ffiRAFTjFEN

2-1/4 x 3-1/4 RB Series 8

Service & Parts Manual

2 1/4 x 3 1/4 RB SERHS 8 GRAFLEX

with REVOLVING BACK

TABLE OF CONTENTS

SERVICE INSTRUCTIONS SECTION

Front Door

TOp DOor

Front Plate

Body Parts

Bellows

Ground Glass

Ektalite Field Lens

Hood

Idler Frame

Mirror Frame

Release

Focal Plane Shutter

Disassembly

Clean and Lubricate

Reassemble, Adjust, Time

Revolving Back

Attaching Back

Slide Lock or Retaining Strip

Velvet - Revolving Frame

Wood Spacer Strips

Revolving Ring

Revolving Latch Back

Parts Catalog

Front Door

Top Door

Front Plate

Body Parts

Bellows

Ground Glass

Ektalite Field Lens

Hood

Idler Frame

Mirror Frame

Release

Focal Plane Shutter

Revolving Back

Stock Screws

Lubricants

Cement

-(..

2E X 3± R® a. Sel`ies 8 GRAFLEX

EE2QiE2Pg± !p±p_Ppp± , Front Plate

£p_ecial P±eQa_a_t±ons _f_Q±r=:

1. Front Door

i Panel

h Spring

iL covering

2. Top Door.

fu Replacement

h Handle

fu Brace

i Catch

fu Cover`ing

3. Front Plate

ji± Removal

h Adjustment

i Pinion Replacement

1. EiQp__t Door___(#_7_?=Z2±

fl lhe fl.ont door. (#777) is secured by three #0 x i" oval head wood scl`ews (#15280-4).

:§s:::i::::£§e::::w:::::ode:;a::::::g:i:::=:::k:§§::£::o::£:§C:i:;i.U=:±:S5b:°::c::::ry°r

h The panel spring (#8) is replaced by I.emoving hinge rod (#30172-P20). Position the

::Wt£:r:::±¥:?h ;£:Sc::Lt:;r±::±€:;s±'g:t:u:tp::e:::u:Ea¥o°£=f:ft::ep:::f ::p:::;: tension

Section 20A

Page 1

fi The cover.ing (#64-6) is secured to the

metal-panel.by cement and four rivets (#7329).

Use hot animal. glue or 3hi-EC-860 cement for

the lea.t`her covering.

i-inr-i

jL Io remove the top dool`, it will be neces-

sary to disconnect the I`ight and left brace

from the body--then, either. remove the hinge

rod (#30172-P21) or peel the leather from the

back and I'emove the hinge scI`ews.

Ihe serial number is stamped on the inside front edge of the top door. If this part

\f)

/I cut off excess

::p::€L:::i , t::eo::S::=e:e:h::Se:et:°£±:i::s::a::: :::p:¥:e:sa£:lie:s±8kErrfu :::u::I_

rect camera registration.

fat ¥£'gd::d`f|::33ingafe3:a::p::::gt:::ep:::::nif:::::in:ietE:v::p (.a:g59;5 ::in:g3?,., d2::ll

meter escutcheon pin, cut to length allowing a.bout i/16" above the washel' for I.iveting.

fu The top door 3::i:p::±g±trf€:€3{#Z§#.±3£:43r::ea:::¥b::: g::E :::e:of¥v:%:E:: E::t:t

to the ot]tside.

mnst inove freely.. .

a.. n.e::%.:5±d.:%:_%:.cg:.:_c.:.i:::s ::rL:¥:u3£et3;+i:€t±::I_t£::_%_:p£.gr t:.:_n_:.=.:g£33; , b_2€y.w±£±es; I f

necessa.ry to slide the anchol` plate back or forward respectively.

ti. The citeh..jl``t; (#12) will.requir.e that the leather be lifted along the front edge

for riveting. .File the.rivets flush on top before I.e-cementing leather..

• Re-form the. top.door .catch (#10), so tiat. the tension willbe against the body.

Pull to put tension

Bend off set and

J

On Spring

fr Th.e top door.covering .(#2275).intist be skived (sanded thin) at the edge.for easy and

Smooth cem.enting.

Ihe.:.ieath;r fl}a} be score.a witfi a .hot iron 1/8" wide on a line 5/8" from the edge.

Ihen score 1/16" .wide. on a line 1./4-" fr.om the adge.

Re.as;emble handle .and lugs--see paragl`a.ph fi

•,

Section 20A

Page 2

;.- a + .-.., ;

A,r.

L

J55TLr±3l=

•.J±2JiL-_-€]

j~rfeEL--=itH

r3EEEGLttH

fR!ffDIVo%fy:rr2:pav^

9055

.'giv

15183-8

1- I 5 9 6

FRONT PLATE COMPLETE NQ.15659

2± x 3i R. 8. Series 8 GRAFLEX

POP DOOR, FR0hTT

Section `20A

Page 3

l`f.: . .

\.3.

10

1|_P2

150814

15082-4.

15085-10

15180-3

15280-4.

15281-4-

15282-4

228

717 FRONT DOOR A5SE},BH

CAICH - TOP DOOR

Stl.ap - Top catch

Screw-hinge to body (i" #1 FT] S

Scl`ew - top door bl`ace to body

Scl'ew - Front plate to body

Screw - Top door strap to body

Screw - Front door to body

Screw - Top door catch to body

Screw - Focusing I`od bear.ing to

Hinge - Body section of top door

6 Door -front

8 Spring -fl.ant door

346 g::8:i;gf= °=:o:€°:oof

7329 Rivet - covering to front door.

30172-P20 Rod - front door hinge

2409 DOOR ASSEItBLY - TOP

12

13

17

288

3-P2 Rivet - catch plate to top door

114.20 BEARING T FOCUSING ROD

12696 COV£RING -FRONI

13659 .tmi ONI pinTL cohipLE.TL

Catch plate (Use I'ivet. #16599)

Lug - carrying handle

Washer - handle lug

Rivet - brace to top door

Cctvering -top door (}V;orocco Leather)

Brace assembly -top door, I.ight

Brace assembly -top door, left

Handle -camel`a Carry±nE.o65 diam. )

Rivet - handle lug

(use screw

(use screw

'' #2 FnTt I,17)

3" #5 FH S8)

(I.!ol'occo Leather.)

(Use screin/ #1528-4)

(hbrocco Leather)

_RT. L17)

L17)

QT¥. Unit cost

1.15

List

i.10

5.01

4. . 03

4.04

2.02

3.C|

2.03

3.01

i.30

i.90

15133-8 Screw - beal`ing plate (i" #3 RH L8)

!i:;6 ::::::a::::k:s::::i;n

114.22 Bearing plate - focusing rod

12700 Bolster block

12723 Focusing rod complete

13663 Catch Pin -door

30172-P2l R.od - top door hinge

11428 . Knob - focusing

12722 Focusing rod - complete with pinion

30663-PI Pin - focusing knob

Order by part number. and complete name. State quantity.

•. Prices are .subject to c.hange without notice.

Section 20A

Page 4

3. Front Plate (#13659).

#||Zg8?:n:E: f::a::::tr3Ea5:iri:gwi#lii85? ?gen::::!.:;:n::

(#||428) , the focusing rod bearing (#1142°) 9rE:: :::8:;P378* g .±±:tc£::Eaw.:38 ±::.:+sthe

front bellows frame sol.ew must be removed.

from the camera bottom to free the bc)lstel. block, and remove

(#13659)

2± x 3i R. 8. Series 8 GRAFLEJ£ .

