Page 1

V3HN-I0M-3

82-0400

®

HeatNet

V3

Control Manual

Control adjustment and operation instructions

for firmware versions Version 3.x

This instruction manual applies only to version 3.x

firmware on version 3.x control boards. Current

firmware is backwards compatible with version 2.x

boards, but some current features may not be

available. To replace firmware on an existing

boiler, contact the factory or website

http://www.rbiwaterheaters.com to obtain the

original firmware file or for assistance in applying

current firmware to an older version control board.

Also read and follow:

Futera III Boiler manual or

Futera Fusion Boiler manual or

Futera XLF Boiler manual

This manual is intended only for use by a qualified heating installer/technician. Read and follow this manual, all

supplements and related instructional information provided with the boiler. Install, start and service the boiler only

in the sequence and methods given in these instructions. Failure to do so can result in severe personal injury,

death or substantial property damage.

Do not use the boiler during construction. Construction dust and particulate, particularly drywall dust, will cause

contamination of the burner, resulting in possible severe personal injury, death or substantial property damage.

The boiler can only be operated with a dust-free air supply. Follow the instruction manual procedures to duct air to

the boiler air intake. If the boiler has been contaminated by operation with contaminated air, follow the instruction

manual guidelines to clean, repair or replace the boiler if necessary.

Affix these instructions near to the boiler. Instruct the building owner to retain the instructions for future use by a

qua hnician, and to follow all guidelines in the User’s Information Manual.

Copyright 2019 Mestek, Inc.

Page 2

Information contained in this publication regarding device applications and the like

is provided only for your convenience and may be superseded by updates. It is your

responsibility to ensure that your application meets with your specifications.

RBI MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

http://www.rbiwaterheaters.com/

The RBI name and logo, Mestek name and logo, Futera, HeatNet, and HNet name and logo are registered trademarks of Mestek, Incorporated in the

U.S.A. and other countries.

BACnet is a registered trademark of ASHRAE. LonWorks is a registered

trademark of Echelon Corporation. All trademarks mentioned herein are

property of their respective companies.

© 2019, Mestek Technology Incorporated, Printed in the U.S.A., All Rights

Reserved.

Page 3

TABLE OF CONTENTS

Page 3

Table of Contents

TABLE OF CONTENTS .............................................................................................................................. 3

Introduction ................................................................................................................................................ 5

THE FUTERA III/FUSION-SERIES V3 HEATNET CONTROL ....................................................................................................................... 5

Features & Specifications ......................................................................................................................... 7

STANDARD FEATURES OVERVIEW ........................................................................................................................................................ 7

Specifications ................................................................................................ ............................................ 9

Components & Accessories ................................................................ ................................................... 10

Setup & Operation ................................................................................................................................... 11

BASIC MULTI BOILER SYSTEM OPERATION................................ ................................................................ ................................ .......... 11

MIXED BOILER TYPES USING PRIORITY SETS ..................................................................................................................................... 12

MIXED BOILER SYSTEM OPERATION ................................................................................................................................................... 12

START/STOP PRIORITY CONDITIONS ................................................................................................ .................................................. 14

SELECTING MIXED BOILERS .............................................................................................................................................................. 15

MIXED SYSTEM TYPE 1: HIGH SYSTEM TURNDOWN ............................................................................................................................ 15

MIXED SYSTEM TYPE 2: CONDENSING / NON-CONDENSING .................................................................................................................. 18

Heating Control Methods ........................................................................................................................ 22

HEATING METHOD 1 ......................................................................................................................................................................... 22

HEATING METHOD 2 ......................................................................................................................................................................... 22

HEATING METHOD 3 ......................................................................................................................................................................... 22

HEATING METHOD 4 ......................................................................................................................................................................... 22

HEATING METHOD 5 ......................................................................................................................................................................... 22

OPERATING LIMIT ............................................................................................................................................................................. 22

INPUT PRIORITIES ............................................................................................................................................................................ 22

HEATING METHOD 1 HEAT DEMAND .............................................................................................................................................. 23

HEATING METHOD 2 STAGE CONTROL T1-T2 ................................................................................................................................... 23

HEATING METHOD 3 4-20MA CONTROL ............................................................................................................................................. 24

HEATING METHOD 4 AA INPUT .......................................................................................................................................................... 24

HEATING METHOD 5 MODBUS COMMUNICATIONS .............................................................................................................................. 24

BASE LOADING, RELAY CONTROL ...................................................................................................................................................... 25

SETTING UP BASE LOADING ............................................................................................................................................................... 28

Domestic Hot Water Methods ................................................................................................................. 28

DHW MAXIMUM RUNTIME ................................................................................................................................................................. 29

DHW METHOD 1: DHW HEATING ONLY USING A DHW MASTER AND MEMBER BOILER(S) EMPLOYING H-NET .................................. 30

DHW METHOD 2: FAILSAFE COMBINATION DHW AND SPACE HEATING WITH A MASTER BOILER AND MEMBER BOILERS UTILIZING VALVES

(MASTER TYPE: COMBINATION) ...................................................................................................................................................... 34

DHW METHOD 2: FAILSAFE COMBINATION DHW AND SPACE HEATING WITH A MASTER BOILER AND MEMBER BOILERS UTILIZING PUMPS

(MASTER TYPE: COMBINATION) ...................................................................................................................................................... 36

DHW METHOD 3: DHW HEATING ONLY, USING A HEADER SENSOR INPUT ........................................................................................... 40

DHW METHOD 4A: SPACE HEATING WITH DHW OVERRIDE OF SETPOINT ON MASTER, USING AN AQUASTAT ......................................... 43

DHW METHOD 4B: SPACE HEATING WITH DHW OVERRIDE OF SETPOINT ON MASTER, USING A DHW 10K TANK SENSOR ..................... 46

DHW METHOD 5A: LOCAL DHW TANK HEATING USING A 10K TANK SENSOR. ....................................................................................... 49

DHW METHOD 5B: LOCAL DHW TANK HEATING USING A THERMOSTAT & HYBRID SENSOR. ................................................................... 53

DHW METHOD 6: DHW USING DIRECT CONTROL (NOT PREFERRED) ................................................................................................. 55

Using the 4-20mA input (OPTIONAL) ..................................................................................................... 55

SETPOINT PRIORITIES ....................................................................................................................................................................... 57

Circulator Pump Options ........................................................................................................................ 57

Local Pump Option ................................................................ ................................................................ .. 59

Page 4

TABLE OF CONTENTS HeatNet Control V3

Page 4

Auxiliary Function Options ................................................................................................ ..................... 59

Outdoor Reset ......................................................................................................................................... 60

Sensors .................................................................................................................................................... 60

Stack Temperature .................................................................................................................................. 60

Security .................................................................................................................................................... 61

Save/Restore Configuration Settings ..................................................................................................... 61

USB Features ........................................................................................................................................... 61

Saving/Restoring Settings ...................................................................................................................... 61

Diagnostics .............................................................................................................................................. 61

Communications ..................................................................................................................................... 62

Failsafe Modes ......................................................................................................................................... 62

FAILSAFE REQUIREMENTS: ................................................................................................................................................................ 62

Category 1 Venting .................................................................................................................................. 63

Limited Flow Boiler Control Options ...................................................................................................... 63

HeatNet Online ......................................................................................................................................... 65

Wiring Connections ................................................................................................................................. 66

* Status Information ................................................................................................................................ 78

STATUS INFORMATION SCREENS ........................................................................................................................................................ 78

Status Screen Fault Display .................................................................................................................... 80

Calibration ................................................................................................................................................ 83

Log Entry.................................................................................................................................................. 84

Line 4 Log Entries: .................................................................................................................................. 85

Default Settings & Menu Item Descriptions — SETUP .......................................................................... 88

Default Settings & Menu Item Descriptions — ADVANCED SETUP ..................................................... 94

MODBUS Communications ................................................................................................................... 101

Troubleshooting .................................................................................................................................... 112

Futera III/Fusion-Series HeatNet Control Run Screen ......................................................................... 117

Futera III/Fusion-Series HeatNet V3 Control Menu Tree ..................................................................... 119

Futera III/Fusion HeatNet V3 Control Advanced Menu Tree ............................................................... 120

Worksheet .............................................................................................................................................. 121

Page 5

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 5

Introduction

The Futera III/Fusion-Series V3

HeatNet Control

The Futera III/Fusion-Series V3 boiler control is the third

generation of the HeatNet control platform. Control

hardware has been added to make use of many new heating

applications. These new features are outlined in the Features

& Specifications section.

Two versions of the Control are available. The full version

and the “Lite” version. The Full version is available as an

option. Consult the factory or sales. The Lite version:

1.) Supports (1) system pump

2.) HeatNet Online monitoring requires a Touchscreen

display on the Master boiler (Full and Lite).

3.) Only a 0-10 VDC output (no 4-20mA)

4.) Does not support (3) alternate staging relays

5.) Pluggable colored terminal strips.

