Page 1

He

at

N

et

Control adjustment and operation instructions

HN-IOM-2

3382-0331

®

manual

for firmware versions 3.37

This instruction manual applies only to version

3.37 firmware on version 2.x control boards.

Current firmware is backwards compatible with

version 1.x boards, but some current features may

not be available. To replace firmware on an

existing boiler, contact the factory to obtain the

original firmware file or for assistance in applying

current firmware to an older version control board.

Also read and follow:

Futera III Boiler manual or

Futera Fusion Boiler manual or

Futera XLF Boiler manual

This manual is intended only for use by a qualified heating installer/technician. Read and follow this manual, all

supplements and related instructional information provided with the boiler. Install, start and service the boiler only

in the sequence and methods given in these instructions. Failure to do so can result in severe personal injury,

death or substantial property damage.

Do not use the boiler during construction. Construction dust and particulate, particularly drywall dust, will cause

contamination of the burner, resulting in possible severe personal injury, death or substantial property damage.

The boiler can only be operated with a dust-free air supply. Follow the instruction manual procedures to duct air to

the boiler air intake. If the boiler has been contaminated by operation with contaminated air, follow the instruction

manual guidelines to clean, repair or replace the boiler if necessary.

Affix these instructions near to the boiler. Instruct the building owner to retain the instructions for future use by a

qualified service technician, and to follow all guidelines in the User’s Information Manual.

Copyright 2010 Mestek, Inc.

Page 2

HeatNet Control REV 3.37-1

TABLE OF CONTENTS

TABLE OF CONTENTS .............................................................................................................................. 2

Introduction ............................................................................................................................................... 4

T

HE FUTERA-SERIES HEATNET CONTROL

Features & Specifications ......................................................................................................................... 6

F

EATURES OVERVIEW

......................................................................................................................................................................... 6

Specifications ............................................................................................................................................ 7

Components & Accessories ..................................................................................................................... 8

P

ART NUMBER

C

OMPONENT

........................................................................................................................................................... 8

SETUP & OPERATION ............................................................................................................................... 9

B

ASIC MULTI BOILER SYSTEM OPERATION

M

IXED BOILER TYPES USING PRIORITY SETS

M

IXED BOILER SYSTEM OPERATION

S

TART/STOP PRIORITY CONDITIONS

S

ELECTING MIXED BOILERS

M

IXED SYSTEM TYPE 1: HIGH SYSTEM TURNDOWN

M

IXED SYSTEM TYPE 2: CONDENSING / NON-CONDENSING

B

ASE LOADING, RELAY CONTROL (VERSION 2.X CONTROL

S

ETTING UP BASE LOADING

.............................................................................................................................................................. 13

................................................................................................................................................................ 20

............................................................................................................................................ 4

............................................................................................................................................ 9

...................................................................................................................................... 10

................................................................................................................................................... 10

.................................................................................................................................................. 11

............................................................................................................................ 13

.................................................................................................................. 16

) .................................................................................................................. 18

Heating Control Methods ........................................................................................................................ 21

H

EATING METHOD

H

EATING METHOD

H

EATING METHOD

H

EATING METHOD

H

EATING METHOD

O

PERATING LIMIT

I

NPUT PRIORITIES

H

EATING METHOD 1

H

EATING METHOD 2

H

EATING METHOD 3

H

EATING METHOD 4 AA INPUT

H

EATING METHOD 5

1 ......................................................................................................................................................................... 21

2 ......................................................................................................................................................................... 21

3 ......................................................................................................................................................................... 21

4 ......................................................................................................................................................................... 21

5 ......................................................................................................................................................................... 21

............................................................................................................................................................................. 21

............................................................................................................................................................................. 21

HEAT DEMAND ............................................................................................................................................... 22

STAGE C

4-20

MODBUS

ONTROL

MA CONTROL

.......................................................................................................................................................... 23

COMMUNICATIONS

T1-T2 ................................................................................................................................... 23

.............................................................................................................................................. 23

.............................................................................................................................. 24

Using the 4-20ma input (OPTIONAL) ...................................................................................................... 25

Circulator Pump Options ........................................................................................................................ 26

Auxiliary Function Options ..................................................................................................................... 27

Outdoor Reset ......................................................................................................................................... 27

Sensors .................................................................................................................................................... 28

Security .................................................................................................................................................... 28

Diagnostics .............................................................................................................................................. 28

Page 2

Page 3

TABLE OF CONTENTS

HeatNet Control REV 3.37-1

Communications ...................................................................................................................................... 29

Failsafe Modes ......................................................................................................................................... 29

FAILSAFE REQUIREMENTS: ....................................................................................................................................................... 29

Version 2.x Control .................................................................................................................................. 30

Domestic Hot Water Methods ................................................................................................................. 31

DHW METHOD 1: DHW T

A

VAILABLE ON

DHW METHOD 1A: DHW H

DHW METHOD 1B: C

DHW METHOD 2: DHW H

A

VAILABLE ON BOTH

DHW METHOD 3: S

A

VAILABLE ON BOTH

DHW METHOD 4: DHW

A

VAILABLE ON BOTH

V2.X C

ANK SENSOR INPUT

ONTROLS

OMBO

V1.X

PACE HEATING WITH

V1.X

V1.X

ONLY .............................................................................................................................................. 31

EATING

DHW

AND SPACE HEATING USING A

EADER SENSOR INPUT

AND

V2.X C

AND

V2.X C

USING DIRECT CONTROL

AND

V2.X C

................................................................................................................................ 31

ONLY

USING A SINGLE BOILER OR A

............................................................................................................................. 33

ONTROLS

ONTROLS

ONTROLS

................................................................................................................................. 33

DHW O

VERRIDE

................................................................................................................................. 33

............................................................................................................................ 34

................................................................................................................................. 34

DHW MASTER

MASTER B

............................................................................................................... 33

OILER AND MEMBER BOILER(S) EMPLOYING

AND MEMBER BOILER(S) EMPLOYING

H-NET ............. 32

H-NET ... 31

Wiring Connections ................................................................................................................................. 35

Calibration ................................................................................................................................................ 50

Log Entry .................................................................................................................................................. 51

Default Settings & Menu Item Descriptions — SETUP .......................................................................... 52

Default Settings & Menu Item Descriptions — ADVANCED SETUP ..................................................... 56

MODBUS Communications ..................................................................................................................... 60

Troubleshooting ...................................................................................................................................... 68

