Razor RipRider 360, RipRider 360 Caster Trike, 20036501 Owner's Manual

OWNER’S MANUAL

Read and understand this entire manual before riding!

For assistance contact Razor. DO NOT RETURN TO STORE.

Item Number:

20036501

CASTER TRIKE

WARNING: Riding the RipRider 360˚ Caster Trike can be a

hazardous activity. Certain conditions may cause the equipment to fail

without fault of the manufacturer. The RipRider 360˚ Caster Trike can and is

intended to move, and it is therefore possible to lose control, fall off and/or

get into dangerous situations that no amount of care, instruction or expertise

can eliminate. If such things occur you can be seriously injured or die, even

when using safety equipment and other precautions. RIDE A

T YOUR OWN

RISK AND USE COMMON SENSE.

This manual contains many warnings and cautions concerning the

consequences of failing to maintain, inspect or properly use your RipRider

360˚ Caster T

rike. Because any incident can result in serious injury or even

death, we do not repeat the warning of potential serious injury or death each

time such a possibility is mentioned.

A

PPROPRIATE RIDER USE AND

P

ARENTAL SUPERVISION

This manual contains important safety information. It is your responsibility

to review this information and make sure that all riders understand all

warnings, cautions, instructions and safety topics and assure that young

riders are able to safely and responsibly use this product. Razor recommends

that you periodically review and reinforce the information in this manual with

younger riders, and that you inspect and maintain your children’s vehicle to

insure their safety

.

The recommended rider age of 5 and older for RipRider 360˚ Caster Trike is

only an estimate, and can be affected by the rider’s size, weight or skills. Any

rider unable to fit comfortably on the RipRider 360˚ Caster Trike should not

attempt to ride it. A parent’s decision to allow his or her child to ride

this product should be based on the child’

s maturity, skill and ability

to follow rules.

Keep this product away from small children and remember that this product

is intended for use only by persons who are, at a minimum, completely

comfortable and competent while operating the vehicle.

D

O NOT EXCEED THE WEIGHT LIMIT OF 160 pounds.

Rider weight does not necessarily mean a person’

s size is appropriate to fit

or maintain control of the RipRider 360˚ Caster Trike.

Refer to the section on safety for additional warnings.

A

CCEPTABLE RIDING PRACTICES AND

CONDITIONS

Always check and obey any local laws or regulations which may affect

the locations where the RipRider 360˚ Caster T

rike may be used on public

property. The RipRider 360˚ Caster Trike is meant to be used only in

controlled environments free of potential traffic hazards and not on public

streets. Do not ride your RipRider 360˚ Caster Trike in any areas where

pedestrian or vehicle traffic is present.

Ride defensively. Watch out for potential obstacles that could force you to

swerve suddenly or lose control. Be careful to avoid pedestrians, skaters,

skateboards, scooters, bikes, children or animals who may enter your path,

and respect the rights and property of others.

Maintain a hold on the handlebars at all times.

Never carry passengers or allow more than one person at a time to ride the

RipRider 360˚ Caster T

rike.

Never use near steps or swimming pools.

Never use headphones or a cell phone when riding.

Never hitch a ride with another vehicle.

The RipRider 360˚ Caster T

rike is intended for use on solid, flat, clean and dry

surfaces such as pavement or level ground without loose debris such as rocks

or gravel. W

et, slick or uneven and rough surfaces may impair traction and

contribute to possible accidents. Do not ride the RipRider 360˚ Caster Trike

in mud, ice, puddles or water. Avoid excessive speeds that can be associated

with downhill rides. Never risk damaging surfaces such as carpet or flooring

by use of a RipRider 360˚ Caster Trike indoors.

Do not ride at night or when visibility is impaired.

P

ROPER RIDING ATTIRE

Always wear proper protective equipment such as an approved safety

helmet, elbow pads and kneepads. A helmet may be legally required by local

law or regulation in your area. Always wear shoes, never ride barefooted or

in sandals, and keep shoelaces tied and out of the way of the wheels.

F

AILURE TO USE COMMON SENSE AND HEED THE

ABOVE WARNINGS INCREASES RISK OF SERIOUS

INJURY. USE WITH APPROPRIATE CAUTION AND

SERIOUS ATTENTION TO SAFE OPERATION.