The Futera III/Fusion-Series boiler control is designed to

provide the Futera III/Fusion-Series of boilers with an

integrated boiler management system on every boiler.

Designed for the Air-Fuel coupled Futera III/Fusion-Series

boilers, the Futera III/Fusion-Series HeatNet control

provides for optimized heating efficiency without the need

for a “wall mount control”. Since the Futera III/FusionSeries modular control method is based on digital

communications, analog control signals are not required.

Although the use of analog control signals is still supported

(4-20mA control loops and 0-10vdc control voltages), a

higher level of control precision, repeatability, and feedback

is gained with digital communications control.

With the Futera III/Fusion-Series, optimized heating

efficiency is accomplished by setting the Modulation

Maximum (Mod-Max) setting to exploit the inverse

efficiency curve. This value can be adjusted so that as each

boiler is added, it operates at its maximum turndown. This

allows the maximum number of boilers to operate at their

lowest inputs, until all boilers are firing. Once all boilers are

firing, full range modulation control is allowed. An outdoor

reset function is also provided to assist in the optimized

heating efficiency of the Futera III/Fusion-Series boilers.

The Futera III/Fusion-Series boiler with the Futera

III/Fusion-Series H-Net control, can be operated in multiple

ways:

1. As a standalone boiler.

2. A boiler, in a Boiler Network, using the HeatNet®

(H-Net®) protocol.

3. A Member boiler to a boiler management system with

multiple input control methods.

The primary purpose of the control is to maintain the boiler

water temperature at the supply or the header sensor using a

target setpoint. While performing this task, the control also

monitors dedicated external limits in a limit string and

provides an orderly shutdown and fault indication in the

event of a tripped limit. The monitored limits include a

HIGH LIMIT AQUASTAT, LOW WATER CUTOFF,

GAS PRESSURE, FLOW, IGNITION CONTROL fault,

GAS VALVE alarm, VARIABLE FREQUENCY DRIVE

alarm, and other optional or user selectable limits.

The HIGH LIMIT circuit is independent of

the control and shuts down the ignition

control and the boiler if the control board or

other component of the boiler was to

malfunction. The control will continue to

function and report the fault, but its ability to

control the boiler will end.

Each Futera III/Fusion-Series boiler employing this control

can function as either a Master or a Member. This allows

one boiler (Master) to be in control of a target temperature.

The other boilers (Members) only respond to the commands

issued by the Master. If using an external control, all boilers

can be setup as Member s. The following will define the

roles of Master and Member.

Master

A boiler becomes a Master when a temperature sensor is

connected to the J10 “SYSTEM HEADER” terminals. The

sensor is auto-detected.

The Master senses and controls the common system

header/loop water temperature using a system setpoint. It

uses any boilers it finds (over the H-Net communications

cable) to accomplish this. It can also monitor the Outside

Air (OA) temperature to provide outdoor reset functionality.

Only one Master is allowed in a system.

When operating as a Master, the boiler provides a control

method using a PID algorithm to regulate water

temperature. This algorithm allows a single boiler (Master),

or multiple (Master + Member) boilers. There are two PID

algorithms that can be used. One PID is used for space

heating, and the other for Domestic Hot Water (DHW)

heating. This allows both space and DHW to be controlled

simultaneously.

Page 6

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 6

Figure 1 Heat band

The control algorithm is based upon a Heat Band, at the

center of which is the setpoint. While below the Heat Band,

boilers are staged on and modulated up until the Heat Band

is entered. Once in the Heat Band, modulation is used to

maintain setpoint. Boilers are shut down only when the top

of the Heat Band is breached. Timers are also used to

prevent short cycling.

The control algorithm is based upon a Heat Band, at the

center of which is the setpoint. While below the Heat Band,

boilers are staged on and modulated up until the Heat Band

is entered. Once in the Heat Band, modulation is used to

maintain setpoint. Boilers are shut down only when the top

of the Heat Band is breached. Timers are also used to

prevent short cycling.

While staging the boilers on, a modulation clamp

ADVANCED SETUP: MODULAR BOILER SET:

MOD MAX-LAST FIRE is used to hold the boilers at a

lower fire rate until the last boiler is fired. Once the last

boiler fires, the modulation clamp is removed and all boilers

are allowed to fire above this clamped percentage up to

100%. This “boiler efficiency” clamp is defaulted to 70%

and thus limits all of the boilers individual outputs to 70%

until the last boiler fires. All running boilers modulate up

and down together, always at the same modulation rate. As

a general rule, this percentage should be no lower than twice

the minimum turndown to minimize short cycling.

When additional boilers are needed to achieve setpoint in

the system, the Master boiler employs an ADAPTIVE

MODULATION algorithm to prevent over firing of the

system. The Master communicates over the H-Net to view

the exact status of each Member boiler. When a new boiler

is added, the Master boiler adjusts the system modulation

rate lower to compensate for the BTUs that will be

introduced by the newly added boiler. This adjustment

occurs when the newly added Member boiler enters its ON

CALL state (default setting). This can be changed to PILOT

when the new boiler is called using the menu:

ADVANCED SETUP: ADAPTIVE MOD: DROP

DOWN. Once the Main Valve (on the newly added boiler)

is opened, and the DELAY RELEASE timer equals zero,

the PID algorithm is allowed to control the system

modulation. Setting the DELAY RELEASE timer will

allow some “soak” time of the newly added boiler before

releasing modulation control to the PID.

The ADAPTIVE MOD menus are disabled

on a Member boiler, but are still visible.

Member

If a “SYS/DHW HEADER” sensor is not connected to J10,

a boiler always defaults to the role of Member.

The Member boiler can operate as part of a multi-boiler

system or as a standalone unit.

In a multi-boiler system the Member typically receives its

command signals from a designated Master-boiler. It is also

capable of receiving inputs from an external control system.

The boiler responds to these signals, to start/stop the burner,

and/or to modulate the firing rate. The outlet water

temperature is also monitored. If the outlet temperature

approaches the operating limit temperature setpoint

(adjustable), the boilers firing rate is limited and its

modulation value is reduced to minimize short-cycling. If

the operating limit is exceeded, or if an interlock trips, the

boiler is shut down. When connected with a network cable,

in a Master/Member role, the Members' status is

interrogated by the Master boiler.

Any standalone boiler will perform

better when controlling to a header sensor.

A Fusion, as a standalone boiler,

requires a header sensor to control properly.

In a standalone installation the Member typically receives

its command signals internally and operates based upon the

outlet water temperature input and the established settings in

the menu (Local Set-point) to start/stop the burner, and/or to

modulate the firing rate. If the operating limit is exceeded,

or if an interlock trips, the boiler is shut down. As in a

multi-boiler system, a standalone Member boiler is also

capable of receiving inputs from an external control system.

When using the H-Net network cable in a Master/Member

system, the system setpoint is sent from the Master as a

digital signal, along with the modulation value to control

firing rate. It also receives its command to start or stop over

the H-Net cable. Also, the SYSTEM CLOCK only needs to

be set on the MASTER. The Master will then set the time

on all Member boilers.

If not using the H-Net protocol (cable), an external control

can send a 4-20mA or 0-10V signal along with a 4-20mA

enable signal to control the setpoint or firing rate. The boiler

may also be treated as a 2-stage boiler or an ON-OFF boiler

using the dedicated T-inputs.

Page 7

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 7

Features & Specifications

HeatNet Version 3.x Discontinued

Features

1. With this hardware release the service power, switched

power, and the power switch connector have been

removed. These were available on prior versions of the

HeatNet control. Upgrading to this control from prior

versions will require some wiring changes using an

upgrade kit.

2. The J10B input is no longer supported for proving the

damper. Damper proving switches will need to be wired

to J12B, 7 & 8.

3. If a stack sensor is used with this version, the alarm

silence switch cannot be connected and the

disconnected wires should be terminated appropriately.

Silencing the alarm can be done by holding the BACK

and SELECT keys down at the same time.

Hardware Version 3.x Control

Additional Features

(Identified by circuit board color: BLACK)

1. Support for (2) Circulator pumps (1 if Lite version).

Two rotation modes are provided: Based on system

runtime or system pump runtime hours. Pump failure

switchover/retry mode.

2. Warm weather shutdown, (2) pump jog (1 if Lite

version) and local pump jog to keep pumps from

seizing.

3. The Modbus, BACnet or LonWorks communications

port can be accessed concurrently with the USB port

(HeatNet Control Pro). The BACnet, LonWorks, or

Modbus connections do not need to be disabled to use

the USB ports.

4. The DHW pump and the Local Pump relay connections

now provide a normally closed contact. This allows for

the use of a power open/power close valve.

5. Support for 5mA 0-10v control signals using third party

controls.

6. Support for (2) display types: Vacuum Florescent and

Color LCD using the same 20 pin ribbon cable. The

color LCD provides an interface for the HeatNet Online

monitoring.

7. System Return sensor input.

8. Enhanced boot loader and firmware storage. One

firmware storage location for user updates. One

firmware program that always remains resident so that a

factory program can be restored. Primary loading is

with a flashdrive. The P3 shunt restores the previous

firmware.