Front Door., _TQp_ ___D__oQ__I=`„ FI`ont Plate

I.emove the focusing knob

th.e front plate..complete.

±seisi;s[#;g;55:o::dp:::e --

;;±=~;+ri/d;"{#ii536}`iovL[L.;_

move play. Check.tension

of yoke tension springs (#74.02).

Adequate tension Th-ill prever.t

f::g±ao: ±::gt::i::1:rE ::=¥.re_

quire incl`eased eff ol.t and

dissatisfied operation at

normal bellows extension.

fu Pinion replacement (#12722).

See paragraphs fu --there is no

short cut.

.---- f .

2± x 3i R. 8. Series 8 GRAFux

Body Parts

ipg.cial pre£Lautions for:

i. Bellows

2. Ground Glass and Ektalite Field Lens

3. Hood

4. Idler. Frame

5. Mirrol' Frame

6. Release

i Bello-ws (#7752).

i Remove thef font panel. Remove four #2-56 x i" oval head screws (10482-4.). At the

bottom of the rear. bellc>ws fl`ame, I'emove two #2 x i" I'ound head screws (#15182-4.). At the

top partition plate, loosen the three round head scl`ews and slide the bellows down and out.

h Inspect the front and I.ear bellows frame for flatness. Straighten if necessary.

fr Replace the back fl.ame by sliding t.he top beneath the partition plate. Reassemble

:E:n::t:::p::::Tl;::in:::np::#::: :?ed:::i::::ni E:::eo:c:i::;e.As;:::::in::: :::Sf:::t

fl.ame and position the threaded flange, so that the lens diaphragm index will be near the

top right.

2. Eoun££Llas±££=een As s±E±±1z__I (.£±3Q±Z_)___=a.pd_...T.F±_eld...LLe_P.a _.G±3±£.8±E3 ).

a. Assemble the serrations of the Ektalite field lens (#3188l-P3) to the ground surface

3f the ground glass (#13017) and bind the two opposed 3-1/16" long edges together with

papel' tape (#11504).

(i) Position the-asserr,bly with tape to the outside edges and the polished side of the

ground glass to the top.

(2) Bend the frame ears inward enough to hold the assembly. Do not attempt to bend

the ears down--it will crack the glass.

Section 208 .

Page 1

h Form the mounting tabs outwal`d to increase the sliding friction when focusing. Re-

assem`ole two #1 x i/4-" long round head sol.ews (#15181-4) at the back, and two special

machine screws (#118) at the front:

g. F.ocus as follows:

(i) Set lens wide open. Set camera f.ilm plane pal.allel and about 6 feet from a 4 foot

square target. Use pie charts ol. similar, or old calendar sheets having large and

small figures.

(2) Using a GRfiFLLX focusing panel, focus on film plane. Ijower mirror and adjust top

ground glass--check each corner and center.

(3) Check infinity focus using pro6edure of step (2). Tighten scl'ews when general

focus is satisfactol'y.

3. H=Q_Q€__±±_.a.sfnE,±I£J.#1271_€±.

If the. hood sags inwal.d and does not open fully at the top, an adjustment can be made by

lowering hood catch (#50). Plug old sol.ew holes and I.elocate.

•4 !..___I_.£±e_I..___E±ape._4.s=SLepb_ly. =£.#242£±. `.

The i.dler frame ass:mbly. is secured by fo.ur #2 x i/2" flat head wood screws (#150-2-8)--

two on eac.h side. '

• fie.in-eve-th`e b-a-c-k-; .-...-.

Mark .side index.of case and frame to assure co.rrect realignment.

•Lift fran.e .arid swi.ng .out at the top to avoid damage to the lower curved metal shieJ.dn

•... The lower idlel' should .turn free--lubricate.very lightly with graphite grease.

The. top idler. s.hould be staked to prevent .tul`ning and produce a quieter shutter.

Form metal shield, so. that it will not bind against the .tension roller and curtairl.

Replace squal`ely, and. be Sure .each aorner is pl`essed down tightly. If fl.ame is not square

or one side is h.igh,.. the cu.rtain ini.ght ride off to one side.

Section 208

Page 2

3,'= .

:--::=::-::::::-I:=__::---i:--::::::I--::

10645:

!N:.E2F2T68\, `t52--.- Z.-8.i

•.-Ni'i,,6±H3T€!

0-

: 7 7 5_2J

!~

ti §1- a 2 =_41

Jar§J

126:

-r3_.OJ_50;

(

`Li2.I

-`-. Ll.27-'8

-

'.

-i--:::--*-i:iiir---rfe_:i----:_--_--:ir_-:::-iif-:::-:---_-:

EffiHH EEi E=

.-

!l_!.T`.a_T±!

t

•iL52iir-:4J

.15ae+aj,

• '2i_2!

L2-±i!