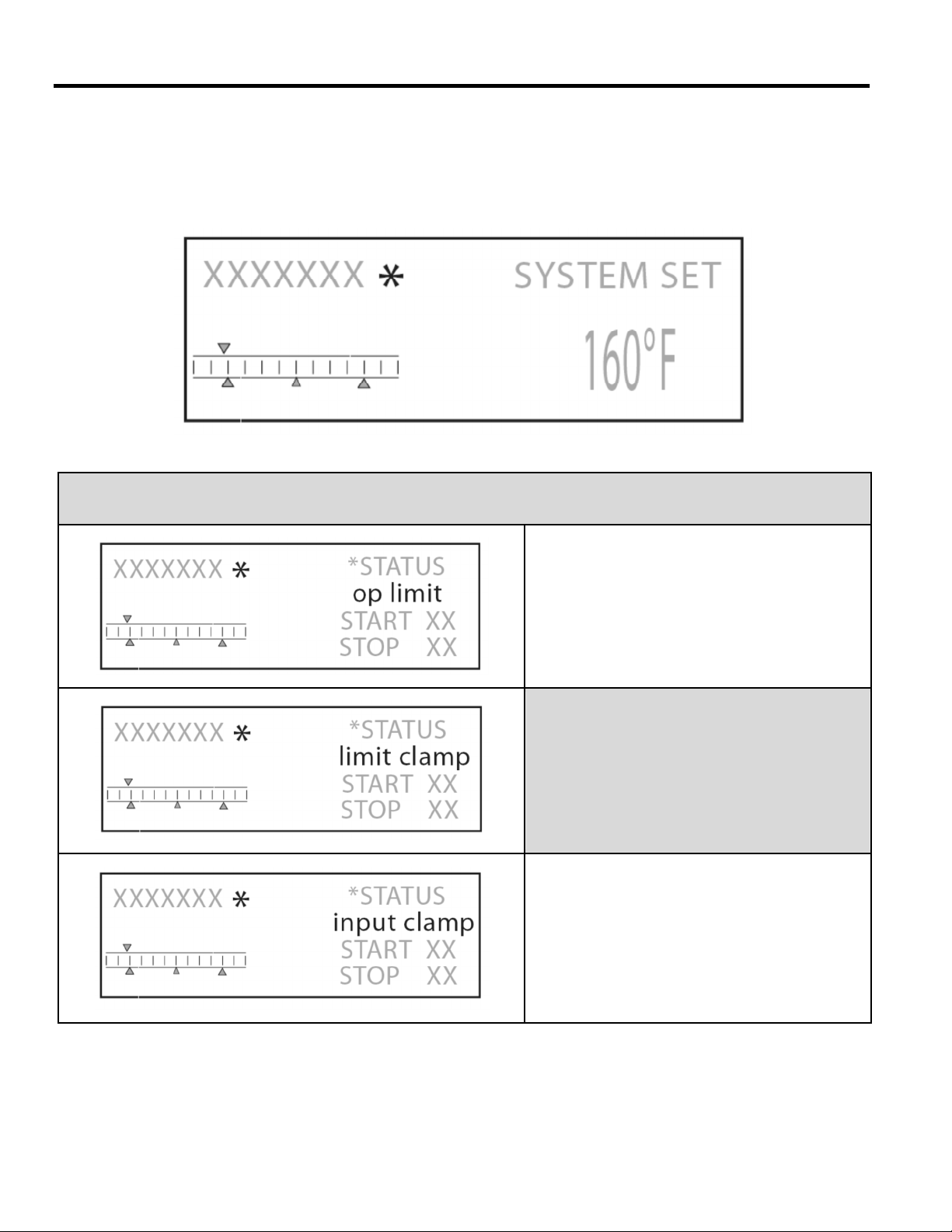

Futera HeatNet Control Run Screen ....................................................................................................... 73

* Status Information ................................................................................................................................. 74

S

TATUS INFORMATION SCREENS

........................................................................................................................................................ 74

Futera HeatNet Control Menu Tree — Version 3.37 ............................................................................... 76

Futera HeatNet Control Advanced Menu Tree — Version 3.37 ............................................................. 77

Worksheet ................................................................................................................................................ 78

Thermistor Resistance/Temperature Table ............................................................................................ 82

Status Screen Fault Display .................................................................................................................... 83

Line 4 Log Entries: .................................................................................................................................. 86

Information contained in this publication regarding device applications and the like

is provided only for your convenience and may be superseded by updates. It is your

responsibility to ensure that your application meets with your specifications.

RBI MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

http://www.rbiwaterheaters.com/

The RBI name and logo, Mestek name and logo, Futera, HeatNet, and HNet name and logo are registered trademarks of Mestek, Incorporated in the

U.S.A. and other countries.

BACnet is a registered trademark of ASHRAE. LonWorks is a registered

trademark of Echelon Corporation. All trademarks mentioned herein are

property of their respective companies.

© 2010, Mestek Technology Incorporated, Printed in the U.S.A., All Rights

Reserved.

Page 3

Page 4

Introduction

The Futera-Series HeatNet Control

The Futera-Series boiler control is designed to provide the

Futera-Series of boilers with an integrated boiler

management system on every boiler. Designed for the AirFuel coupled Futera-Series boilers, the Futera-Series

HeatNet control provides for optimized heating efficiency

without the need for a “wall mount control”. Since the

Futera-Series modular control method is based on digital

communications, analog control signals are not required.

Although the use of analog control signals is still supported

(4-20mA control loops and 0-10vdc (20mA minimum)

control voltages), a higher level of control precision,

repeatability, and feedback is gained with digital

communications control.

With the Futera-Series, optimized heating efficiency is

accomplished by setting the Modulation Maximum (ModMax) setting to exploit the inverse efficiency curve. This

value can be adjusted so that as each boiler is added, it

operates at its maximum turndown. This allows the

maximum number of boilers to operate at their lowest

inputs, until all boilers are firing. Once all boilers are firing,

full range modulation control is allowed. An outdoor reset

function is also provided to assist in the optimized heating

efficiency of the Futera- Series boilers.

The Futera-Series boiler with the Futera-Series H-Net

control, can be operated in multiple ways:

1. As a stand-alone boiler.

2. A boiler in a Boiler Network using the HeatNet®

(H-Net®) protocol.

3. A member boiler to a boiler management system with

multiple input control methods.

The primary purpose of the control is to maintain the boiler

water temperature at the supply or the header sensor using a

target setpoint. While performing this task, the control also

monitors dedicated external limits in a limit string and

provides an orderly shutdown and fault indication in the

event of a tripped limit. The monitored limits include a

HIGH LIMIT AQUASTAT, LOW WATER CUTOFF,

GAS PRESSURE, FLOW, IGNITION CONTROL fault,

GAS VALVE alarm, VARIABLE FREQUENCY DRIVE

alarm, and other optional or user selectable limits.

The HIGH LIMIT circuit is independent of

the control and shuts down the ignition

control and the boiler if the control board or

other component of the boiler was to

malfunction. The control will continue to

function and report the fault, but its ability to

control the boiler will end.

HeatNet Control REV 3.37-1

Each Futera-Series boiler employing this control can

function as either a master or a member. This allows one

boiler (Master) to be in control of target temperature. The

other boilers (Members) only respond to the commands

issued by the Master. If using an external control, all boilers

can be setup as members. The following will define the

roles of master and member.

Master

A boiler becomes a master when a temperature sensor is

connected to the J10 “SYS/DHW HEADER” terminals. The

sensor is auto-detected.

The master senses and controls the common system

header/loop water temperature using a system setpoint. It

uses any boilers it finds (over the H-Net communications

cable) to accomplish this. It can also monitor the Outside

Air (OA) temperature to provide outdoor reset functionality.

Only one master is allowed in a system.

When operating as a master, the boiler provides a control

method using a PID algorithm to regulate water

temperature. This algorithm allows a single boiler (Master),

or multiple (Master + Member) boilers.

Figure 1 Heat band

BOILERS

UPPER HEAT

BAND LIMIT

SETPOINT

LOWER HEAT

BAND LIMIT

WATER

TEMPERATURE

The control algorithm is based upon a Heat Band, at the

center of which is the setpoint. While below the Heat Band,

boilers are staged on and modulated up until the Heat Band

is entered. Once in the Heat Band, modulation is used to

maintain setpoint. Boilers are shut down only when the top

of the Heat Band is breached. Timers are also used to

prevent short cycling.

While staging the boilers on, a modulation clamp

ADVANCED SETUP: MODULAR BOILER SET:

MOD MAX-LAST FIRE is used to hold the boilers at a

lower fire rate until the last boiler is fired. Once the last

boiler fires, the modulation clamp is removed and all boilers

are allowed to fire above this clamped percentage up to

100%. This “boiler efficiency” clamp is defaulted to 70%

and thus limits all of the boilers individual outputs to 70%

until the last boiler fires. All running boilers modulate up

and down together, always at the same modulation rate. As

a general rule, this percentage should be no lower than twice

the minimum turndown to minimize short cycling.

STAGED

OFF

Boilers Staged

ON

Time

Page 4

Page 5

Features & Specifications

HeatNet Control REV 3.37-1

When additional boilers are needed to achieve setpoint in

the system, the Master boiler employs an ADAPTIVE

MODULATION algorithm to prevent over firing of the

system. The Master communicates over the H-Net to view

the exact status of each Member boiler. When a new boiler

is added, the Master boiler adjusts the system modulation

rate lower to compensate for the BTUs that will be

introduced by the newly added boiler. This adjustment

occurs when the newly added Member boiler enters its ON

CALL state (default setting). This can be changed to PILOT

when the new boiler is called using the menu:

ADVANCED SETUP:ADAPTIVE MOD:DROP

DOWN. Once the Main Valve (on the newly added boiler)

is opened, and the DELAY RELEASE timer equals zero,

the PID algorithm is allowed to control the system

modulation. Setting the DELAY RELEASE timer will

allow some “soak” time of the newly added boiler before

releasing modulation control to the PID.

The ADAPTIVE MOD menus are disabled

on a Member boiler, but are still visible.

Member

If a “SYS/DHW HEADER” sensor is not connected to J10,

a boiler always defaults to the role of Member.

In a stand-alone installation the Member typically receives

its command signals internally and operates based upon the

outlet water temperature input and the established settings in

the menu (Local Set-point) to start/stop the burner, and/or to

modulate the firing rate. If the operating limit is exceeded,

or if an interlock trips, the boiler is shut down. As in a

multi-boiler system, a stand-alone Member boiler is also

capable of receiving inputs from an external control system.

When using the H-Net network cable in a Master/Member

system, the system setpoint is sent from the Master as a

digital signal, along with the modulation value to control

firing rate. It also receives its command to start or stop over

the H-Net cable. Also, the SYSTEM CLOCK only needs to

be set on the MASTER. The Master will then set the time

on all member boilers.

If not using the H-Net protocol (cable), an external control

can send a 4-20ma signal along with a 4-20ma enable signal

to control the firing rate or setpoint. The boiler may also be

treated as a 2-stage boiler or an ON-OFF boiler using the

dedicated T-inputs.