SAFETY WARNINGS

Safety Warnings ............................................................ 1

Before You Begin ........................................................... 2

Assembly and Set-Up ................................................. 3-4

Repair and Maintenance ................................................ 5

1

T

roubleshooting Guide ................................................... 5

R

ipRider 360˚ Caster Trike Parts .................................... 6

Safety Reminders .......................................................... 7

Warranty ........................................................................ 7

CONTENTS

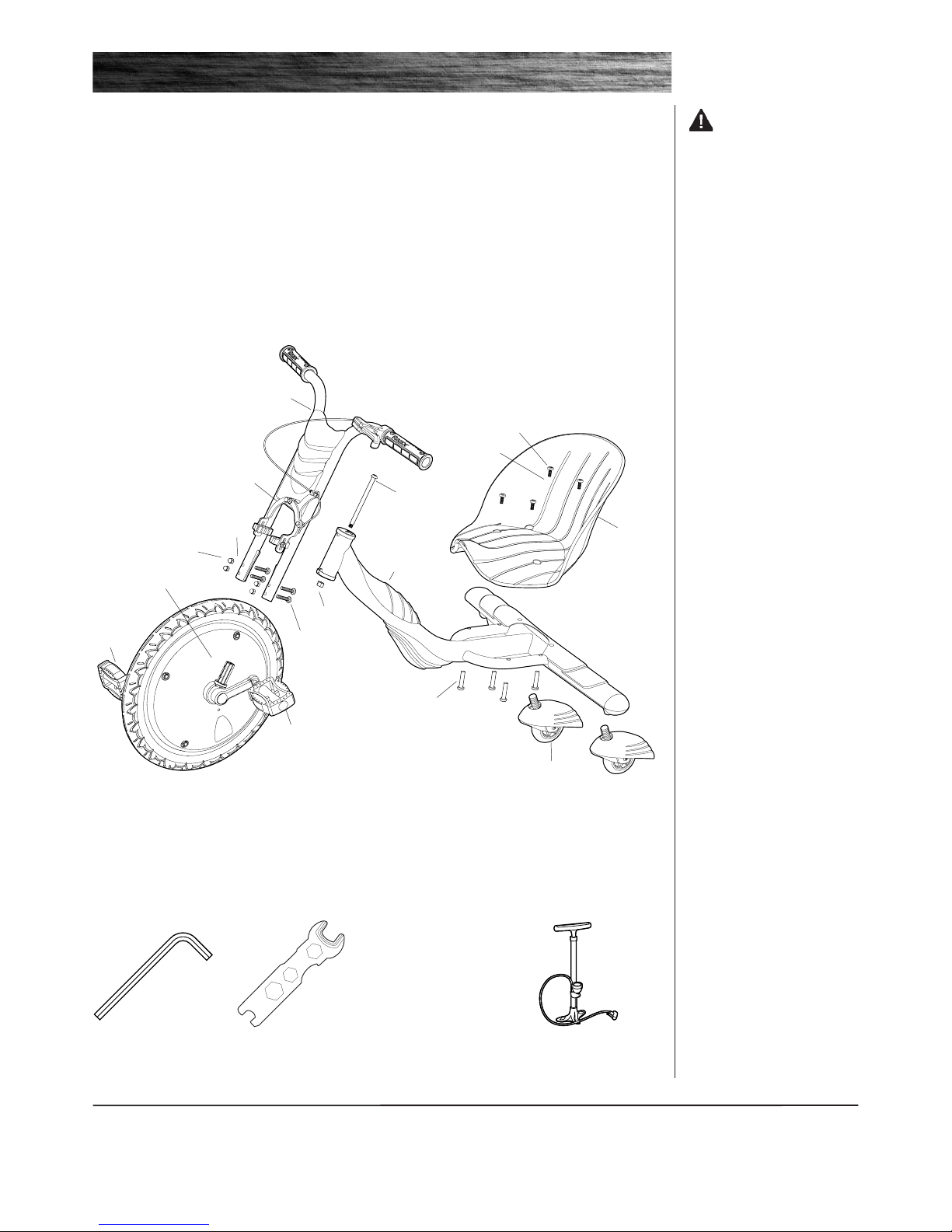

Remove contents from box and check parts against part diagram below. Remove the foam separators that protect the

components from damage during shipping. Inspect the contents of the box for scratches in the paint, dents or kinked

cables that may have occurred during shipping. Because the Rip Rider 360˚ was partially assembled and packed at the

factory

, there should not be any problems, even if the box has a few scars or dents.

❑ Estimated Assembly and Set-Up Time

Razor recommends assembly by an adult with experience in bicycle mechanics.

