Page 1

INSTALLATION & OPERATING

INSTRUCTIONS

RayTemp™ Hot Water

Energy Management

Control

For Raytherm™ & Hi Delta™

Hot Water Supply Boilers &

Water Heaters

Catalog No. 5000.61E Effective: 09-08-10 Replaces: 02-06-08 P/N 241098 Rev. 6

Page 2

Rev 6 includes the following:

Changes to: Fig. 1 on page 6, Fig. 4 on page 8, “20 characters” was “20 lines” on page 10, screen code

index on pages 14-15

Additions: Warnings and notes on page 3, General Safety information on page 4, contact number for ProTemp Controls on page 12

Deletions: None

2

Page 3

CONTENTS

WARNINGS 4

GENERAL SAFETY 5

Time/Temperature Relationships in

Scalds 5

GETTING STARTED . . . . . . . . . . . . 6

The Big Picture . . . . . . . . . . . . . . . . . . . . . .6

What Comes with the Control . . . . . . . . . . .6

INSTALLING THE CONTROL . . . . . . 7

Attaching the Temperature Sensors . . . . . . .7

Providing 24 VAC Power to the Control . . . .7

Installation Layout . . . . . . . . . . . . . . . . . . . 8

“DIP” Switch Settings on Circuit Board . . . . .9

Connecting the Optional “ELSA” Brand

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using the Front Panel to Check Sensors and

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CONNECTING A COMPUTER . . . . .10

Building or Buying Interface Cables . . . . . . 11

Installing PTT Software on Your PC . . . . . . 11

Simulated Front Panel Display . . . . . . . . . .11

Reading Logged Data (Not All Models). . . .12

Using Your PC, PTT and Modem to Call a

Control . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PROGRAMMING . . . . . . . . . . . . . . .13

Quick Reference . . . . . . . . . . . . . . . . . . . . 13

First Screen at Power-up . . . . . . . . . . . . . .16

Manual Override . . . . . . . . . . . . . . . . . . . . .16

View Sensors and Relays . . . . . . . . . . . . . .16

Time and Date . . . . . . . . . . . . . . . . . . . . . .16

Celsius / Fahrenheit Scale. . . . . . . . . . . . . .16

Erase Memory / Reset Program . . . . . . . . .16

Security Password (“G” Models Only). . . . .16

Front Panel Menu / Lock . . . . . . . . . . . . . . 16

Time Schedule . . . . . . . . . . . . . . . . . . . . . .17

Supply Temperature . . . . . . . . . . . . . . . . . .17

Return Temperature . . . . . . . . . . . . . . . . . .18

Branch Temperature . . . . . . . . . . . . . . . . . .18

Relay Sequencing (4-Stage Control) . . . . . 18

Relay Sequencing (2-Stage Control) . . . . . 18

Sensor Override Test . . . . . . . . . . . . . . . . .19

Savings Test Setup . . . . . . . . . . . . . . . . . . .19

Savings Test Results . . . . . . . . . . . . . . . . . 19

Sensor Calibration . . . . . . . . . . . . . . . . . . .20

Location Text . . . . . . . . . . . . . . . . . . . . . . .20

Data Modem Setup . . . . . . . . . . . . . . . . . . 20

Fax Modem Setup and Test (“G” Models

Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

WARRANTY . . . . . . . . . . . . . . . . . . 23

Service/Return Authorization Procedure . . 23

3

Page 4

WARNINGS

Pay Attention to These Terms

DANGER:

WARNING:

CAUTION:

NOTE:

NOTE: Minimum 18 AWG, 105°C, stranded wire

must be used for all low voltage (less than 30 volts)

external connections to the unit. Solid conductors

should not be used because they can cause excessive tension on contact points. Install conduit as

appropriate. All high voltage wires must be the same

size (105°C, stranded wire) as the ones on the unit

or larger.

Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

NOTE: Piping diagrams in this manual are not

intended to replace an engineered piping system.

4

Page 5

GENERAL SAFETY

Water temperature over 125°F can

cause instant severe burns or death

from scalds.

Children, disabled, and elderly are

at highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are

available, see manual.

Water

Temp.

Time to Produce

Serious Burn

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table co urtesy of The Shriners Burn Institute

To meet commercial hot water use needs, the high

limit safety control on this water heater is adjustable up

to 210°F. However, water temperatures over 125°F

can cause instant severe burns or death from scalds.

When supplying general purpose hot water, the recommended initial setting for the temperature control is

125°F.

Safety and energy conservation are factors to be considered when setting the water temperature on the

thermostat. The most energy-efficient operation will

result when the temperature setting is the lowest that

satisfies the needs of the application.

Water temperature over 125°F can cause instant

severe burns or death from scalds. Children, disabled

and elderly are at highest risk of being scalded.

• Feel water before bathing or showering.

• Temperature limiting valves are available.

NOTE: When this water heater is supplying general

purpose hot water for use by individuals, a thermostatically controlled mixing valve for reducing point of

use water temperature is recommended to reduce

the risk of scald injury. Contact a licensed plumber or

the local plumbing authority for further information.

Maximum water temperatures occur just after the

heater’s burner(s) have shut off. To determine the

water temperature being delivered, turn on a hot water

faucet and place a thermometer in the hot water

stream and read the thermometer.

Time/Temperature

Relationships in Scalds

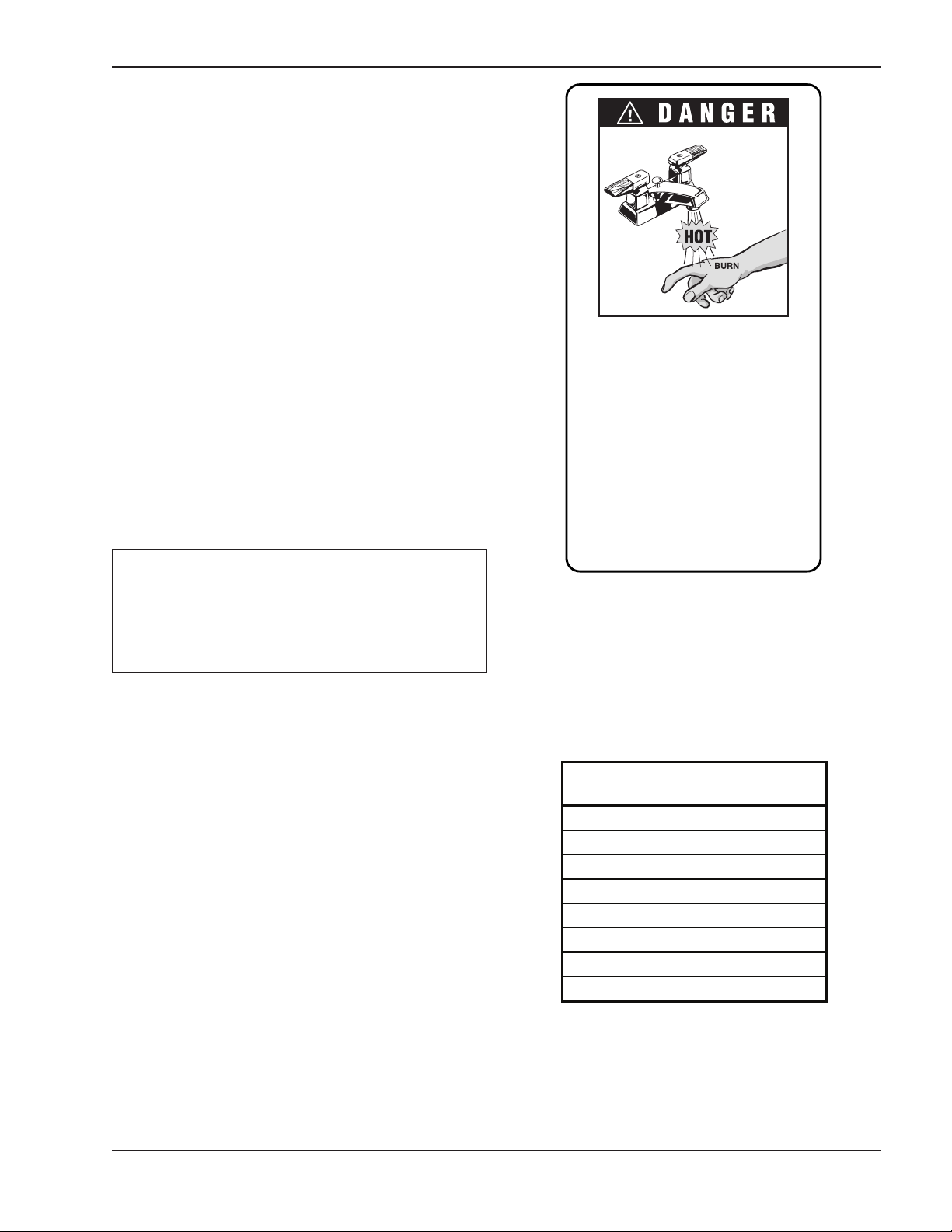

The following chart details the relationship of water

temperature and time with regard to scald injury and

may be used as a guide in determining the safest

water temperature for your applications.

