Page 1

Installation, Operating,

and Service Manual

PS165VSP

Variable Speed Pool Pump

LISTED 31B4

Catalog No. 6000.555 Effective. 01/16/2013 Replaces: NEW P/N 241508 Rev 1

Page 2

Technical Support

Address: 7920 Interstate Court

North Ft. Myers, FL. 33917

Toll Free: 1-877-213-3726

Website: www.raypak.com

Manufactured for Raypak by Speck Pumps, Jacksonville Florida USA, © 2012-2013 All Rights Reserved.

This document is subject to change without notice.

Date of Installation:

Installed by:

Serial Number:

For Service Call:

Safety

Safety is emphasized throughout the user manual. These are safety alert symbols. They alert the user to

potential personal injury hazards. Obey all safety messages to avoid possible injury or death or damage

to equipment.

CAUTION

WARNING

DANGER

2999999292 - Rev 01/2013 v1

SAVE THESE INSTRUCTIONS!

Page 3

Table of Contents

1 Important Safety Instructions 4

2 General Description 6

3 Installation Information 7

Preparation Guide . . . . . . . . . . . . . . . 7

Pump Location . . . . . . . . . . . . . . . . 8

Pipe Sizing . . . . . . . . . . . . . . . . . . 8

Plumbing Installation . . . . . . . . . . . . . . 9

Bonding and Grounding . . . . . . . . . . . . . 9

Electrical Installation . . . . . . . . . . . . . . 10

Pressure Testing . . . . . . . . . . . . . . . . 11

4 Operation 12

Start-Up Guide . . . . . . . . . . . . . . . . 12

Energy Savings Optimization . . . . . . . . . . . 13

Programming . . . . . . . . . . . . . . . . . 14

Menu Structure . . . . . . . . . . . . . . . . 15

Keypad Lock . . . . . . . . . . . . . . . . . 16

Motor Pause . . . . . . . . . . . . . . . . . 16

Power Outage . . . . . . . . . . . . . . . . . 16

Schedule Advance . . . . . . . . . . . . . . . 17

Using an existing or new 24 hour timer . . . . . . . 17

Optional PS165VSP-RM Controller . . . . . . . . 17

Freeze Protection . . . . . . . . . . . . . . . 18

Override . . . . . . . . . . . . . . . . . . . 18

Communication . . . . . . . . . . . . . . . . 18

3rd Party Controllers (Wiring) . . . . . . . . . . . 20

Heat Pump Pool Heater Connections (Wiring) . . . . 24

5 Service and Maintenance 27

Routine Maintenance . . . . . . . . . . . . . . 27

Winterizing . . . . . . . . . . . . . . . . . . 28

6 Troubleshooting 28

Fault LED . . . . . . . . . . . . . . . . . . 28

General Troubleshooting Problems . . . . . . . . 29

Blocked Impeller . . . . . . . . . . . . . . . . 29

Removal and Replacement of the Impeller . . . . . 30

Motor Replacement . . . . . . . . . . . . . . 31

7 32

Product Specifications

Performance Curve & Dimensional Drawing . . . . . 32

Replacement Parts and Exploded View . . . . . . . 33

Page 4

1 Important Safety Instructions

READ THIS MANUAL CAREFULLY BEFORE USING THE PUMP

READ AND FOLLOW ALL INSTRUCTIONS!

Important Notice:

This manual contains important information about the installation, operation and safe use of this product.

This information should be given to the owner and/or operator of this equipment.

WARNING: This product must be installed and serviced by a qualied pool professional, and must

conform to all national, state, and local codes.

WARNING: Before Installing this product, read and follow all warning notices and instructions which are

included. Failure to follow safety warnings and instructions can result in severe injury, death, or property

damage. Call 1-877-213-3726 or visit www.raypak.com for additional copies of these instructions.

WARNING: California Proposition 65: This product contains chemicals known to the state of California to

cause cancer, birth defects or other reproductive harm.

