Page 1

CATALOG NO. 2100.52A Effective: 05-22-13 Replaces: 06-01-09

Page 2

Subject to technical changes!

Slight changes may be made to the illustrations, process steps

and technical data as a result of our policy of continuous

improvement.

About these instructions

These Installation Instructions contain important information for

the safe and professional installation, start-up and maintenance

of the boiler with boiler capacities 87,000 and 120,000 btu/hr.

These Installation Instructions are intended for qualified installers,

who have the necessary training and experience for working on

heating and gas systems.

About the XPak

The boiler was designed for heating water for a space heating

system and generating hot water e.g. for domestic purposes.

The boiler can be fitted with a remote control or an On/Off room

thermostat (24 V), external sensor and with a 3-way valve for

DHW indirect storage tank controlled either with a tank thermostat

or a tank sensor (accessories).

Dear Costumer,

Thank you for choosing the XPak

boiler. This Raypak product provides

more efficiency and greater comfort to

the living space, thanks to its unique

features.

The new patented aluminum heat

exchanger provides ultra low

emissions, higher efficiency and easier

recycling after the boiler life.

Rev. A reflects the following:

Changes to: ASME Mark on page 1, AFUE values on page 10, piping diagrams on pages 19-21, Flue Gas

System on page 25, Warranty on pages 65-66.

Additions: Fig. 32A on page 33.

2

Page 3

CONTENTS

1 - WARNINGS 4

PAY ATTENTION TO THESE TERMS 4

2 - GENERAL SAFETY 6

TIME/TEMPERATURE RELATIONSHIPS IN SCALDS 6

3 - BEFORE INSTALLATION 6

4 - REGULATIONS AND GUIDELINES 7

5 - INTRODUCTION 8

TECHNICAL DATA 10

PRINCIPLE COMPONENTS 12

MODE OF OPERATION (AT REST) 12

MODE OF OPERATION 12

SAFETY DEVICES 12

BANNED MATERIAL STATEMENT 12

MANUAL HANDLING STATEMENT 12

XPAK INTERNAL HYDRAULIC CIRCUIT 12

PIPING CONNECTIONS 13

DIMENSIONS AND CONNECTIONS 1 4

PACKAGING AND TRANSPORTATION 15

1. Scope of delivery 15

2. Transporting the boiler 15

3. Boiler box content 15

6 - INSTALLATION 16

PREPARE XPAK LOCATION 16

1. Installations must comply with 16

2. Before locating the XPak boiler 16

3. Clearances for service access 16

4. Residential garage installation 16

5. Exhaust vent and intake air vent 16

6. Prevent combustion air contamination 16

7. When removing an existing boiler from an existing common 16

vent system

PREPARE XPAK 16

1. Remove XPak boiler from box 16

2. Placing the wall-mounted XPak boiler 17

3. XPak wall mounting instructions 17

4. Installation steps 17

XPAK PIPING 17

1. Relief valve 17

2. General piping information 17

3. Separate low water cutoff 17

4. Backflow preventer 17

5. Fitting the heating circuit supply and return pipes 17

6. Expansion tank and make-up water 17

7. Sizing space heat system piping 17

8. Boiler with DHW tank 18

9. Waterside Flow (primary circuit) 18

10.Procedure summary 18

11.Fill and purge heating system 18

XPAK INSTALLATION DIAGRAMS 19

MAKING THE GAS CONNECTION 22

BOILER TEMPLATE 23

COMBUSTION AIR AND VENTILATION OPENINGS 24

INSTALLATION OF THE EXHAUST AND AIR INTAKE SYSTEM 24

VENT SYSTEMS 25

1. Flue gas system 25

2. Boiler supply 25

3. Installations of supplied vent components 25

4. Minimum Clearances from Vent/Air Inlet Termination 26

CONNECTING THE CONDENSATE WATER DRAIN 34

1. Condensate Connection 34

7 - ELECTRICAL CONNECTIONS 34

1. External connection board connections 34

2. Electrical supply 34

3. Field wiring 34

4. Casing removal 35

5. Appliance terminal block 35

6. Connecting the electrical supply (120V) 35

7. External wiring 35

8. External wiring limitations 35

9. Connecting thermostat 35

10.Other devices 35

11 .Terminal strip details 36

12.Outdoor sensor connection 3 7

13.3-way valve wiring connection 3 7

14.Remote control connection 37

WIRING FUNCTIONAL DIAGRAM 38

9 - COMMISSIONING 40

1. Check/control water chemistry 40

2. Freeze protection (when used) 40

3. The heating system 40

4. Initial filling of the system 40

5. Purge air from boiler manual air release 40

6. System drain 40

7. Check thermostat circuit(s) 41

8. Testing for gas leaks 41

9. Initial flushing of the system 41

10. Pre-operation checks 4 1

11. Initial lighting 41

12. Checking gas pressure and combustion analysis 41

13. Final flushing of the heating system 41

14. Setting the boiler operating temperature 41

15. Regulating the central heating system 41

16.Final checks 42

17.Instructing the user 42

18.Warranty 42

10 - START-UP AND OPERATION 43

1. Switching on the appliance 43

2. How to read the display temperature 43

3. Adjusting heating water temperature with an outdoor probe connected 43

4. Adjusting domestic hot water temperature (if a storage tank with

sensor and 3-way valve is installed) 43

5. Working the boiler 43

6. Reset function 43

7. Switching off 43

8. Indicator LEDs and faults 44

11 - CHECKS, ADJUSTMENTS AND FAULT FINDING 46

1. Checking appliance operation 46

2. Appliance modes of operation 46

3. Selector switch in the off/stand by position 46

4. On-board functions 46

5. Heating mode 46

6. DHW mode 46

7. Boiler fan speeds 47

8. Checking the CO2 and adjusting the gas valve 47

9. Gas valve maximum setting 47

10 .Gas valve minimum setting 47

11.Combustion analysis test 47

12. External faults 47

13. Electrical checks 48

14.Component values & characteristics 48

15 .Boiler configuration 48

16.Setting the outdoor reset curve with outdoor sensor 49

17 .Fault codes 51

12 - SERVICING INSTRUCTIONS 52

1. General 52

2. Routine annual servicing 52

3. Replacement of components 52

4. Component removal procedure 52

13 - LPG INSTRUCTIONS 56

PROPANE GAS 56

14 - EXPLODED DIAGRAMS 59

IMPORTANT INSTRUCTIONS FOR THE

COMMONWEALTH OF MASSACHUSETTS 64

LIMITED PARTS WARRANTY 65

START-UP CHECKLIST FOR FAN-ASSISTED

RAYPAK PRODUCTS 67

8 - START-UP PROCEDURE 39

3

Page 4

1 - WARNINGS -

PAY ATTENTION TO THESE TERMS

DANGER:

Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property

damage if ignored.

WARNING:

Indicates the presence of hazards or unsafe practices which

could cause severe personal injury, death or substantial

property damage if ignored.

CAUTION:

Indicates the presence of hazards or unsafe practices which

could cause minor personal injury or product or property

damage if ignored.

NOTICE:

Indicates special instructions on installation, operation, or

maintenance which are important but not related to personal

injury hazards.

DANGER: Make sure the gas on which the boiler will operate

is the same type as that specified on the boiler rating plate and

on the coloured sticker near the boiler gas connection.

WARNING: Should overheating occur or the gas supply valve

fail to shut, do not turn off or disconnect the electrical supply to

the boiler. Instead, shut off the gas supply at a location e xternal

to the boiler.

WARNING: Do not use this boiler if any part has been under

water. Immediately call a qualified service technician to inspect

the boiler and to replace any part of the control system and any

gas control which has been under water.

AVERTISSEMENT: En cas de surchauffe ou de non fermeture

de la vanne d’alimentation en gaz, n’éteignez ou ne

débranchez pas l’alimentation électrique de la chaudière.

Coupez plutôt l’alimentation en gaz à l’extérieur de la

chaudière.

AVERTISSEMENT: N’utilisez pas cette chaudière si une partie

de celle-ci s’est retrouvée sous l’eau. Appelez immédiatement

un technicien de service qualifié pour inspecter la chaudière

et pour remplacer toute partie du système de contrôle et toute

commande de gaz s’étant retrouvée sous l’eau.

WARNING: To minimize the possibility of improper operation,

serious personal injury, fire, or damage to the boiler:

• Always keep the area around the boiler free of combustible

materials, gasoline, and other flammable liquids and vapors.

• Boiler should never be covered or have any blockage to the

flow of fresh air to the boiler.

WARNING: Risk of electrical shock. More than one disconnect

switch may be required to de-energize the equipment before

servicing.

WARNING - CALIFORNIA PROPOSITION

65: This product contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive

harm.

CAUTION: This boiler requires forced water circulation when

the burner is operating. See minimum and maximum flow rates.

Severe damage will occur if the boiler is operated without proper

water flow circulation.

NOTE: Minimum 18 AWG, 105°C, stranded wire must be used

for all low voltage (less than 30 volts) external connections to

the unit. Solid conductors should not be used because they

can cause excessive tension on contact points. Install conduit

as appropriate. All high voltage wires must be the same size

(105°C, stranded wire) as the ones on the unit or larger.

NOTE: When the boiler has been filled for the first time or the

system has been drained and refilled, it will be necessary to

release any air that may have become trapped within the

appliance heat exchanger. Loosen the bleed screw until water

is released and then close.

IMPORTANT, THERE ARE NO OTHER MANUAL AIR

RELEASE VALVES LOCATED ON THE APPLIANCE.

The following instructions must be observed

– The boiler must only be used for its designated purpose,

observing the Installation Instructions.

– Only use the boiler in the combinations and with the

accessories and spares listed.

– Other combinations, accessories and consumables must only

be used if they are specifically designed for the intended

application and do not affect the system performance and the

safety requirements.

– Maintenance and repairs must only be carried out by

authorized professionals.

– You must report the installation of a condensing gas boiler to

the relevant gas utility company and have it approved.

– You are only allowed to operate the condensing gas boiler

with the combustion air/flue gas system that has been

specifically designed and approved for this type of boiler.

– Please note that local permission for the flue system and the

condensate water connection to the public sewer system may

be required.

You must also observe:

– The local building regulations stipulating the installation rules.

– The local building regulations concerning the air intake and

outlet systems and the chimney connection.

– T he regulations for the power supply connection.

– The technical rules laid down by the gas utility company

concerning the connection of the gas burner fitting to the local

gas main.

– The instructions and standards concerning the safety

equipment for the water/space heating system.

– The Installation Instructions for building heating systems.

– The boiler must be located in an area where leakage of the

tank or connections will not result in damage to the area

adjacent to the boiler or to lower floors of the structure. When

such locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed under

the boiler. The pan must not restrict combustion air flow.

– The boiler must be installed such that the gas ignition system

components are protected from water (dripping, spraying, rain

etc.) during boiler operation and service.

– The boiler must not be installed on carpeting.

– The boiler must only be installed on a wall.

– Do not restrict or seal any air intake or outlet openings.

– If you find any defects, you must inform the owner of the system

of the defect and the associated hazard in writing.

4

Page 5

DANGER

if flammable gas explodes.

Beware if you smell gas: there may be an explosion hazard!

Warning: If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other boiler.

What to do if you smell gas

- Do not try to light any boiler.

- Do not touch any electrical switch; do not use any phone in your

building.

- Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Observe these instructions as general warnings:

– Chemicals used to clean the system and/or inhibit corrosion

must be pH neutral, i.e. they should ensure that the level of the

pH in the system water remains neutral.

Premature failure of certain components can occur if the pH

level in the system water is out of normal levels.

– Raypak recommends that an inhibitor - suitable for use with

aluminum heat exchangers - is used to protect the boiler and

system from the effects of corrosion and/or electrolytic action.

The inhibitor must be administered in strict accordance with

the manufacturers instructions.

– A properly sized expansion tank must be installed in the boiler

system. No valve is to be placed between the boiler and the

expansion tank.

– When the boiler has been filled for the first time or the system

has been drained and refilled, it will be necessary to purge

any air that may have become trapped within the appliance

heat exchanger.

NOTE: Glycol in the system must not exced 40%.

Observe these instructions for space heating water:

– Thoroughly flush the system prior to filling.

Only use untreated main water to fill and top off the system.

– Do not use water softners in the system.

– Do not use inhibitors or other additives!

– The maximum permissible flow rate of the XPAK 85 this is 5.7

GPM (1,300 ltr/hr), for the XPAK 120 is 6.2 GPM (1,400 ltr/hr).

– When using oxygen-permeable pipes, e.g. for floor heating

systems, you must separate the system using heat exchangers.

Unsuitable heating system water promotes the formation of

sludge and corrosion. This may damage the heat exchanger

or affect its operation.

– A properly sized expansion tank must be installed in the boiler

system.

T ools, materials and additional equipment

For the installation and maintenance of the boiler you will need

the standard tools for space heating, gas and water fitting.

In addition, a handtruck with a fastening belt is very useful.

Disposal

– Dispose of the boiler packaging in an environmentally sound

manner.

– Dispose of components of the heating system (e. g. boiler or

control device), that must be replaced, by handing them in to

an authorized recycling facility.

5

Page 6

2 - GENERAL SAFETY

T o meet domestic hot water use needs , the high limit safety control

on this boiler is adjustable up to 140°F (60°C).Water temperatures

over 125°F (50°C) can cause instant severe burns or death from

scalds.

When supplying general purpose hot water, the recommended

initial setting for the temperature control is 125°F (50°C).

Safety and energy conservation are factors to be considered

when setting the water temperature on the thermostat. The most

energy-efficient operation will result when the temperature setting

is the lowest that satisfies the needs of the application.

Water temperature over 125°F (50°C) can cause instant severe

burns or death from scalds. Children, disabled and elderly are at

highest risk of being scalded.

• Feel water before bathing or showering.

• Temperature limiting valves are available.

NOTE: When this boiler is supplying general purpose hot

water for use by individuals, a thermostatically controlled

mixing valve for reducing point of use water temperature is

recommended to reduce the risk of scald injury. Contact a

licensed plumber or the local plumbing authority for further

information.

Maximum water temperatures occur just after the boiler’s burner

has shut off. To determine the water temperature being deliv ered,

turn on a hot water faucet and place a thermometer in the hot

water stream and read the thermometer.

WARNING: This boiler cannot supply hot water for use by

individuals directly. A heat exchanger must be used in

conjunction with this boiler to meet DHW needs.