The Member boiler can operate as part of a multi-boiler

system or as a stand-alone unit.

In a multi-boiler system the Member typically receives its

command signals from a designated Master-boiler. It is also

capable of receiving inputs from an external control system.

The boiler responds to these signals, to start/stop the burner,

and/or to modulate the firing rate. The outlet water

temperature is also monitored. If the outlet temperature

approaches the operating limit temperature setpoint

(adjustable), the boilers firing rate is limited and its

modulation value is reduced to minimize short-cycling. If

the operating limit is exceeded, or if an interlock trips, the

boiler is shut down. When connected with a network cable,

in a Master/Member role, the Members' status is

interrogated by the Master boiler.

Page 5

Page 6

Features & Specifications

Features Overview

Hardware Version 1.x Control

(Identified by circuit board color: BLUE)

1. Five levels of external control inputs, including

modulation and staging that provide application

flexibility.

2. Digital Communications Control (analog 4-20ma and 0-

10vdc control supported, but not required).

a. Boiler to Boiler : HeatNet (H-Net)

b. Building Management System (MODBUS,

Optional BACnet or LonWorks) to Boiler

3. Distributed control using the HeatNet (H-Net) protocol

for up to 16 boilers. Eliminates the need for “wall

mounted” controls.

4. Analog Control 4-20ma and 0-10vdc (20mA minimum

current) signals supported.

5. System/Boiler operating status text display

6. Interlock, Event, and System logging with a time

stamp.

7. Advanced PID algorithm optimized for the Futera-

Series boilers.

8. (4) Dedicated temperature sensor inputs for: Outside

Air Temperature, Supply (Boiler Outlet) Temperature,

Return (Boiler Inlet) Temperature, and Header

(Common System Supply) Temperature.

9. Automatically detects the optional temperature sensors

on power up.

10. Menu driven calibration and setup menus with a bright

(Adj.) 4 line Vacuum Fluorescent Display.

11. (8) Dedicated 24vac interlock monitors, and 8 dedicated

120vac system monitors used for diagnostics and

providing feedback of faults and system status.

12. Multiple circulator pump control modes.

13. Combustion Air Damper control with proof time,

support for a common combustion air damper.

14. USB/RS485 network plug-in to allow firmware updates

or custom configurations.

15. Optional BACnet or LonWorks interface.

16. Alarm Relay dry contacts, and Audible Alarm.

17. Runtime hours, and Cycles(based on Main Valve

Open).

18. Outdoor Air Reset with programmable setpoint and

ratio.

HeatNet Control REV 3.37-1

19. Time of Day clock to provide up to (4) night setback

temperatures.

20. Failsafe mode when a Building Management System is

controlling setpoint. If communications is lost, the

boiler/system automatically transfers to local boiler

setpoint control.

21. Rotation Methods(Lead-Lag): True Rotation (based on

boiler runtime)is default. First On First Off (FOFO),

and Last On First Off (LOFO) is an optional

programmable setting.

22. Programmable password protection to secure the

programmable settings.

23. Heat exchanger delta T limiting feature. If the

temperature across the heat exchanger is greater than

40F, a menu selection can set to one of (2) modes. (1.)

The input rate is reduced to half of the called for rate.

(2.) The boiler will shut down, but when the Delta

temperature across the heat exchanger drops by 10 °F

the boiler will restart.

24. Low inlet temperature warning if return water

temperature drops below 130°F.

25. Remote 4-20mA setpoint control using a mapped

setpoint range to the 4-20mA control signal.

26. Freeze Protection allowing automatic starting of

boiler(s) using (2) Failsafe modes.

27. Adaptive Modulation. When additional boilers are

called, the Master adjusts all boilers fire rates to

compensate.

28. Mixed boiler types in a system.

Hardware Version 2.x Control

Additional Features

(Identified by circuit board color: GREEN)

1. Support for Domestic Hot Water (DHW) using a 10k

Sensor or a dry contact input from a tank thermostat.

2. Domestic Hot Water relay for use with a pump or

valve.

3. Separate power for a pilot blower (12 VDC @ 1amp –

J3 connector).

4. On-board power and socket for Protocessor

BACnet/LonWorks module.

5. HI/LO relay control option from connector J4

6. Resettable Fused interlock power circuit.

7. Additional terminal connector for H-Net shielded cable.

8. Backwards compatible to Version 1.x hardware.

9. Communications board integrated with the main board

from version 1.x control.

10. Base Loading of (1) boiler.

Page 6

Page 7

Features & Specifications

HeatNet Control REV 3.37-1

Specifications

Control Microprocessor based PID modulating control ( NOT a safety limit )

Environment -40 °F to 140 °F, <90% RH non-condensing

Input Power 24 VAC, 500 ma

Relays System Pump, Damper, Circulator, Alarm, DHW Pump (v2.x), 8A 250 VAC resistive

K8 on J4.2 &.6 for Base Loading version 2.x Control

AC Interlocks 24 VAC – 120 VAC input

Control Inputs AA, Heat Demand, 4-20ma Enable, OA override, T1-T2 (dry contact inputs)

4-20mA, 0-10 VDC (20mA source current)

Dimensions 9” wide: 6” high : 2” deep

Temperature Sensors NTC thermistor, 10K @ 77 °F, 335.67K @ -40 °F, 185 @ 150 °F ,+/- 1 °F

USB 1.0

RS485 MODBUS Modbus RTU

Boiler-to-Boiler HeatNet (H-Net)

Network Optional LonWorks, BACnet available bridge to MODBUS port

Page 7

Page 8

Components & Accessories

Part Number Component

02-4277 Futera-Series Control Board Version 1.x

16-0038 Futera-Series Control Board Version 2.x

02-4279 RS485 Communications Board

02-4278 Graphics Display Board

02-3926 Temperature probe (bullet type, 1x.250 inch) ACI/10K-CP-BP

02-4283 Supply, Header, Return Sensors ACI 10k-CP-I-NW

02-4285 Sensor with well ACI CP-I-2.5”

02-4286 Sensor with well ACI CP-I-4”

HeatNet Control REV 3.37-1

02-4281 Strap-on sensor ACI 10k-CP-S

02-4280 Outside Air Sensor with Housing ACI 10k-CP-O

42-9529 Installation & Operation Manual

40-5409 RJ45 Communications Cable Assembly, 25 feet

40-5411 Ribbon Cable Assembly (Display Control)

58-1833 10k ohm Calibration Resistor

40-5408 USB Cable Assembly, 6ft

60-5631 Terminal Block Screwdriver

Contact Factory MODBUS to BACnet bridge

Contact Factory MODBUS to LonWorks bridge

Page 8

Page 9

SETUP & OPERATION

Master

Members

1 to 15 boilers total

SETUP & OPERATION

Basic Multi Boiler System Operation

For boiler system setup/installations please

refer to Refer to the 2008 ASHRAE

Handbook, CH12 or later revision.

A basic multi boiler system typically uses boilers of the

same size and type. With HeatNet, this includes (1) Master

and (1-15) Member boilers. The boilers are connected

together using an H-Net communications cable effectively

creating (1) boiler. This allows the system heating BTUs to

be evenly distributed amongst all of the boilers. (See: Figure

43, Typical Single Boiler System, page 46).

Figure 2 Basic multiple boiler system

A basic multi boiler system can be configured using the

boiler menus to create custom systems/features. These

features are best described in the section: Default Settings

& Menu Item Description, page 52. Along with these

menu items are hardware support for many

auxiliary functions.

Once the system has been properly setup (all default menu

values used and H-Net addresses assigned), the system is

enabled by placing the REMOTE/LOCAL switch to the

LOCAL position on the Master boiler. All Member boilers

must have their respective switches in the REMOTE

position. When the Master boiler’s Heat Demand input

(LOCAL switch) closes, the system becomes operational

and will fire as many boilers as it needs to maintain the

header water temperature’s setpoint.

When a boiler is to be fired in a multi boiler system (header

water temperature is below the heating band), the Master

checks the HeatNet boilers it has available. Then the Master

checks if a Lead Boiler is to be used (LEAD BOILER > 0).

The Master boiler then looks at which type of firing rotation

it has selected: LOFO, FOFO, TRUE (runtime), or MIXED.

In our example we will use the TRUE (runtime) rotation

since it is the default.

The Master now checks all of the runtimes to determine

which boiler has the least runtime based on the MIN

HeatNet Control REV 3.37-1

RUNTIME setting in ADVANCED SETUP:FIRING

MODE:. The MIN RUNTIME setting is the minimum

runtime interval in hours that is used to compare boiler to

boiler runtimes.

