Page 1

Raynger® Series

3i Plus

Handheld Infrared Thermometer

Operating Instructions

Rev. A1 Jan 2015

4557194

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Worldwide Headquarters

solutions@raytek.com

European Headquarters

raytek@raytek.de

France

United Kingdom

Fluke Service Center

info@raytek.com.cn

© Raytek Corporation

Raytek

All rights reserved. Specifications

Santa Cruz, CA USA

Tel: +1 800 227 – 8074

+1 831 458 – 3900

Fax: +1 831 458 – 1239

Contacts

(USA and Canada only)

Berlin, Germany

Tel: +49 30 4 78 00 80

Beijing, China

Tel: +86 10 6438 4691

Tel: +86 10 4008103435

Internet: http://www.raytek.com/

Thank you for purchasing this Raytek product. Register today at www.raytek.com/register to receive

the latest updates, enhancements and software upgrades!

(Service)

info@raytek.fr

ukinfo@raytek.com

and the Raytek Logo are registered trademarks of Raytek Corporation.

subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

WARRANTY

The manufacturer warrants this instrument to be free from defects in material and workmanship

under normal use and service for the period of one year from date of purchase. This warranty extends

only to the original purchaser. This warranty shall not apply to fuses, batteries, or any product that

has been subject to misuse, neglect, accident, or abnormal conditions of operation.

In the event of failure of a product covered by this warranty, the manufacturer will repair the

instrument when it is returned by the purchaser, freight prepaid, to an authorized Service Facility

within the applicable warranty period, provided manufacturer’s examination discloses to its

satisfaction that the product was defective. The manufacturer may, at its option, replace the product in

lieu of repair. With regard to any covered product returned within the applicable warranty period,

repairs or replacement will be made without charge and with return freight paid by the manufacturer,

unless the failure was caused by misuse, neglect, accident, or abnormal conditions of operation or

storage, in which case repairs will be billed at a reasonable cost. In such a case, an estimate will be

submitted before work is started, if requested.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR USE.

THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE.

SOFTWARE WARRANTY

The manufacturer does not warrant that the software described herein will function properly in every

hardware and software environment. This software may not work in combination with modified or

emulated versions of Windows operating environments, memory-resident software, or on computers

with inadequate memory. The manufacturer warrants that the program disk is free from defects in

material and workmanship, assuming normal use, for a period of one year. Except for this warranty,

the manufacturer makes no warranty or representation, either expressed or implied, with respect to

this software or documentation, including its quality, performance, merchantability, or fitness for a

particular purpose. As a result, this software and documentation are licensed “as is,” and the licensee

(i.e., the User) assumes the entire risk as to its quality and performance. The liability of the

manufacturer under this warranty shall be limited to the amount paid by the User. In no event shall

the manufacturer be liable for any costs including but not limited to those incurred as a result of lost

profits or revenue, loss of use of the computer software, loss of data, the cost of substitute software,

claims by third parties, or for other similar costs. The manufacturer’s software and documentation are

copyrighted with all rights reserved. It is illegal to make copies for another person.

Specifications subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Content

CONTENT ............................................................................................................................................................ 4

1 SAFETY INSTRUCTIONS ............................................................................................................................. 6

2 PRODUCT DESCRIPTION .......................................................................................................................... 11

2.1 FEATURES ................................................................................................................................................... 12

3 TECHNICAL DATA ...................................................................................................................................... 13

3.1 MEASUREMENT SPECIFICATIONS ............................................................................................................... 13

3.2 OPTICAL CHARTS ....................................................................................................................................... 14

3.3 GENERAL SPECIFICATIONS ......................................................................................................................... 14

3.4 ELECTRICAL SPECIFICATIONS .................................................................................................................... 15

3.5 SCOPE OF DELIVERY ................................................................................................................................... 15

4 BASICS ............................................................................................................................................................. 16

4.1 MEASUREMENT OF INFRARED TEMPERATURE .......................................................................................... 16

4.2 EMISSIVITY OF TARGET OBJECT .............................................................................................................. 16

5 OPERATION ................................................................................................................................................... 17

5.1 QUICK START.............................................................................................................................................. 17

5.2 OVERVIEW .................................................................................................................................................. 17

5.3 DISTANCE AND SPOT SIZE ......................................................................................................................... 18

5.4 HIGH TEMPERATURE NOSE ....................................................................................................................... 19

5.5 POWER SUPPLY ........................................................................................................................................... 19

5.6 DISPLAY ...................................................................................................................................................... 20

5.7 SIGHTING .................................................................................................................................................... 20

5.7.1 Dual Laser .......................................................................................................................................... 20

5.7.2 Red Dot Scope ..................................................................................................................................... 20

5.8 TEMPERATURE RECORDS ........................................................................................................................... 20

5.9 SAVE BUTTON ............................................................................................................................................. 21

5.10 MENU ....................................................................................................................................................... 21

5.10.1 Overview........................................................................................................................................... 21

5.10.2 EMS - Emissivity ............................................................................................................................. 23

5.10.3 Light .................................................................................................................................................. 23

5.10.4 Profile ................................................................................................................................................ 23

5.10.5 Trend ................................................................................................................................................ 25

5.10.6 MnMx – Minimum, Maximum ....................................................................................................... 26

5.10.7 Avg – Average .................................................................................................................................. 26

5.10.8 Lock – Trigger Button....................................................................................................................... 26

5.10.9 Laser .................................................................................................................................................. 27

5.10.10 Setup ............................................................................................................................................... 27

5.10.10.1 Time/Date ................................................................................................................................ 27

5.10.10.2 Alarm........................................................................................................................................ 28

5.10.10.3 Transmissivity ......................................................................................................................... 28

5.10.10.4 Background Temperature ...................................................................................................... 28

5.10.10.5 Bluetooth .................................................................................................................................. 28

5.10.10.6 Language ................................................................................................................................. 28

5.10.10.7 To Default ................................................................................................................................ 29

5.10.11 Log .................................................................................................................................................. 29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

5.10.12 °C and °F ......................................................................................................................................... 30

5.10.13 Scope ................................................................................................................................................ 30

5.11 DATA DOWNLOAD ................................................................................................................................... 30

6 ACCESSORIES ................................................................................................................................................ 31

7 WINDOWS SOFTWARE .............................................................................................................................. 32

7.1 INTRODUCTION ........................................................................................................................................... 32

7.2 SYSTEM REQUIREMENTS ............................................................................................................................. 33

7.3 SOFTWARE INSTALLATION ....................................................................................................................... 33

7.4 COMMUNICATION ...................................................................................................................................... 34

7.5 REAL-TIME DATA ....................................................................................................................................... 36

7.5.1 Display ................................................................................................................................................ 36

7.5.2 Settings ............................................................................................................................................... 36

7.5.3 Replay .................................................................................................................................................. 37

7.6 RECORDED DATA ........................................................................................................................................ 39

7.6.1 Basic Data ........................................................................................................................................... 39

7.6.2 Trend Data .......................................................................................................................................... 40

7.6.3 Profile Data ......................................................................................................................................... 40

7.6.3.1 Local .............................................................................................................................................. 41

7.6.3.2 Device ........................................................................................................................................... 42

8 MOBILE APP ................................................................................................................................................... 45

8.1 REAL TIME VIEW......................................................................................................................................... 45

8.2 BASIC TEST DATA ....................................................................................................................................... 46

8.2.1 Data Review ........................................................................................................................................ 47

8.2.2 Data Review by Time .......................................................................................................................... 48

8.3 PROFILE TEST DATA ................................................................................................................................... 50

9 MAINTENANCE ............................................................................................................................................ 53

9.1 TROUBLESHOOTING .................................................................................................................................... 53

9.2 LENS CLEANING ......................................................................................................................................... 54

9.3 HOUSING CLEANING .................................................................................................................................. 54

9.4 LASER FAULT .............................................................................................................................................. 54

9.5 BATTERY EXCHANGE .................................................................................................................................. 55

10 APPENDIX ..................................................................................................................................................... 56

10.1 DETERMINATION OF EMISSIVITY .............................................................................................................. 56

10.2 TYPICAL EMISSIVITY VALUES ................................................................................................................... 56

10.3 COMPLIANCE STANDARDS ....................................................................................................................... 59

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Safety Instructions

1 Safety Instructions

This document contains important information, which should be kept at all times with the instrument

during its operational life. Other users of this instrument should be given these instructions. Eventual

updates to this information must be added to the original document. The instrument can only be

operated by trained personnel in accordance with these instructions and local safety regulations.

Acceptable Operation

This instrument is intended only for the measurement of temperature. The instrument operates

reliably in demanding conditions, such as in high environmental temperatures, as long as the

documented technical specifications for all instrument components are adhered to. Compliance with

the operating instructions is necessary to ensure the expected results.

Unacceptable Operation

The instrument should not be used for medical diagnosis.

Replacement Parts and Accessories

Use only original parts and accessories approved by the manufacturer. The use of other products can

compromise the operation safety and functionality of the instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

6 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 7

Safety Symbols

°C

°F

Li-ion

recycling information.

Restriction of the Use of Certain Hazardous Substances in Electrical and

Electronic Equipment

and is not to be used in homes.

Safety Instructions

Risk of danger. Important information. See manual.

Hazardous voltage. Risk of electrical shock.

Warning Laser.

RoHS

Helpful information regarding the optimal use of the instrument.

Celsius

Fahrenheit

Lithium-Ion Battery

This product complies with the WEEE Directive (2002/96/EC) marking

requirements. The affixed label indicates that user must not discard this

electrical/electronic product in domestic household waste. Product Category:

With reference to the equipment types in the WEEE Directive Annex I, this

product is classed as Category 9 "Monitoring and Control Instrumentation." Do

not dispose of this product as unsorted municipal waste. Go to Fluke’s website for

Conforms to European Union directive.

Conforms to China Metrology Certification

CMC mark with Implement standard Q/SXAV 16

Conforms to Canadian Standards Association Certification.

Electromagnetic Compatibility Applies to use in Korea only. Class A Equipment

(Industrial Broadcasting & Communication Equipment)

This product meets requirements for industrial (Class A) electromagnetic wave equipment and the

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 7

seller or user should take notice of it. This equipment is intended for use in business environments

www.GlobalTestSupply.com

Page 8

Safety Instructions

Class A digital device: This equipment has been tested and found to comply with

be required to correct the interference at their own expense.

the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if it is not installed

and used in accordance with the instruction manual, it may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will

See figure below for the safety markings.

Find Quality Products Online at: sales@GlobalTestSupply.com

8 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 9

Safety Instructions

Warnings

A warning identifies conditions and procedures that are dangerous to the user.

To prevent possible electrical shock, fire, or personal injury follow these guidelines:

• Read all safety information before you use the product.

• Use the product only as specified, or the protection supplied by the product can be

compromised.

• Do not use the product around explosive gas, vapor, or in damp or wet environments.

• Do not use the product if it operates incorrectly.

• See emissivity information for actual temperatures. Reflective objects result in lower than

actual temperature measurements. These objects pose a burn hazard.

• Do not look directly into the laser with optical tools (for example, binoculars, telescopes,

microscopes). Optical tools can focus the laser and be dangerous to the eye.

• Do not look into the laser. Do not point laser directly at persons or animals, or indirectly off

reflective surfaces.

• Use the product only as specified, or hazardous laser radiation exposure can occur.

• Do not use laser viewing glasses as laser protection glasses. Laser viewing glasses are used

only for better visibility of the laser in bright light.

• Do not open the product. The laser beam is dangerous to eyes. Have the product repaired

only through an approved technical site.

• Have an approved technician repair the product.

Cautions

A caution identifies conditions and procedures that can cause damage to the instrument or the

equipment under test.

For safe operation and maintenance of the product:

• Remove the batteries if the product is not used for an extended period of time, or if stored in

temperatures above 50°C (122°F). If the batteries are not removed, battery leakage can damage

the product.

• Recharge the batteries when the low battery indicator appears to prevent incorrect

measurements.

• Have the product repaired before use if the batteries leak.

• Do not short the battery terminals.

• Do not keep cells or batteries in a container where the terminals can be shorted.

• Do not put battery cells and battery packs near heat or fire. Do not put in sunlight.

To avoid damage to the product or the equipment under test, protect them from:

• EMF (electro-magnetic fields) from arc welders, induction heaters, etc.

• Static electricity

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 9

www.GlobalTestSupply.com

Page 10

Safety Instructions

Battery Warning

The battery is a safety device. Do not attempt to disassemble or alter the battery. Always observe the

following precautions:

• Do not short-circuit the battery by directly connecting the negative terminals with positive

terminal.

• Do not heat the battery or discard it in a fire.

• Do not expose the battery to temperatures over 50°C (122°F). Keep the battery away from fire

and other heat sources.

• Do not charge the battery near a heat source, such as, a fire or heater.

• Do not leave the battery in direct sunlight.

• Do not pierce the battery with a sharp object, hit or step on it.

• Do not use a damaged battery.

• Do not apply solder to a battery.

• Do not connect the battery to an electrical power outlet.

To prevent the battery bursting, igniting, or fumes from the battery causing equipment damage,

always observe the following precautions:

• Do not immerse the battery in water or allow it to get wet.

• Do not place the battery in a microwave oven or pressurized container.

• If the battery leaks or emits an odor, remove it from all possible flammable sources.

• If the battery emits an odor or heat, is deformed or discolored, or in a way appears abnormal

during use, recharging or storage, immediately remove and stop using it.

Instrument

• If the unit is exposed to significant changes in ambient temperature (hot to cold or cold to

hot), allow 30 minutes for temperature stabilization before taking measurements.

