Page 1

OPERATING INSTRUCTIONS

Remote

Control

Panel

For Models 85 & 120

REC08

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

Effective: 01-26-10 Replaces: NEW P/N 208873 Rev. 1

Page 2

2

Page 3

TO USE THE REMOTE CONTROL PANEL CORRECTLY, CAREFULLY READ

THE CONTENTS OF THIS DOCUMENT.

WARNINGS:

1) The remote control must be installed where it can

be easily accessed for ambient temperature control

(generally in the living room).

2) To optimize legibility of the display, the control

panel must be positioned 5 feet from the floor, as

required by regulations.

3) The control panel is powered by low voltage

directly from the boiler.

4) The control panel must be kept away from heat

sources or drafts, as these can compromise the

accuracy of the ambient probe incorporated in the

panel.

5) Never open the panel, as it is maintenance-free.

6) Never press on the glass of the liquid crystal

display, as this may damage the glass and impair

viewing.

7) Only use a dry cloth to clean the display, as any

infiltration of liquids may damage the liquid crystals.

GLOSSARY OF TECHNICAL TERMS

• Heating water: This is the water which flows in the

comfort heat radiators after having been heated by

the boiler.

• Domestic hot water: This is the potable water

which flows to the fixtures in the home.

• Fault code: This is a code which appears on the

display to report any boiler or control panel operational problems.

• Initial configuration: This is the configuration of

the control panel after initial start-up or resetting.

• Display: This is the liquid crystal screen showing

all the symbols corresponding to the various functions.

• Freeze protection function: This function prevents low temperatures from freezing the water

flowing inside the pipes and damaging the heating

system. This function activates when the ambient

temperature falls below 40°F (5°C).

GENERAL INFORMATION

WHAT DOES THE REMOTE CONTROL

PANEL DO?

The remote control panel allows you to control the

temperature in your home and the operation of your

boiler without having to access the boiler directly. For

reasons of space, in fact, your boiler may be installed

outside the living space (e.g.: basements, garages,

external areas, etc.). The control panel, on the other

hand, is generally installed in the largest room of the

home, where control and adjustment operations can

be performed with ease.

OPERATING METHOD

The control panel allows more refined home heating

management, as you can decide how and when to

start the boiler. It also allows you to set the domestic

hot water temperature without having to access the

boiler panel. This manual sets out to explain each of

these operating methods and their connected functions.

• Control panel reset: This operation is performed

to reset the initial configuration of the control panel

by deleting any user program apart from the system clock.

• Summer mode: Set the control panel to this mode

when the heating system is not required (e.g.:

spring, summer). The boiler only delivers domestic

hot water (when piped to domestic hot water).

• Automatic heating and continuous heating

mode: Set the control panel to this mode when

heating is required (e.g.: autumn, winter). The boiler delivers both domestic hot water and heating

water.

• Comfort temperature: This temperature optimizes

heating in the home.

• Setback temperature: This temperature is used

when the home is uninhabited, or during the night.

• Ambient temperature: This is the temperature

measured in the room in which the remote control

panel is installed.

3

Page 4

• Outdoor temperature: This is the temperature

easured outside the house by the external sensor

m

(if installed) connected to the boiler.

• Outdoor reset curve: This is the relationship

between the external temperature and the temperature of the heating water. If the outdoor probe is

installed with the boiler, the temperature of the

heating water is automatically adjusted according

to the changes in outdoor temperature in order to

maintain a constant temperature in the home. The

outdoor reset curve is chosen by the installer

according to the geographical location and system

NOTE:

• The ambient temperature display ranges from

32°F to 210°F (0°C to 99°C).

• The outdoor temperature display ranges from

-38°F to 102°F (-39°C to 39°C).

• Temperatures outside these ranges are displayed

with three dashes “---”.

• Temperatures below 100° (°F or °C) will be displayed in tenths of a degree (XX.X).