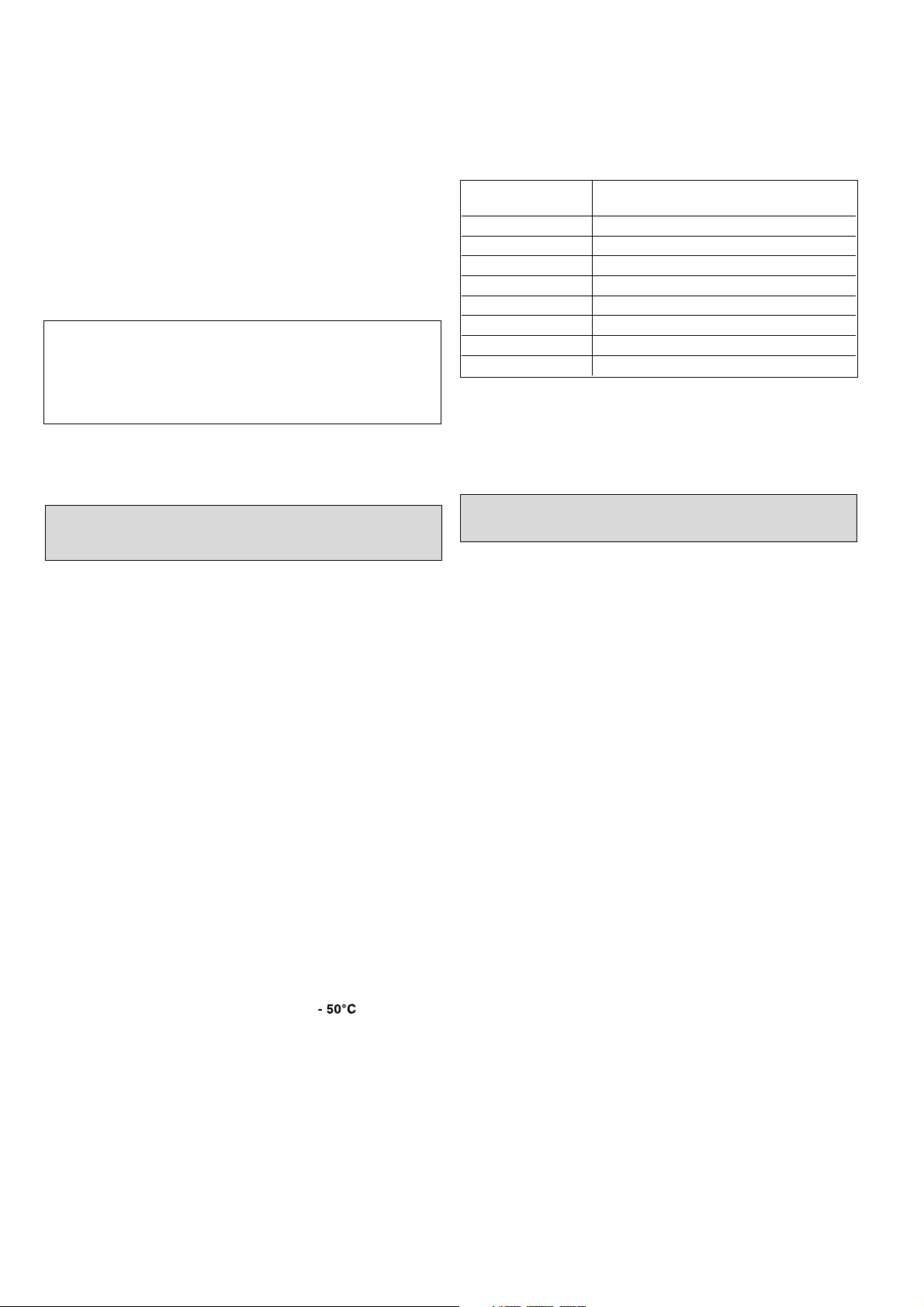

TIME/TEMPERATURE

RELATIONSHIPS IN SCALDS

The following chart details the relationship of water temperature

and time with regard to scald injury and may be used as a guide

in determining the safest water temperature for your applications.

Water Time to Produce Serious

Temperature Burn

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table courtesy of The Shriners Burn Institute

The temperature of the water in the boiler can be regulated by

using the Raypak Remote Control REC08. To comply with safety

regulations, the control is set when shipped from the factory.

CAUTION: Hotter water increases the risk of scalding! There

is a hot water scald potential if the thermostat is set too high.

3 - BEFORE INSTALLATION

Raypak strongly recommends that this manual be reviewed

thoroughly before installing your XPak boiler. Please review the

General Safety information before installing the boiler. Factory

warranty does not apply to boilers that have been improperly

installed or operated. (Refer to the warranty at the back of this

manual.) Installation and service must be performed by a qualified

installer, service agency or gas supplier. If, after reviewing this

manual, you still have questions which this manual does not

answer, please contact the manufacturer or your local Raypak

representative. Thank you for purchasing a Raypak product. We

hope you will be satisfied with the high quality and durability of

our equipment.

Product Receipt

On receipt of your boiler it is suggested that you visually check

for external damage to the shipping package. If the package is

damaged, make a note to that effect on the Bill of Lading when

signing for the shipment. Remove the boiler from the shipping

packaging. Report any damage to the carrier immediately. On

occasion, items are shipped loose. Be sure that you receive the

correct number of packages as indicated on the Bill of Lading.

Claims for shortages and damages must be filed with the carrier

by consignee. Permission to return goods must be received from

Raypak prior to shipping. Goods returned to the factory without

an authorized Returned Goods Receipt number will not be

accepted. All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and serial

number of the boiler. When ordering under warranty conditions,

you must also specify the date of installation. Purchased parts

are subject to replacement only under the manufacturer’s

warranty. Debits for defective replacement parts will not be

accepted and will be replaced in kind only per Raypak’ s standard

warranty.

Model Identification

The model identification number and boiler serial number are

found on the boiler rating plate located on the casing right side.

Also the boiler serial number can be found on the back page of this

manual and inside the front control panel flap.

6

Page 7

Ratings and Certifications

Standards:

• Gas fired hot water boiler for either direct vent installation or for

installation using indoor combustion air. Design according to:

ANSI Z21.13b 2007 – CSA 4.9b 2007 – Fired low pressure hot

water boilers. Categor y IV.

• SCAQMD Rule 1146.2

All Raypak boilers are National Board Approved, and designcertified and tested by the Canadian Standards Association

(CSA) for the U.S. and Canada. Each boiler is constructed in

accordance with Section IV of the American Society of Mechanical

Engineers (ASME) Boiler Pressure Vessel Code and bears the

ASME H stamp. This boiler also complies with the latest edition

of the ASHRAE 90.1 Standard.

WARNING: Altering any Raypak pressure v essel by installing

replacement heat exchangers, tube bundle headers, or any

ASME parts not manufactured and/or approved by Raypak

will instantly void the ASME and CSA ratings of the vessel

and any Raypak warranty on the vessel. Altering the ASME

or CSA ratings of the vessel also violates national, state,

and local approval codes.

Installations at Elevation

Rated inputs are suitable for up to 4,500 ft elevation (see technical

data table). Consult the factory for installations at altitudes over

4,500 ft above sea level. No hardware changes are required to

the boilers for installations up to 10,000 ft (adjustments may be

required).

4 - REGULATIONS AND

GUIDELINES

The installation must be conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1. In Canada, installation must be in

accordance with the requirements of CAN/CSA B149.1,

Natural Gas and Propane Installation Code. Where required

by the authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

Install CO detectors per local regulations. Boiler requires

yearly maintenance, see chapter “Checks, adjustments and

fault finding”.

Operating Limits of the boiler:

Max. boiler temperature: 194°F (90 °C)

Max. operating pressure: 45 psi (3.1 bar)

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an e xisting

boiler, it is important to check the condition of the entire hot

water distribution system to ensure safe operation.

7

Page 8

5 - INTRODUCTION

The XPak boiler is a wall hung, fan assisted, direct vent, heating

boiler only. These boilers – by design – incorporate electronic

ignition, circulating pump, pressure relief valve, pressure gauge,

and automatic bypass.

As supplied, the boiler will automatically modulate to provide

central heating outputs between 25,600 - 87,000 Btu/hr (7.5-25.5

kW) - XPak 85 and 27,300 - 119,500 Btu/hr (8-35 kW) XPak 120.

IMPORTANT

It is the law that all gas appliances are installed by a competent

person.

It is in your own interest and that of safety to ensure that the law is

complied with.

• The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 Where

required by the authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

• The installation should conform with CGA B149 INST ALLATION

CODE and/or local installation Code, plumbing or waste water

codes and other codes as applicable.

• Clearances from combustible material must be strictly adhered to.

• Manufacturers instructions must NOT be interpreted in anyway

as overriding statutory obligations.

The XPak family comprises a range of high-efficiency hot water

boilers with outputs ranging from 87,000 Btu/hr (25.5 kW) to

119,500 Btu/hr (35 kW). Each appliance is provided with a fan

powered flue outlet with an annular co-axial combustion air intake

that can be rotated – horizontally – through 360 degrees for

various horizontal or vertical applications. The XPak can also be

used with two pipe flue vent system. These appliances are

designed for use with a sealed system only; consequently they

are not intended for use on open vented systems.

This booklet is an integral part of the appliance. It is therefore

necessary to ensure that the booklet is handed to the person

responsible for the property in which the appliance is located/

installed. A replacement copy can be obtained from Raypak

customer services.