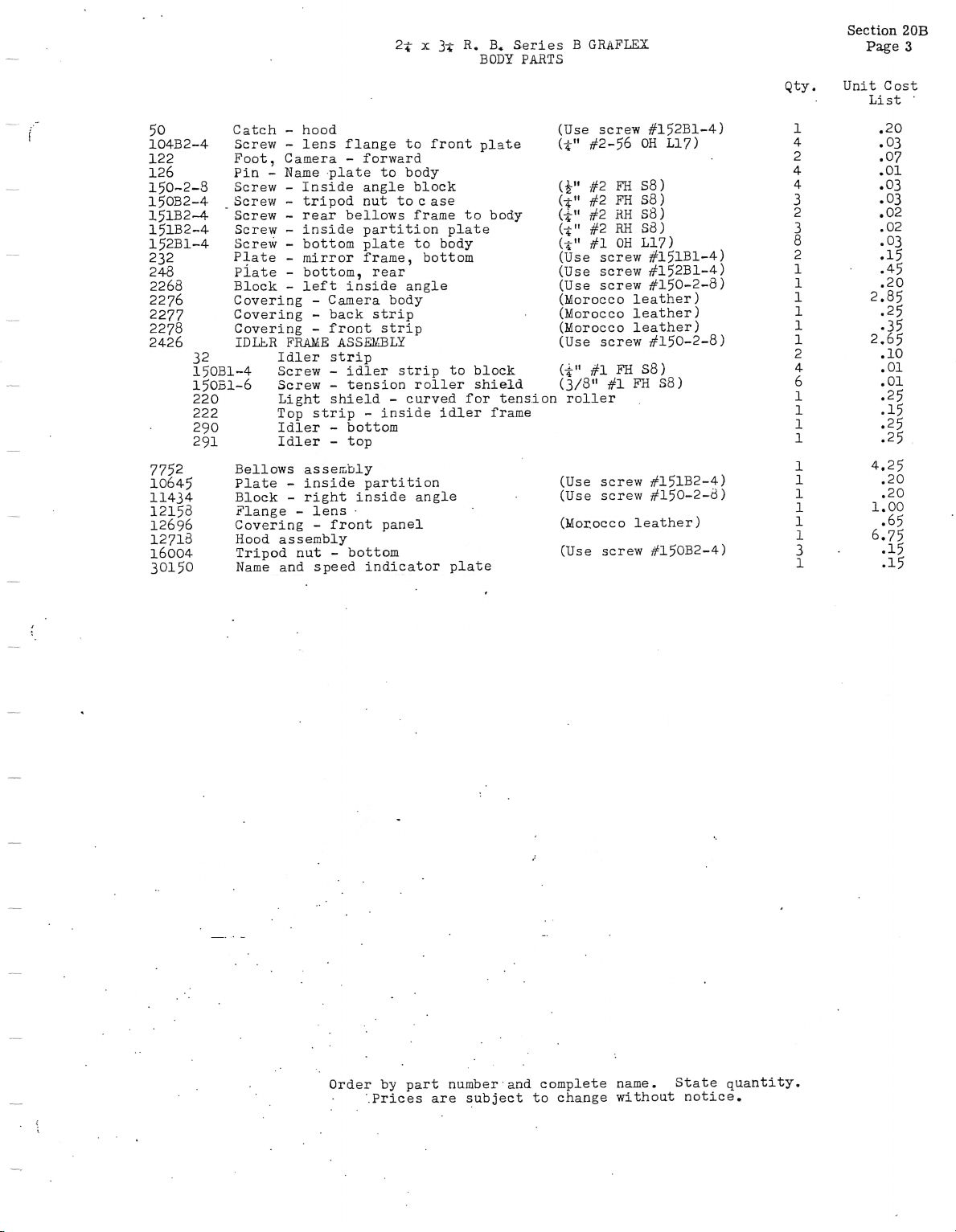

2± x 3E R. 8. Series a GRAFIEX

BODY PARTS

Qty.

Section 208

Page 3

Unit Cost

List .

50

10482-4

122

126

150-2-8

15082-4.

151824

15182~4.

15281-4

232

24.8

Catch - hood

Screw - lens flange to front plate

Foot, Camera -forward

Pin - Name .plate to body

Screw

Screw

Screw

Screw

Screvi

Plate

plate

Block

Covering - CaJnera body

- Inside angle block

- tripod nut to c ase

- rear bellows frame to body

~ inside pal`tition plate

- bottom plate to body

-mirl.or frame, bottom

- bottom, rear

- lef t inside angle

Covering - back strip

Covering - front strip

IDLER FRAME ASSERE3LY

:;8:±=€ ::::i :t:::::o:t::Ei:: :i::¥d (3;8#L#FF£838j

220 Ijight shield - curve.d fol` tension I'oller

77rf2

10645

11434.

12158

12696

12718

16004-

30150

222

290

291

Top strip - inside idler fl`ame

Idler - bottom

Idler - top

Bellows asserubly

Plate - inside partition

Block - I`ight inside angle

Flange - lens .

Covering - fl.ont panel

Hood assembly

Tripod nut - bottom

Name and speed indicator plate

(Use screw #15281-4)

(±" #2-56 0H L17)

518

(Use screw #1528

(Use sol.ew #150-

(Mol`occo leathel`

(Morocco leather

(Morocco leather.

(Use scl`ew #150-2-8

(Use screw #15182-4)

(Use screw #150-2-8)

(Mor`occo leather)

(Use screw #15082-4)

Order by part numbel'.and complete name. State quantity.

•.PI.ices al`e subject to change withotlt notice.

Section 208

Page 4

-

15o .80-51,

24o7i tar"

•f-a:ir

245'

-TAPE ;

No.11504

©

- !1 lT6`5 i

ta-

15.2 81 -`4,

i-35TB o =3

L~

'T

•10 0 -2-4

i 2 2 § -6 0

L==

©£

.2285 2

ck.I

•1' 52 81 -4

a 255:

G-ROUND CLASS ASSEMBLY N5.13017'

®

•.I 0,6 4 5 .

a-- ,L5J±2_-4J

!2?i&9-

:"BRDR FRA"E.COMPLETE No.22803

.`',",,-"T,,,,,,fl!j,,,':,iapl,ap,,,,,,,,,,,

.€_2_9 5

[I,l!,ill,;,;

2289

2+- x 3f R. 8. Series 8 GRAFIIEjt

GROUND GRASS, ELI.iAsh, hREOR FRch4E

Section 208

Page 5

-If..-.

13ol7 Gi{uuND GLesD scELjn' A3sLIiBLr

2g36 g:=: : g::::: :::::nscreen

11504. Tape -scl`een edge

3188l-P3 Field Lens - Ektalite

14.278 REhASL IEvjiR - iflRROR FRch{E

:::Z8 i;:::8:I::::::::::::Se lever plate

228o3 hilREOR Ffich:a c ompLETh`

i:i ::;::-;:lF::::;:::i!:t::;::e

§§§§ i;i::::::::1::::i:=:I:::::::::Et i:::::::I:::::;side)

24.07 Lever - mirrol' set

24.2C Hirror frame assembly (Ordel` covet.ing #2287 a #2288)

loo-2-4 Screw - mirl.or frame to rod

205 hiirl'or frame

263 Rod -mirror frame

34.

96

118

15080-3

15180-3

15181-4

i5nel-4

i2431

1064-5

1116 5

22852

Spring - mirror fl`ame lif ting

Plate - mirl`or frame beal.ing

Screw -.ground glass scl`een assembly to body

Screw - mirror frame beal`ing 'plate to body (3/16

Screw - inside frame to body

Screw ~ ground glass scl`een assembly

ScI.ew - mirror frame plate to bod}r

Scl`ew - inside par.tition plate to body

Scl`ew - release level` to body

Screw - bushing container tc` body

Plate -mil`ror fl`ame, bottom

Inside fl.ace

Bushing container -for. rod and spring.

I & I s.lide assembly

Plate - inside par.tition

Light break for I'elease

Light bl'eak - mirror f fame I.6d

(Use screirs #113 i #15181-4) i

(Order 2 of #11504-)

(Use screw #15281-4)

(Use screw #15080-3)

e screw #15181-4-

e screw #15080-3

e screw #15281-4

(Use scl`ew #15182-4)

(Mohair)

7)

'=.ty' Unit cost

List

i

i.50

.50

i.00

.01

Qrdel. by part. number and complete name. State quantity.

. Prices are .subject to change without notice.

Section 208

Page 6

2+ x 3± R. 8. Sel'ies 8 GRAFI.FX

Body Parts

i_ ___ng±r_rQr ____F_ra_fpe (#?2_8_Q3±.

a. Mirl.or (#229

5i#5!5|::;::::ment

h Frame.spring

fr Frame complete (#22803) replacement

fu Hil`ror (#2295) replacement. ..

(i) |t will be convenient to I.emove the hook::gn8L9::Erg:i:;.::r=:; (£i±85a::8:::h 2

and 3. Set focal plane ctirtain open.

clip.-Remove two mirl'or Clip screws from 6ther .clip; I`.emov§ this clip, and then

remove the mirror.

(2).Patch the mirror frame covering, if torn when .re.moving. a cem.ented mirror..

(3) Insert the new mirror with first-surface up.. Replace mirror frame clip; tighten

screws. Reassemble ground glass and refocus--see paragraph.2 .e+ a.fol`enentioned;

i Frame spring (#34) I`eplacement.

Apply spring tension by ttil.ning mirror. frame spring container.. (#262) c.lockwise.

Enough tension should be applied to lift the nirrc>r, but it must not be tog much aha

cause camel.a movement.

c. Frame cc>mplete (#22803) replacement.

Disassembly.

(i) Remove hood and ground glass. Remove mirror set lever (#2407) th.at is secured

by a taper. pin (#120).

t#34.j. From frame and I:::o¥:in:::I:£r.::a#;_;gr±nE„c:£::±£::dt¥:f:*saE£L88:±:E,.