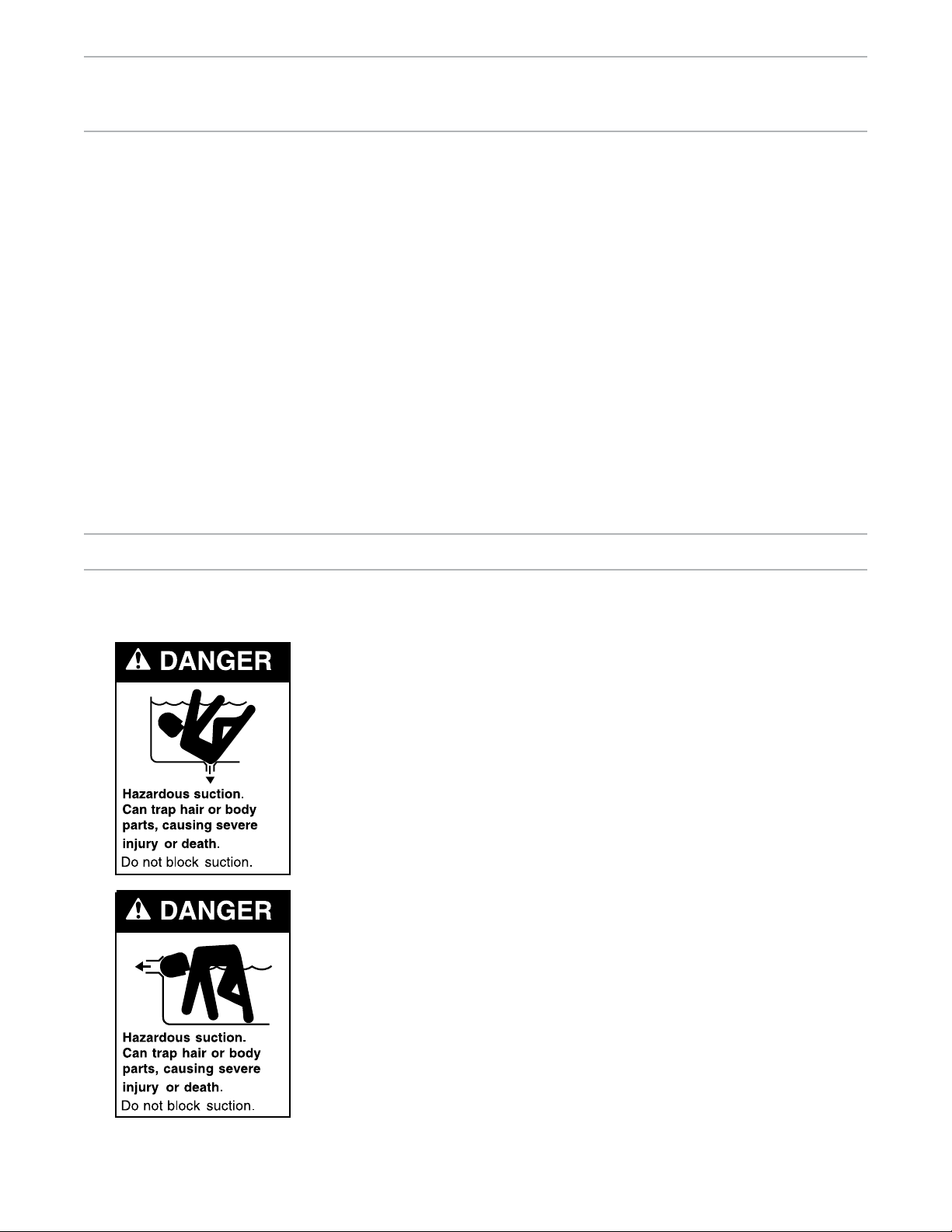

WARNING - Entrapment Prevention

DANGER: DO NOT BLOCK SUCTION

SUCTION HAZARD. Can cause serious injury or death. Do not use

this pump for wading pools, shallow pools, or spas containing bottom

drains, unless pump is connected to at least two (2) functioning suction

outlets.

WARNING: Pump suction is hazardous and can trap and drown

or disembowel bathers. Do not use or operate swimming pools,

spas, or hot tubs if a suction outlet cover is missing, broken, or

loose.

The following guidelines provide information for pump installation

that minimizes risk of injury to users of pools, spas, and hot tubs:

Entrapment Protection: The pump suction system must provide

protection against the hazards of suction entrapment.