Table A: Time to Produce Serious Burn

5

Page 6

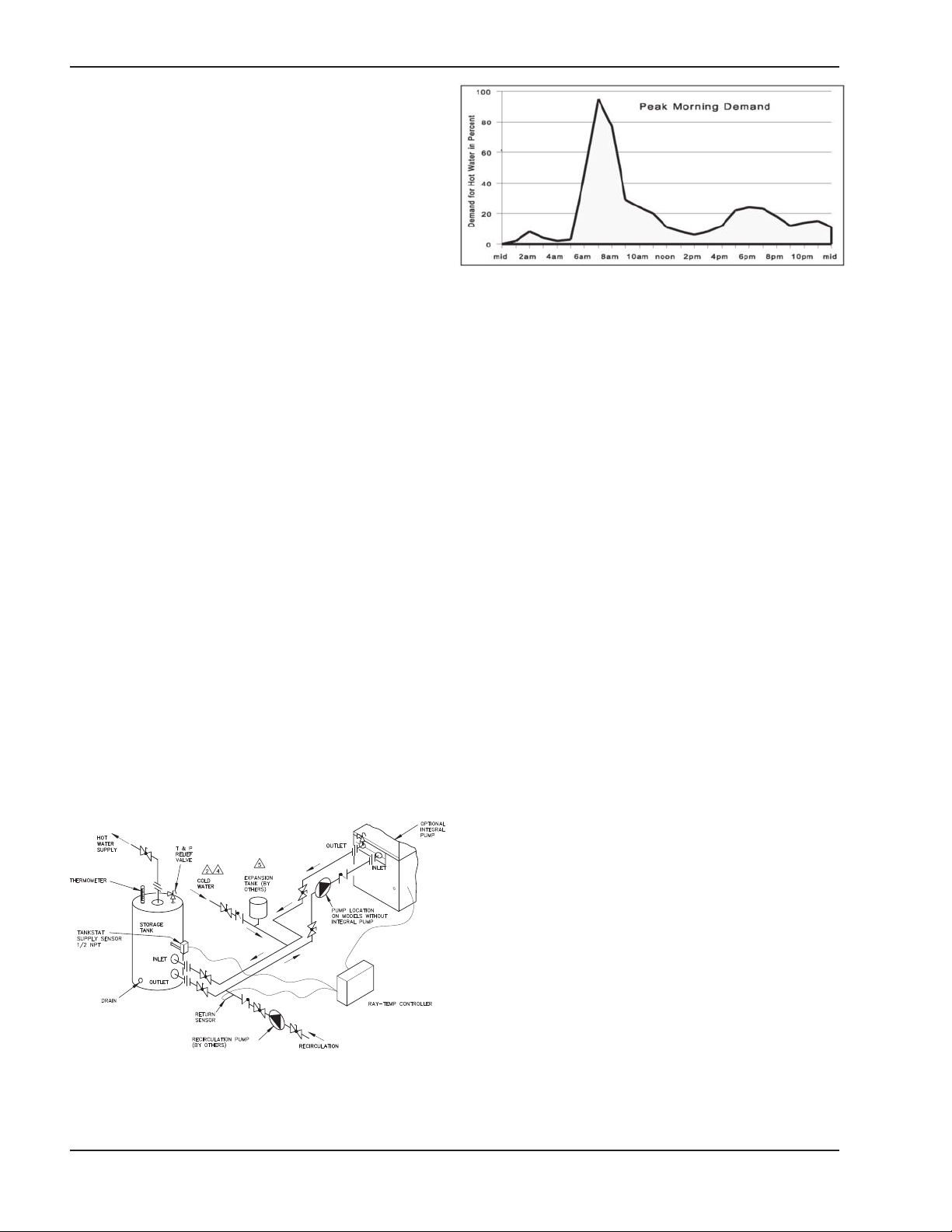

GETTING STARTED

The Big Picture

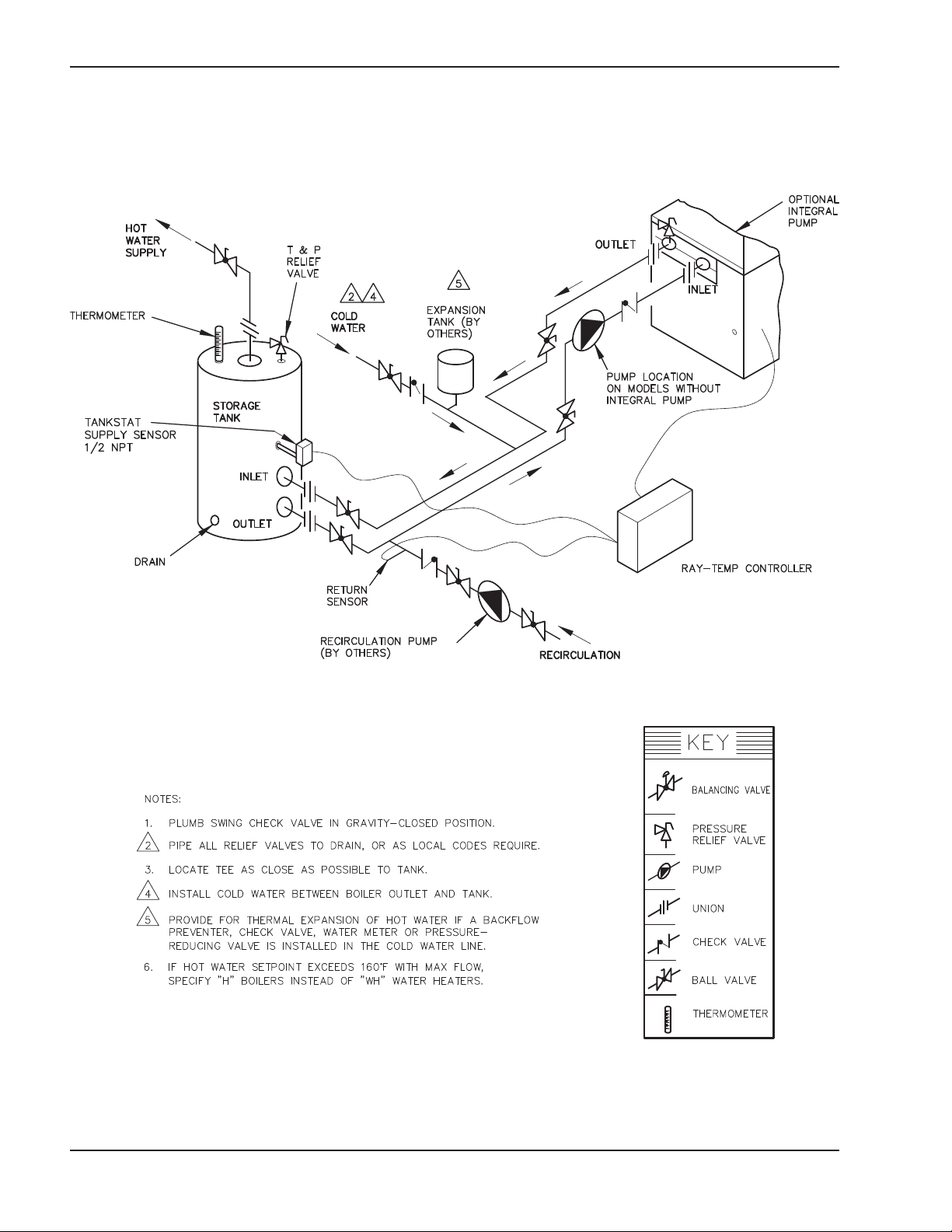

This RayTemp control is designed to make recirculating domestic hot water heating systems energy

efficient. In a recirculating system, hot water is continuously pumped throughout the building. This large

loop has many branches which extend to fixtures in

the rooms. It is essentially a giant radiator which has

tremendous heat loss. By lowering the temperature of

this loop it is possible to dramatically reduce this heat

loss. The trick is knowing when to lower the temperature without running out of hot water.

