Owner’s Manual

Read and understand this entire manual before riding!

DO NOT RETURN TO STORE!

NOTE: E100/125/150 must be traveling

3mph before motor will engage. Kick start to

3mph then twist the throttle to start motor.

Item Numbers

E100 13100E-BL

E125 13125E-BK Black

13111110 Red

E150 13111612

E200 13200E-SL

E200S 13201S-SL

E225S 13112850

E300 13300E-SL

E300S 13301S-SL

E325S 13116390

CONTENTS

Safety Warnings ............................................................ 1

Before You Begin ........................................................... 2

Assembly and Set-Up ................................................. 3-4

Repair and Maintenance ........................................... 4-10

SAFETY WARNINGS

WARNING: Riding the E100, E200 or E300 scooter can be

a hazardous activity. Certain conditions may cause the equipment to

fail without fault of the manufacturer. Like other electric vehicles,

the scooter can and is intended to move, and it is therefore possible

to lose control, fall off and/or get into dangerous situations that no

amount of care, instruction or expertise can eliminate. If such things

occur you can be seriously injured or die, even when using safety

equipment and other precautions. RIDE AT YOUR OWN RISK AND

USE COMMON SENSE.

This manual contains many warnings and cautions concerning the

consequences of failing to maintain, inspect or properly use your

E100, E200 or E300 scooter. Because any incident can result in serious

injury or even death, we do not repeat the warning of possible serious

injury or death each time such a possibility is mentioned.

APPROPRIATE RIDER USE AND

PARENTAL SUPERVISION

This manual contains important safety information. It is your

responsibility to review this information and make sure that all riders

understand all warnings, cautions, instructions and safety topics and

assure that young riders are able to safely and responsibly use this

product. Razor recommends that you periodically review and reinforce

the information in this manual with younger riders, and that you

inspect and maintain your children’s vehicle to insure their safety.

The recommended rider ages of 8 and older for the E100 scooter and

12 and older for the E200 and E300 scooters are only estimates, and

can be affected by the rider’s size, weight or skills. Any rider unable to

fit comfortably on the scooter should not attempt to ride it.

A parent’s decision to allow his or her child to ride this

product should be based on the child’s maturity, skill and

ability to follow rules.

Keep this product away from small children and remember that it is

intended for use only by persons who are, at a minimum, completely

comfortable and competent while operating the vehicle.

DO NOT EXCEED THE WEIGHT LIMIT OF 120 pounds for the E100 and

E150 scooter or 220 pounds for the E200 and E300 scooters.

Rider weight does not necessarily mean a person’s size is appropriate

to fit or maintain control of the scooter.

Do not touch the brakes or motor on your scooter when in use as

these parts can become very hot.

Refer to the section on safety for additional warnings.

ACCEPTABLE RIDING PRACTICES AND

CONDITIONS

Always check and obey any local laws or regulations which

may affect the locations where the E100, E200 or E300 scooter

may be used.

Ride defensively. Watch out for potential obstacles that could catch

your wheel or force you to swerve suddenly or lose control. Be careful

to avoid pedestrians, skaters, skateboards, scooters, bikes, children or

animals who may enter your path, and respect the rights and property

of others.

Do not activate the speed control on the hand grip unless you are on

the scooter and in a safe, outdoor environment suitable for riding. The

E100 scooter must be moving at 3 miles per hour before the motor

will start.

Troubleshooting Guide ............................................ 11-12

E100, E150, E200 and E300 Scooter Parts ............ 13-20

Safety Reminders .......................................... Back Cover

Warranty ........................................................ Back Cover

Failing to properly adjust and tighten the clamps and retainers that affix

the handlebars and folding system can cause you to lose control and

fall. When properly adjusted, you cannot twist the front wheel out of

line with the handlebars or move the T-tube out of adjustment. If you can

twist or force these components to move or come off by hand, readjust

and properly retighten clamp mechanisms.

Do not attempt or do stunts or tricks on your E100, E200 or E300 scooter.

The scooters are not made to withstand abuse from misuse such as

jumping, curb grinding or any other type of stunts.

Maintain a hold on the handlebars at all times.

Never carry passengers or allow more than one person at a time to ride

the scooter.

Never use near steps or swimming pools.

Keep your fingers and other body parts away from the chain, drive chain,

steering system, wheels and all other moving components.

Never use headphones or a cell phone when riding.

Never hitch a ride with another vehicle.

Do not ride your scooter in wet or icy weather and never immerse

the scooter in water, as the electrical and drive components could be

damaged by water or create other possibly unsafe conditions.

The E100, E200 and E300 scooters are intended for use on flat, dry

surfaces such as pavement or level ground without loose debris such

as sand, leaves, rocks or gravel. Wet, slick, bumpy, uneven or rough

surfaces may impair traction and contribute to possible accidents. Do

not drive your scooter in mud, ice, puddles or water. Avoid excessive

speeds that can be associated with downhill rides. Never risk damaging

surfaces such as carpet or flooring by use of an E100, E200 or E300

scooter indoors.

Do not ride at night or when visibility is limited.

PROPER RIDING ATTIRE

Always wear proper protective equipment such as an approved safety

helmet (with chin strap securely buckled), elbow pads and kneepads. A

helmet may be legally required by local law or regulation in your area.

A long-sleeved shirt, long pants, and gloves are recommended. Always

wear athletic shoes (lace-up shoes with rubber soles), never drive

barefooted or in sandals, and keep shoelaces tied and out of the way of

the wheels, motor and drive system.

USING THE CHARGER

The charger supplied with the E100, E200 or E300 scooter should be

regularly examined for damage to the cord, plug, enclosure and other

parts, and in the event of such damage, the bike must not be charged

until the charger has been repaired or replaced.

Use only with the recommended charger.

The charger is not a toy.

Always disconnect from the charger prior to wiping down and cleaning

your scooter with liquid.

FAILURE TO USE COMMON SENSE AND HEED

THE ABOVE WARNINGS INCREASES RISK OF

SERIOUS INJURY. USE WITH APPROPRIATE

CAUTION AND SERIOUS ATTENTION TO SAFE

OPERATION.