Suction Outlet Covers: All suction outlets must have correctly installed,

screw-fastened covers in place. All suction outlet (drain) covers must be

maintained. Drain covers must be listed/certied to the latest published

edition of ANSI/ASME A112.19.8 (ANSI/APSP-16, 2011). They must be

replaced if cracked, broken, or missing.

Number of Suction Outlets Per Pump: Provide at least two (2)

hydraulically-balanced main drains, with covers, as suction for each

circulating pump suction line. The centers of the main drains (suction

outlets) on any one (1) suction line must be at least three (3) feet apart,

center to center.

4

Page 5

WARNING - Entrapment Prevention - continued

The system must be built to include at least two (2) suction outlets (drains) connected to the pump

whenever the pump is running. However, if two (2) main drains run into a single suction line, the single

suction line may be equipped with a valve that will shut off both main drains from the pump. The system

shall be constructed such that it shall not allow for separate or independent shutoff or isolation of each

drain.

More than one (1) pump can be connected to a single suction line as long as the requirements above are

met.

Water Velocity: The maximum water velocity through the suction tting or cover for any suction outlet

must be 1.5 feet per second, unless the outlet complies with the latest published edition of ANSI/ASME

A112.19.8 (ANSI/APSP-16, 2011), the standard for Suction Fittings For Use in Swimming and Wading

Pools, Spas, Hot Tubs, and Whirlpool Bathtub Applications. In any case, do not exceed the suction

tting’s maximum designed ow rate.

If 100% of the pump’s ow comes from the main drain system, the maximum water velocity in the pump

suction hydraulic system must be six (6) feet per second or less, even if one (1) main drain (suction

outlet) is completely blocked. The ow through the remaining main drain(s) must comply with the latest

published edition of ANSI/ASME A112.19.8 (ANSI/APSP-16, 2011), the standard for Suction Fittings For

Use in Swimming and Wading Pools, Spas, Hot Tubs, and Whirlpool Bathtub Applications.

Testing and Certication: Suction outlet covers must have been tested by a nationally recognized

testing laboratory and found to comply with the latest published edition of ANSI/ASME A112.19.8 (ANSI/

APSP-16, 2011), the standard for Suction Fittings For Use in Swimming and Wading Pools, Spas, Hot

Tubs, and Whirlpool Bathtub Applications.

Fittings: Fittings restrict ow; for best efciency use fewest possible ttings (but at least two (2) suction

outlets).

Avoid ttings that could cause an air trap.

Pool cleaner suction ttings must conform to applicable International Association of Plumbing and

Mechanical Ofcials (IAPMO) standards.