• Temperatures of 100° or higher (°F) will be displayed in whole degrees (XXX°F)

OTE: Refer to Figure 35 on page 36 of the XPak

N

Installation and Operating Instructions for connections from this Remote Control Panel to the XPak

boiler.

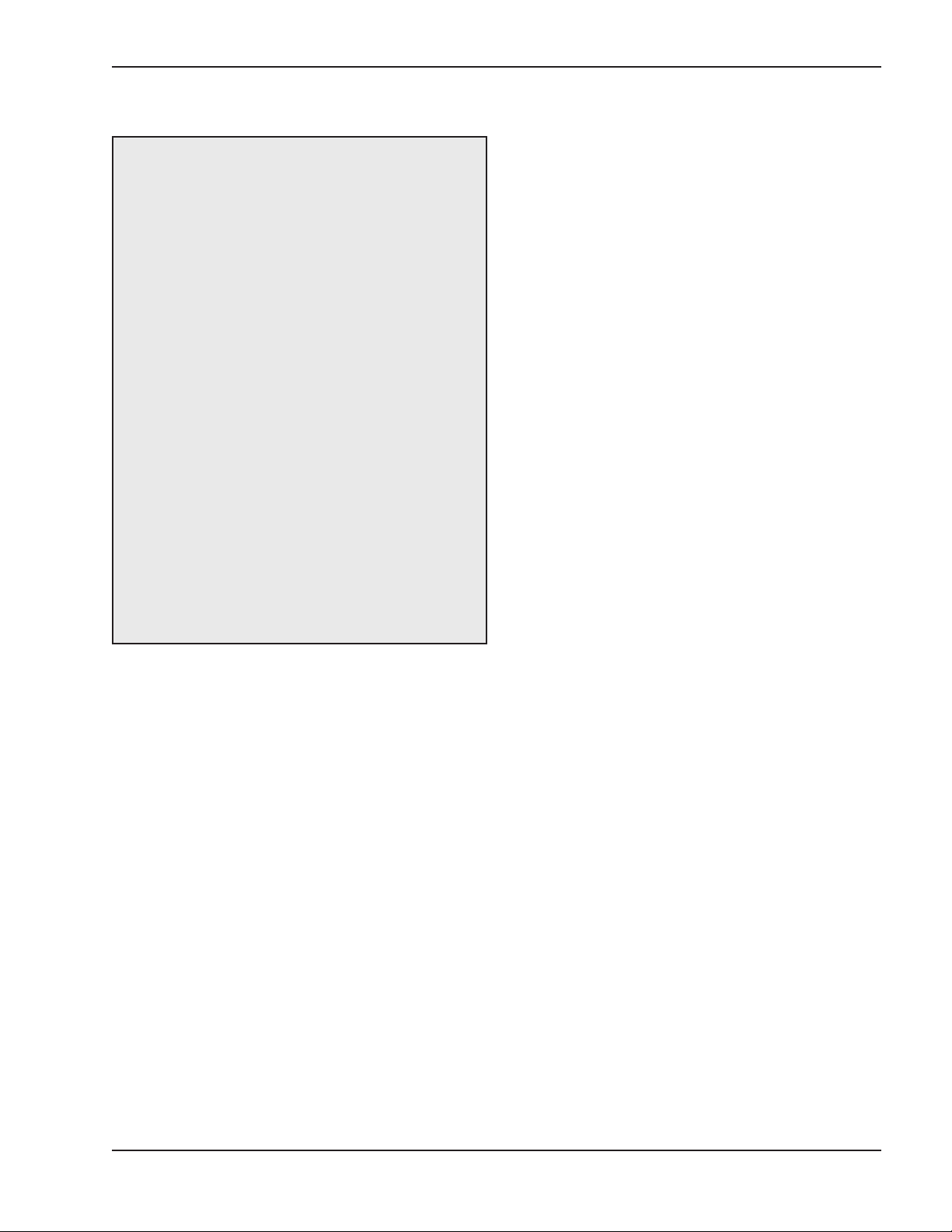

SWITCHES

The remote control unit features two directly accessible ENCODER knobs. The left-hand knob (SELECT)

is used to select the operating mode. Turn to “RUN”

for normal operation. The right-hand knob (EDIT) is

used to modify the selected value.