1

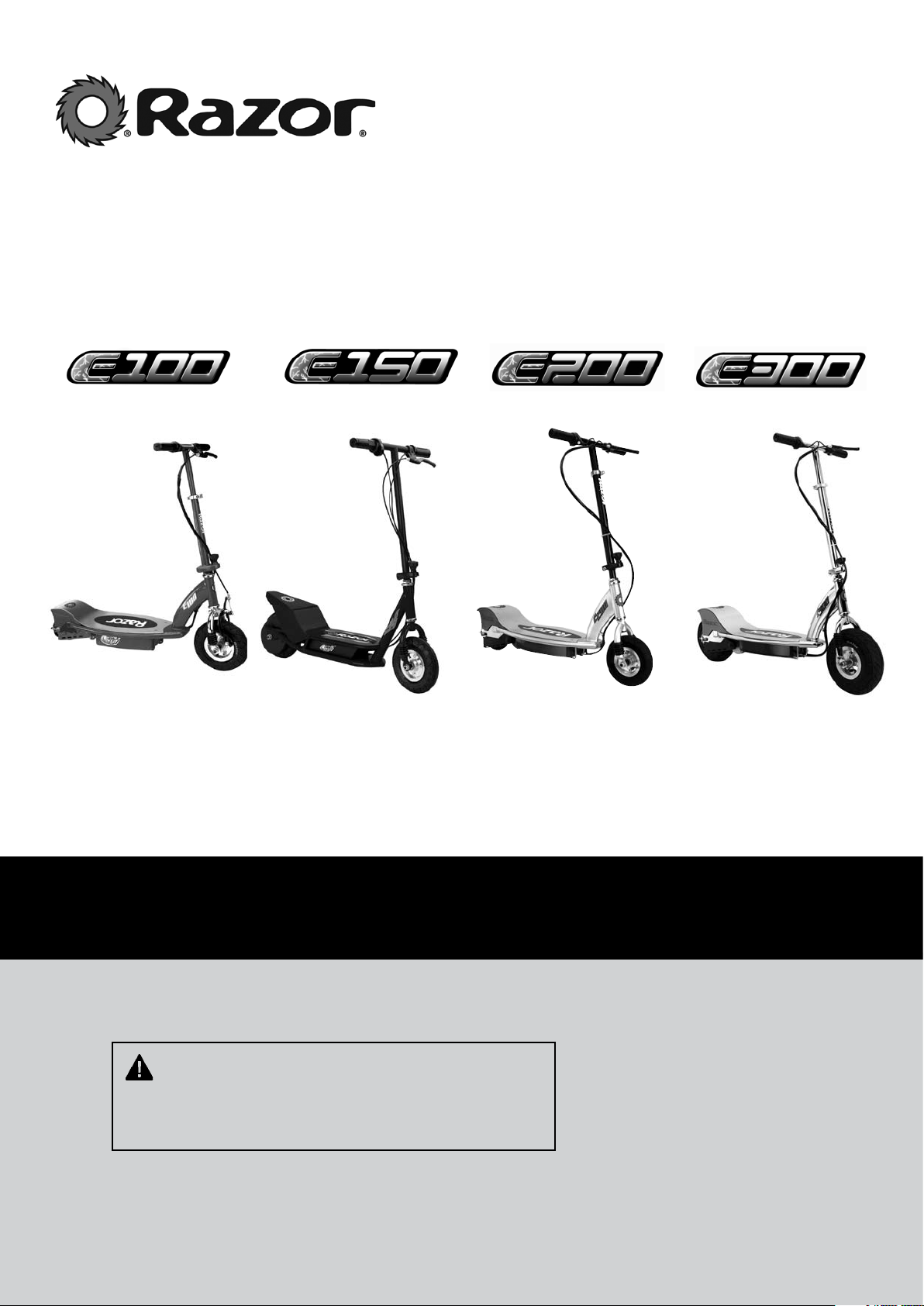

BEFORE YOU BEGIN

Remove contents from box. Remove the foam separators that protect the components from damage during

shipping. Inspect the contents of the box for scratches in the paint, dents or kinked cables that may have

occurred during shipping. Because the scooter was 95 percent assembled and packed at the factory, there

should not be any problems, even if the box has a few scars or dents.

Estimated Assembly and Set-Up Time

Razor recommends assembly by an adult with experience in bicycle mechanics.

Allow up to 20 minutes for assembly, not including initial charge time.

Allow up to 12 hours for initial charge (see page 3 for charging information.

Brake Lever

Speed Control

Brake Lever

Adjuster

Charger

Charger

Plug

T-tube

Charger

Port

Folding System

On/off switch

and charging port

Handlebar height adjust

quick-release

Extension Tube

Locking Knob

Headset

WARNING:

DO NOT USE NONRAZOR PRODUCTS WITH

YOUR RAZOR ELECTRIC

SCOOTER. The scooter has

been built to certain Razor design

specifications. The original

equipment supplied at the time of

sale was selected on the basis of

its compatibility with the frame,

fork and all other parts. Certain

aftermarket products may or may

not be compatible.

Front Fork

Battery pack

and motor

controller

Wheel

Tire

Required Tools

Some tools may be supplied; however, we recommend the use of mechanic’s grade tools. Use the supplied

tools only as a last resort.

6mm hexagonal

key wrench

(included)

Inflation valve

adapter/extender

(with E200 & E300

only)

Bicycle-style tire pump

for Schrader valve

tires, with pressure

gauge

Need Help? Visit our web site for updates and a list of authorized service centers at www.razor.com

or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

2

ASSEMBLY AND SET-UP

q Charging the Battery

Your electric scooter may not have a fully charged battery. Therefore it is a good idea to charge the battery

prior to use.

• Initial charge time: 12 hours • Run time: up to 40 minutes

• Recharge time: up to 8 hours, • Average battery life: 250 charge/discharge cycles

Battery should be recharged

a minimum of 8 hours after

each use. When the vehicle

is not in regular use, recharge

the battery at least once a

month until normal use

is resumed.

Charger

Plug

Charger

Port

1 Plug the charger port into the

port on the scooter. The charger

works with the power switch

in either the on or off position.

The charging input, on/off

switch and overload breaker are

located under the deck at the

front left-hand side.

2 Plug the charger plug into a

wall outlet.

q Attaching the Handlebars

WARNING: Always

disconnect your scooter from

the charger before cleaning with

liquid.

Note: If your charger does not

look like the one illustrated,

your unit has been supplied

with an alternative charger.

The specifications and charging

procedure would not change.

The charger has a small window

with one LED or two LEDs to

indicate the charge status.

Refer to the illustration on

the charger unit for the actual

“charging” and “charged” status

indications for your model

charger.

Chargers have built-in overcharge protection to prevent

battery from being over-charged.

Be sure to properly align the

groove on the charger input

plug with the corresponding

socket on the case;

otherwise, no charging

action will occur.