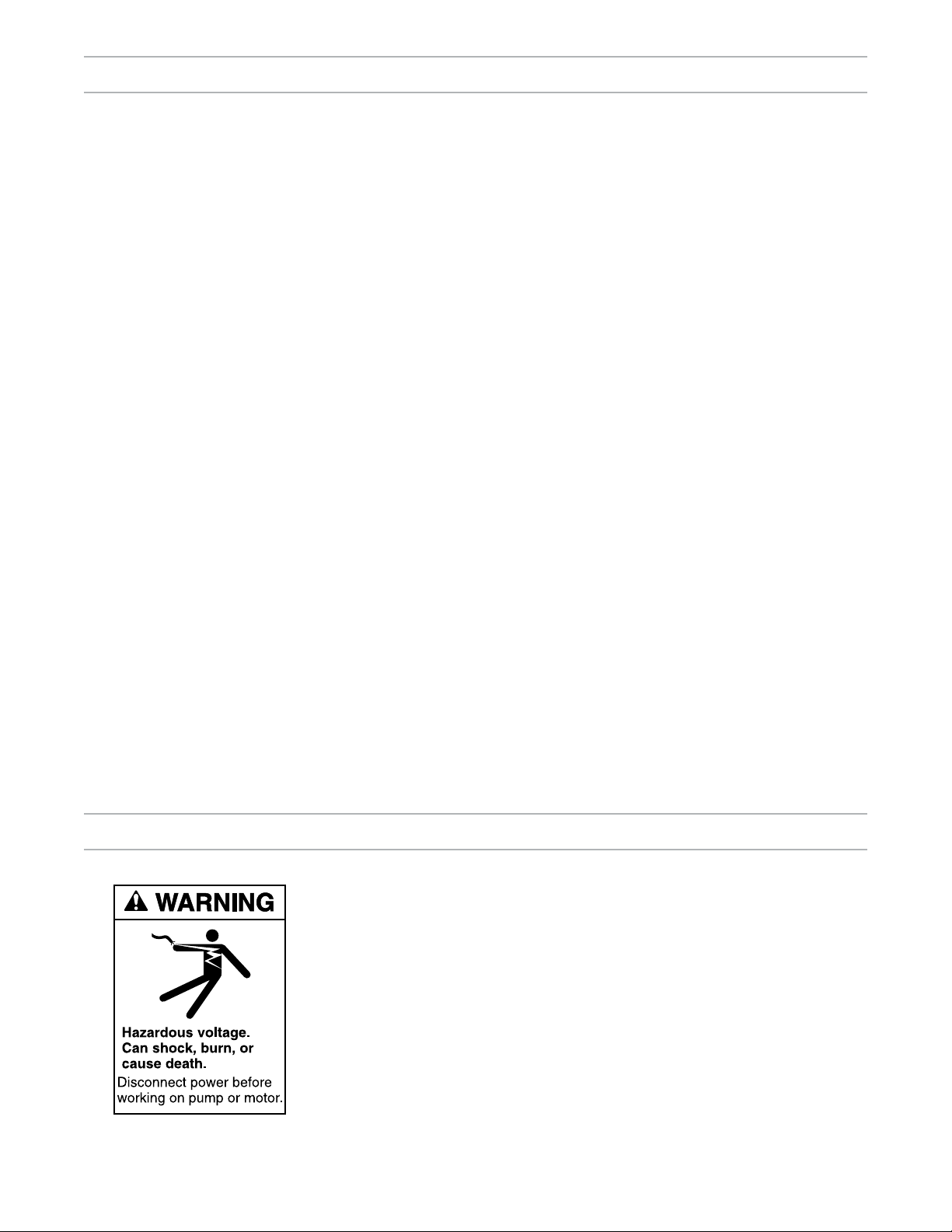

WARNING - Risk of Electrical Shock or Electrocution

This pool pump must be installed by a licensed or certied electrician or

a qualied pool serviceman in accordance with the National Electrical

Code and all applicable local codes and ordinances. Improper installation

will create an electric hazard which could result in death or serious injury

to pool users, installers, or others due to electrical shock, and may also

cause damage to property.

Always disconnect power to the pool pump at the circuit breaker

before servicing the pump. Failure to do so could result in death or

serious injury to serviceman, pool users, or others due to electric shock.

5

Page 6

Important Safety Instructions

When installing and using this electrical equipment, basic safety precautions should always be

followed, including the following:

READ AND FOLLOW ALL INSTRUCTIONS

WARNING: To reduce the risk of injury, do not permit children to use this product unless they are closely

supervised at all times.

WARNING: Risk of Electrical Shock. Connect only to a grounding type receptacle protected by a groundfault circuit-interrupter (GFCI). Contact a qualied electrician if you cannot verify that the receptacle is

protected by a GFCI.

The unit must be connected only to a supply circuit that is protected by a ground-fault circuit-interrupter

(GFCI). Such a GFCI should be provided by the installer and should be tested on a routine basis. To test

the GFCI, push the test button. The GFCI should interrupt power. Push the reset button. Power should be

restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to

the pump without the test button being pushed, a ground current is owing, indicating the possibility of an

electric shock. Do not use this pump. Disconnect the pump and have the problem corrected by a qualied

service representative before using.

CAUTION: This pump is for use with permanently installed pools and may also be used with hot tubs

and spas if so marked. Do not use with storable pools. A permanently installed pool is constructed in or

on the ground or in a building such that it cannot be readily disassembled for storage. A storable pool is

constructed so that it may be readily disassembled for storage and reassembled to its original integrity.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, connect ground wires to grounding screw located in

the motor. Use no smaller than a #12 AWG (3.3mm2) wire.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, a bonding connector is provided for bonding to

metal water pipes, metal rails, or other metal within 5 feet of the swimming pool. All local points should be

bonded with a #8 AWG (8.4mm2) wire.