9. 32 bit Microcontroller operating @ 64 Mhz with 5-

stage pipeline, and prefetch cache.

10. (3) Stage control relay outputs for TBD applications.

11. Backwards compatible with existing HeatNet versions

1.x and 2.x controls and applications.

12. Support for 135 Ohm control actuators.

13. 1k Platinum Stack sensor.

14. Flow meter input or BMS GPM input/control

15. Dual PID controls. One for space heating and one for

DHW heating. Allows for simultaneous DHW/Space

heating.

Standard Features Overview

1. Five levels of external control inputs, including

modulation and staging that provide application

flexibility.

2. Digital Communications Control (analog 4-20mA and

0-10vdc control supported, but not required).

a. Boiler to Boiler : HeatNet (H-Net)

b. Building Management System (MODBUS,

Optional BACnet or LonWorks) to Boiler

3. Distributed control using the HeatNet (H-Net) protocol

for up to 16 boilers. Eliminates the need for “wall

mounted” controls.

4. Analog Control 4-20mA and 0-10vdc (5mA minimum

current) signals supported.

5. System/Boiler operating status text display

6. Interlock, Event, and System logging with a time

stamp.

7. Advanced PID algorithm optimized for the Futera

III/Fusion-Series boilers.

8. (4) Dedicated temperature sensor inputs for: Outside

Air Temperature, Supply (Boiler Outlet) Temperature,

Return (Boiler Inlet) Temperature, and Header

(Common System Supply) Temperature.

Page 8

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 8

9. Automatically detects the optional temperature sensors

on power up (Outdoor Air Temp sensor is enabled in

the settings menu).

10. Menu driven calibration and setup menus with a bright

(Adj.) 4 line Vacuum Fluorescent Display.

11. (8) Dedicated 24vac interlock monitors, and 8 dedicated

120vac system monitors used for diagnostics and

providing feedback of faults and system status.

12. Multiple circulator pump control modes.

13. Combustion Air Damper control with proof time,

support for a common combustion air damper.

14. USB/RS485 network plug-in to allow firmware updates

or custom configurations.

15. Optional BACnet or LonWorks interface.

16. Alarm Relay dry contacts, and Audible Alarm.

17. Runtime hours, and Cycles (based on Main Valve

Open).

18. Outdoor Air Reset with programmable setpoint and

ratio.

19. Time of Day clock to provide up to (4) night setback

temperatures.

20. Failsafe mode when a Building Management System is

controlling setpoint. If communications is lost, the

boiler/system automatically transfers to local boiler

setpoint control.

21. Rotation Methods (Lead-Lag): True Rotation (based on

boiler runtime) is default. First-On First-Off (FOFO),

Last-On First-Off (LOFO) and MIXED are optional.

22. Programmable password protection to secure the

programmable settings.

23. Remote 4-20mA setpoint control using a mapped

setpoint range to the 4-20mA control signal.

24. Freeze Protection allowing automatic starting of

boiler(s) using (2) Failsafe modes.

25. Adaptive Modulation. When additional boilers are

called, the Master adjusts all boilers fire rates to

compensate.

26. Mixed boiler types in a system.

27. Support for Domestic Hot Water (DHW) using a 10k

Sensor or a dry contact input from a tank thermostat.

28. Domestic Hot Water relay for use with a pump or

valve.

29. On-board power and socket for Protocessor

BACnet/LonWorks module.

30. HI/LO relay control option from connector J4

31. Resettable Fused interlock power circuit.

32. Additional terminal connector for H-Net shielded cable.

33. Backwards compatible to Version 1.x hardware.

34. Communications board integrated with the main board

from version 1.x control.

35. Base Loading of (1) boiler.

36. Domestic Hot Water time out for maximum DHW

runtime.

Page 9

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 9

Specifications

Control Microprocessor based PID modulating control (NOT a safety limit)

Environment -40 °F to 140 °F, <90% RH non-condensing

Input Power 24 VAC, 500 mA

Relays 1 System Pump (Lite version), 2 System Pumps (Full Version), Damper, Circulator, Alarm, DHW

Pump (v2.x), 8A 250 VAC resistive* - Refer to wiring diagram for application specific ratings

K8 on J4.2 &.6 for Base Loading

AC Interlocks 24 VAC – 120 VAC input

Control Inputs AA, Heat Demand, 4-20mA Enable, OA override, T1-T2 (dry contact inputs)

4-20mA, 0-10 VDC

Dimensions 9” wide: 6” high: 2” deep

Temperature Sensors NTC thermistor, 10K @ 77 °F, 335.67K @ -40 °F, 185 @ 150 °F ,+/- 1 F

USB 1.0

RS485 MODBUS Modbus RTU

Boiler-to-Boiler HeatNet (H-Net)

Network Optional LonWorks, BACnet available bridge to MODBUS port

Page 10

FEATURES & SPECIFICATIONS HeatNet Control V3

Page 10

Components & Accessories

Part Number

Component Description

16-0046

Futera III/Fusion-Series Control Board Version 3.x Full- Optional

16-0047

Futera III/Fusion-Series Control Board Version 3.x Lite - Standard

40-0088

Graphics Display Board

40-0091

Graphics Display, Color Touchscreen (HeatNet Online Interface)

16-0026

Temperature probe (bullet type, 1x.250 inch) ACI/10K-CP-BP

14-0325

Supply, Header, Return Sensors ACI 10k-CP-I-NW

14-0328

ACI-X/(2) CP-PO-4 4” probe with dual sensor

14-0329

ACI-X/(2) CP-PO-6 6” probe with dual sensor

13-0104

3” Immersion Well

14-0319

Outside Air Sensor with Housing ACI 10k-CP-O

Installation & Operation Manual

44-0060

RJ45 Communications Cable Assembly, 25 feet

40-0115

Ribbon Cable Assembly (Display Control)

44-0061

USB Cable Assembly, 6ft

14-0354

MODBUS to BACnet Bridge

14-0353

MODBUS to LonWorks Bridge

14-0356

MODBUS to HeatNet Online Module

Page 11

SETUP & OPERATION HeatNet Control V3

Page 11

SETUP & OPERATION

Basic Multi Boiler System Operation

For boiler system setup/installations please

refer to Refer to the 2008 ASHRAE

Handbook, CH12 or later revision.

A basic multi boiler system typically uses boilers of the

same size and type. With HeatNet, this includes (1) Master

and (1-15) Member boilers. The boilers are connected

together using an H-Net communications cable effectively

creating (1) boiler. This allows the system heating BTUs to

be evenly distributed among all of the boilers. (See:, Typical

Single Boiler System, page 74).

Figure 2 Basic multiple boiler system

A basic multi boiler system can be configured using the

boiler menus to create custom systems/features. These

features are best described in the section: Default Settings

& Menu Item Description. Along with these menu

items are hardware support for many auxiliary

functions.

Once the system has been properly setup (all default menu

values used and H-Net addresses assigned), the system is

enabled by placing the REMOTE/LOCAL switch to the

LOCAL position on the Master boiler. All Member boilers

must have their respective switches in the REMOTE

position. When the Master boiler’s Heat Demand input

(LOCAL switch) closes, the system becomes operational

and will fire as many boilers as it needs to maintain the

header water temperature’s setpoint. See the DHW section

to fire to two setpoints.

When a boiler is to be fired in a multi boiler system (header

water temperature is below the heating band), the Master

checks the HeatNet boilers it has available. Then the Master

checks if a Lead Boiler is to be used (LEAD BOILER > 0).

The Master boiler then looks at which type of firing rotation

it has selected: LOFO, FOFO, TRUE (runtime), or MIXED.

In our example we will use the TRUE (runtime) rotation

since it is the default.

The Master now checks all of the runtimes to determine

which boiler has the least runtime based on the MIN

RUNTIME setting in ADVANCED SETUP: FIRING

MODE:. The MIN RUNTIME setting is the minimum

runtime interval in hours that is used to compare boiler to

boiler runtimes.

Once the boiler to fire has been determined, the Master

sends the command over the H-Net cable to fire that boiler,

and resets the ADD BOILER delay timer to prepare for the

next boiler to fire. If the header water temperature is still

below the heating band, and the ADD BOILER delay timer

has expired to zero, the process is repeated until the header

water temperature enters the heating band.

When a boiler receives a command to fire:

1. The system pump relay is enabled and the H-Net

control displays 'Flow Wait' until the flow-switch closes

between J11A, 1 & 2 within the programmed time

(10seconds).

2. All elements in the interlock string, terminated between

J11A and J11B, must be closed before the sequence is

allowed to continue.

3. If all interlocks are closed relay K5 is enabled to

command the combustion-air damper open (if used).

The H-Net control displays 'Damp: Wait' until the

damper end switch closes on input DAMPER, J12B.

4. Relay K6 is enabled energizing the local pump (if

used). The H-Net control commences its 'Flow-Wait'

timer (adjustable 10–240 sec.). The flow switch contact

is checked on terminals J11B, 5 & 6.

