Page 1

PO Box 1 Ilkley West Yorkshire LS29 8EU

Phone: 01943 602001 Fax: 01943 816796

n

Phone: 01943 602001 Fax: 01943 816796

Website: www.issltd.co.uk Email: sales@issltd.co.uk

i

nstrumentation

Systems & Services

ThermoView Ti30

User’s Manual

Ltd

July 1, 2003

Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 2

CONTENTS

Introduction..................................................................................................................... 7

Quick Specifications Table............................................................................................. 8

Chapter 1 Unpacking Your New Imager ................................................... 9

First, the Batteries ......................................................................................................... 10

Charging the Rechargeable Battery Pack ..................................................................... 12

Normal Charge Cycle ............................................................................................... 12

Chapter 2 Getting Started.......................................................................... 14

Attaching the Wrist Strap.............................................................................................. 14

Turning the Unit On...................................................................................................... 15

Displaying Images ........................................................................................................ 15

Settings and Controls .................................................................................................... 18

Keypad ...................................................................................................................... 18

Laser On/Off Toggle Button..................................................................................... 20

Centigrade/Fahrenheit Toggle Button....................................................................... 22

LCD Backlight Illumination Switch ......................................................................... 22

Palette Switch............................................................................................................ 22

Measurement Mode Switch ...................................................................................... 22

Gain and Level Thumbwheels .................................................................................. 23

Focus Wheel.............................................................................................................. 23

Trigger....................................................................................................................... 24

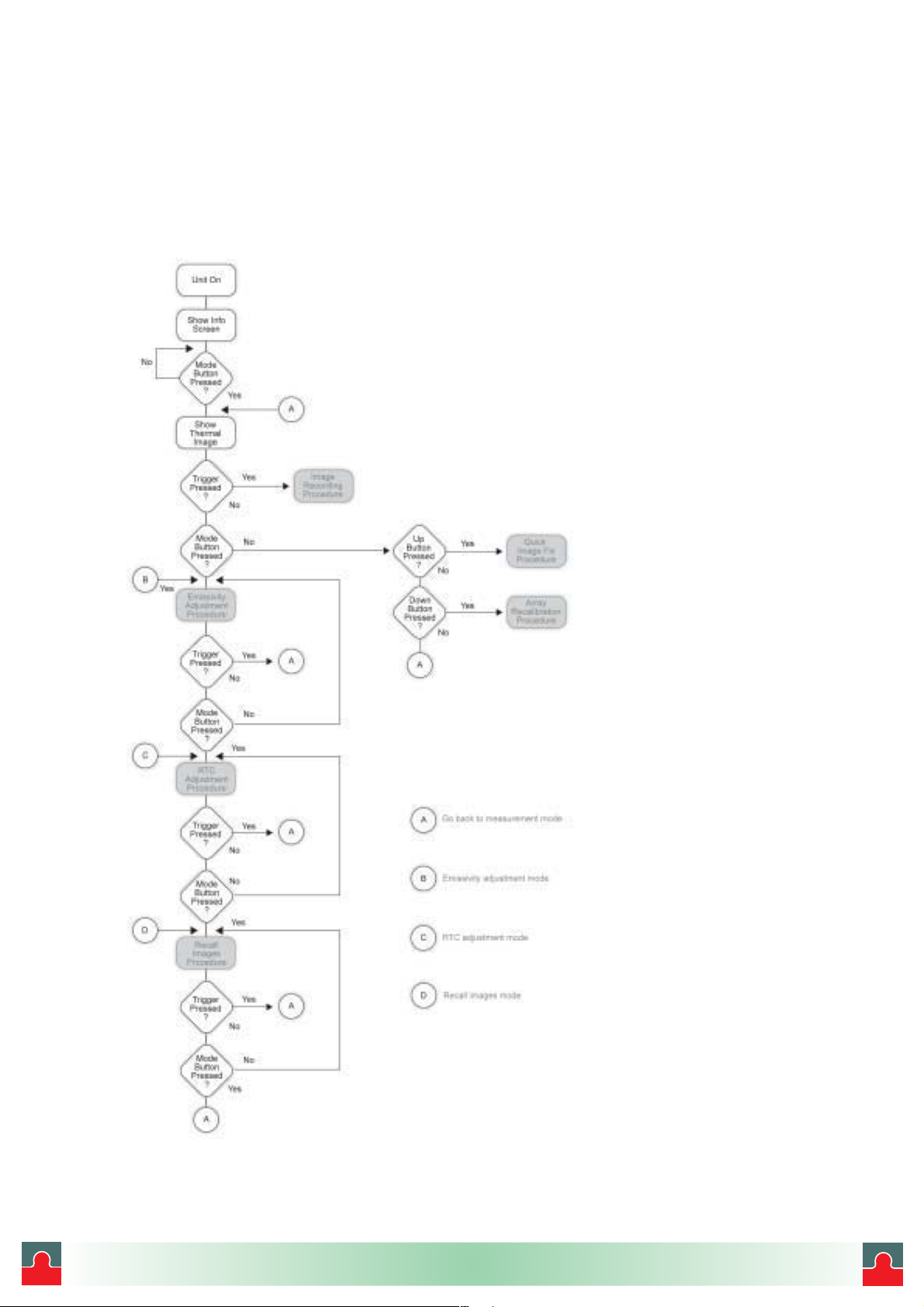

Man Machine Interface Flow Charts ............................................................................ 25

Main Loop................................................................................................................. 25

Image Recording Procedure...................................................................................... 26

Emissivity Adjustment Procedure............................................................................. 26

Reflected Temperature Compensation Adjustment Procedure................................. 27

Recall Images Procedure........................................................................................... 27

Quick Image Fix Procedure ...................................................................................... 28

Array Recalibration Procedure ................................................................................. 28

Recording an Image ...................................................................................................... 28

Retrieving an Image...................................................................................................... 29

Chapter 3 Downloading and Looking at Images ..................................... 30

Installing the Software .................................................................................................. 30

Connecting the Docking Station to Your Computer..................................................... 31

Hooking Up the Docking Station.............................................................................. 31

Downloading Images .................................................................................................... 34

Saving Images............................................................................................................... 35

Setting the Imager Clock .............................................................................................. 36

Field USB Port.............................................................................................................. 38

July 1, 2003 - 2 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 3

Looking at Your Downloaded Images.......................................................................... 38

Chapter 4 Obtaining the Best Image ........................................................ 41

The Importance of Focusing ......................................................................................... 41

Selecting the Color Palette............................................................................................ 42

Selecting the Measurement Mode................................................................................. 42

Gain and Level Thumbwheels .................................................................................. 45

Chapter 5 Qualitative and Quantitative Temperature Measurements 46

Distance to Target (Spot) Ratio .................................................................................... 46

D:S ratio: D / S = 90 ................................................................................................. 47

Optical Diagram........................................................................................................ 47

Field-of-View................................................................................................................ 47

Environmental Conditions ............................................................................................ 48

Ambient Temperatures.................................................................................................. 48

Emissivity ..................................................................................................................... 49

Reflected Temperature Compensation.......................................................................... 49

Chapter 6 Organizing Your Data.............................................................. 51

File Management .......................................................................................................... 51

Uploading Data to the Imager................................................................................... 52

Chapter 7 Analyzing Your Data................................................................ 55

The Single Image Screen .............................................................................................. 55

Scale Limits .............................................................................................................. 55

Isotherms................................................................................................................... 57

Additional Image Analysis Tools ............................................................................. 58

The Temperature Table Tab...................................................................................... 58

The Profile Tab ......................................................................................................... 59

The Histogram Tab ................................................................................................... 60

The Menu Bar ........................................................................................................... 61

File ........................................................................................................................ 61

Temperature Scale ................................................................................................ 62

Palette.................................................................................................................... 62

Image..................................................................................................................... 63

Window................................................................................................................. 64

Help....................................................................................................................... 64

Reporting Your Findings .............................................................................................. 65

Appendix A - Technical Reference............................................................ 66

Imager Accuracy Chart................................................................................................. 66

Imager Reading Error vs Source D:S............................................................................ 67

Typical Emissivity Values ............................................................................................ 67

July 1, 2003 - 3 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 4

Appendix B – Infrared Theory Q&A........................................................ 71

Glossary ....................................................................................................... 75

July 1, 2003 - 4 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 5

© 2003 Raytek Corporation.

The information contained in this document is subject to change without notice.

Raytek and the Raytek logo are registered trademarks and ThermoView and InsideIR are

trademarks of Raytek Corporation. Windows is a registered trademark of Microsoft

Corporation in the United States and/or other countries. Pentium is a registered trademark

of Intel Corporation or its subsidiaries in the United States and other countries. All other

trademarks are the property of their respective holders.

Warranty Information

Raytek warrants this product to be free from defects in material and workmanship under

normal use and service for a period of one year from date of purchase, except as hereinafter

provided. This warranty extends only to the original purchaser (a purchase from Raytek or

Raytek-licensed distributors is an original purchase).

The warranty shall not apply to any product that has been subject to misuse, neglect,

accident, or abnormal conditions of operation or storage. In the event of failure under

warranty, return this product to the distributor or retailer from whom it was purchased for

replacement or repair at manufacturer’s discretion. Purchaser’s exclusive remedy under

warranty shall be replacement, repair, or refund of the purchase price. This warranty shall

not apply to batteries.

The foregoing warranty is in lieu of all other warranties, expressed or implied, including but

not limited to any implied warranty of merchantability, fitness, or adequacy for any particular

purpose or use. Raytek shall not be liable for any special, incidental, or consequential

damages, whether in contract, tort, or otherwise.

July 1, 2003 - 5 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 6

Customer Service Contact Information

Instrumentation Systems & Services Ltd

P.O. Box 1

ILKLEY

West Yorks

LS29 9QE UK

July 1, 2003 - 6 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 7

Introduction

The Raytek ThermoView Ti30 imager is a state-of-the-art, lightweight, gun-grip

style thermal imaging unit that lets you obtain instant and accurate thermal images

and radiometric readings at a remote distance from your target. Ergonomically

designed for either left or right-handed use, the ThermoView imager captures

thermal images and data with a simple click of the trigger. The unit can store up to

100 images that can then be downloaded to your personal computer where the

images can be stored, evaluated further or added to reports and presentations.

The ThermoView’s docking station allows effortless connection to a host computer,

and offers rapid data downloading and uploading. The docking station also

automatically recharges the (rechargeable) batteries when the unit is not in use.

The companion software application, InsideIR, included with the imager lets you

display, examine, and analyze your images and data to discover qualitative and

quantitative trends associated with the target. InsideIR software allows you to define

maintenance databases based on your specific equipment condition, monitoring, and

asset management needs.

The ThermoView imager contains 100 image storage locations that can also be

predefined with unique equipment data and parameters. Notes and comments can

also be included for the technician performing the given maintenance routine.

Maintenance reports and follow-up actions can be created quickly and accurately

using information carried over from image files. Reports can be easily printed or sent

electronically.

Using the ThermoView imager’s structured database, maintenance professionals can

ensure consistent, repeatable measurements over time. They can efficiently and

accurately communicate with co-workers, management, equipment manufacturers,

and service providers by incorporating thermal images in emails and reports. In

addition, customers can easily create permanent inspection records indicating

temperature behavior before and after repairs, and monitor thermal trends over long

periods.

We are confident the ThermoView Ti30 imager is both an easy-to-use, yet powerful,

thermal imaging tool on the market today. We know you will find it a valuable and

indispensable tool for your workplace and for your professional growth.