R

XPAK 120

XPAK 85

GF

P

C

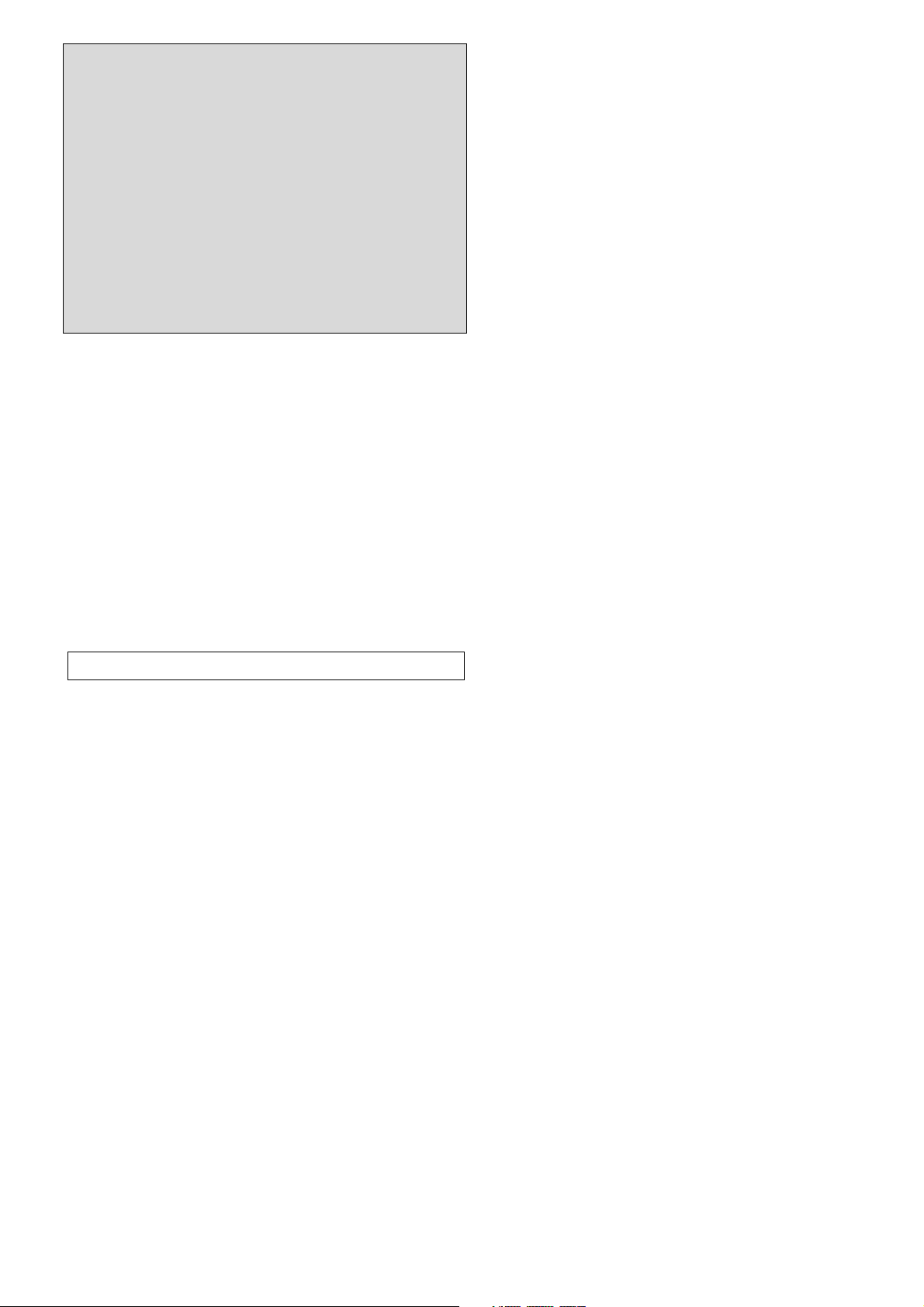

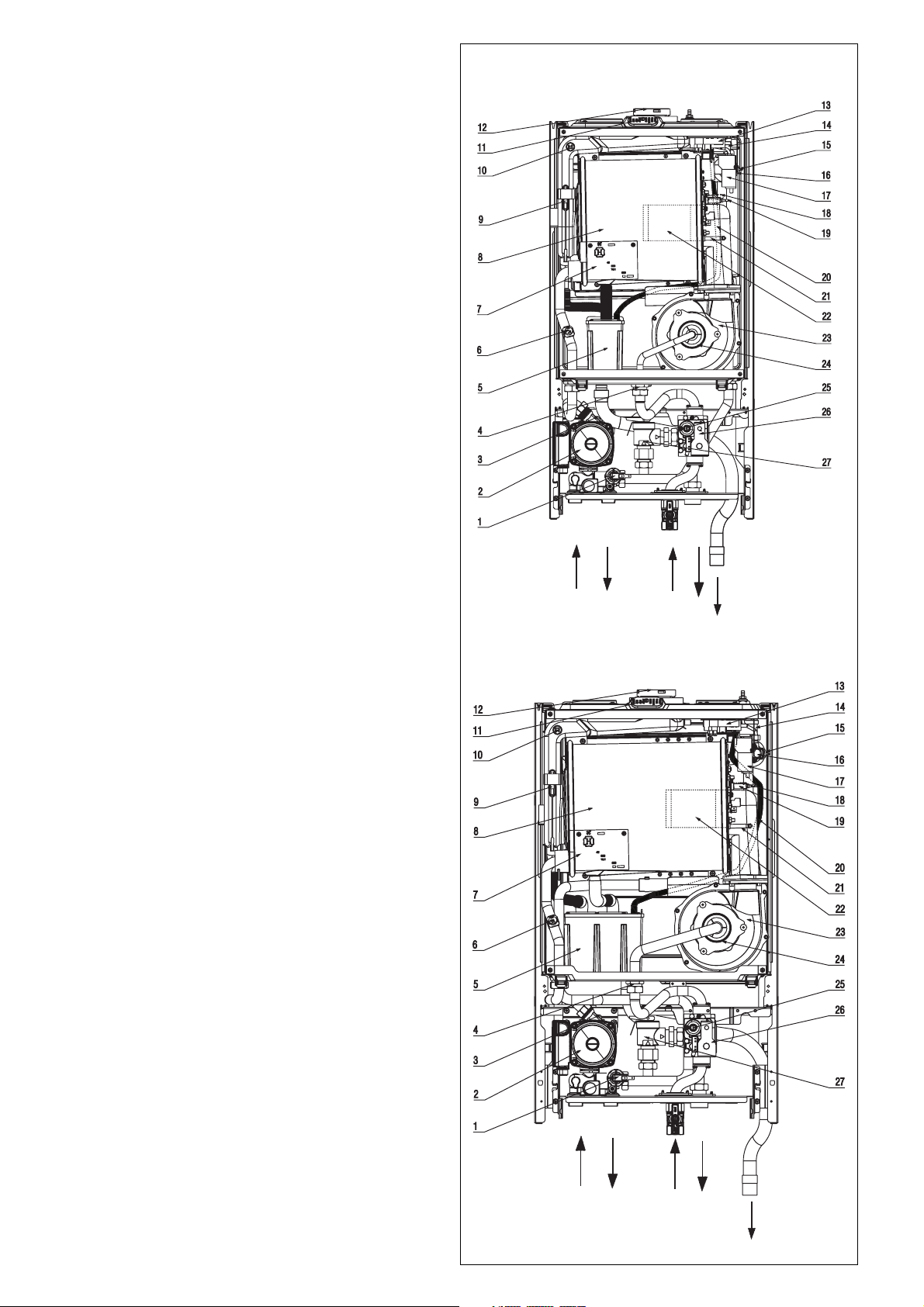

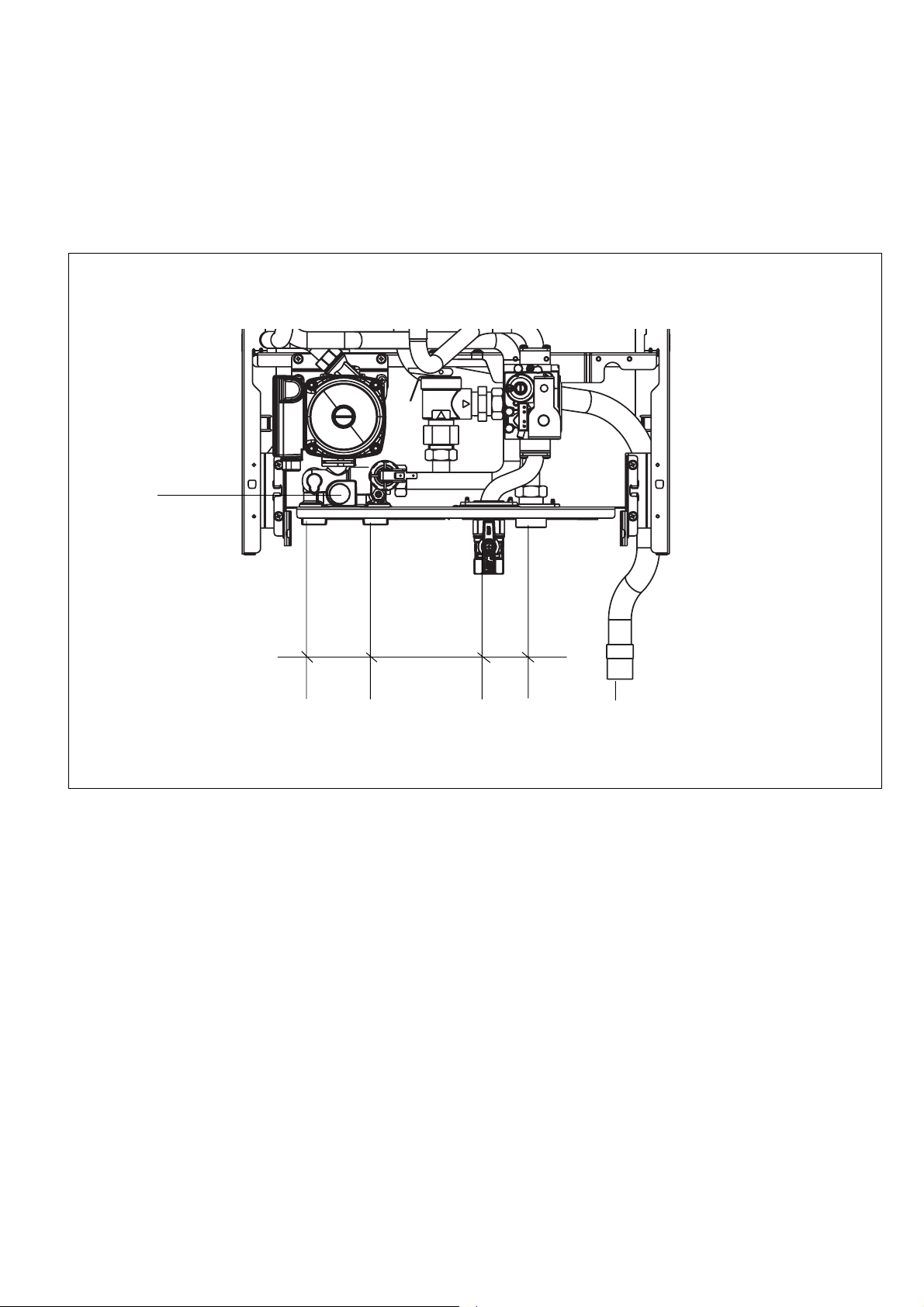

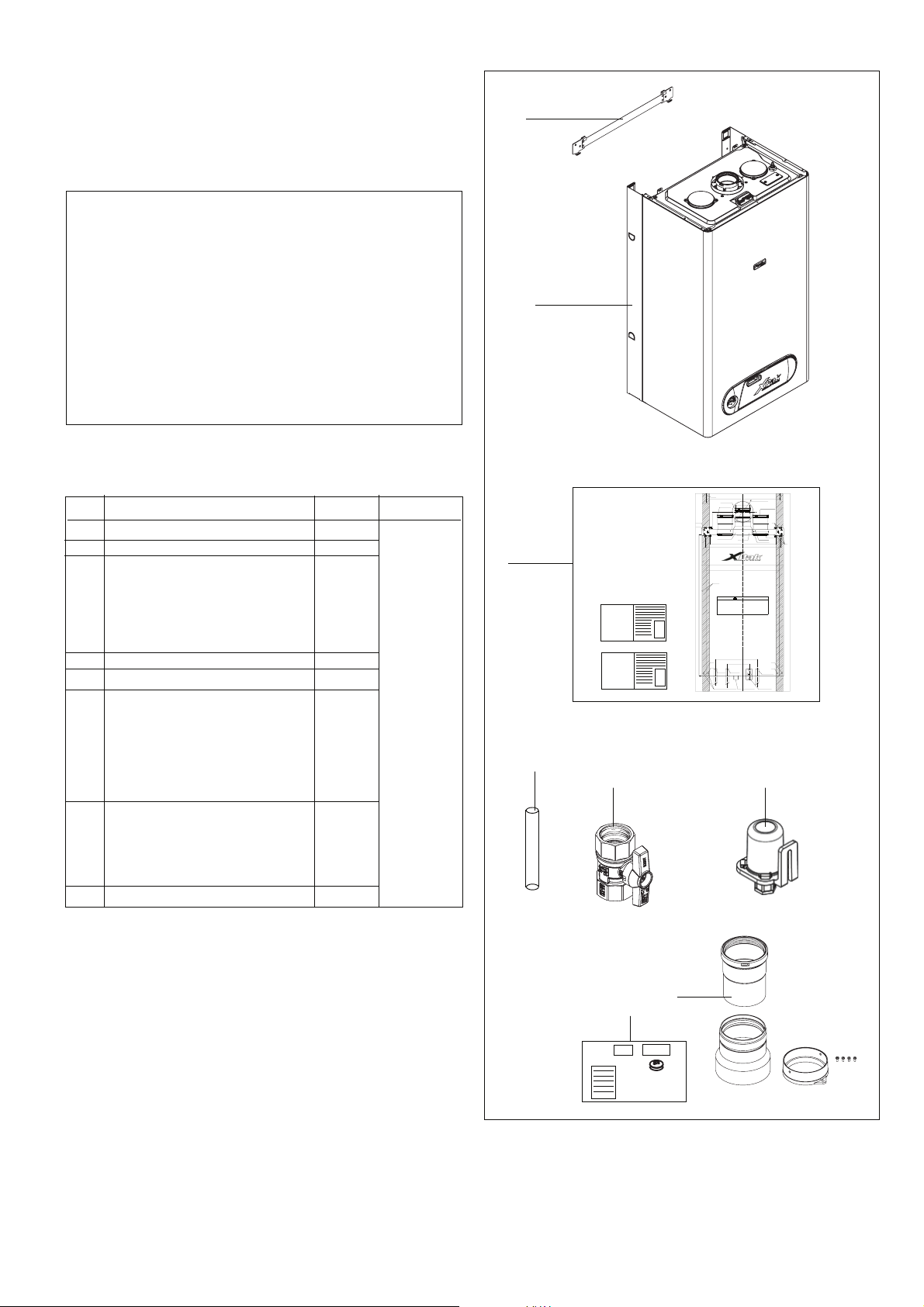

General layout (Fig. 1)

1 Water pressure switch

2 Pump

3 Bottom auto air vent (AAV)

4 Gas injector

5 Condense trap

6 Return sensor

7 H stamp main heat exchanger

8 Main heat exchanger

9 Flue thermostat

10 Flue sensor

11 Flue gas analysis test point

12 Flue outlet & air intake

13 Blocked flue switch

14 Top automatic air vent

15 Flow sensor

16 High limit thermostat

17 Ignition transformer

18 Sensing Electrode

19 Spark Electrode

20 Top automatic air vent drain pipe

21 Condensate level sensor

22 Cylindric Burner

23 Fan assembly

24 Mixer

25 Gas modulator coil

26 Gas valve

27 Pressure relief valve

R Boiler IN connection

F Boiler OUT connection

G Gas connection

P Pressure relief valve drain

C Condensate drain pipe

8

Fig. 1

R

F

G

P

C

Page 9

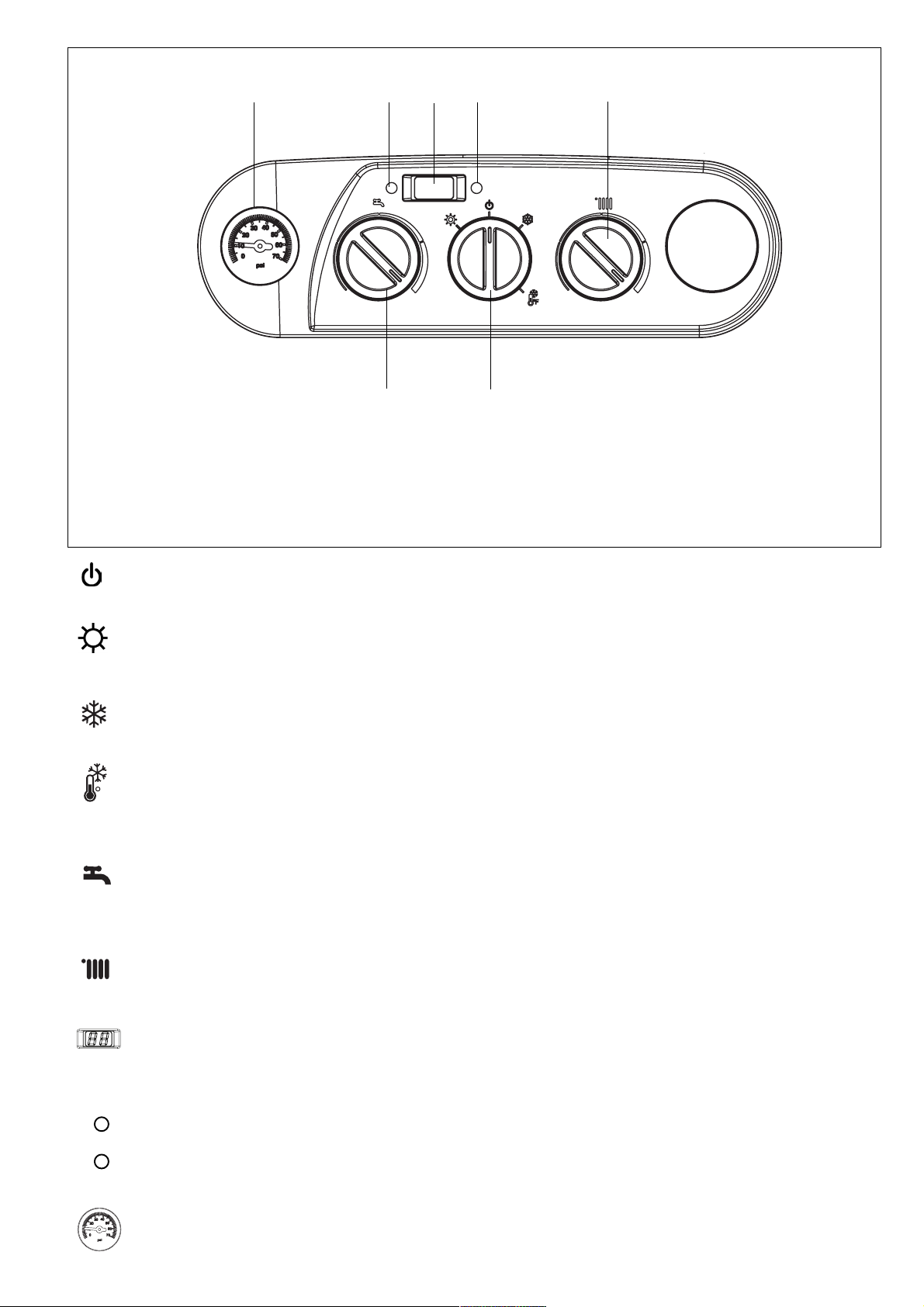

Fig. 1A

A

A Pressure gauge

B Green led

C 2-digit LED display

D Red led

E Temperature selector space heating

F Mode selector switch

G Temperature selector Domestic Hot Water

BC

G

D

E

F

Off/reset - Select this position when the boiler needs to be

reset or switched off.

Summer mode - The domestic hot water function provided

by the water tank is activated. The display indicates the

storage tank temperature (only with the external water tank

connected with a sensor).

Winter mode - The boiler produces hot water for heating

and, if connected to an external water tank, it provides

domestic hot water. The display indicates the boiler flow temperature.

Winter mode tank temperature - The boiler produces hot

water for heating and, if connected to an external water tank

F

with a sensor, it provides domestic hot water. The display

indicates the storage tank temperature.

Temperature selector DHW- Move the temperature selector

clockwise to increase the hot water temperature in the water

tank or counter-clockwise to reduce the temperature (working

only if a tank sensor is connected).

Temperature selector Heating - Move the temperature

selector clockwise to increase the heating temperature or

counterclockwise to reduce the temperature.

2-digit LED display - Displays the temperature according

the mode selector switch. During a fault condition, the

appropriate code will be displayed (refer to the installation

instructions regarding fault codes).

Green LED lit - Boiler is working/responding to a heating/

tank request (flame ON).

Red LED lit - Boiler has identified a fault and has shut down.

Refer to installation instructions on how to reset.

