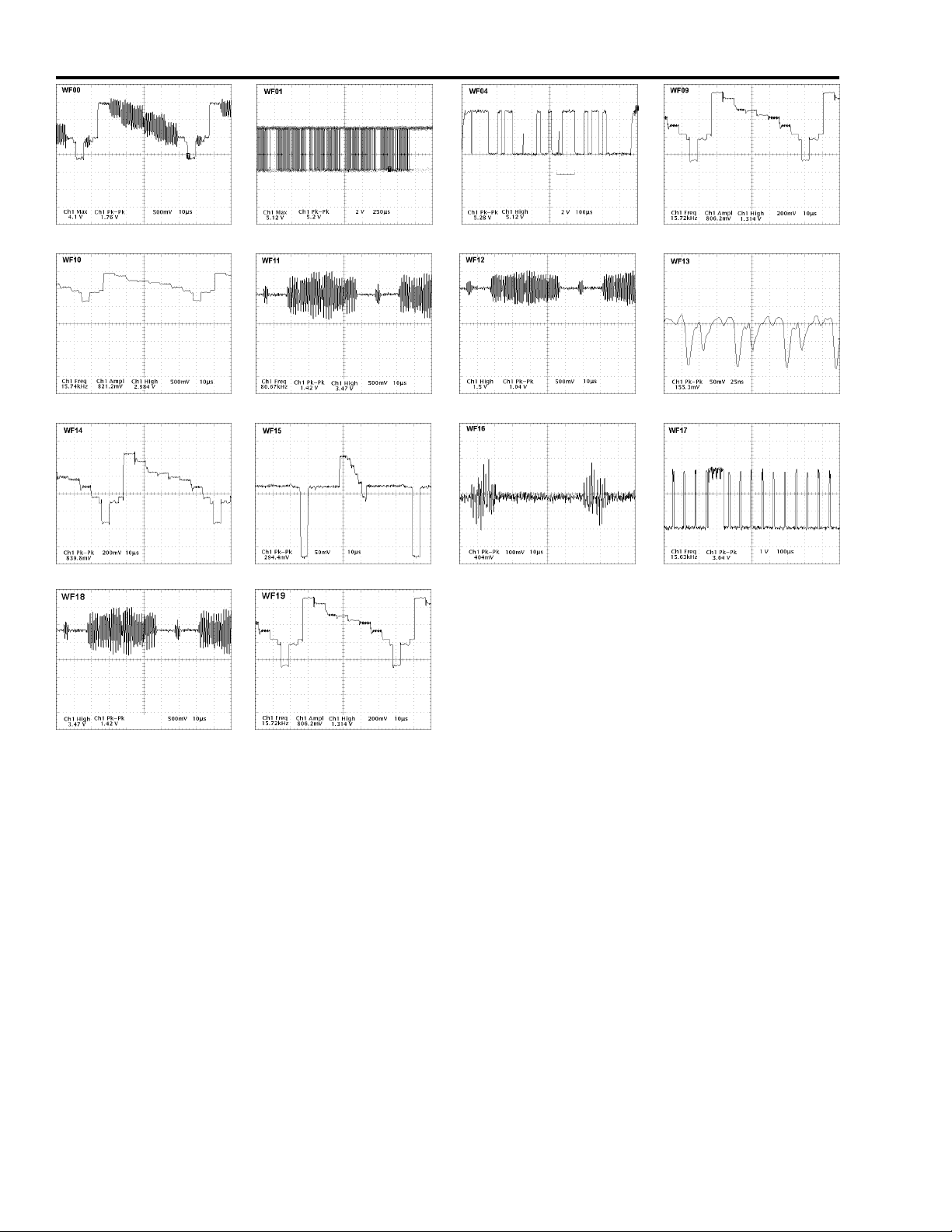

Main Power Supply Waveforms

Page 22

22 Main Power Supply (CTC195/197)

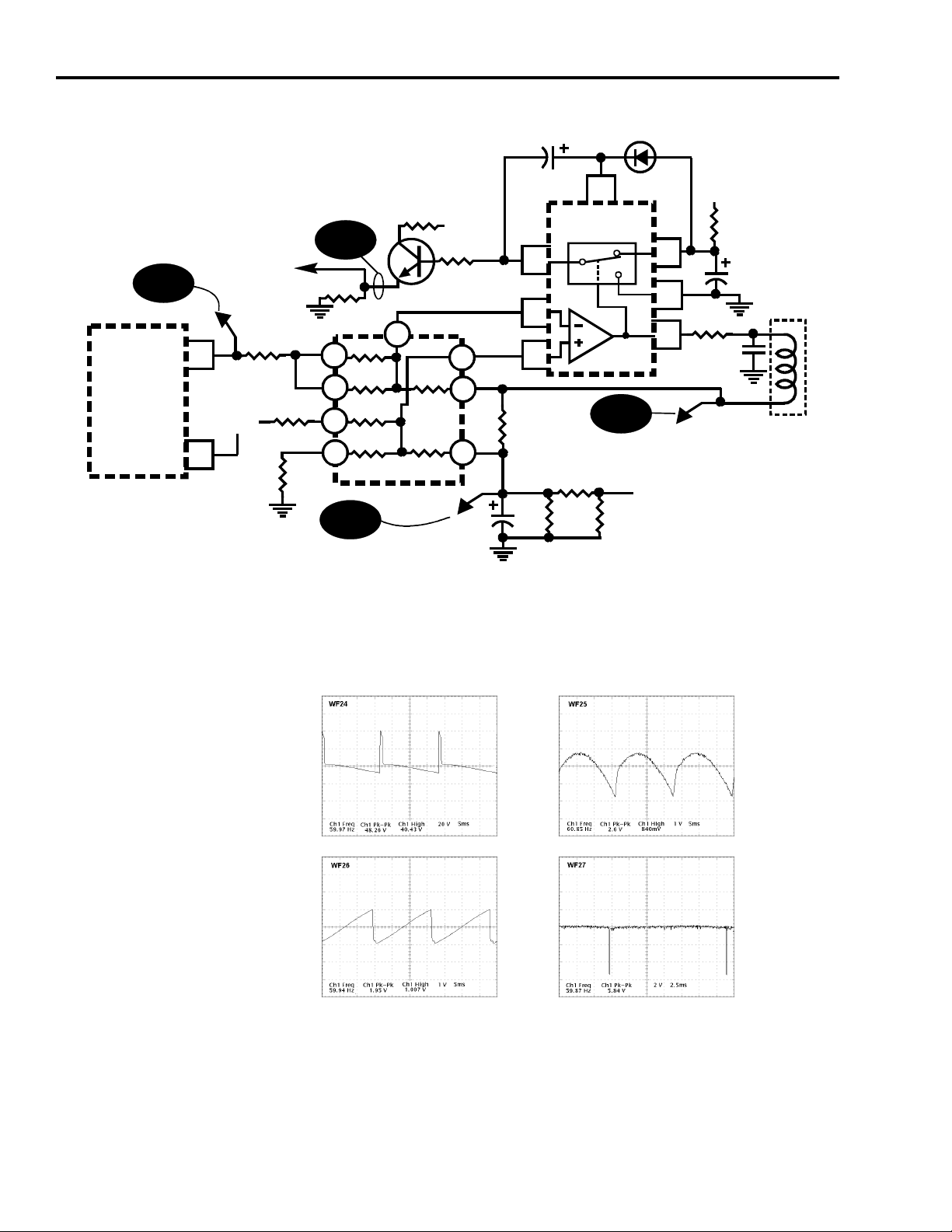

Auxiliary Power Supply Operation

The auxiliary power supplies on the Main CBA consist of three (3) regulator IC’s

U14104 (+7.5VDC), U18101 (3.3VDC) and U14601 (+5VDC). Series pass

transistor regulator Q11600 provides the +9.5VDC supply. U14104, U18101 and

Q11600 obtain their input voltages (+12V & +5V) from Main Regulator U14701.

These power supplies are only On when U14701 is power up, which occurs only

when the instrument is turned on. Regulator IC U14601 uses the +16VDC supply

from the Main Power supply and outputs the StandBy +5V for the microcomputer

and EEPROM. This power supply is always present whenever the instrument is

plugged into AC power.

Page 23

Main Power Supply (CTC195/197) 23

TP14103

+12V

6

U14701

Main

Reg

(Main Pwr Supply)

7

+5V

+16VDC Stdby

DeCoder PCB

(+12V)

(+16V)