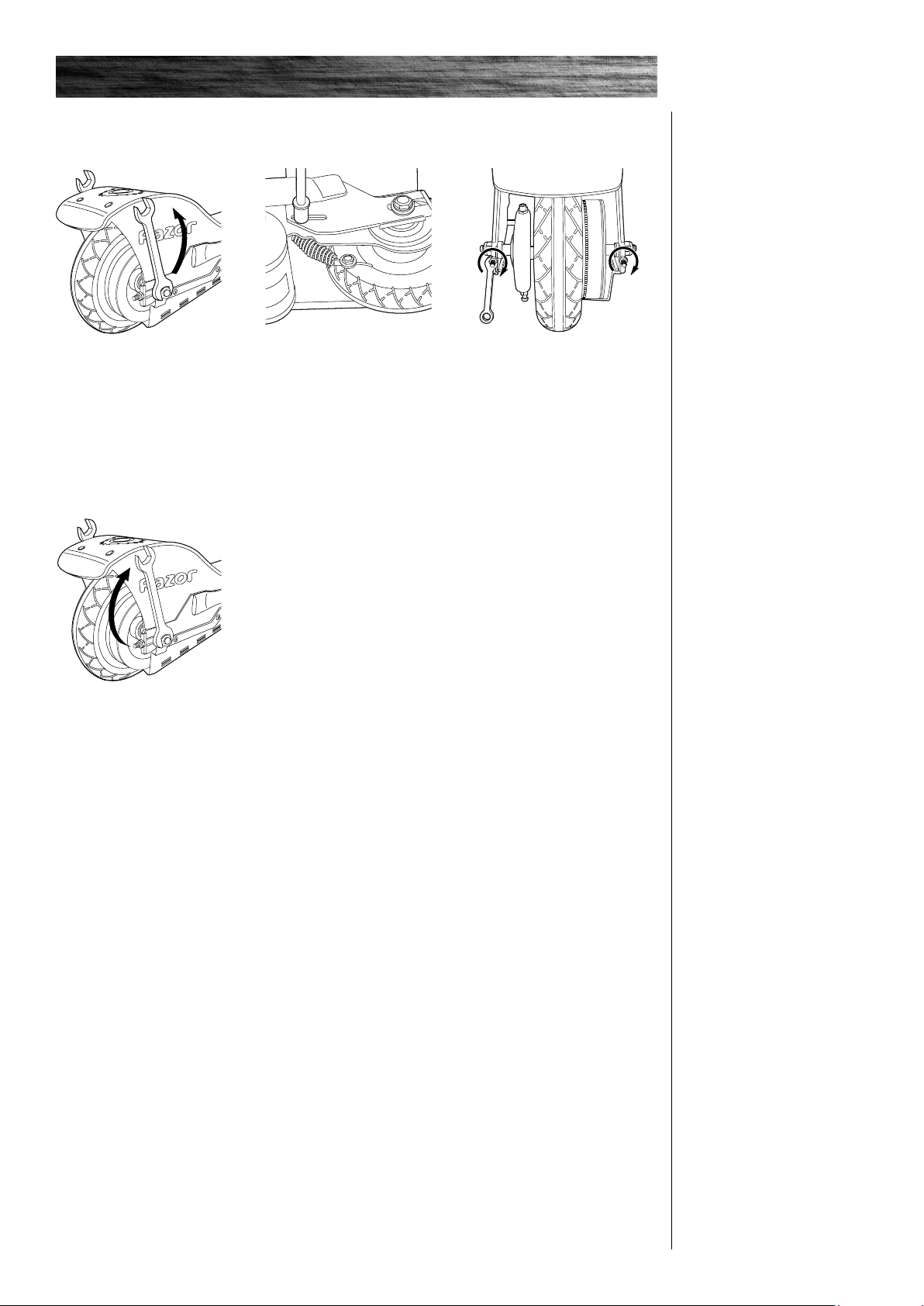

1 Loosen the locking knob

and swing to the 6 o’clock position to unfold the handlebar.

4 Using a 6mm hexagonal

key wrench, tighten the

wedge by turning the bolt

clockwise. The wedge is

properly tightened when the

handlebars cannot be twisted

out of alignment with the

front wheel.

2 Remove the plastic protector

covering the base of the handlebar assembly. Insert the “quill”

part of the handlebar assembly

into the fork. You may have to

loosen the wedge to allow it to

slip into the fork.

5 Pivot the handlebar assembly

upright.

3 Slide the quill into the

fork until it bottoms on the

headset.

6 Swing the locking knob to

the 12 o’clock position and

tighten by hand as firmly as

possible.

WARNING: Failure

to recharge the battery at least

once a month may result in

a battery that will no longer

accept a charge.

WARNING: Failure

to properly tighten the wedge

may allow the handlebars to

dislodge while riding and may

cause you to lose control and

fall. When correctly tightened,

the handlebars will not rotate

out of alignment with the

front wheel under normal

circumstances.

WARNING: Keep your

fingers clear of the pivoting

mechanism when folding or

unfolding the scooter, and make

sure others are standing clear.

Note: The cable and wire

assembly from the handlebar

must not wrap around the

steering tube or handlebar

as shown in step 3. Sharp

bends or twisting of the brake

cable can cause the brakes to

malfunction.