Pressure gauge - Ensure the system pressure is set

correctly (minimum 7 p.s.i. (0.45 bar))

9

Page 10

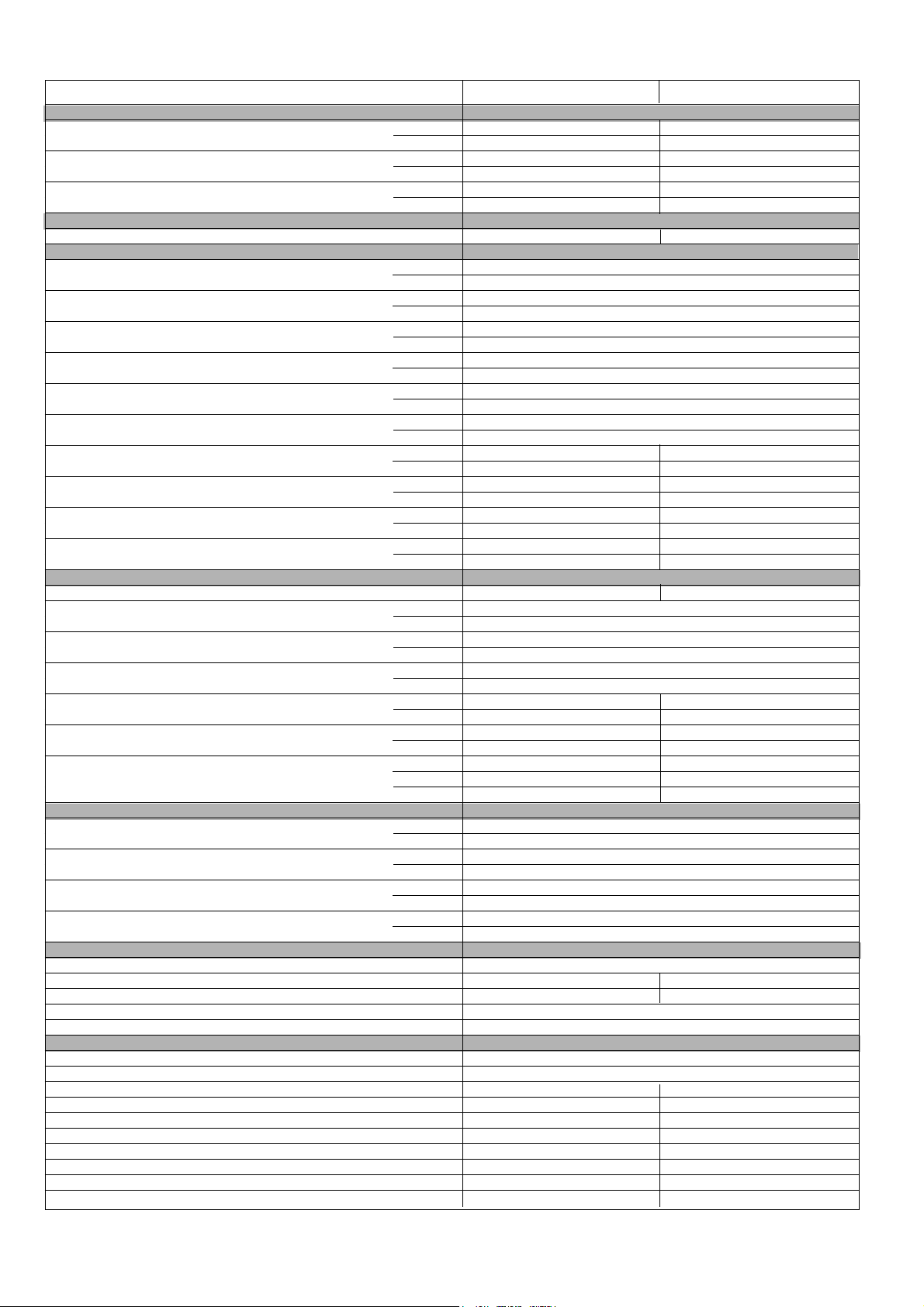

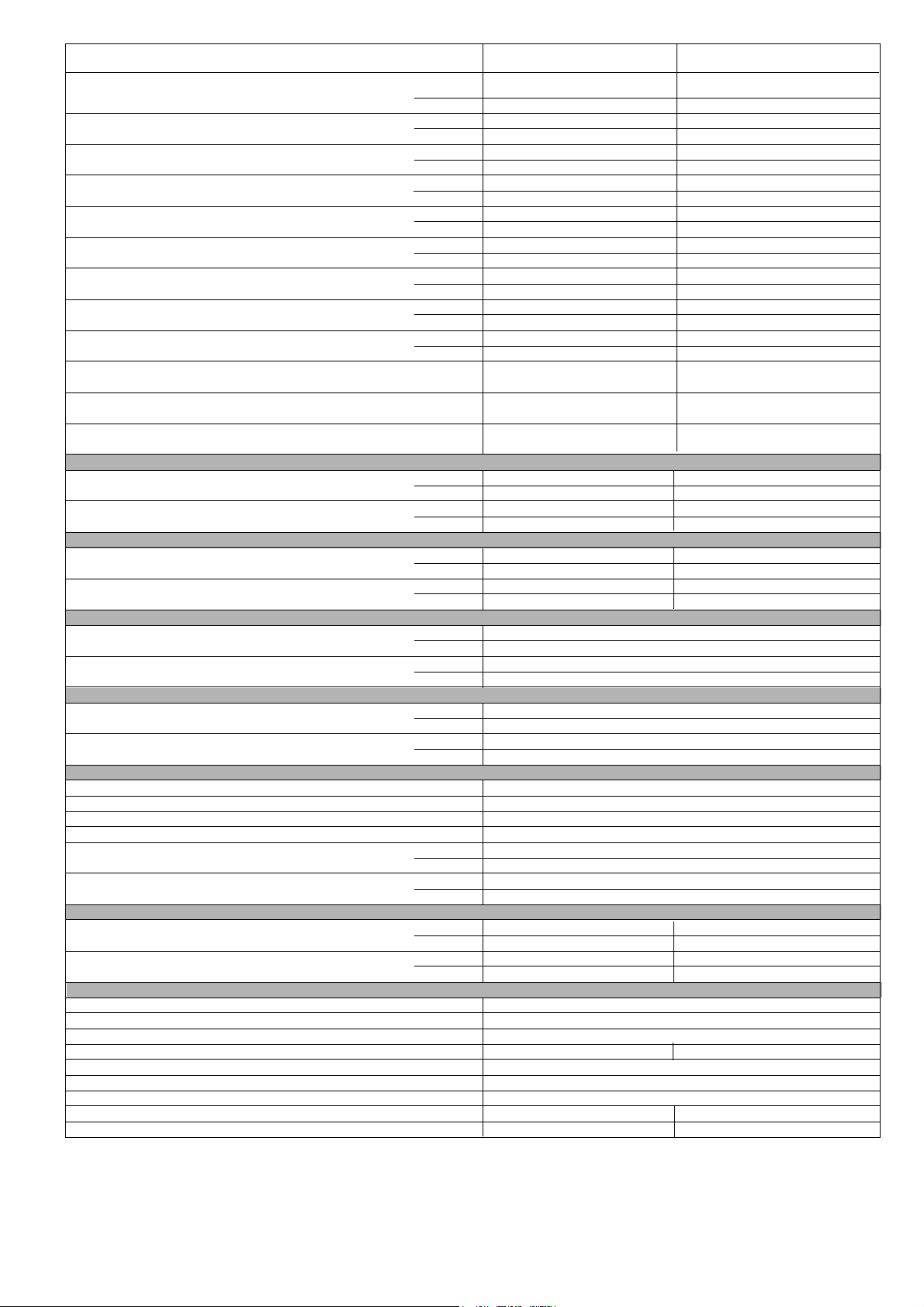

TECHNICAL DATA

Tab. 1

Input - Output

Input - (0 - 2000 ft / 0 - 610 m) Btu/hr 25,600 - 87,000 27,300 - 119,500

kW 7.5 - 25.5 8.0 - 35.0

Input - (2000 - 4500 ft / 610 - 1375 m) Btu/hr 25,600 - 82,900 27,300 - 114,300

kW 7.5 - 24.3 8.0 - 33.5

Output (176°F - 86°F / 80°C - 30°C) Btu/hr 25,200 - 76,600 26,600 - 108,300

kW 7.4 - 22.5 7.8 - 31.7

Energy Guide

AFUE % 90.3 90.5

Gas

Gas supply pressure Natural Gas (A) in w. c. 6.82

kPa 1.70

Min. gas supply pressure Natural Gas (A) in w. c. 3.5

kPa 0.87

Max. gas supply pressure Natural Gas (A)** in w. c. 10.5

kPa 2.62

Gas supply pressure LPG (E) in w. c. 11

kPa 2.75

Min. gas supply pressure LPG (E) in w. c. 8

kPa 1.99

Max. gas supply pressure LPG (E)** in w. c. 13

kPa 3.24

Gas Rate max natural rh/3tf)A( sag 10.12177.78

sm3/hr 34.394.2

Gas Rate min natural gas (A) ft3/hr 26.14 28.01

sm3/hr 97.047.0

Gas Rate max LPG (E) lbs/hr 55.520.4

kg/hr 25.228.1

Gas Rate min LPG (E) lbs/hr 82.102.1

kg/hr 85.045.0

System Data

Minimum relief valve capacity lbs/hr 87 119.50

Maximum operating pressure 54.i.s.p

bar 3.1

Minimum operating pressure p.s.i. 6.52

bar 0.45

Recommended system pressure p.s.i. 15

bar 1

Boiler max flow rate (ltr/hr) GPM 5.72 6.2

ltr/hr 004,1003,1

Pump residual head at max flow rate in w. c. 60.22 44.11

mbar 150 110

Primary water content CAN G 0.70 0.84

USG 0.85 1.0

ltr 3.2 3.8

Boiler Water Temperature

Adjustable high limit range - high temp. (radiators heating)* °F 104 - 176

°C 40 - 80

Adjustable high limit range - low temp. (space heating)* °F 68 - 113

°C 20 - 45

DHW production - set point °F 95 - 140

°C 35 - 60

Max boiler temperature °F 194

°C 90

Electric Data

Electric rate voltage V - Hz 120 - 60

Current less than A 1.19 1.25

Electric consumption (pump included) W 133 141

Electrical protection rating D5XPIPI

Fuses A - VAC 4 - 250

Flue Gas Values

CO2 setting natural gas (A) % 8.5%

CO2 setting LPG (E) % 10.0%

NOx @ max (A) ppm < 20 < 20

NOx @ min (A) ppm < 15 < 15

CO @ max (A) without air ppm < 135 < 170

CO @ min (A) without air ppm < 15 < 25

NOx @ max (E) ppm < 20 < 20

NOx @ min (E) ppm < 15 < 20

CO @ max (E) without air ppm < 200 < 220

CO @ min (E) without air ppm < 40 < 35

XPak 85 XPak 120

10

Page 11

XPak 85 XPak 120

Boiler flue gas connection in 2 3/8 2 3/8

Combustion air connection outer dia. in 4 4

Free fan unit feed pressure in w. c. 0.26 0.18

Flue gas mass flow rate at rated full load (A) lbs/hr 90.39 123.17

Flue gas mass flow rate at rated full load (E) lbs/hr 88.89 121.18

Flue gas mass flow rate at rated partial load (A) lbs/hr 26.58 28.48

Flue gas mass flow rate at rated partial load (E) lbs/hr 25.08 27.99

Condensate flow rate (A) at max - 122/86 °F (50/30°C)USG/hr 0.37 0.41

Condensate flow rate (A) at min. - 122/86 °F (50/30°C) USG/hr 0.13 0.16

Flue temperature at boiler return temp. 86°F/30°C °F 186.0 170.0

at full load (A) °C 86.0 77.0

Flue temperature at boiler return temp. 86°F/30°C °F 163.0 165.0

at partial load (A) °C 73.0 74.0

Flue temperature at boiler return temp. 140°F/60°C °F 194.0 186.0

at full load (A) °C 90.0 86.0

Max flues length de-rate less 2%

Max length horizontal coaxial 60/100 mm ft 6.5 6.5

Max total length 2 pipe 3” (80 mm) (air + flues) ft 40+40 16+16

Max flues length de-rate less 5%

Max length horizontal coaxial 60/100 mm ft 26 26

Max total length 2 pipe 3” (80 mm) - (air + flues) ft 130+130 115+115

Minimum Clearances To Combustibles

Top - front - rear in 0 - 0 - 0

Left - right - vent pipe in 0 - 0 - 0

Recommended Minimum Service Clearances

Top - front - rear in 12 - 24 - 0

Left - right in 1 - 1

Pipe Connections

Gas supply connection (shut off valve) i n 3/4 NPT - female

Boiler in connection in 3/4 NPT - male

Boiler out connection in 3/4 NPT - male

Pressure relief valve in 3/4 NPT - female

Condensate connection diameter (rubber flexible) in 0.825 female

Boiler drain valve - open-ended wrench dimension in 7/16

Boiler Dimensions And Weight

Height x Width x Dept in 30.7 x 15.75 x 14.1 30.7 x 17.7 x 14.1

Weight net lb s 73 8 0

Components

Burner Stainless Steel

Main heat exchanger ASME approved extruded aluminum

Gas valve SIT 848

Pump Groundfos UPM 15-52 Groundfos UPM 15-62

Pressure relief valve Watts M350 - M2 ASME approved

Fan MVL RG 128

3-way valve for DHW tank (field supply) Honeywell VC6011 + VCZMK6000

Injector Natural Gas (A) Ø 0.20 inch (5.1 mm) 0.26 inch (6.7 mm)

Injector LPG (E) - black coated Ø 0.15 inch (3.9 mm) 0.19 inch (5.0 mm)

mm 60 60

mm 100 100

Pa 65 45

kg/hr 41 55.87

kg/hr 40.32 54.97

kg/hr 12.06 12.92

kg/hr 11.88 12.70

ltr/hr 1.41 1.56

ltr/hr 0.48 0.6

m2 2

m 12+12 5+5

m 7.8 7.8

m 40+40 35+35

mm 0 - 0 - 0

mm 0 - 0 - 0

mm 300 - 600 - 0

mm 25 - 25

mm 21 female

mm 11

mm 780 x 400 x 358 780 x 450 x 358

kg 33 36

notes

*See jumpers configurations for heating temperature range setting

**If the gas supply pressure exceeds the maximum gas supply pressure value, a separate gas pressure regulator must be installed

upstream of the heating system.

11

Page 12

PRINCIPAL COMPONENTS

A fully integrated electronic control board featuring electronic

temperature control, anti-cycle control, pump over-run, actuator

anti-block function, self-diagnostic fault indicator, full air/gas

modulation.

- Radial aluminum heat exchanger.

- Electronic ignition with flame supervision

- Integral pump

- Fan

- Water pressure switch

- Condensate level sensor

- Pressure gauge

- Pressure relief valve

- Flue thermostat

- Flue sensor

- Blocked flue switch

MODE OF OPERATION (AT REST)

When the appliance is at rest and there are no requests for heating

or hot water, the following functions are active:

- 2-stage freeze protection system – the freeze protection system

protects the appliance against the risk of freeze damage. The

first stage enables activation of the pump should the temperature of the appliance fall to 43°F (6

become active, the appliance will function on minimum +25%

power until it reaches 95°F (35

- Anti-seize function – the anti-seize function enables the pump

to be energized for short periods, when the appliance has been

inactive for more than 24-hours.

o

C). Should the first stage

o

C).