July 1, 2003 - 7 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 8

Quick Specifications Table

p

Thermal Measurement Range 0 to 250°C (32 to 482°F)

Accuracy ±2% or ±2°C, whichever is greater at calibration geometry and 25°C

Repeatability ±1% or ±1°C, whichever is greater

NETD 250 mK

Thermal

Temperature Indication Resolution 0.1 (°F or °C)

Spectral Range 7-14 microns

Target Sighting Single Laser Dot (Meets lEC Class 2 & FDA Class II requirements)

Optical Resolution 90:1

Minimum Diameter Measurement Spot 7mm (0.27”) at 60cm (24”)

Image Frame Rate 20Hz

Optical / IR

Field of view (FOV) 17° Horizontal x 12.8° Vertical

Instantaneous Field of view (IFOV) 1.9mrad

Focus Focusable, 61 cm / 24” to infinity

Temperature Scale °C or °F selectable

Palettes Gray, Ironbow, or Rainbow selectable

Measurement Modes Automatic, Semi-Automatic, or Manual selectable

Laser On/Off

Controls

Gain Control

Level Control

LCD Backlight Bright, Dim, Off selectable

Adjustable Emissivity

(0.10 to 1.00 by 0.01)

Display Type Liquid Crystal Display - TFT technology optimized for both indoor and

Reflected Background Temperature -50 to 460°C (58 to 860°F)

Ambient Operating Temperature 0 to 50°C (32 to 122°F)

Relative Humidity 10 to 90% Non-condensing

Storage Temperature -25 to 70°C (-13 to 158°F) [without batteries]

Storage Capacity

Laser On Icon

Operational

Low Battery Icon

Palette Icon

Measurement Mode Icon

Thermal Analysis Software InsideIR (included)

PC Software Operating Systems Microsoft® Windows® 98, Windows 2000 or Windows XP

Power 6 AA batteries(not included) or rechargeable battery pack (included)

Battery Life Min. 5 hours continuous use

Data Transfer USB interface, total transfer time up to 30s for 100 pictures

Storage Device Flash Memory

Electrical

9

9

9

9

outdoor use

✑✐✐ ❉❍❁❇❅▲

9

9

9

9

Tripod Mount

Other

Accessories /

(6.35 mm (1/4) 20 unc threading)

Weight (includes batteries) 1kg (2.2 lb)

Standard Accessories • Multi-language Interactive Manual (CD ROM) • InsidelR Software •

tions

O

Options NIST Calibration certificate

9

Docking station with Universal Power Adapter and USB Connection •

Hardshell Carry Case • USB Computer Cable • Rechargeable and

Non-rechargeable Battery Packs (batteries not included) • Multi

Language Thermography Training Presentation (CD ROM) • Carrying

Pouch • Wrist Strap • Quick Reference Card

July 1, 2003 - 8 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 9

Chapter 1 Unpacking Your New Imager

Begin by opening the shipping box. Be sure to save the box and shipping materials in

the event you need to ship the imager.

In the shipping box, you will find a hard carrying case, containing the following

items:

x 1 ThermoView Ti30 Imager x 1 Quick Reference Card

x 1 ThermoView Imager Docking

Station

x 1 Universal power supply and plug

adapters

x 1 CD ROM containing multi-

language training materials

x 1 CD ROM containing InsideIR¥

software and multi-language

interactive manual

x 1 Carrying pouch and 1 Wrist Strap

x 1 USB Cable

x 1 rechargeable battery pack

x 1 battery pack for 6 AA non-

rechargeable batteries (batteries not

included)

July 1, 2003 - 9 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 10

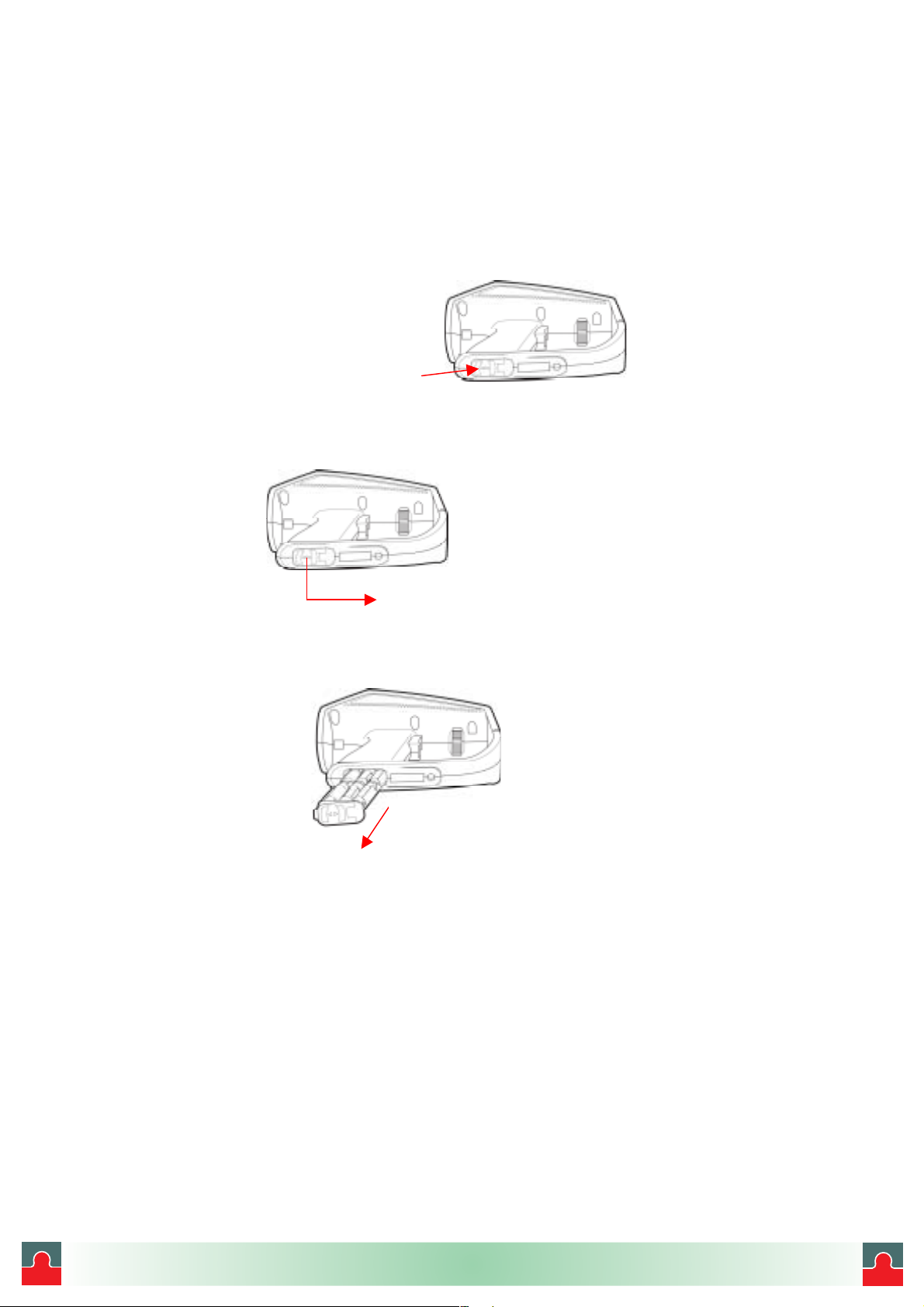

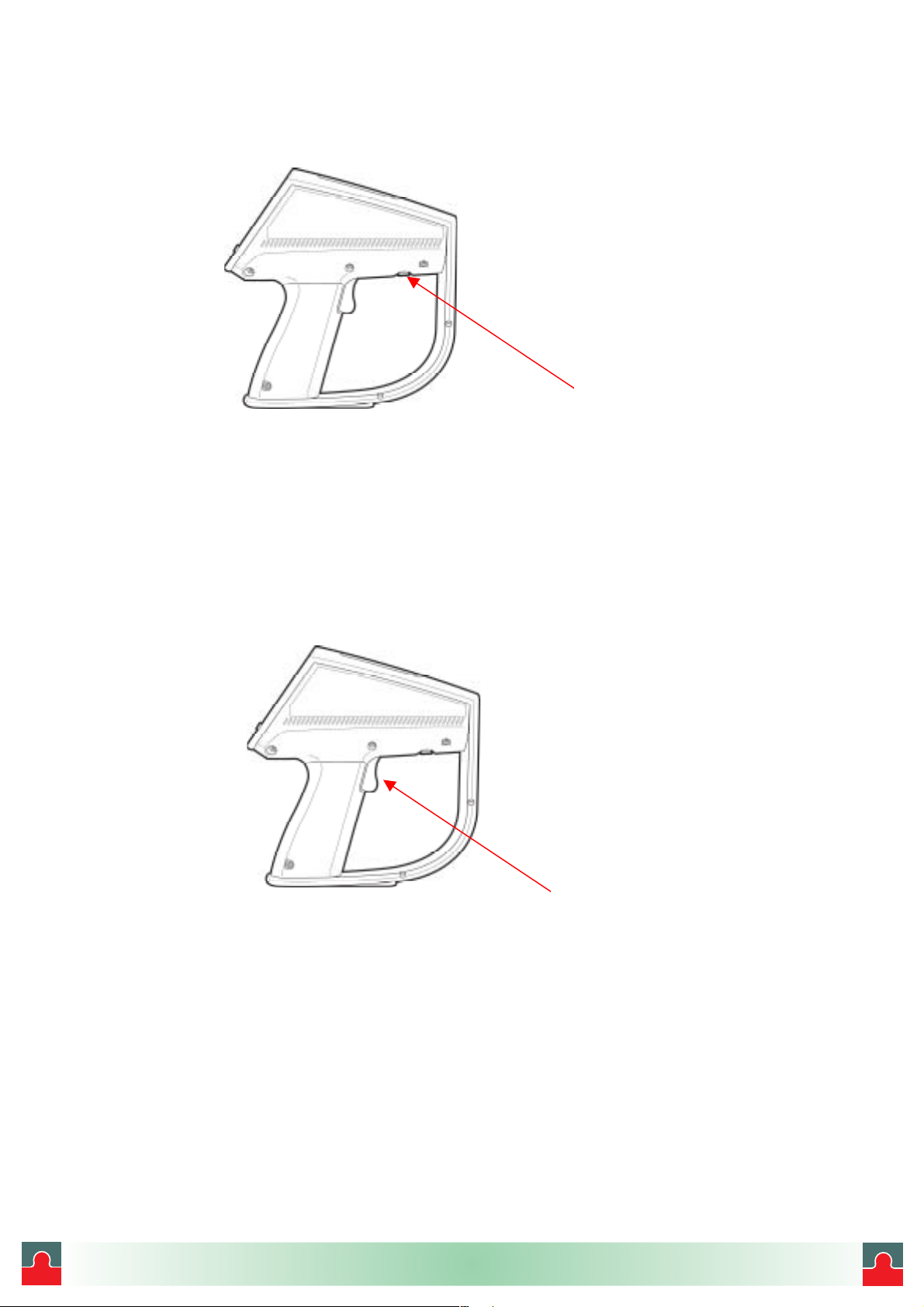

First, the Batteries

The battery compartment is located in the handle of the unit.

The unit is shipped with an empty battery pack for non-rechargeable batteries installed in the

battery compartment.

Battery Lock Tab

Remove the empty battery pack from the battery compartment.

The battery pack can be removed by sliding the lock tab towards the trigger.

Move the lock tab in this direction

Once the lock is released, the battery pack will slide down. Tilt the top of the unit up to slide

the battery pack out.

Battery pack slides out

(AA batteries not included)