SAVE THESE INSTRUCTIONS.

2 General Description

Raypak Professional PS165VSP - Variable Speed

The PS165VSP - Variable Speed swimming pool pump is both environment friendly and cost efcient.

This Premium Efciency Variable Speed Pump provides tremendous exibility in motor speed and time

settings. The integrated electronic interface controls the speed settings between 600 and 3450 rpm

and the start and stop times. It is designed to maximize energy conservation, optimize chemical usage,

and yet still be simplistic to use. The PS165VSP is intended to run on the lowest speeds needed to

maintain a healthy pool environment, which in turn translates into money savings. With speed settings

of 3450, 3100, 2850, 2600, 2350, 2100, 1850, 1600, 1350, 1100, 850, 600, and 0, it easily allows you to

choose the most appropriate speed for the maximum savings. With pump parts made of 100% recyclable

plastic and engineering designed to signicantly reduce greenhouse emissions, it is sure to please the

environmentally minded consumer.

6

Page 7

General Description - continued

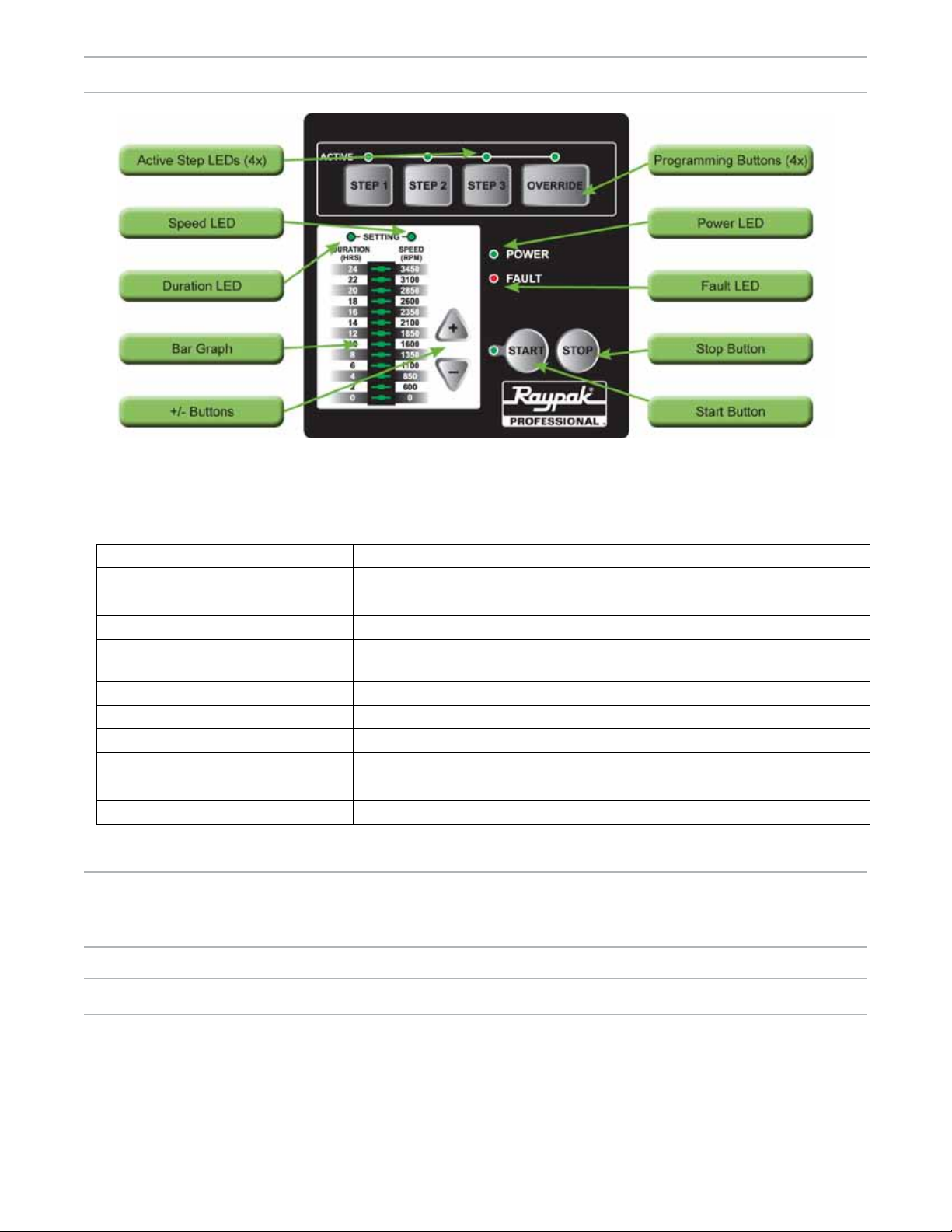

Figure 1

The PS165VSP - Variable Speed control panel provides manual speed controls for the pump.

Controls and LEDs Description

LED Lights (Active Step LEDs) When lit, indicates it is in operation or active.

Speed LED When lit, Bar Graph displays speed.

Duration LED When lit, Bar Graph displays duration in hours speed will run.

Bar Graph Shows current speed and duration (hours) of active programmed button

or selected value during programming.

Programming Buttons Four programmable buttons, to be set for speed and length of time.

Power LED Indicates unit has power.

Fault LED Indicates the unit has a fault error.

+/- Buttons Increases or decreases speed or duration of selected value.

STOP button Stops pump and programming.

START button Must be pressed to start the pump and programming.

3 Installation Information

Preparation Guide

1. Upon receipt of the pump, check the carton for damage. Open the carton and check the pump for

concealed damage, such as cracks, dents, or a broken base. If damage is found, contact the shipper or

distributor where the pump was purchased.

2. Inspect the contents of the carton and verify that all parts are included. See Section 7, Parts List and

Exploded View for details.

7

Page 8

Pump Location

WARNING: This product must be installed and serviced by a qualied pool professional, and must

conform to all national, state, and local codes. Before installing this product, read and follow all warning