3

ASSEMBLY AND SET-UP

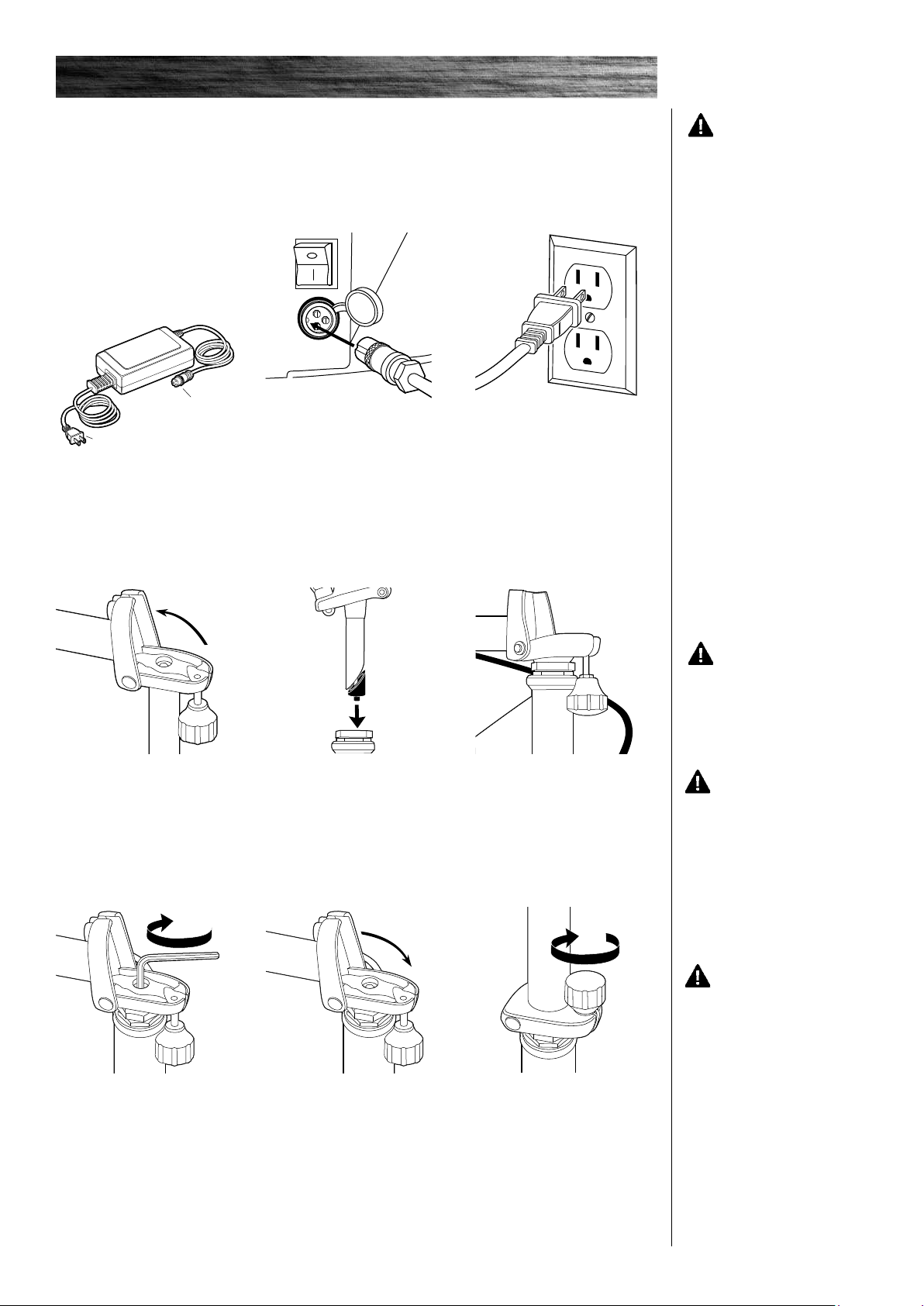

q Adjusting the Handlebar Height (E100/E200/E300 only)

1 Pull the quick-release lever

outward.

2 Slide the T-tube to the

desired position and secure by

pushing the quick-release lever.

3 The tension of the quick-

release clamping mechanism

can be adjusted by tightening

or loosening the bolt with

your fingers.

q Riding Your Scooter

Testing the Brakes – To use the brakes, squeeze the front and back brake levers to increase the

pressure on the brake. The brake lever is fitted with a cable adjuster to compensate for cable stretch

and/or to fine-tune the lever movement to brake engagement. If brake is not engaging properly, follow

instructions for adjusting the brakes on page 5.

Note: The E100 must be going 3 mph before the motor will start. Kick to 3 mph then activate the speed

control while simultaneously pressing the green“go” button to engage the motor.

WARNING: Failure

to properly engage the quickrelease clamp may cause the

T-tube to move up or down

while riding, which may cause

you to lose control and fall.

With the quick-release properly

adjusted and engaged, the

handlebars will not move up or

down.

Note: Be careful not to overtighten. You should be able

to open and close the quickrelease lever by hand, and the

T-tube should move up and

down freely with the quickrelease open.

REPAIR AND MAINTENANCE

Check the Razor web site for any updates on the latest repair and maintenance procedures.

Turn power switch off before conducting any maintenance procedures.