5. With all the interlocks closed, the boiler start relay K1

is enabled and energizes terminal 6 on the ignition

control. This signal is present on J5 Boiler Start

Operator.

6. The ignition control begins its cycle and provides an

output signal from terminal 4 to the H-Net control J5

Blower. The H-Net control responds and provides an

output signal to the VFD which sets the blower to the

programmed pre-purge speed.

7. After air-flow is established the ignition control waits

for the air switch to close. When the air switch closes it

provides an input to terminal 7 and pre-purge timing

commences. The H-Net display indicates 'Pre Purge'.

8. When purge is complete the ignition control energizes

the pilot gas valve from terminal 8, and the spark

generator from terminal 10, beginning a 10-second Pilot

Flame Establishing Period (PFEP). The H-Net control

responds to J5 Pilot Valve and provides an output

signal to the VFD which sets the blower to the

programmed ignition speed. The H-Net display

indicates 'Pilot'.

9. At the end of the PFEP the spark generator is de-

energized. If the pilot flame is detected, by the UV

scanner, the ignition control energizes the main gas

valve from terminal 9 to J5 Main Valve. The H-Net

display indicates 'Run'.

Page 12

SETUP & OPERATION HeatNet Control V3

Page 12

10. If main-flame is detected the H-Net control holds the

burner at the low-fire rate for the MODULATION

DELAY time period. After this timer expires, the PID

allows the boiler to modulate and places the boiler into

the running state.

As boilers are added to the system settings in the ADVANCED

SETUP: ADAPTIVE MOD: DROP DOWN menu determines

when the modulation rate drops down to compensate for the

newly added BTUs. For the drop down to be active, one

boiler needs to be running when a new boiler is added (see:

Introduction: The Futera III/Fusion-Series H-Net Control:

Master).

If all boilers are firing, the modulation rate is released to go

to 100%. If all boilers are not firing, the modulation is

limited to the MOD-MAX clamp value. The MOD-MAX

clamp is used to keep the boilers running as efficiently as

possible. The following Mixed Boiler System Operation:

Selecting Mixed Boilers section outlines this with examples.

NOTE: If the boiler is running as a standalone boiler or

is direct modulated (including the AA input),

the MOD-MAX clamp will also be in effect

for the ADD BOILER DELAY time. This is to

minimize thermal shock to the boiler.

Once the header water temperature is in the heating band,

only the modulation rate is used to achieve the target

setpoint. The system will maintain the setpoint until the load

demand increases or decreases.

As the load decreases, the header water temperature will

start approaching the top of the band. The PID now lowers

the modulation rate to the boilers, attempting to keep the

temperature within the heating band. If the system is

delivering too many BTUs, the water temperature will cross

the top of the heating band.

When the header water temperature first exceeds the top of

the heating band, the boilers are again checked for the one

with the most runtime. The selected boiler will turn off

immediately and a shed boiler delay timer will be loaded

with the delay time. This time will need to expire before the

next boiler will be stopped, but only if the header water

temperature remains above the heating band. This timer is

used to allow the header water temperature to return back

into the band when a boiler is stopped. When a boiler is

stopped there is a fixed rate of BTUs (Min Fire) that will be

removed (PID discontinuity to modulate from Min Fire to 0

BTUs on a boiler). The timer allows for this loss of BTUs.

This cycle will continue until the call for heat is satisfied or

the Warm Weather Shutdown feature is enabled.

Mixed Boiler Types Using

Priority Sets

Using the Basic Multi Boiler System Operation, a MIXED

boiler Priority method may be added to control condensing,

non-condensing, base load, or other boiler SETs in a system

together. These sets compose a system which provides for

optimal performance and economy. Having dedicated sets

of boilers gives the system engineer a tool to create many

different boiler systems.

A boiler set can be constructed by simply setting the firing

Priority on each boiler (to be in a set) at the same priority.

Setting all (example) condensing boilers to the highest

Priority of 1, and then setting all (example) non-condensing

boilers to a Priority of 2, will create (2) sets of boilers, one

condensing and the other non-condensing. Once this is

done, the Priority 1 set of condensing boilers will have a

firing order that has a higher Priority and is independent of

the other non-condensing set with the lower priority. The

boiler set with the highest Priority can then be fired based

on a conditional settings menu. The lower Priority set will

follow. If the priority set is used with condensing and noncondensing boilers a boiler may also go offline when a

return temperature is too low.

Boilers will be staged on and off using the ADD and SHED

timers as always, but the boilers can now be grouped.

Mixed Boiler System Operation

Starting Boilers:

When a boiler is to be fired (water temp is below the heating

band), the Master checks the HeatNet boilers it has

available. The Master boiler then looks at which boilers are

returning Priority firing status (set on a boiler in:

(ADVANCED SETUP: SYSTEM: BOILER TYPE:

PRIORITY: 1). If the Start condition for the Priority 1set is

met (ADVANCED SETUP: FIRING MODE: MODE:

MIXED: SET FIRST (example), the Master or Member

boiler that is configured as PRIORITY 1, with the lowest

runtime, will be fired FIRST (example).

As long as the start condition for Priority 1 is met, all

boilers in the PRIORITY 1 set will fire based on runtime.

Once all boilers in the PRIORITY 1 set have fired, the

PRIORITY 2 set of boilers will fire based on runtime.

If the Start condition changes and/or is not met (such as

with: OA T or RET temp), the PRIORITY 2 set of boilers

will fire first/next based on runtime. This has the effect of

flipping the Priority of the sets.

Stopping Boilers:

When a boiler is to be stopped (water temp is above the

heating band), the Master checks the HeatNet boilers it has

Page 13

SETUP & OPERATION HeatNet Control V3

Page 13

available. The Master boiler then looks at which boilers are

returning Priority firing status (set on a boiler in:

(ADVANCED SETUP:FIRING MODE: MODE:

MIXED: SET LAST (example) If the Stop condition for

Priority 1 is met, the Master or Member boiler that is

configured as PRIORITY 1 with the highest runtime will be

stopped LAST (example). As long as the stop condition and

SHED DELAY time are met, all remaining PRIORITY 1 set

of boilers will stop based on runtime. If the Stop condition

changes and/or is not met (such as with: OAT or RET

Temp), the PRIORITY 2 set of boilers will stop first/next

based on their highest runtime.

A boiler’s firing Priority can be designated as such in:

ADVANCED SETUP: SYSTEM: BOILER TYPE:

FIRING PRIORITY: 1 menu on each boiler. A Priority of

‘1’ is the highest priority, a ‘2 the lowest (default is always

2).