notices and instructions of this product. Failure to follow warning notices and instructions may result in

property damage, personal injury, or death.

ATTENTION INSTALLERS: This manual contains important information about the installation, operation,

and safe use of this product. This manual should be given to the owner/operator of this equipment.

1. Raypak recommends in order to achieve better priming, to install the pump as close to the pool as

practical and run suction lines as direct as possible to reduce friction loss.

2. It is recommended that a minimum length of straight pipe, equivalent to ve (5) times the pipe diameter

be used between the pump suction inlet and any plumbing ttings (elbows, valves, etc.).

3. Install the pump on a level, solid foundation which provides a rigid and vibration-free base. Secure the

pump to the base with screws or bolts to further reduce vibrations and stress on the plumbing.

4. Protect the pump against ooding and excess moisture. Select an area that will not ood when it rains.

DO NOT install the pump in a damp or non-ventilated location.

5. Keep the motor clean and provide free circulation of air for cooling.

6. Although the pump is designed for outdoor use, it is recommended to protect the pump from direct

sunlight and excessive moisture (rain, sprinklers, etc.).

7. DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this pump. DO NOT

store pool chemicals near the pump.

8. DO NOT remove any safety alert labels such as DANGER, WARNING, or CAUTION. Keep safety

labels in good condition and replace any missing or damaged labels.

9. Provide access for future services by leaving a clear area around the pump. Allow plenty of space

above the pump to remove lid and basket for cleaning.

WARNING: Some Safety Vacuum Release System (SVRS) devices are not compatible with the installation

of check valves. If the pool has an SVRS device, be sure to conrm that it will continue to safely operate

when the check valves are installed.

NOTE: In Canada, the pump must be located a minimum of three (3) meters (approximately ten (10) feet)

from the water (CSA C22.1).

Pipe Sizing

NOTE: All pipe sizes are able to withstand the pressures the pump will deliver, but not necessarily the

ow. If the pipe is too small for the pump, or is elevated above water, the maximum gallons per minute

(GPM) may not be delivered. If this happens, the pump will develop a pocket of air (cavitation) that makes

noise. This may shorten the life of the pump.