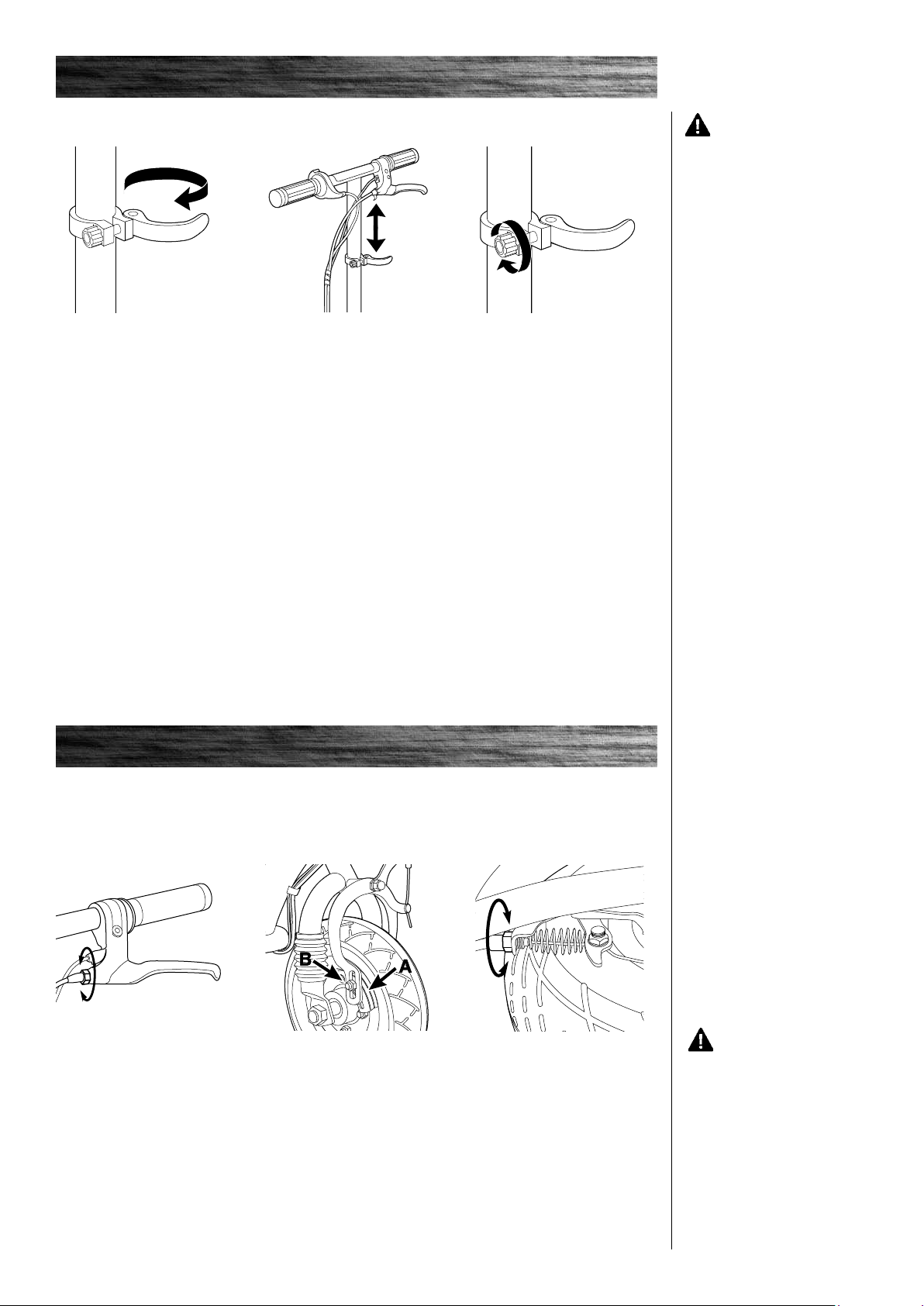

q Adjusting the Brakes

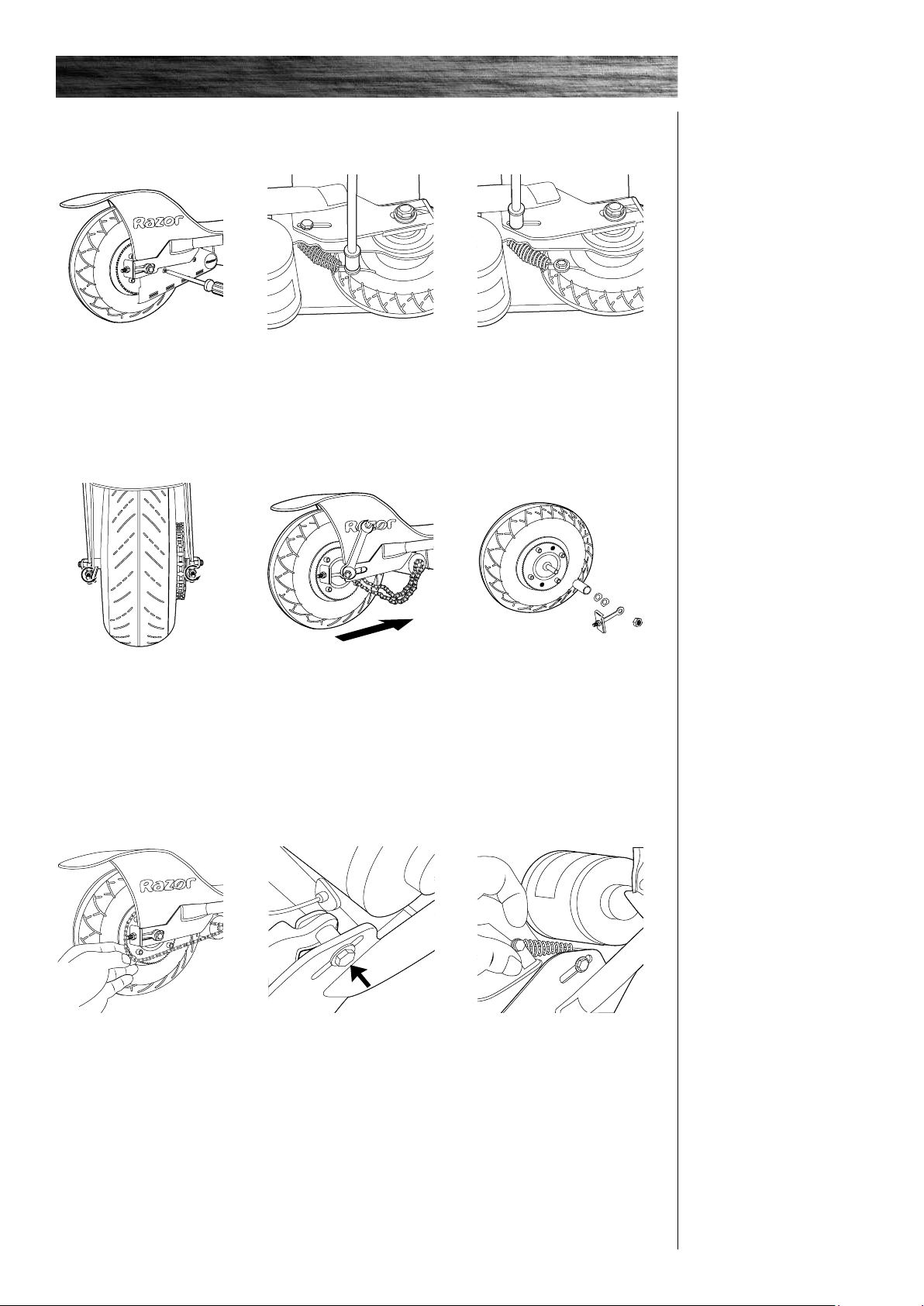

1 To adjust the brake cable

play, thread the brake lever

adjuster in or out 1/4 to 1/2 turn

until the desired brake adjustment is attained. Most

adjustments are complete at

this step. If brake still needs

further adjustment, proceed to

step 2.

2 (E100)

Inspect the brake pads (A)

for proper alignment against

the wheel or excess wear. To

realign brake pads, loosen the

fixing nut (B) and adjust the pad

to contact the rim. Retighten

and test the function, readjust

as needed.

2 (E125, E200 & E300)

If the brake lever adjuster is

threaded outward and the brake

still has too much slack, use the

rear brake adjuster for additional

adjustment.

WARNING: The

brake is capable of skidding

the tire and throwing an

unsuspecting rider. Practice

in an open area free from

obstacles until you are familiar

with the brake function. Avoid

skidding to a stop as this can

cause you to lose control or

damage the rear tire.

4

REPAIR AND MAINTENANCE

q Inflating the Tires

Tires are inflated when shipped, but they invariably lose some pressure between the point of

manufacturing and

your purchase.

E150 / E200 / E300 Rear Tire

1 Use the special valve

extender/adapter supplied.

The valve adapter is located

in the bag with the owners

manual supplied at the time

of purchase.

E150 / E200 / E300 Front Tire and E100 Tires

2 Align the access hole in

the drive sprocket with the

tire valve. Thread the adapter

completely onto the valve and

attach the pump. Inflate to

the PSI indicated on the tire

sidewall.

3 Remove valve adapter

immediately after inflating.

WARNING: Failure

to remove the valve adapter

after inflating will cause the

inner tube and/or adapter to

be severed by the rear drive

sprocket.

Note: If you lose the adapter,

a valve stem extender can be

purchased at almost any auto

parts store.

Note: The pressurized air

supplies found at gasoline

stations are designed to inflate

high-volume automobile tires.

If you decide to use such an air

supply to inflate your electric

scooter tires, first make sure

the pressure gauge is working,

then use very short bursts to

inflate to the correct PSI. If you

inadvertently over-inflate the

tire, release the excess pressure

immediately.

1 Using a bicycle style tire

pump equipped for a Schradertype valve, inflate the front

tire to the PSI indicated on the

sidewall of the tire.