TP14601

3

+10V Reg

+9.5V

Reg

C14715

C14714

U23902

Q11600

CR11600

CR14604

2

1

10V

3

1

Main PCB

U14104

+7.5 Reg

1

U18101

+3.3 Reg

U14601

+5 Reg

2

1

3

2

DeCoder PCB

3

2

+9.5VDC

(Run)

+7.5VDC

+3.3VDC

(Run)

+5VDC

C13163

+5VDC

+12VDC

+10VDC

(Run)

(Stdby)

(Stdby)

(Run)

(Stdby)

Fig. 2-2 Auxiliary Power Supply

Page 24

24 PTV Power Supply (CTC195)

120VAC

(From Main

Pwr Supply)

R0

R1

R2

Q700

4

3

WF62

R14

2W

.39

C05

WF61

U701

CR11

8.2V

Ω

T700

8

7

WF60

1

Q1

R26

U700

Amp

On/Off

Signal

2

Q2

CR717 thru

CR720

R3

+23V

R4

1.2K

R5

10K

R24

1K

R6

ZD1

TR3

From Digital

Convergence

PCB, CR200

R20

CR13

CR14

10V

10K

240K

TR1

D1

Error Det

(-40.5V Ref)

1

WF63

Q5

Q8

R22

C702

R3

11

4

3

WF59

Q3

C14

CR3

WF57

WF58

C700

CR5 R18

R25

R10

CR01

10V

R11

"HOT"

7

T701

1

"HOT"

Q4

WF64

WF65

5

2

3

Q7

Np

Nd1

Nd2

"COLD"

14

Ns1

12

9

Ns2

10

Ns3

11

13

Ns4

"COLD"