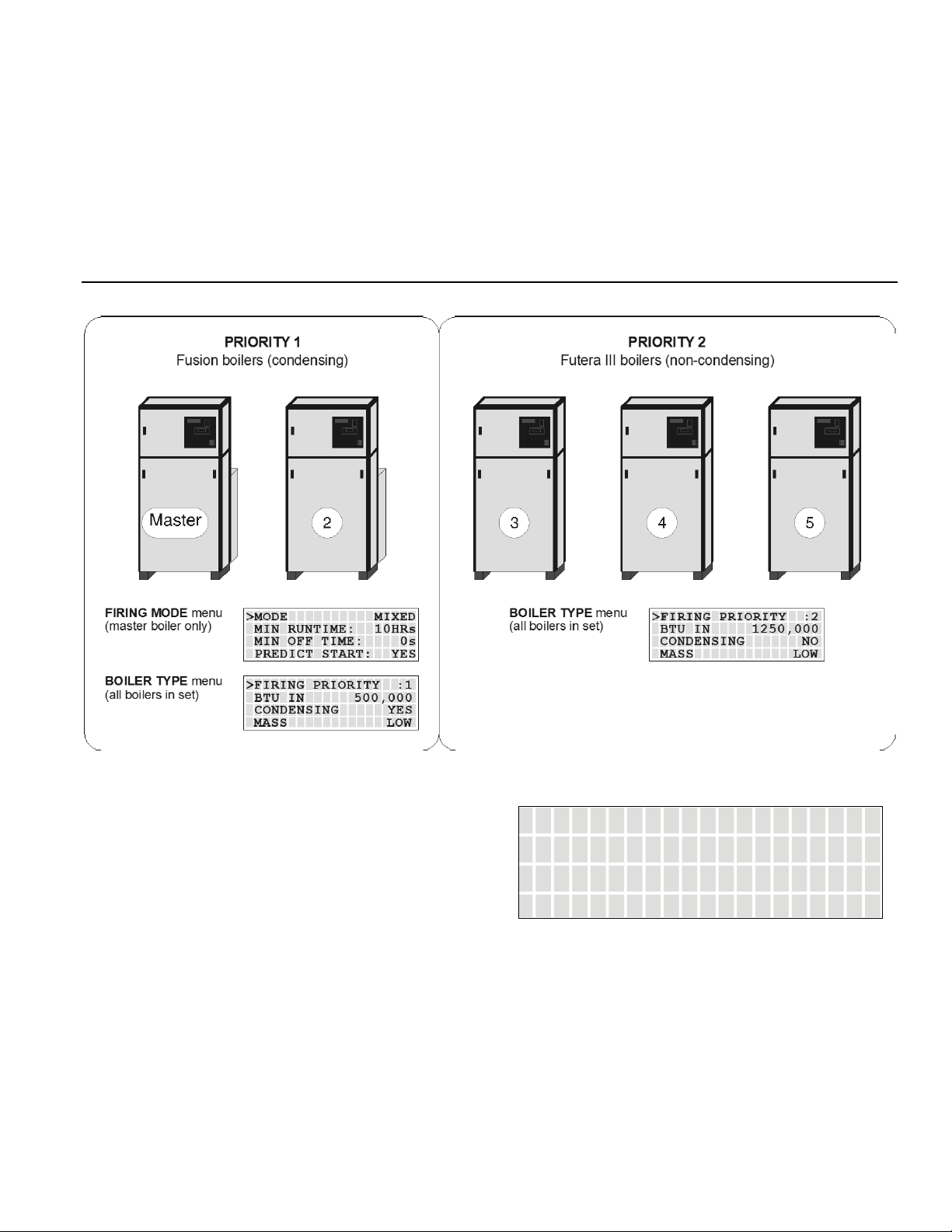

Figure 3 Mixed Boilers: Example: Condensing/Non-Condensing

In the example Mixed Boilers: Condensing/NonCondensing, condensing boilers and non-condensing boilers

are used, but other combinations may also be used. Another

example could use (2) small boilers and set them to

Priority 1 and then use (3) larger boilers and set them to

Priority 2. Using these Priority settings (with the conditions

menu), the small boilers can run first during the shoulder

months (Spring and Fall) and the larger boilers can fire last

during the colder Winter season (base loading set).

Before the MIXED method can be used, the firing mode on

the Master boiler must be set to MIXED. ADVANCED

SETUP: FIRING MODE: MODE: MIXED. Pressing the

SELECT key when the cursor is pointing to MIXED will

enter the conditions menu. The START and STOP

conditions for starting and stopping the Priority boiler set

may be configured here. Temperatures are adjustable.

Once the conditions menu has been entered, the firing order

and stop order of the Priority 1 boiler set can be selected

based on up to (3) conditions in the conditional settings

menu. All conditional settings apply to the Priority 1 boiler

set. When the conditional settings do not apply to the

Priority 1 set, the conditional settings will apply to the

Priority 2 boiler set.

START P R I O R I T Y 1

>SET : FIRST

STOP P R I O R I T Y 1

SET : OAT < 15°F

Page 14

SETUP & OPERATON HeatNet Control V3

Page 14

Start/Stop Priority Conditions

The following is an example using mixed

condensing and non-condensing boilers:

FIRE FIRST

Condensing boilers may be configured to fire first (set to

PRIORITY 1) when:

2. The Return water temperature is below 140F and

condensing occurs. (The Master’s return water sensor

would need to be moved to the header return.)

3. The Outside Air Temperature is above a setpoint

determined by the system configuration. This setpoint

ensures that the more efficient condensing boilers run

first during shoulder months (Spring and Fall) when

minimal heating is required. Below this setpoint, larger

boilers should be brought on first to “base load” the

system.

4. Greater efficiency is required.

STOP FIRST

Condensing boilers may be configured to stop first (set to

PRIORITY 1) when:

The Return water temperature is above 140F and

condensing is minimized, thus leaving the larger lower cost

boilers running to carry the load.

1. The Outside Air Temperature is below an adjustable

setpoint determined by the system configuration. This

setpoint ensures that the larger non-condensing boilers

run during the coldest months when maximum heating

is required. Above this setpoint smaller condensing

boilers should be brought on first to run the system as

efficiently as possible.

2. Maximum heating is required

START PRIORITY 1 SET

Selections (always the lowest runtime first):

The condensing boiler set (Priority 1) has a

higher Priority to fire when one of these

conditions is met. Values are adjustable.

FIRST: The condensing boilers (Priority 1) are always

started FIRST

OA T > 15F: The condensing boilers (Priority 1) are

started when the OA temperature is greater than the Mixed

Boiler Outdoor Air Temperature setting.

RET < 140F: The condensing boilers (Priority 1) are

started when the Return water temperature is less than the

Mixed Boiler Return temperature setting (This may not

applicable in most configurations since the local return

temperature on the Master is used to provide a difference

temperature across the heat exchanger. A System Return

sensor will be required. However, the return temperature

sensor may have been moved on the Master to provide

system return temperature on existing installations and is

still supported).

STOP PRIORITY 1 SET

Selections (always the highest runtime first):

The condensing boiler set (Priority 1) has a

higher Priority to stop when one of these

conditions are met. Values are adjustable.

LAST: The condensing boilers (Priority 1) are always

stopped LAST.

OA T < 15F: The condensing boilers (Priority 1) are

stopped first when the OA temperature is less than Mixed

Boiler Outdoor Air Temperature.

RET > 140F: The condensing boilers (Priority 1) are

stopped first when the Return water temperature is greater

than the Mixed Boiler Return temperature. (This may not

applicable in most configurations since the local return

temperature on the Master is used to provide a difference

temperature across the heat exchanger A System Return

sensor will be required. However, the return temperature

sensor may have been moved on the Master to provide

system return temperature on existing installations and is

still supported).

Start/stop settings

Any combination of Start Conditions and Stop Conditions

can be used to optimize the mixing of condensing

(Priority 1) and non-condensing boilers (Priority 2) for best

performance/economy.

The default settings for the start and stop conditions of the

condensing set are:

The default start setting always starts the condensing boilers

(Priority 1 example) first, except for the lead boiler setting.

The lead boiler will always start first if enabled, unless

there is a boiler already running (this includes a Member

boiler in LOCAL). The default stop condition setting always

stops the condensing boilers (Priority 1) last.

If prolonging the life of the heat exchanger(s) on noncondensing boilers is very important, consider starting the

START P R I O R I T Y 1

>SET : FIRST

STOP P R I O R I T Y 1

SET : L A S T

Page 15

SETUP & OPERATON HeatNet Control V3

Page 15

condensing boilers (Fusion-Series) when the return water

temperature is below 140F.

The return water temperature sensor would

need to be moved from the Master’s return

inlet to the system return. The EXCHGR

DELTA may need to be adjusted in SETUP:

AUX FUNCTIONS: HEAT EXCHANGER

to prevent the Master from going to ½ input

when a high DELTA T is reached.

This method would lead to the non-condensing boilers

carrying the load when the system temperature stabilizes

above 140F, since non-condensing boilers will start first

with the Return water temperature is > 140F. The

condensing boilers can then be stopped first when the RET

water temperature is above the 140F. Remember, any

combination of the Start and Stop conditions may be applied

for best performance and economy in the system. Also, noncondensing boilers may be set to go offline when a return

temperature is too low using the SETUP: AUX

FUNCTIONS: HET EXCHANGER: TEMP DISAB menu.

Base load boilers can also be mixed in the same way as

condensing and non-condensing boilers. The base load

boiler(s) can be prioritized in one set (example, Priority 2)

and non-base load boilers (Priority 1). The non-base load

boilers can then be set to fire first and once they are all

firing, the base load boiler would fire.

To minimize the cycling of a large base load boiler, consider

using the stop condition. Change it to the OAT < 15F

(Outside Air Temperature) condition. This setting may be

used to stop the Priority 1 boiler set when the OAT drops

below the OAT setpoint, thus leaving the large base loaded

boiler on and shutting off the condensing boilers first. This

is also true when using the OAT setting to start the

Priority 1 boiler set when the OAT is above the start

setpoint. To use temperatures as start and stop conditions,

the system design temperatures must be known.

Selecting Mixed Boilers

There are a few factors to consider when choosing which

type of boilers to use in a mixed system. These factors need

to be considered when boilers are added or shed. When

BTUs are introduced into the system by adding boilers, the

amount of introduced BTUs should be smooth (linear). If

these factors are not considered, discontinuity in BTUs may

occur when boilers are added and as a result, short cycling

will occur.

1. Turndown: This is the ratio of minimum fire rate to

maximum fire rate: Example: a 20% minimum

modulation = 5:1 turndown (100%mod / 20% mod). A

(1) million BTU boiler = 200,000 BTUs minimum

input.

2. MOD MAX CLAMP: This value determines the

maximum modulation % at which the boilers will fire

to, until all available boilers are firing.

3. Total System BTUs.

4. Desired Effective Turndown. This is the lowest

firing rate of the system relative to the maximum firing

rate of the system. The larger the value, the lower the

BTUs that can be delivered to a light load.

5. Piping.

Mixed System Type 1:

High System Turndown

The following examples are of mixed boiler systems with

high effective system turndown and fault tolerance built in.