With RayTemp, water temperatures are automatically

scheduled in anticipation of demand. So for the peak

demand in the morning, the water is preheated to a

higher temperature. The control does this automatically by recording a seven day profile of demand, and

then it uses this information to establish setpoints. The

control continually adjusts this setpoint to meet

demand, always maintaining the lowest temperature

which will fully meet user needs. This operation dramatically lessens costly heat loss, lime deposits, and

increases the life of the system.

The control is preprogrammed with typical settings,

making installation very simple. However, the program

values can be adjusted to accommodate many types

of water heating systems. Output control is provided

for up to 4 stages of heat or four heaters. Two standard

temperature sensors are connected to the water heating systems at locations called “Supply”and “Return.”

Fig. 2: Hot Water Use Throughout the Day

What Comes with the Control

Before beginning the installation, it’s important to first

inspect the system and determine what materials you

will need. Some parts are included with the control

while the others you will need to provide. Check the

following list to verify that you received the following

parts.

Included in the box:

1 Control, 10.5” x 8” x 3.5”

1 Panel Cover, Metal, 4” x 7.5”

4 Mounting Screws, 3/4”

2 Temperature Sensors, Copper housing,10 K Ohm

at 25°C

4 Cable Ties,15”, black, -40ºF to 221ºF rated

2 Knockout Connectors, 1/2” to romex

1 Warranty Card

1 Manual

1 24v Grounded Transformer

Other parts you will need:

Fig. 1: Typical Installation

Cable, twisted pair with shield, stranded, 18 AWG.

Belden type 8208 (braid shield) or 9552 (2 twisted

pairs, foil shield)

Thermal Insulation Tape

Cable Ties

Wire Nuts

Heat Conducting Paste

6

Page 7

INSTALLING THE

CONTROL

he control should be mounted on a wall, preferably at

T

eye level with AC power as close as possible.

Consider the length of cable required for routing along

walls, along pipes, and for connecting the temperature

sensors.

Notice on the bottom of the control that two of the five

knockouts have been removed for routing of cables. If

you want to use one or more of the other knockouts,

these should be removed before mounting the control

onto the wall.

n the sensor end, roll the shielding and tape so it will

O

not contact a conductor. On the control end, the shield

should be grounded. Do not ground both ends of

the shielding.

Avoid routing wiring on or near other electrical wires,

onduit, motors, spark igniters or other sources of

c

high, intermittent voltage or current. EMI (spikes) can

disrupt information flow and retention.

Procedure for Installing Supply Sensor in Tank:

1. Install sensor into dry well utilizing thermal conductive paste.

2. Install dry well into tank stat opening.

Attaching the Temperature

Sensors

To get an accurate reading of the water temperatures,

the sensors must be in good thermal contact with the

pipe. Follow this procedure when connecting the temperature sensors.

Procedure for Connecting Temperature Sensors to

Pipes:

1. Remove any existing insulation.

2. Clean the pipe surface using sandpaper.

3. Apply thermal conducting paste to the pipe surface.

4. Fasten the sensor tightly to the pipe using the

black cable tie.

5. Attach 18 AWG shielded cable to the 6 in. leads

using wire nuts or electrical tape.

6. Fasten the cable to the pipe using a second black

cable tie.

7. Replace the existing insulation or wrap thermal

insulation tape around the pipe. Overlap each

turn and DO NOT STRETCH the tape.

Providing 24 VAC Power to the

Control

CAUTION: DO NOT connect power until all wiring

is complete and checked.

CAUTION: DO NOT connect 120 VAC to the

RayTemp!!! Resulting damage will void your

warranty.

The RayTemp requires an external power transformer

connected at terminals one and two. Complete and

check all wiring before connecting this transformer.

The transformer must be rated for 24 VAC at 16 VA or

higher.

When 24 VAC power is applied to the control the LCD

display will be blank for a few seconds. During this

time the RayTemp is configuring any modem that may

be connected. Afterwards, the opening screen

appears, which identifies the model number, type of

control, software version, and copyright notice.

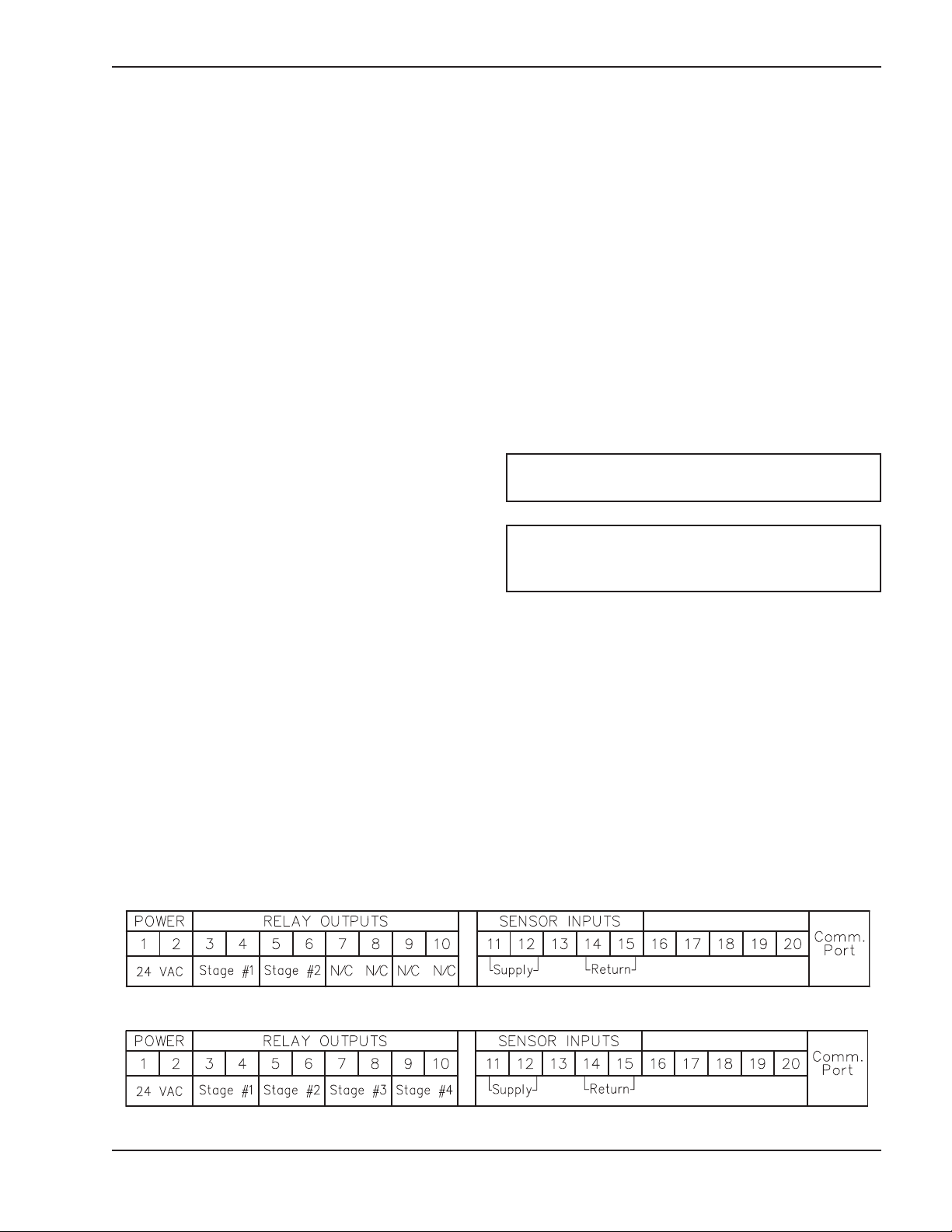

2-Stage Control

4-Stage Control

Fig. 3: Stages and Sensor Connections

7

Page 8

Installation Layout

Fig. 4: Installation Layout

8

Page 9

“DIP” Switch Settings on

Circuit Board

AUTION: Incorrect DIP switch settings may

C

damage the RayTemp! Make all adjustments with

ALL power off.

hese switches are factory set and should not need

T

adjustment.