Once the boiler to fire has been determined, the Master

sends the command over the H-Net cable to fire that boiler

and resets the ADD BOILER delay timer to prepare for the

next boiler to fire. If the header water temperature is still

below the heating band and the ADD BOILER delay timer

has expired to zero, the process is repeated until the header

water temperature enters the heating band.

When a boiler receives a command to fire it:

1. The system pump relay is enabled and the H-Net

control displays 'Flow Wait' until the flow-switch closes

between J11A, 1 & 2 within the programmed time (10240 seconds).

2. All elements in the interlock string, terminated between

J11A and J11B, must be closed before the sequence is

allowed to continue.

3. If all interlocks are closed relay K5 is enabled to

command the combustion-air damper open (If used).

The H-Net control displays 'Damp: Wait' until the

damper endswitch to closes.

4. Relay K6 is enabled energizing the local pump (if

used). The H-Net control commences its 'Flow-Wait'

timer (adjustable 10–240 sec.). The flow switch contact

is interrogated on terminals J11-B 5 and 6.

5. With all the interlocks closed the boiler start relay K1 is

enabled and energizes terminal 6 on the ignition

control.

6. The ignition control begins its cycle and provides an

output signal from terminal 4 to the H-Net control. The

H-Net control responds and provides an output signal to

the VFD which sets the blower to the programmed prepurge speed.

7. After air-flow is established the ignition control waits

for the air switch to close. When the air switch closes it

provides an input to terminal 7 and pre-purge timing

commences. The H-Net display indicates 'Pre Purge'.

8. When purge is complete the ignition control energizes

the pilot gas valve from terminal 8, and the spark

generator from terminal 10, beginning a 10-second pilot

flame establishing period (PFEP). The H-Net control

responds and provides an output signal to the VFD

which sets the blower to the programmed ignition

speed. The H-Net display indicates 'Pilot'.

9. At the end of the PFEP the spark generator is de-

energized. If the pilot flame is detected, by the UV

scanner, the ignition control energizes the main gas

valve from terminal 9. The H-Net display indicates

'Run'.

10. If main-flame is detected the H-Net control holds the

burner at the low-fire rate for the MODULATION

DELAY time period. After this timer expires, the PID

allows the boiler to modulate and places the boiler into

the running state.

Page 9

Page 10

HeatNet Control REV 3.37-1

As boilers are added to the system settings in the

ADVANCED SETUP:ADAPTIVE MOD:DROP DOWN

menu determines when the modulation rate drops down to

compensate for the newly added BTUs. For the drop down

to be active one boiler needs to be running when a new

boiler is added (see: Introduction: The Futera-SERIES H-

Net Control: Master).

If all boilers are firing, the modulation rate is released to go

to 100%. If all boilers are not firing, the modulation is

limited to the MOD-MAX clamp value. The MOD-MAX

clamp is used to keep the boilers running as efficiently as

possible. The following Mixed Boiler System Operation:

Selecting Mixed Boilers section outlines this with examples.

Once the header water temperature is in the heating band,

only the modulation rate is used to achieve the target

setpoint. The system will maintain the setpoint until the load

demand increases or decreases.

As the load decreases, the header water temperature will

start approaching the top of the band. The PID now lowers

the modulation rate to the boilers, attempting to keep the

temperature within the heating band. If the system is

delivering too many BTUs, the water temperature will cross

the top of the heating band.

Setting all (example) condensing boilers to the highest

Priority of 1, and then setting all (example) non-condensing

boilers to a Priority of 2, will create (2) sets of boilers, one

condensing and the other non-condensing. Once this is

done, the Priority 1 set of condensing boilers will have a

firing order that has a higher Priority and is independent of

the other non-condensing set with the lower priority. The

boiler set with the highest Priority can then be fired based

on a conditional settings menu. The lower Priority set will

follow.

Mixed Boiler System Operation

Starting Boilers:

When a boiler is to be fired (water temp is below the heating

band), the Master checks the HeatNet boilers it has

available. The Master boiler then looks at which boilers are

returning Priority firing status (set on a boiler in:

(ADVANCED SETUP:SYSTEM:BOILER

TYPE:PRIORITY : 1). If the Start condition for the

Priority 1set is met (ADVANCED SETUP:FIRING MODE:

MODE: MIXED:SET FIRST (example), the Master or

Member boiler that is configured as PRIORITY 1, with the

lowest runtime, will be fired FIRST (example).

When the header water temperature first exceeds the top of

the heating band, the boilers are again checked for the one

with the most runtime. The selected boiler will turn off

immediately and a shed boiler delay timer will be loaded

with the delay time. This time will need to expire before the

next boiler will be stopped, but only if the header water

temperature remains above the heating band. This timer is

used to allow the header water temperature to return back

into the band when a boiler is stopped. When a boiler is

stopped there is a fixed rate of BTUs (Min Fire) that will be

removed (PID discontinuity to modulate from Min Fire to 0

BTUs on a boiler). The timer allows for this loss of BTUs.

This cycle will continue until the call for heat is satisfied or

the Warm Weather Shutdown feature is enabled.

Mixed Boiler Types Using

Priority Sets

Using the Basic Multi Boiler System Operation, a MIXED

boiler Priority method may be added to control condensing,

non-condensing, base load, or other boiler SETs in a system

together. These sets compose a system which provides for

optimal performance and economy. Having dedicated sets

of boilers gives the system engineer a tool to create many

different boiler systems.

A boiler set can be constructed by simply setting the firing

Priority on each boiler (to be in a set) at the same priority.

As long as the start condition for Priority 1 is met, all

boilers in the PRIORITY 1 set will fire based on runtime.

Once all boilers in the PRIORITY 1 set have fired, the

PRIORITY 2 set of boilers will fire based on runtime.

If the Start condition changes and/or is not met (such as

with: OA T or RET temp), the PRIORITY 2 set of boilers

will fire first/next based on runtime. This has the effect of

flipping the Priority of the sets.

Stopping Boilers:

When a boiler is to be stopped (water temp is above the

heating band), the Master checks the HeatNet boilers it has

available. The Master boiler then looks at which boilers are

returning Priority firing status (set on a boiler in:

(ADVANCED SETUP:FIRING MODE: MODE:

MIXED:SET LAST(example) If the Stop condition for

Priority 1 is met, the Master or Member boiler that is

configured as PRIORITY 1 with the highest runtime will be

stopped LAST (example). As long as the stop condition and

SHED DELAY time are met, all remaining PRIORITY 1 set

of boilers will stop based on runtime. If the Stop condition

changes and/or is not met (such as with: OA T or RET

temp), the PRIORITY 2 set of boilers will stop first/next

based on their highest runtime.

A boiler’s firing Priority can be designated as such in:

ADVANCED SETUP:SYSTEM:BOILER TYPE:FIRING

PRIORITY : 1 menu on each boiler. A Priority of ‘1’ is

the highest priority, a ‘2 the lowest (default is always 2).

Page 10

Page 11

SETUP & OPERATION

PRIORITY 2

Futera III boilers (non-condensing)

>

S E T : O A T < 1 5 ° F

Figure 3 Mixed Boilers: Condensing/Non-Condensing

PRIORITY 1

Fusion boilers (condensing)

HeatNet Control REV 3.37-1

FIRING MODE

(master boiler only)

BOILER TYPE

(all boilers in set)

menu

menu

>MODE MIXE D

MIN RUNT IM E: 10HRs

MIN OFF T IM E: 0s

PREDICT ST ART: YES

>FIRIN G P RIORITY :1

B TU I N 50 0,000

C ON DENSING YES

MASS LOW

In the example Mixed Boilers: Condensing/NonCondensing, condensing boilers and non-condensing boilers

are used, but other combinations may also be used. Another

example could use (2) small boilers and set them to

Priority 1 and then use (3) larger boilers and set them to

Priority 2. Using these Priority settings (with the conditions

menu), the small boilers can run first during the shoulder

months (Spring and Fall) and the larger boilers can fire last

during the colder Winter season (base loading set).

Before the MIXED method can be used, the firing mode on

the Master boiler must be set to MIXED. ADVANCED

SETUP:FIRING MODE: MODE: MIXED. Pressing the

SELECT key when the cursor is pointing to MIXED will

enter the conditions menu. The START and STOP

conditions for starting and stopping the Priority boiler set

may be configured here. Temperatures are adjustable.

BOILER TYPE

(all boilers in set)

menu

FIRING PR IORITY :2

BTU IN 1250, 00 0

CONDE NS ING NO

MASS LOW

menu. All conditional settings apply to the Priority 1 boiler

set. When the conditional settings do not apply to the

Priority 1 set, the conditional settings will apply to the

Priority 2 boiler set.