Allow up to 15–20 minutes for assembly.

BEFORE YOU BEGIN

2

WARNING: DO

NOT USE NON-RAZOR

PRODUCTS WITH YOUR

RIPRIDER 360˚.

The RipRider 360˚ has been built to

certain Razor design specifications.

The original equipment supplied at

the time of sale was selected on

the basis of its compatibility with

the frame, fork and all other parts.

Certain aftermarket products may

or may not be compatible.

❑ Required Tools

Some tools are supplied; however, we recommend the use of mechanic’s grade tools. Use the supplied tools only as a

last resort.

Need Help? Visit our web site for replacement parts, product support, live chat and a list of

authorized service centers at www.razor.com or call toll-free at 866-467-2967 Monday - Friday

8

:00 AM - 5:00 PM Pacific Time.

(2) 5mm

hexagonal key wrenches

(included)

Bicycle-style tire pump

for Schrader valve tires,

with pressure gauge

10mm, 13mm and 15mm

open end wrenches

(included)

Front Fork Assembly

Front Wheel Assembly

Seat

Rear Castor

Wheels

Steering Bolt

Front Caliper Brake

Locknut

Allen Socket Screw

W

asher

Allen Long Screw

Combinatory Nut

W

asher

Allen Socket Screw

Left Pedal

Right

Pedal

Frame

Assembly

3

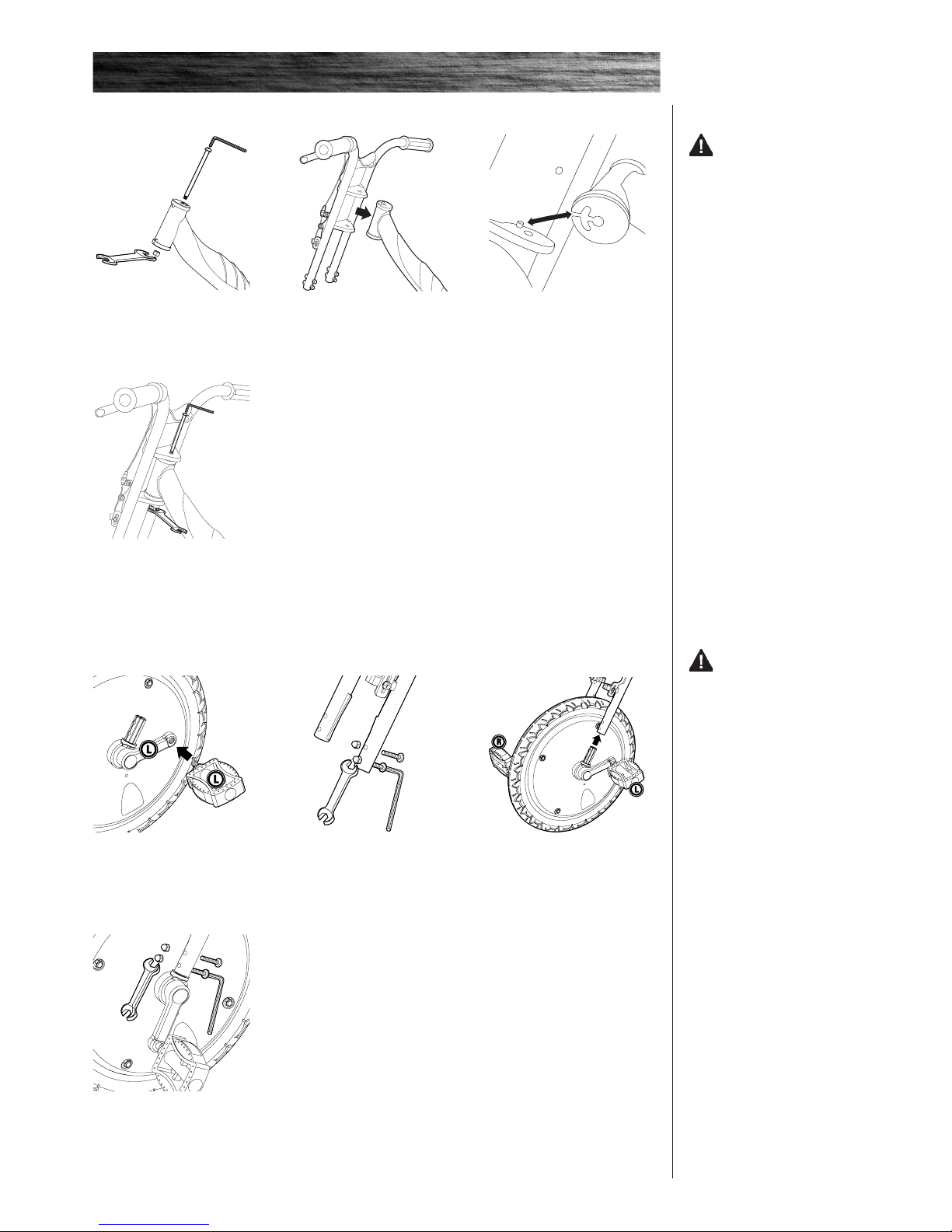

ASSEMBLY AND SET-UP

WARNING: Failing to

properly tighten the steering bolt

that attaches the handlebar can

cause you to lose control and fall.

2 Remove the four Allen socket

screws and nuts from the front

fork with a 10mm open wrench

and 5mm hexagonal wrench.

3 Insert the wheel assembly into

the front fork assembly and align

holes.

Note: Refer to R (right) and L (left)

stickers on pedals for orientation.

❑ Attaching the Pedals and Front Wheel

4 Re-insert the Allen socket

screws through the front fork and

secure with nuts. T

ighten nuts with

a 10mm open wrench and 5mm

hexagonal wrench.

1 Remove the steering bolt and

locknut from the frame assembly

with a 13mm open wrench and

5mm hexagonal wrench.

2 Insert the front fork assembly

into the frame assembly.

❑ Attaching the Front Fork

4 Re-insert the steering bolt and

secure with locknut using a 13mm

open wrench and 5mm hexagonal

wrench.

1 Install the left pedal into the

crank marked (L). Tighten with

15mm open end wrench. Repeat

step for right pedal and crank.

3 Be sure to align slot in headset

tube with pin on fork properly as

shown.

WARNING: Failing to

install the correct pedal on the

correct crank (left and right) can

cause the pedal to strip.