• Do not operate the unit near large electrical or magnetic fields such as arc welders and

induction heaters. These fields can cause measurement errors.

• For the short wavelength units (e.g., 1.0 µm and 1.6 µm) — avoid taking temperature

measurements in bright sunlight. High levels of ambient light may produce apparently valid

high-temperature readings when no target is in the thermometer’s field-of-view.

Find Quality Products Online at: sales@GlobalTestSupply.com

10 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 11

Product Description

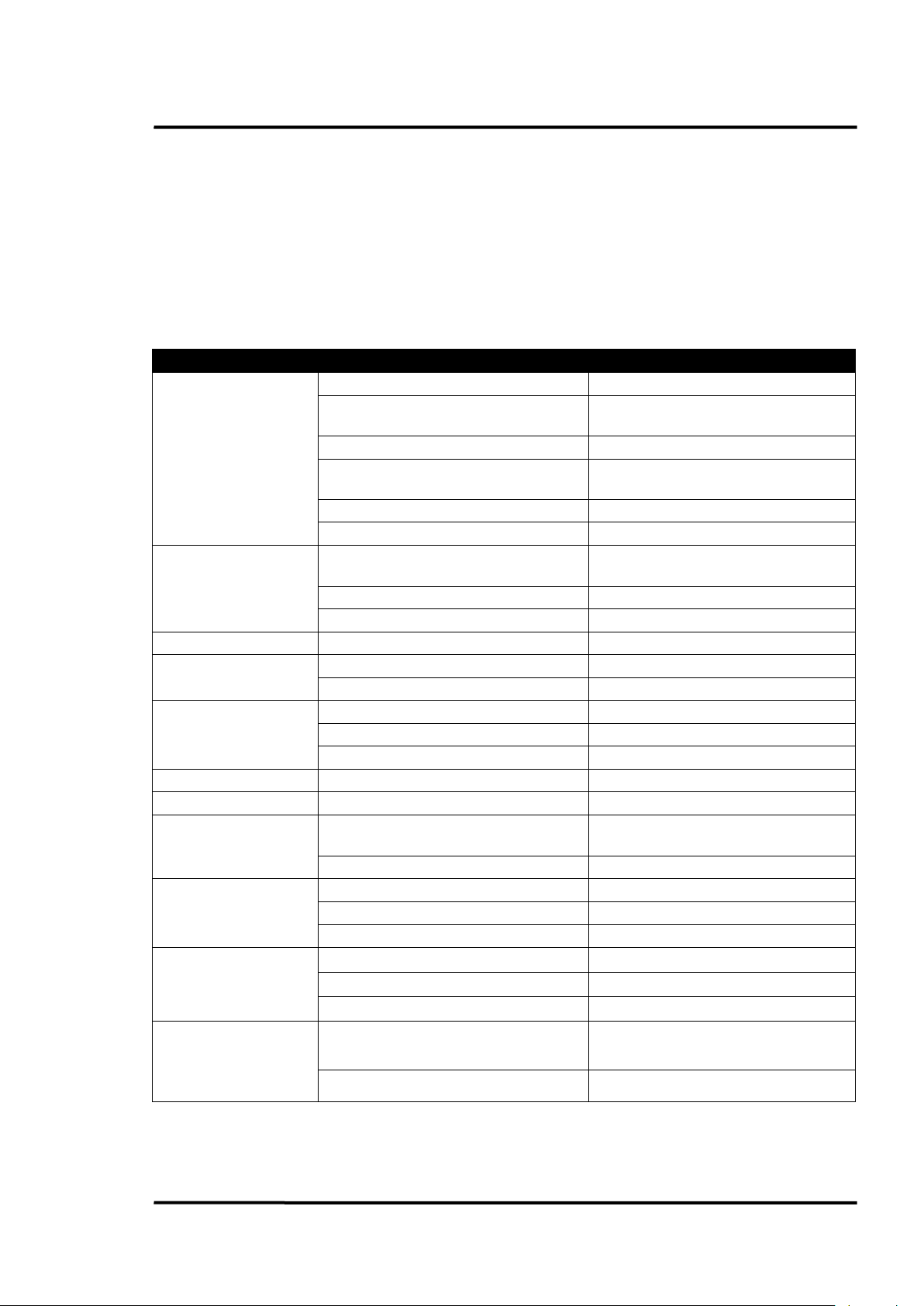

Model

Temperature

Optics

Spectral

Sighting

700 to 3000°C

(1292 to 5432°F)

700 to 3000°C

(1292 to 5432°F)

400 to 2000°C

(752 to 3632°F)

400 to 2000°C

(752 to 3632°F)

2 Product Description

The Raynger 3i Plus Series of instruments are portable infrared temperature measurement devices.

Each model is rugged and easy to use for making fast, noncontact, nondestructive temperature

measurements. They can measure product temperatures during manufacturing or storage without

contaminating or marring the product.

Figure 1: Raynger 3i Plus Series

The Raynger 3i Plus Series thermometer is an upgraded version of Ranger 3i Series. It provides high

performance with better accuracy, increased optical resolution, a larger memory and other highlighted

functions. It is the best solution for monitoring process temperature and initial breakdown for the

steel, cement, heat treatment, and petrochemical industries.

Refer to the following table for a list of standard models along with their temperature ranges, optical

resolutions, spectral ranges, and sighting systems.

RAYR3IPLUS1ML

RAYR3IPLUS1MSCL

RAYR3IPLUS2ML

RAYR3IPLUS2MSCL

Table 1: Available Models

250:1 1 µm Dual laser

250:1 1 µm Dual laser + Scope

250:1 1.6 µm Dual laser

250:1 1.6 µm Dual laser + Scope

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 11

www.GlobalTestSupply.com

Page 12

Product Description

2.1 Features

The Raynger 3i Plus Series has the following features:

• Dual laser sighting

• Current temperature plus MAX, MIN, DIF, AVG temperatures

• Audible/visual alarms for target temperature, ambient temperature, and low battery

• Adjustable emissivity and predefined emissivity table

• Background temperature compensation

• Transmissivity compensation

• User selectable °C or °F

• Profile definition to convenient measurement

• Curve to display trend with selectable time span

• Tripod mount

• Auto off

• 12- or 24-hour real time clock

• Last reading hold (20 seconds)

• English and Chinese user interface

• Data storage: up to 4,900 units with location, date, and time stamp

• Trigger lock

• USB 2.0 computer interface

• Lithium-ion battery, charged with or without unit

• Red dot scope sighting (scope model)

• Special material for 120°C (248°F) high temperature

• Warning system to prevent high temperature damage

®

• Bluetooth

• Documenting personal computer (PC) software

wireless technology1 for communication with a mobile device

1

Bluetooth® is a registered trademark owned by Bluetooth SIG, Inc.

Find Quality Products Online at: sales@GlobalTestSupply.com

12 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 13

3 Technical Data

3.1 Measurement Specifications

Temperature Range

1M 700 to 3000°C (1292 to 5432°F)

2M 400 to 2000°C (752 to 3632°F)

Spectral Response

1M 1.0 µm

2M 1.6 µm

Optical Resolution D:S

All models 250:1

System Accuracy

1M ± (0.5% or reading + 1°C) for < 2700°C

2M ± (0.5% or reading + 1°C)

Repeatability

3

± (0.3% or reading + 1°C)

1

16 mm spot @ 4000 mm distance (0.63 in @ 157 in)

2

± (0.5% or reading + 2°F) for < 4892°F

± 2% or reading for > 2700°C (4892°F)

± (0.5% or reading + 2°F)

± (0.3% or reading + 2°F)

Technical Data

Temperature Resolution

Display ± 0.1°C (0.1°F)

Exposure Time 40 ms (95%)

Display Refresh Time 200 ms

Emissivity 0.01 to 1.00

Signal Processing Max / Min / Avg / Diff

1

at 90% energy in minimum and distance 4000 mm (157 in.)

2

Calibration geometry at ambient temperature 23°C ±2°C (73°F ±4°F), emissivity = 1.0

3

Calibration geometry at ambient temperature 23°C ±2°C (73°F ±4°F), emissivity = 1.0

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 13

www.GlobalTestSupply.com

Page 14

Technical Data

3.2 Optical Charts

Figure 2: Spot Size Charts

3.3 General Specifications

Operating Temperature 0 to 50°C (32 to 122°F)

Storage Temperature -20 to 60°C (-4°F to 140°F) without battery

Operating Humidity 10 to 90% RH, not condensing at 30°C (86°F)

Environmental Rating IP40 (NEMA 1)

Drop Performance 1 m (3.3 ft)

Operating Altitude ≤ 2 000 m (6,500 ft.)

Storage Altitude ≤ 12 000 m (40,000 ft.)

Size

Standard 218 x 172 x 74 mm (8.6 x 6.8 x 2.9 in.)

with scope 218 x 222 x 74 mm (8.6 x 8.7 x 2.9 in.)

Find Quality Products Online at: sales@GlobalTestSupply.com

14 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 15

Technical Data

Weight

Standard 700 g (25 oz)

with scope 950 g (34 oz)

Display Illuminated backlight display

(On/Off, white color, orange color)

display Hold (20 s)

Laser Dual laser (EN60825 Class 2, FDA Class II)

3.4 Electrical Specifications

Power Supply Battery or USB

Battery Lithium-ion, single cell, 3.6 V, 2500 mAh

1

Battery Life

USB Version 2.0, Mini USB (type B)

Bluetooth Version 4.0

24 h

Item Specifications

Frequency 2402 MHz in 2 MHz steps

Data Rate and Modulation 1Mbps, GFSK

Number of Channels 40:37 data / 3 advertising (0,12,39)

Receive Sensitivity (w/ chip antenna) -95 / -89 dBm

Output Power -23 to 4 dBm

Link Budget Up to 99 dB

RX/TX Turnaround 150 µs

3.5 Scope of Delivery

The scope of delivery includes the following:

• Raynger 3i Plus

• Carrying case

• CD with software for real-time graphic temperature display and data download, and

operator's manual (PDF format)

• Lithium-ion battery 2.5 Ah

• Mini USB port adapter (100 – 240 VAC 50/60 Hz)

• Mini USB to DC jack converter for charging battery separately

• 1.5 m (4.9 ft.) computer cable with USB to Mini USB

• Operator’s manual (printed format)

1

Laser: off, Bluetooth: off

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 15

www.GlobalTestSupply.com

Page 16

Basics

4 Basics

4.1 Measurement of Infrared Temperature

All objects emit an amount of infrared radiation according to their surface temperature. The intensity

of the infrared radiation changes according to the temperature of the object. Depending on the

material and surface properties, the emitted radiation lies in a wavelength spectrum of approximately

1 to 20 µm. The intensity of the infrared radiation (”heat radiation”) is dependent on the material. For

many substances this material-dependent constant is known. It is referred to as ”emissivity value”

(see section 10.2 Typical Emissivity Values, page 56.

Infrared thermometers are optical-electronic sensors. These sensors are able to detect ”radiation of

heat.” Infrared thermometers are made up of a lens, a spectral filter, a sensor, and an electronic signalprocessing unit. The task of the spectral filter is to select the wavelength spectrum of interest. The

sensor converts the infrared radiation into an electrical signal. The signal processing electronics

analyzes the electrical signal and converts it into a temperature measurement. As the intensity of the

emitted infrared radiation is dependent on the material, the required emissivity can be selected on the

sensor.

The biggest advantage of the infrared thermometer is its ability to measure temperature without

touching an object. Consequently, surface temperatures of moving or hard to reach objects can easily

be measured.

4.2 Emissivity of Target Object

Determine the emissivity of the target object as described in section 10.1 Determination of Emissivity,

page 56. If emissivity is low, measured results could be falsified by interfering infrared radiation from

background objects (e.g., heating systems, flames, fireclay bricks, etc., close beside or behind the target

object). This type of problem can occur when measuring reflecting surfaces and very thin materials

such as plastic films and glass.

This measuring error can be reduced to a minimum if particular care is taken during installation, and

the sensing head is shielded from these reflecting radiation sources.

Find Quality Products Online at: sales@GlobalTestSupply.com

16 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 17

Operation

modes and functions, and for full

5 Operation

5.1 Quick Start

To use the instrument right away, complete the following steps:

1. Point the instrument at the object the user wants to measure (as perpendicular as possible to

the object) and pull the trigger. The current temperature (in °C or °F), emissivity value, and

maximum and minimum measured temperature are displayed.

2. Change the emissivity value to correspond to the targeted material by pressing the <F1> key

twice to show the target material table. Press the ▲ and ▼ buttons to select the target material.

For complete definitions of the instrument’s

explanation of operation, refer to the later sections.

5.2 Overview

Portable infrared thermometers measure surface temperatures without touching the surface. They

collect the infrared energy radiated by a target and compute its surface temperature. They also

compute the running average, and maximum/minimum/differential temperatures and present them

on a digital display in either degrees Celsius or Fahrenheit. The instrument is battery-powered or can

be powered by a computer’s USB interface. Internal memory circuits store temperature data for later

recall, and a data-logging feature allows users to store and multiple temperature, emissivity, and

alarm readings (valuable for comparative analysis).