Start/Stop Priority Conditions

The following is an example using mixed

condensing and non condensing boilers:

FIRE FIRST

Condensing boilers may be configured to fire first (set to

PRIORITY 1) when:

1. The Return water temperature is below 140F and

condensing occurs. (The Master’s return water sensor

would need to be moved to the header return.)

S T A R T P R I O R I T Y 1

> S E T : F I R S T

S T O P P R I O R I T Y 1

Once the conditions menu has been entered, the firing order

and stop order of the Priority 1 boiler set can be selected

based on up to (3) conditions in the conditional settings

2. The Outside Air Temperature is above a setpoint

determined by the system configuration. This setpoint

ensures that the more efficient condensing boilers run

first during shoulder months (Spring and Fall) when

minimal heating is required. Below this setpoint, larger

boilers should be brought on first to “base load” the

system.

3. Greater efficiency is required.

Page 11

Page 12

S E T :

L A S T

HeatNet Control REV 3.37-1

STOP FIRST

Condensing boilers may be configured to stop first (set to

PRIORITY 1) when:

The Return water temperature is above 140F and

condensing is minimized, thus leaving the larger lower cost

boilers running to carry the load.

1. The Outside Air Temperature is below an adjustable

setpoint determined by the system configuration. This

setpoint ensures that the larger non-condensing boilers

run during the coldest months when maximum heating

is required. Above this setpoint smaller condensing

boilers should be brought on first to run the system as

efficiently as possible.

2. Maximum heating is required

START PRIORITY 1 SET

Selections (always the lowest runtime first):

The condensing boiler set (Priority 1) has a

higher Priority to fire when one of these

conditions is met. Values are adjustable.

FIRST: The condensing boilers (Priority 1) are always

started FIRST

OA T > 15F: The condensing boilers (Priority 1) are

started when the OA temperature is greater than the Mixed

Boiler Outdoor Air Temperature setting.

RET < 140F: The condensing boilers (Priority 1) are

started when the Return water temperature is less than the

Mixed Boiler Return temperature setting (This may not

applicable in most configurations since the local return

temperature on the Master is used to provide a difference

temperature across the heat exchanger. However, the return

temperature sensor may be moved on the Master to provide

system return temp if the difference temp is not required).

STOP PRIORITY 1 SET

Selections (always the highest runtime first):

The condensing boiler set (Priority 1) has a

higher Priority to stop when one of these

conditions are met. Values are adjustable.

LAST: The condensing boilers (Priority 1) are always

stopped LAST.

OA T < 15F: The condensing boilers (Priority 1) are

stopped first when the OA temperature is less than Mixed

Boiler Outdoor Air Temperature.

RET > 140F: The condensing boilers (Priority 1) are

stopped first when the Return water temperature is greater

than the Mixed Boiler Return temperature. (This may not

applicable in most configurations since the local return

temperature on the Master is used to provide a difference

temperature across the heat exchanger. However, the return

temperature sensor may be moved on the Master to provide

system return temp if the difference temp is not required)

Start/stop settings

Any combination of Start Conditions and Stop Conditions

can be used to optimize the mixing of condensing

(Priority 1) and non-condensing boilers (Priority 2) for best

performance/economy.

The default settings for the start and stop conditions of the

condensing set are:

S T A R T P R I O R I T Y 1

> S E T : F I R S T

S T O P P R I O R I T Y 1

The default start setting always starts the condensing boilers

(Priority 1 example) first, except for the lead boiler setting.

The lead boiler will always start first if enabled, unless

there is a boiler already running (this includes a Member

boiler in LOCAL). The default stop condition setting always

stops the condensing boilers (Priority 1) last.

If prolonging the life of the heat exchanger(s) on noncondensing boilers is very important, consider starting the

condensing boilers (Fusion series) when the return water

temperature is below 140F.

The return water temperature sensor would

need to be moved from the Master’s return

inlet to the system return. The EXCHGR

DELTA may need to be adjusted in

SETUP:AUX FUNCTIONS:HEAT

EXCHANGER to prevent the Master from

going to ½ input when a high DELTA T is

reached.

This method would lead to the non-condensing boilers

carrying the load when the system temperature stabilizes

above 140F, since non-condensing boilers will start first

with the Return water temperature is > 140F. The

condensing boilers can then be stopped first when the RET

water temperature is above the 140F. Remember, any

combination of the Start and Stop conditions may be applied

for best performance and economy in the system.

Base load boilers can also be mixed in the same way as

condensing and non-condensing boilers. The base load

boiler(s) can be prioritized in one set (example, Priority 2)

and non-base load boilers (Priority 1) . The non-base load

boilers can then be set to fire first and once they are all

firing, the base load boiler would fire.

Page 12

Page 13

SETUP & OPERATION

System

Effective

MOD

Priority

1

Priority

2

HeatNet Control REV 3.37-1

To minimize the cycling of a large base load boiler, consider

using the stop condition. Change it to the OA T < 15F

(Outside Air Temperature) condition. This setting may be

used to stop the Priority 1 boiler set when the OA T drops

below the OA T setpoint, thus leaving the large base loaded

boiler on and shutting off the condensing boilers first. This

is also true when using the OA T setting to start the

Priority 1 boiler set when the OA T is above the start

setpoint. To use temperatures as start and stop conditions,

the system design temperatures must be known.

Selecting Mixed Boilers

There are a few factors to consider when choosing which

type of boilers to use in a mixed system. These factors need

to be considered when boilers are added or shed. When

BTUs are introduced into the system by adding boilers, the

amount of introduced BTUs should be smooth (linear). If

these factors are not considered, discontinuity in BTUs may

occur when boilers are added and as a result, short cycling

will occur.

1. Turndown: This is the ratio of minimum fire rate to

maximum fire rate: Example: a 20% minimum

modulation = 5:1 turndown (100%mod / 20% mod). A

(1) million BTU boiler = 200,000 BTUs minimum

input.

The Futera III Mixed Boiler System (examples) is

advantageous in providing low BTU input for light loads

and high BTUs for heavy loads. The effective system

turndown minimizes short cycling when light loads are

present by assigning smaller boilers to Priority 1, running

them first, and then stopping them last.

In order to achieve the high effective

turndown, smaller boilers are required

(plumbing considerations need to be

considered here due to differing flow/volume

characteristics through the large and small

boilers).

Example Systems:

Figure 4 Non-Mixed Boiler System

MMBTU

10.0 20:1 70%

5.0 20:1 70%

2.5 20:1 70%

Turndown

MAX

MB/MW 4:1

2000, 2000, 2000,

2000, 2000

1000, 1000, 1000,

1000, 1000

500, 500, 500, 500,

500

2. MOD MAX CLAMP: This value determines the

maximum modulation % at which the boilers will fire

to until all available boilers are firing.

3. Total System BTUs.

4. Desired Effective Turndown. This is the lowest

firing rate of the system relative to the maximum firing

rate of the system. The larger the value, the lower the

BTUs that can be delivered to a light load.

5. Piping.

Mixed System Type 1:

High System Turndown

The following examples are of mixed boiler systems with

high effective system turndown and fault tolerance built in.

When boiler types are the same, the system turndown is

limited to the boiler’s min input and fault tolerance is

always present. When the system has mixed boiler types,

consideration needs to be taken on what types can be mixed

properly to achieve a high system turndown and provide

some fault tolerance.

Fault tolerance allows for one boiler in the Priority 1 system

to fail and any boiler(s) in the Priority 2 system to fail and

still provide near linear (continuity) BTU response when

adding boilers. This is illustrated in the following examples

using the Boiler System Response graphs.

With the traditional Non-Mixed boiler system, the effective

turndown increases by the turndown ratio for every boiler

added. The min fire rate is equal to the minimum BTUs that

can be delivered to the system.

Number of boilers * Turndown Ratio = Effective System

Turndown: 5 * 4:1 = 20:1.

Figure 5 Mixed Boiler System

System

MMBTU

4.5 24:1 46% 750, 750

4.75 32:1 60% 500, 500

6.5 26:1 45% 1000, 1000

6.0 48:1 55%

Effective

Turndown

MOD

MAX

MB/MW

4:1

500, 500,

500

MB/MW

4:1

1000, 1000,

1000

1250, 1250,

1250

1500, 1500,

1500

1500, 1500,

1500

With the mixed boiler system, a lower minimum fire

rate/BTU can be delivered to the system by using small

boilers with larger boilers. This works in much the same

way as base loading.