Figure 1. Removing the Battery Pack

July 1, 2003 - 10 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 11

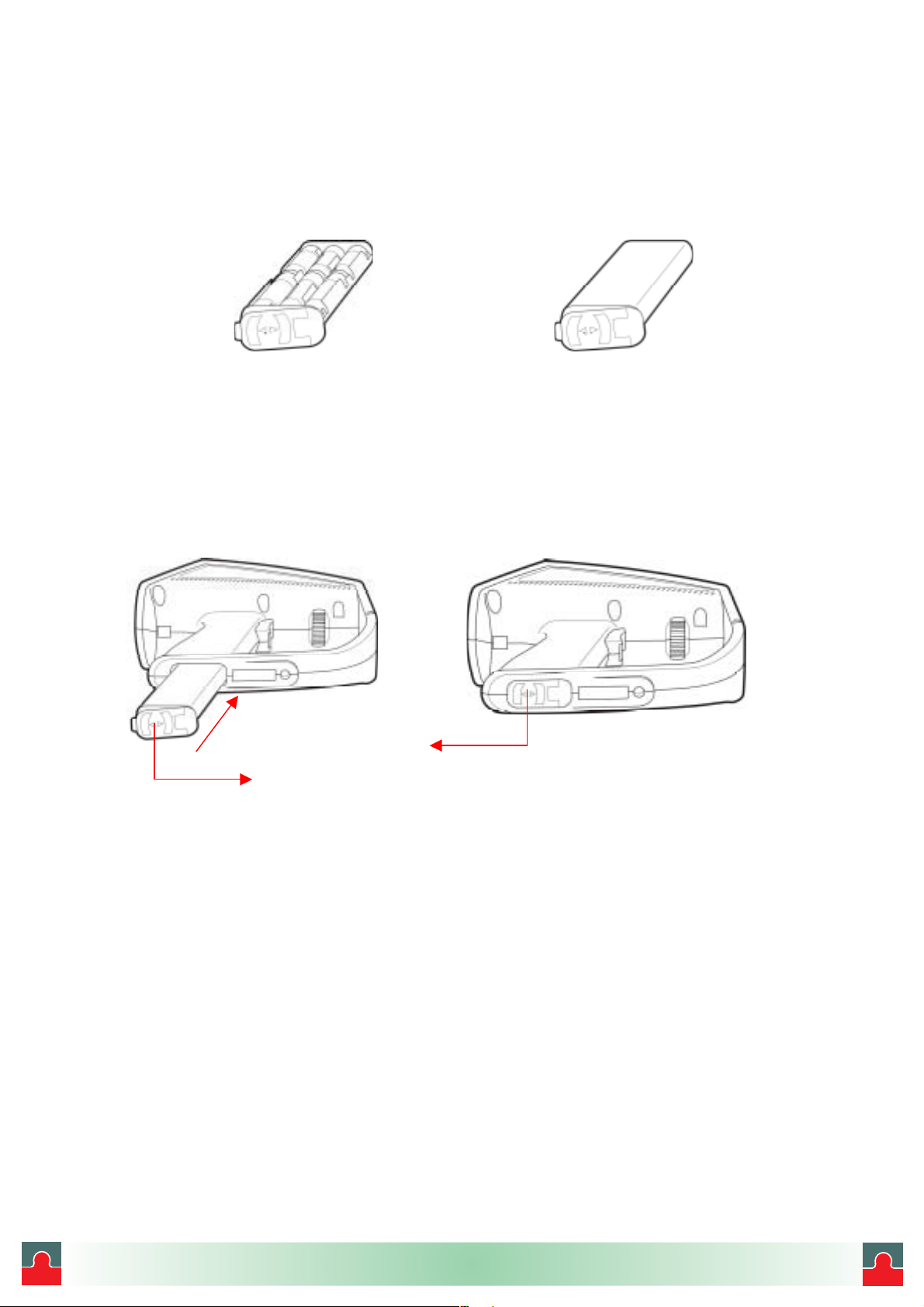

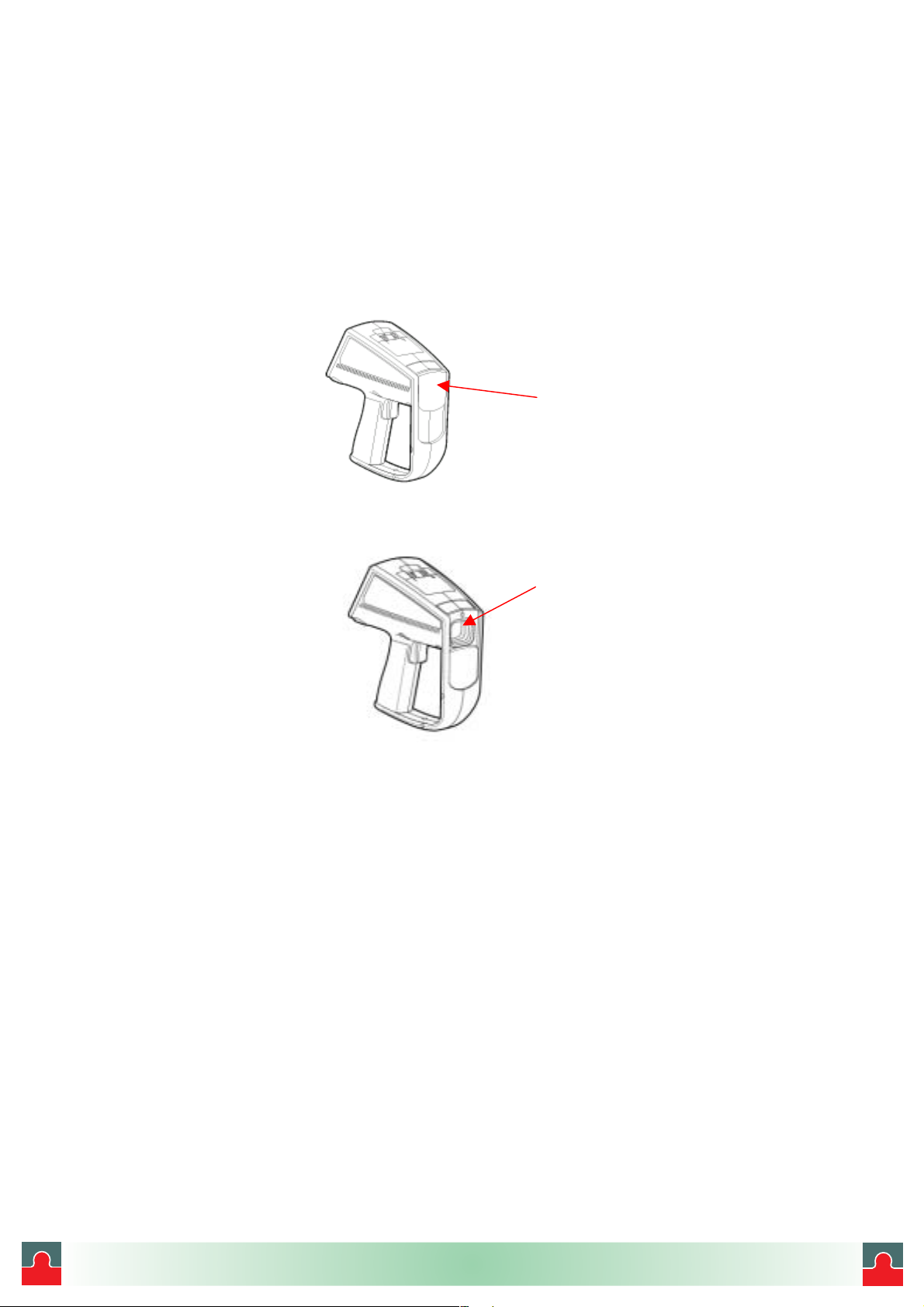

At this point, you have two options: insert six new AA batteries into the empty nonrechargeable batteries pack or replace it with the supplied rechargeable battery pack. You will

notice the difference between the two battery packs as shown in Figure 2 below:

Non-rechargeable battery pack

(batteries not included)

Figure 2. Battery Packs

To replace the battery pack just slide it back in, making sure the plastic tab lock is in the

unlocked position (to the right of the pack). Use the rails on battery pack as guides. Once it

is inserted, slide the lock tab back into the locked position as shown below in Figure 3.

Battery pack slides in

Move the lock tab back to the locked position

Keep the lock tab in the unlocked position

Figure 3. Installing Batteries

Rechargeable battery pack

July 1, 2003 - 11 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 12

Charging the Rechargeable Battery Pack

Connect the docking station to a power

outlet using the supplied universal

power adapter. Be sure to use the plug

adapter that fits your local electrical

standards. Connect the power jack of

the power adaptor to the DC power

inlet located on the docking station.

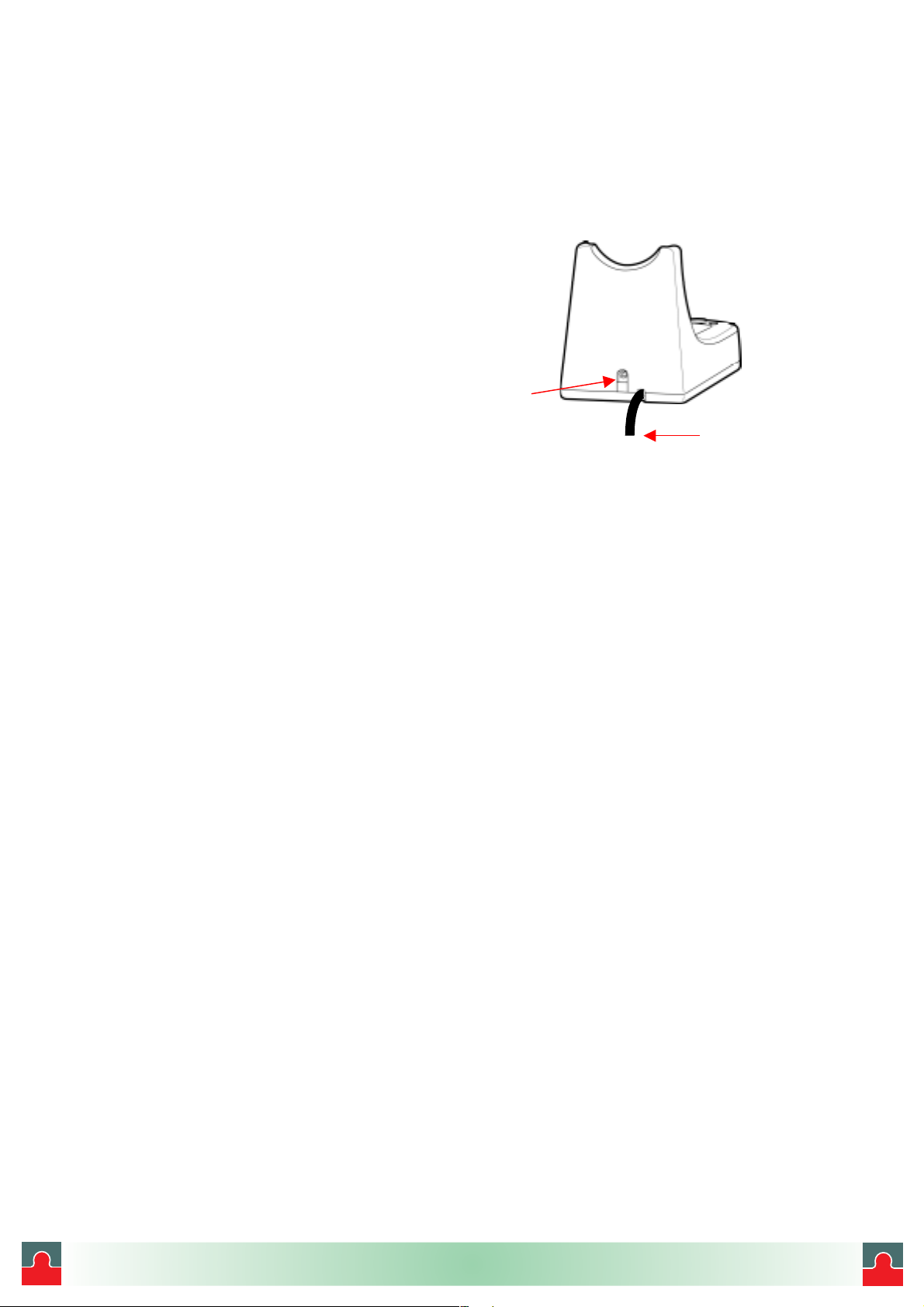

DC Power inlet

Docking Station

USB cable

Normal Charge Cycle

x With the ThermoView unit powered off, place it on the docking station.

x Do not connect the USB cable to the computer at this point.

x The red LED (on the left) will flash several times as the circuit senses a rechargeable

battery pack and determines its state of charge.

Note:

The remaining points assume that the imager contains a sealed, rechargeable battery pack.

x The red LED turns on continuously to indicate that charging is in progress. This process

x The red LED turns off once the battery pack is fully charged and the green LED (on the

x Momentarily lifting the ThermoView unit from the docking station for about 5 seconds

x The imager may be removed from the docking station before recharging is completed

x An imager containing single-use batteries may safely be placed on the docking station for

If a non-rechargeable battery pack is sensed by the docking station, neither LED

will blink.

can take from a few minutes to more than an hour.

right) turns on continuously.

or longer interrupts the charging process. The green light will come on and no further

charging will occur. Press the Restart / Sync button between the LEDs to resume

charging. Pressing the button if the batteries are completely charged will have no effect.

without harm. However, the imager may not be fully charged and its operating time may

be reduced accordingly.

storage or image transfer. In fact, we recommend the imager always be placed on the

docking station when not in use.

July 1, 2003 - 12 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 13

A charge cycle takes a rechargeable battery pack from whatever level of charge it presently

has and brings it to a fully charged condition. The charger will not over-charge a battery pack

no matter how many times the button is pushed.

RED

ght

li

Restart / Sync button

Figure 4. Docking Station LED Indicators

Note:

Once the batteries are charged, you are ready to begin taking thermal images and

temperature measurements. Take a moment now to read the next section and become

acquainted with the basic features and controls of the imager.

July 1, 2003 - 13 - Version 1.0

You may download stored images from the ThermoView imager to a personal

computer if the docking station’s USB cable is connected to a computer running

the InsideIR software. Press the Restart / Sync button to transfer stored images to

the computer (see Chapter 3 Downloading and Looking at Images for details).

Pressing the Restart / Sync button also starts the charging cycle.

GREEN

light

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 14

Chapter 2 Getting Started

Your ThermoView imager has settings and capabilities that let you customize its

operation for the task at hand. The following section describes each setting on the

imager.

Attaching the Wrist Strap

Your ThermoView imager comes with a wrist strap, which can be attached by

clipping the metal part of the strap to the small metal bar at the base of the imager

(see Figure 5 below).

Attach wrist strap

Figure 5. Attaching the Wrist Strap

July 1, 2003 - 14 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 15

Turning the Unit On

Power is switched on or off by opening or closing the lens door. Sliding down the

lens door turns the imager on (see Figure 6 below). Slide the door up to turn off the

imager.