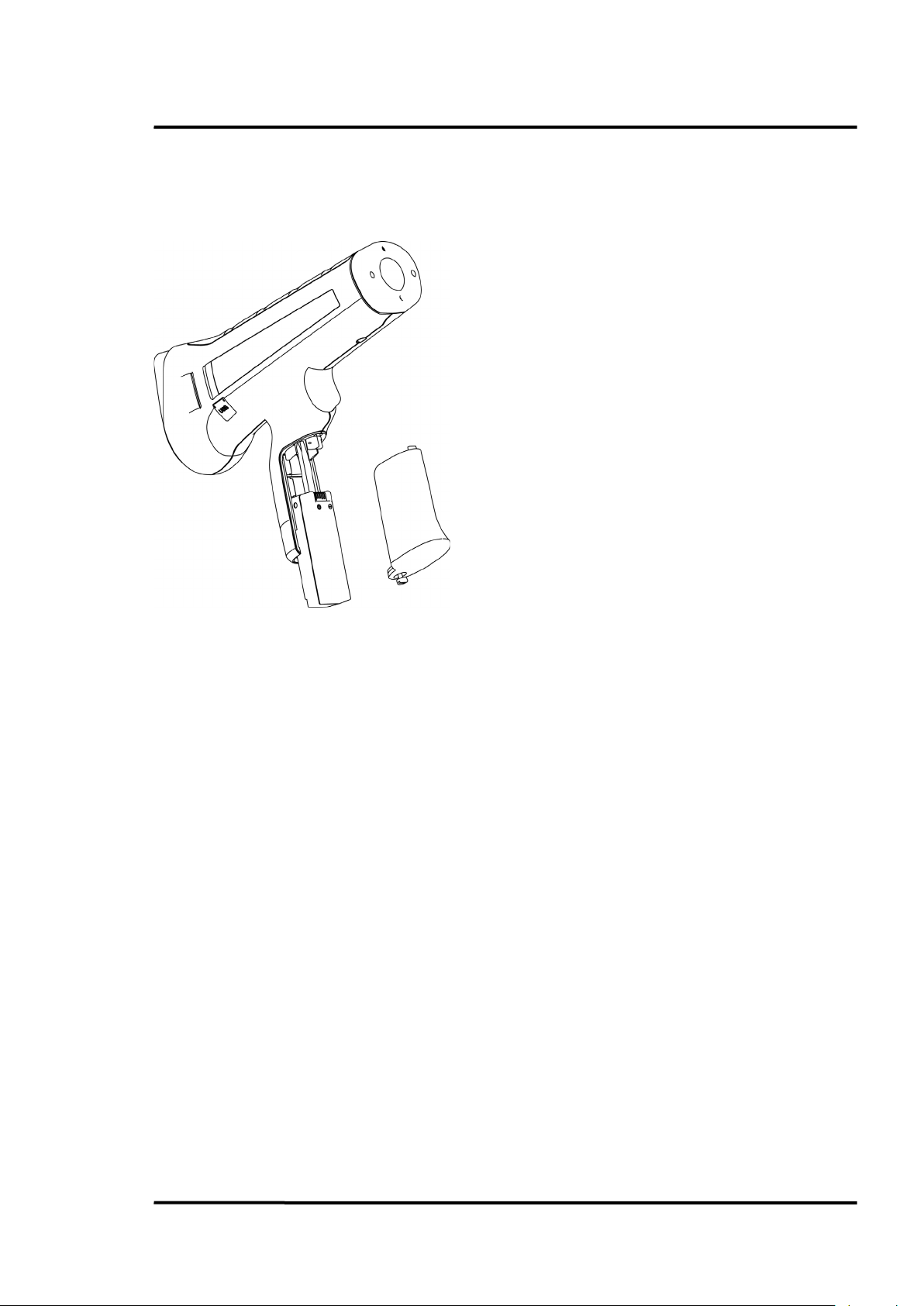

The following figure shows the features of the portable infrared thermometer.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 17

www.GlobalTestSupply.com

Page 18

Operation

Nose with Temperature

Tripod Screw

Trigger

Battery Cover and Screw

USB Interface

Save Key

Return Key

3x Soft Keys

Red Dot Scope

Polaroid Frame

Scope Adjustable Screw

2 Laser Aperture

Sensor inside

Figure 3: Portable Thermometer with Scope

The portable thermometer has the following:

Trigger: One-stage trigger, which activates the unit to take temperature readings.

Control Panel and Display: All controls (except the trigger) are located on the control panel. The

display shows temperature and setup values, mode and operating information.

Mini USB Output: Connects the instrument to the PC for downloading data or to DC Adaptor for

charging the battery.

Nose with Temperature Sensor inside: Has the thermistor on the nose for high temperature

protection.

Sighting System: Laser or red dot scope sighting is provided with each model for aiming. Note: Read

the laser warning label before operating the laser.

Polaroid Frame: To adjust brightness of red dot scope.

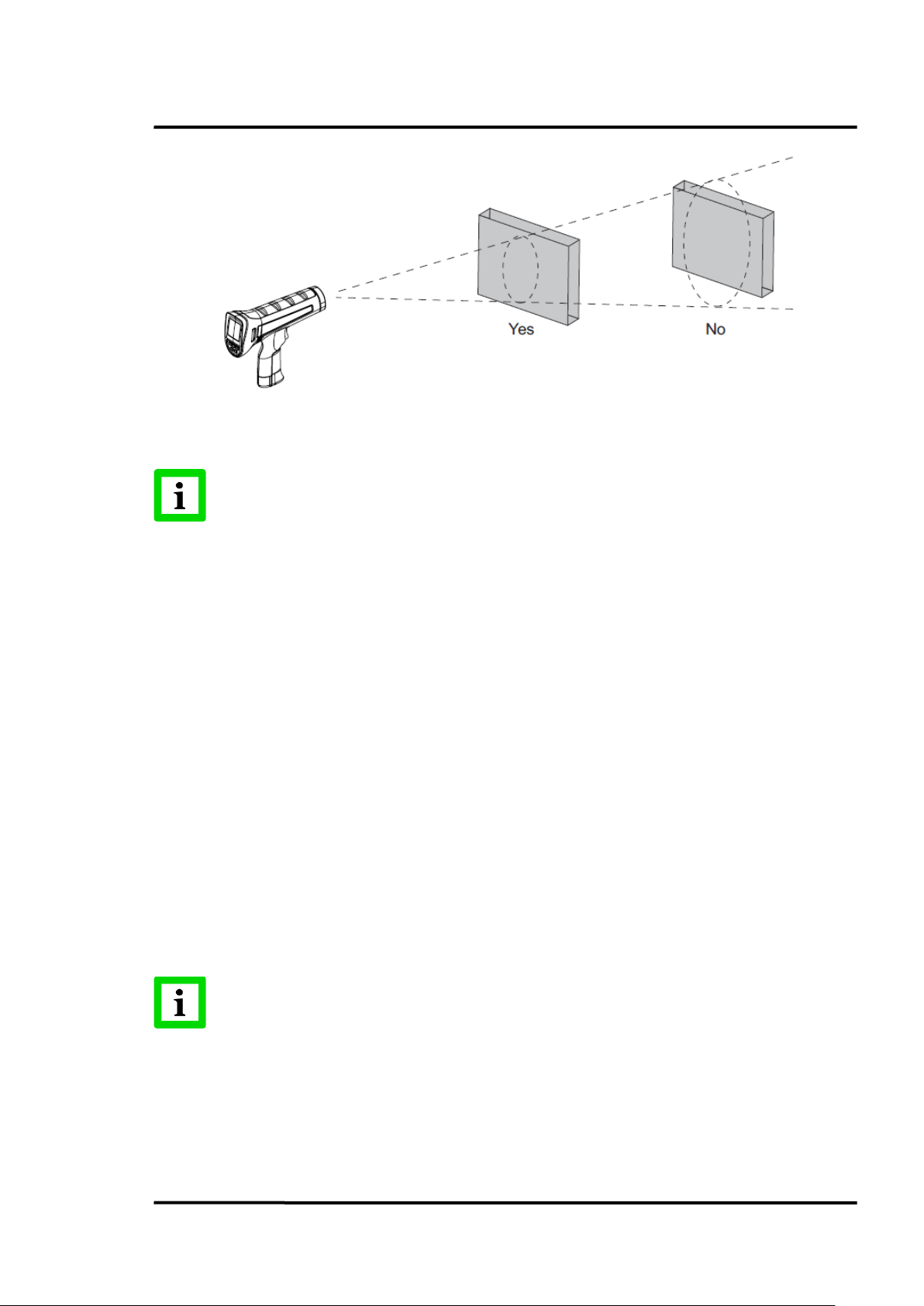

5.3 Distance and Spot Size

As the distance (D) from the object being measured increases, the spot size (S) of the area measured by

the instrument becomes larger. For the relationship between distance and spot size (D:S), see section

3.2 Optical Charts, page 14.

During measurements, please make sure that the target is larger than the instrument’s measurement

spot size at that distance. The smaller the target, the closer user should be to it.

Find Quality Products Online at: sales@GlobalTestSupply.com

18 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 19

For accurate measurements the target size must be at least two times bigger than the

Spot diameter

there is

Operation

Figure 4: Field of View

5.4 High Temperature Nose

The instrument has a specially designed nose with high temperature resistant plastic material to avoid

damage from high temperature targets. On the other hand, please avoid over exposure when aiming

at a high-temperature target.

There is a temperature sensor inside the nose. During measurement, the instrument is monitoring the

temperature of the nose. If it is too hot, there will be a warning on the LCD display (ambient highlight

display and backlight change to red plus audible buzzer). Please move the unit away from the hightemperature target when seeing this alarm.

5.5 Power Supply

The instrument is powered by a battery or USB cable when connect to the PC. The battery is located in

the base of the handle.

The instrument provides two charging methods:

• AC adaptor through Mini USB port on the right side of the unit.

• Remove the battery, and use the AC adaptor plus Mini USB-to-DC jack converter to charge.

An indicator on the battery will show a “charging” red light and “charge complete” green

light.

The instrument can be powered when connecting the USB cable to the PC but

no charging since many USB ports have not enough power capability!

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 19

www.GlobalTestSupply.com

Page 20

Operation

5.6 Display

The display retains the last infrared measurement for 20 s when the trigger is released and <HOLD> is

shown on the display. To hold the infrared temperature, release the trigger until <HOLD> shows on

the display.

5.7 Sighting

5.7.1 Dual Laser

All models use a dual laser method to show the measurement spot position and size. The two laser

points show the diameter of the spot circle, with the middle laser point as the center of the spot circle.

5.7.2 Red Dot Scope

The scope models for the Raynger 3i Plus series provide an additional red dot scope; the measurement

target can be seen through the scope. That aiming system can be used when the laser points are hard

to see due to the brightness of the target.

The scope's red dot shows the center of the measuring spot circle, which does not display on the real

object under measurement.

The intensity of the field sight can be adjusted by rotating the knob on the top of the instrument while

keeping the brightness of the red dot. This function is helpful for the user to clearly see the red dot

position when the instrument is measuring high-temperature objects.

If the scope's red dot does not match with the circle of the two laser points, use the following

adjustment method:

1. Open the two circular rubber caps on the top of the unit, and the scope's two adjustable

screws are shown.

2. Affix the unit to a tripod.

3. Aim at a target 4 m (13 ft.) off in the distance, like a wall, for viewing the two lasers clearly.

4. Adjust the two screws on the aiming scope to the center of the two laser points. Please try to

look straight through the aiming scope.

5. Remove the unit from the tripod.

6. Close the two circular rubber caps.

Warning: Please do not use the unit with the two rubber caps open, since unexpected contact with

the screws may introduce noise pulse to the units, resulting in noise readings or disorder of the

display

5.8 Temperature Records

The instrument can store measurement records, including time, date, emissivity, and measurement

record numbers. It can store 1,000 records for basic test data, 10 pcs trend display and 300 records for

profile.

The following types of data are available:

• Basic test data: Test data without a dedicated setting like profile. User can record random

measurement data in this area with a maximum 1,000 records.

• Trend data the data saved under trend mode which includes three screens of data with 360

test values. The data will be saved in a curve format and the user can review the value of each

test point with PC software. Press <View> to review the trend picture. User can press up and

Find Quality Products Online at: sales@GlobalTestSupply.com

20 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 21

Operation

down arrows to select each saved trend data. The user can then use left and right arrows to

view the three screens for each piece of trend data.

• Profile test data: Profile setting under which 300 test data records (maximum) are saved.

Profile test data is defined as the test data under profile setting which could save maximum

300 records. By using the load value of each profile, these test data has been divided by group

according to the profile setting in PC software. User can find the temperature distribution

status in one group and convenient the measurement by using the setting in advance.

5.9 Save Button

The instrument can store up to multiple data records. The information below is stored in each record:

• Record number

• IR temperature in °F or °C

• Date/Time

• Emissivity

To save the current temperature reading (Basic test data):

1. Pull the trigger to take a measurement.

2. Release the trigger to stop taking the measurement.

3. Push the <Save> soft key to enter the Save menu.

4. Push the <Yes> soft key to save the reading.

The user can also push the <Cancel> soft key to not save the reading.

The <Save> soft key is also used to save records as profile or trend.

5.10 Menu

The instrument can display two languages, English and Simplified Chinese. To change the displayed

language, see section 5.10.10.6 Language, page 28.