Four Stage Control

The four relay outputs are factory set for normally

closed dry contacts. These DIP switches are located

behind the terminal block, on the right side. The black

dots in the diagram indicate where to set the 20

switches for normally closed dry contacts. As shown,

all four outputs will be the same. Relay #1 is set on

SW1 positions 6 thru 10. Relay #2 is set on SW1 positions 1 thru 5. Relay #3 is set on SW2 positions 6 thru

10. Relay #4 is set on SW2 positions 1 thru 5.

These switches are factory set and should not need

adjustment.

Fig. 5: DIP Switch Setting on Circuit Board, 4-Stage

The RayTemp can control up to 4 stages:

ig. 6: DIP Switch Setting on Circuit Board, 2-Stage

F

The RayTemp can control up to 2 stages:

• Two single-stage heaters

• One two-stage heater

NOTE: For On/Off and staged connections, consult

the water heater manual(s).

Connecting the Optional

“ELSA” Brand Modem

Raypak recommends the ELSA Microlink 56k modem

for data communication. This modem will work with

RayTemp and technical support will be provided if this

modem is installed with the correct cables. Raypak will

not be able to provide support if you use other modem

brands or build your own cables. In either case, we

strongly recommend that you test the

RayTemp/modem connection in your office before

installing the system.

• Four single-stage heaters

• Two two-stage heaters

• One four-stage heater

Two Stage Control

The two relay outputs are factory set for normally

closed dry contacts. These DIP switches are located

behind the terminal block, on the right side. The black

dots in the diagram indicate where to set the 10

switches for normally closed dry contacts. As shown,

both outputs will be the same. Relay #1 is set on SW1

positions 1 thru 5. Relay #2 is set on SW2 positions 1

thru 5.

If possible, plan ahead, and have the phone line/jack

installed about two feet from the heater. Secure the

ELSA modem and connect the phone cable (that

comes with the modem) from the wall jack to the ELSA

modem jack labeled “Line”.

Connect the RayTemp cable 5-423 from the modem’s

8-pin connector to the RayTemp’s “Serial to RJ11”

adapter then connect the six-line data cable from the

adapter to the RayTemp’s six-pin “RJ11” port (see Fig.

7 on the next page). Plug in the modem’s power transformer and turn on the power switch. Testing is

covered in the next section.

CAUTION: DO NOT connect a live phone line

directly to the RayTemp control. Doing so will

damage the internal communication circuit!

9

Page 10

MODEM

RayTemp

RJ11 to 9-pin

C

onnector

Active Phone Line

From Wall

Fig. 7: Modem Connections

SE-Sensors

Supply 136.4

Desired 135.0

Return 128.2

RT-Relay Status

#1 #2 #3 #4

ON OFF OFF OFF

Using the Front Panel to

Check Sensors and Relays

The RayTemp front panel features an alphanumeric

LCD display of four rows by 20 characters. Six keys

are provided to select screens, fields, and make program changes. The up-arrow and down-arrow

"WINDOW" keys are used to step thru each of the

screens. The down-arrow screen selects the next

screen while the up-arrow key selects the previous

screen.

The left-arrow and right-arrow "FIELD" keys move a

flashing cursor to select different sections within a

screen. The plus and minus "VALUE" keys are used to

make changes to a selected field or numeric value.

Plus increases the selected number or selects the next

option. Minus decreases the selected number or

selects the previous option.

Fig. 9: Relay Status Screen (4-Stage Control)

Next select the “RELAY STATUS” screen and manually verify that you can turn each water heater or stage

on and off. You do this using the field and value keys.

If the heater does not turn on it may be necessary to

increase the optional secondary mechanical aquastat

setting a few degrees.

Use a multimeter to troubleshoot if problems persist.

Return to the second screen titled “Master On/Off

Mode” and put the control in “Bypass”.

The water heaters will now run using the optional secondary mechanical aquastats until programming of the

control has been completed, explained in the next section

Fig. 8: Sensors Screen

Using the down-“WINDOW” key select the “SENSORS” screen and verify that each temperature

sensor is measuring the correct value. It’s best to use

a reliable temperature reading device, like a surface

thermocouple or a digital infrared thermometer.

Thermostats and mercury thermometers are frequently inaccurate. If the readings disagree by more than

two degrees there may be a problem with how the sensor is attached. Also check for correct wiring at the

terminal block.

CONNECTING A

COMPUTER

This section explains how to connect your personal

computer to the RayTemp. Once connected, you can

view all of the front panel screens covered in the previous section. You can also retrieve the recorded data

and view color graphs of temperature and demand

profiles. "PTT" is the optional software tool for your

personal computers that works with RayTemp controls. It simulates the front panel and retrieves logged

data.

10

Page 11

TT software and interface cables are available direct-

P

ly from Raypak. The computer must be able to accept

a serial (RS-232) cable.

Building or Buying Interface

Cables

Table B lists the cables available from Raypak.

RayTemp to Modem Pin Assignments

RJ-11 Wire

color codes:

White = 1

Black = 2

ed = 3

R

Green = 4

Yellow = 5

Blue = 6

RJ-11 Pin

(RayTemp)

Ground 6 7 Ground

Receive 5 3 Transmit

Transmit 4 2 Receive

DB-25 Pin

(Modem)

Description Part Number

PTT Software Communication for

Windows PC to 70 series control

Direct Connect Communication

Cable Connects a 70 series control

to a PC

Modem Communication Cable

Connects a 70 series control to a

modem

Table B: Cables Available from Raypak

Wiring pin assignments are provided in Tables C and

D for building your own cables.

CAUTION: Never plug a telephone line into the RJ11 connector! The control may be damaged.

RayTemp to PC/Modem Pin Assignments

RJ-11 Wire

color codes:

White = 1

Black = 2

Red = 3

Green = 4

Yellow = 5

Blue = 6

Table C: Wiring Pin Assignments

RJ-11 Pin

(RayTemp)

Ground 6 5 Ground

Program 2 4 Program

Receive 5 3 Transmit

Transmit 4 2 Receive

PTT

5-424

5-423

DB-9 Pin

(PC/Modem)

able D: Wiring Pin Assignments

T

Installing PTT Software on

Your PC

This section provides instructions for installing PTT

communication software. First insert the PTT CD into

your CD drive. Double click on the folder Ptt258 then

double click on Install. The PTT communication software will then be installed on your C:\GBX

subdirectory. To run PTT, type PTT (then press enter)

from the C:\GBX subdirectory. Within a few seconds

the main menu, software version I.D., and copyright

notice will appear.

Use the arrow keys and enter key to select items from

the menu bar at the top of the screen. First check the

default options by selecting the “Options” menu item.

There are several items that can be changed. Most

PC’s have several communication ports. Port 1 is usually for direct connections and Port 2 is usually used

for internet modems.

The second option sets the communication speed.

The default speed for RayTemp is 9600 Baud. Next is

the print quality, 1 = draft mode (fast), 2 = medium, 3 =

high resolution (but slow). Press Ctrl-Enter to save

your selection.

Simulated Front Panel Display

This “Laptop” selection from the menu bar opens up a

window on the PC screen to receive formatted data

and program information sent by a RayTemp control,

connected at the serial (RS232) port. From the main

menu select "LapTop" and press enter. Connect the

cable to the RayTemp control and press F1 to begin

communication. The screen and keyboard will operate

similar to the front panel but with enhanced features to

take advantage of the larger screen.

Table E shows the function keys for accessing all

RayTemp display and programming features. These

keys apply to both the PC and LapTop display, except

11

Page 12

s noted. A screen saver clears the display after five

a

minutes. Press F1 thru F5 to restore the screen.

Key Action

F1

F2 Select next screen

F3 Select previous screen

Press two keys for direct access to

ny screen

a

he "Print" option under "History Report" allows you to

T

send site reports and graphs to any supported printer.