BANNED MATERIAL STATEMENT:

No banned materials or substances have been used in the

manufacture or production of this appliance or its inherent

components

MANUAL HANDLING STATEMENT:

CAUTION: This appliance may require 2 or more persons

to lift or carry it to the installation location; due to the weight

of the appliance it may be necessary for two people to lift

and attach the appliance to its mounting. To avoid the

possibility of injury during the installation, servicing or

cleaning of this appliance, care should be taken when

handling component edges.

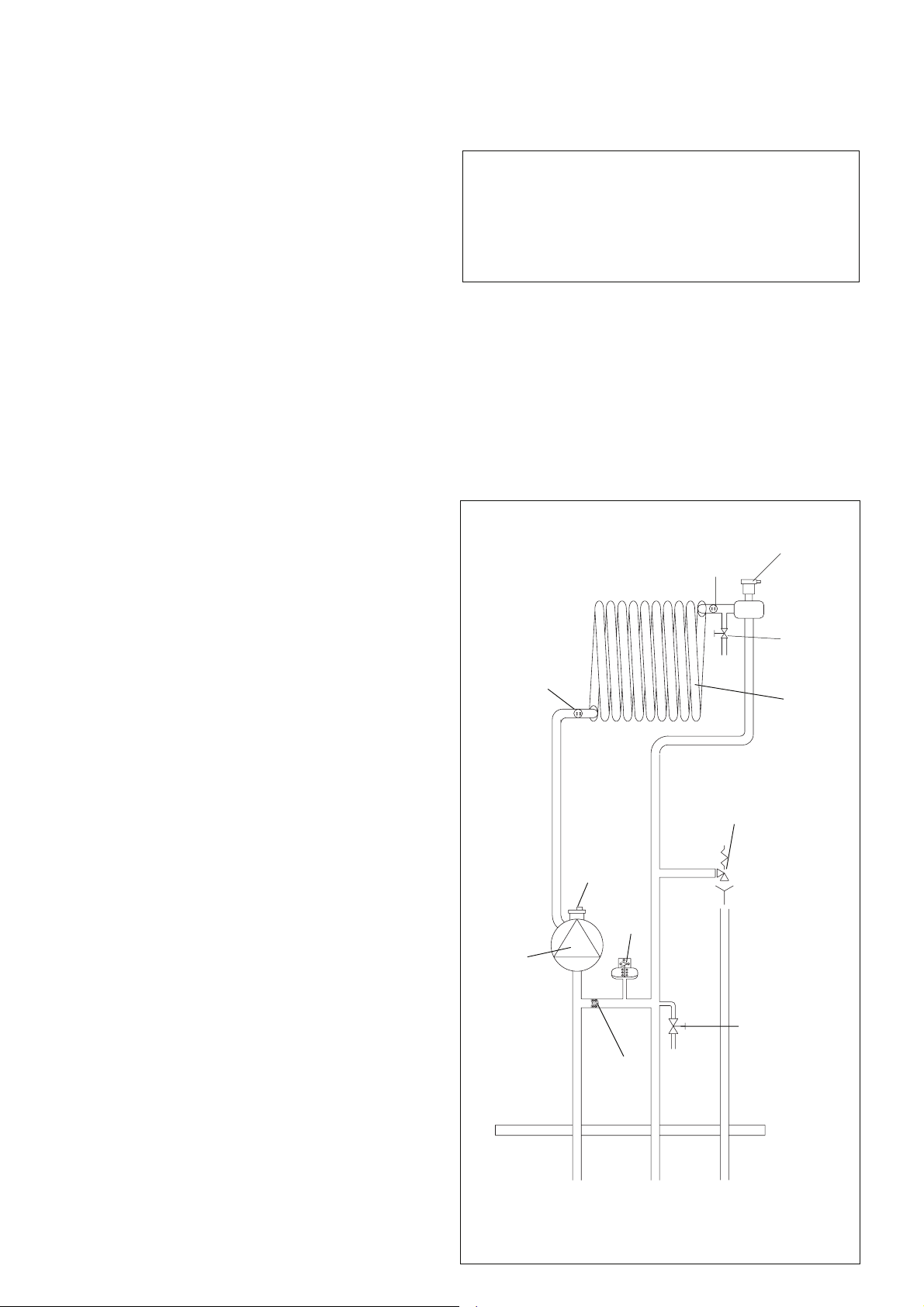

XPAK INTERNAL HYDRAULIC

CIRCUIT (FIG. 2)

MODE OF OPERATION

When there is a request for heat and/or hot water, via the

programmer/time clock and/or any external control, the pump and

fan are started, the fan speed will modulate until the correct signal

voltage

is received at the control PCB. At this point an ignition

sequence is enabled.

Ignition is sensed by the electronic circuitry to ensure flame

stability at the burner. Once successful ignition has been

achieved, the electronic circuitry increases the gas rate to 75% of

the MAX Heating (set by the corresponding HTG trimmer) for a

period of 15 minutes. Thereafter, the boiler’s output will either

increase to maximum or modulate to suit the set requirement.

When the appliance reaches the desired temperature the burner

will shut down and the boiler will perform a three-minute post purge

(timer delay).

When the request for heat has been satisfied the appliance pump

and fan may continue to operate to dissipate any residual heat

within the appliance.

SAFETY DEVICES

When the appliance is in use, safe operation is ensured by:

- a water pressure switch that monitors system water pressure

and will de-activate the pump (when lockout condition is

reached), fan and burner should the system water pressure

drop below the rated tolerance;

- blocked flue switch that monitors flue pressure and will de-

activate

burner should the flue pressure increase over the rated tolerance;

- fan speed sensor to ensure safe operation of the burner;

- a high limit thermostat that over-rides the temperature control

circuit to prevent or interrupt the operation of the burner;

- flame sensor that will shut down the burner when no flame signal

is detected;

- a sensor that interrupts the operation of the appliance if the

condensate pipe becomes blocked;

- a pressure relief valve which releases excess pressure from the

primary circuit;

- a flue sensor that controls the flue temperature continuously

checking to be right according the output;

- a flue thermostat that over-rides the temperature control circuit

to prevent or interrupt the operation of the burner.

the pump (when lockout condition is reached), fan and

temperature

pump

return

sensor

bottom

auto air

valve

pressure

switch

automatic

bypass

flow

temperature

sensor

pressure

relief

valve

drain

valve

top

auto air

valve

manual air

release

main heat

exchanger

12

Fig. 2

Heating

return

Heating

flow

pressure

relief valve

Page 13

PIPING CONNECTIONS (FIG. 3)

Legend

A - boiler in connection 3/4” NPT - male

B - boiler out connection 3/4” NPT - male

C - gas supply connection 3/4” NPT - female

D - pressure relief valve drain connection 3/4” NPT - female

E - condensate connection Ø (rubber flexible) 0.825” (21 mm) female

F - boiler drain valve - open-ended spanner dimension 7/16” (11 mm)

F

Fig. 3

A

2.55”

65 mm

4.73”

120 mm

B

1.76”

45 mm

CD

E

13

Page 14

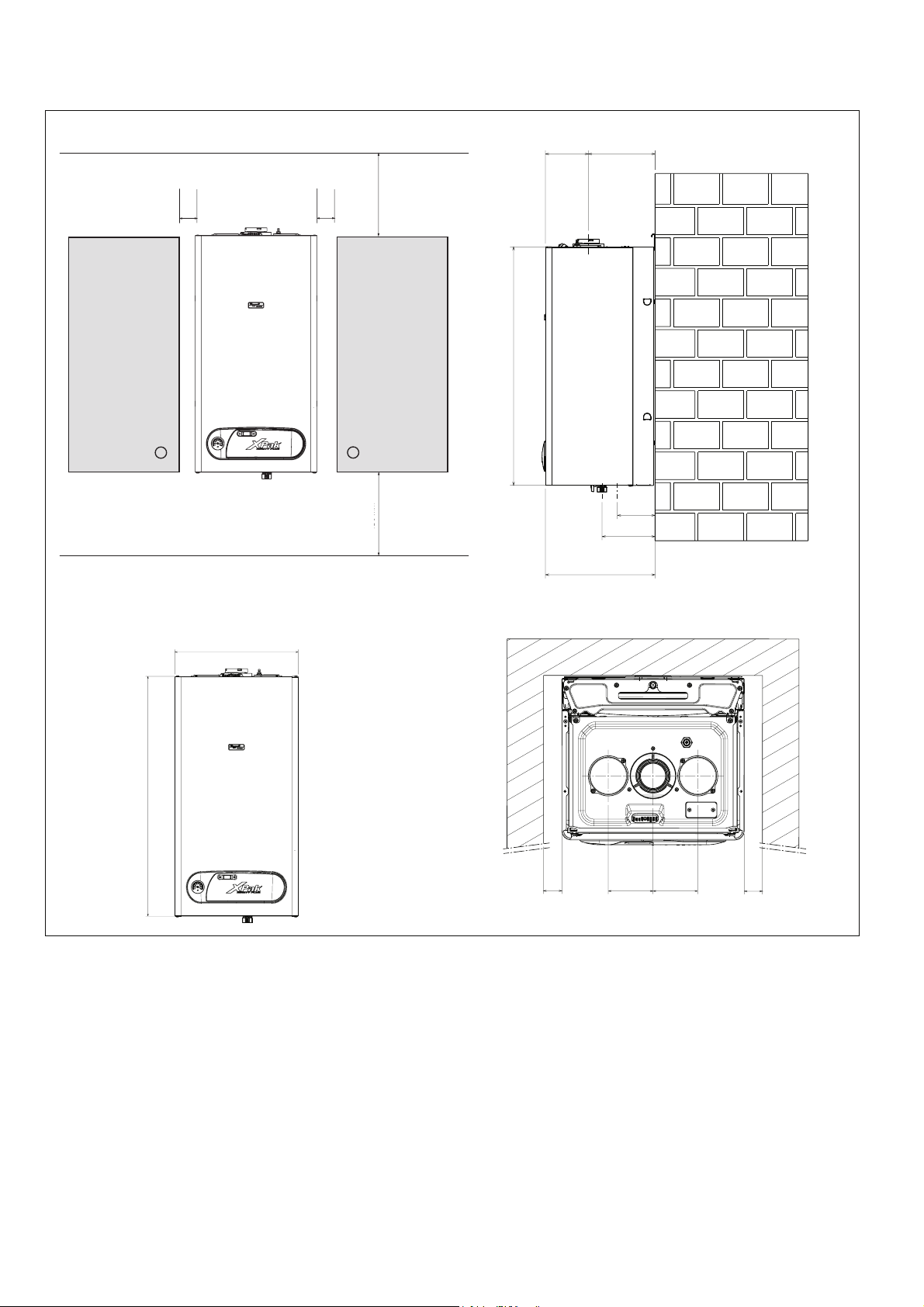

DIMENSIONS AND CONNECTIONS (Fig. 4)

Recommended minimum service clearances

1” (25 mm)

1” (25 mm)

5-1/2”

(140 mm)

12” (300mm)

30-3/4” (781 mm)

6” (150 mm)

14-1/8” (359 mm)

8-5/8”

(219 mm)

water 4-7/8” (124 mm)

gas 6-13/16” (173 mm)

XPak 85 = 15-3/4” (400 mm)

XPak 120 = 17-3/4” (451 mm)

30-3/4” (781 mm)

= =

1” (25 mm)

Fig. 4

1” (25 mm)

XPak 85= 3-15/16“ (97 mm)

XPak 120= 4-1/2“ (114 mm)

Minimum Clearances to Combustibles

Top=0

Front =0 AL, CL

Rear=0

Left=0

Right=0

AL = Alcove

CL = Closet

Note:

The XPak boiler has passed the zero inches vent clearance to combustibles testing requirements provided by the boiler Harmonized

Standard ANSI Z21.13b 2007 – CSA 4.9b 2007 and therefore is listed for zero clearance to combustibles when vented with a single

wall special venting system (AL29-4C material) or UL/ULC-listed gas vent material. The zero inches vent clearance to combustibles

for the XPak boiler supersedes the clearance to combustibles listing that appears on the special venting system label.

14

Page 15

PACKAGING AND TRANSPORTATION

1. SCOPE OF DELIVERY

The boiler is delivered fully assembled.

- When receiving the delivery, check if the packaging is intact.

- Check that all the items listed in Table 2 are included in the

delivery.

2. TRANSPORTING THE BOILER

CAUTION: The boiler may be damaged when it is improperly

secured.

- Only transport the boiler using the right transportation

equipment, such as a handtruck with a fastening belt or

special equipment for maneuvering steps.

- During transportation the boiler must be secured on the

transportation equipment to prevent it from falling off.

- Protect all parts against impacts if they are to be

transported.

- Observe the transportation markings on the packaging.

- Packaged boilers must always be lifted and carried to

their destination by two people, or you must use a handtruck

or special equipment to transport them to their destination.

- Transport the boiler to the room where it is to be installed.

2

1

3. BOILER BOX CONTENT (Table 2)

Pos. Parts Quantity Packaging

1 Boiler with casing 1 1 box

2 Wall bracket 1

3 Technical documents 1

including:

- User’s Instructions

- Installation Instructions

- Wall Mounting Template

4 Top manual air vent drain pipe 1

5 Gas shut off valve 1

6 Flue gas adaptors including: 1

- vent adaptor for two pipes

vent system

- intake air adaptor for two pipes

- 3” adaptor

- 4 screws

7 LPG conversion kit 1

- injector black coated

- LPG sticker

- LPG conversion labelling

- Conversion instructions

8 1Outside air sensor

Refer to Fig. 5 for Boiler box contents.

Wall stud

"61 C/C

4,53"Hole for 60/100mm coaxial vent

3" vent adaptor (supplied)

1.5"

inside 3"

Inlet air either right or left

Exhaust vent adapter (supplied)

Screw (2x) (supplied)

14.17"

16.25"

XPak 120 - 17.81"

XPak 85 - 15.75"

C

L

CENTER LINE

OF BOILER

WARNING

This boiler is heavy and awkward to lift. It is

recommended and safer to install the boiler with two

people. Use caution as to not drop this boiler which

could cause personal injury. Verify that the boiler is

securely mounted before leaving the boiler unsupervised.

Ensure there is adequate clearances for mounting the boiler (details given in

installation instructions).

The wall mount bracket is designed for a stud spacing of 16 inches from

center. For other stud spacing a solid mounting surface must be provided by

the installer.

Do not mount the boiler to a hollow wall. Be sure to mount the boiler to the

studs only.

Mount the wall bracket using 4 5/16" lag screws. Ensure the bracket is level

when mounted.

Extreme care is needed to ensure the bolts are secured in the studs.

Hang the boiler on the bracket and secure the bottom of the boiler with two (2)

additional lag screws.