Closed

Off

(Unit

Open

(UnitOn)

)

Figure 6. Powering the ThermoView Imager On and Off

Note:

Important:

The unit is self-protected against excessive levels of infrared radiation and it will

cause the unit to automatically shut down. If that happens, slide the lens door

closed, wait a minute and slide it open again.

Always dock the imager in the docking station when not in use. By doing so,

you will assure the batteries will be always fully charged when using the

rechargeable battery pack. The image will not show thermal images or

respond to controls while it is in the docking station.

Displaying Images

The ThermoView imager performs an initial auto-check each time it is activated and then

immediately shows the Information Screen. The Information Screen displays the

following information about the ThermoView imager unit:

July 1, 2003 - 15 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 16

x Unit Serial Number

x Date and Time (configured by the user through the software)

x Tag name is the name of the user-defined folder from which data was uploaded

through the software. Useful tag names are department names or area associated

with the unit. This space is blank until configured by the user.

x Station is the name of the networked computer associated with a specific unit. This

is blank until configured by the user.

x Palette is the type of palette currently selected

x Firmware revisions

x Icons for LCD illumination, palette type, measurement mode and laser status

Figure 7. The Information Screen

Press the MODE button to exit the Information Screen. (Refer to Figure 9, the MODE

button is located center, below the LCD screen.) The ThermoView imager immediately goes

into measurement mode, showing a real time thermal image of what is in front of the lens. A

reticle with a crosshatch at the center of the display shows the temperature spot.

Note:

Do not change any of the settings yet. User configurable parameters will be

explained later in Figure 31.

July 1, 2003 - 16 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 17

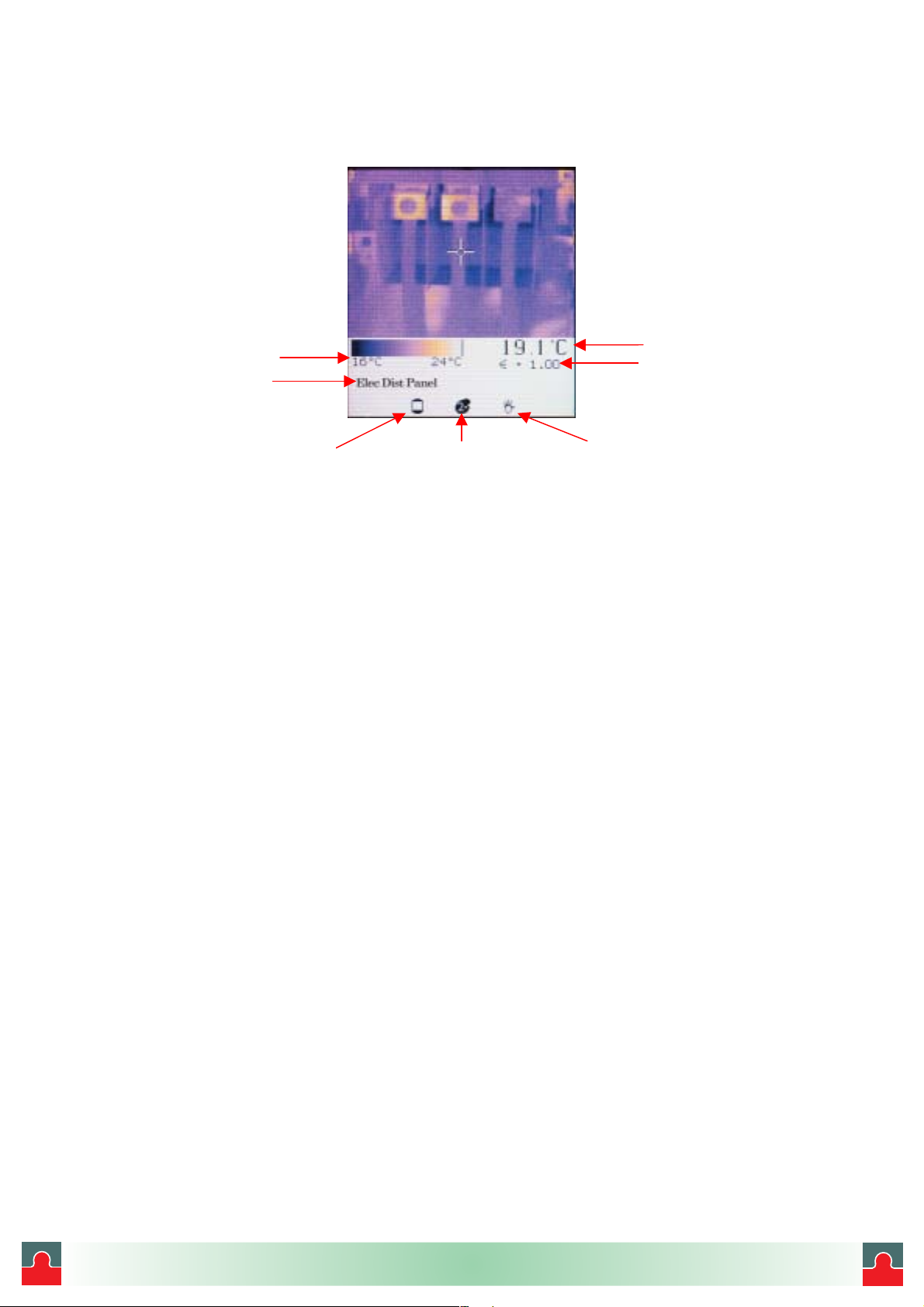

Temperature scale

Location name

Mode icon Palette iconLCD backlight icon

Figure 8. Normal Mode

Take time to experiment with the imager and become familiar with how the thermal image is

updated on the display as you aim the imager at different targets with different thermal

patterns. Notice how images display in varying colors, which are related to the different

target temperatures. The color scale at the bottom of the thermal image shows the minimum

and maximum temperature value in the thermal scene at any moment. These values will

change as you point the imager at other targets, or if the temperatures of the current target

change. The sequence or progression of different colors along the color scale indicates the

distribution of the different temperatures on the thermal scene. Notice how the colors along

the beginning of the color scale represent lower temperatures and colors along the end of

the color scale represent higher temperatures.

Target Temperature

Emissivity value

Note:

The ThermoView imager settings can be customized for your particular application. The

following sub-section reviews the settings and controls.

July 1, 2003 - 17 - Version 1.0

At this point you probably have noticed that the image freezes briefly from time to

time while an hourglass icon is briefly displayed. This is a normal process that

happens when the unit momentarily shuts down the optical channel to eliminate

offset errors. This is a recalibration sequence that begins immediately after the unit

is turned on. Recalibration occurs at 5 seconds, then 10 seconds, then 20 seconds,

then 30 seconds and then finally at every other minute. It is a good idea to keep the

unit On if you are using it constantly over a period of time to avoid resetting the

recalibration procedure counter.

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 18

Settings and Controls

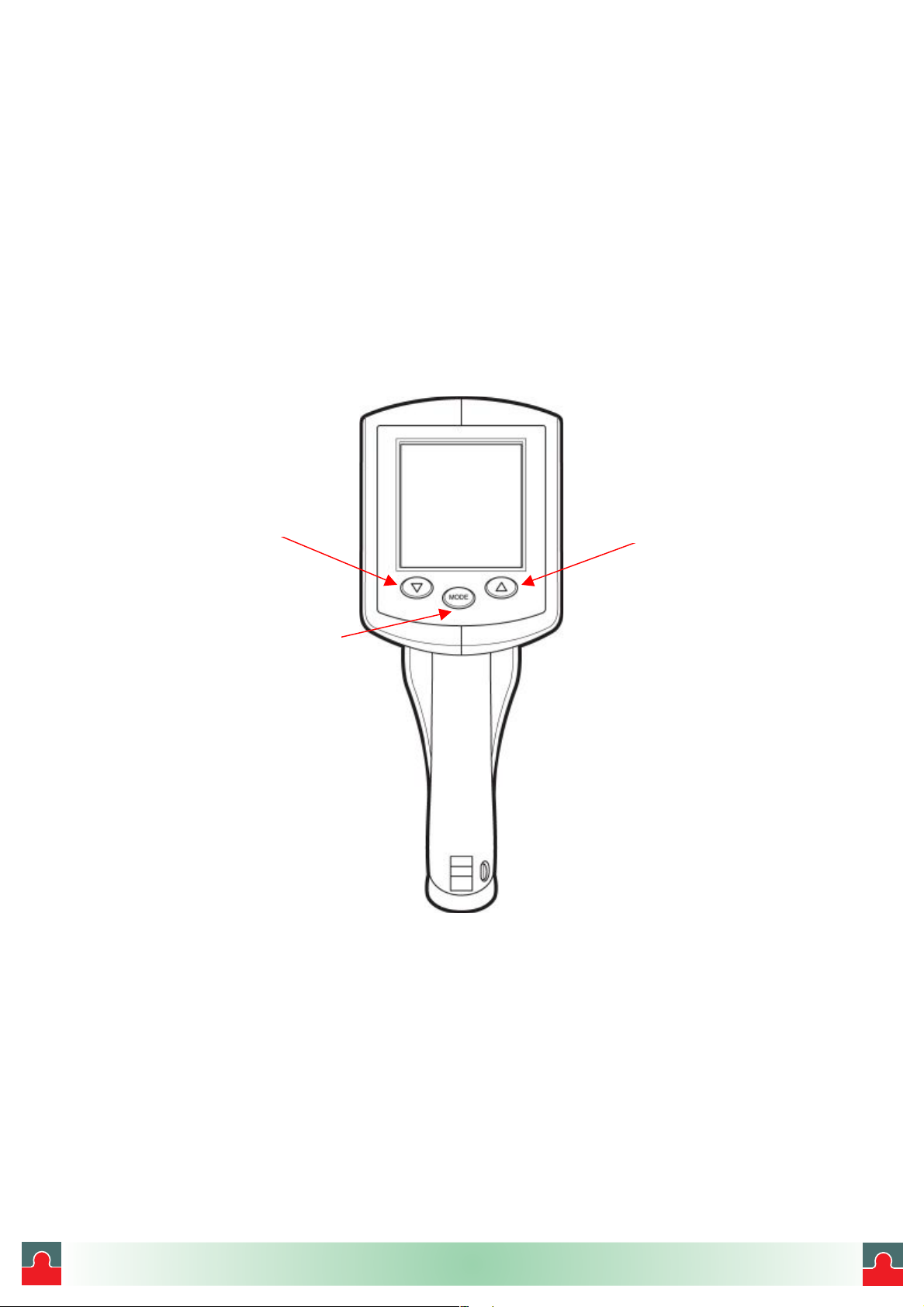

Keypad

Three buttons located below the LCD screen allow you to select operation modes and

change parameter values. These buttons are the MODE button, the Up button, and the

Down button. The Up and Down buttons are used mostly to increment and decrement

parameter values. They activate some special functions as well. The MODE button is used

mostly to cycle between the different operations. Details about the function of each button

are discussed later.