When boiler types are the same, the system turndown is

limited to the boiler’s min input and fault tolerance is

always present. When the system has mixed boiler types,

consideration needs to be taken on what types can be mixed

properly to achieve a high system turndown and provide

some fault tolerance.

Fault tolerance allows for one boiler in the Priority 1 system

to fail and any boiler(s) in the Priority 2 system to fail and

still provide near linear (continuity) BTU response when

adding boilers. This is illustrated in the following examples

using the Boiler System Response graphs.

The Futera III/Fusion-Series Mixed Boiler System

(examples) is advantageous in providing low BTU input for

light loads and high BTUs for heavy loads. The effective

system turndown minimizes short cycling when light loads

are present by assigning smaller boilers to Priority 1,

running them first, and then stopping them last.

In order to achieve the high effective

turndown, smaller boilers are required

(plumbing considerations need to be

considered here due to differing flow/volume

characteristics through the large and small

boilers).

Example Systems:

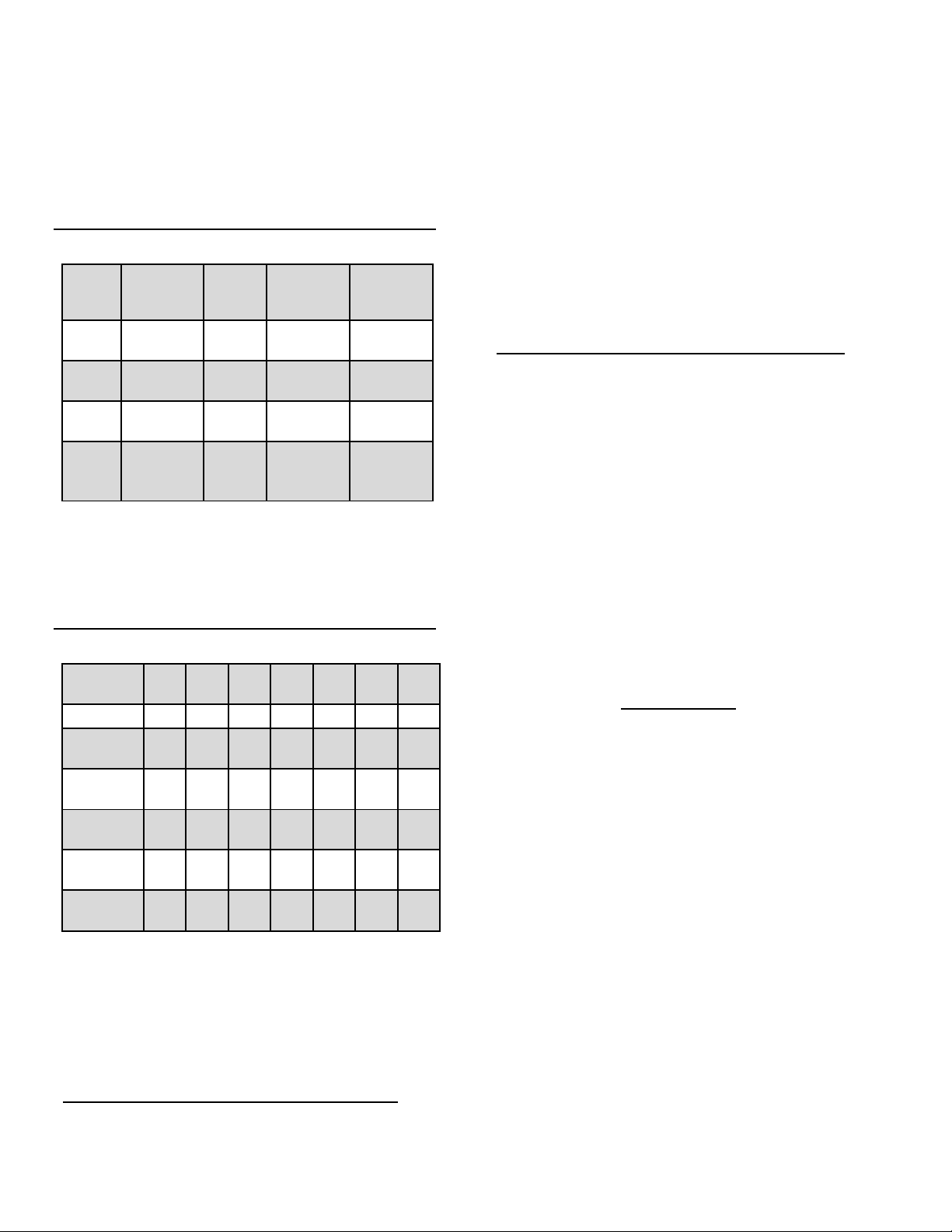

Figure 4 Non-Mixed Boiler System

System

MMBTU

Effective

Turndown

MOD

MAX

MB/MW 4:1

10.0

20:1

70%

2000, 2000, 2000,

2000, 2000

5.0

20:1

70%

1000, 1000, 1000,

1000, 1000

2.5

20:1

70%

500, 500, 500, 500,

500

Page 16

SETUP & OPERATON HeatNet Control V3

Page 16

With the traditional Non-Mixed boiler system, the effective

turndown increases by the turndown ratio for every boiler

added. The min fire rate is equal to the minimum BTUs that

can be delivered to the system.

Number of boilers * Turndown Ratio = Effective System

Turndown: 5 * 4:1 = 20:1.

Figure 5 Mixed Boiler System

System

MMBTU

Effective

Turndown

MOD

MAX

Priority 1

MB/MW

4:1

Priority 2

MB/MW

4:1

4.5

24:1

46%

750, 750

1000, 1000,

1000

4.75

32:1

60%

500, 500

1250, 1250,

1250

6.5

26:1

45%

1000, 1000

1500, 1500,

1500

6.0

48:1

55%

500, 500,

500

1500, 1500,

1500

With the mixed boiler system, a lower minimum fire

rate/BTU can be delivered to the system by using small

boilers with larger boilers. This works in much the same

way as base loading.

Figure 6 Futera III/Fusion Boiler Btu Chart (MBH)

MB/MW

CB/CW

500

750

1000

1250

1500

1750

2000

Max Input

500

750

1000

1250

1500

1750

2000

Min Input

4:1

125

188

250

312

375

437

500

Mod Max

80%

400

600

800

1000

1200

1400

1600

Mod Max

70%

350

525

700

875

1.05

1220

1400

Mod Max

60%

300

450

600

750

900

1050

1200

Mod Max

50%

250

375

500

625

750

875

1000

When selecting the Priority 1 boiler(s) for a high effective

system turndown, the BTU Min Input is selected first. (See:

Futera III/Fusion Boiler Btu Chart). Next, the MOD-MAX

value of this Priority 1 boiler needs to be greater than: Mod

MAX % =

(Priority 1 ‘s Min Input + Priority 2 ‘s Min Input)

Max Input of the Priority 1 boiler

The reason for this is to keep the continuity of BTUs linear

without a BTU bump (discontinuity) when boilers are added

or shed. This is illustrated in the Boiler System Response 2

graph.

If redundancy is not required, the min inputs of the

Priority 1 boilers may be summed to lower the Mod Max %

value so smaller Priority 1 boilers can be used. The sum of

the min inputs would then need to be divided by the sum of

the Max Input of the Priority 1 boilers. The effect of this

would create a higher turndown. See: EXCEPTION NOTES:

Mod MAX % =

(((Priority 1 Min) * (#Priority 1’s)) + Priority 2 Min)

Max Input of Priority 1 boiler * (#Priority 1’s)

Example: (2) CB/CW500, (2) MB/MW1250

Redundancy: (125 + 312) / 500 = 88%

No Redundancy: (125 * 2) + 312) / (500 * 2) = 56%

EXCEPTION NOTES:

1. Mixing more than two different size/type boilers

becomes more complex than the scope of this manual

and is not recommended.

2. If using more than one Priority 1 boiler and the

calculated value is <

Priority 1Min * 2

Priority 1 Max Input

Use this result PLUS note 3 value as the

ModMax%.

3. Always add a few % (3-5%) to the calculated MOD

MAX % value to allow a guard band (tolerance).

4. If boilers are of different sizes, try to use larger Priority

2 boilers.

If the calculated Mod MAX % value is greater

than 99%, the combination cannot be used

since short cycling will occur.

Once the Priority 1 and Priority 2 boilers are selected, they

can be multiplied in each Priority set to achieve the desired

system design BTUs. If the # of boilers becomes a large

number, a Priority 1 boiler with a higher Min Input may

need to be selected.

While considering the MOD-MAX value, the lower the

MOD-MAX the greater the combustion efficiency since it

effectively limits the input rate. The Typical Efficiency of

Page 17

SETUP & OPERATON HeatNet Control V3

Page 17

Non-Condensing Boilers chart can help illustrate how the

MOD-MAX value can affect the efficiency by limiting the

input until all boilers have fired. Non-condensing boiler

efficiency is relatively flat compared with condensing as

illustrated in the Typical Efficiency of Condensing Boiler

graph.