USING THE CONTROL PANEL

ELECTRICAL CONNECTIONS

1 = OT Bus

2 = OT Bus

3 = Phone switch

4 = Phone switch

5 = Not used

Fig 2: Switches

Fig. 1: Electrical connections

4

Page 5

Boiler status

The boiler status and communication

status are displayed

OT+ communication correct

Flame present in boiler

Current heating demand in boiler

Current domestic hot water

demand in boiler

Current heating program

Control panel operating mode

The current operating status of the control panel is

shown on this row of the display:

Standby / OFF

Automatic operation Heating according to

program 1

Automatic operation Heating according to

program 2

Continual heating at comfort temperature

Continual heating at setback temperature

Summer mode

System information

Some system information is shown on the central line of the display.

The ambient temperature and time are normally displayed 70 °F 16:32

If the holiday function is enabled, the time remaining in days

.deyalpsidsi

In case of a fault, ambient temperature and fault code are displayed. 70 °F E001

Turn the right-hand knob (EDIT) to view:

- Outdoor temperature (only if the outdoor air sensor is installed

in the )reliob

- Boiler supply temperature

°F 128.7

- Boiler supply temperature setpoint

(calculated by the remote control unit)

°F 128.7

- Domestic hot water temperature at boiler

°F 116.0

The day of the week is

indicated by the corresponding

segment lighting up on the

first row of the display.

Day of the week

Shows the current heating program.

AF °F 60.3

HO 05

Radio communication function

(not used on REC08)

Solar panel thermostatic control

Status during Service Technician repair

(not used on REC08)

(not used on REC08)

-- --

- Battery charge status (not used on REC08)

Fig. 3: Run Mode

5

Page 6

“”

“”

PL

HO

“”

RUN MODE

With the left-hand knob (SELECT) turned to “RUN,”

the control panel displays the information required to

check the status of the control panel and boiler. The

information is displayed in Fig. 3 on page 5.

Technical level

Setting of parameters 1-17.

oliday setting

H

CONTROL PANEL OPERATING MODE

SETTINGS

Turn the left-hand knob (SELECT) to “MODE” and

turn the right-hand knob (EDIT) to set one of the following

operating modes:

Standby / OFF

Heating and hot water are disabled. Only the freeze

protection function remains enabled.

Automatic operation - heating according to

program 1

Heating with program 1. Domestic hot water production enabled.

Automatic operation - heating according to

program 2

Heating with program 2. Domestic hot water production enabled.

Continual heating in comfort mode (manual)

24-hour heating at comfort temperature. Domestic

hot water production enabled.

Continual heating in setback mode (manual)

24-hour heating at setback temperature. Domestic

hot water production enabled.

Heating and hot water are disabled. Only the

freeze protection function remains enabled.

After setting the parameters, turn the SELECT knob

back to “RUN.”

Setting the comfort temperature

Turn the left-hand knob (SELECT) to

and turn the EDIT knob to set the required temperature from 40°F to 104°F (5°C to 40°C). After setting

the parameter, turn the SELECT knob back to “RUN.”

Setting the night setback temperature

Turn the left-hand knob (SELECT) to

and turn the EDIT knob to set the required temperature from 40°F to 104°F (5°C to 40°C). After setting

the parameter, turn the SELECT knob back to “RUN.”

Setting the domestic hot water temperature

Turn the left-hand knob (SELECT) to and

turn the EDIT knob to set the required temperature

from 95°F to 122°F (35°C to 50°C). After setting the

parameter, turn the SELECT knob back to “RUN.”