(2) Ihe back covering (#2286) of trie mil'ror frame is cemented to the light shi6ld

(#220) of the idler frame asseITlbly. Remove carefully--do not teal'.

Reas{:Tb5¥;an old cement from the ap|`on of the mirror frame. back covering. Reassemble

.

{;ggg325:ds#::3 , {#jz5:w:n£#:S£=:;4: :n¥:=::: {;E6±3Terc:#::%7tAeL:g::nb::t¥ EC.88o

cement or rubber cement.

(4) Replace gI'ound glass and focus--see pal`agraph 2 i

£Lje±?Tas±I£3££±J±E±42ZEl .

fr the release lever is. secured witfj f our #0 x ±" oval h.ead

screws (#15281-4). Check the mohaiI' light break (#11165)--

dust or replace.if matted. Ihe mirl.or I.elease arm must be

positioned in relation to the mirror. as sketched.

•Since the mirl'or depression may be changed when the re-

lease lever is replaced, it is necessal`y to che.ck focus--

see pal.agraph 2 gL

2± x 3± R. 8. Series 8 GRAELEX

Focal Plane Shutter

Section 20C

Page 1

SDecial Precautions for:

i. Disassembly

jit Shutter setting plate

h Tension setting plate

2. Clean and Lubricate

3. Reassemble, Adjust, Time

jL Curtain and Rollers

i. Disassemfty.

jL Shutter setting plate (#12724.) is secured by f our #3 x

NOTE: Screw in forward top plate hole is cut off to.3/

Remove the mil'ror lever assembly

The illustration does not show the outside f.ace--see

" oval head screws (#15283-8).

„ long.

g

the parts layout on. Page 2.

h Tension setting plate (#14-231) is secured by four #3 x i" oval head screws (#15283-8).

Io replace the tension pawl spring (#14227), it may be necessaLI.y to remove the riveted

tension winding knob (#14228). In this case, supply new knob.

*he :::£¥:sr:I:±V3£EE8=896 :3£e§:%:ton 2°D. the Curtain assembly-(#242i) -i-s cemented to

roughe.n brass tube for adhesive tooth.Use C°az'Se Sam.qpaper I.O.I.9F.oy?. olq 9.?Ipent apd

The axis of the roller must be cemented squarely to the longitudinal dimension of the

cul`taino Failul'e to do this will cause the curtain to roll to one side and bind against

the camera body. Remove rollers from the camera to be assured of the best alignment when

I ec eme nti n g .

0 0

TT---

The gear roller assembly (#24-18) must be removed after the idler assembly has been re-

moved. Mal'k side index of case and frame to assure col'rect I.ealignment. Lift fl`ame and

swing out at the. top to avoid damage to the curved metal shield.

The tensic>n rolle.r assembly (#14251) must be.removed through the bottom of the camel`a.

Remove the bottom plate (#24-8) that is secured by eight #0 x i" ova.i head scl`ews (#152814]

2. Cleaning and Lubric.ation. .

i Clean all metal p.arts by. immel`sing in cleaning solvent. Wash thor-oughly to remove all

d.i|`t and foreign matter. All par.ts should b e dry before I.eassembly.

h Lubl.icate as follows:

I±§E _I_Q C _a ±± Q_LB_

EScapement Spring . .Lubricate area tha.t. opel`ates with master gear #107 Lubriplate

Lubr i c ati on

s:::=ngs I:E=:::::p:::i::gbga:=ng:a:€. each end. %::EE±:: ::: a::::: #3

Springs Dip. springs for rust prevention and ligbt Singer Sewing Machine

CAUTI0H: I,ubricate .moderately. Do not allc>w. any lubrication to contact the rubber. of the

lubricati.on. Oil

shutter curtain.

Section 20C

Page 2

1-g155,,

Hit ffi

„*3-a

a_06

I 3- 0 I 3

163---pZ

; LEVER :