Figure 7 Typical Efficiency of Non-Condensing Boilers

Figure 8 Typical efficiency of condensing boilers

(GAMA BTS2000 method)

In the Mixed Boiler System table line 2 example, (2)

MB/MW 500s are set as Priority 1 and MB/MW 1250s set

as Priority 2. With a MOD MAX of 60%, each 500 can run

to 300M (600M total) before a 1250 is called ON (Add

Delay timer). Once both 500s are running and the 1250 is

called on, all (3) boilers will drop to a total of the 600M

BTUs: The sum of the 500, 500, and 1250 would equal

about 27% modulation: (.27 * 500M) + (.27 * 500M) + (.27

* 1.25MM) or: 135M +135M + 337M = 607M and operate

at higher combustion efficiencies (noncondensing boilers

have minimal effect individually, but can have an effect if

many are used).

If CB/CW Fusion boilers are substituted for the MB/MW

Futera III boilers, the efficiency is greatly increased due to

the condensing mode of these boilers. When using CB/CW

Fusion boilers, during the first 2850 MBTH of load, the

combustion efficiency is maximized by running the CB/CW

Fusion boilers from low to middle input rates. See: Typical

Efficiency of Condensing Boiler graph.

Figure 9 Boiler System Response 1

(2) MB/MW 500s, (3) MB/MW 1250s

When running non condensing boilers at low

input rates, the risk of condensing should be

considered.

The Boiler System Response 1 chart illustrates how each

boiler (in the example) is brought on and fires to 60%, drops

to a lower fire rate and then adds the next boiler (vertical

dashed lines). Once all boilers are firing, the modulation is

released allowing all boilers to fire to 100%.

Now, if (1) MB/MW 500 (one of the MB/MW 500s was

brought offline) were used with (3) MB/MW 1250s and the

Mod-Max is set to 60%, the MB/MW 500 would fire to 300

MBTUs and wait for the MB/MW 1250 (Boiler System

Response 2 graph). Now, the minimum input rate would be

312M (MB/MW 1250) + the 125M (MB/MW 500) (already

running, but dropped to low fire when the MB/MW 1250

fired), the total being 437M. With a 60% MOD-MAX

clamp, there would be 137 MBTUS more than needed and

added to the system when the MB/MW 1250 fired.

The PID algorithm would then compensate for the

discontinuity (bump) in BTUs and the MB/MW 1250 could

shut off (short cycle).

This discontinuity is observed in the graph below, (Boiler

System Response 2) where the jump from the MB/MW 500

@60% to the firing of the MB/MW 1250 is apparent.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000

Input, %

System Load, Btu/Hr

Blr 1+2+3 (2250 MBTU)

Blr 1+2+3+4 (3500 MBTU)

Blr 1+2+3+4+5 (4750 MBTU)

Page 18

SETUP & OPERATON HeatNet Control V3

Page 18

Figure 10 Boiler System Response 2

(1) MB/MW 500, (3) MB/MW 1250, 60% ModMax

To correct this would require the MB/MW 500 to set the

MOD-MAX to roughly 90% (Boiler System Response 3: not

as efficient as it could be when using CB/CW Fusion

boilers) in order to have a linear BTU transfer when the

MB/MW 1250 is added (fired).

Figure 11 Boiler System Response 3

(1) MB/MW 500, (3) MB/MW 1250, 90% ModMax

An MB/MW 500 running with a MB/MW 1250 may not be

an optimal choice unless (2) MB/MW 500s are used in the

Priority 1 set or (3) MB/MW 500s and one is allowed to be

taken offline.

A system employing this redundancy where (1) is allowed

to be taken offline is listed in the MIXED BOILER SYSTEM

chart. This system uses (3) MB/MW 500s and (3) MB/MW

1500s. Two of the MB/MW 500s are treated as one when

adding the min inputs of the Priority 1 set.

Figure 12 Boiler System Response 4

(2) MB/MW 500s, (3) MB/MW 2000s

The Boiler System Response 4 graph illustrates another

system where 80% is used as the MOD-MAX clamp. With

this example, when using all non-condensing boilers, the

system can maximize the use of the smaller boilers before

calling the larger ones.

In summary, the system should be tuned using the boiler

selection charts and the MOD-MAX value. Since selecting

the Priority 1 boiler is integral to the fault tolerance of the

system, it is important to note any discontinuities in BTUs if

a Priority 1 boiler fails when multiple Priority 1 boilers are

used.

Mixed System Type 2:

Condensing / Non-Condensing

This mixed system may also have mixed boilers with

differing sizes as outlined in the Mixed System Type 1:

High System Turndown section. In the following examples

condensing high mass boilers will be used with noncondensing low mass boilers. The reason for creating a

mixed system is primarily to control the system cost.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000

Input, %

System Load, Btu/Hr

Blr 1+2 (1750 MBTU)

Blr 1+2+3 (4250 MBTU)

Blr 1+2+3 (3000 MBTU)

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000

Input, %

System Load, Btu/Hr

Blr 1+2 (1750 MBTU)

Blr 1+2+3 (4250 MBTU)

Blr 1+2+3 (3000 MBTU)

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000

Input, %

System Load, Btu/Hr

Blr 1+2+3 (3000 MBTU)

Blr 1+2+3+4 (5000 MBTU)

Blr 1+2+3+4+5 (7000 MBTU)

Page 19

SETUP & OPERATON HeatNet Control V3

Page 19

Figure 13 Mixed Condensing/Non-Condensing Boiler

System

Local Pump

Local Pump

MASTER

Condensing

MEMBER 1

Condensing

HNETHNET

Header Sensor

System Return Sensor

HNET

Local Pump

Local Pump

System Pump

MEMBER 2

Non-

Condensing

MEMBER 3

Non-

Condensing

Priority 1 Set Priority 2 Set

M

Combustion Air Damper

Outdoor Air Sensor

Outdoor Air

Sensor

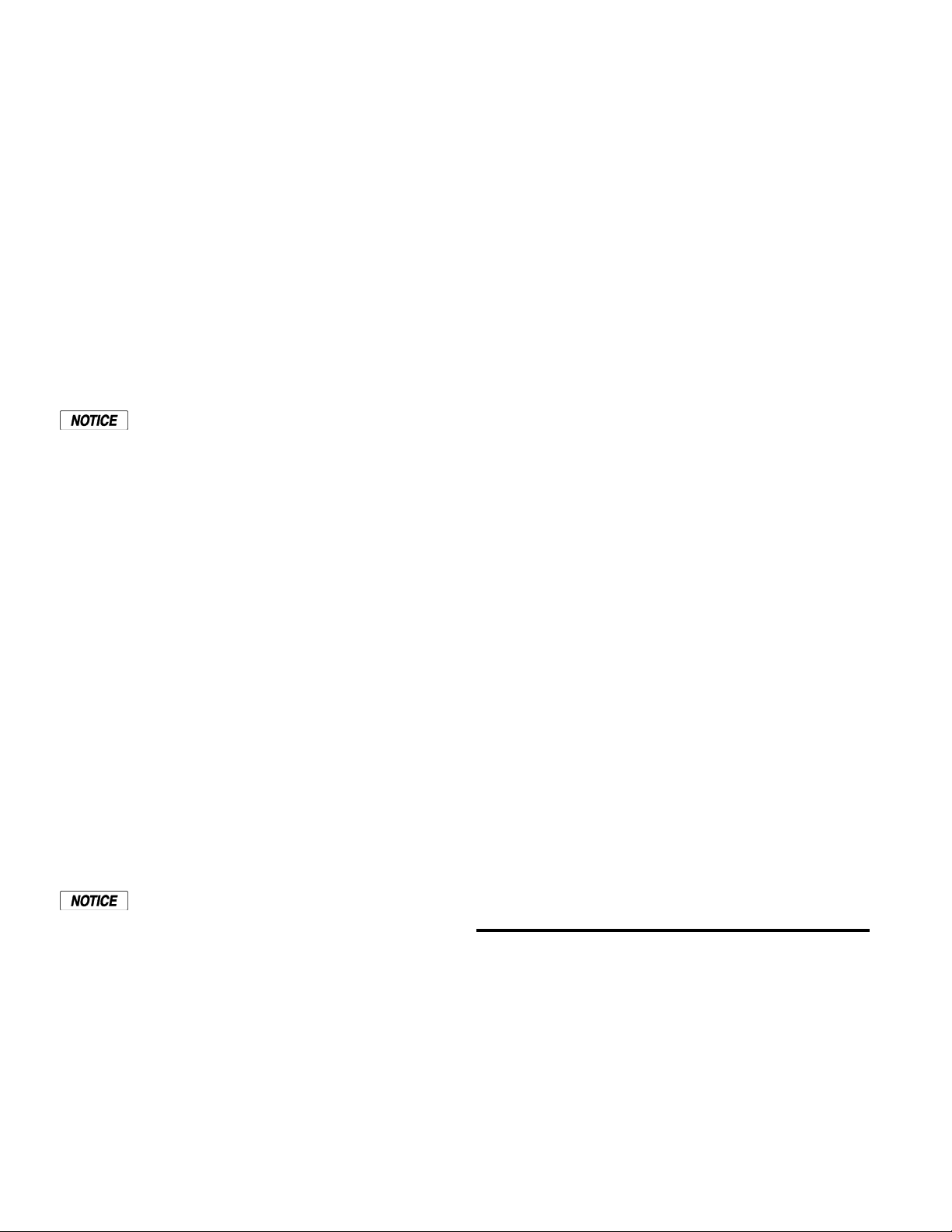

Figure 14 Mixed Boiler System

System

MMBTU

Effective

Turndown

MOD

MAX

Priority 1

CB/CW 4:1

Priority 2

MB/MW

4:1

4.5

24:1

60%

750, 750

1000, 1000,

1000

4.75

32:1

60%

500, 500

1250, 1250,

1250

6.5

26:1

65%

1000, 1000

1500, 1500,

1500

6.0

48:1

65%

500, 500,

500

1500, 1500,

1500

For the examples, the RBI FIII/Fusion series water heaters

will be used. These boilers are non-Condensing, fully

modulating, low mass, and HeatNet compatible.