4

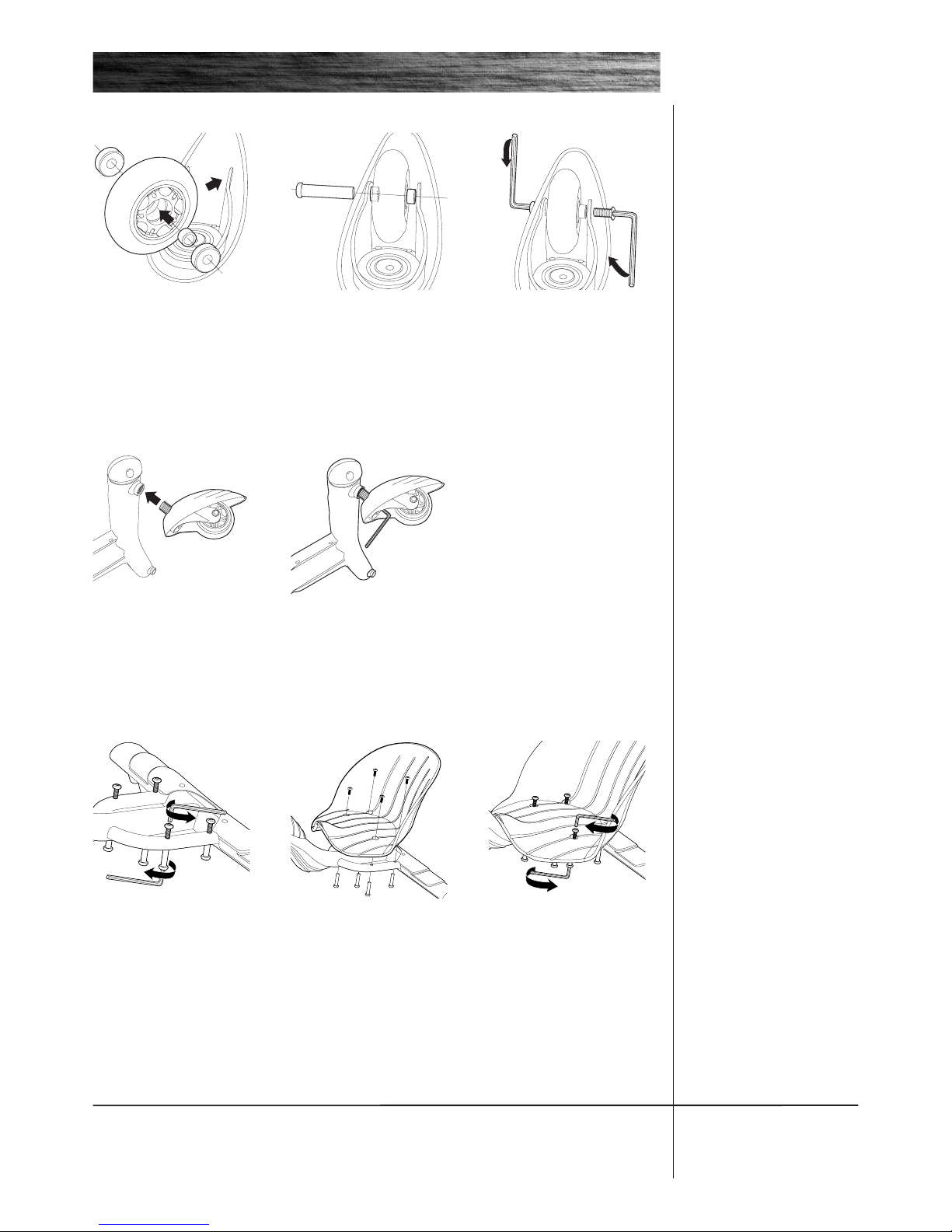

4 Locate the threaded hole

on the rear underside of frame.

Screw caster wheel into hole.

5 Tighten with 5mm hexagonal

wrench.

❑ Attaching the Rear Caster Wheels

1 Remove the four Allen socket

screws and Allen long screws

from the frame with two 5mm

hexagonal wrenches. One on top

and one on bottom.

2 Align four holes in seat with

four holes in frame. Insert Allen

long screws through the bottom of

the frame.

❑ Attaching the Seat

ASSEMBLY AND SET-UP

3 Secure with Allen socket

screws. Tighten screws with two

5mm hexagonal wrenches. One on

top and one on bottom.

2 Insert one small spacer between

wheel and caster and align holes.

Insert axle bolt through caster

, small

spacer, wheel and into small spacer

on other side of wheel.

Need Help? Visit our web site for replacement parts, product support, live chat and a list of

authorized service centers at www.razor.com or call toll-free at 866-467-2967 Monday - Friday

8

:00 AM - 5:00 PM Pacific Time.

3 Insert Allen socket screw

through caster, small spacer and

into axle bolt. Tighten with 5mm

hexagonal wrench on both sides.

1 Insert large spacer into wheel

and insert bearings into each side

of wheel. Make sure all holes are

aligned. Insert wheel into caster

.

Vehicle runs sluggishly

Vehicle does not stop when

applying the brake

P

roblem Possible Cause Solution

Front tire is not properly inflated

Brake is not adjusted properly

The tire is infl

ated when shipped, but it will invariably will lose some

pressure between the point of manufacturing and your purchase.

Refer to tire inflation instructions above.