5.90"

3.14"

3.35" 1.38"

NPT male

IN 3/4"

OUT 3/4"

NPT male

Condensate piping exible (supplied)

4/5" female

Ø1/4" holes for earthquake restraint (2 places)

inside 3.15"

Inlet air adapter (supplied)

Screw (2x) (supplied)

Gas shut o valve (supplied)

3/4" NPT female

3" inlet air adapter (not supplied)

Pressure relief valve drain

3/4" NPT female

XPak

120

Screw (2x) (tted)

XPak

85

XPak

120

XPak

85

Boiler bracket

3.54"

(supplied)

Ø1/4" holes

for 5/16" lag

screws (4 places)

3

Boiler outline

30.71" Boiler height

XPak

120

XPak

85

4

5

8

Fig. 5

6

7

15

Page 16

6 - INSTALLATION

PREPARE XPAK LOCATION

1. INSTALLATIONS MUST COMPLY WITH:

- Local, state, provincial, and national codes, laws, regulations

and ordinances.

- National Fuel Gas Code, ANSI Z223.1 – latest edition.

- National Electrical Code.

- For Canada only: B149 Installation Code, CSA C22.1 Canadian

Electrical Code Part 1 and any local codes.

NOTICE: To prevent combustion air contamination when

considering exhaust vent and intake air vent termination.

Intake and exhaust may be vented vertically through the roof

or out a side wall.

The intake and exhaust venting methods are detailed in the

Venting Section. Do not attempt to install the XPak Boiler using any

other means. Be sure to locate the boiler such that the air intake

and exhaust vent piping can be routed through the building and

properly terminated. The air intake and exhaust vent piping

lengths, routing and termination method must all comply with the

methods and limits given in the Venting section.

NOTICE: The XPak boiler gas manifold and controls meet safe

lighting and other performance criteria as specified in ANSI

Z21.13b 2007 – CSA 4.9b 2007

2. BEFORE LOCATING THE XPAK BOILER

1. Check for nearby connection to:

- System water piping

- Venting connections

- Gas supply piping

- Electrical power

2. Check area around boiler. Remove any combustible materials,

gasoline and other flammable liquids.

WARNING: Failure to keep boiler area clear and free of

combustible materials, gasoline and other flammable liquids

and vapors can result in severe personal injury, death or

substantial property damage.

3. The XPak must be installed so that gas control system

components are protected from dripping or spraying water or

rain during operation or service.

4. If the new XPak is to replace an existing boiler, check for and

correct any existing system problems such as:

- System leaks.

- Incorrectly-sized expansion tank.

- Lack of freeze protection in heating water causing system and

boiler to freeze and leak.

- Excessive glycol which will affect the boiler system operation.

3. CLEARANCES FOR SERVICE ACCESS

1. See figure for recommended service clearances. If you do not

provide minimum clearances shown, it might not be possible to

service the boiler without removing it from the space.

WARNING: The space must be provided with combustion/

ventilation air openings correctly sized for all other

appliances located in the same space as the XPak boiler.

The boiler internal front cover must be securely fastened to

the boiler to prevent boiler from drawing air from inside the

boiler room in the case of sealed combustion operation.

This is particularly important if the boiler is located in the

same room as other appliances. Failure to comply with the

above warnings could result in sev ere personal injury, death

or substantial property damage.

4. RESIDENTIAL GARAGE INSTALLATION

Precautions

Take the following special precautions when installing the XPak

in a residential garage. If the boiler is located in a residential

garage, per ANSI Z223.1, paragraph 5.1.9:

- Mount the boiler with a minimum of 18 inches above the floor

of the garage to the bottom of the boiler to ensure the burner

and ignition devices will be no less than 18 inches above the

floor.

- Locate or protect the boiler so it cannot be damaged by a

moving vehicle.

5. EXHAUST VENT AND INTAKE AIR VENT

XPaks are rated ANSI Z21.13b 2007 – CSA 4.9b 2007 – Fired low

pressure steam and hot water boilers. Category IV.(pressurized

vent, likely to condense in the vent). Also installations with air

dependent operation are allowed providing proper openings in

the room are provided.

16

6. PREVENT COMBUSTION AIR CONTAMINATION

Install intake air piping for the XPak as described in the Venting

section. Do not terminate exhaust in locations that can allow

contamination of intake air.

WARNING: You must pipe outside air to the boiler air intake

for sealed combustion operation. Ensure that the intake air

will not contain any of the contaminants below. Contaminated

air will damage the boiler, resulting in possible severe personal

injury, death or substantial property damage. For example, do

not pipe intake air vent near a swimming pool. Also avoid

areas subject to exhaust fumes from laundry facilities. These

areas may contain contaminants.

7. WHEN REMOVING AN EXISTING BOILER FROM AN

EXISTING COMMON VENT SYSTEM

Do not install the XPak boiler into a common vent with any other

appliance.

This will cause flue gas spillage or appliance malfunction, resulting

in possible severe personal injury, death or substantial property

damage.

WARNING: Failure to follow all instructions can result in flue

gas spillage and carbon monoxide emissions, causing severe

personal injury or death.

At the time of removal of an existing boiler, the following steps shall

be followed with each appliance remaining connected to the

common venting system placed in operation, while the other

appliances remaining connected to the common venting system

are not in operation.

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and horizontal

pitch and determine there is non blockage or restriction, leakage,

corrosion and other deficiencies which could cause an unsafe

condition.

c. Insofar as is practical, close all building doors and windows and

all doors between the space in which the appliances remaining

connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn on any

exhaust fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

d. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will operate

continuously.

e. Any improper operation of the common venting system should

be corrected so the installation conforms with the National Fuel

Gas Code, ANSI Z223.1 — latest edition. Correct by resizing to

approach the minimum size as determined using the

appropriate tables in Table 13 of ANSI Z223.1 2006 of that

code. Canadian installations must comply with B149 Installation

Code.

PREPARE XPAK

CAUTION: CAUTION:

CAUTION: Cold weather handling — If boiler has been

CAUTION: CAUTION:

stored in a very cold location (below 0°F (-18°C)) before

installation, handle with care until the plastic components

come to room temperature.

1. REMOVE XPAK BOILER FROM BOX

1. XPak is heavy and awkward to lift.

Care must be taken to place it in a safe location prior to installation

on the wall to prevent damage to the bottom mechanical

connections.

Page 17

2. PLACING THE WALL-MOUNTED XPAK BOILER

XPak boilers are wall mounted. Use only the XPak boiler wall

mounting instructions included in the box.

WARNING: The wall must be capable of carrying the weight

of the boiler and its related components. The weights of the

boiler are approximately:

XPak 85 = 82 lbs (37 kg).

XPak 120 = 93 lbs (42 kg).

Failure to comply with above could result in severe personal

injury, death or substantial property damage

3. XPAK WALL MOUNTING INSTRUCTIONS

WARNING: This boiler is heavy and awkward to lift. It is

recommended and safer to install the boiler with two people.

Use caution as to not drop the boiler which could cause

personal injury. Verify that the boiler is securely mounted

before leaving the boiler unsupervised.

The wall must be vertically plumb and capable of carrying the

weight of the XPak and its related components.

The building frame (studs) must be 16" on center. If not, you must

use 1/2" minimum plywood 24" x 48", fastened with at least (14)

#12 x 3" (3/16" x 3") round head tapping screws to the frame of the

building to provide proper support for the boiler. Alternate methods

of mounting must not be used. (ex. toggle bolts, hollow wall

anchors) or any other fastener other than #12 x 3" (3/16" x 3") round

head tapping screws.

CAUTION: If the XPak is not vertically plumb, improper and

unsatisfactory operation may occur. This will cause excessive

condensation build-up causing unnecessary maintenance

and nuisance fault codes.

4. INSTALLATION STEPS

Prior to lifting the XPak Boiler onto the wall, use the enclosed

template to level and locate the wall bracket. Mount the wall

bracket using lag screws. Ensure the bracket is level when

mounted. Extreme care is needed to ensure the bolts are secured

in the studs. Hang the boiler on the bracket and secure the bottom

of the boiler with two (2) additional lag screws. This will provide

additional strength and support to the XPak boiler.

XPAK PIPING

1. RELIEF VALVE

The XPak has a pressure relief valve factory fitted.

Connect discharge piping to safe disposal location, following

guidelines in the WARNING below:

WARNING: To avoid water damage or scalding due to relief

valve operation:

- Discharge line must be connected to relief valve outlet and

run to a safe place of disposal. Terminate the discharge line

in a manner that will prevent possibility of severe burns or

property damage should the valve discharge.

- Discharge line must be as short as possible and be the same

size as the valve discharge connection throughout its entire

length.

- Discharge line must pitch downward from the valve and

terminate no more than 6” (150 mm) above the floor drain

where any discharge will be clearly visible.

The discharge line shall terminate plain, not threaded, with

a material serviceable for temperatures of 375 °F (190°C) or

greater.

- Do not pipe the discharge to any place where freezing could

occur.

- Do not plug or place any obstruction in the discharge line.

- Test the operation of the valve after filling and pressurizing

system by lifting the lever. Make sure the valve discharges

freely. If the valve fails to operate correctly, replace it with a

new relief valve.

- For boilers installed with only a pressure relief valve, the

separate storage vessel must have a temperature and

pressure relief valve installed. This relief valve shall comply

with the standard for Relief Valves for Hot Water Supply

Systems, ANSI Z21.22/CSA4.4.

- Failure to comply with the above guidelines could result in

failure of the relief valve to operate, resulting in possibility of

severe personal injury, death or substantial property damage.

2. GENERAL PIPING INFORMATION

CAUTION: Use two wrenches when tightening water piping

at boiler, using one wrench to prevent the boiler return line or

supply line from turning. Failure to support the boiler piping

connections to prevent them from turning could cause damage

to boiler components.

NOTICE: The XPak boiler control module uses temperature

sensors to provide both high limit protection and modulating

temperature control. The PCB also provides low water

protection using a water pressure switch (minimum 6.5 psi

(0.45 bar)) and blocked flue switch. Some codes/jurisdictions

may require additional external controls for high limit and/or

low water cutoff protection.

3. SEPARATE LOW WATER CUTOFF

A low water cutoff may be required by state local code or some

insurance companies. Check code requirements before

installation of the XPak boiler.

If required:

- Use a low water cutoff designed for hydronic installations

- Follow low water cutoff manufacturer’s instructions

NOTICE:

A hot water boiler installed above radiation level or as required

by the Authority having jurisdiction, must be provided with a

low water cut off device either as apart of the boiler or at the

time of the boiler installation.

4. BACKFLOW PREVENTER

Use a backflow preventer specifically designed for hydronic boiler

installations. This valve should be installed on the cold water fill

supply line per local codes.

5. FITTING THE HEATING CIRCUIT SUPPLY AND RETURN

PIPES

NOTICE:

- To protect the entire heating system Raypak recommends

installing a filter in the return circuit. When connecting the

boiler to an existing heating system this filter must definitely

be installed.

- Install shut-off valves immediately before and after the dirt

particle filter to enable the filter to be cleaned.

- Install a filling and drain cock in the heating system supply

pipe if required.

- Also install a safety valve in the system.

NOTICE: When using oxygen-permeable pipes, e. g. for floor

heating systems, you must separate the system using heat

exchangers.

- Thoroughly flush all pipes and radiators.

- Refer to the installation template for the pipe connection

dimensions.

- Connect the pipes so that they are free from strain.

6. EXPANSION TANK AND MAKE-UP WATER

1. Ensure expansion tank size will handle boiler and system

water volume and temperature. Allow 2 gallons for the boiler

and its piping.

CAUTION: Undersized expansion tanks cause system water

to be lost from relief valve and makeup water to be added

through fill valve. Eventual failure can result due to excessive

make-up water addition.

2. Expansion tank must be located near to the boiler as shown

in Piping “XPak installation diagrams”. No valve is to be placed

between the boiler and the expansion tank.

7. SIZING SPACE HEAT SYSTEM PIPING

- Size the piping and components in the space heating system

using recognized design methods.

NOTICE:

- The boiler, when used in connection with a refrigeration

system, must be installed so the chilled medium is piped

in parallel with the boiler and with appropriate valves to

prevent the chilled medium from entering the boiler.

- The boiler piping system of a hot water boiler connected to

heating coils located in air handling units where they may

be exposed to refrigerated air circulation must be equipped

with flow control valves or other automatic means to prevent

gravity circulation of the boiler water during the cooling cycle.

17

Page 18

8. BOILER WITH DHW TANK

- Connect the external hot-water tank according to the Installation

instructions of the hot-water tank and fittings concerned.

Domestic Hot Water Production via DHW Storage Tank

XPak boilers can be used in conjunction with the stand-alone

DHW storage tanks.

The boiler can control the DHW tank temperature directly from

the boiler control panel. In case a tank sensor is installed (see

boiler configuration jumpers Fig. 61) adjust the tank temperature

via the DHW selector. The display shows the tank temperature if

main selector in proper position.

Boiler can accept also a DHW tank controlled by a thermostat

(see boiler configuration jumpers Fig. 61), in this case the DHW

set point can not be adjusted on the control panel but only on the

tank thermostat (field supplied).

Both cases the supplied water temperature to the tank is 176°F

(80°C) and it goes ahead with priority over heating until the tank

request is satisfied (either the sensor or the termostat open).

The boiler can control a 3-way valve directly from the boiler control

panel (see 3-way installations Fig. 38).

Refer to electrical connections for 3-way valve installation.

Size and select the DHW storage tank based on the forecast

DHW consumption of the building in question.

If different method of DHW production are used, the boiler flow

temperature is set as heating mode (see boiler configuration

jumpers Fig. 61).