5.10.1 Overview

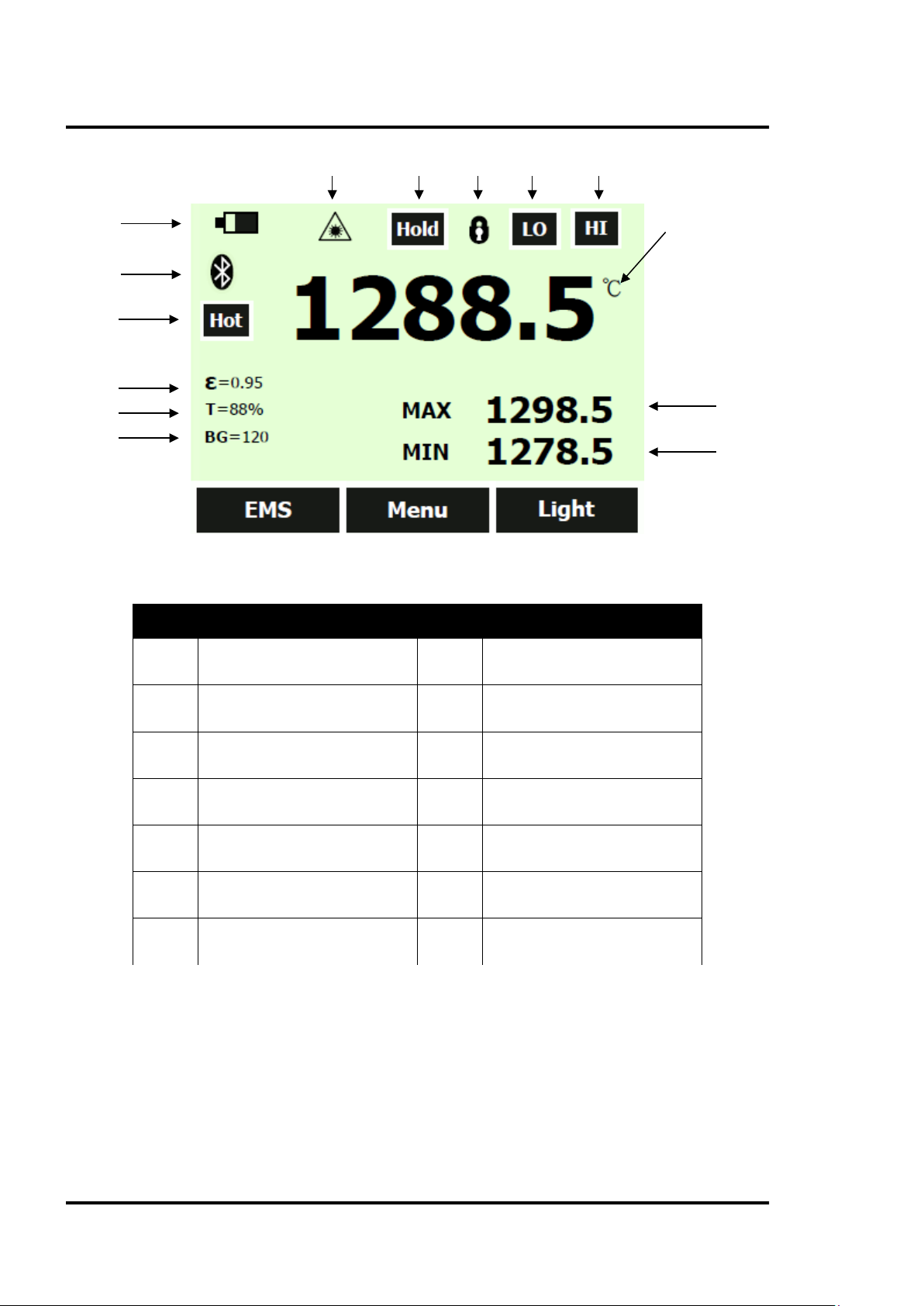

There are many settings that can be changed with the menu. The following figure shows the LCD and

menu interface.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 21

www.GlobalTestSupply.com

Page 22

Operation

② ③ ④ ⑤ ⑥ ⑦ ⑧

①

⑭

⑬

⑫

⑪

⑩

⑨

Figure 5: User Interface

Number Description Number Description

①

②

③

④

⑤

⑥

⑦

The Raynger 3i Plus series has three soft keys (F1, F2, and F3) just below the LCD display. There is a

“Soft Key Bar” on the LCD above the three soft keys to define their active function. By using soft keys,

the instrument has a convenient menu function. Each menu item and function is explained in detail in

the following sections.

In addition to the soft keys, there are also the <Save> and <Return> soft keys below the LCD display.

Selecting the <Menu> soft key advances the menu to the next level. The following table shows the toplevel description of the menu.

Battery Symbol

Laser Indicator

Scan/Hold

Lock/Unlock

Low Temperature Alarm

High Temperature Alarm

Main Temperature Display

Table 2: Menu Overview

⑧

⑨

⑩

⑪

⑫

⑬

⑭

Max. Value Display

Min. Value Display

Background Temp. Compensation

Transmissivity

Emissivity

“Hot” Warning Area

Bluetooth Symbol

Find Quality Products Online at: sales@GlobalTestSupply.com

22 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 23

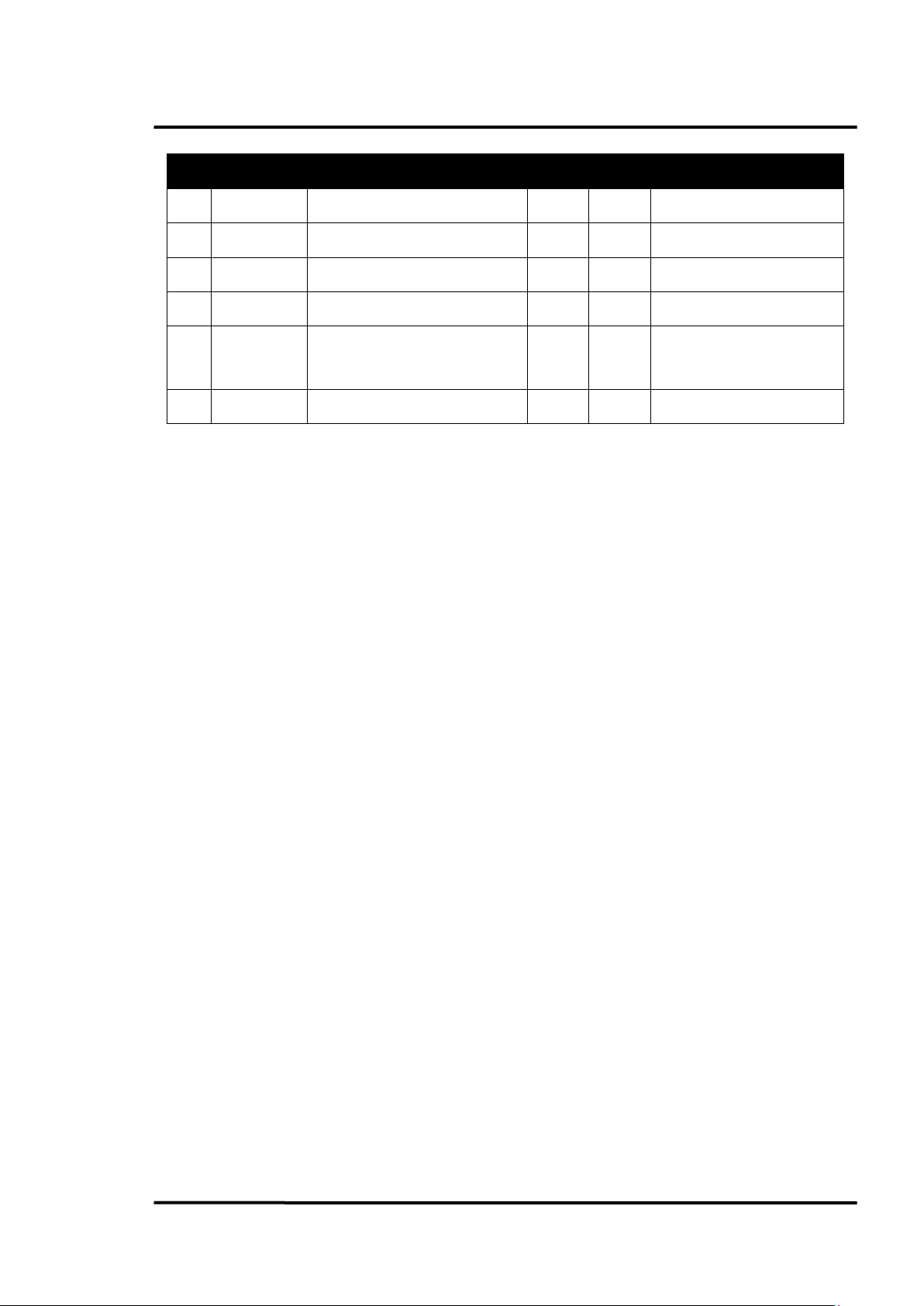

Operation

Level

<F1>

Description

<F2>

<F3>

Description

3

MnMx

Enables minimum/maximum

Menu

Avg

Enables average/difference

4

Lock/Unlock

Locks/unlocks the trigger button

Menu

Laser

Toggles the laser

Time/Date, Alarm, Transmissivity,

Language

6

°C/°F

Toggles between C and F

Menu

Scope

Toggles the red dot in the scope

1 EMS Sets the emissivity value Menu Light Toggles the LCD backlit

2 Profile Calls predefined profiles Menu Trend Reviews recorded trends

5 Setup

<Save> button Save Reading to Memory <Return> button Back to Last Menu

Background Temperature, Bluetooth,

Table 3: Top-Level Menu Description

Menu Log

Review/Delete recorded

temperatures

5.10.2 EMS - Emissivity

The <Emissivity> menu includes a list of pre-defined materials and their typical emissivity values, see

section 10.2 Typical Emissivity Values, page 56. The instrument’s default emissivity value is 1.00.

To access the Emissivity menu:

1. Push the <Menu> soft key until EMS (emissivity) is shown as the right soft key function.

2. Push the <EMS> soft key.

The user can push the table soft key to access the emissivity list. The user can also push the <No.> soft

key to manually enter the typical emissivity of a material.

If the Emissivity table is accessed, a list of materials and their suggested emissivity is shown.

1. Use the down arrow to navigate through the list.

2. Push the <Done> soft key to choose the desired material.

To enter an emissivity value manually:

1. Push the <No.> soft key.

2. Use the down or up arrow soft key to change the entry. Hold down the up or down arrow soft

key to increase the rate of change.

3. Push the <Done> soft key when finished to return to the main menu.

5.10.3 Light

The instrument has a backlit display. The backlight can be toggled by pushing the <Light> soft key.

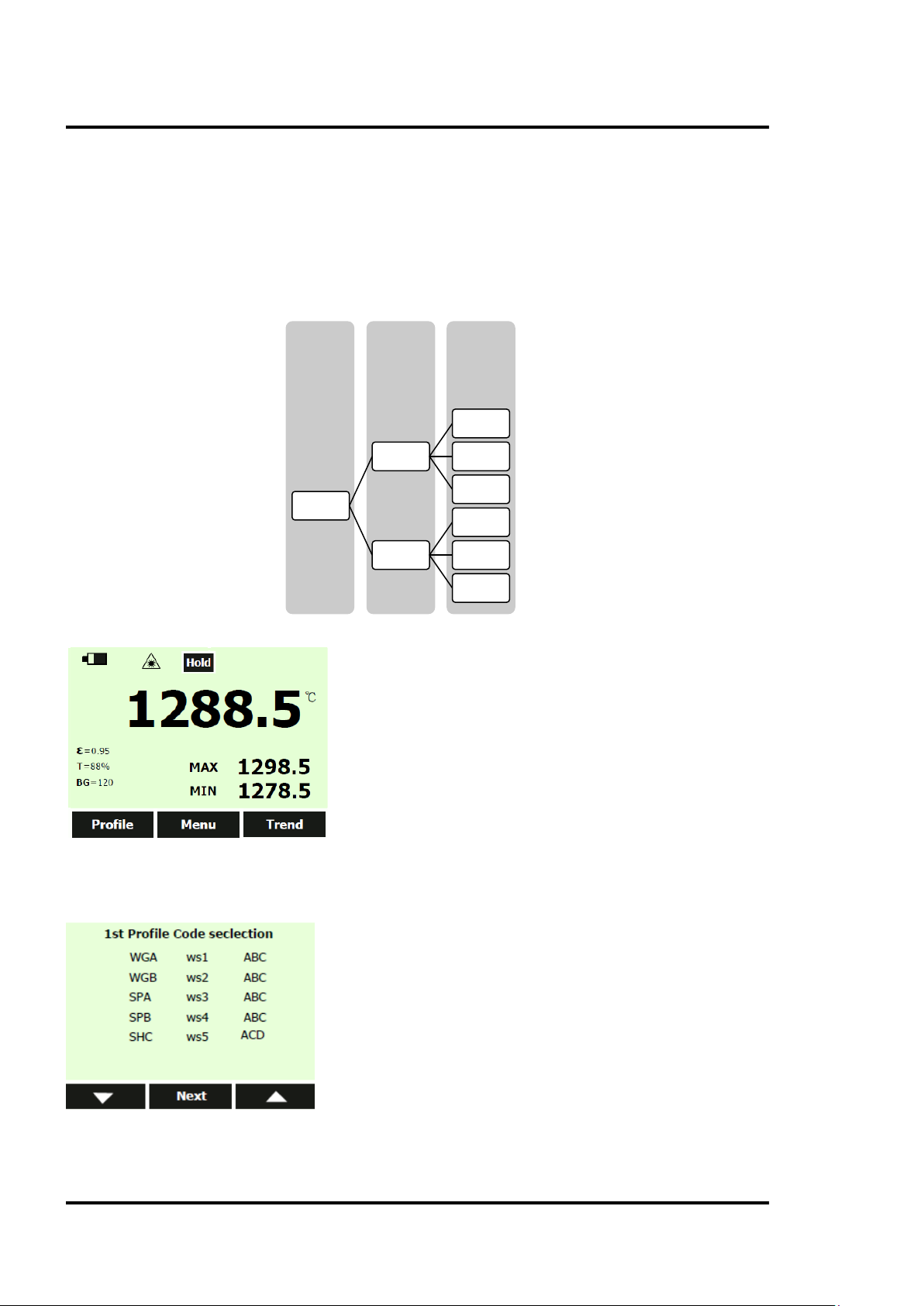

5.10.4 Profile

To manage regular testing points, different profiles can be created by the Raynger 3i Plus software.