Page 13

Page 14

MB/MW

Mod Max

HeatNet Control REV 3.37-1

Figure 6 Futera Fusion & III Boiler Btu Chart (MBH)

CB/CW

Max Input 500 750 1000 1250 1500 1750 2000

Min Input

4:1

Mod Max

80%

70%

Mod Max

60%

Mod Max

50%

500 750 1000 1250 1500 1750 2000

125 188 250 312 375 437 500

400 600 800 1000 1200 1400 1600

350 525 700 875 1.05 1220 1400

300 450 600 750 900 1050 1200

250 375 500 625 750 875 1000

When selecting the Priority 1 boiler(s) for a high effective

system turndown, the BTU Min Input is selected first. (See:

Futera Fusion & III Boiler Btu Chart). Next, the MODMAX value of this Priority 1 boiler needs to be greater than:

Mod MAX % =

(Priority 1 ‘s Min Input + Priority 2 ‘s Min Input)

Max Input of the Priority 1 boiler

The reason for this is keep the continuity of BTUs linear

without a BTU bump (discontinuity) when boilers are added

or shed. This is illustrated in the Boiler System Response 2

graph.

If redundancy is not required, the min inputs of the

Priority 1 boilers may be summed to lower the Mod Max %

value so smaller Priority 1 boilers can be used. The sum of

the min inputs would then need to be divided by the sum of

the Max Input of the Priority 1 boilers. The effect of this

would create a higher turndown. See: EXCEPTION NOTES:

EXCEPTION NOTES:

1. Mixing more than two different size/type boilers

becomes more complex than the scope of this manual

and is not recommended.

2. If using more than one Priority 1 boiler and the

calculated value is <

Priority 1Min * 2

Priority 1 Max Input

Use this result PLUS note 3 value as the

ModMax%.

3. Always add a few % (3-5%) to the calculated MOD

MAX % value to allow a guard band (tolerance).

4. If boilers are of different sizes, try to use larger Priority

2 boilers.

If the calculated Mod MAX % value is greater

than 99%, the combination cannot be used

since short cycling will occur.

Once the Priority 1 and Priority 2 boilers are selected, they

can be multiplied in each Priority set to achieve the desired

system design BTUs. If the # of boilers becomes a large

number, a Priority 1 boiler with a higher Min Input may

need to be selected.

While considering the MOD-MAX value, the lower the

MOD-MAX the greater the combustion efficiency since it

effectively limits the input rate. The Typical Efficiency of

Non-Condensing Boilers chart can help illustrate how the

MOD-MAX value can affect the efficiency by limiting the

input until all boilers have fired. Non-condensing boiler

efficiency is relatively flat compared with condensing as

illustrated in the Typical Efficiency of Condensing Boiler

graph.

Mod MAX % =

Example: (2) CB/CW500, (2) MB/MW1250

Redundancy: (125 + 312)/500 = 88%

No Redundancy: (125 * 2) + 312)/(500*2) =56%

Page 14

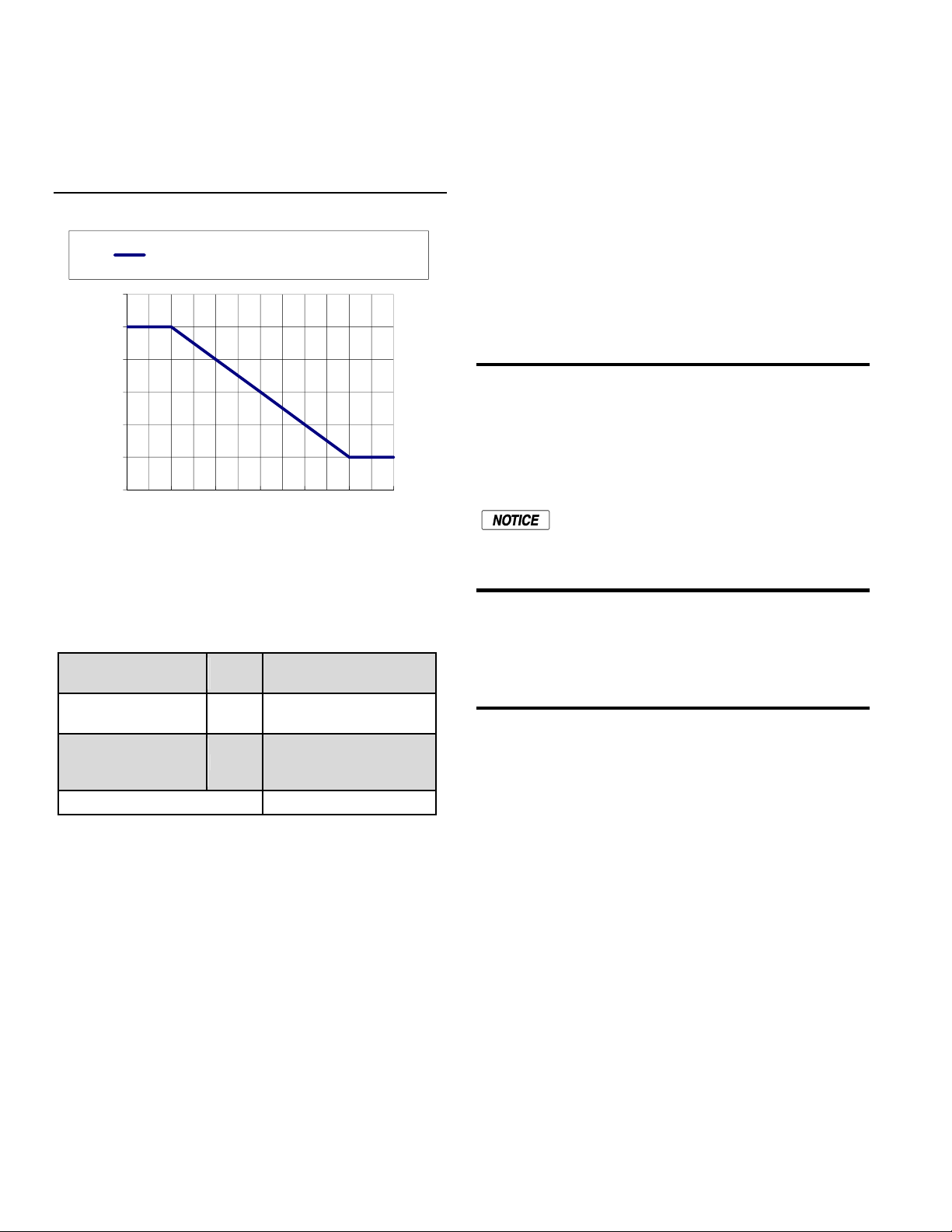

Figure 7 Typical Efficiency of Non-Condensing Boilers

( ((Priority 1 Min) * (#Priority 1’s)) + Priority 2 Min)

Max Input of Priority 1 boiler * (#Priority 1’s)

Page 15

SETUP & OPERATION

5,000,000

I

n

p

u

t

,

%

System Load, Btu/Hr

Blr 1+2+3 (2250 MBTU)

Blr 1+2+3+4 (3500 MBTU)

Blr 1+2+3+4+5 (4750 MBTU)

5,000,000

I

n

p

u

t

,

%

System Load, Btu/Hr

Blr 1+2+3 (4250 MBTU)

HeatNet Control REV 3.37-1

Figure 8 Typical efficiency of condensing boilers

(GAMA BTS2000 method)

In the Mixed Boiler System table line 2 example, (2)

MB/MW 500s are set as Priority 1 and MB/MW 1250s set

as Priority 2. With a MOD MAX of 60%, each 500 can run

to 300M (600M total) before a 1250 is called ON (Add

Delay timer). Once both 500s are running and the 1250 is

called on, all (3) boilers will drop to a total of the 600M

BTUs: The sum of the 500, 500, and 1250 would equal

about 27% modulation: (.27* 500M) + (.27* 500M) + (.27*

1.25MM) or: 135M +135M + 337M = 607M and operate at

higher combus tion efficiencies (non condensing boilers

have minimal effect individually, but can have an effect if

many are used).

If CB/CW Fusion boilers are substituted for the MB/MW

Futera III boilers, the efficiency is greatly increased due to

the condensing mode of these boilers. When using CB/CW

Fusion boilers, during the first 2850 MBTH of load, the

combustion efficiency is maximized by running the CB/CW

Fusion boilers from low to middle input rates. See: Typical

Efficiency of Condensing Boiler graph.

Figure 9 Boiler System Response 1

(2) MB/MW 500s, (3) MB/MW 1250s

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 1,000,000 2,000,000 3,000,000 4,000,000

When running non condensing boilers at low

input rates, the risk of condensing should be

considered.

The Boiler System Response 1 chart illustrates how each

boiler (in the example) is brought on and fires to 60%, drops

to a lower fire rate and then adds the next boiler (vertical

dashed lines). Once all boilers are firing, the modulation is

released allowing all boilers to fire to 100%.