The Mixed Boiler System table show some examples of

mixed systems using different sizes along with Fusion

condensing (Priority 1) and Futera III non condensing

(Priority 2) boilers.

Using the boiler charts and the examples used in: Mixed

System Type 1: High System Turndown, a mixed boiler

system can be designed. The Priority 1 boilers should be

setup so as to keep the non-condensing boilers from seeing

return water temperatures of less than 140F to ensure a long

heat exchanger life.

Normally, the Priority 1 boilers will fire first. Once all the

Priority 1 boilers are firing, the next boiler to fire (after the

ADD BOILER timer expires) would be the Priority 2 (noncondensing). If the return water temperature has not come

up to ~140F, the non-condensing boilers could fire in a

condensing mode. The ADD BOILER delay timer would

have to be set to a long enough period to ensure this does

not happen. Even then, the load may be too great. The

following note will explain an alternative way (not

depending on the ADD BOILER DELAY) to keep noncondensing boilers from firing in a condensing mode.

When running with a remote BMS setpoint, care must be

taken that an Outside Air reset setpoint (or other setpoint)

sent by the BMS is not set too low. If the BMS system is

controlling the setpoint close to the condensing temperature,

the return water temperature may never rise sufficiently to

keep boilers out of a condensing mode. HeatNet online is a

good way to monitor this scenario if suspected.

If the firmware version for a HeatNet V2

board is at least 3.47(or a version 3

board), the non-condensing boiler may hold itself off from

being added to the HeatNet Master’s available to fire list.

This would effectively keep the non-condensing boiler

from firing in a condensing mode, but as a result, may not

satisfy the system setpoint.

In order to use this feature, the version 2 board would

need to monitor the system or local return temperature.

This can be done locally by setting SETUP: AUX

FUNCTIONS: HEAT EXCHNAGER: TEMP DISAB:

RETURN if the there is no pump/valve limiting flow

continuously through the boiler. If there is a pump/valve

limiting the flow through the boiler, the SETUP: AUX

FUNCTIONS: HEAT EXCHNAGER: TEMP DISAB: SYS

RET needs to be set. Then the Master boiler needs to set

SETUP: AUX FUNTIONS: HEAT EXCHNAGER: SEND

RETURN: to which of its return temperatures it would

send to all boilers. These include the Local Return

temperature or the System Return temperature.

The Member’s menu “SETUP: AUX FUNCTIONS: HEAT

EXCHNAGER: TEMP DISAB:” if set to RETURN or SYS

RET, will force the boiler to become unavailable to

HeatNet when the SETUP: AUX FUNCTIONS: HEAT

EXCHNAGER: TEMP< 140F. This value is adjustable to

135F if a forced air fan is used. When the SYS RET or

RETURN temperature is <140F the boiler responds to a

HeatNet Master’s request as” unavailable”. As soon as

the return temperature reaches 140F, the boiler will

respond to the Master’s request that it is available to fire.

If the Master boiler is a version 2 board, the Master will

always transmit its Local Return temperature to all

boilers. If the Master is set to Priority 1 and all other

non-condensing boilers are set to Priority 2, the Master

should always remain on if there is a call for heat. This

requires that the Priority 1 boiler be set up to start first

and stop last. Using this method should always send a

valid return temperature to the Member boilers. This

method can also be used with a version 3 board, but a

system return sensor is preferred.

When this condition is in effect, the STATUS * screen will

indicate “blr offline”. While the boiler is in this “not

Page 20

SETUP & OPERATON HeatNet Control V3

Page 20

available” state, it can still be fired locally and failsafe is

still available.

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

SEND RETURN:

OFF The Master sends its return

temperature to all boilers

RETURN The Master sends its return

temperature to all boilers

SYS RET The Master sends the system

return temperature to all boilers

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

LOW TEMP:

OFF No check is made to the return

temperature – boiler remains

online

RETURN Uses the boilers own return

sensor (No pump /valve present)

SYS RETURN Uses the System Return temp

received from the Master Boiler

(its Local or System Return).

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

TEMP < 140F

Adjustable threshold temperature below which the

boiler will take itself offline.

1 degree F of hysteresis is provided so as to not

toggle offline<-to->online at the threshold temp.

Since the FIII boiler is non-condensing, the efficiency vs.

input is relatively flat. The MOD MAX value will not have

the same impact if the FIII non-condensing boilers were

placed in the Priority 1 set.

Futera III/ Fusion Boiler BTU Chart

In the Mixed Boiler System table (Figure 15) line 2

example, (2) CB/CW 500s are set as Priority 1 and (3)

MB/MW 1250s set as Priority 2. With a MOD MAX of

60%, each 500 can run to 300M (600M total) before a 1250

is called ON (Add Delay timer). Once both 500s are running

and the 1250 is called on and running, all (3) boilers will

drop to a total of the 600M BTUs: The sum of the 500, 500,

and 1250 would equal about 27% modulation: (.27 * 500M)

+ (.27 * 500M) + (.27 * 1.25MM) or: 135M +135M + 337M

= 607M and operate at higher combustion efficiencies: 27%

is roughly between the top two lines on the Typical

Efficiency of Condensing Boilers chart.

The Boiler System Response 5 chart illustrates how each

boiler (in the example) is brought on and fires to 60%, drops

to a lower fire rate and then adds the next boiler (vertical

dashed lines). Once all boilers are firing, the modulation is

released allowing all boilers to fire to 100%.

Figure 15 Boiler System Response 5

(2) CB/CW 500s, (3) MB/MW 1250s

So, for the first 600 MBTH of load, the combustion

efficiency is maximized by running the (2) fusion boilers

from low to middle input rates. Running the (2) fusion

boilers first also has the added effect of minimizing the

return water temperatures of <140F from reaching the

noncondensing boilers.

Figure 16 Futera III/Fusion Boiler Btu Chart (MBH)

MB/MW

CB/CW

500

750

1000

1250

1500

1750

2000

Max Input

500

750

1000

1250

1500

1750

2000

Min Input

4:1

125

188

250

312

375

437

500

Mod Max

80%

400

600

800

1000

1200

1400

1600

Mod Max

70%

350

525

700

875

1.05

1220

1400

Mod Max

60%

300

450

600

750

900

1050

1200

Mod Max

50%

250

375

500

625

750

875

1000

In summary, the system should be tuned using the boiler

selection charts and the MOD-MAX value so that boilers

are brought on and fired in their respective efficiency curve

while maintaining continuity in BTUs. Since selecting the

Priority 1 boiler is integral to the fault/offline tolerance of

the system, it is important to note any discontinuities in

BTUs if a Priority 1 boiler goes offline when multiple

Priority 1 boilers are used.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000

Input, %

System Load, Btu/Hr

Blr 1+2+3 (2250 MBTU)

Blr 1+2+3+4 (3500 MBTU)

Blr 1+2+3+4+5 (4750 MBTU)

Page 21

SETUP & OPERATION HeatNet Control V3

Page 21

Figure 17 Mixed Boilers: Example: Condensing/Non-Condensing

Page 22

CONTROL METHODS HeatNet Control V3

Page 22

Heating Control Methods

An overview of the (5) methods for controlling the Futera

III/Fusion series boiler are presented here. They are outlined

in more detail at the end of this section.

Heating Method 1

The first method is to use the Futera III/Fusion Series boiler

in its standalone modulating method. This method uses a

PID algorithm to maintain a setpoint and is enabled using

the HEAT DEMAND input. Closing a relay contact or

switch across the HEAT DEMAND input will cause the

Master boiler to control all Member boilers using H-Net.

Any standalone boiler will perform better

when controlling to a header sensor.

A Fusion, as a standalone boiler, requires a

header sensor to control properly.

A Member boiler may also be controlled by the HEAT

DEMAND input (LOCAL mode). The Member boiler will

then ignore commands from the Master and maintain its