Each profile includes the settings for Emissivity, Alarm Temperature, Transmissivity, Background

Temperature, etc., as well as a unique profile name. When the setting is ready, the user can simply

select the profile name to call up the settings, save data and review accordingly.

The maximum number of test points is 300. These test points are arranged in three levels, and the

maximum allowed for the second level is 50. The first and second levels could be represented by three

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 23

www.GlobalTestSupply.com

Page 24

Operation

characters (combination of number and letter), and the third level can be defined by a sequential test

point number. The user can define the unique structure to meet complicated needs.

The following example can be regarded as a sequential structure:

• First level: WGA and WGB represent two heating ovens.

• Second level: ECA and ECB belong to WGA. The second level can be set up to 50 test points.

• Third level: Indicates the location number in each second-level folder. The sums for location

numbers in all third levels can up to 300 points.

3rd Level 2nd Level 1st Level

1

ECA

WGA

ECB

Examples are as follows:

Press <Profile> to enter the first level menu selection. Each displayed name is edited under the PC

interface, and then uploads to the instrument. Here the user can continue to the next screen using the

arrow keys if the item quantity is more than 15.

...

100

1

...

20

Press <Next> to continue to the second level menu, and upload to the instrument. Here, the user can

also continue to the next screen using the arrow keys.

Find Quality Products Online at: sales@GlobalTestSupply.com

24 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 25

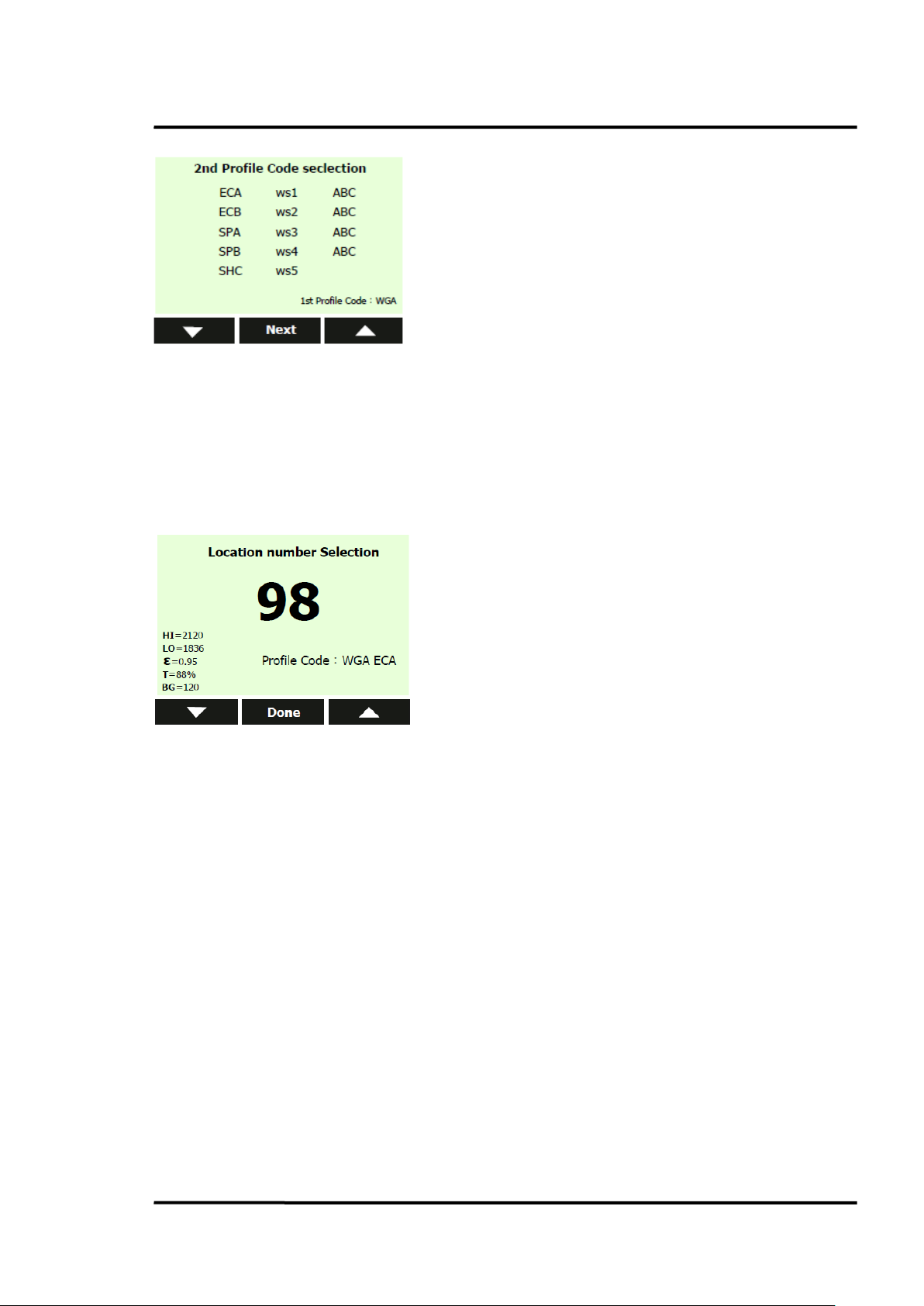

Operation

Choose the <Next> button, and the user can select location number and use various preset parameters

to perform test.

In the following example, selecting profile code WGA ECA location number 98 has a setting of:

High -temperature Alarm HI = 2120

Low -temperature Alarm LO = 1836

Emissivity ε = 0.95

Transmissivity T = 88%

Background Temperature Compensation BG = 120

Press <Done> to adopt this setting for this location and perform normal measurement.

If the user chooses to save the test data, the test point number will auto jump to the next one. If the

user doesn’t save the test data, the profile will keep the current test point.

Note: In this mode, the user can modify the emissivity values to adapt to field test conditions and use

<Save> soft key to save this change.

5.10.5 Trend

Press the <Menu> button, until <Trend> displays for the right function key and press enter.

The instrument provides two modes to display the trend.

• <Auto>: The user does not need to consider how to set upper and lower limits for the

displayed temperature. The temperature axis will be changed according to the actual

measurement range. After the user chooses an appropriate time span, the curve can be

displayed on the screen.

• <Manual>: The user should manually set the upper and lower limits for the Y-axes and the

time span for the X-axes in accordance to his needs.

Press the left key to enter the <Auto> mode. Enter the time axis settings. Press the arrow keys to select

the time interval. The unit can select 20 ms, 200 ms, 1 s, 10 s, 1 min, and 5 min time spans. After the

user has confirmed the selected time span and presses the trigger, the trend can be displayed on the

screen.

User also can choose the <Manual> mode to set the upper and lower limits and the time span.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 25

www.GlobalTestSupply.com

Page 26

Operation

The instrument will save three pages of curves when the user presses <Save>.

The maximum record in trend mode is 10 pcs curve; each curve can be displayed in three pages.

The figure below is under trend auto mode.

1. The data show on Y-axes is automatically displayed using the maximum and minimum value

in the record period.

2. The data show on X-axes is calculated by the time span the user has chosen.

Every page can store 120 points, so if you choose a time span with 200 ms, the maximum value on Xaxes should be 24 s.

5.10.6 MnMx – Minimum, Maximum

The instrument can measure the minimum (Min), maximum (Max) temperatures each time a reading

is taken.

To turn on the Min-Max mode:

1. Push the <Menu> soft key until <MnMx> (Min-Max) in shown as the F1 soft key function.

2. Push the <MnMx> soft key.

The display shows now the minimum and maximum readings.

5.10.7 Avg – Average

The instrument can measure the average (Avg) and differential (Dif) temperatures each time a reading

is taken.

To turn on the Avg/Dif mode:

1. Push the <Menu> soft key until <Avg> shows as the right soft key function.

2. Push the <Avg> soft key.

The display shows the average reading and the differential reading which is the difference between

the present minimum and the maximum temperature.

Averaging can be useful when an average temperature over a specific duration is desired, or when a

smoothing of fluctuating temperature is required. The signal is smoothed depending on the defined

time basis. In other words, the output signal tracks the detector signal with significant time delay but

noise and short peaks are damped.

5.10.8 Lock – Trigger Button

The instrument’s trigger can be locked to take temperature readings continuously without pressing

the trigger button all the time.

To lock the trigger button:

Find Quality Products Online at: sales@GlobalTestSupply.com

26 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 27

Operation

1. Push the <Menu> soft key until the lock symbol shows as the left soft key function.

2. Push the soft key to lock the trigger. The lock symbol

a locked trigger. When the trigger is locked, the soft key changes to unlock. Push this soft key

to unlock the trigger.

5.10.9 Laser

The laser is to be used for aiming purposes only. It turns off when the trigger is released.

To enable or disable the laser:

1. Push the <Menu> soft key until <Laser> shows as the right soft key function.

2. Push the <Laser> soft key to enable or disable the laser. The laser symbol is shown on the

display when the laser is enabled.

To prevent eye damage and personal injury, do not look into the laser. Does not point

Do not point the laser directly at persons or animals or indirectly off reflective surfaces.

5.10.10 Setup

From the <Setup> menu, the time and date, alarm, transmissivity, background temperature, display

language and Bluetooth switch can be changed. In the <Setup> menu, transmissivity, and background

temperature can be set by the user.

is shown on the display to designate

5.10.10.1 Time/Date

To change the time on the instrument:

1. Push the <Menu> soft key until <Setup> shows as the left soft key function.

2. Push the <Setup> soft key to enter the <Setup> menu.

3. Push the down arrow soft key to select <Time/Date>.

4. Push the <Enter> soft key.

5. Push the <Time> soft key.

6. Push the necessary time format soft key (24-hour or 12-hour).

7. Use the up and down soft keys to the desired hour.

8. Push the <Next> soft key to select the minutes.

9. Use the up and down soft keys to the desired minute.

10. When in 12-hour mode, push the <Next> soft key to highlight the AM/PM parameter.

11. Use the up and down soft key to change to <AM> or <PM>.

12. Push the <Done> soft key when finished. The display reverts to the first page of the Time/Date

menu.

To change the date on the instrument:

1. From the main menu, push the <Menu> soft key until <Setup> shows as the left soft key

function.

2. Push the <Setup> soft key.

3. Push the down arrow soft key to select <Time/Date>.

4. Push the <Enter> soft key.

5. Push the <Date> soft key.

6. Select the date format: <Day/Month/Year> (DMY) or <Month/Day/Year> (MDY).

7. Use the up and down soft keys to change the selected parameter.

8. Push the <Next> soft key and the arrow soft keys to select the month, date, or year

parameters.

9. Use the up and down soft keys to change the selected parameter.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 27

www.GlobalTestSupply.com

Page 28

Operation

10. Push the <Next> soft key to move through each parameter.

11. Push the <Done> soft key when finished. The display reverts to the start of the <Time/Date>

menu.

5.10.10.2 Alarm

The instrument has a programmable alarm to designate high or low readings, depending on the

thresholds entered. When the alarm level is reached, an alarm will sound and the display will flash

orange and white. To set either the high or low alarm:

1. Push the <Menu> soft key until <Setup> shows as the right soft key function.

2. Choose the <Alarm> soft key to access the <Alarm> menu.

3. Push either the <Hi> or <Lo> soft key, depending on which alarm will be set.

4. Push the <On> soft key to turn the alarm on.

5. Push the <Off> soft key to turn the alarm off.

6. Use the <Set> soft key to access the <Hi> or <Lo> Alarm Set menu.

7. Use the down or up soft keys to change the alarm setting.

8. Once the necessary settings have been entered, push the <Done> soft key.

5.10.10.3 Transmissivity

To change the <Transmissivity> value when measuring target temperature through glass windows:

1. Push the <Menu> soft key until setup shows as the right soft key function.

2. Choose <Transmissivity> to access the <Alarm> menu.

3. Push the <On> soft key to turn the transmissivity on.

4. Use the <Set> soft key to access the transmissivity set menu.

Transmissivity could be set between 1% and 100%.

5. Push the <Off> soft key to turn <Transmissivity> off.

5.10.10.4 Background Temperature

This feature is useful when the target emissivity is below 1.0 and the background temperature is not

significantly lower than the target temperature. For instance, the higher temperature of a furnace wall

could lead to too-high temperatures being measured especially for lower emissivity targets. A built-in

ambient background temperature utility compensates for the impact of the reflected radiation in

accordance to the reflective behavior of the target. User can set this function as follows:

1. Push the <Menu> soft key until setup shows as the right soft key function.

2. Choose <Background Temperature> to access the <Alarm> menu.

3. Push the <On> soft key to turn the <Background Temperature> on.

4. Use the <Set> soft key to access the <Background Temperature Set> menu.

5. Push the <Off> soft key to turn the <Background Temperature> off.

5.10.10.5 Bluetooth

Menu to turn Bluetooth on and off.

5.10.10.6 Language

To change the display language:

1. From the main menu, push the <Menu> soft key until <Setup> shows as the left soft key

function.

2. Push the <Setup> soft key.

3. Use the down arrow soft key to move the indicator to <Language>.

4. Push the <Enter> soft key.

5. Push the <F1> soft key to complete the language selection or push the <Back> soft key to

return to the Setup menu.