Now, if (1) MB/MW 500 (one of the MB/MW 500s was

brought offline) were used with (3) MB/MW 1250s and the

Mod-Max is set to 60%, the MB/MW 500 would fire to 300

MBTUs and wait for the MB/MW 1250 (Boiler System

Response 2 graph). Now, the minimum input rate would be

312M (MB/MW 1250) + the 125M (MB/MW 500) (already

running, but dropped to low fire when the MB/MW 1250

fired), the total being 437M. With a 60% MOD-MAX

clamp, there would be 137 MBTUS more than needed and

added to the system when the MB/MW 1250 fired.

The PID algorithm would then compensate for the

discontinuity (bump) in BTUs and the MB/MW 1250 could

shut off (short cycle).

This discontinuity is observed in the graph below, (Boiler

System Response 2) where the jump from the MB/MW 500

@60% to the firing of the MB/MW 1250 is apparent.

Figure 10 Boiler System Response 2

(1) MB/MW 500, (3) MB/MW 1250, 60% ModMax

Blr 1+2 (1750 MBTU)

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 1,000,000 2,000,000 3,000,000 4,000,000

Blr 1+2+3 (3000 MBTU)

To correct this would require the MB/MW 500 to set the

MOD-MAX to roughly 90% (Boiler System Response 3: not

as efficient as it could be when using CB/CW Fusion

boilers) in order to have a linear BTU transfer when the

MB/MW 1250 is added (fired).

Page 15

Page 16

Priority

2

5,000,000

I

n

p

u

t

,

%

System Load, Btu/Hr

Blr 1+2+3 (4250 MBTU)

5,000,000

I

n

p

u

t

,

%

System Load, Btu/Hr

Blr 1+2+3 (3000 MBTU)

Blr 1+2+3+4 (5000 MBTU)

Blr 1+2+3+4+5 (7000 MBTU)

HeatNet Control REV 3.37-1

Figure 11 Boiler System Response 3

(1) MB/MW 500, (3) MB/MW 1250, 90% ModMax

Blr 1+2 (1750 MBTU)

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 1 ,000,000 2,000,000 3,000,000 4,000,000

Blr 1+2+3 (3000 MBTU)

An MB/MW 500 running with a MB/MW 1250 may not be

an optimal choice unless (2) MB/MW 500s are used in the

Priority 1 set or (3) MB/MW 500s and one is allowed to be

taken offline.

A system employing this redundancy where (1) is allowed

to be taken offline is listed in the MIXED BOILER SYSTEM

chart. This system uses (3) MB/MW 500s and (3) MB/MW

1500s. Two of the MB/MW 500s are treated as one when

adding the min inputs of the Priority 1 set.

Figure 12 Boiler System Response 4

(2) MB/MW 500s, (3) MB/MW 2000s

system, it is important to note any discontinuities in BTUs if

a Priority 1 boiler fails when multiple Priority 1 boilers are

used.

Mixed System Type 2:

Condensing / Non-Condensing

This mixed system may also have mixed boilers with

differing sizes as outlined in the Mixed System Type 1: High

System Turndown section. The reason for creating a mixed

system is primarily to control the system cost.

Figure 13 Mixed Boiler System

System

MMBTU

4.5 24:1 60% 750, 750

4.75 32:1 60% 500, 500

6.5 26:1 65% 1000, 1000

6.0 48:1 65% 500, 500, 500

The Mixed Boiler System table show some examples of

mixed systems using different sizes along with Fusion

condensing (Priority 1) and Futera III non condensing

(Priority 2) boilers.

Effective

Turndown

MOD

MAX

Priority 1

CB/CW 4:1

MB/MW

4:1

1000, 1000,

1000

1250, 1250,

1250

1500, 1500,

1500

1500, 1500,

1500

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 1,000,000 2,000,000 3,000,000 4,000,000

The Boiler System Response 4 graph illustrates another

system where 80% is used as the MOD-MAX clamp. With

this example, when using all non condensing boilers, the

system can maximize the use of the smaller boilers before

calling the larger ones.

In summary, the system should be tuned using the boiler

selection charts and the MOD-MAX value. Since selecting

the Priority 1 boiler is integral to the fault tolerance of the

Using the boiler charts and the examples used in: Mixed

System Type 1: High System Turndown, a mixed boiler

system can be designed. The Priority 1 boilers should be

setup so as to keep the non-condensing boilers from seeing

return water temperatures of less than 140F to ensure a long

heat exchanger life.

Futera III/ Fusion Boiler BTU Chart

In the Mixed Boiler System table line 2 example, (2)

CB/CW 500s are set as Priority 1 and (3) MB/MW 1250s

set as Priority 2. With a MOD MAX of 60%, each 500 can

run to 300M (600M total) before a 1250 is called ON (Add

Delay timer). Once both 500s are running and the 1250 is

called on and running, all (3) boilers will drop to a total of

the 600M BTUs: The sum of the 500, 500, and 1250 would

equal about 27% modulation: (.27* 500M) + (.27* 500M) +

(.27* 1.25MM) or: 135M +135M + 337M = 607M and

operate at higher combustion efficiencies: 27% is roughly

between the top two lines on the Typical Efficiency of

Condensing Boilers chart.

Page 16

Page 17

SETUP & OPERATION

MB/MW

Max

5,000,000

I

n

p

u

t

,

%

System Load, Btu/Hr

Blr 1+2+3 (2250 MBTU)

Blr 1+2+3+4 (3500 MBTU)

Blr 1+2+3+4+5 (4750 MBTU)

PRIORITY 2

Futera III boilers (non-condensing)

>

HeatNet Control REV 3.37-1

The Boiler System Response 5 chart illustrates how each

boiler (in the example) is brought on and fires to 60%, drops

to a lower fire rate and then adds the next boiler (vertical

dashed lines). Once all boilers are firing, the modulation is

released allowing all boilers to fire to 100%.

Figure 14 Boiler System Response 5

(2) CB/CW 500s, (3) MB/MW 1250s

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 1,000,000 2,000,000 3,000,000 4,000,000

So, for the first 600 MBTH of load, the combustion

efficiency is maximized by running the (2) fusion boilers

from low to middle input rates. Running the (2) fusion

boilers first also has the added effect of minimizing the

return water temperatures of <140F from reaching the non

condensing boilers.

Figure 15 Futera Fusion & III Boiler Btu Chart (MBH)

CB/CW

500 750 1000 1250 1500 1750 2000

Max Input 500 750 1000 1250 1500 1750 2000

Min Input

4:1

Mod Max

80%

Mod

70%

Mod Max

60%

Mod Max

50%

125 188 250 312 375 437 500

400 600 800 1000 1200 1400 1600

350 525 700 875 1.05 1220 1400

300 450 600 750 900 1050 1200

250 375 500 625 750 875 1000

In summary, the system should be tuned using the boiler

selection charts and the MOD-MAX value so that boilers

are brought on and fired in their respective efficiency curve

while maintaining continuity in BTUs. Since selecting the

Priority 1 boiler is integral to the fault/offline tolerance of

the system, it is important to note any discontinuities in

BTUs if a Priority 1 boiler goes offline when multiple

Priority 1 boilers are used.

Figure 16 Mixed Boilers: Condensing/Non-Condensing

PRIORITY 1

Fusion boilers (condensing)

FIRING MODE

(master boiler only)

BOILER TYPE

(all boilers in set)

menu

menu

>MODE MI XE D

MIN RUNT IM E: 1 0H Rs

MIN OFF T IM E: 0s

PREDICT ST AR T: YES

>FIRING PRIOR IT Y : 1

B TU IN 50 0, 00 0

CON DE NS ING YE S

MASS LOW

BOILER TYPE

(all boilers in set)

menu

FIRING PR IO RITY :2

BTU IN 1250, 00 0

CONDE NS IN G NO

MASS L OW

Page 17

Page 18

>BOILER TY PE

LOAD FIRM WARE

OPTION: B ASE LOAD

>BASE LOAD BOILERS: 1

START>MO D 95

DELAY TIM E 10m ins

Master

FIII/Fusion

Baseload

>BOILER TY PE

LOAD FIRM WARE

OPTION: B ASE LOAD

>BASE LOAD BOILERS:1

START>MOD 95

DELAY TIME 10mins

Master

Baseload

Dominator

HeatNet Control REV 3.37-1

Base Loading, Relay Control

(Version 2.x control)

The control has the ability to control (1) base load boiler

using the K8 Relay contacts on J4 pins 2 & 6. In order to

connect to this plug, (2) wires with pins are required and

inserted in J4. Base Loading via relay requires these (2)

flying leads (loose wires available from the factory) to be

inserted into J4, pins 2 & 6. These (2) wires then make up

the Normally Open contacts. This feature also requires a rev

2.x control board and can be used on Master or Member

boilers. It is not applicable in version 1.x control boards (no

relay). The solid state relay K8, with contact connections on

J4.2 & J4.6 has a rating of: 0.1 to 1 Amp.