Down

button

Up

button

MODE

Figure 9. Keypad Controls

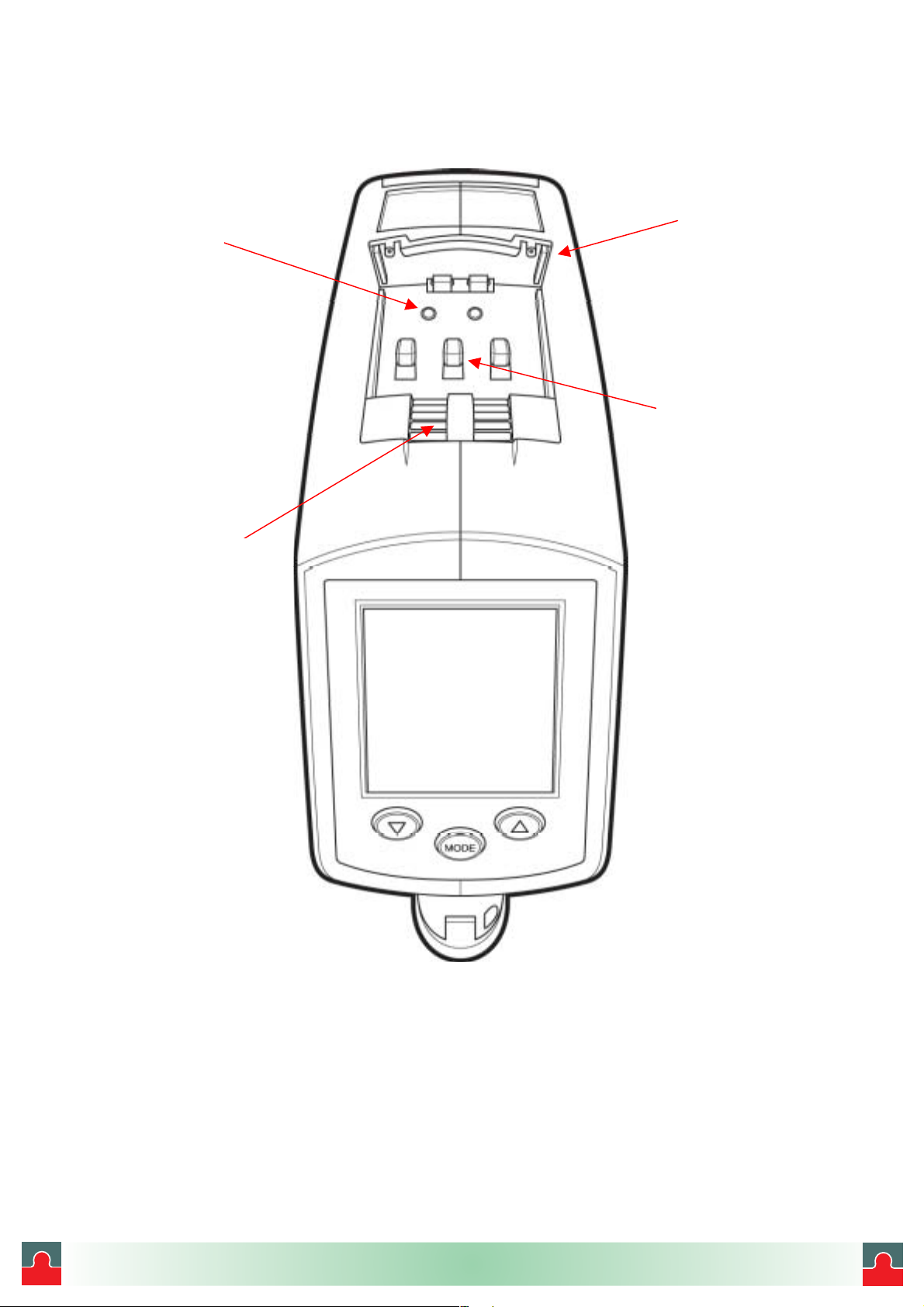

A hinged door on the top surface of the ThermoView imager hides five switches that allow

you to change the basic imager settings. Open the hinged door by lifting it up.

button

July 1, 2003 - 18 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 19

Push buttons

(toggle)

Thumbwheels

Pull door up to

show control

switches

3-position

Switches

Figure 10. ThermoView Imager Settings Switches (icons not shown)

The illustration below shows the top view of the switch bay without the door. There is an

icon printed near each switch and near each switch position indicating the function of each

switch and switch position. These functions are explained in the next paragraphs.

July 1, 2003 - 19 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 20

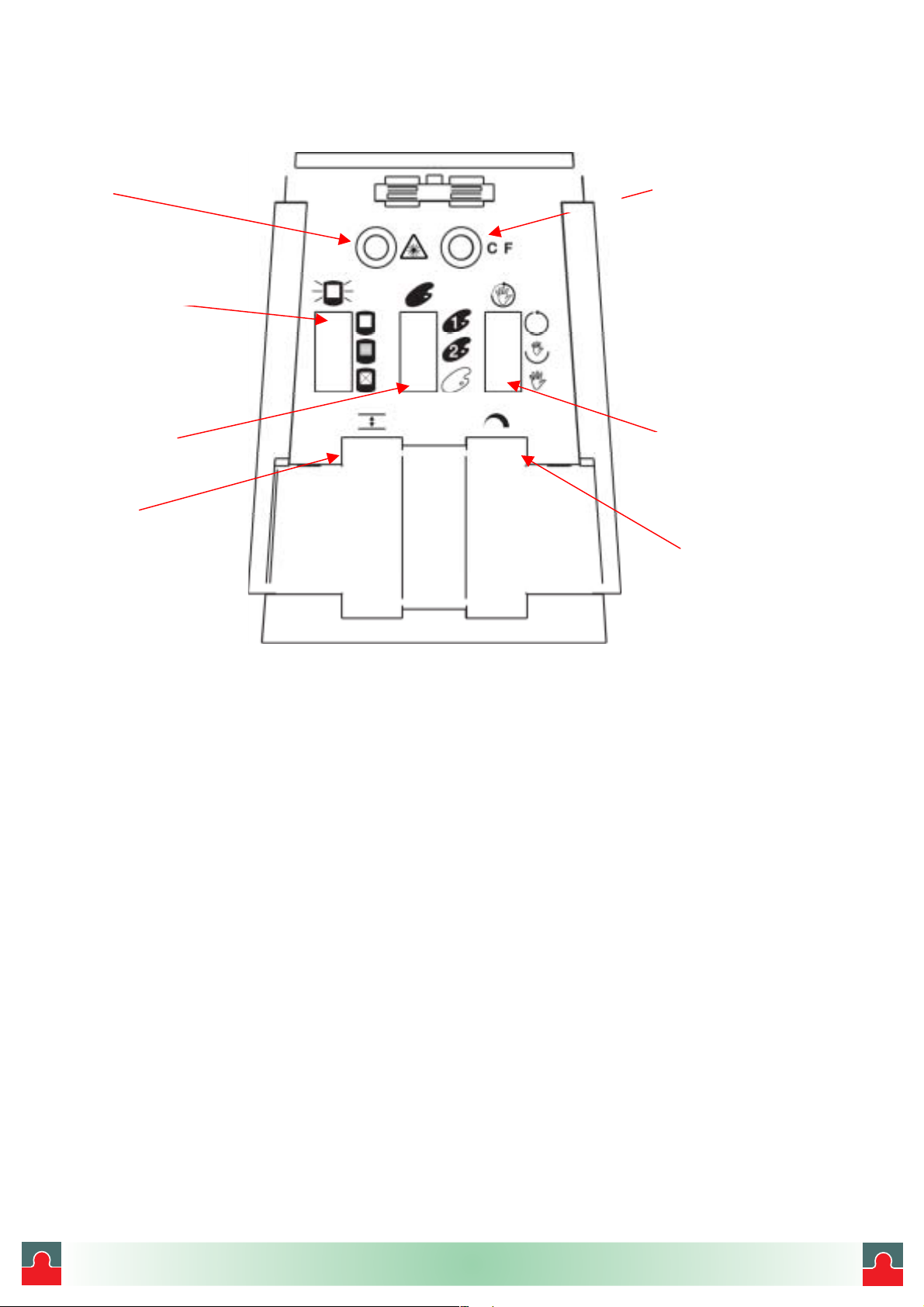

Laser ON/OFF

LCD backlight selection

Centigrade /

Fahrenheit selection

Palette selection

Level adjustment

Figure 11. ThermoView Imager Settings Switches

Laser On/Off Toggle Button

The Laser On/Off toggle button switches the laser on and off. By default, the guiding

beam.

Measurement mode selection

Gain adjustment

tion you may or may not need the laser guidancelaser beam is off. Depending on the situa

July 1, 2003 - 20 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 21

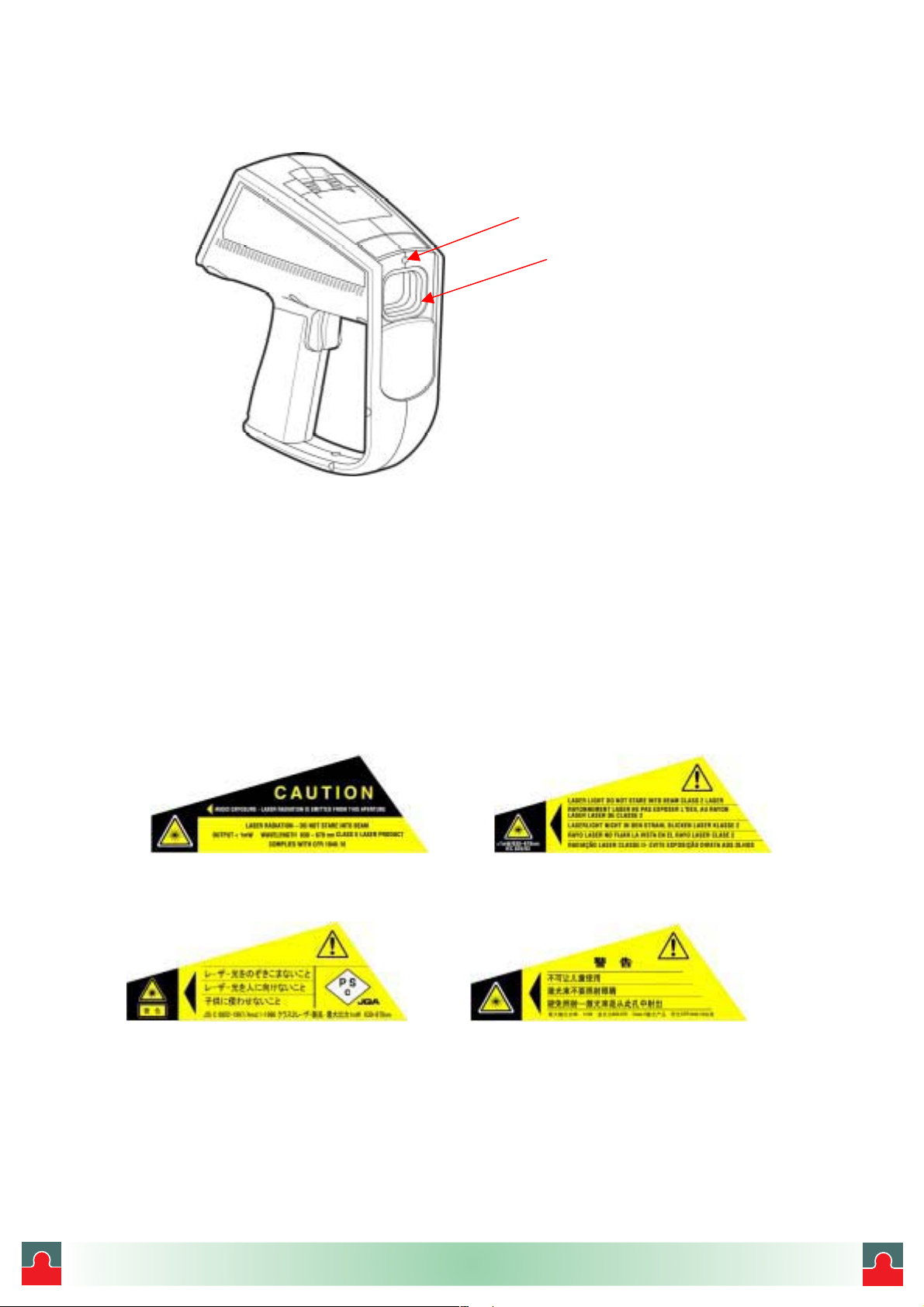

Figure 12. Laser Aperture and Optical Channel

Laser Aperture

Optical Channel

Note:

Important:

The laser is only a sighting aid. It is not required to take measurements. The laser is

not coaxial with the infrared channel, thus the laser dot is offset from the center of

the thermal image. The laser dot is not visible in the thermal image.

Avoid directing the laser to people’s eyes. See important safety information

on the warning laser label located on the side of the unit. There are different

laser warning labels for different geographic regions. These are identified

below.

North America

Europe / Latin America

Japanese Chinese

Figure 13. Laser Warning Labels For Different Geographic Regions

July 1, 2003 - 21 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 22

Centigrade/Fahrenheit Toggle Button

Centigrade/Fahrenheit button toggles the displayed temperature data in either

Centigrade or Fahrenheit temperature scales. The factory default is Centigrade.

LCD Backlight Illumination Switch

LCD Backlight Illumination switch provides three backlight illumination levels as

shown below.

Off Medium Full

Full brightness is recommended for indoor use; use Medium brightness to save battery life,

and set backlight Off for outdoor applications. The default position is Full brightness.

Palette Switch

The Palette switch allows the ThermoView imager to display temperature patterns in

three different palettes as indicated below:

x Rainbow

x Ironbow

x Grayscale

See Selecting the Color Palette on page 42 for more information. The default position is

Rainbow.

Measurement Mode Switch

The Measurement mode switch permits the user to change the way thermal

information is presented on the display. Depending on the mode you choose, you will have

all temperature points shown on the thermal image, or you may have just a narrow interval

of temperature points being displayed at a time. The decision of which mode to use depends

on each operator’s needs and limitations.

July 1, 2003 - 22 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 23

There are three measurement mode positions associated with this switch:

Automatic Semi Automatic Manual

In Automatic mode the ThermoView imager automatically adjusts the image to show

the lowest temperature value present in the thermal scene (MIN) and the highest

temperature value in the scene (MAX).

In

(lowest temperature value on the thermal scene) automatically.

In Manual mode the user can adjust Gain and Level manually.

See Selecting the Measurement Mode on page 42 for more information. The default position

is automatic mode.

Semi-Automatic mode the ThermoView imager keeps calculating the MIN limit

Gain and Level Thumbwheels

The Level Thumbwheel control adjusts the median point of a given temperature

scale.