Q6

CR9

CR10

CR15

20V

R21

CR16

13V

CR7

CR8

-45VDC

+45VDC

+15VDC

-15VDC

CR12

13V

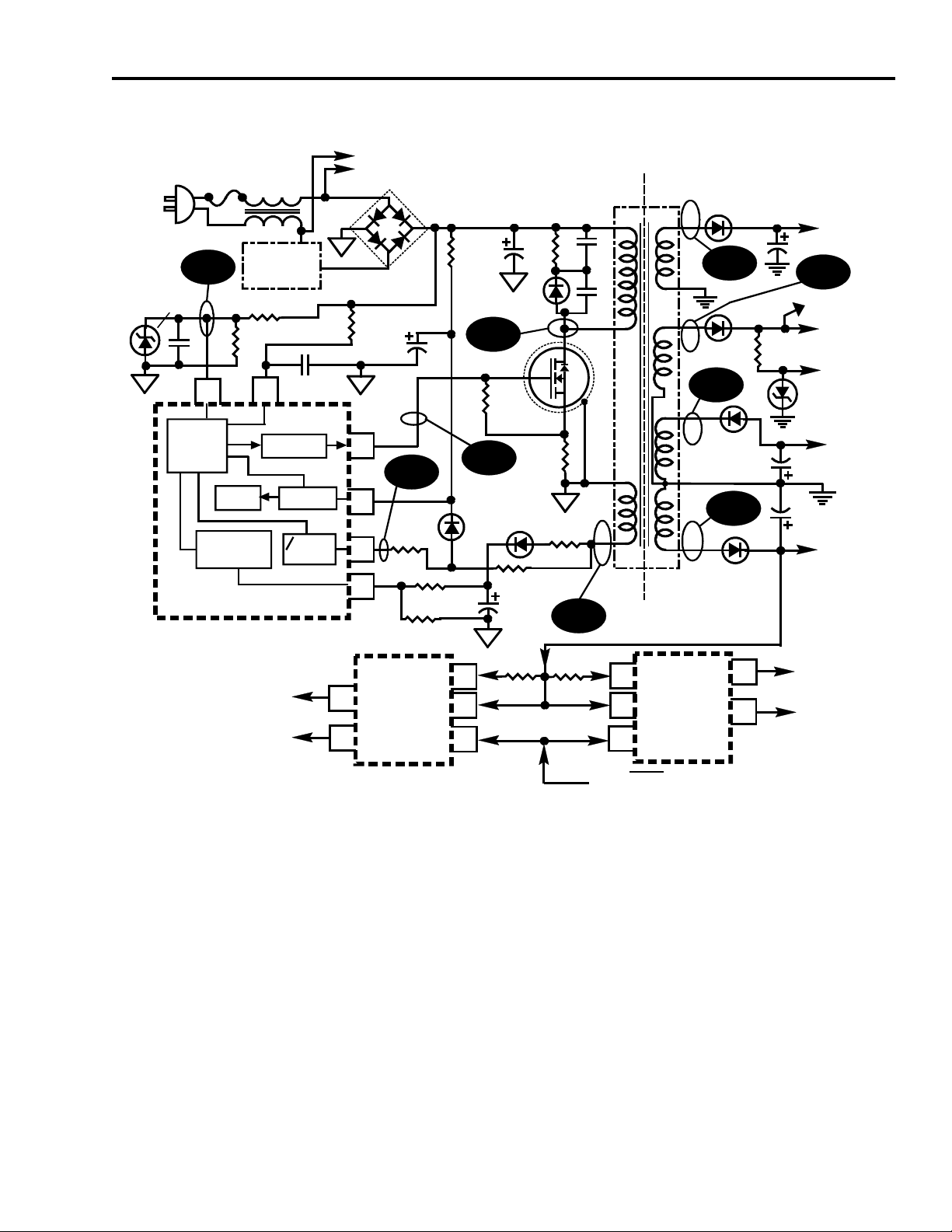

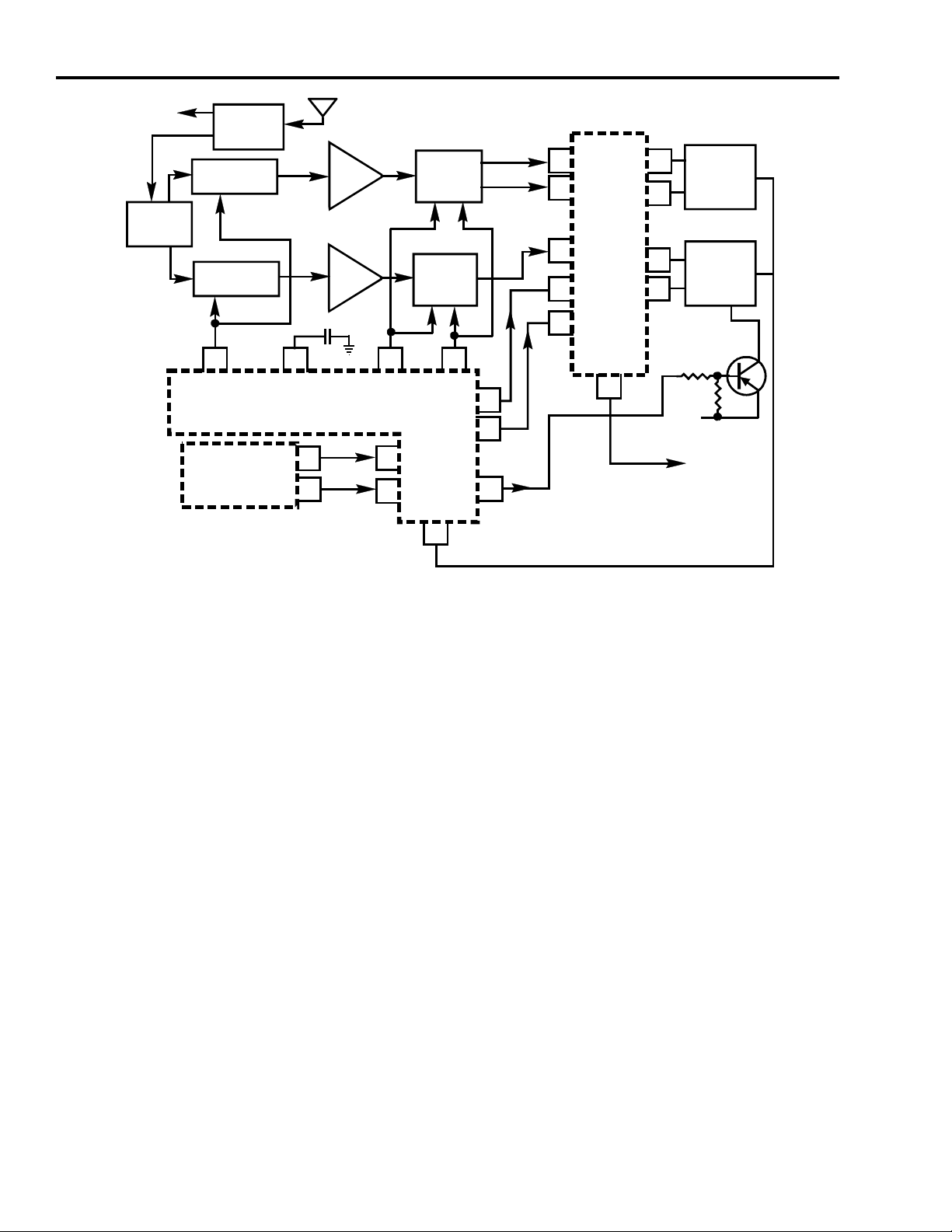

Figure 3-1 Digital Convergence Power Supply

See Waveforms Page 29.

Page 25

PTV Power Supply (CTC195) 25

CTC195 Convergence Power Supply Overview

The convergence auxiliary power supply is a variable frequency-variable pulse

width switch mode power supply. AC power is supplied to the rectifier from the

main chassis. The Raw B+ for the PTV power supply is generated by a bridge

rectifier (CR717 thru CR720) and filtered by C702. With Raw B+ applied, the gate

of TR1 begins to charge up through R03 and R22. When the turn-on voltage of the

FET inside U700 (TR1) is reached, the FET begins conducting. With TR1

conducting, current flows through the primary (Np) of the transformer (T701), FET

(U700), and through the current sense resistor R14 (U700-8). The current flowing

through the primary winding causes a electromagnetic field to develop around the

winding of Np (pins 7 and 5). As the field around Np rises a voltage is induced into

winding Nd1 (pins 2 & 3). The voltage developed at pin 2 of T701 is coupled by

R10 and C700 to the gate of TR1 (U700-4). The polarity of this winding is such that

it generates a positive voltage which keeps TR1 conducting. When the current

through TR1 reaches the current limit threshold set by R14 and C05, TR1 is turned

off. When the FET (TR1) turns off, the magnetic field around the winding Np

collapses and the energy stored in the primary of the transformer is transferred to

the secondaries. As the field around Np collapse, a positive pulse is generated at

pin 2 of Nd1 that is applied to the gate of TR1 turning it on again. This will continue

for several cycles until stable oscillation is achieved.

The voltage developed across Nd2 rectified by CR5 and compared to an internal

reference of -40.5V (+/- .5V) at pin 1 of U700. Once operation begins, this

feedback winding controls the duty cycle of TR1. The Nd2 winding is responsible

for regulating the output voltages. The duty cycle of the power supply is altered so

that the voltage across Nd2 is maintained at -40.5V. The secondary supply voltage

windings (Ns1 through Ns4) are wound so they reflect any load changes on the

secondary back to winding Nd2.

During normal operation as the load on the power supply increases, the On time of

the FET increases. This increased On time causes higher currents to flow through

the FET and the primary winding of T701 (Np). When the voltage across R14

reaches approximately +.6V, TR3 (inside U700) turns on. This turns off the FET

and causes the output voltage to decrease. Zener diode CR01 and resistor R11 are

used to compensate for any fluctuations in line voltage that result in changes in the

Raw B+.