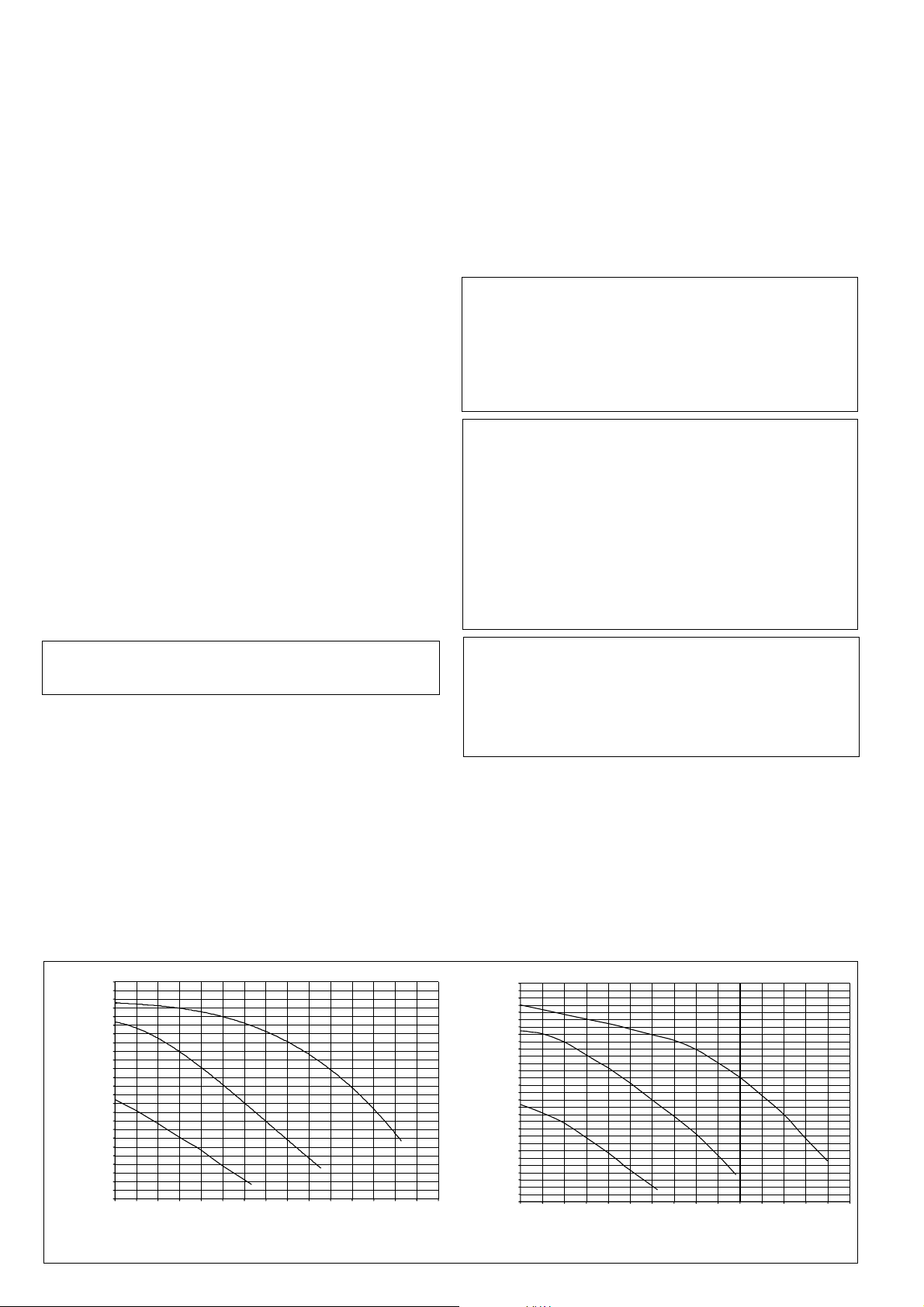

9. WATERSIDE FLOW (PRIMARY CIRCUIT)

The boiler is designed only for closed loop, forced circulation hot

water heating systems.

XPak is equipped with an internal 3 speed pump.

PUMP DUTY

Fig. 6 below shows the flow-rate available – after allowing for

pressure loss through the appliance – for system requirements.

When using this graph, apply only the pressure loss of the system.

The graph is based on a 36°F (20°C) temperature differential.

required system volume and capacity, no valve is to be placed

between the boiler and the expansion tank.

6. Install an Air Elimination Device on the system supply if

required, the boiler has two auto air vents built in.

7. Install a drain valve at the lowest point of the system.

Note: The XPak has a proper internal drain valve. (see Fig.

42a)

8. The Safety Relief Valve is installed at the factory. Pipe the

discharge of the safety relief valve to prevent injury in the

event of pressure relief. Pipe the discharge to a maximum of

6” (152 mm) above the floor to a drain. Provide piping that is

the same size as the safety relief valve outlet. Never block the

outlet of a safety relief valve.

11. FILL AND PURGE HEATING SYSTEM

CAUTION: For installation that incorporates standing Iron

Radiation and systems with manual vents at the high points.

Follow above section and starting with the nearest manual air

vent, open vent until water flows out, then close vent. Repeat

procedure, working your way toward furthest air vent. It may

be necessary to install a basket strainer in an older system

where larger amounts of sediment may be present. Annual

cleaning of the strainer may be necessary.

WARNING: Use only inhibited propylene glycol solutions

which are specially formulated for hydronic systems. Ethylene

glycol is toxic and can attack gaskets and seals used in

hydronic systems. Glycol mixtures should not exceed 40%.

1.Glycol in hydronic applications which is specially formulated

for this purpose includes inhibitors that prevent the glycol

from attacking metallic system components. Make certain

that the system fluid is checked for the correct glycol

concentration and inhibitor level.

2.The glycol solution should be tested at least once a year and

as recommended by the glycol manufacturer.

3.Anti-freeze solutions expand more than water. Allowances

must be made for this expansion in the system design.

CAUTION: The XPak should not be operated as a potable

Hot Water Boiler. The XPak should not be operated in a open

system.

10. PROCEDURE SUMMARY

1. Connect the system return marked “In”.

2. Connect the system supply marked “Out”.

3. Install a Back Flow preventor on the Cold Feed Make-Up

Water line.

4. Install a Pressure Reducing Valve if required on the Cold

Feed Make-Up Water line, 15 PSI (1 bar) nominal on the

system return. Check Pressure Gauge which should read

minimum pressure of 12 PSI (0.8 bar)

5. Install an Expansion Tank on the system supply. Consult the

tank manufacturer’s instruction for specific information relating

to expansion tank installation. Size the expansion tank for the

16

15

14

12

11

10

9

7

6

5

3

Residual head (ftwc)

2

0.6

0

0 20 41 61 81 102 122 142 163 183 203 224 244 264 285 305

XPak 85

3rd speed

2nd speed

1st speed

Flow rate (gph)

Fig. 6

CAUTION: It is highly recommended that you carefully follow

the glycol manufacturer’s recommended concentrations,

expansion requirements and maintenance recommendations

(pH additive breakdown, inhibitor reduction, etc.). You must

carefully calculate the additional friction loss in the system as

well as the reduction in heat transfer co-efficients; pH must be

maintained between 6-8.

16

15

14

12

11

10

9

7

6

5

3

Residual head (ftwc)

2

0.6

0

0 20 41 61 81 102 122 142 163 183 203 224 244 264 285 305

XPak 120

3rd speed

2nd speed

1st speed

Flow rate (gph)

18

Page 19

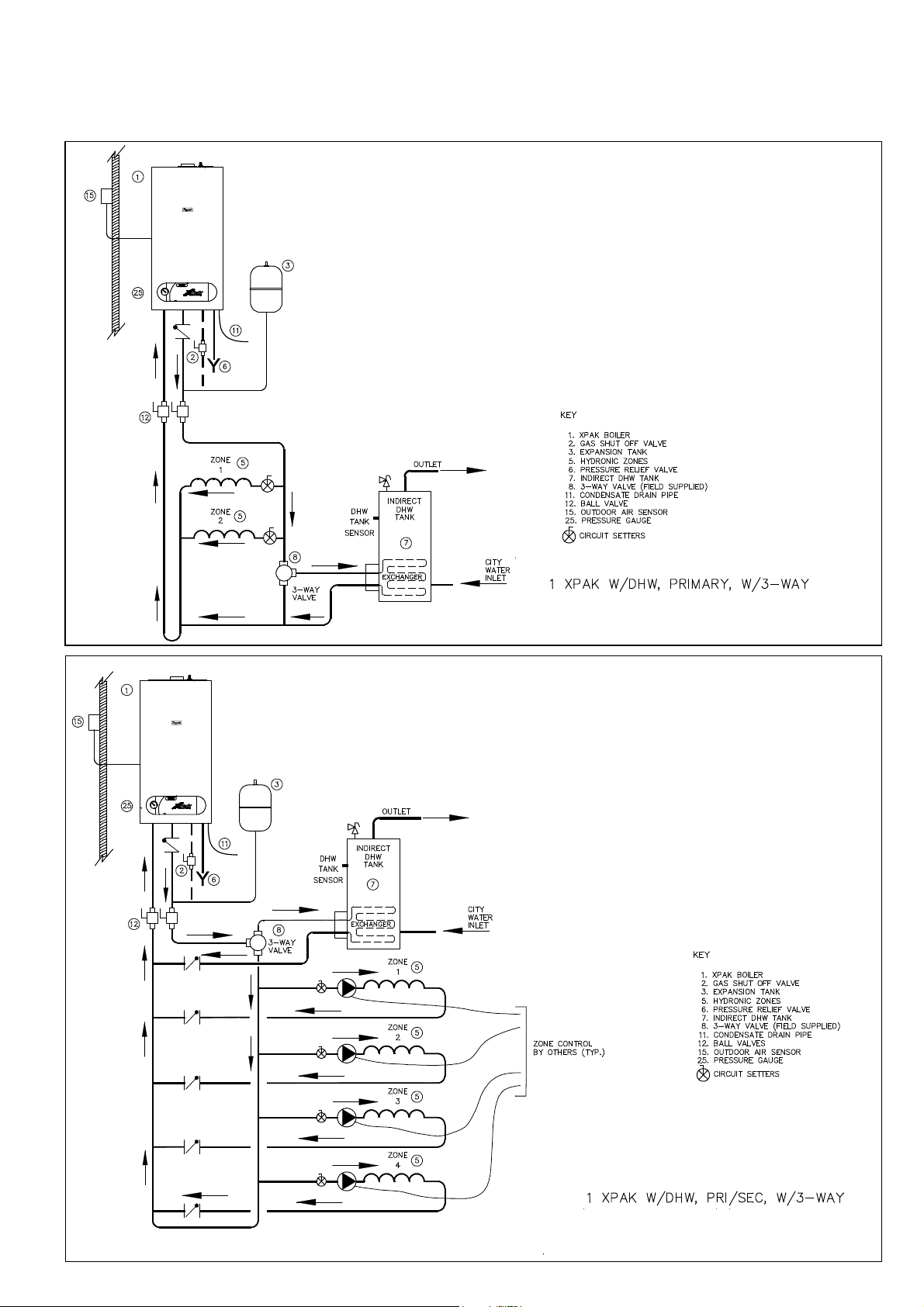

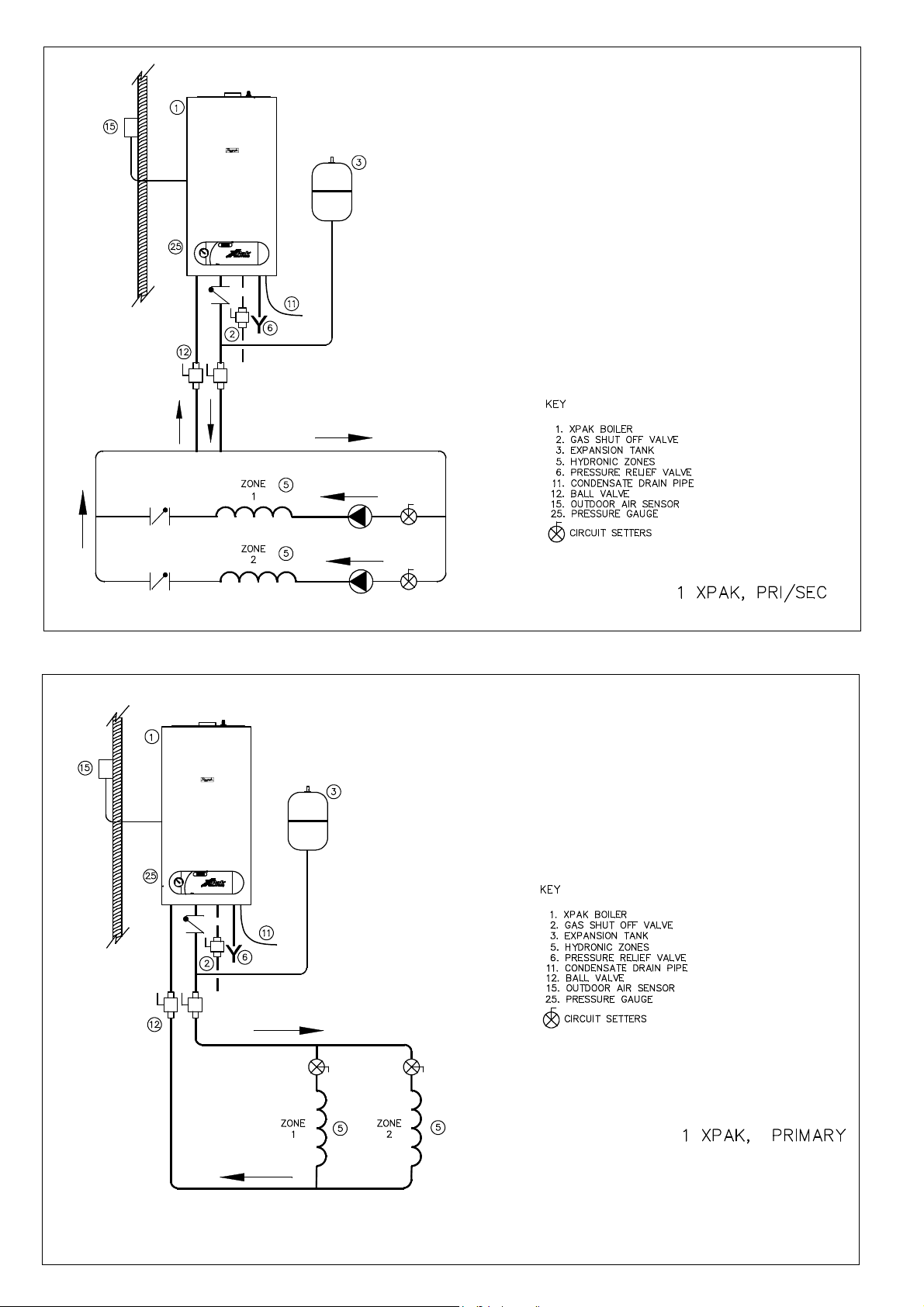

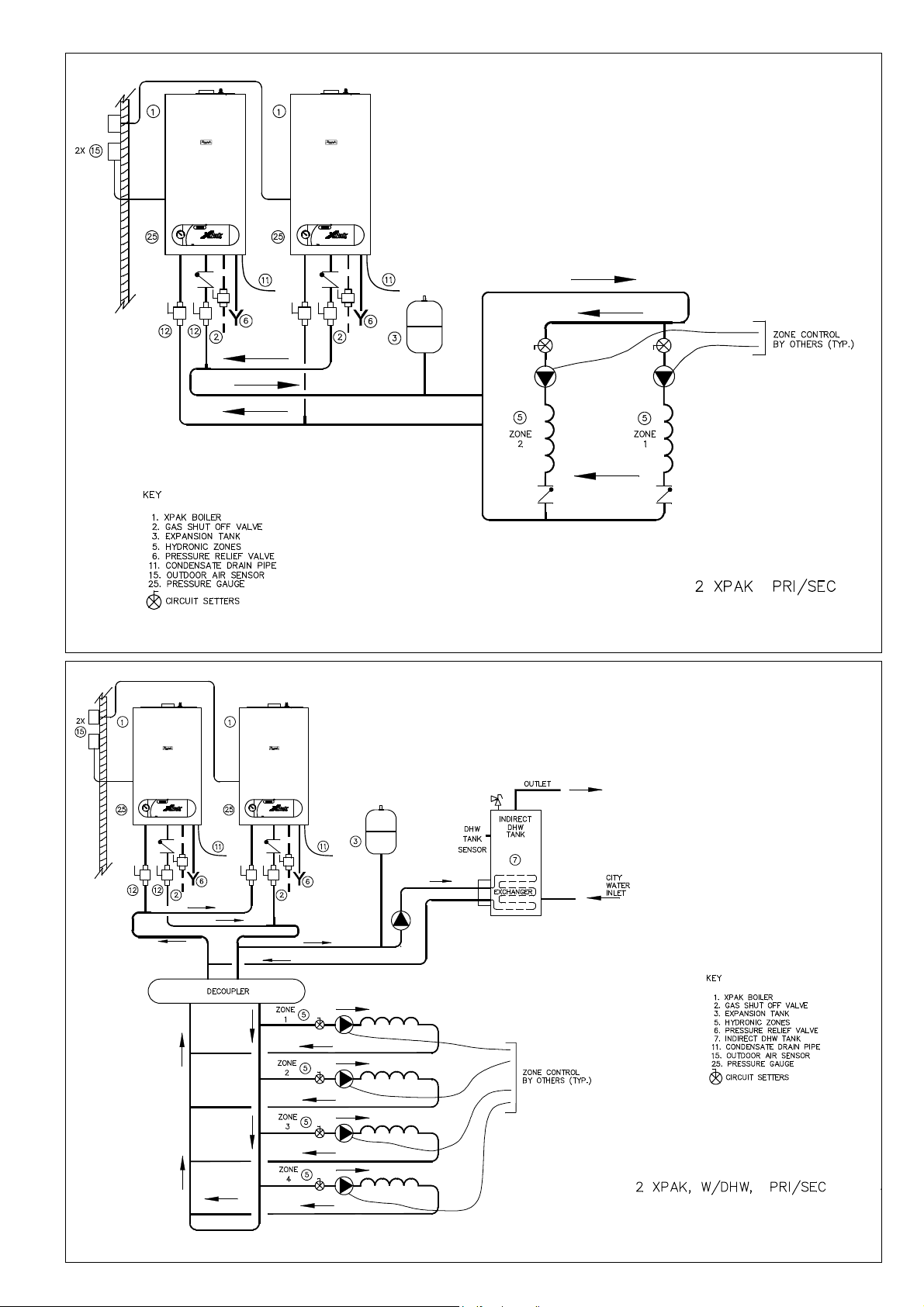

XPAK INSTALLATION DIAGRAMS

NOTICE: The following illustrations are simplified conceptual

illustrations only.