Find Quality Products Online at: sales@GlobalTestSupply.com

28 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 29

Operation

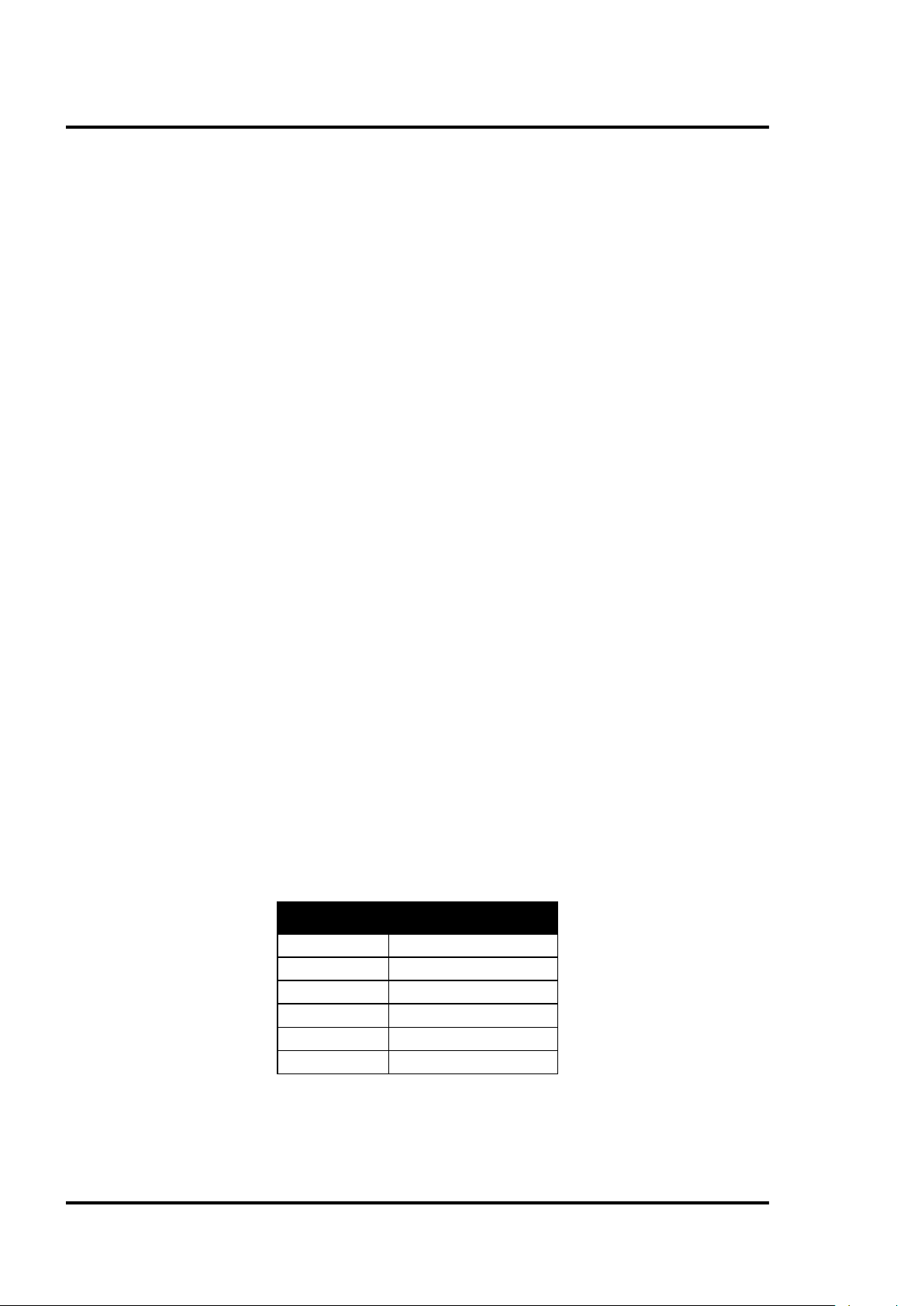

Parameter

Factory Default

Scope

OFF

Laser

OFF

Date Format

DD/MM/YY

Time

00:00:00

Temperature Unit

Celsius

Transmissivity

100%

Background Compensation Enable

OFF

High Alarm Temperature

Upper limit of measurement range

Low Alarm Enable

OFF

Trend Curve Limit Mode

Auto

5.10.10.7 To Default

To restore the instrument to the original factory default settings, press the <To Default> soft key. The

following table provides the values in case of a factory default.

White Backlight OFF

Orange Backlight OFF

Buzzer OFF

Date 2014.01.01

Time Format 24-Hour

Bluetooth Enable False

Language English

Emissivity 1.00

Transmissivity Enable OFF

Background Compensation Temperature 25°C (77°F)

High Alarm Enable OFF

Low Alarm Temperature Lower limit of measurement range

Trend Curve Upper-Limit Upper limit of measurement range

Trend Curve Lower-Limit Lower limit of measurement range

Trend Time Span 200 ms

Table 4: Factory Default Values

5.10.11 Log

This menu allows reviewing or deleting of previously stored temperature records.

To review temperature records follow the steps given below:

1. Push the <Menu> soft key until <Log> shows as the right soft key function.

2. Push the <Log> soft key and the select the temperature record of interest (Profile, Basic, or

Trend) to review it.

Additionally, pushing the <Delete> soft key allows you to remove an individual or all sets of the

temperature record.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 29

www.GlobalTestSupply.com

Page 30

Operation

Delete All Data

To delete all of the records:

1. Push the <All> soft key.

2. At the confirmation screen, push the <Yes> soft key.

Delete Individual Data Records

To delete individual records:

1. Push the one soft key.

2. Use the down and up arrow soft keys to access the desired record.

Once the desired record is shown, push the <Yes> soft key to delete the record.

5.10.12 °C and °F

To toggle between °C (Celsius) and °F (Fahrenheit) measurements, push the <Menu> soft key until °C

or °F is shown as the left soft key function. All temperature values are converted automatically. Push

the corresponding soft key to change between the measurements.

5.10.13 Scope

This is used by the scope model and is not available in the standard model.

Push the <Menu> soft key until <Scope> is shown as the right soft key function. Scope can be on or off

by pressing this soft key, which means the user can find an illuminated red dot when looking through

the scope.

5.11 Data Download

The stored data can be downloaded to a PC with the included USB cable and the included software.

See the software documentation for details. The USB input port is located on the right side of the

instrument.

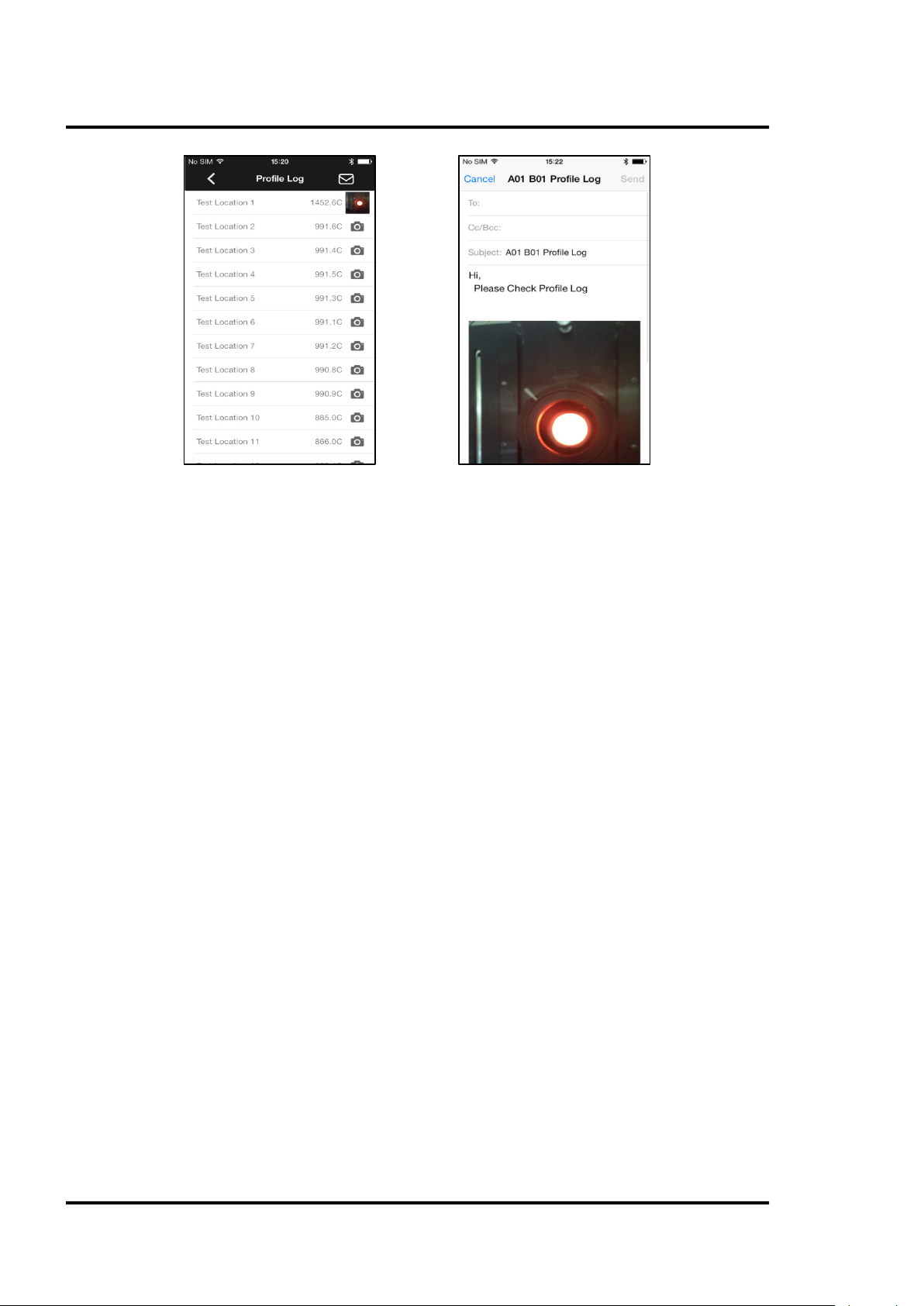

The stored data can also be downloaded through the Bluetooth

iOS 7.0 and above. After activating Bluetooth on the instrument, the user can find it on the iPhone.

Use the “Raytek 3i Plus” App, which can be downloaded from the App Store (please search by its

name). To monitor real-time measurement in a relative faraway place, download the Basic test data

and Profile test data, take photos and send via e-mail.

®

4.0 interface to iPhone, support for

Find Quality Products Online at: sales@GlobalTestSupply.com

30 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 31

Accessories

6 Accessories

Accessories include items that may be ordered at any time and added on-site:

• Carrying case (XXXR3IPLUSCC)

• Neck strap (XXXR3IPLUSSTRAP)

• CD with software for real-time graphic temperature display and data download

• Lithium-ion battery, 2.5 Ah (XXXR3IPLUSACCU)

• Mini USB port adaptor with multi-country power plug (100 – 240 VAC, 50/60 Hz), including

SAA, EU, UK, US and CCC (XXXR3IPLUSPS)

• Mini USB-to-DC jack converter for charging battery separately (XXXR3IPLUSPSCON)

• Computer cable with USB-to-Mini USB, 1.5 m (4.9 ft) (XXXR3IPLUSUSBCB)

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 31

www.GlobalTestSupply.com

Page 32

Windows Software

7 Windows Software

7.1 Introduction

The DataTemp® Raynger 3i Plus is the PC software application for Raynger 3i Plus series instruments.

With this software, the user can perform real-time monitoring, download test data, and create profiles

to optimize measurement.

DataTemp Raynger 3i Plus software features:

• Displays acquired results in graphs and tables

• Real-time monitoring while connected to a PC, and records the wave according to your needs.

• Replays saved wave and exports record list to .CSV format.

• Downloads Basic test data, Trend data, and Profile test data to PC and exports to .CSV format

• Creates new profile in PC and uploads to the instrument

• Produces final reports in .csv format, and provides standard form templates

Standard users launch DataTemp Raynger 3i Plus software. Connect the meter to the PC, and transfer

data, monitor in real-time and download test data for reporting. More advanced users might spend

time to define and create a profile through the PC to optimize their measurement.

Figure 6: Main Screen

Find Quality Products Online at: sales@GlobalTestSupply.com

32 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 33

No. Description

4

Profile

6

End Measuring button

12

Graph area shows the wave in real time.

Current area to indicate the big size showing data

n with Administrator

While installing the software, the USB driver for the instrument is installed

1

2

3

5

Real -time Monitor tab

Basic Test Data tab

Trend Test Data tab

create, edit, upload and Profile Test Data tab

Start Measuring button

Windows Software

7

8

9

10

11

13

14

Start Recording button

Pause Recording button

Setting button updates the instrument setting through the PC.

Table area shows test data in record list.

Replay button opens the saved wave file.

Display button which can real time monitor temperature change.

7.2 System Requirements

Minimum requirements for the PC:

• Operating system: Windows XP, Windows 7, Windows 8

• Communication: USB 2.0

To install DataTemp Raynger 3i Plus software you must log i

privileges!