The Gain Thumbwheel control adjusts the temperature band around the median

Level point.

See Gain and Level Thumbwheels on page 45 for more information about these controls.

Focus Wheel

The Focus Wheel is located on the bottom of the imager’s housing in from of the trigger as

shown in Figure 14. Adjust the focus by turning the Focus Wheel with your fingers or

thumb.

July 1, 2003 - 23 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 24

Focus Wheel

Figure 14. Location of the Focus Wheel

See The Importance of Focusing on page 41 for more details.

Trigger

Actuating the trigger freezes an image prior to storage. While in a regular measurement

mode, pull the trigger momentarily, release it, and the thermal image on the display will be

frozen so you can evaluate it for storage. If you don’t want to store it, simply pull the trigger

again and the unit will go back to measurement mode.

Trigger

Figure 15. Location of the Trigger

July 1, 2003 - 24 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 25

Man Machine Interface Flow Charts

Main Loop

July 1, 2003 - 25 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 26

Image Recording Procedure

Emissivity Adjustment Procedure

July 1, 2003 - 26 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 27

Reflected Temperature Compensation Adjustment Procedure

Recall Images Procedure

July 1, 2003 - 27 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 28

Quick Image Fix Procedure

Array Recalibration Procedure

Recording an Image

Recording images with the ThermoView imager is simple. Repeat the steps below and record

as many images you want until you get familiar with the process.

x First, note the number of the current image location. At this point, if you have not

stored any images, the location number should be set at 1 (default) and the location

descriptor will be blank. Similar to a camera, each image is numbered, so you may refer

to images as one, two, three, etc. up to 100 images.

x Point the ThermoView imager at the target you want to record. Make sure the

crosshatch at the center of the image pinpoints the spot of interest. Pull the trigger once

and release it. This freezes the displayed image.

x Carefully inspect the image: If the result is satisfactory, press the Up button and the

image will be stored at the current location, and the location counter will increment to

next position automatically.

x If the image is not satisfactory: Press and release the trigger to discard the frozen image.

x Repeat the procedures described above to record more images.

July 1, 2003 - 28 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 29

Note:

p

To erase an image, just store a new image over the one you wish to delete. To do

this, go to Recall Images Procedure, press Down button once to decrement the

location, press Mode button or trigger to get back to measurement mode, and pull

trigger again to save a new image.

Retrieving an Image

On Measurement mode, press the MODE button 3 times, browsing through Emissivity

Adjustment and Reflected Temperature Adjustment modes (these adjustments are

explained in Chapter 3 ). The thermal image and related data of the current location is

shown on the display. Use the Up and Down buttons to scroll through the images you have

previously recorded. All stored images can be downloaded to your computer later. To go

back to measurement mode just pull the trigger or press the MODE button once more.

High alarm

Reflected Temperature

Compensation (RTC) value

Date stam

Temperature scale

Location name

Figure 16. Retrieve Mode

The next chapter, Downloading and Looking at Images, leads you through installing the

InsideIR software. You may then start downloading your images to your computer.

Stored image

Low alarm

Time stamp

Stored target temperature

Emissivity value

July 1, 2003 - 29 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 30

Chapter 3 Downloading and Looking at

Images

This chapter begins with the InsideIR software installation. Prior to installing the software

however, please take a moment to verify that your computer meets the minimum

requirements shown below:

®

x Microsoft

x Personal computer with a Pentium® III processor (450 MHz or higher recommended)

x 256 megabytes (MB) of RAM

x 500 MB of free hard disk space

x SuperVGA monitor with the screen resolution set to at least 800 x 600, recommended

1024 x 768 or greater; small fonts setting; and true color (32 bits)

x CD ROM drive

x USBrev.1.1port

x Printer, optional for printing reports

Windows® 98, Windows 2000 or Windows XP operating system

Installing the Software

If you have exited your Interactive User's Manual, relaunch it by putting the User's Manual

CD back in your CD-ROM drive. Once the application launches and you've selected your

language, click the Install InsideIR™ Companion Software button.

The installation wizard will lead you through the installation process.

Note:

An icon for the InsideIR application is created and added to your folder during software

installation. Do not launch the program yet. Wait until you have completed the next section,

Connecting the Docking Station to Your Computer.

Please take a few minutes to complete your product registration. You can register

quickly online at http://www.raytek.com/register/ti30_sw (preferred) or you can

print the form and fax it to the number provided on the form.

Product registration is very important since it allows you to get free software

updates from Raytek and helps us provide you with the fastest and most efficient

technical support.

July 1, 2003 - 30 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 31

Connecting the Docking Station to Your Computer

The docking station provides a solid and convenient base for the ThermoView imager. The

docking station keeps the ThermoView imager available and connected to the computer or

workstation. In addition, it keeps the batteries charged and ready to go. The docking station

connects to your computer through its USB port. The USB cord should remain connected

to the computer at all times.

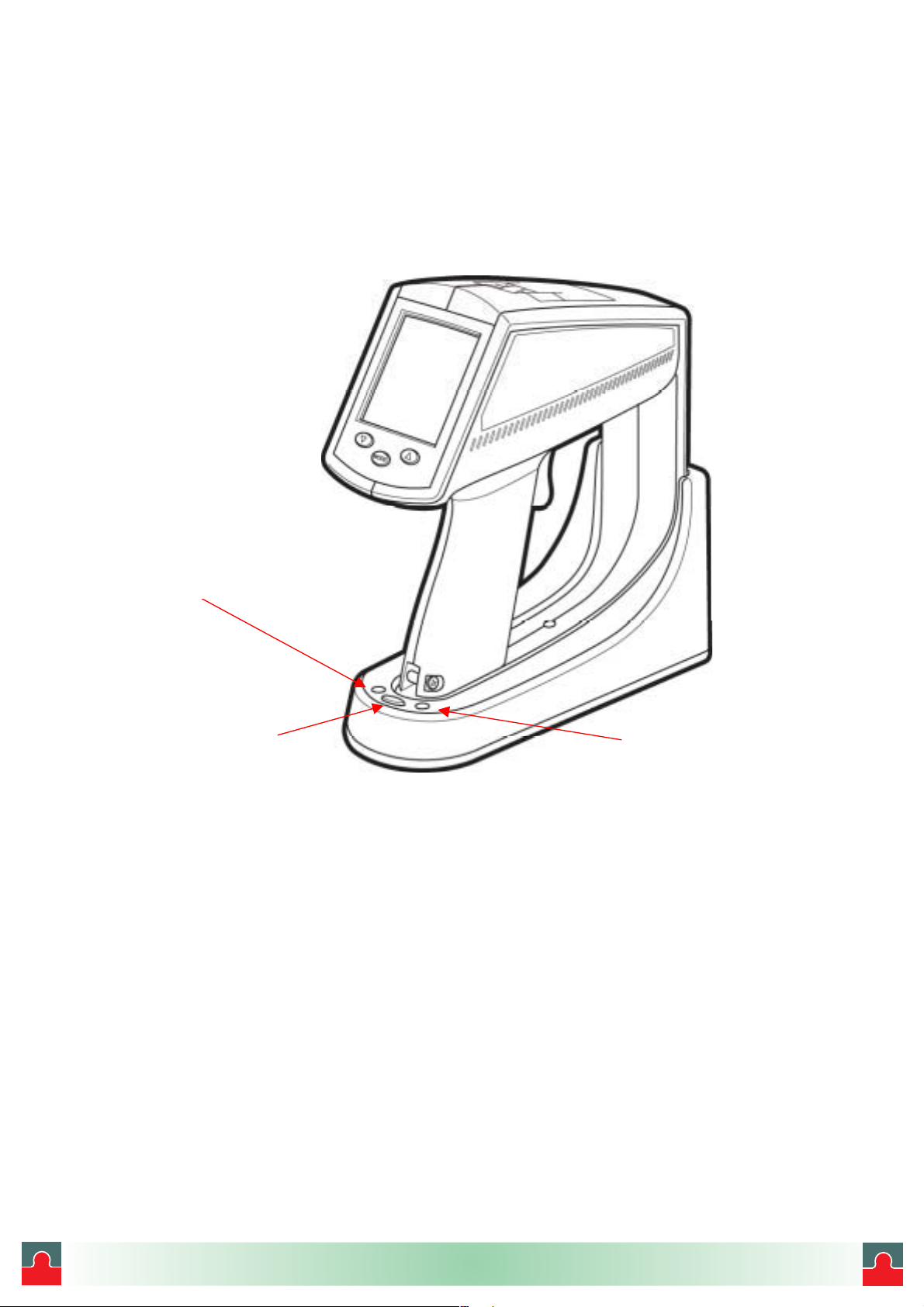

Hooking Up the Docking Station

x Connect the power adapter plug into the Docking Station’s power jack.

x Connect the power plug to a power outlet. (Depending on the power requirements in

your country you may need to use one of the several adapters provided that matches the

power plug to the local power outlet.)

Power jack

USB communication cord

USB connector

Figure 17. The Docking Station

x Find the USB port on your computer. Look for this symbol on your computer.

x Locate the USB communication cord permanently attached to the docking station. (The

USB communication cord is equipped with an USB connector.)

x Insert the USB connector on the cord to the USB port on your computer (see Figure

18).

July 1, 2003 - 31 - Version 1.0

Power adapter plug

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 32

Figure 18. Connecting the USB Connector to the USB Port

x Dock the imager in the docking station.

x The first time you place the imager in its docking station and press the SYNC button

with the docking station connected, your computer's operating system will detect new

hardware and locate the correct communication driver. Your computer will automatically

launch its own driver installation program. Follow the installation instructions. You will

only have to go through this process once.

You are now ready to launch the InsideIR application. Go to your computer desktop and

double-click on the InsideIR program icon to launch it.

The following screen will appear:

Figure 19. InsideIR Splash Screen

The screen appears momentarily and then the following screen appears:

July 1, 2003 - 32 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 33

Figure 20. InsideIR Main Screen at Program Launch

If you wish to view the sample images now, click the plus sign to the right of the Samples

folder to open it. Then double-click on the session name (My collection, in our example

below).

Figure 21. InsideIR Main Screen With Session Open

July 1, 2003 - 33 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 34

Downloading Images

You are now ready to download the images you recorded in your ThermoView Ti30 imager.

Locate the SYNC button in the docking station. Press the SYNC button once to begin the

download process.

SYNC button

Figure 22. The SYNC button

When synchronization completes, the following window appears:

Once all data are downloaded, the information is saved into a temporary area where you may

inspect the data before saving it to the disk. The following dialog window appears (images

and data are for example only):

July 1, 2003 - 34 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 35

Figure 23. Download Data Screen

You can browse through the images by clicking and dragging the horizontal and vertical

scroll bars.

You cannot delete individual images. You must decide whether to save the entire collection

or not. Click Save Data to save it. By clicking Cancel, the data is not saved to the disk.

The following window appears when images are saved, signaling a successful operation:

Click on OK.

Saving Images

Following data storage, the application automatically opens the folder called “Images”

showing the newly saved collection of images. The collection of images and their associated

data is automatically saved, using the computer’s date / time settings. You can change the

file names by right-clicking on the current name, although it is strongly recommended you

keep the date / time information so you can keep track of your periodic inspections.

The screen below shows sample contents of the Images folder, with the newly saved file

highlighted:

July 1, 2003 - 35 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 36

Figure 24. Contents of Images Folder

Your newly recorded images appear as thumbnails as they are downloaded into the program.

Each set of images is in a fixed order so that you cannot rearrange the images. Use the scroll

bars to browse through the thumbnail images.

Setting the Imager Clock

It is very important to set the Imager Clock in your ThermoView Ti30 imager because it

records a time / date stamp with each stored image. This is important for meaningful reports

and trending.

The imager’s internal clock can only be set or changed from the computer. You cannot set

or adjust it on the imager. It is very important to have the internal clock set to your local

time / date, since your inspections will be tracked based on time / date information.

To set the time:

1. Press the Set Imager Clock button on the lower portion of the Main menu.

July 1, 2003 - 36 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 37

The following window appears:

2. Click the Date arrow to see the calendar.

The following window appears:

x Click on the side arrow buttons to change the current year / month

x Click to select the day of the month.

The following windows appears:

July 1, 2003 - 37 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 38

x To set the current time, click on the hour and min (minute) boxes to enter time

information. Use the 24-hour time format only.

x Press the Set button to upload the information to the imager.