Fig. 7

Fig. 8

19

Page 20

Fig. 9

Fig. 10

20

Page 21

Fig. 11

Fig. 12

21

Page 22

MAKING THE GAS CONNECTION

DANGER: Only carry out work on gas conduits and fittings if

you are licensed for such work.

- Determine proper size gas pipe for the installation using

Table 3 and

and observe proper size of the fittings.

- Install the furnished 3/4” female gas cock on the gas

connection (3/4” male on the boiler) (Fig. 13).

- Connect the gas pipe to the gas cock so that it is free from

any strain.

CAUTION: The boiler and its individual shutoff valve must

be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess

of 1/2 psi (3.5 kPa).

Fig. 13

A- Manual main gas shutoff

valve (supplied)

B- Coupling (field supplied)

C- To gas supply

Table 4. Do not forget the pipe fitting losses

A

B

C

position

Fig. 14

Open

Closed

position

NOTICE: When installing the gas supply connection, it must

comply with local regulations or, if such regulations do not e xist,

with the National Fuel Gas Code, ANSI Z 223.1.

In Canada, the gas supply connection must comply with local

regulations or, if such regulations do not exist, with CAN/CSA

B149, Natural Gas and Propane Installation Code. A sediment

trap must be provided upstream of the gas controls.

Gas Pipe Capacity for different pipe sizes

Length of Gas Volume Capacity

pipe (feet) (ft3/h)

*

Ta b . 3

3/4” 1” 1 1/4” 1 1/2”

10 278 520 1,060 1,600

20 190 350 7 3 0 1,100

30 152 285 590 890

40 130 245 500 760

50 115 215 440 670

75 93 175 360 545

100 7 9 160 305 480

150 6 4 120 250 380

* Maximum pipe capacity in ft3/hr, based on a specific gravity of 60 (42

mbar) and a inlet gas pressure of 14 inches W.C. (35 mbar) or less and a

pressure drop of 0.3 inches W.C. (20 mbar)

Equivalent length for pipe fittings in feet

Ta b. 4

Steel pipe Equivalent length for Pipe Fittings in feet

diameter Type of pipe fitting

in inches 90° Elbow Tee Gate valve Gas cocks

(flow thru

branch)

Equivalent length in feet

3/4 2.1 4.1 0.5 1.25

1 2.6 5.2 0.6 1.60

1 1/4 3.5 6.9 0.8 2.15

1 1/2 4.0 8.0 0.9 2.50

NOTICE: The boiler must be isolated from the gas supply

piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psi (3.5 kPa).

22

Page 23

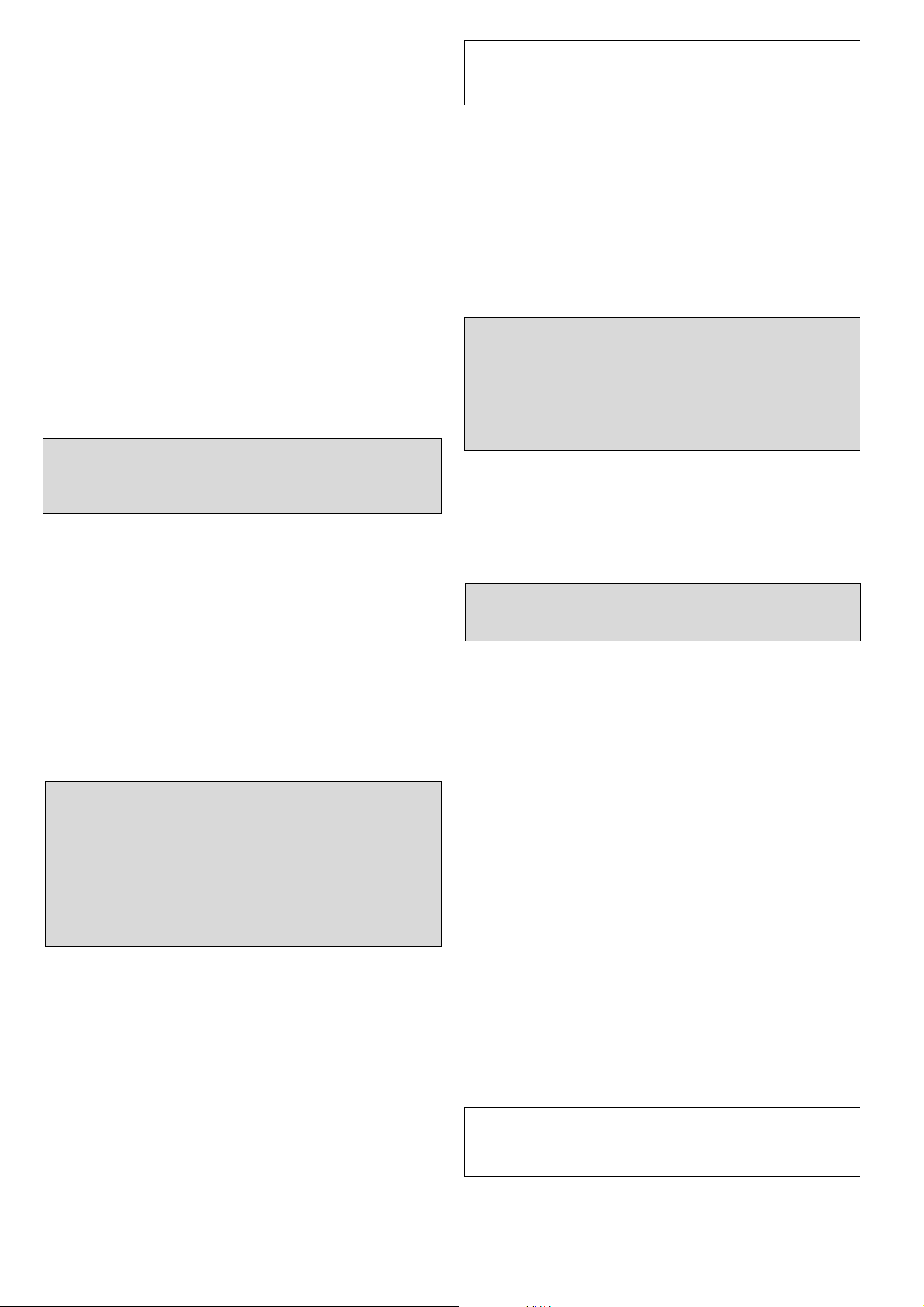

BOILER TEMPLATE (Fig. 15)

Boiler bracket

(supplied)

Ø1/4" holes

for 5/16" lag

screws (4 places)

1.5"

Wall stud

3.54"

Exhaust vent adapter (supplied)

3" vent adaptor (supplied)

Inlet air either right or left

C/C16"

inside 3"

Screw (2x) (supplied)

14.17"

16.25"

XPak 120 - 17.81"

XPak 85 - 15.75"

4,53" Hole for 60/100mm coaxial vent

3" inlet air adapter (not supplied)

inside 3.15"

Screw (2x) (supplied)

Inlet air adapter (supplied)

XPak

120

Screw (2x) (fitted)

Wall Mounting Information

XPak comes with a template,

which allows you to easily mark

the location of the screws for the

mounting bracket and the location

of the flue gas pipe on the wall

(Raypak coaxial PP vent system

only).

The connection to the gas circuits

must be made on site, 3/4” gas

cock is supplied with the boiler .

XPak

85

30.71" Boiler height

C

Boiler outline

CENTER LINE

OF BOILER

This boiler is heavy and awkward to lift. It is

recommended and safer to install the boiler with two

people. Use caution as to not drop this boiler which

could cause personal injury. Verify that the boiler is

securely mounted before leaving the boiler unsupervised.

Ensure there is adequate clearances for mounting the boiler (details given in

installation instructions).

The wall mount bracket is designed for a stud spacing of 16 inches from

center. For other stud spacing a solid mounting surface must be provided by

the installer.

Do not mount the boiler to a hollow wall. Be sure to mount the boiler to the

studs only.

Mount the wall bracket using 4 5/16" lag screws. Ensure the bracket is level

when mounted.

Extreme care is needed to ensure the bolts are secured in the studs.

Hang the boiler on the bracket and secure the bottom of the boiler with two (2)

additional lag screws.

L

WARNING

XPak

120

XPak

85

IN 3/4"

NPT male

Ø1/4" holes for earthquake restraint (2 places)

5.90"

OUT 3/4"

3.35" 1.38"

NPT male

Condensate piping flexible (supplied)

0.825” female

4/5" female

3.14"

Pressure relief valve drain

3/4" NPT female

Gas shut off valve (supplied)

3/4" NPT female

XPak

120

XPak

85

Fig. 15

23

Page 24

COMBUSTION AIR AND

VENTILATION OPENINGS

Provisions for combustion and ventilation air must be made in

accordance with section 5.3, Air for Combustion and Ventilation,

of the National Flue Gas Code, ANSI Z223.1, or Sections 7.2, 7.3

or 7.4 of CAN/CGA B149, Installation Codes, or applicable

provisions of the local building codes.

CAUTION: BOILER DAMAGE AND OPERATIONAL

FAILURES !

Due to insufficient or lacking openings for combustion air

and/or ventilation of the boiler room. Provisions for

combustion air and ventilation are always required,

regardless whether the combustion air is taken from the

outside (sealed combustion) or inside (room air for

combustion). Insufficient ventilation of the boiler room can

lead to high air temperatures.

This can result in boiler damage.

– Make sure that intake and exhaust openings are sufficiently

sized and no reduction or closure of openings takes place.

– When the problem is not resolved, do not operate the boiler.

– Please note these restrictions and its dangers to the operator

of the boiler.

WARNING: BOILER DAMAGE !

Due to contaminated air.

– Boiler must be clear and free from combustible materials,

gasoline and other flammable vapors and liquids, and

corrosive liquids and vapors. Never use chlorine and

hydrocarbon containing chemicals (such as spray

chemicals, solution and cleaning agents, paints, glues etc)

in the vicinity of the boiler.

– Do not store and use these chemicals in the boiler room.

– Avoid excessive dust formation and build-up.

NOTICE: When one expects contaminated combustion air

(near swimming pools, chemical cleaning operations and

hair salons), sealed combustion operation is recommended.

DANGER: FIRE DANGER !

Due to flammable materials or liquids.

– Do not store flammable materials and liquids in the

immediate vicinity of the boiler.

All Air from Inside the Building (room air)

The room shall be provided with two permanent openings

communicating directly with an additional room(s). The total input

of all gas utilization equipment installed in the combined space

shall be considered in making this determination. Each opening

shall have a minimum free area of 1 square inch per 1,000 Btu per

hour of total input rating of all gas utilization equipment in the

confined space, but no less than 100 square inches. One opening

shall commence within 12 inches (305 mm) of the top, and one

opening shall commence within 12 inches (305 mm) of the bottom

of the enclosure. The minimum dimension of air openings shall be

not less than 3 inches (75 mm).

All Air from Outdoor (sealed combustion)

The room shall be provided with two permanent openings, one

commencing within 12 inches (305 mm) from the top, and one

commencing within 12 inches (305 mm) from the bottom of the

enclosure. The openings shall communicate directly, or by ducts,

with the outdoors or spaces (crawl or attic) that freely communicate

with the outdoors.

The minimum dimension of air openings shall be no less than 3

inches (75 mm).

1. Where directly communicating with the outdoors, each opening shall have a minimum free area of 1 square inch per 4,000

Btu/hr of total input rating of all equipment in the enclosure.

2. Where communicating with the outdoors through vertical ducts,

each opening shall have a minimum free area of 1 square inch

per 4,000 Btu/hr of total input rating of all equipment in the

enclosure.

3. Where communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of 1 square

inch per 2,000 Btu/hr of total input rating of all equipment in the

enclosure.

4. Where ducts are used, they shall be of the same cross-sectional

area as the free area of the opening to which they connect.

INSTALLATION OF THE EXHAUST

AND AIR INTAKE SYSTEM

NOTICE: Consult local and state codes pertaining to special

building code and fire department requirements. Adhere to

national code requirements.

NOTICE: Observe the listed maximum lengths of vent system,

which are boiler model dependent. The maximum permissible

lengths are listed in the main specification Tab. 5.

An optional concentric vent/air intake body can be used for the

installation of a vertical venting system as well as for a horizontal

venting system. The concentric vent/air intake body can be ordered

through Raypak Inc.

The boiler can also be operated with separate air intake and

exhaust piping.

The termination shall be at least 4 ft (1220 mm) for the U.S. and

6ft. (1830 mm) for Canada away from a gas utility meter, service

regulator or the like (for room air applications only).

The termination shall terminate at least 4 ft (1220 mm) below, 4 ft

(1220 mm) horizontally from, or 1 ft (305 mm) above any door,

window, or gravity air inlet into any building.

Vent must be at least 12 inches (305 mm) above grade, anticipated

snow line or roof surface (Canada 18” (457 mm) minimum).

Vent termination must be at least 7 ft (2135 mm) above a public

walkway (see Fig. 20).

Vent must be 3 ft (915 mm)above any forced air intake within 10

ft (3050 mm) (see Fig. 20).

Do not extend exposed vent pipe outside the building beyond

recommended distance. Condensate could freeze and block vent pipe.

Vent should terminate at least 3 ft (915 mm) away from adjacent

walls, inside corners and below roof overhang.

It is not recommended to terminate vent above any door or