Setting the day of the week

Turn the left-hand knob (SELECT) to “1….7” and turn

the EDIT knob to set the required day of the week.

After setting the parameter, turn the SELECT knob

back to “RUN.”

Summer mode

No heating (only freeze protection). Domestic hot

water production enabled.

6

Page 7

Setting the time

“”

Turn the left-hand knob (SELECT) to

and turn the EDIT knob to set the current time. After

setting the parameter, turn the SELECT knob back to

“RUN.”

Setting the holiday program

Turn the SELECT knob to “MODE,” and then turn the

EDIT knob to “HO” and set the required number of

days holiday. Turn the SELECT knob back to “RUN.”

The function begins immediately and ends at midnight

on the last set day.

Heating program 2 is be used to modify parameters 1

(Monday) to 7 (Sunday). To set heating program 2,

enter the technical menu and select parameters 1 to 7

depending on the day being set. To do so, turn the

SELECT knob to “MODE” and then select “PL” with

the EDIT knob.

Select the required parameter by turning the SELECT

knob clockwise: 01 for Monday through 07 for Sunday.

Next to the heating program sign, the display shows

the current program in hours, the day or group of days

to which the programming refers, the programming

time and, the first hour block, which will be flashing. On

and off times are then set for both heating programs.

Turn the right-hand (EDIT) knob counter-clockwise to

set the heating phases at setback temperature. Turn

it clockwise to set the heating phases at comfort temperature. Every turn of the knob corresponds to a 15minute increase in time, and every movement of the

cursor corresponds to a 1-hour increase.

To exit heating program 1 settings, turn the SELECT

knob to “RUN.”

Fig. 4: Setting the holiday program

(Example shown indicates a 5-day holiday.)

Setting the heating program

The remote control unit can be used to set two heating

programs.

Heating program 1 is used to modify two blocks of

days independently: Monday-Friday and SaturdaySunday.

To set heating program 1, turn the SELECT knob to “6

– 7” in order to modify Saturday and Sunday settings

or to “1 – 5” in order to modify those of the rest of the

week.

To exit heating program 2 settings, after programming

the days of the week, turn the SELECT knob clockwise

to “PL,” turn the EDIT knob counter-clockwise until it

reaches the required operating mode (see the dedicated section). Then turn the SELECT knob to “RUN.”

Programming takes place throughout the 24 hours.

After 23:45, the hour block switches to 0:00.

Fig. 5: Setting the heating program

7

Page 8

Fault display

Reset blocks in case of boiler error

Faults are displayed with EXXX, where XXX is the

efault code generated by either the remote control

d

unit or the boiler. The code is displayed instead of the

time on the information line. The signal is fixed if the

alarm does not require a RESET while it flashes if it

requires the RESET procedure. Table A shows the

fault codes generated by the thermostat timer.

Fig. 6: Fault display

Some boiler alarms can be directly reset from the

emote control unit. In these cases, in addition to the

r

code flashing on the display, a triangle lights up next to

the RESET message on the right-hand side of the display (see Fig. 6). At this point, the RESET function can

be activated. Turn the EDIT knob clockwise. A

RESET command equivalent to pressing the button on

the boiler is generated and the release command is

sent to the boiler. The arrow disappears after the

RESET command has been given.

Error # Description

No communication with boiler. Data

E 201

E 81

E 80 Fault in the ambient temperature sensor.

Table A: Fault codes generated by the thermostat timer

For definitions of the alarms generated by the boiler,

please consult the XPak Installation and Operating

Instructions.

transmission to the boiler must be

checked.

EEPROM Error

This code means the memory of the termostat timer has been altered (e.g. via

EMV). Following the error, the default

data is loaded.

All the set values must be checked.

Fig. 7: Reset blocks in case of boiler error

Technical menu

To enter the technical menu, turn the SELECT knob

to “MODE,” turn the EDIT knob to “PL” and then

select the required parameter using the SELECT

knob.