Page 26

26 PTV Power Supply (CTC195)

Power Supply Operation

As mentioned earlier, the power supply starts when the gate voltage of the FET (pin

4 of U700) is allowed to charge up thus turning on TR1. However, the power supply

only needs to run when the instrument is turned on. Transistor Q700 is responsible

for hold the gate of the FET low (OFF) until an On/Off signal is received from the

Digital Convergence CBA. When raw B+ is present, transistor Q700 is biased On

via R700, R701 and R702. With Q700 on, the gate of the FET is pulled low thus

preventing the power supply from starting. The On/Off signal is obtained from the

digital convergence board by rectifying the filament pulse and is approximately

+23V when the instrument is running. This On/Off signal voltage supplies the B+

to the emitter of Q1 via R4. This allows Q1 to turn on providing a current path

through the photo-diode. When the ON/OFF signal reaches approximately 16V,

Q1 allows current to flow through the photo-diode. Initially the current flowing

through the photo-diode of the opto-coupler is supplied by Q3 on the ground end

of the circuit. The components (Q5, C14 and R20) on the base of Q3 form a delay

circuit that that turns off Q3 after a short delay to allow the supply to start and

stabilize. When the +23V is present, capacitor C14 begins to charge up through

R20. As the base voltage of Q5 rises, Q5 turns off, thus turning off Q3 removing

the current path for the photo-diode. By this time the supply is up and running and

the current path for the photo-diode (ground end) is provided via Q4. This allows

the photo-transistor to remain on, keeping the base of Q700 grounded thus keeping

it turned Off. This allows the gate voltage of TR1 to rise and the power supply to

operate normally.

As mentioned earlier, the current path for the opto-coupler during normal operation

is provided by Q1 and Q4. Q4 is turned on only when the +15V and -15V supplies

are within a specific operating range. When an excessive load is put on the supply,

the supply goes into current limiting. In order not to damage the convergence

amplifiers, we need to turn off the supply whenever a major overload or overvoltage occurs. When the +15 of the -15 volt supply drops to approximately 13V

the transistor Q1 is turned off. Since Q3 is already off (after the initial startup delay)

the current path for the opto-coupler is removed. This causes the supply to

immediately turn off until the instrument is turned off and back on again. Monitoring

the +/- 45V is not required since a failure in the convergence amplifier causes a

large enough load on the supply that the current limiting circuit within U700 will

shut down the power supply. Q4 is biased on by the output of the secondary voltage

supplies. In this way the secondary output is monitored for overload on the supplies

or in the event that a supply is lost. Q4 monitors the +15V supplies for “Under 13V”

(CR12) and Q6 monitors for “Over 20V” via CR15. If the +15V secondary output

supply falls below 13V, Q4 turns off. If the +15V rises over 20V, Q6 turns on and

grounds the base of Q4, turning it off causing the power supply to shut down

because Q700 will turn back on. Q7 monitors the -15V supply via CR16. If the

-15V supply rises to -13V (supply falls) Q7 turns on grounding the base of Q4.

Whenever Q4 is turned off, this removes the current path for the photo-diode in

U700. This causes the photo-transistor in U700 to turn off allowing Q700 to turn

back on grounding the gate of the FET (TR1) thus shutting down the power supply.

Page 27

PTV Power Supply (CTC195) 27

120VAC

(From Main

Pwr Supply)

R0

R1

R2

Q700

4

3

WF62

R14

2W

.39

C05

WF61

U701

CR11

8.2V

T700

Ω

8

7

WF60

1

Q1

Q2

R26

CR717 thru

CR720

U700

Amp

On/Off

Signal

2

R4

1.2K

+23V

R5

10K

R3

TR3

From Digital

Convergence

PCB, CR200

R20

R24

1K

CR14

R6

10K

ZD1

240K

CR13

10V

TR1

D1

Error Det

(-40.5V Ref)

1

WF63

Q5

Q8

C702

Q3

C14

R22

R3

11

4

3

WF59

CR5

C700

R25

CR3

WF57

WF58

CR01

10V

R10

R11

R18

"HOT"

7

T701

Q4

WF64

WF65

5

2

3

1

Q7

Np

Nd1

Nd2

"COLD"

14

Ns1

12

9

Ns2

10

Ns3

11

13

Ns4

"COLD""HOT"