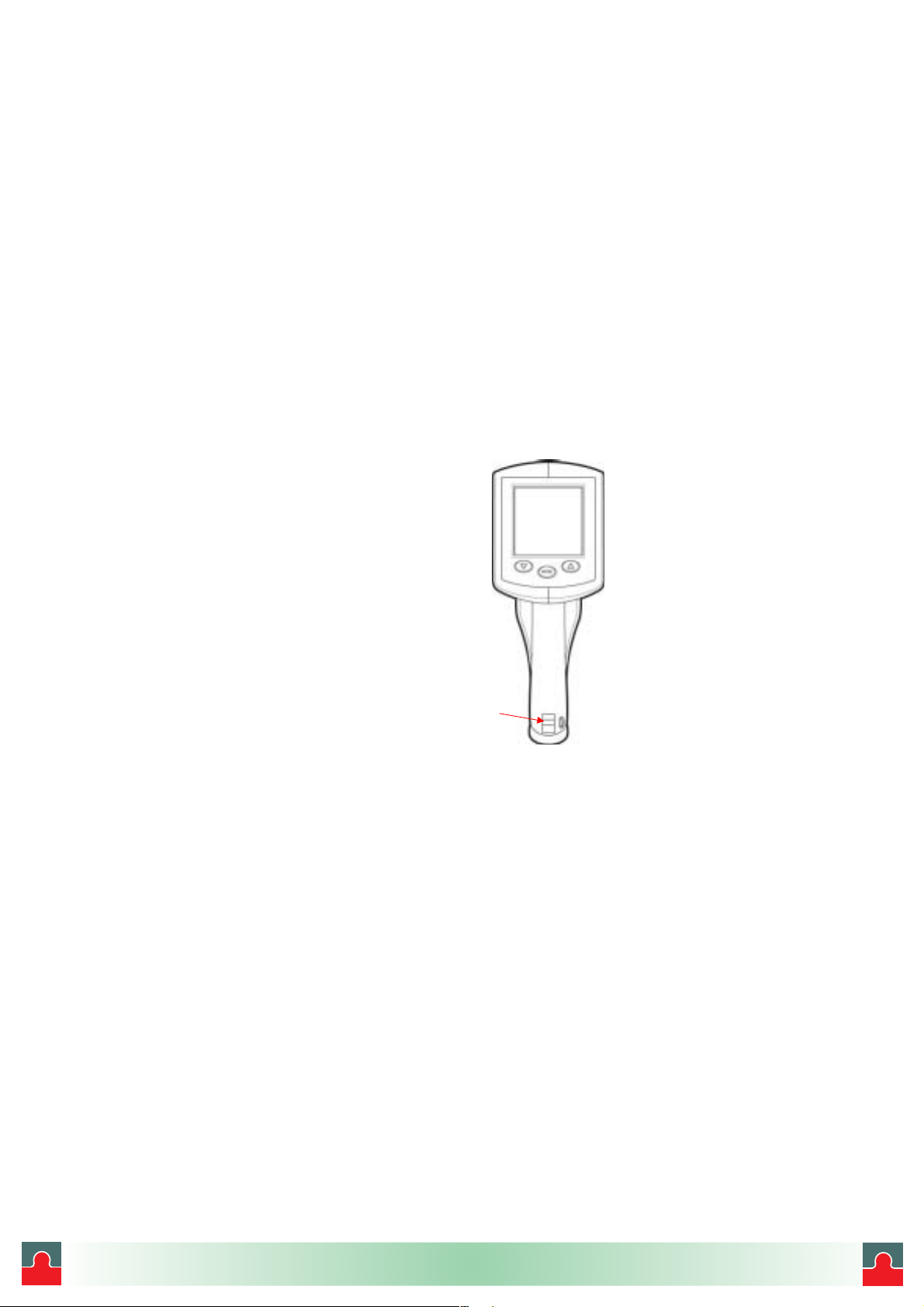

Field USB Port

In the event you need to download your images to a computer without the docking station,

you may use the USB cable included with your ThermoView Ti30. Connect the cable to the

Field USB port, under the display. (See Figure 25) Once the cable is connected, follow all

steps previously described.

Field USB Port

Figure 25. Field USB Port

Looking at Your Downloaded Images

Images are automatically organized into directories as they are downloaded into the software

program. All images from your latest download appear in a window that looks like the screen

below. You can look at all image thumbnails by clicking on the two scroll bars.

July 1, 2003 - 38 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 39

Figure 26. Viewing Thumbnail Images

You can view a larger version of a single image by clicking on the thumbnail of the image

you wish to view. When viewing a single image, you may move to the next or the previous

image by clicking on the Previous Image or Next Image button on the left side of the

screen (see Figure 27 below).

July 1, 2003 - 39 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 40

Figure 27. Viewing a Single Image

July 1, 2003 - 40 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 41

Chapter 4 Obtaining the Best Image

The Importance of Focusing

The focusing ability of the imager is similar to the one found on regular photographic

cameras, and it is defined as the ability to adjust the optical system to capture the highest

amount of infrared energy from the target, thus allowing the sharpest thermal image of the

target to be displayed. Properly focusing the unit is of paramount importance for obtaining a

crisp clear image. There is no way to compensate for an improperly focused thermal image

afterwards.

®

Focus Wheel

Figure 28. Locating the Focus Wheel

Focusing is accomplished by rotating the Focus Wheel in either direction. The minimum

focusing distance is 61cm (24 inches). That means you have to be at least 61cm (24 inches)

away from your target to get it focused.

Rotating the Focus Wheel to the leftmost position (as viewed from operator’s perspective)

will focus the optics to the minimum focus distance of 61cm (24 inches) away from the unit.

Rotating the Focus Wheel to the right, the optical system will gradually focus to longer

distances. Rotating the Focus Wheel to the furthest right position will focus the optics at

infinity.

To make sure your target is in focus, try starting with the Focus Wheel in the leftmost

position, rotate slowly to the right, and stop when the image is at its sharpest. You may need

to go back and forth until reaching the best focus adjustment. Alternately, you may move in

and out while viewing a subject to determine where focus is best.

July 1, 2003 - 41 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 42

Tip:

When focusing an image, look for identifiable patterns or shapes on the object

surface that can help establishing the best image definition. Objects contours,

dividing lines or limits are particularly useful. Proper focusing is not only important

to the image quality, but also greatly affects the accuracy of temperature

measurements. One way to verify if the unit is properly focused is to find what

focus adjustment produces the highest temperature indication on the display (keep

E and RTC values constant, preferably E set at 1.0 and RTC disabled).

Selecting the Color Palette

The selected color scheme is mostly a matter of personal preference. In some cases, it makes

sense to use a specific palette for specific applications. The rainbow palette provides more

contrast between areas with close temperature values; on the other hand the ironbow palette

may provide more visual comfort in some cases because the colors blend in smoothly.

However, despite the popularity of color palettes, the gray scale is recommended for most

measurements because it is easier for the human eye to discern subtle thermal changes on

gray tones than colors.

Tip:

Always begin with the gray scale palette while you get a feel for the thermal scene

you are viewing. Then, work with the available measurement modes and the Level

and Gain adjustments before choosing which color palette to use.

Selecting the Measurement Mode

Measurement modes are simply different ways to present thermal information on the

display. Depending on the mode you choose, you may display all temperature points shown

on the thermal image, or you may select a narrow interval of temperature points being

displayed at one time. The decision of which mode to use depends on your needs and

limitations. From a thermal resolution standpoint, you are better off working with a narrow

interval of temperature points, because you will be able to see very subtle temperature

differences, since you have more colors or gray tones to represent fewer temperature points;

on the other hand, if you are just looking for larger temperature differences, you can not

work with a narrow temperature interval because important temperature values might not be

displayed.

There are three measurement mode positions associated with this switch:

Automatic Semi Automatic Manual

In Automatic mode the ThermoView Ti30 imager automatically adjusts the image to

show the lowest temperature value present in the thermal scene (MIN) and the highest

July 1, 2003 - 42 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 43

temperature value in the scene (MAX). The MIN and MAX values are displayed at the

beginning and at the end of color scale. This mode does not require any other adjustment

(other than properly focusing the unit). Automatic mode is recommended every time the

user first starts looking at a given target since the temperature limits are unknown. This

mode is also recommended when the user is looking for fairly large temperature differences

(such as, looking for hot spots in electrical devices).

Note:

Different from Automatic mode, Manual and Semi Automatic modes work jointly with

two adjustable parameters: Level and Gain. These two parameters are adjustable by using

the two thumbwheels located on the switch bay (see Figure 11 on page 20).

Level is defined as the median point of a given temperature scale. For example, if the unit is

currently in Automatic mode, and there is a given thermal scene with MIN and MAX

temperature limits, the moment you switch the unit to Manual mode, the Level value is set

by the unit according to the following formula:

The Quick Image Fix feature is a sub set of the Automatic mode. This is a

convenient feature that fixes the MIN and MAX temperature values and thus

creates a more stable thermal image for the user to view. To quick fix the image,

simply press the Up button on the keypad once, and the temperature limits will

stop adjusting automatically. Fixing the temperature limits provides a more

comfortable experience for thermal image evaluation. The thermal boundaries

(highest and lowest temperature values) will adjust automatically again when you

record another image (see Recording an Image on page 28 for more information) or

by pressing the Up button again while in the Automatic measurement mode. The

Quick Image Fix feature is active only when the unit is set to Automatic mode.

Level Gain

MinMax

Level

Gain is defined as a temperature band around the median point of the scale (Level). In the

same way described above, if the unit is currently set at Automatic mode, and there is a

given thermal scene with MIN and MAX temperature limits, then switching the unit to

Manual or Semi Automatic mode causes the Gain value to be set according to the

following formula:

Gain

July 1, 2003 - 43 - Version 1.0

2

MinMax

2

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 44

Graphically, it would look like this:

The imager automatically calculates Level and Gain when switched

from Automatic to Manual or Semi Automatic modes, thus

providing a smooth and meaningful transition of the thermal

boundaries of the scene.

Once initially set by the ThermoView imager, Gain and Level can

then be adjusted by the user in order to accommodate their specific

requirements.

Of course, in practical terms you can’t actually see the values for

Gain and Level. You will adjust Gain and Level, but you will see

the changes on the MIN and MAX temperature values at each end

of the thermal scale. Since we know how Level and Gain are

calculated by the imager, it is easy to understand how variations in

Gain and Level change the MIN and MAX limit values by solving

the Gain and Level equations for MIN and MAX as follows:

GainLevelMin

GainLevelMax

In summary: you need to adjust Level to get close to temperature level you are interested in

and then adjust Gain to get you more or less resolution as needed around the desired level.

Tip:

In Semi-Automatic mode the ThermoView imager keeps calculating the Level

automatically. This mode is recommended when the user is interested in controlling the

resolution around a varying temperature level, thus saving the user a lot of trouble and time

trying to constantly adjust Level.

Always begin by selecting the Automatic mode. Automatic mode will suffice for

most applications. The unit automatically adjusts the image to show the lowest

temperature value present in the thermal scene (MIN) and the highest temperature

value in the scene (MAX), at all times. This mode does not require any other

adjustment (other than properly focusing the unit). Once you are familiar with the

thermal scene you are looking at just press the Up button to activate the Quick

Image Fix feature, described on the previous pages. When you press the Up

button the imager fixes the MIN and MAX temperature values, thus allowing a

more stable thermal image for the viewer. The next step is to capture the image for

downloading later. To freeze the image, simply pull the trigger once and then press

the Up button to actually save the image.

July 1, 2003 - 44 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 45

In Manual mode the user can adjust Gain and Level manually. Use this measurement

mode when you need more freedom to define Level and Gain values. This mode provides

the flexibility to bring both MIN and MAX values to the desired cut-off levels and to adjust

the temperature interval to a minimum, thus maximizing color resolution. Using the Manual

mode efficiently requires more experience with both thermal imaging techniques and specific

knowledge of the equipment being inspected. However, Manual mode provides the best

possible image definition as to the specific inspection situation at hand, both from a thermal

resolution and temperature level standpoint.

Tip:

The minimum temperature interval between the MIN and MAX values is 5q C / 9q

F. It is important to remember that by decreasing the difference between MIN and

MAX values increases the likelihood of image noise. Only bring the difference

between MIN and MAX to the minimum when you absolutely need the best

thermal resolution available.

Gain and Level Thumbwheels

The Level Thumbwheel control increases Level by pulling the wheel towards the

back of the imager and decrease Level by pushing the wheel forward towards the front of

the imager. When Level is increased both MIN and MAX values increase accordingly and

when Level is decreased both MIN and MAX values are decreased accordingly.

The Gain Thumbwheel control increases Gain by pulling the wheel towards the back

of the imager and decreases Gain by pushing the wheel toward the front of the imager.

When Gain is increased, MIN value decreases and MAX value increases accordingly. When

Gain is decreased, MIN value increases and MAX value decreases accordingly. Gain can be

decreased up to the point when the difference between MIN and MAX values is 5q C / 9q F.

Note:

Both wheels have endless adjustment action (no détente).