7.3 Software Installation

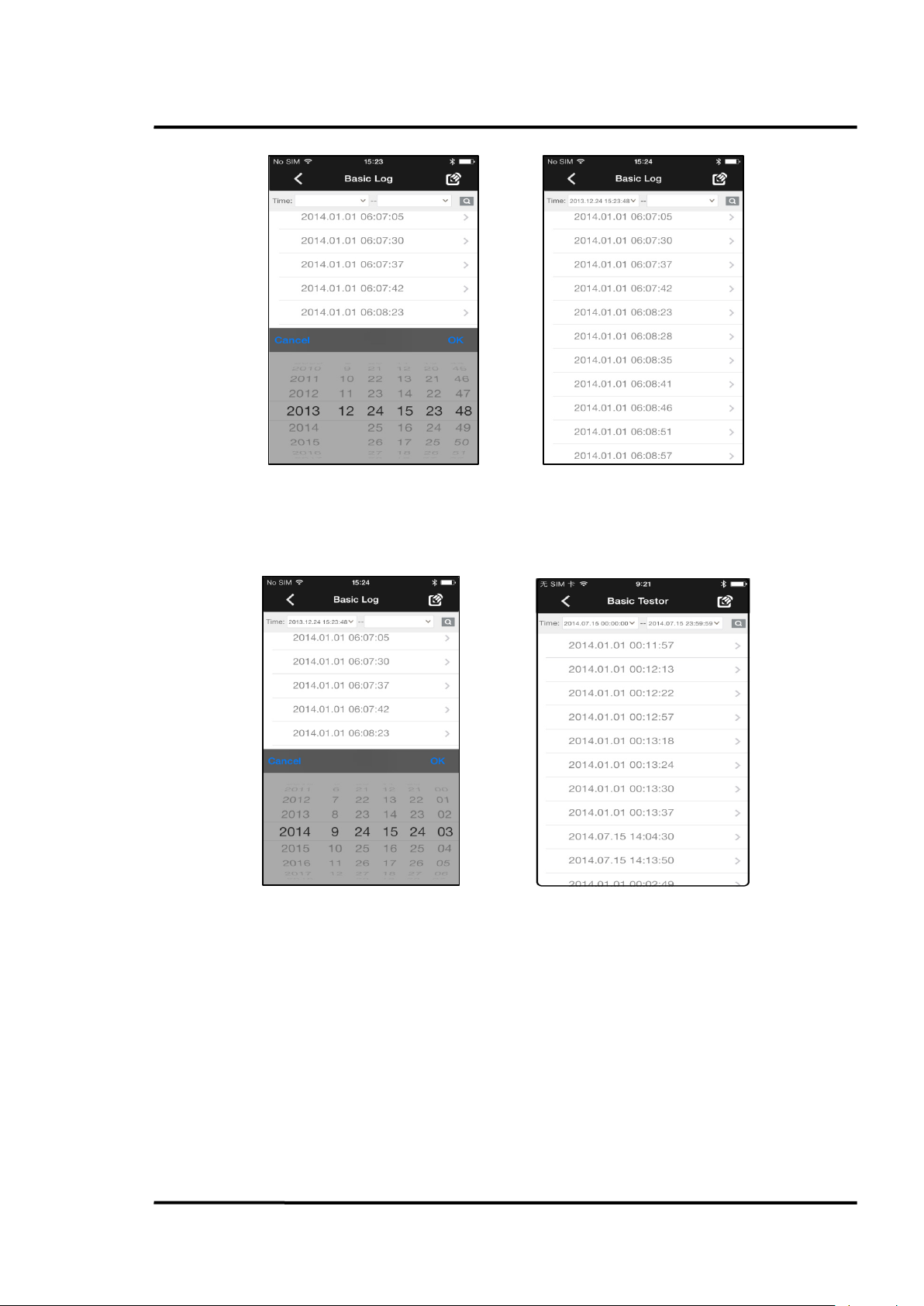

From the CD, launch the executing file to install the software on a computer. Follow the installation

wizard’s instructions on the screen.

Automatically!

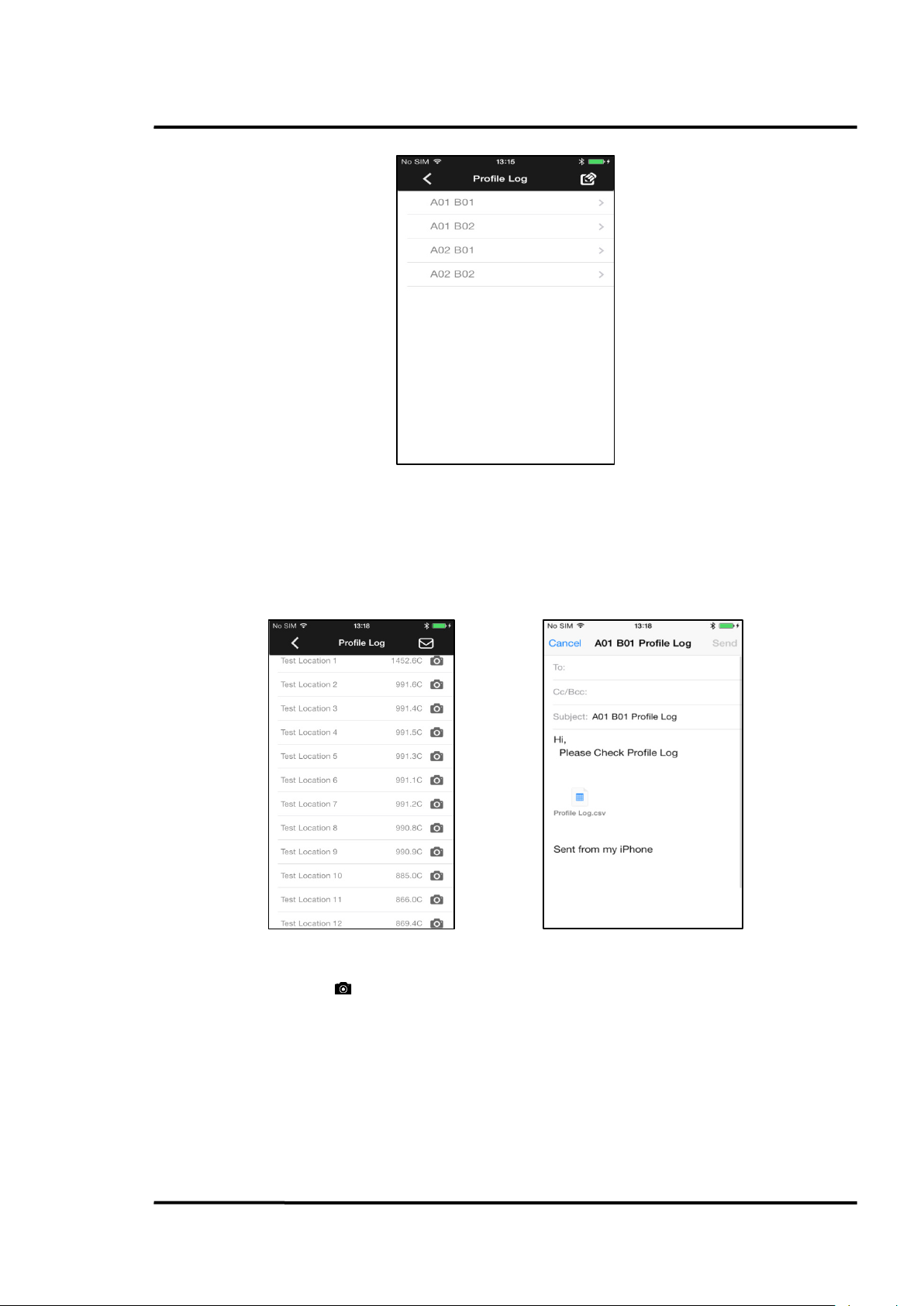

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 33

www.GlobalTestSupply.com

Page 34

Windows Software

7.4 Communication

To establish communication between the instrument and the PC software, follow the steps below:

Step 1: Connect the instrument to the PC via USB

Step 2: Open the <File> menu

Figure 7: Open File

Step 3: Choose appropriate COM Port with Raynger 3i Plus Device and click <Connect>

Figure 8: COM Port Selection

Find Quality Products Online at: sales@GlobalTestSupply.com

34 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 35

Windows Software

A simultaneous communication via USB and Bluetooth is not allowed!

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 35

www.GlobalTestSupply.com

Page 36

Windows Software

7.5 Real-Time Data

7.5.1 Display

Under the real-time mode, the software provides multiple views. After pressing <Start Recording>,

you can enter real-time monitor mode, the trigger of the instrument is locked automatically. The

record list and the graph display will keep recording all test results until you press <Pause

Recording>.

• Display current temperature (1)

• Record list in a table (2)

• Real-time display curve as graph (3)

Figure 9: Display Window

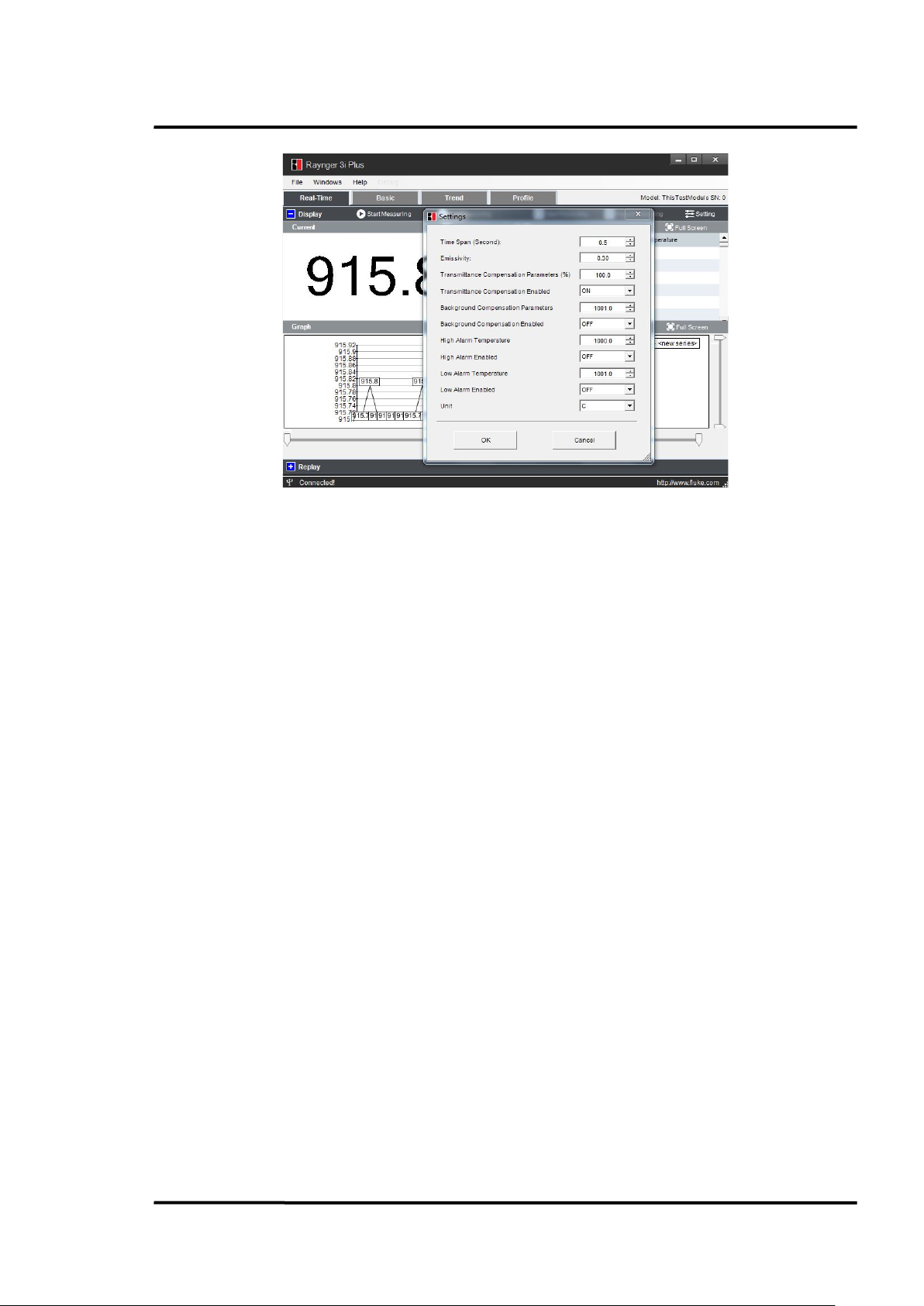

7.5.2 Settings

When the instrument is connected to the PC, the software will read the instrument’s setting at first

and will add this information to the test report.

The user can also change these settings through the PC interface and upload to the instrument. Click

on the <Setting> button to launch the corresponding dialog box.