Q6

CR9

CR10

CR15

20V

R21

CR16

13V

CR7

CR8

-45VDC

+45VDC

+15VDC

-15VDC

CR12

13V

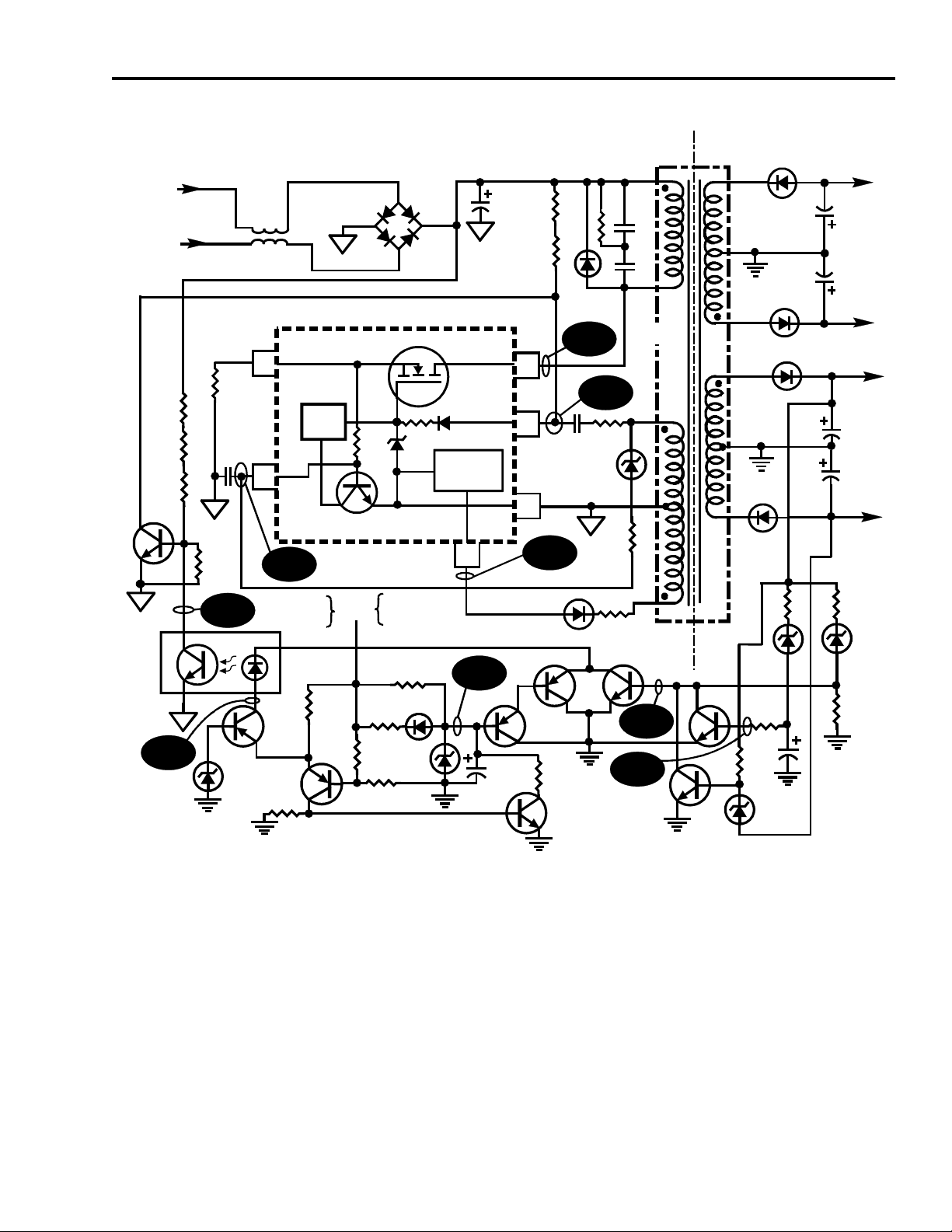

Figure 3-1 (Repeated) Digital Convergence Power Supply

See Waveforms Page 29.

Page 28

28 PTV Power Supply (CTC195)

The differential pair consiting of Q1 and Q2 alos control the turn off of the power

supply. When the On/Off voltage starts to fall, the comparator switches the current

to Q2 when the voltage falls below 16VDC. This allows current to flow into the

base of Q8, turning it on. This discharges the voltage on C14 readying it for the next

ON cycle. Since Q1 is off, current flow to the opto-coupler is stopped. With the

opto-coupler turned off, Q700 turns back on and shuts down the power supply.

Transistor Q2 is responsible for monitoring the +23 volts from the convergence

CBA. If the +23 volts starts to fall, Q2 turns on when the emitter falls below the

level that the base is biased at via R6 and R5. When Q2 turns on the emitter of Q1

is grounded, removing its B+ supply and turning it off. This instantly turns off the

opto-coupler U700. With the opto-coupler off, Q700 turns back on and shuts down

the power supply.

120VAC

(From Main

Pwr Supply)

R0

R1

R2

Q700

4

3

WF62

R14

2W

.39

C05

WF61

U701

CR11

8.2V

Ω

T700

8

7

WF60

1

Q1

R26

CR717 thru

CR720

U700

Amp

On/Off

Signal

2

Q2

R4

1.2K

10K

+23V

R5

R3

TR3

From Di gita l

Convergence

PCB, CR200

R20

R24

1K

CR14

R6

10K

ZD1

240K

CR13

10V

TR1

D1

Error Det

(-40.5V Ref)

1

WF63

Q5

Q8

C702

Q3

C14

R22

R3

11

4

3

WF59

CR5

C700

R25

CR3

WF57

WF58

CR01

10V

R10

R11

R18

"HOT"

7

T701

2

3

1

"HOT"

Q4

WF64

WF65

5

Q7

Np

Nd1

Nd2

"COLD"

14

Ns1

12

9

Ns2

10

Ns3

11

13

Ns4

"COLD"