5

REPAIR AND MAINTENANCE

q Adjusting the Chain

Tools required: 10mm wrench, two (2) 8mm wrenches, and two (2) 17mm wrenches.

Note: This system of adjusters

is common to motorcycles and

BMX bicycles. If you are not

familiar with it or do not feel

comfortable performing the adjustment, consult an authorized

Razor service center or a qualified BMX bike or motorcycle

mechanic.

1 Using two 17mm wrenches,

loosen the rear axle bolts by

turning the wrenches counter

clockwise.

4 Once the tension is correct,

tighten the axle and brake anchor bolt. Test run the scooter.

Readjust as needed.

2 Using two 8mm wrenches,

loosen the brake housing anchor

which is located in the long slot

on the left side of the rear fork.

3 Using a 10mm wrench,

tighten the tension adjusters on

the axle 1/8 to 1/4 turn to finetune the chain tension. Both

adjusters must be tightened the

exact same amount to maintain

wheel alignment.

The chain should be “just taut”

– in other words snug, but not

piano-wire tight. The tension

should be similar to the fan

chain on an automobile. BE

CAREFUL NOT TO ADJUST TOO

TIGHT. The tensioning system

can easily impart too much tension and snap the chain or bend

the motor shaft. Adjust 1/8 to

1/4 turn at a time and check the

tension each time.

6

REPAIR AND MAINTENANCE

q Chain and Rear Tire Replacement

Tools required: Phillips screwdriver, 10mm wrench, two (2) 8mm wrenches, and two (2) 17mm wrenches.

1 With a Phillips screwdriver,

loosen the two screws and

remove the chain guard.

4 With a 10mm wrench, loosen

both axle adjusters an equal

amount, about five turns.

2 With a 10mm wrench,

loosen the brake cable anchor

and disconnect the cable.

5 With two 17mm wrenches,

loosen the axle. Push the wheel

forward in the slots to loosen

the chain.

3 With two 8mm wrenches,

loosen brake housing anchor

and disconnect. Keep the spacer

and washers together.

6 Pull the wheel out. Note the

arrangement of the hardware

sequence. The spacer order is

small, medium and large, with

the small spacer between the

brake and frame, the medium

between the brake and wheel

and the long between the wheel

and frame.

7 Install new chain or wheel by

maneuvering the chain onto the

sprocket and slipping the axle

into the slots on the frame.

8 To hook up the brake housing

anchor, align the cable guide

adjuster and install the spacer

and bolt. Do not tighten until

final step.

9 Install the brake spring and

thread the cable wire into the

cable anchor. Thread the cable

to its original position and

tighten securely.

7

REPAIR AND MAINTENANCE

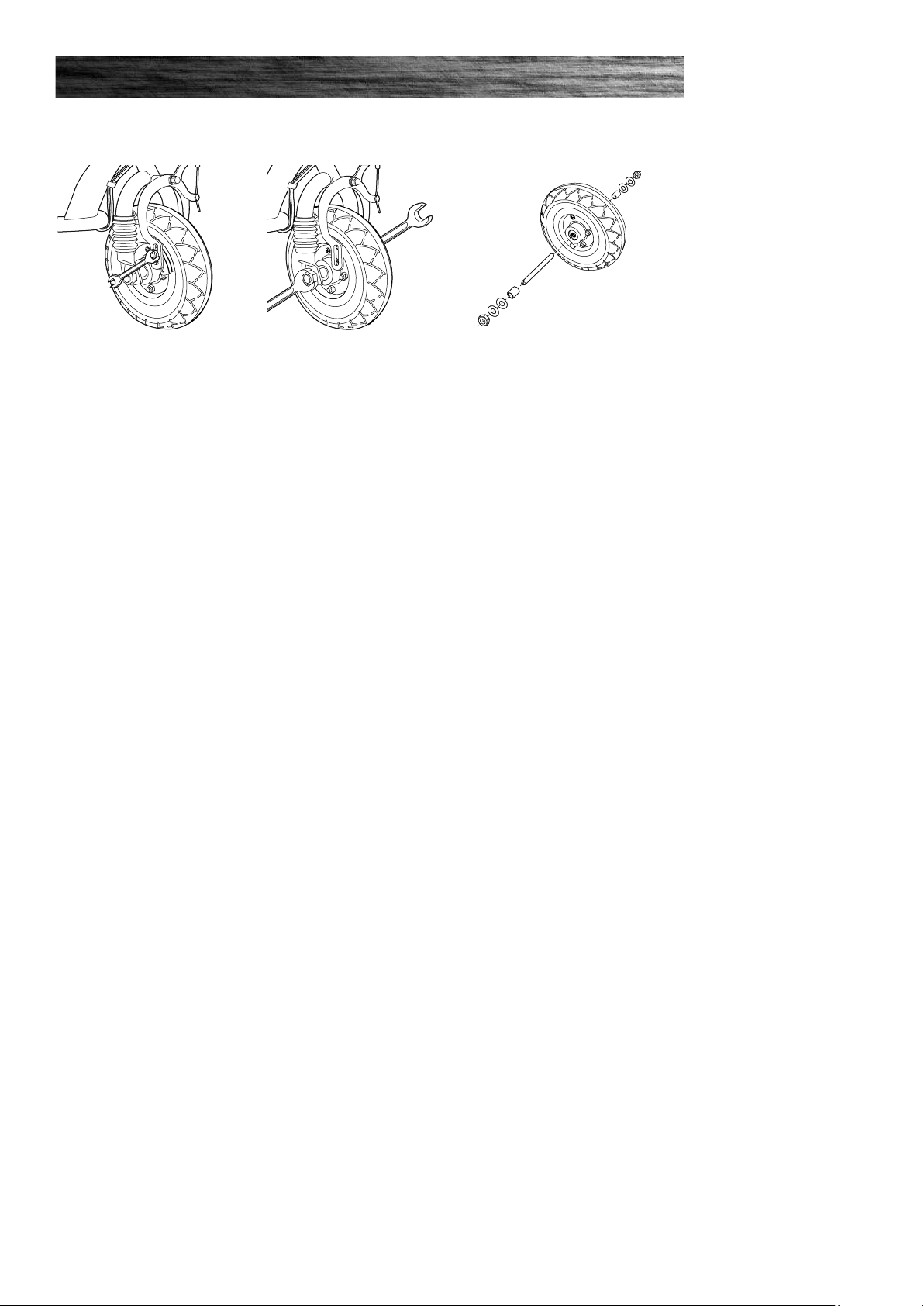

10 Install the axle adjusters

and axle nuts. Tighten until they

just barely hold the hardware

in place.

13 Replace the chain guard.

11 Tighten both axle adjust-

ers the same number of turns

to fine-tune the tension on the

chain and to approximately

maintain the centering of the

wheel.