When this item is selected a directory of data files will

appear. Point to a file using the arrow keys then press

nter to select the file. A check mark will appear. Place

e

check marks next to all data file you wish printed, then

ress Ctrl-Enter to continue. A second screen will

p

appear for selecting graphs within a report. Place a

check mark (press enter) by each graph you want

included in the printed report. Press ESC to start printing.

F4 Increase program value

F5 Decrease program value

Space Select next field in a screen

Back Space Select previous field in a screen

F6 Activate full-screen viewing (PC)

Shift+F6 Restore LapTop window (PC)

Table E: Function Keys

Reading Logged Data

Under the "History Report" menu item, logged data

can be retrieved from a RayTemp control, saved to a

disk file, viewed graphically on screen, or output to a

printer. To retrieve history, connect the RayTemp serial cable between the RayTemp and your laptop PC.

Then select "Retrieve". The RayTemp will transmit

logged data to your PC. This takes about one minute

at 9600 Baud. A status window will be present while

the data is being received.

Using Your PC, PTT and

Modem to Call a Control

If this is your first attempt at modem communication

with a RayTemp control we recommend that you first

try everything in your office using two phone lines.

Connect the RayTemp to an external modem and connect this modem to one line and your PC modem to

another. Next, configure the RayTemp modem as

described in the previous section. Make sure that the

modem’s auto answer “AA” light is on.

Also, buy a modem cable from Pro-Temp Controls

(800-669-8367) — at least for your first installation.

This will prevent 80% of your possible problems.

To “get on-line” with the RayTemp, start the PTT software and select “Options” from the menu bar at the top

of the screen. Enter the port number (usually 1 or 2) for

the modem connected to your PC and make sure the

speed is set to 9,600. Then press Ctrl-Enter and select

“TechTerm” from the menu bar. A set of seven windows

will appear.

Start entering the phone set up commands:

The logged data consists of a report, seven detailed

daily graphs (Monday thru Sunday), and twelve

monthly graphs (January thru December). A menu will

appear from which you can view any of these graphs.

This data will be automatically saved to a disk file,

based on the file name in the report data. PTT creates

a unique name for each file by setting the last position

of the file name prefix.

The codes are 0 thru 9 and then A thru Z. For example, REDLION.GIX will be saved as REDLION0.GIX,

REDLION1.GIX, REDLION2.GIX, etc.

To view an existing history file select "Display", and

select a file by pressing enter. After the graphs are prepared, a window will appear from which you can select

any daily graph or monthly graph to view on the

screen.

“ATE1” “ENTER” Return should show “OK”. If not, reenter.

“AT&F” “ENTER” Return should show “OK”.

“AT&D0” (zero) “ENTER” Return should show “ok”.

For example, to place a call, dial “ATDT5551212” and

wait for a “Connect” message (replace the “5551212”

with your actual phone number). If the screen is blank,

type “ATE1” and try again.

NOTE: The “Modem” section on the menu bar does

not work with the RayTemp. Once you see the

“Connect” message in the TechTerm window, press

F1 and then F6 to begin communication.

12

Page 13

o end the modem session, select the following screen

MC-Modem Control

F4 to Hang-Up

T

in the LapTop window.

t's also a good idea to have an actual telephone con-

I

nected to the line. Make sure a dial tone is present to

verify that the call has been terminated.

PROGRAMMING

Quick Reference

Fig. 10: Modem Hang-Up Screen

This screen is used to terminate the call. The

RayTemp will actually terminate the phone connection

and prevent the modem from answering the phone for

about five minutes. The message "CARRIER LOST"

will appear in the LapTop window. Another call may

then be placed to contact another RayTemp sharing

the same phone line. Always use this method to end a

modem call to the RayTemp in shared phone-line

applications.

Front Panel Key

WINDOW UP & DOWN F1

WINDOW DOWN F2 Select next screen

Laptop or PC

This section describes all the programmable features

of the control. You make program changes from the

front panel or by using a laptop. For information on

connection with a LapTop using PTT software, refer to

the previous section.

The following keys provide access to all RayTemp display and programming features. These keys apply to

the front panel or LapTop display as shown in Table F.

A screen saver clears the display after five minutes on

the LapTop. Press F1, then F6 to restore the screen

Key

Screen Selected

Returns to first screen, then

press two keys for direct

access to any screen as listed

on the next screen

WINDOW UP F3 Select previous screen

VALUE+ F4 Increase program value

VALUE- F5 Decrease program value

FIELD RIGHT SPACE Select next field in a screen

FIELD LEFT BACK SPACE

F6

SHIFT F6

Table F: Front Panel or Laptop Display Keys

13

Select previous field in a

screen

Activate full-screen viewing

(PC with PTT only)

Page 14

Screen code and description, in sequence of appearance See page

FM

S

OS

RT

ST

RM

DL

TL

CK

TS

ER

MC

PD PERFORMANCE DATA - Savings Analysis 19

DN

PN

SL

FN

MS

SH

AD

FD

PW

PM

RL

PRODUCT IDENTIFICATION - Model, type, and version

E

ENSORS - Displays temperature of each standard sensor

S

OPTIONAL SENSORS - Displays other sensors

RELAY TEST - On/Off relay status and manual override

SENSOR TEST - Simulates sensor temperatures

RUN TIME METERS - Total on-time for each heater or stage

DETAIL LOG - Shows history values for seven days

TREND LOG - Shows history values for one year

CLOCK - Display and set time and date

TIME SCHEDULE - Seven day, 20 schedule, time clock

ERASE/RESET - Selective clear or restart

MODEM TEST - Terminate call or test modem or fax

TEXT - Company Name

TEXT - Property Name

TEXT - Site Location

TEXT - Disk File Name

TEXT - Modem Setup

TEXT - Modem Disconnect

TEXT - Pager Dial-Out

TEXT - Fax Dial-Out

TEXT - Security Password

TEXT - Front Panel Menu

TEXT - Relay Logic (1-12)

16

1

16

16

19

16

17

16

21

20

20

20

20

20

20

20

21

16

16

18

6

T1

T8

C0

C1

C2

C3

C4

C5

C6

C7

Screen codes in bold are described in detail on the pages listed.

SELECT - Supply Sensor Offset

Not used for this model

SELECT - Maximum Supply Temperature

SELECT - Minimum Supply Temperature

SELECT - Outside Temperature for Maximum Supply

SELECT - Outside Temperature for Minimum Supply

SELECT - Night Setback at Maximum Supply

SELECT - Night Setback at Minimum Supply

SELECT - Morning Boost at Maximum Supply

SELECT - Morning Boost at Minimum Supply

14

20

20

17

17

17

17

17

17

17

17

Page 15

Screen code and description, in sequence of appearance See page

HL

L

W

D

DM

DA

R0

R1

R2

E0

E1

E2

B0

S0

S1

S2

HS

SP

SQ

US

DD

D1

SELECT - Supply High Limit

L

ELECT - Supply Low Limit

S

ELECT - Demand window in minutes

S

SELECT - Demand % for maximum temperature

SELECT - Demand % for ASL strategy

SELECT - # of Room Sensors Installed

SELECT - Desired Daytime Room Temperature

SELECT - Desired Nighttime Room Temperature

SELECT - Recovery sensor installed

SELECT - Minimum recovery time

SELECT - Recovery sensor response

SELECT - # Branch sensors installed

SELECT - Days to Acclimate Residents

SELECT - Day of Month for Savings Test

SELECT - Old Maximum Supply Temperature

SELECT - # of water heaters

SP SELECT - # stages per heater

SQ SELECT - Alternating Relay Sequencing

US SELECT - Use 24Volt on/off sensing

DD SELECT - Deadband (also known as hysteresis)

D1 SELECT - Temperature Delay Between Stages

17

1

1

17

17

18

18

18

18

19

19

18

18

18

18

18

18

7

7

LK

CU

LG

XX

XN

XM

XW

XH

MO

BA

NI

Screen codes in bold are described in detail on the pages listed.