iNo. 2 4 0 7

--,

1L±231

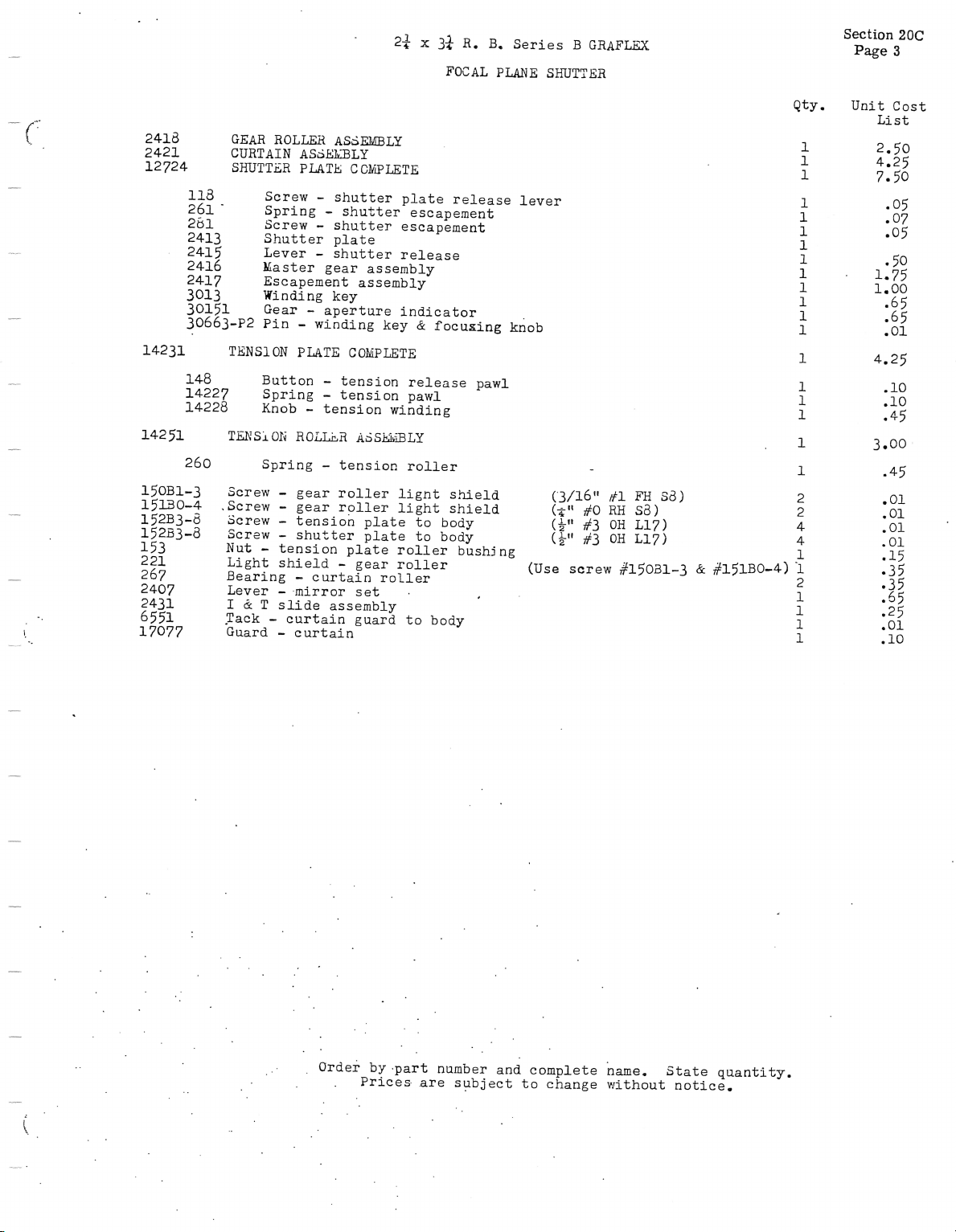

2± x 3± R. a. Series a GRAFLEX

FOCAL PLANE SRTTTER

Section 20C

Page 3

i.`.-

24.18 GEAR R0I.LEE AS5EREI;Y

24.21 CURTAIN ASSREI,Y

12724. SHUTTER PIAIE com>IEIE

j!i;i i§:#€:::i¥i::::::i:i:::Sse lever

30663-P2 Pin - winding key a focuging kdob

14.231 TENsloN PLATE COMPLETE

:::2g :;:::; :e;::::::i;:I::se pawl

14.251 rEh'si oi¢ ROLhiR Assrfu.BI,I

260 Spring -tension. roller

15081-3

15BO-4

15283-8

152j33-8

153

221

267

24.07

2431

6551

17077

Screw' - gear. roller light shield

Screw - gear roller light shield

Screw - tensioh plate to body

Screw - shutter plate to body

Nut -tension plate roller bushjng

Light shield - gear roller

Bearing - cul.tain I`ol.Ier

Lever -.nil.For set ,

I a I slide assembly

.rack - oul`tain guard to body

Gual`d - curtain

(3/16" #1 FH S8)

(a" #0 RH S8)

(±„ #3 0H L17)

(i„ #3 011 L17)

(Use scl`ew #15081-3 & #15180-4.)

Qty. Unit cost

List

2.50

4.25

7.50

.05

.07

.05

4.25

.10

.10

.45

3,00

.45

Order. by.pal.t number and complete .none. State quantity.

Prices. .al`e spbject to change v,Tithout notice.

Section 20C

Page 4

2± x 3± R. 8. Series 8 GRAFLEX .

Focal Plane Shutter

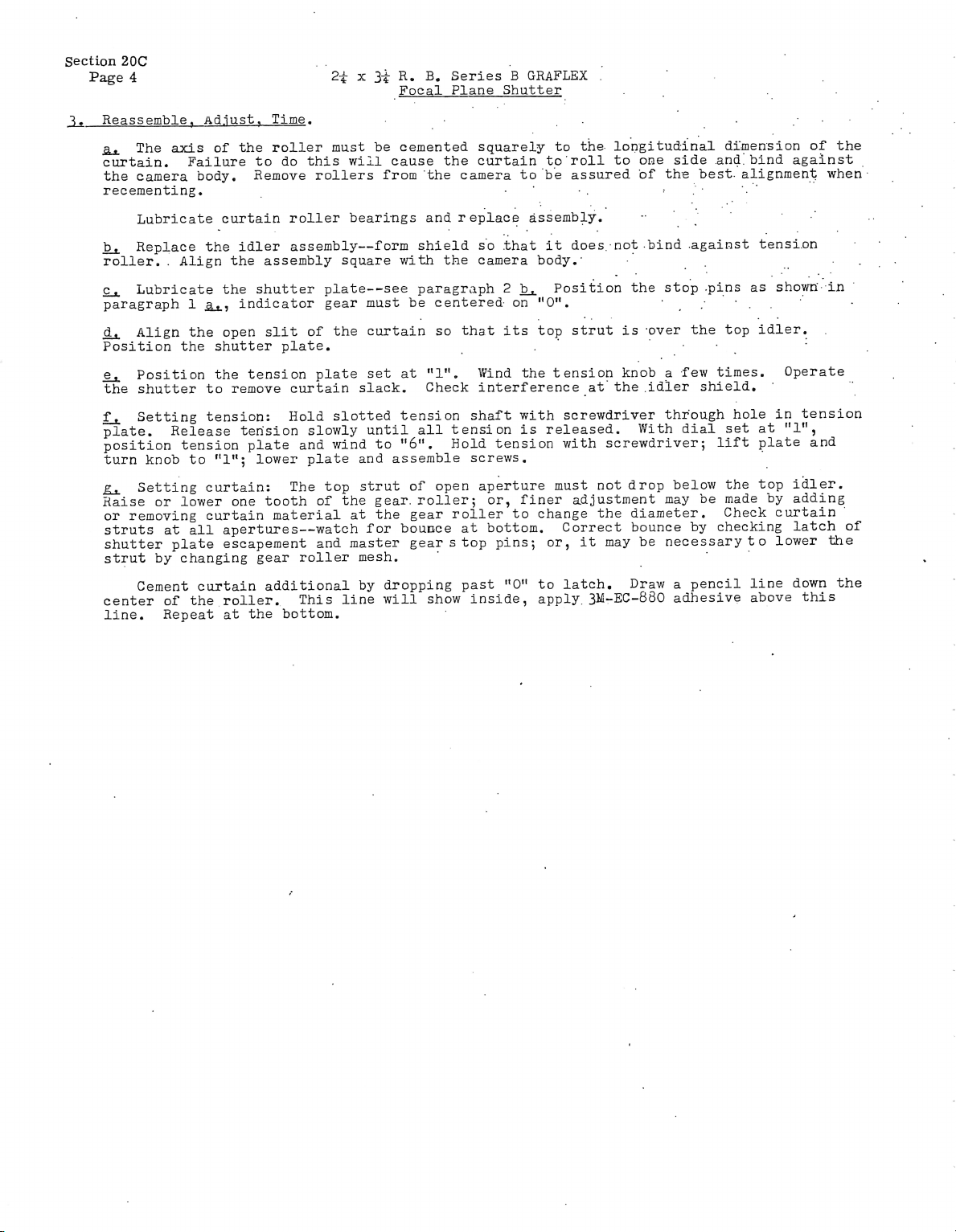

i+___Reass_epple,__fld.iust+I__E±_PL§.

fu The axis of the roller must be cemented squarely to

curtain. Failul.e to do this will cause the curtain to.

the camera body. Remove rc>llers from .the camera to .b.e

I.ecementing.

the. lop.gitud.inal di-.men.sion of the

roll to one side .and:bind against

assul.ed .of th.e best..alignment when

Lubricate curtain roller beari.ngs and replac; assembly. . .

h Replace the idler assembly--form shield s.o :that it does..not .bind .against t.ensi.on

roller. . Align the assembly square with the camera body..

g+ Lubricate the shutter plate--see paragr`'iph 2 h Position the stop .pi.ns as shoyn...in .

paragraph 1 a„ indicator gear mst be centel`ed. on ''0''. , .

i Align the open slit of the ctntain so that its top strut is .over the top idler.. .

Positic>n the shutter plate.

j2± Position the tension plate set at "1''. Wind the tension knc)b a .flew times. Operate

the shutter to remove curtain slack. Check interference at-the.idler shield.

...

i Setting tension: Hold slotted tension shaft with screwdl`iver thr.ough hole in tension

B::::ionR::::=:nt;::::na::°#:¥du::i:6:+i ::±:i ::n::o:e:::£eg;rex:::v:i?Li:f€ ;±a::"and

turn knob to ''l't; lower. plate and assemble screws.

jL Setting curtain: Ihe top stl.ut of open aperture must not drop below the top idler.

f{aise or lower one tooth of the gear. roller; or, finer adjustment nay `De made by adding

or I'emoving cur.tain material at the gear roller to change the diameter. Check curtain

struts at all apel.tunes--watch for bounce at bottom. Corl`ect bounce by checking latch of

shutter plate escapement and master gear s top pinsi or, it may be necessary to lower the

strut by changing gear I.oller mesh.

a

Cement curtain additiona.I by dropping past '`0" to latch. Draw a pencil line down the

center of the roller. Ihis line will show inside, apply.3m-EC-880 adhesive above this

line. Repeat at the bottom.