12 Tighten the brake housing

anchor securely. Test ride and

check. Readjust as needed.

8

REPAIR AND MAINTENANCE

q Front Tire Replacement

Tools required: 10mm wrench, two (2) 17mm wrenches and a flathead screwdriver.

1 (E100 only, other

models go to Step 2)

Loosen the brake pad bolt and

remove one brake pad.

2 Using two 17mm wrenches,

loosen the front axle bolts by

turning the wrenches counter

clockwise.

3 Remove wheel and replace

tire. To reinstall wheel, reverse

these steps. Helpful hint: You

may need to use a flathead

screwdriver to center the axil

and the bolts.

9

REPAIR AND MAINTENANCE

q Battery Care and Disposal

Do not store the battery in temperatures above 75° or below -10° F.

CONTAINS SEALED LEAD BATTERY. BATTERY MUST BE RECYCLED.

Disposal: Your Razor product uses sealed lead-acid batteries which must be recycled or disposed of in

an environmentally sound manner. Do not dispose of a lead-acid battery in a fire. The battery may explode

or leak. Do not dispose of a lead-acid battery in your regular household trash. The incineration, land filling

or mixing of sealed lead-acid batteries with household trash is prohibited by law in most areas. Return

exhausted batteries to a federal or state approved lead-acid battery recycler or a local seller of automotive

batteries. If you live in Florida or Minnesota, it is prohibited by law to throw away lead-acid batteries in the

municipal waste stream.

q Charger

The transformer/charger supplied with the scooter should be regularly examined for damage to the cord,

plug, enclosure and other parts, and, in the event of such damage, the scooter must not be charged until it

has been repaired

or replaced.

Use ONLY with the recommended charger.

q Replacement Parts

The most frequently requested replacement parts (wheels, tires, tubes, batteries and chargers) are

available for purchase at some Razor retail partners or online at www.razorama.com. For other parts

contact an authorized Razor repair center.

q Repair Centers

For a list of authorized Razor repair centers:

• Check online at www.razor.com.

• Send e-mail to customerservice@razorusa.com or call 866-467-2967 for the center nearest you.

WARNING:

battery leak develops, avoid

contact with the leaking acid

and place the damaged battery

in a plastic bag. Refer to the

disposal instructions at left. If

acid comes into contact with

skin or eyes, flush with cool

water for at least 15 minutes

and contact a physician.

If a

10

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

Scooter does not run

Undercharged battery

Charge the battery. A new battery should have been charged for at

least 12 hours before using the scooter for the first time and up to 8

hours after each subsequent use.

Check all connectors. Make sure the charger connector is tightly

plugged into the charging port, and that the charger is plugged into

the wall.

Scooter was running but

suddenly stopped

Short run time (less than

30 minutes per charge)

Charger is not working

Loose wires or connectors

E100 only - Scooter must be

traveling 3mph before motor will

engage.

Tripped circuit breaker

Undercharged battery

Make sure power flow to the wall outlet is on.

You may check to see if your charger is working by using a volt meter

or asking your local Razor authorized service center to test your

charger for you.

Kick start to 3mph then twist the throttle to start motor.

Check all wires and connectors to make sure they are tight.

The circuit breaker (next to on/off switch) will automatically shut off

the power if the motor is overloaded.

An excessive overload, such as too heavy a rider or too steep a hill,

could cause the motor to overheat. If the scooter suddenly stops

running, wait a few seconds and then push the breaker to reset the

circuit. Correct the conditions that caused the breaker to trip and

avoid repeatedly tripping the breaker.

Charge the battery. A new battery should have been charged for at

least 12 hours before using the scooter for the first time and up to 8

hours after each subsequent use.

Check all wires and connectors. Make sure the battery connector is

tightly plugged into the charger connector, and that the charger is

plugged into the wall.

Scooter runs sluggishly

Battery is old and will not accept

full charge

Brakes are not adjusted properly

Driving conditions are too stressful

Tires are not properly inflated

Scooter is overloaded

Brake dragging

Make sure power flow to the wall outlet is on.

Even with proper care, a rechargeable battery does not last forever.

Average battery life is 1 to 2 years depending on scooter use and

conditions. Replace only with a Razor replacement battery.

Refer to adjusting the brakes instructions on page 4.

Use only on solid, flat, clean and dry surfaces such as pavement or

level ground.

The tires are inflated when shipped, but they invariably will lose

some pressure between the point of manufacturing and your

purchase. Refer to instructions on page 5 of this manual to properly

inflate tires.

Make sure you do not overload the scooter by allowing more than

one rider at a time, exceeding the E100 120 lb. or E200 and E300 220

lb. maximum weight limit, going up a hill or towing objects behind

the scooter. If the scooter is overloaded, the circuit breaker may trip

and shut off power to the motor. Correct the driving conditions that

caused the overload, wait a few seconds, and then push the breaker

to reset the circuit. Avoid repeatedly tripping the circuit breaker.

E100: Use your fingers to twist the adjuster in either direction until

wheel is centered between pads.

E200/E300: Adjust brake at lever (page 4) to allow wheel to spin

without brake contact.

11

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

Sometimes the scooter

doesn’t run, but other

times it does

Brakes are not adjusted properly

Loose wires or connectors

Refer to adjusting the brakes instructions on page 4.

Check all wires around the motors and all connectors to make sure

they are tight.

Charger gets warm

during use

Scooter does not stop

when applying the brake

Scooter makes loud

noises or grinding

sounds

Motor or electrical switch

damage

Normal response to charger use

Brakes are not adjusted properly

Chain is too dry

Brake rotor is dragging on brake

pads

Contact your local Razor authorized service center for diagnosis and

repair.

No action required. This is normal for some chargers and is no cause

for concern. If your charger does not get warm during use, it does not

mean that it is not working properly.

Refer to adjusting the brakes instructions on page 4.

Apply a lubricant such as 3 in 1TM or Tri-FlowTM to the chain.

Use your fingers to twist the caliper adjuster in either direction until

rotor is centered between pads.

Need Help? Visit our web site for updates and a list of authorized service centers at www.razor.com

Need Help? Visit our web site for updates and a list of authorized service centers at www.razor.com

or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

12

E100 PARTS

Keep your scooter running for years with genuine Razor parts. Visit our web site or e-mail us for more information on spare part availability.

(Specifications subject to change without notice.)