Refer to adjusting the brakes instructions above.

TROUBLESHOOTING GUIDE

5

REPAIR AND MAINTENANCE

1 Slide the panel on the wheel

cover to the side to expose

tire valve.

Note: The pressurized air supplies

found at gasoline stations are

designed to inflate high-volume

automobile tires. If you decide to

use such an air supply to inflate

your RipRider 360˚ Caster T

rike tire,

first make sure the pressure gauge

is working, then use very short

bursts to inflate to the correct PSI.

If you inadvertently over

-inflate the

tire, release the excess pressure

immediately.

Check the Razor web site for any updates on the latest repair and maintenance procedures.

❑ Inflating the Tires

The front tire is inflated when shipped, but it will invariably lose some pressure between the point of manufacturing

and your purchase.

2 Use a bicycle style tire pump

equipped for a Schrader-type valve.

❑ Adjusting the Brakes

1 To adjust the brake play, thread

the brake lever adjuster in or out 1/4

to 1/2 turn until the desired brake

adjustment is attained. Most

adjustments are complete at this

step. If brake still needs further

adjustment, proceed to step 2.

2 If the brake lever adjuster is

threaded outward and the brake

still has too much slack, use the

front caliper brake adjuster for

additional adjustment.

3 Inflate the front tire to the lbs.

indicated on the sidewall of tire.

3 If brake still has too much slack,

adjust the brake cable by loosening

the nut that secures the cable with

a 10mm wrench. Pull the brake

closed so the pads almost touch

the wheel. Pull cable tight and

tighten the nut.

Loading...

Loading...