SELECT - +- Keys Locked

SELECT - Celsius Units

SELECT - Access Data Logger #

SELECT - Fax Graph Max Temp

SELECT - Fax Graph Min Temp

SELECT - Fax on Day Of Month

SELECT - Fax on Day of Week

SELECT - Fax on Hour of Day

SELECT - Operating Mode

SELECT - Communication BAUD Rate

SELECT - Network address number

16

16

21

21

21

21

21

16

20

15

Page 16

First Screen at Power-up

FM - PRODUCT IDENTIFICATION. This screen dis-

lays the model number, type of control, copyright

p

notice, and software version number. Press F2 to

elect the next screen in order, or press two keys for

s

direct access to any one of the following screens.

Manual Override

MO - SELECT (MODE) - Operating Mode selects one

of three states of operation. In Run mode all control

functions are operational. In Bypass mode, control is

returned to the mechanical controls if provided. In Off

mode all systems are shut off and remain off indefinitely. In all three modes the RayTemp data logger and

modem/fax functions continue to operate.

View Sensors and Relays

SE - SENSORS - Displays the setpoint and current

temperature reading from each primary temperature

sensor.

OS - OPTIONAL SENSORS - Displays current temperature reading from each optional temperature

sensor.

et BAUD Rate will reconfigure the serial port accord-

S

ing to the BA screen. If the speed is different, then

reset the BAUD rate on your LapTop (garbage characters will appear).

Zero Run Meters set all run-time meters to zero.

Erase History sets all 7-day and 365-day history to -

30.

Reset Program sets all program values to factory

default values.

Erase All does all the above (requires 30 seconds).

Security Password

PW - TEXT - Security Password: This screen is used

to prevent unauthorized access to the RayTemp, either

by modem or direct connection. To use this feature,

select a password up to 40 characters and enter it on

this screen. Then, all future communication with the

control will be blocked until this password is entered. A

screen will appear asking for the password. Make a

note of your password, since you will not be able to

access the control without it! By default, no password

is required. To disable password protection erase all

text in this field.

RT - RELAY TEST - Displays on/off status of each

relay output. Press SPACE or BKSP to a select relay

(flashes). Then press F4 to test on, F5 to test off. To

return control to the RayTemp, press SPACE or BKSP

until no locations flash. The RayTemp will automatically retake control if no manual testing takes place for

five minutes.

Time and Date

CK - CLOCK - Displays present time and date. To set,

press SPACE, F4 and F5.

Celsius / Fahrenheit Scale

CU - SELECT - For Celsius units, select Yes and all

process and program values will be displayed in the

Celsius temperature scale. (The default setting of No

selects the Fahrenheit scale.)

Erase Memory / Reset Program

ER - ERASE/RESET - Press F4 or F5 to select which

item will be reset or cleared, then press CTRL+E to

confirm each action.

Front Panel Menu / Lock

PM - TEXT - Front Panel Menu: This option provides

for limited access by the building caretaker to a fixed

set of screens from the front panel. By default, 13 of

the most commonly used screens are accessible from

the front panel. They are identified in this screen by

their two character access code. This line of text can

be modified to select a custom set of screens, in any

order, up to 13 screens. If the first character on this line

is a space (' ') then this menu system will be disabled

and all screens will be accessible from the front panel.

To gain access to all of the screens using only the front

panel, press both VALUE keys while in the PRODUCT

IDENTIFICATION screen. This enters a first character

space as described above.

LK - SELECT - +- Keys Locked When Activated:

This option prevents changing of programmed values

from the RayTemp front panel + and - keys.

WARNING: This option cannot be deactivated

from the control itself. Deactivating this screen

requires either (1) a connection to a PC running the

PTT software, or (2) returning the control to the

manufacturer to have them reset this option.

16

Page 17

Time Schedule

TS - TIME SCHEDULE: This is a seven-day time

lock. Each line is a program for starting a new period

c

(such as Night) on a day (such as M-F) and at a time

such as 6:00 am). Up to 20 lines can be displayed or

(

programmed using the SPACE, F4 and F5 keys.

Periods end automatically when a new one starts. The

day codes are M-F (Monday thru Friday), S-S

(Saturday and Sunday), F-S (Friday thru Sunday), and

--- (no days). The recommended setting for initial programming is --- (no days) on all settings. Changes can

be made to accommodate individual schedules.

Supply Temperature

The RayTemp control strategy closely matches water

temperature to demand as hot water use varies

throughout the day. The setpoint is adjusted based on

a demand profile which is recorded for the last seven

days. The RayTemp scans this profile and adjusts the

setpoint in anticipation of demand. This strategy is

complemented with a seven-day time clock which can

provide fixed temperatures during certain hours for

special requirements, such as laundry.

C0 - SELECT - Maximum Regular Temperature:

During Regular periods the desired temperature will be

set between (screen) C0 and C1 according to

demand. The time clock schedule determines when

Regular takes effect. Default Temp 140°F.

C1 - SELECT - Minimum Regular Temperature: The

supply temperature will not be set below this value

during Regular periods. Default Temp 130°F.

6 - SELECT - Maximum Extra Temperature: C6

C

and C7 are an extra set of temperatures which can be

scheduled for any purpose. They will become the maximum and minimum supply temperature if the Extra

chedule is activated by the time clock. Default Temp

s

140°F.

C7 - SELECT - Minimum Extra Temperature: See

C6 above. Default Temp 130°F.

HL - SELECT - Supply High Limit: If the recovery

temperature or the return temperature is very low, the

RayTemp may need to take the supply temperature

above the programmed maximum. Regardless of any

conditions, the RayTemp will not take the supply or

any branch temperature above this high limit value. If

the supply temperature exceeds this value by 10°F

then alarm dialout will be activated. Default Temp

140°F.

LL - SELECT - Supply Low Limit: The RayTemp will

not schedule the supply temperature lower than this

value (or programmed minimum). If the supply temperature drops 10°F below this value then alarm dial-out

will be activated. Default Temp 120°F.

DW - SELECT - Demand Windows in Minutes: This

value sets the time period of demand history to be

used in calculating desired temperature. The default

value should yield a smooth profile. Decreasing this

value will cause faster response to changing demand

at the risk of instability. Increasing this value will produce a very smooth desired temperature profile,

however the temperature may not rise quickly enough

during peak demand periods. The range is from 10 to

90 minutes. Default Value 40.

C2 - SELECT - Maximum Peak Temperature: C2

and C3 become the new maximum and minimum temperatures when the time clock schedule is in Peak

mode. Default Temp 140°F.

C3 - SELECT - Minimum Peak Temperature: During

peak periods the supply temperature will not be set

below this value. Default Temp 130°F.

C4 - SELECT - Maximum Laundry Temperature: C4

and C5 will be the maximum and minimum temperatures in effect if Laundry is activated by the seven-day

time clock. For laundry needs C4 and C5 will usually

be set to the same value. Default Temp 140°F.

C5 - SELECT - Minimum Laundry Temperature:

See C4 above. Default Temp 140°F.

DM - SELECT - Demand % for Maximum

Temperature: This feature provides a means of

increasing temperature in oversized systems which

show very little demand. Example: Set to 50%. When

demands of 50% or more are encountered, the

desired temperature will be at programmed maximum.

Below 50% the desired temperature will be proportional between maximum and minimum programmed

values. The range is from 10 to 100 percent. Default

Value 100.

DA - SELECT - Demand % for ASL Strategy: This

feature automatically adapts to manual changes in the

optional, secondary aquastat setting which may occur

after installation. This ensures continued savings even

if the aquastat is lowered. (ASL is an acronym for

Aquastat Set too Low). The strategy works by lowering

the setpoint temperature until the RayTemp has

regained control. For each 24-hour period that

demand exceeds this DA percent, the setpoint is low-

17

Page 18

red by 5°F. Then for each 24-hour period that heater

e

demand is less than one half of DA, the setpoint is

increased by 1°F until the original value is restored.

The default value is 70%. The PERFORMANCE DATA

creen titled Temp Reduced by ASL Strategy will show

s

a value other than zero if this strategy is in effect.

efault Value 70.

D

Q - SELECT - Firing Options: Four options for

S

stage sequencing are available. Select number 1, 2, or

3 as follows:

1 No Lead/Lag: Stage 1 of heater #1 always fires

#

first. The remaining stages and heaters will fire in

rder as demand increases.

o

Return Temperature

The return sensor is used to compensate for seasonal

changes in loop heat loss. The strategy may raise the

supply/branch temperature in cold weather to ensure

that the last rooms on the loop have hot enough water

even during low demand periods.