Q6

CR9

CR10

CR15

20V

R21

CR16

13V

CR7

CR8

-45VDC

+45VDC

+15VDC

-15VDC

CR12

13V

Figure 3-1 (Repeated) Digital Convergence Power Supply

Page 29

PTV Power Supply (CTC195) 29

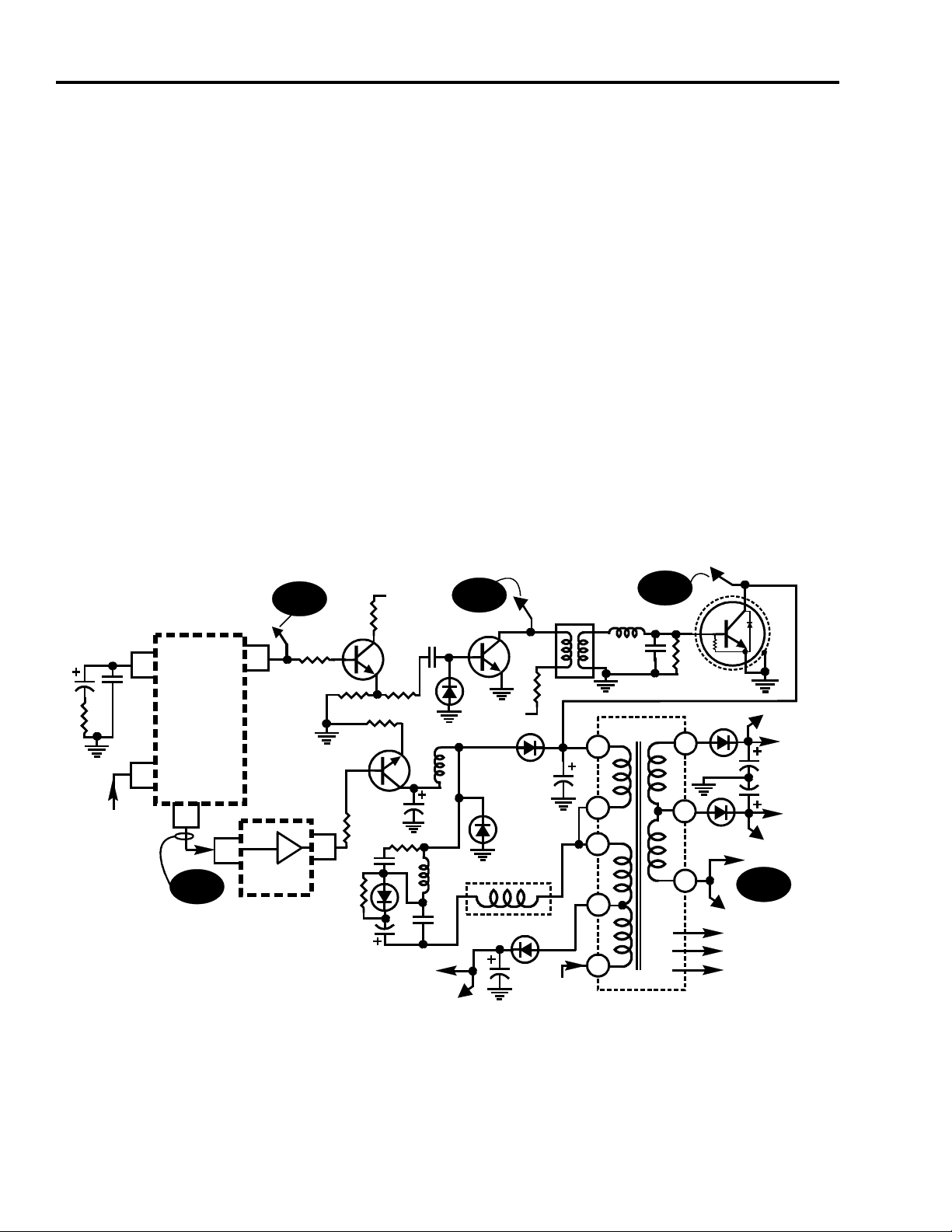

Convergence Power Supply Waveforms

Page 30

30 Horizontal Deflection

Horizontal Deflection Overview

The horizontal deflection system has two main functions in the CTC195/197 chassis.

First, it supplies the current for the horizontal yoke coils providing the energy necessary

to move the electron beam horizontally across the face of the picture tube. Second, it

provides a number of power supplies needed for operation of the chassis and picture

tube.

The horizontal yoke current is provided by a circuit consisting of a switch (HOT), the

primary inductance of the IHVT, a retrace capacitor, the trace capacitor (S-Shaping

capacitor), and the horizontal yoke coils.

The voltage supplies provided by the horizontal deflection system are derived from

secondary and tertiary windings on the IHVT. From the previous discussions of the

power supplies, they are used by the video amplifier, the tuner, the CRT, and the

vertical amplifier.

The low level signal processing circuits for the horizontal deflection system are contained

in the T4 Chip. These include the horizontal sync separator and a two-loop horizontal

AFPC system. The T4 allows bus control of several parameters associated with the

horizontal deflection system including horizontal drive pulse width, AFC Gain, Sync

Kill, and ON/OFF.

The XRP circuit in the CTC195/197 is similar to that of CTC179 and CTC185. A

peak detector sets a latch in the T4 Chip. The latch can then be reset only by I2C

communication.

The T4 Chip also generates the ramp waveform used to drive the vertical amplifier.