If the base load boiler is of the modulating type, a 4-20mA

signal is also provided on J4 pins 1 and 5. Jumper shunt J18

will then need to be set to 4-20mA position. Two additional

wires (available from the factory) will need to be added to

the J4 pins at 1 & 5. Pin 1 is the + output of the 4-20mA

transmitter, and pin 5 is the – output. This modulating

control signal is used to modulate the base load boiler along

with the HeatNet boilers in parallel. The ADAPTIVE MOD

does not function in lowering the modulation rate when the

base load boiler is added. The PID will adapt to the newly

fired base load boiler and lower its modulation rate when

the increase in water temperature is observed.

Figure 17 Base loading with Futera II boiler

FII

Figure 18 Base loading with Dominator boiler

FIII/Fusion

BASE LOADING

(master boiler only)

menu

STOP FIRST

SYSTEM

( )master boiler only

Enable the base load feature by setting:

ADVANCED SETUP:SYSTEM:OPTION to BASE LOAD.

This setting the OPTION Relay to be used as control for a

Base Load Boiler.

1. The ADVANCED SETUP:BASE LOAD BOILERS:

menu

BASE LOAD BOILERS: to 1. Currently allows (1)

base load boiler.

BASE LOADING

(master boiler only)

SYSTEM

( )master boiler only

menu

Page 18

menu

STOP FIRS T

2. The START & STOP qualifier condition to the method

discussed below.

3. The DELAY TIME to the amount of time required after

the start qualifier condition has been met to start the

boiler.

If a MINIMUM OFF time of the Base Load boiler is

needed, the Base Load boiler will share the MIN OFF

TIME of the boiler controlling it. If the base load boiler was

running and shuts off, the MIN OFF TIME will need to

expire before the boiler can start again. Once this time

expires, the DELAY TIME also needs to expire to start the

boiler. This will help in minimizing short cycle conditions

and can be set at: ADVANCED SETUP:FIRING MODE:

MODE:MIN OFF TIME.

Page 19

Control Methods

HeatNet Control REV 3.37-1

Preferred:

A modulating base load boiler that can accept a 4-20mA

control signal is preferred or a non-modulating base load

boiler that is sized correctly to the H-Net boilers. A 0–135

ohm input for the base load boiler will need a converter

from 4-20mA to 0–135 ohm. Consider the Futera II or the

Dominator series for the Base Load role.

http://www.rbiwaterheaters.com/

If the base load boiler is not of the modulating type,

stopping the Base Load boiler will require that the size of

the Base Load boiler in BTUs is known relative to the

HeatNet boilers. Boiler selection is ideally; having more

total BTUs in the HeatNet boilers than total BTUs of the

Base Load boiler. This will prevent short cycling. Example:

(4) 2 million BTU HeatNet boilers = 8 million BTUs and

(1) 6 million BTU Base Load boiler.

When all (4) HeatNet boilers are running @ 95%, the Base

Load boiler is called on (demand is approx. 8 million

BTUs). As the Base load boiler comes on it introduces 6

million BTUs and the HeatNet boilers modulate down to

25% for a total output of 2 million BTUs and running at

high efficiency. The HeatNet boilers can now modulate to

the load from 1.6 million BTUs (20% mod) to another 8

million BTUs.

Not Preferred:

Example of having a larger Base Load boiler that is not of

the modulating type: If there is a 6 Million BTU Base Load

boiler running with (3) 2 million BTU HeatNet boilers, a

short cycling situation will arise when the (3) 2 million BTU

boilers are running @ 95% and the Base Load boiler is

called on. At this point there is a need for approximately 6

million BTUs. The (3) smaller boilers will then modulate

down to low fire. At this point, the (3) smaller boilers need

to shut off or the Base load boiler needs to shut off. There is

no overlap. A selection for stopping the boiler now needs to

be determined. Setting the Stop qualifier; Modulation to

40% or a low fire rate will shut the Base Load boiler off and

allow the (3) smaller boilers to modulate up again (short

cycle of the Base Load boiler; Use the Delay Timer and Min

OFF timer). The Stop qualifier; OA T > xxF may also be

used if the system design temperature is known. Then let the

Base Load boiler cycle off its limits, whether a 2 stage,

Hi/Lo, or modulating boiler. The default setting is for the

Base Load boiler to stop first once the water temperature

exceeds the top of the heating band.

Figure 19

Base loading relay

Page 19

Page 20

HeatNet Control REV 3.37-1

Setting up base loading

The base load boiler is controlled using a set of contacts to

enable it (location J4). Enabling/Disabling this relay contact

can be done using any combination of (3) qualifiers to start

the boiler and (4) to stop the boiler. These qualifiers are:

1. Modulation %:

a. START menu item: The relay contact will close

when the MOD % from the Master boiler exceeds

this value. ADVANCE SETUP:BASE LOADING:

START>MOD

b.

STOP menu item

when the MOD % from the Master boiler falls

below this value.

LOADING: STOP<MOD

If the START>MOD value is set to a value

higher than the ADVANCED SETUP:MOD-

MAX: all boilers will be firing before this

modulation rate is reached. This will ensure

that all available boilers are firing before the

base load boiler relay is enabled.

c. Setting the : STOP<MOD to a % value slightly

above the min fire rate % of the system will ensure

that the base load boiler will stop before the first

condensing boiler stops. This is due to the

Modulation rate being close to the min modulation

rate before the water temperature exceeds the top

of the heating band.

2. Outside Air Temperature:

a. START menu item: The relay contact will close

to enable the boiler when the OA T read from the

Outside Air Temperature sensor (if Equipped) falls

below this temperature. ADVANCE SETUP:BASE

LOADING: START< OA T

b. STOP menu item: The relay contact will open to

disable the boiler when the OA T read from the

Outside Air Temperature sensor (if equipped) rises

above this value. ADVANCE SETUP:BASE

LOADING: STOP> OA T

: The relay contact will open

ADVANCE SETUP:BASE

3. Return Water Temperature

a.

4.

START menu item

close to enable the boiler when the RET read

from the Return Water Temperature sensor (if

Equipped) falls below this temperature.

ADVANCE SETUP:BASE LOADING: START>

RET

b.

STOP menu item

to disable the boiler when the RET

temperature read from the Return Water

Temperature sensor (if Equipped) rises above

this temperature.

LOADING: STOP< RET

:

FIRST

a.

STOP menu item

to disable the boiler when the temperature

exceeds the heating band. This gives the

result of stopping the Base Load boiler First.

Default setting.

: The relay contact will

: The relay contact will open

ADVANCE SETUP:BASE

: The relay contact will open

Delay time

The DELAY TIME is also included to hold off starting the

boiler until the delay time is met. Once the start condition

qualifier term is met, the DELAY TIME will start counting

down. When the time expires, the base load relay contacts

will close. ADVANCE SETUP:BASE LOADING:DELAY

TIME. It is adjustable in a range of: 0 to 60 minutes.

Base Load Failsafe

If there are no boilers available to fire (offline or faulted)

and there are no boilers in local override, and there is a call

for heat, The J4 Base Load relay will close. If a boiler

becomes available and needs to fire, the Base Load boiler

will remain firing until the temperature exceeds the band.

This is provided to keep the system from entering a no heat

situation.

Page 20

If the OA T qualifier is used as the Start and

Stop qualifier, ensure that there is at least a

few degrees difference for hysteresis.

Page 21

Control Methods

Heating Control Methods

An overview of the (5) methods for controlling the Futera

series boiler are presented here. They are outlined in more

detail at the end of this section. See Figure 33, page 36,

through Figure 39, page 42.

Heating Method 1

The first method is to use the Futera Series boiler in its

stand-alone modulating method. This method uses a PID

algorithm to maintain a setpoint and is enabled using the

HEAT DEMAND input. Closing a relay contact or switch

across the HEAT DEMAND input will cause the Master

boiler to control all member boilers using H-Net.

A member boiler may also be controlled by the HEAT

DEMAND input (LOCAL mode). The member boiler will

then ignore commands from the Master and maintain its

LOCAL SETPOINT at the supply sensor.

Heating Method 2

The second method is to view the Futera boiler as two

separate boilers or as a HIGH/LOW boiler using T1 & T2.

Heating Method 3

The third method is to allow a remote 4-20 ma or 0-10 VDC

signal to control the firing rate (modulation) of the boiler

using the 4-20ma input, along with the 4-20ma REMOTE

ENABLE input.

Heating Method 4

HeatNet Control REV 3.37-1

Short cycling may occur when a firing rate is

sent to a member boiler that would cause the

supply temperature to rise high enough to trip

the operating limit (low flow rate). After the