SUCTION & DISCHARGE:

When the pump is located up to fty (50) feet from the pool, the recommended minimum pipe size for both

the suction and discharge is 2”.

8

Page 9

Pipe Sizing - continued

For better efciency and less restriction, use as few ttings (elbows, tees, valves, etc.) as possible.

Suction line diameter must be equal or be greater than the discharge line diameter.

Suction and discharge lines should be independently supported at a point near the pump to avoid strains

being placed on the pump.

NOTE: If more than ten (10) suction ttings are needed, the pipe size must be increased.

Plumbing Installation

When installing the pump, care should be taken to see the suction line is below water level to a point

immediately beneath and in front of the pump to ensure quick priming via a ooded suction line. The

height between the pump and water level should not be more than ve (5) feet.

If the pump is located below water level, isolation valves must be installed on both sides of the pump to

prevent the back ow of pool water during any routine or required servicing. The PS165VSP - Variable

Speed comes equipped with unions on both the suction and discharge ports. This feature simplies

installation and service and eliminates the possibility of leaks at the threaded adaptors.

Before starting the pump for the rst time, remove the see-through lid. (Turn lid ring counter clockwise

to remove.) Fill strainer tank with water until it is level with the suction inlet. Replace lid, making sure the

o-ring is in place and not damaged. Screw down, hand tight.

Every new installation must be pressure tested according to local codes. See the Pressure Testing

Section on page 11.

Bonding and Grounding

WARNING: Ground and bond the pump before connecting to electrical power supply. Failure to ground

and bond the pump can cause serious or fatal electrical shock hazard. DO NOT ground to a gas supply

line. To avoid dangerous or fatal electrical shock, turn OFF power to the pump before working on electrical

connections.

1. The motor frame must be grounded to a reliable grounding point using a solid copper conductor, No. 8

AWG or larger. In Canada, No. 6 AWG or larger must be used. If the pump is installed within ve (5) feet

of the inside walls of the swimming pool, spa, or hot tub, the motor frame must be bonded to all metal

parts of the swimming pool, spa, or hot tub structure and to all electrical equipment, metal conduit, and

metal piping within ve (5) feet of the inside walls of the swimming pool, spa, or hot tub.

2. Bond the motor using the provided external lug.

WARNING: In order to avoid the risk of property damage, severe personal injury, and/or death, make

sure that the control switch, time clock, or control system is installed in an accessible location, so that in

the event of an equipment failure or loose plumbing tting, the equipment can be easily turned off.

CAUTION: The pump must be permanently connected to a dedicated electrical circuit. No other equipment,

lights, appliances, or outlets may be connected to the pump circuit, with the exception of devices that may

be required to operate simultaneously with the pump, such as a chlorinating device or heater.

9

Page 10

Electrical Installation

WARNING: All electrical wiring must conform to the local NEC guidelines. A licensed, qualied

electrician should complete the wiring for this product.