Bus-controlled vertical parameters include DC bias, amplitude, linearity, and

S-Correction. The same ramp that is used to generate the vertical driving waveform is

also used to create the parabola used for East-West pin correction. Bus controllable

parameters in East-West pin correction include bias (width), amplitude (pin), tilt, and

top and bottom corner. These same parameters are adjustable in both the CTC195

and CTC197. The CTC195 uses a slightly different method to achieve proper

adjustment due to the Digital Convergence system. Discussion on that is provided in

the Digital Convergence section of this manual.

East-West pincushion correction and horizontal width adjustment are provided by a

diode modulator for the direct view CRT assemblies that do not include yoke pin

correction. The modulator is driven by a linear pincushion driver. The parabola used to

develop the correction waveform is generated in the T4 Chip. The T4 provides bus

control of the horizontal width and pin amplitude as well as horizontal trap and corner

correction. In addition, a voltage developed across the high voltage return resistor is

summed at the pin driver to compensate for the decrease in width that occurs as the

high voltage increases with decreased beam current.

A new feature in the CTC197 chassis is the bus controlled Z-Axis correction. This will

allow Z-Axis correction via the remote control, making it much easier for the user than

prior back panel switches. This circuit is used in 32" and larger direct view instruments.

Page 31

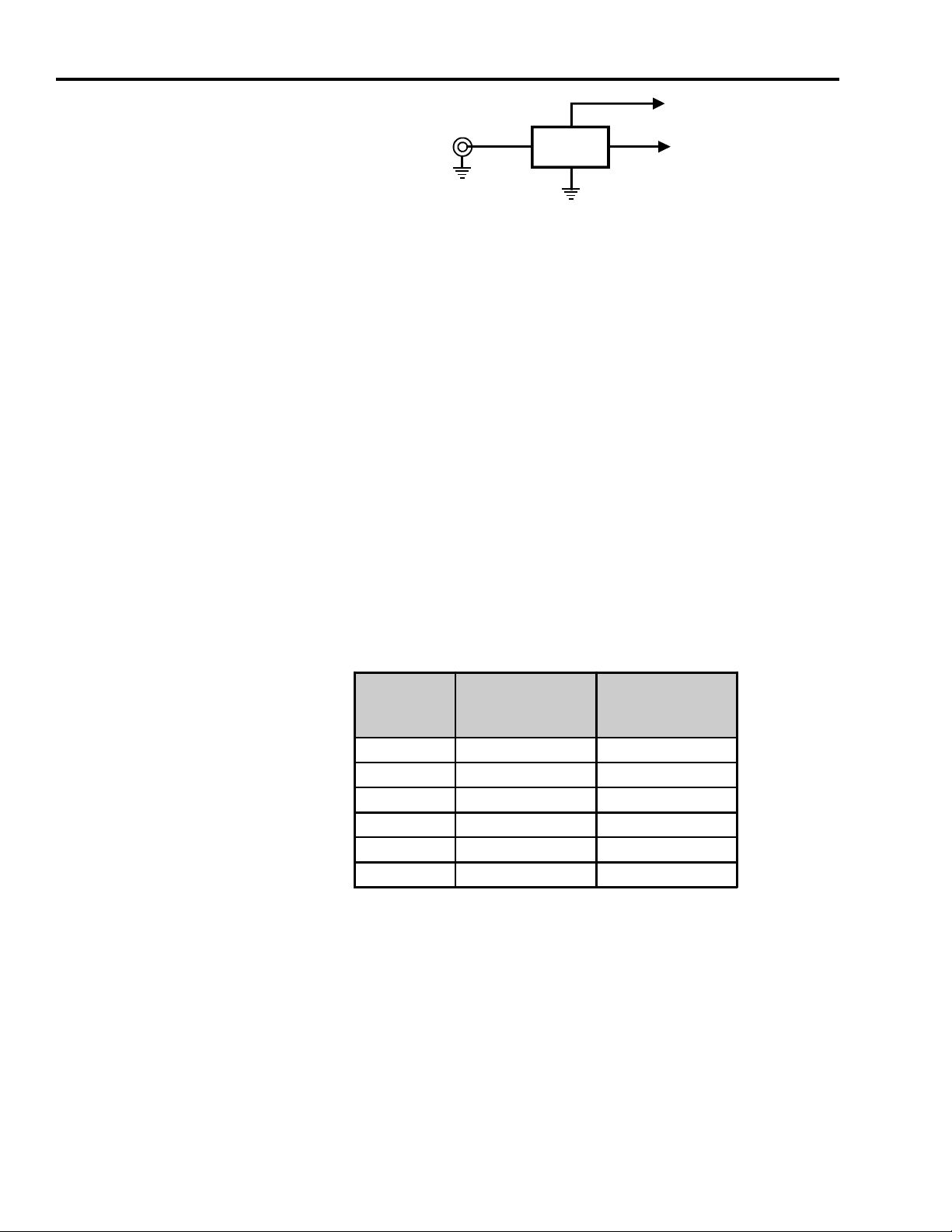

Luma

In

Horizontal Deflection 31

Divide

by 16

On/Off