-~,

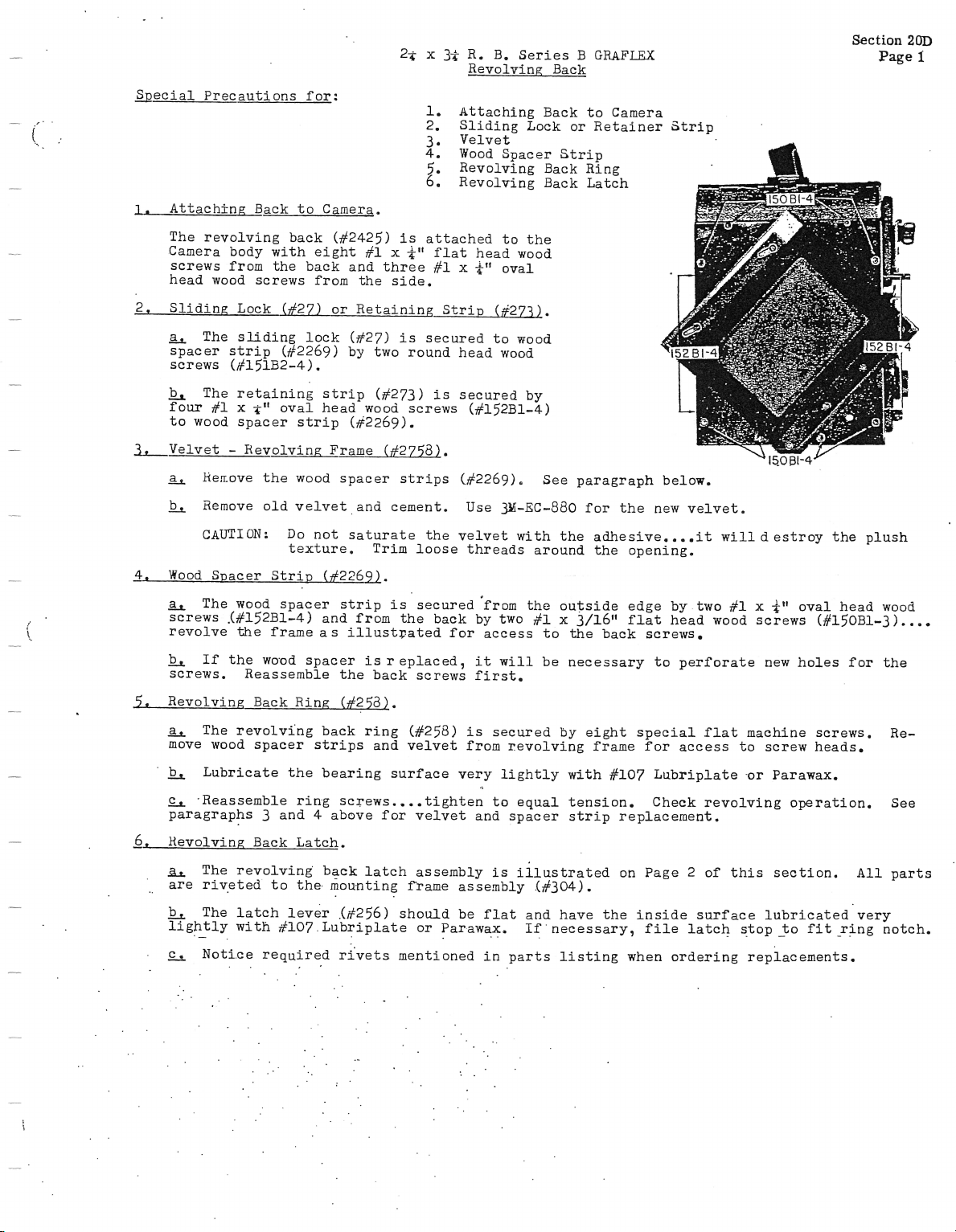

2¥ x 3± R. a. Series a GRAFIEX

Biv_p lvi n g _ _P_e=j2¥

Section 20D

Page 1

Special PI.ecautions for:

Attaching Back to Camera

(

Sliding Lock or Retainer Stl`ip

Velvet

Wood Spacer Strip

Revolving Back Ring

Revolving Back Ijatch

li___ ___Attach±_pg___Back to Camera.

Ihe revolving back (#24.25) is attached to the

Camera body with eight #1 x ±`' flat head wood

scl`ews from the back and three #1 x i" oval

head wood sol.ews from the side.

LS|i di ng _I Qcl€ . _ i.{._#? 7J.. _ Q_I_ _ Re ta±±±±ngj±±±_i.p i_#2Z±J .

i The sliding lock (#27) is secured to wood

S8:::: {#;EB£¥£3:9) by two round head wood

h The retaining strip (#273) is secured by

four rfl x z'. oval head wood screws (#15281-4-)

to wood spacel` stl'ip (#2269).

L]I±±.Iret I._ =Fej[Q_lvinj3 F=g±p_e _ (.#?=Z5£2.

fr Heir.ove the wood spacer strips (#2269). See pal`agraph beloiF.

h Remove old velvet and cement. Use 3H-EC-880 for. the new velvet.

CAUTION: Do not saturate the velvet i^rith the adhesive .... it willdestl'ey the plush

texture. II.in loose threads around the opening.

4+ _ ngoo_d___=SpLa_Qe_r St_I_ip (#2?6_2)=.

%re::e.t#£;gB£:a;e:n3tf:8mL:h:e%::=dbfrto#o t#= £u5;±g: :£g: £¥aEwfo€± =c±,:w:vE±L38%£.¥;::..

I'evolve the frame as illustpated for access to the back scl.ews.

h If the wo.od spacer is r eplaced, it will be necessary to perfol.ate new holes for the

scl`ews. Reassemble the back screws fit.st.

i____a_ev.ol_¥±ngEapk..Ring_I_rf2_E§J.

i The I'evolvi.ng back ring (#258) is secured by eight special flat machine scl'ews. Re-

move wood spacer strips and velvet from revolving fl'ame for access to screw heads.

• h Lubricate the bearing surface vel.y lightly with #107 I.ubriplate -or Parawax.

•.,

fu .Reassemble rin.g screws .... tighten to equal tension. Check I`evolving operation. See

paragraphs 3 and 4 above for velvet and spacer strip replacement.

£tuLevc>1viQLg__Ea__c_*___Latiqut.

¥e :::.e::¥°±¥±:Eeb:::n±:::hf::::in::¥e.::i;L{#:gz}?ed On Page 2 of this section. All pal.ts

h The latch lev:r .(#256) should be flat and have the inside stirface lubricated.very

lightly with rfl07.Lubl.iplate or Parawax. If.necessary, file latch s.top _to fit _I.ing notch.

fr Noti.ce required ri.vets mentioned in pal.ts listing when ol`dering I.eplacements.

Section 20D

Page 2

~,

. _ . _ ,--..- ;

?H3-

®

•....

;L:2i!

¥.[l_50-a--i3]

•!£-E'6-9;

:FTBAfaLEAs~s_EinBL7NQ-fo66Oj

i i.,ji-zTffl¥:

;±i3l`:. t

..a.