R0 - SELECT - Return Sensor Installed: Select YES

if this sensor is connected, otherwise select NO.

Default is YES.

R1 - SELECT - Minimum Return Temperature: If the

return temperature drops below this value then the

return sensor strategy will be activated. Above this

value, the strategy will have no effect on desired temperature. Default Temp 108°F.

R2 - SELECT - Return Sensor Response: This is a

multiplier which increases the desired temperature as

the return temperature drops. Example: desired = 130,

return = 100, R1 (above) = 102, R2 = 5. The desired

temperature will be increased to 140 = 130 + (102-

100) X 5. Default Value is 1.

Branch Temperature - Not

Used

B0 - SELECT - # of Branch Sensors Installed: Not

used.

Relay Sequencing

(4-Stage Control)

#2 24-Hour Rotation: At midnight each day, the firing

order is rotated to the next heater. This distributes

the work load equally among all heaters.

#3 Lead/Lag & Rotate: With this option, heater #1

always fires first, then the remaining heaters fire in

rotation. Since some flue designs require heater

#1 to fire first; this option meets this requirement

while still providing limited rotation.

US - SELECT - Use 24volt on/off sensing. Do not use.

DD - SELECT - Differential: Increasing DD lengthens

the heater burn cycle; decreasing DD improves temperature stability. For instance: desired=140,

deadband=1, heater turns off at 141 and on at 139.

This deadband applies equally to all stages.

D1 - SELECT - Temperature Delay Between Stages

(In addition to differential setting): This value caus-

es successive output stages to come on according to

the deviation to target temperature. D1 activates additional heaters or stages as demand increases. For

example with a setpoint of 140°F and a temperature

delay of 1°F, stage 1 will fire at 140, stage 2 at 138,

stage 3 at 136, etc., assuming 2°F deadband.

RL - TEXT - Relay Logic (1-12): The default value is

++++++++++++.

NOTE: If you select minus (-) and the RayTemp

loses power or fails, then the heater or pump will

remain off!!! Edit text with SPACE, BACKSP, F4, and

F5 to return to a plus setting.

HS - SELECT - # of Heaters: Enter 1 thru 4 for the

number of heaters connected to relay outputs 1 thru 4.

This allows the RayTemp to correctly sequence

heaters and record demand.

SP - SELECT - Stages Per Heater: Enter the number

of stages in each heater, from 1 to 4.

Relay Sequencing

(2-Stage Control)

HS - SELECT - # of Heaters: Enter 1 or 2 for the number of heaters connected to relay outputs 1 and 2. This

allows the RayTemp to correctly sequence heaters

and record demand.

SP - SELECT - Stages Per Heater: Enter the number

of stages in each heater, 1 or 2.

18

Page 19

Q - SELECT - Firing Options: Four options for

S

stage sequencing are available. Select number 1, 2,

or 3 as follows:

1 No Lead/Lag: Stage 1 of heater #1 always fires

#

first. The remaining stages and heaters will fire in

rder as demand increases.

o

es will be frozen at the values you select. To restore

u

the actual sensor values, press SPACE or BKSP until

Inactive ###.# appears. The RayTemp will automatically restore actual sensor values 30 minutes after

xiting this screen.

e

Savings Test Setup

#2 24-Hour Rotation: At midnight each day, the firing

order is rotated to the next heater. This distributes

the work load equally among all heaters.

#3 Lead/Lag & Rotate: With this option, heater #1

always fires first, then the remaining heaters fire in

rotation. Since some flue designs require heater

#1 to fire first; this option meets this requirement

while still providing limited rotation.

US - SELECT - Use 24volt on/off sensing. Do not use.

DD - SELECT - Differential: Increasing DD lengthens

the heater burn cycle; decreasing DD improves temperature stability. For instance: desired=140,

deadband=1, heater turns off at 141 and on at 139.

This deadband applies equally to all stages.

D1 - SELECT - Temperature Delay Between Stages

(In addition to differential setting): This value caus-

es successive output stages to come on according to

the deviation to target temperature. D1 activates additional heaters or stages as demand increases. For

example with a setpoint of 140°F and a temperature

delay of 1°F, stage 1 will fire at 140, stage 2 at 138,

etc., assuming 2°F deadband.

RL - TEXT - Relay Logic (1-12): The default value is

++++++++++++.

NOTE: If you select minus (-) and the RayTemp

loses power or fails, then the heater or pump will

remain off!!! Edit text with SPACE, BACKSP, F4, and

F5 to return to a plus setting.

Sensor Override Test

S1 - SELECT - Day of Month for Savings Test:

Selecting a value other than 0 (default) activates the

flip-flop savings test. This test will cause a simulation

of conditions before the RayTemp was installed - for

24 hours on the day specified every month.

The test will run only on the day of month selected

AND on multiples of that day. Examples: Values 16

thru 28 will run test for that day only. Value 14 will run

test on day 14 and 28. Value 5 will run test on day 5,

10, 15, 20, 25, and 30. One day of testing may not

yield accurate results, while four or more days of testing will significantly cut into savings. The

recommended value is 14 (2 test days).

S2 - SELECT - Old (Maximum) Supply

Temperature: Enter the supply temperature prior to

installing the RayTemp if you wish to use the Acclimate

feature or Savings Test feature (above). If the preexisting control operated at a fixed temperature enter that

value here and also in the next screen.

Savings Test Results

PD - PERFORMANCE DATA: From this screen press

F4 or F5 to view savings analysis statistics as

described below:

Average Energy Savings % displays the average

energy savings in percent during the last 365

days. This can be used to determine actual dollars

savings and payback period. This feature will not

operate unless a day of month for savings test is

selected. A flip-flop test then is activated which

alternates between RayTemp mode and baseline

mode (which has higher energy consumption).

ST - SENSOR TEST: This feature allows you to simulate any sensor temperature and observe the affect on

desired temperature and relay sequencing. Press

SPACE or BKSP to select a sensor, then override the

actual sensor temperature by pressing F4 or F5. Each

key stroke changes the temperature by one degree F.

Press Shift+F4 or Shift+F5 to adjust the temperature

by one-tenth of a degree (works with PTT). You can

change any or all sensors values and then look at

other screens. While in this mode all temperature val-

Baseline Heater Run Time % displays average

heater demand during Baseline mode for the last

365 days (simulating a fixed setpoint control). This

is diagnostic information used in calculating savings.

RayTemp Heater Run Time % displays average

heater demand for all heating days except baseline days during the last 365 days. This is

diagnostic information used in calculating savings.

19

Page 20

ays in Baseline Mode shows the number of

D

days during the last year that RayTemp was in

baseline mode - simulating the preexisting fixed

setpoint control.

N - TEXT - Property Name: Accepts entry of site

P

name into RayTemp memory. This information will

appear in installation reports. Edit with SPACE, BACKSP, F4, and F5.

Days in RayTemp Mode shows the number of

ays during the last 365 days when there was

d

demand for heat and baseline mode was not in

effect.

Total days in service displays the total operating days

in modes RUN, BYPASS, and OFF. When 24 VAC

power is absent this value will not increase however

the clock will still operate.

Number of power interruptions value is incremented

each time 24 VAC power is removed or interrupted.

ASL strategy temp reduced a value other than zero

indicates that the RayTemp has reduced its setpoint

temperature by this amount. This was done to regain

control because the existing aquastat setting was lowered.

Sensor Calibration

The following screens allow you to introduce a fixed

positive or negative offset to any temperature input.

You will not normally need to make any adjustments

here since RayTemp sensors and electronics are very

accurate.

The default values in these screens compensate for a

small self-heating affect on the thermistor sensor. For

small-mass base thermistors, the offset is -2.5°F. For

thermistors mounted in housings or attached to a pipe

with thermal paste the offset is -1.5°F.

You can check measurement accuracy of RayTemp

using fixed resistors and the resistance/temperature

chart published by Independent Energy. Before doing

this first set each offset below to zero.

T1 - SELECT - Supply Offset for sensors 1 thru 7

T8 - SELECT - Supply Offset for sensors 8 thru 15.