Find Quality Products Online at: sales@GlobalTestSupply.com

36 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 37

Figure 10: Settings Dialog

1

Time Span

2

Emissivity

3

Transmittance Compensation Parameters (%)

4

Transmittance Compensation Enabled

5

Background Compensation Parameters

6

Background Compensation Enabled

7

High Alarm Temperature

8

High Alarm Enabled

9

Low Alarm Temperature

10

Low Alarm Enabled

11

Unit

The user can change the following settings:

Windows Software

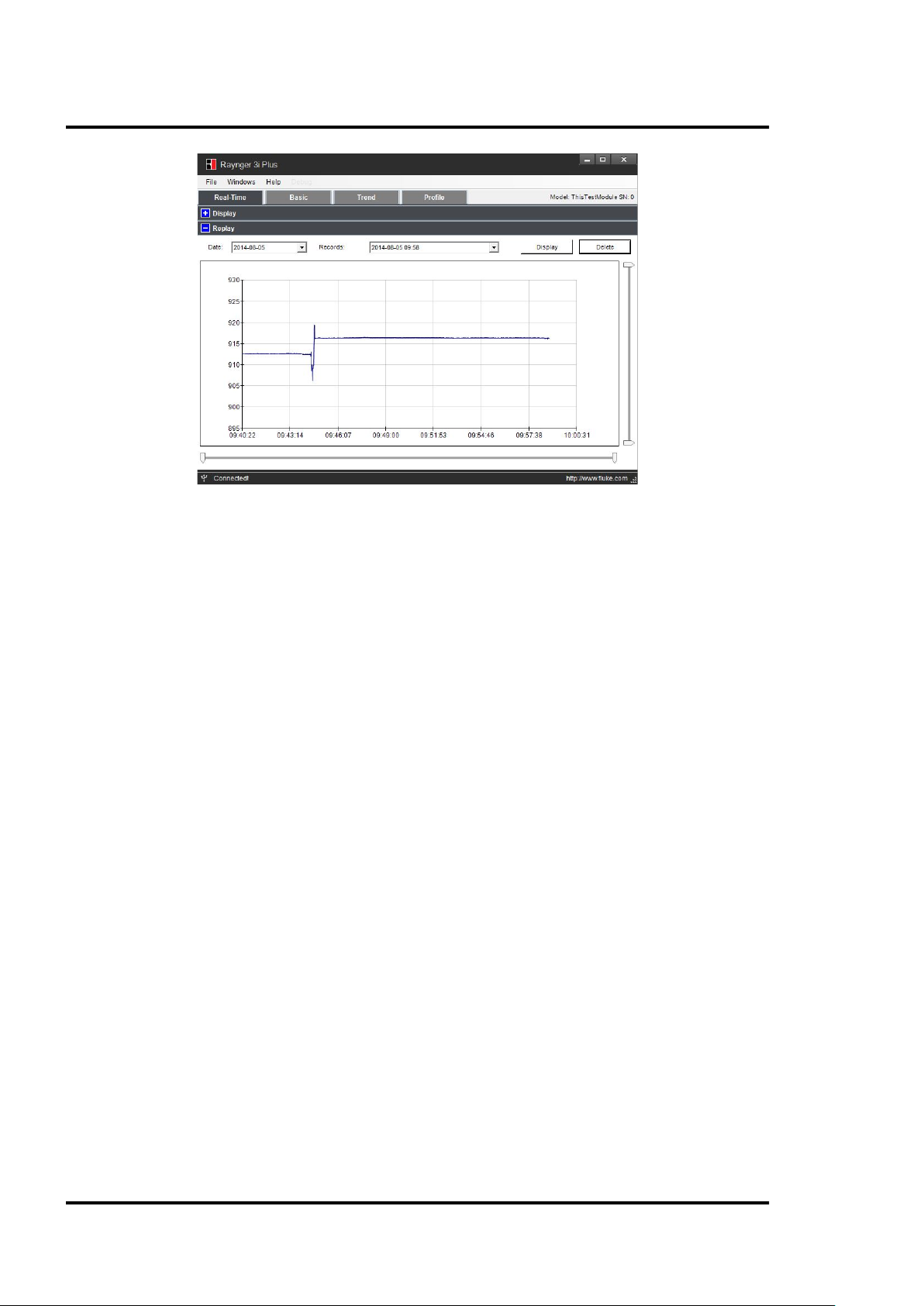

7.5.3 Replay

The user can replay the file recorded in real-time mode, search it according to date, and open the file

to review the trend change. The user can also export the saved curve into the .csv file format.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 37

www.GlobalTestSupply.com

Page 38

Windows Software

Figure 11: Replay Window

Find Quality Products Online at: sales@GlobalTestSupply.com

38 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 39

Windows Software

7.6 Recorded Data

The recorded data is divided into three groups: <Basic test data>, <Trend data>, and<Profile test data>.

• <Basic test data> is the test data without dedicated settings. The user can record random

measurement data in this area with a maximum of 1,000 records.

• <Trend data> is saving data under trend mode, which should include three-screen data with

360 test values. The minimum interval for trend is 20 ms. In this mode, the user can capture

instant temperature changes. This data will be saved as a curve format. The user can review

the trend on the instrument, and the value of each test point by PC software.

Press <View> to review the trend picture, and the up and down arrows to choose each saved

trend data. The left and right arrows help in viewing the three screens for each piece of trend

data.

• <Profile test data> is the test data under the profile setting, which can save a maximum of

300 records. By using the load value of each profile, these test data have been divided by

group according to the profile setting in the PC software. The user can find the temperature

distribution status in one group. When starting the measurements, the user can easily recall a

profile instead of having the need to set each parameter individually such as emissivity or

temperature alarm thresholds.

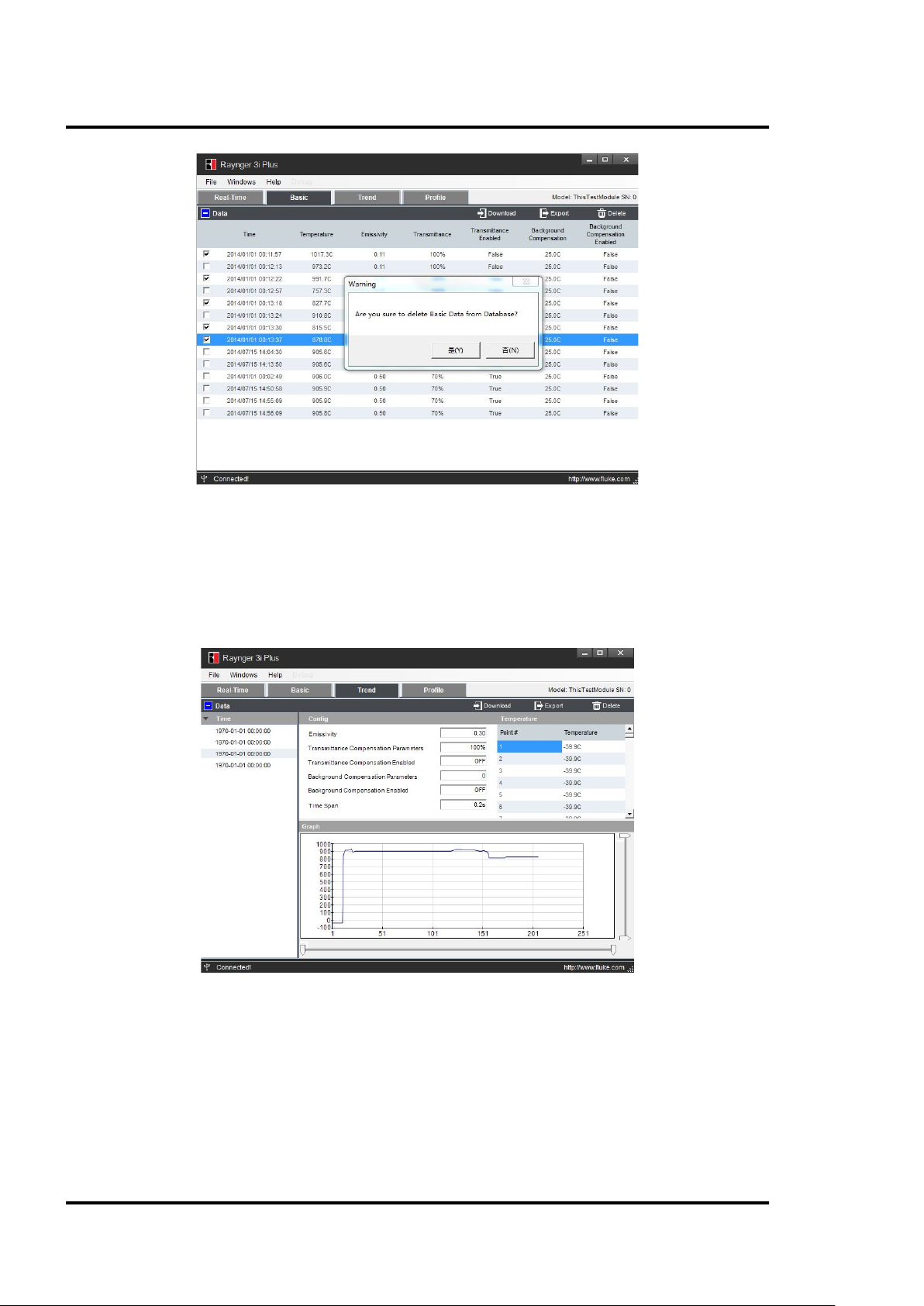

7.6.1 Basic Data

The user can import the test data under <Basic> measurement mode.

After pressing the <Download> button, the test data from the instrument will be read and appear in a

bivariate table format with time, temperature, emissivity, transmittance and background

compensation information.

Figure 12: Basic Window

There is a check box with each table row, so the user can choose the data to edit or export to a test

report with *. csv format.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 39

www.GlobalTestSupply.com

Page 40

Windows Software

7.6.2 Trend Data

Figure 13: Data Deletion

After the user has imported the trend test data from the instrument, the data will appear in a table

formatted with the point# and corresponding temperature value.

There is also a graphical area to display the trend data.

Figure 14: Trend Data

7.6.3 Profile Data

This feature provides a convenient method for the user to create settings through this function

according to their use case just before the measurements.

There are two locations to store the profile: <Local> and <Device>. The user can upload, edit, and

create the profile under the <Local> place, and download the device profile and device test data in

<Device> place.

Find Quality Products Online at: sales@GlobalTestSupply.com

40 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 41

Figure 15: Profile Data

Windows Software

7.6.3.1 Local

Under this mode, in <Local> the user can create their own setting group with three level menus and

also with EMS, transmittance compensation, background compensation, high-temperature alarm, lowtemperature alarm setting, and laser and backlight enable or disable. For each profile, it will have a

profile code that includes the names of the first level menu, second level menu and test point number.

For example:

1. User named the first level “qwe,” the second level “asd,” and the test point is 20 pcs.

2. After these profiles were created, the user can upload these profiles to the instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 41

www.GlobalTestSupply.com

Page 42

Windows Software

Figure 16: Local Profile

3. Before measurement, the user can call up this profile in the instrument:

7.6.3.2 Device

In <Device> mode, the user can download the existing profile from the instrument to the PC. Put the

mouse cursor on the 2

be found in this place, click <Import to Local> to perform editing both the profile structure and the

profile test data in <Local> place.

User can also delete the profile structure and profile test data in this place.

nd

level profile name, then click <Show Device Data>, afterwards all test data can

Find Quality Products Online at: sales@GlobalTestSupply.com

42 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 43

Figure 17: Device Profile

Windows Software

The user can also download the test data with the <Export> function into a csv format.

Figure 18: Export Data to the PC

Find Quality Products Online at: sales@GlobalTestSupply.com

3i Plus Rev. A1 Jan 2015 43

www.GlobalTestSupply.com

Page 44

Windows Software

Profile

Name

Level 1

Profile

Name

Level 2

Test

Poin

t #

Tempera

ture

Value

Uni ts

Type

Record Time EMS

Transimit

tance

Compens

ation

Transimit

tance

Compens

ation

Backgro u

nd

Compens

ation

Backgro u

nd

Compens

ation

High

Alarm

Tempera

ture

High

Alarm

Enabled

Low

Alarm

Tempera

ture

Low Alarm

Enabled

SN

tes af d 1 768.2 C 2014/1/ 10 8:20 0. 1 FALSE 10% FALSE 25. 0C

2999.0C FALSE 699.0C FALSE 803

tes af d 1 768.5 C 2014/2/ 10 9:22 0. 1 FALSE 10% FALSE 25. 0C 2999.0C

FALSE

699.0C FALSE 803

tes af d 1

768.7 C 2014/ 3/10 10:25 0.1 FALSE 10% FALSE 25.0C 2999.0C FALSE 699. 0C

FALSE 803

tes af d 1 768.5

C 2014/4/ 10 8:23 0.1 FALSE 10% FALSE 25.0C 2999. 0C FALSE 699. 0C FALSE

803

tes af d 1 769.1 C 2014/5/ 10 8:22

0.1 FALSE 10% FALSE 25.0C 2999.0C FALSE 699.0C FALSE 803

tes af d 2 765.1 C 2014/1/ 10 9:09 0.25

FALSE

100% FALSE 25. 0C 2999. 0C FALSE 699. 0C FALSE 803

tes af d 2 765.4 C 2014/2/ 10 8:54 0.25 FALSE 100% FALSE

25.0C 2999.0C FALSE 699.0C FALSE 803

tes af d 2 765.7 C 2014/3/ 10 8:31 0.25 FALSE 100% FALSE 25.0C 2999.0C

FALSE 699. 0C FALSE 803

tes

afd 2 765.8 C 2014/ 4/10 8:39 0.25 FALSE 100% FALSE 25. 0C 2999.0C

FALSE

699.0C FALSE 803

tes af d 2

766.1 C 2014/5/ 10 8:29 0.25 FALSE 100% FALSE 25.0C 2999.0C FALSE 699. 0C

FALSE

803

The csv file will include the historical record of the same test points which is useful to the user to find

the change rule of each point. For example, in the table below, test point 1 and test point 2 all have 5

records with different times and the data shows the temperature is stable on these days.

Figure 19: Exemplary Historical Record

Find Quality Products Online at: sales@GlobalTestSupply.com

44 Rev. A1 Jan 2015 3i Plus

www.GlobalTestSupply.com

Page 45

Mobile App

8 Mobile App

The “Raytek 3i Plus” mobile app is a computer program designed to run on smartphones, tablet

computers and other mobile devices. The app requires the support of the iOS

system 7.0 or higher.

Please download the mobile app in the App Store by searching for its name, and install the app on

your mobile device.

After opening the Bluetooth switch on the instrument, the user can find the instrument on the mobile

device. Use the “Raynger 3i Plus” mobile app to monitor real-time temperature changes, download

Basic test data and Profile test data, and e-mail data in the .csv format.

Connecting the Instrument

Click on the <Raytek 3i Plus> icon; enter following <DataTemp Raynger 3i+> interface.