.i_5ZLj2t4

~,,.a~r.+:...:..,.`.;..`,...._.<`..-.!E£~CK`.C.gee,.E±E.IE.¥.?..24?i.5.I.-i_:.::...._~,..w....`.::.i....:i.,.`

*

+

__---.----.--.--'.-

2¥ x 3± R. 8. Series a GRAFIEX

REV0IjvING BACK

Section 20D

Page 3

24.2 5

REVo|,i.riNG BACK CoMPRETE

27 Lock -sliding

119 Screw - ring to I`evolving frame

(Order attaching screws)

(Use scl'ew #15182-4)

:g:::i ::::; : ::::e::.;:: :: I:;::;:::p::::: (:#: a ::7;8)

±5:BL_4 §::e¥ =L:::a±::Ego:::::i:: Wood

258 Ring -I.evolving back

273 Strip -plate holder retaining

304 FI`ame assembly -mounting

:87 #::::I--i::::ai:v::ung er

178 Plunger -release

256 Level` -latch

257 Spring -latch lever

30363-P6 Rivet - latch lever spring

2258 Velvet -revolving frame

2269 Strip -wood spacel`, I`evolving fl`ame (Use scl`ews #15081-3 &

10660 Frajne assembly -revolving

259 FI.ame -I`evolving

2399 Felt.-revolving frame

Attaching screws - revolving back to body

15081-4.

15281-4

Scl`ew - revolving back to body

Screw.-I`evolving I?ack to body

strip (i" #1 OH L17)

(Use screw #15281-4)

#15281-4)

(±„ #1 FH L17)

(±„ #1 OH L17)

Qty. Unit cost

i 9.85

Z

I.ist

i

i

i

30

Ofdel' by. part nun'ber.and complete name. State quantity.

`.Prices are .S.tibject to change.without notice.

!,

i

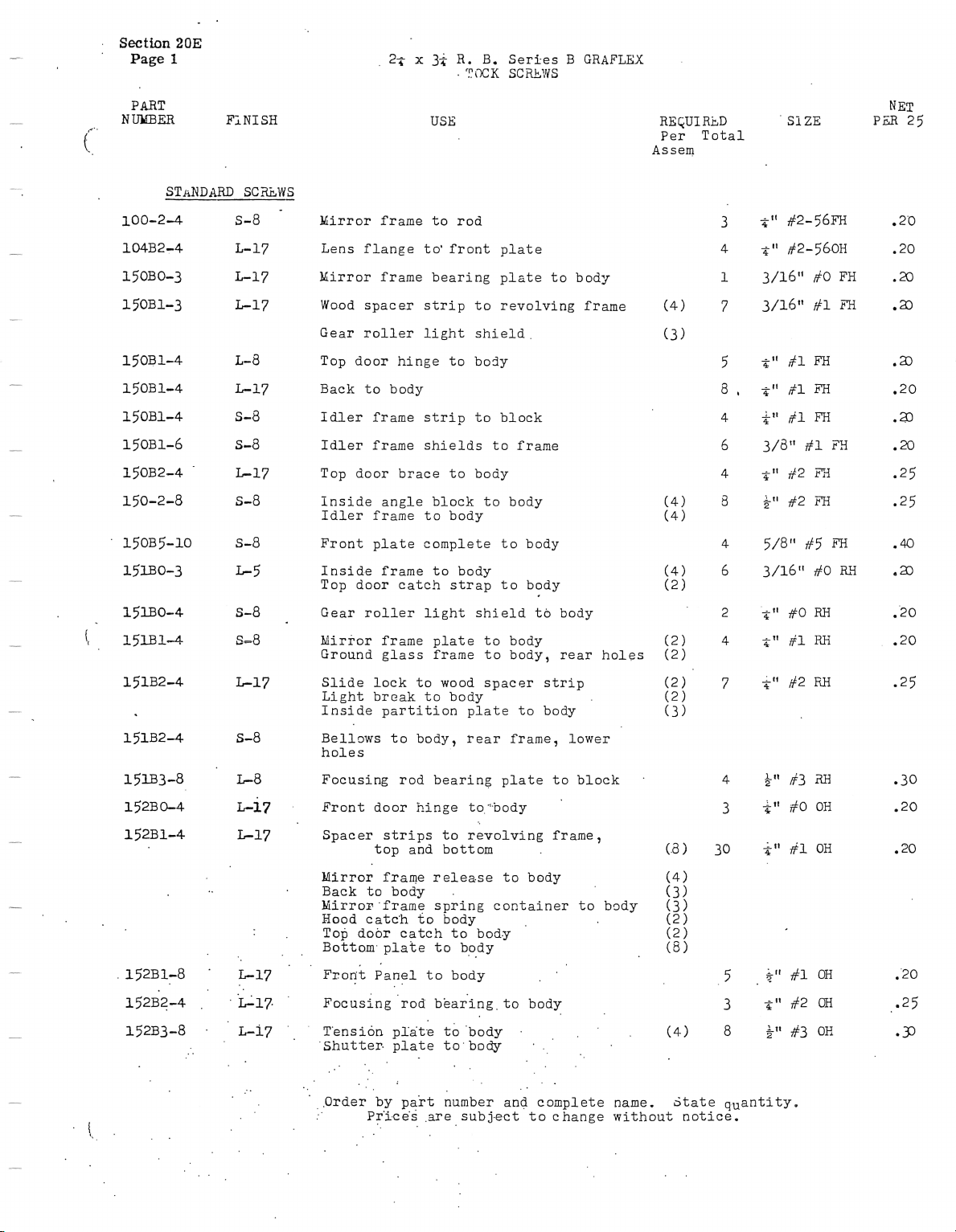

• Section 20E

Page 1

2Tf x 3± R. 8. Seri-es 8 GRAFLEX

. r.T\TX=K SCRLtws

PARI

NURERE

STANDARD SC^ELWS

FiNISH

loo-24 S-8

10482-4.

15080-3

15081-3

15081-4. I-8

15081-4 L17

15081-4. S-8

15081-6 S-8

15082-4 L17

150-2-8 S-8

• 15085-1o s-8

151BO-3 L5

15DO-4 S-8

{t 15lB ltd s-8

USE

Hirl-or frame to rod

Lens flange to` front plate

Mil`ror fl.ame bearing plate to body

Wo.od spacer strip to revolving fl`ame

Geal` roller light shield.

Top door hinge to body

Back to body

Idler frame strip to block

Idlel' fl`ame shields to frame

Top door brace to body

Inside angle block to body

Idler frame to body

Front plate complete to body

Inside frame to body

Pop door catch strap to body

Gear I.oller light shield t6 body

mirior frame plate to body

Ground glass frame to body, rear holes

RBQUIRLD

Per. Total

Assem

' SIZE

¥„ #2-56FT

a" #2-56OH

1 3/16„ #O FH

7 3/16" #1 rH

5 €„ #|FH

8 . i " #1 t"

4. ±„ rfl FH

6 3/8„ #| FH

±„ #2 Fi

i„ #2 FH

4- 5/8" #5 rH

(4) 6 3/16" #O R+i

(2)

2 ir" #O RE

4- ±„ #1 RE

NEI

Pm25

.2'0

.20

.20

.2D

15182-4. L17

151824

151B3-8

152Bon4

15281-4-

. L52BL_8 I.]7

1528.2-4 . .L17.