July 1, 2003 - 45 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 46

Chapter 5 Qualitative and Quantitative

Temperature Measurements

Most of the time thermal imager users are measuring apparent temperatures that are inextricably

linked to qualitative inspections. Qualitative inspections focus on temperature differences as opposed

to actual temperatures. The reason is that temperature differences are sufficient to indicate most

abnormalities in electrical and mechanical equipments. In other words, qualitative

inspections don’t aim at taking accurate temperature measurements. Their goal is to capture

and identify different thermal patterns in a given thermal scene, which are indicative of

potential failures and / or equipment malfunctioning. Since there is no intention to measure

the actual or absolute value, the technician has no need to correct for target emissivity (which is

set at “1” on qualitative inspections), reflected temperature from the environment (which is

not enabled in the unit on qualitative inspections) or account for target spot size and

distance from the target (quite often the target of interest is always compared to a similar

target in the same thermal scene). Also, the operator does not need to adjust or account for

atmospheric attenuation, angle of incidence and other interfering factors.

On the other hand, quantitative inspections are intended to accurately measure the actual

temperatures of specific areas in electrical or mechanical equipment. Although less common

than qualitative inspections, quantitative inspections are sometimes required. One good

example would be measuring electric motor temperatures: in this case, the absolute

temperature value is required since it is closely linked to the useful life of the motor. To

accurately measure temperature using infrared temperature measurement technology, the

customer should be aware of the key concepts and factors that can radically interfere with

the quality of the quantitative temperature measurement.

The following reviews each of these factors.

Distance to Target (Spot) Ratio

The optical system of an infrared sensor collects the infrared energy from a circular

measurement spot and focuses it on the detector. Optical resolution is defined by the ratio

of the distance from the instrument to the object, compared to the size of the spot being

measured (D:S ratio). The larger the ratio factor the better the instrument's resolution, and

the smaller the spot size that can be measured from a greater distance.

All non-contact infrared thermometers and thermal imagers have a specific optical

resolution, expressed by the D:S ratio and by the optical diagram, which shows the geometry

of the infrared radiation path as seen by the lenses of the instrument.

See Figure 29 for an illustration of the D:S ratio and the optical chart for the ThermoView

Ti30 unit.

July 1, 2003 - 46 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 47

D:S ratio: D / S = 90

The number “90” means that at a distance D equal to 1 meter the unit will measure a circle

of diameter S equal to 1.1cm (1meter divided by 90); at distance D equal to 2 meters it will

measure a circle with diameter S equal to 2.2cm and so on in a linear progression.

Optical Diagram

The optical diagram shows the graphical representation of the optical ratio. The optical path

of the infrared radiation is a cone that has its vertex at 61cm (24”) away from the front of

the unit, and progresses at the same ratio towards infinity. The circle diameter can be

calculated by dividing the distance by 90 at any point in the centerline of the cone. Below it

is presented the diameters S for three different distances: 61cm (minimum distance), 2m and

5m. There is no maximum distance. Although, in practical terms, accurately measuring

temperatures of targets further than 5m requires fairly big objects.

Figure 29. Illustration of Distance to Target / Spot Ratio

The explanation of optical resolution is key for the understanding of the next concept, vital

for accurate temperature measurement in quantitative inspections.

Field-of-View

Make sure that the target is larger than the spot size that the unit is measuring. The

smaller the target, the closer you should be to it.

July 1, 2003 - 47 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 48

Figure 30. Field of View

Tip:

When accuracy is critical make sure that the target is at least twice as large as the

spot size.

Environmental Conditions

Watch for environmental conditions in the working area. Steam, dust, smoke, etc.,

can prevent accurate measurement by obstructing the path between the target and the unit's

optics. Noise, electromagnetic fields, or vibration are other conditions that can interfere with

temperature measurements, and should be considered before starting temperature

measurements.

Tip:

If interfering factors can not be mitigated try to change your position relative to the

source of interference, or pick a time when interfering factors are not present or at

a smaller level.

Ambient Temperatures

The imager’s operating temperature range is 0 to 50q (32 to 122qF). Its calibration is

maintained within this range. The unit will not perform in terms of the accuracy and

repeatability if used outside the stated operating temperature range. Also, if the imager is

exposed to abrupt ambient temperature differences of 10qC (18qF) or more, allow it to

adjust to the new ambient temperature for at least 20 minutes.

Tip:

July 1, 2003 - 48 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

When inspecting equipment in a plant, plan the sequence of locations to be

inspected so the ambient temperature changes are gradual.

i

Page 49

Emissivity

Emissivity is the measure of an object's ability to emit infrared energy. Emitted infrared

energy is exponentially proportional to the temperature of the object. Emissivity can have a

value from 0 (shiny mirror, perfect reflector) to 1.0 (blackbody, perfect emitter). Most

organic, painted, or oxidized surfaces have emissivity values close to 0.95. If you are

performing qualitative inspections with your imager, leave the emissivity set at 1.0. If you

need to measure actual temperature values, set the emissivity value according to the

emissivity of the material the object you are measuring is made of. Again, if you need

accuracy, you will need to find the emissivity value of the material before taking the

measurement. See Table 1 on page 68 and Table 2 on page 69 for the emissivity values for

the most common materials.

There are a couple of methods that help you to find the emissivity value of materials:

x Tape method: this method requires the usage of the Scotch® brand PVC tape

(emissivity value 0.97) or equivalent. Cover the surface you want to measure with tape.

Wait some seconds for the temperature to stabilize. Set the emissivity of the imager at

0.97 and measure the temperature. Make a note of the temperature value. Then, remove

the tape and measure the new temperature value. Adjust the emissivity accordingly until

the temperature value found previously is displayed on the unit. This emissivity value is

the one of the material being measured. This method is good for objects that are at low

temperatures (under 100qC (212qF)), not electrically energized and not in motion.

x Contact thermometer method: this method will need a contact probe and good quality

temperature meter. Initially, use the contact probe temperature meter to measure the

temperature of the object you want to know the emissivity value, allowing time for the

contact probe to stabilize (this may take up to a minute). Make a note of the temperature

value. Adjust the emissivity on the imager accordingly until the temperature value found

previously with contact probe temperature meter is displayed on the imager display. This

emissivity value is the one of the material being measured. This method is good for

objects that are at moderately high temperatures (under 250qC (482qF)), not electrically

energized and not in motion.

To set or change the Emissivity value, complete the following:

1. Put the ThermoView Ti30 imager in regular Measurement mode.

2. Press the MODE button once. At this point you will be able to adjust Emissivity.

3. Set the Emissivity value to the proper value, according to the target material, by

pressing the Up and Down buttons.

Reflected Temperature Compensation

Targets that have low emissivities will reflect energy from nearby objects. This additional

reflected energy is added to target’s own emitted energy and may result in inaccurate

readings (see Figure 31 below). In some situations objects near the target (machines,

July 1, 2003 - 49 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 50

furnaces, or other heat sources) have a temperature much higher than that of the target. In

these situations it is necessary to compensate for the reflected energy from those objects.

Note:

To set or change the RTC feature, complete the following steps:

1. You will need an infrared reflector. Take a piece of aluminum foil. Crumple and re-

2. Put the ThermoView Ti30 imager in regular Measurement mode.

3. Press the MODE button once. At this point you will be able to adjust Emissivity.

4. Set the Emissivity value to 1.00.

5. Position the imager at the selected measurement distance from the target to be

6. Now, place the infrared reflector in the field-of-view of imager. Position the reflector in

7. Measure the apparent surface temperature of the surface of the reflector. This

8. It is a good idea to repeat the steps from 5 to 7 and then average the results. Make a note

9. Press the MODE button one more time. At this point you will be able to adjust the

The Reflected Temperature Compensation (RTC) feature is disabled if the

emissivity is set to 1.00.

flatten the foil and put it on a cardboard plate, shiny side up.

measured. Aim and focus the unit on the target.

front of and parallel to the target surface.

temperature is the reflected temperature of the target. Make a note of this temperature

value.

of the average.

RTC value.

10. Enter the value found on step 8 for RTC, by pressing the Up and Down buttons.

11. To enable the RTC, make sure the set the Emissivity properly, according to the object

material. If set at 1.00, the RTC compensation won’t take place.

Figure 31. Reflected Temperature Compensation

July 1, 2003 - 50 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 51

Chapter 6 Organizing Your Data

The ThermoView imager when used together with the InsideIR software provides a

powerful way to organize and track maintenance data. Different groups of equipment can be

inspected and data specific to different plant areas or departments can be individually

named, saved, stored and retrieved in a straightforward fashion. Because all the records are

electronic, they can be backed up and stored without fear of loss or fading of records.

File Management

You can rename or delete files (“sessions”) or folders from the directories by right-clicking

the icons in the file structure on the left side of the screen and choosing the appropriate

command from the pop-up menu. You may move a file by clicking it and dragging it onto

the destination folder.

Note:

Keep in mind that a file (or “session”), is a collection of images—not a single

image.

Figure 32. Organizing Your Files

July 1, 2003 - 51 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 52

Uploading Data to the Imager

Click the Upload Setup Imager button on the InsideIR main screen to upload data

to the ThermoView imager. This displays the following screen:

Select the folder and session you want to upload and press Next.

Figure 33. Uploading Data to Your ThermoView Ti30 Imager

July 1, 2003 - 52 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 53

If you wish to change parameters for different locations such as location name, emissivity,

reflected temperature compensation, low and high alarms, and comments, you can do so by

right-clicking the thumbnail of the image you wish to edit, clicking Edit data in the pop-up

menu, and changing the desired field(s).

Figure 34. Editing Data Before Upload

Note

1:

Note

2:

To upload the data to the imager, press Upload. The imager will begin to load data.

Once the data is loaded, you are ready to perform your inspections. Upon your return, you

simply place the imager in the docking station, and bring up the software. The new data is

sent to the proper destination and is ready for comparison with any earlier data.

Note

1:

Checking the Lock Emissivity or Lock Reflected Temperature Compensation will

prevent the operator of the imager from changing these values in the field.

Because you cannot change the order of image locations it is important to plan the

order of your database carefully.

It isn’t necessary to upload data to the imager in order to perform inspections.

However, it is recommended in order to keep consistency between inspections by

using the same parameters for each location to be inspected.

July 1, 2003 - 53 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 54

Note

2:

If you wish to restore the default parameters on the unit press the Restore button.

By doing this all 100 locations on the imager will be restored with the factory

parameters. These default parameters are:

Location name: blank

Emissivity: 1.00

RTC: OFF

Low alarm: 0°C / 32° F

High alarm: 250°C / 482° F

Comments: blank

July 1, 2003 - 54 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 55

Chapter 7 Analyzing Your Data

There are many ways to analyze your thermal data now that you have it downloaded and

organized. After clicking on a thumbnail in the Main InsideIR screen, the data for that

specific thermal image is displayed in one of four tabs: Image, Temperature Table, Profile,

and Histogram.

While each of these analytical tools possess unique qualities, they also share many features.

For example, data from any of the tabs may be saved in other formats or cut and pasted into

other applications for your own further analysis or communications needs. The four tabs

also share many commands on the menu bar, which will be explained at the end of this

chapter.

InsideIR allows you to open many windows at one time. Keep in mind that functions on the

menu bar are always associated with the active window.

The Single Image Screen

Clicking any of the thumbnail images in the Main InsideIR screen takes you to the Image

tab for that image. On this screen, you can view basic data about the image.

Clicking on any part of the image will display the temperature reading at that spot (indicated

by the crosshatch). You may click as many spots as you wish, with each click adding a

reading to the displayed image. To erase the displayed temperature points, simply click while

moving your mouse. Clicking and dragging around the image will momentarily display the

temperature reading on points along your path.

Scale Limits

When the Scale Limits radio button at the bottom of the Image screen is selected, the limit

bar underneath the image shows the temperature range your ThermoView Ti30 imager is

capable of measuring. The minimum (0º C / 32º F) is represented at the far left of the bar,

and the maximum (250º C / 482º F) is represented by the far right of the bar. The red area

on the bar indicates the range of temperatures, within the minimum and maximum limits,

that are represented in the thermal scene.

In order to see more detail in narrow ranges of temperature, it is often useful to adjust the

scale limits. In order to do this, make sure the Scale Limits radio button is selected. To

adjust the upper or lower limits, click and drag the appropriate arrow at the edge of the red

portion of the bar. To keep the same range span but change the limits, you can drag the

whole red section of the bar left (colder) or right (warmer).

To go back to the original scale, double-click on the scale bar.

July 1, 2003 - 55 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 56

Figure 35. Sample Image at Original Scale Limits

Figure 36. Sample Image After Increasing Scale Limits

July 1, 2003 - 56 - Version 1.0

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796

i

Page 57

Isotherms

When the Isotherm radio button at the bottom of the Image screen is selected, the limit

bar underneath the image shows the temperature range captured in the current thermal