01 Handlebar grip (right/left)

02 Single speed twist grip throttle

02-1 Sleeve

03 Handlebar stem/ T-bar

03-1 Black folding knob

03-2 6mm stem bolt

03-3 Washer

03-4 Wedge

04 Brake lever assemble complete

05 Headset (upper)

06 Frame

07 Headset (lower)

08 Front fork

09 Front wheel complete

10 Front caliper brake

11 Battery tray

12 On/ Off switch

13 Charger port w/ wires

14 Reset button w/ wire

15 Control module

16 Battery (2- 12V/ 4.5Ah)

17 Kickstand

18 Motor (24V / 100W)

19 Rear wheel complete

20 Chain

20 Chain guard

20 Deck plate w/ grip take set

13

E100 PARTS

14

E150 PARTS

Keep your scooter running for years with genuine Razor parts. Visit our web site or e-mail us for more information on spare part availability.

(Specifications subject to change without notice.)

01 Handlebar grip (right/left)

01-1 Valve stem extender/ inflator

01-2 Handlebar end cap/ Extender holder

02 Brake lever assemble complete

03 Handlebar stem/ T-bar

03-1 Black folding knob

03-2 6mm stem bolt

03-3 Washer

03-4 Wedge

04 Speed controller w/ LEDs

04-1 Sleeve

05 Headset (upper)

06 Frame

07 Headset (lower)

08 Front fork

09 Front wheel complete

10 Battery tray

11 On/ Off switch

12 Reset button w/ wire

13 Charger port w/ wires

14 Control module

15 Battery (2- 12V/ 4.5Ah)

16 Motor (24V/ 100W)

17 Kickstand

18 Rear wheel complete

19 Chain

20 Chain guard

21 Deck, Upper plate

22 Main deck board

15

E150 PARTS

16

E200 PARTS

Keep your scooter running for years with genuine Razor parts. Visit our web site or e-mail us for more information on spare part availability.

(Specifications subject to change without notice.)

01 Handlebar Grip (right/left)

01-1 Valve stem extender/ inflator

01-2 Handlebar end cap, Extender holder

02 Speed controller w/ LEDs

02-1 Sleeve

03 T-bar

04 Brake lever assemble complete

05 Quick release

06 Extension tube/ Folding system

06-1 Black folding knob

06-2 6mm stem bolt

06-3 Washer

06-4 Wedge

07 Headset (upper)

08 Frame

09 Headset (lower)

10 Fork front

11 Front wheel complete

12 Battery tray

13 Reset button w/ wire

14 On/ Off switch

15 Charger port w/ wires

16 Control module

17 Motor (24V/ 200W)

18 Kickstand

19 Battery (2- 12V/ 7Ah)

20 Rear wheel complete

21 Chain

22 Chain guard

23 Rear fender

24 Deck

25 Seat post

26 Seat

17

E200 PARTS

Only used on E200S

18

E300 PARTS

Keep your scooter running for years with genuine Razor parts. Visit our web site or e-mail us for more information on spare part availability.

(Specifications subject to change without notice.)

01 Handlebar grips (right/left)

01-1 Valve stem extender/ inflator

01-2 Handlebar end cap, Extender holder

02 Single speed twist grip throttle

02-1 Sleeve

03 Handlebar Stem/ T-bar

03-1 Black folding knob

03-2 6mm stem bolt

03-3 Washer

03-4 Wedge

04 Brake lever assemble complete

05 Headset (upper)

06 Frame

07 Headset (lower)

08 Front fork

09 Front wheel complete

10 Battery tray

11 Reset button

12 On/ off switch

13 Charger port w/ wires

14 Control module

15 Battery (2- 12V/ 7Ah)

16 Motor (24V/ 250W)

17 Kickstand

18 Rear wheel complete

19 Chain

20 Chain guard

21 Deck plate w/ grip tape

22 Seat post

23 Seat

19

E300 PARTS

Only used on E300S

20

SB 1918 (CALIFORNIA) DECLARATION

YOUR INSURANCE POLICIES MAY NOT PROVIDE COVERAGE FOR

ACCIDENTS INVOLVING THE USE OF THIS SCOOTER/ELECTRIC

VEHICLE. TO DETERMINE IF COVERAGE IS PROVIDED, YOU SHOULD

CONTACT YOUR INSURANCE COMPANY OR AGENT.

20

SAFETY REMINDERS

PRE-RIDE CHECKLIST

q

q

q

Loose Parts

Check and secure all fasteners before every

ride. Make sure steering stem clamp bolts are

locked properly in place. There should not be any

unusual rattles or sounds from loose parts or

broken components. If you are not sure, ask an

experienced mechanic to check.

Brake

Check the brakes for proper function. When

you squeeze the lever, the brake should provide

positive braking action. When you apply the

brake with the speed control on, the brake cutoff switch will stop the motor.

Frame, Fork and Handlebars

Check for cracks or broken connections.

Although broken frames are rare, it is possible

for an aggressive driver to bash into a curb or

wall and wreck and bend or break a frame. Get

in the habit of inspecting yours regularly.

DO NOT RETURN TO STORE

Do not use this vehicle for the first time until you have inflated the

tires to the correct PSI and charged the battery for at least 12 hours.

q

q

Tire Inflation

Periodically inspect the tires for excess wear,

and regularly check the tire pressure and reinflate as necessary. If you get a flat tire, the

inner tube can be patched or a new tube can be

purchased from Razor or an authorized repair

center.

Safety Gear

Always wear proper protective equipment such

as an approved safety helmet, elbow pads and

kneepads. Always wear athletic shoes (lace-up

shoes with rubber soles), never drive barefooted

or in sandals, and keep shoelaces tied and out of

the way of the wheels, motor and drive system.

Failure to follow these instructions may damage

your vehicle and void your warranty.

WARRANTY

Razor Limited Warranty

The manufacturer warranties this product to be free of manufacturing

defects for a period of 90 days from date of purchase. This Limited

Warranty does not cover normal wear and tear, tires, tubes or

cables, or any damage, failure or loss caused by improper assembly,

maintenance, or storage or use of the Razor electric chopper.

This Limited Warranty will be void if the product is ever

• used in a manner other than for recreation or transportation

• modified in any way;

• rented.

The manufacturer is not liable for incidental or consequential loss or

damage due directly or indirectly to the use of this product.

Razor does not offer an extended warranty. If you have purchased an

extended warranty, it must be honored by the store at which it was

purchased.

Need Help? Visit our web site for updates and a list of authorized service centers at www.razor.com

or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

For your records, save your original sales receipt with this manual and

write the serial number below.

__________________________________________

Item Numbers

E100 13100E-BL

E125 13125E-BK Black

13111110 Red

E150 13111612

E200 13200E-SL

E200S 13201S-SL

E225S 13112850

E300 13300E-SL

E300S 13301S-SL

E325S 13116390

Community Design No. 130919-0001

U.S. Design Patent D497,397 S

Printed in China for:

Razor USA LLC

PO Box 3610

Cerritos, CA 90703

© Copyright 2007 Razor USA. All rights reserved.

12102007

Loading...

Loading...