15283-8 I-i7

•(

Slide lock to wood spacer strip

Light bl'eak to body

Inside partition plate to body

Bellows to body, rear fl`ame, lowel`

holes

Focusing rod bearing plate to block

Front door :h.inge to<.body

Spacer strips to I`evolving frame,

top and bottom

Llirror fraH}e relea.se to body

Back to body

nil.ror..frame spring cop.tainer to body

Hood ca.tc.h to body

Pop door catch to bod.y

Bottom. plate to body

`®

Fron.t Panel to body

Fc>cusing rod. b.ear.ing. to body

I.ensi6n pl.a.t.e t6 .body .

Shutter. plate to.body

.Order by p.art number anQ complete name. State quantity.

Pr.i.ces .are subs-ect to change without notice.

7 iM rf2 RE

4- £0 #3 RE

3 ±„ #00H

±„ #1 OH

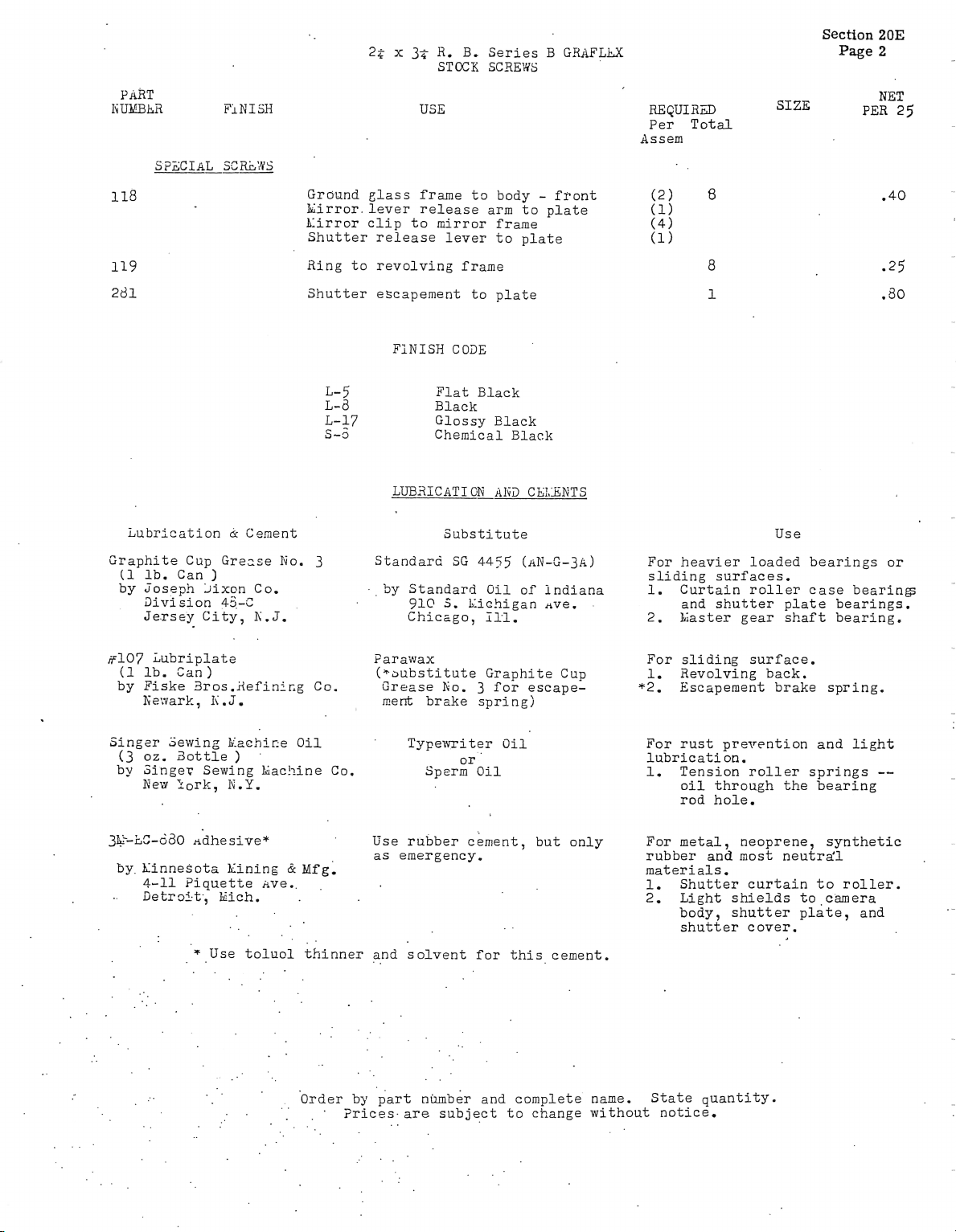

2± x 3+ R. 8. Series 8 GRAFLH

STCCK SCREWS

Section 20E

Page 2

PART

IiunebR

SPECIAL SCELWS

118

Lubl'ication ck Cement

GI'aphite Cup Grease lv-o. 3

(i |b. Can )

by u-oseph Jixon Co.

FI N I SH

Division 45-C

Je.rse-y City, It`.J.

®

USE

Ground glass fra.me to body -front

hill-I'or. lever release arm to plate

A:irl`or clip to mirror frame

Shuttel' release lever to plate

Ring to revolving fl.ame

S.hutter escapement to plate

FINISH CODE

L-5

L-8

L-17

S-3

Flat Black

Black

Glossy Black

Chemical Black

LtJBRICATI ciELAI{D CE!,iENTS

Substitute

Standal'd SG 4-455 (AN-G-3A)

. by Standard Oil of indiana

910 S. I:iGhigan j+ve. .

Chicago, 11.i.

RE QUI RD SIZE

Per Total

Assem

Use

For heavier loaded bearings or

sliding surfaces.

i. Curtain I`oller case bearings

and shut,ter. plate bearings.

2. hiaster gear shaft bearing.

NET

PER 25

ff{!7L5-:b::E])at'e

by Fiske Bros.j{efinir.g Co.

h.e'`vark, I\..J.

Singer Sewing h.:ac]Ljir;e Oil

(3 oz® Bottle )

by Singer Sewing hiac!i.ine Co.

Itlew tlol'k, I\'.Y.

3E`-LC-580 Adhesive*

by. hiinnesc>ta kining a Mfg.

4-11 Piquette Ave..

•. Detroi.t., haich.

I Use toluol t+fiiinnel. and solvent for this cement.

Parawax

(*Dubstitute GI`aphite Cup

Grease No. 3 for escape-

merfe brake spl.ing)

TypeTuriter Oil

Or

Sperm Oil

For sliding surface.

i. Revolving back.

*2. Escapement brake spring.

For I'ust prevention and light

ltlbl`i c ati on ,

i. Tension roller springs --

oil through the bearing

rod hole.

Use rubber cement, but only

as emergency.

For metal, neopl`ene, synthetic

I'ubber and most neutra'l

materials.

1. Shutter curtain to roller.

2. Light shields to camera

body, shutter. plate, and

shutter cover.

OI'der by pal`t ntimb;I and complete name. State qtiantity.

• Prices.are subject to change without notice.

-.

i. _ _I

-__:

e=

i-.'

-__+

.---.

I_ - - -I

T=_-

:__ _ L

`,-.

'`

GRAFI.EX, IHc.

Main Offices and Factories:

Rochester 8, N® Y„ U. So A®

Eastern Service Offices:

50 Roe.kefeller Plaza, Suite 922

New York 20, N.Y.

western mvi8ion:

3045 Wil8hire Blvdo

•Lo8 AngeleB 5, Calif

Loading...

Loading...