Not used for this model

Location Text

DN - TEXT - Company Name: Accepts entry of company name into RayTemp memory. This information

will appear in installation reports. Edit with SPACE,

BACKSP, F4, and F5.

SL - TEXT - Site Location: Accepts entry of city and

tate names into RayTemp memory. This information

s

will appear in installation reports. Edit text with

SPACE, BACKSP, F4, and F5.

FN - TEXT - Disk File Name: Accepts entry of a DOS

file name into RayTemp memory. The installation

report and graphs will be saved in a file under this

name (seven characters maximum). Edit text with

SPACE, BACKSP, F4, and F5. Only needed when logging data to a connected LapTop.

Data Modem Setup

BA - SELECT - Communication Baud Rate: For

direct connect, use 9600 Baud. For modem use, set at

required 9600. Speed is activated only during poweron reset or from ER ERASE/RESET screen.

MS - TEXT - Modem Setup: Accepts entry of AT command string into RayTemp memory. If a modem is

installed, the RayTemp will transmit this command

string to configure your modem. Use the Hayes-compatible modem manual for information about the AT

commands. This text will also appear on installation

reports. Edit text with SPACE, BACKSP, F4, and F5.

Once set, write down at command string.

SH - TEXT - Modem Disconnect: Accepts entry of AT

commands into RayTemp memory. If a modem is

installed the RayTemp will transmit this command to

the modem to terminate the phone connection and

prevent the modem from answering another call.

AD - TEXT - Pager Dial-Out: Accepts entry of AT commands into RayTemp memory. If a modem is installed

the RayTemp will transmit this command to the

modem if an alarm condition exists. For example,

commands can be selected to dial a pager and display

a code to identify the calling RayTemp unit.

Consult your Hayes-compatible modem manual for

more information about AT commands. This text will

appear on installation reports. Edit text with SPACE,

BACKSP, F4, and F5.

20

Page 21

Fax Modem Setup and Test

FD - TEXT - Fax Dial-Out: Use this screen to enter the

hone number of the fax machine which is to receive

p

fax alarm messages, installation reports, and/or graph-

cs. Example "ATDT5551212". Edit text with SPACE,

i

BACKSP, F4, and F5.

XX - VALUE - Fax Graph Max Temp: This value sets

the highest value of the Y-axis temperature scale for all

faxed graphs. This item is unrelated to PC graphics.

Autoscaling is not supported.

XN - VALUE - Fax Graph Min Temp: This value sets

the lowest value of the Y-axis temperature scale for all

faxed graphs. This item is unrelated to PC graphics.

Autoscaling is not supported.

XM - VALUE - Fax on Day of Month: A complete

installation report with graphics of logged data can be

automatically faxed, once a month, to any group III fax

machine. This value sets the day of the month to transmit this data. The report consists of seven pages. The

first two pages give all program values and performance data, such as percent savings.

The next three and one half pages are detailed graphs

for the last seven days. The last one and one-half

pages are trend graphs for the last 12 months. The

default day of zero disables this function.

XW - VALUE - Fax on Day of Week: Detailed graphs

of logged data for the last seven days can be automatically faxed, once a week, to any Group III fax

machine. This value sets the day of the week to transmit this data. Refer to Table G.

H - VALUE - Fax on Hour of Day: This option sets

X

the time of day to transmit fax reports. It works in conjunction with XW and XM, above. The RayTemp will

attempt to fax the specified data on the specified day

above) and at this specified time. Military time is used

(

with values of 0 to 23, 12 is noon. If the first attempt is

ot successful then the RayTemp will make two more

n

attempts at 10 minute intervals.

Where multiple RayTemps are calling into one fax

machine it's very important to set each control to a different day and/or time, otherwise some controls may

always get a busy line.

MC - MODEM TEST: This screen provides for modem

testing and manual fax transmission of reports and

graphics. The following table describes the options in

this window. These options are selected using the

FIELD keys and activated by pressing the PLUS key.

The "Status:" line in this window reports progress of

the action as shown in Table I below.

NOTE: The "Pager Alarm" action will always reply

"Failed" because the modem does not connect with

another modem. In this screen, no actions will retry

in the event of transmission failure (press plus (+)

again). However when actual alarm conditions occur

or when reports are scheduled for automatic

transmission the RayTemp will retry. Up to three

attempts will be made, per day, at 10-minute

intervals.

Value Transmit Day Graphs

0 None None

1 Monday Last 7 days on 3 1/2 pages

2 Tuesday Last 7 days on 3 1/2 pages

3 Wednesday Last 7 days on 3 1/2 pages

4 Thursday Last 7 days on 3 1/2 pages

5 Friday Last 7 days on 3 1/2 pages

6 Saturday Last 7 days on 3 1/2 pages

7 Sunday Last 7 days on 3 1/2 pages

8 Every Day Yesterday full size on 1 page

Table G: Fax on Day of Week Values

21

Page 22

Option Transmit Function Pages

Setup "Modem Setup" command to modem N/A

Disconnect "Modem Disconnect" command to modem N/A

Pager Alarm "Pager Dial-Out" command to modem N/A

Fax Alarm Warning message, identifies location 1

Fax Report Installation report 2

Fax Year Trend graphs for last 12 months 3

Fax Month Trend graph for the 4 month period 1

Fax Week Detailed graphs for the last 7 days 4

Fax Today Detailed graph for one day, today 1

Fax Yesterday Detailed graph for one day, yesterday 1

Fax All Report and all graphs 7

Table H: Transmit Options

Status Description

(blank) No Activity

Sending

Transmission in process. This message may remain for up to

12 minutes depending on the action selected

Data modem or fax modem has successfully completed the

OK

operation. Failed data modem or fax modem did not reply or

was unable to complete the action requested

Failed

Failed Data modem or fax modem did not reply or was

unable to complete the action required

Table I: Progress of Actions

22

Page 23

WARRANTY

The Raypak RayTemp Control is warranted to be free from defects in material and workmanship for a period of

one year from the date of installation or fourteen months from date of shipment, whichever occurs first.

THE FORGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED OR IMPLIED BY OPERATION OR LAW OR OTHERWISE,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OF FITNESS.

At its option, Raypak will repair or replace any RayTemp Control which fails to conform to this warranty. Repair

or replacement shall be the sole remedy of the buyer under this warranty, and Raypak shall not be liable for any

installation, removal or reinstallation costs, or for any damage and/or injury to building, contents, products or persons by reason of the installation of the RayTemp Control, or for incidental or consequential losses, damages or

expenses, including loss or profits, directly or indirectly arising from this sale, handling or use of the goods, or

from any other cause relating thereto, whether such claims are for breach of warranty or negligence.

Any claim by buyer with reference to the Raypak RayTemp Control sold hereunder for any cause shall be

deemed waived by buyer unless submitted to Raypak in writing within thirty (30) days from date buyer discovered, or should have discovered, any claimed breach. To obtain service under this warranty, call or write:

RAYPAK, INC.

2151 Eastman Avenue

Oxnard, CA 93030

805-278-5300

Service/Return Authorization Procedure

Raypak will not accept a returned unit unless the buyer has received prior authorization to return the unit. If a

problem is suspected with the RayTemp control while under warranty, the owner or operator should first call the

installing dealer. The dealer should contact Raypak at the above phone number for return authorization.

Required information: name of site, location, serial number, reason for return. An authorization number will be

issued. Repaired or replacement equipment will be returned to you prepaid.

Warranty Card

Please return this card within 30 days of installation to initiate your warranty and enable us to better serve you

Control Model: ___________________________________ Date Purchased:_________________________

Control Serial Number: _____________________________ Date Installed:___________________________

Water Heater Model Number:_______________________ Water Heater Serial Number:________________

Company Name: __________________________________ Contact Name: _________________________

Company Address: ________________________ City: _________________ State:_____ Zip Code:_______

Installation Location: ______________________________________________________________________

Installation Address: ______________________ City: _________________ State:_____ Zip Code:________

Type of Property: Apt/Condo_______ Hotel/Motel_______ Other ________

RayTemp Dealer: __________________________________ Address: ______________________________

City: _____________________ State: ______ Zip Code: ______________

23

Page 24

www.raypak.com

Raypak Inc., 2151 Eastman Avenue, Oxnard, CA 93030 • (805) 278-5300 • (805) 278-5495

Loading...

Loading...