Turn the EDIT knob to set the required value.

To exit the technical level, select the forward/back

parameter, “PL,” using the SELECT button and then

turn the EDIT knob.

Both heating program 2 and some installer parameters can be set in the technical menu.

To set the heating program, parameters 01-07, consult the above section

8

Page 9

Setting the heating program

Parameters 08 through 17 refer to ambient tempera-

ure adjustment and boiler operation.

t

WARNING: Changing the values of parameters

08 through 17 may compromise the normal operation

of the boiler. These parameters should be changed by

qualified technicians only.

08 Maximum heating temperature

Maximum delivery temperature of boiler in the

heating mode.

09 Minimum heating temperature

Minimum temperature of boiler in the heating

mode. If the outdoor air sensor is not fitted and

parameter 11, internal sensor influence, equals

zero, this parameter is used as a set point for the

temperature of the heating water.

10 Heat adjustment curve for heating water

This is only enabled if an outdoor air sensor is

connected. Relation curve of the outdoor air sensor in the algorithm used to calculate delivery temperature adjustment.

11 Internal sensor influence

Importance of the ambient temperature sensor in

the algorithm used to calculate delivery temperature adjustment.

12 Not used

13 Ambient sensor offset

Temperature offset of the measured internal sensor; this is used to adapt the value to the place of

installation.

14 Loading default parameters

Set this parameter to 1 to load the default configuration of the parameters. The day and time are

not modified.

15 Supplementary heat adjustment constant

Offset parameter in the algorithm used to calculate

delivery temperature adjustment.

16 Software version

This displays the code of the software implemented on the remote control unit.

17 °C/°F selection

This parameter selects whether to view temperatures in °F (Fahrenheit) or °C (Celsius).

9

Page 10

Maximum Delivery Temperature (°C/°F)

Outdoor Air Temperature (°C/°F)

20 16 12 8 4 0 -4 -8 -12 -16 °C

68 61 54 46 39 32 25 18 10 3 °F

68

104

140

176

212

°F °C

Fig. 8: Heat Adjustment Curves for heating water

10

Page 11

CODE CAUSE ALARM TYPE ACTION

AL10 Ignition failure/not flame sensed, Final Reset, check appliance operation

condense sensor activated

AL 20 Limit thermostat fault, blocked flue switch,

flue thermostat

Final Reset, check appliance operation

AL21 External device fault (UHT/CPA) Final Reset, check appliance

A

L26 Return temperature too high Final Reset, check pump, ensure there is sufficient

flow sensor temperature). Circulation around

heating circuit/s

AL2 Temperature differential inverted Final Reset, check pump, ensure there is sufficient

(return sensor temperature higher than circulation around heating circuit/s thermistors

flowsensor temperature)

AL29 Flue sensor over temperature lock out Final Reset check appliance operation

AL34 Fan blower signal fault Final Reset check appliance operation, check fan

AL40 Insufficient system water pressure Final Check/refill system pressure, reset, check

appliance operation

AL41 Insufficient system water pressure Temporary Check/refill system pressure, check appliance

operation

AL52 Internal fault Final Reset, check boiler operation

AL55 Jumper tag fault Final Check jumper tag configuration

AL60 Jumper tag fault Temporary Check jumper tag configuration

AL71 Primary (flow) sensor fault Temporary Check primary thermistor, check wiring

AL73 Return sensor fault Temporary Check return thermistor, check /wiring

AL74 Variation on temperature of primary Final Reset, check boiler operation, check

and/or return too high pump, ensure there is

sufficient circulation around heating circuit/s

AL79

Flow temperature too high, or

Final

Reset, check appliance operation, check

temperature differential between thermistors

primary and return too high

AL91

The main heat exchanger need to be

Advice

Call Raypak technical service

cleaned

XPak Fault Codes

Table B: XPak Fault Codes

11

Page 12

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

12

Loading...

Loading...