Electrical Specications

1. Voltage: 208-230 VAC, 60 Hz, Single Phase

2. Max Amps: 11

3. Speed Range: 600 - 3450

4. Controller: 208-230 Vrms, Single Phase

5. Ambient: 50o C

6. NEMA Type 3R

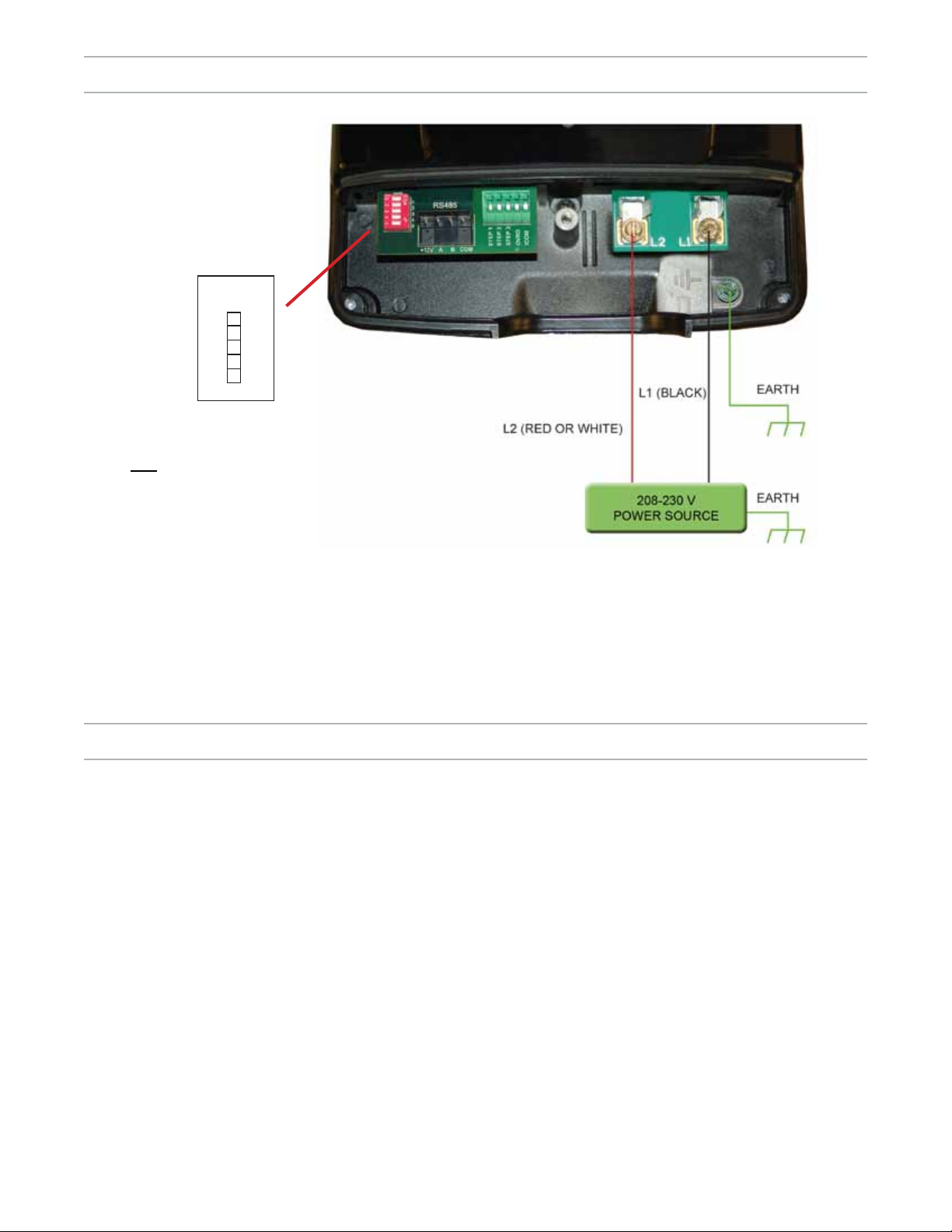

Figure 2

The motor is designed to handle either a bare wire connection or a quick disconnect connection. The

quick disconnect tab is 0.250”. For a direct wire connection, the wire insulation should be stripped to a

length of approximately 0.33” and the screw tightened to a torque of 10 in-lb. The terminals will handle

wire up to 12 AWG in size.

There are two terminals labeled L1 and L2. (See Figure 3) Attach the power leads to these terminals.

Attach the black lead to L1 and the red or white lead to L2. (See Table 1.0) The top rear of the controller

has a single screw. Loosen this screw and lift cover to expose the terminal area.

Table 1.0

Pin# Wire Color Description

L1 Black Hot 1

L2 Red or White Hot 2

GRD Green Ground

10

Page 11

Electrical Installation - continued

On

Off

1 2 3 4 5

Note: All Dip switches should be in the

OFF position when external controllers

are not being used.

Figure 3

CAUTION: Voltage at the pump MUST NOT vary by more than +/- 10% of nameplate voltage. Components

may overheat, causing overload tripping and reduced component life. Consult your power company if this

condition exists.

Note: Use only liquid tight ttings to protect the electronics and motor.

Pressure Test

WARNING: To minimize the risk of severe injury or death, the lter and/or pump should not be subjected

to the piping system pressurization test.

Local codes may require the pool piping system to be subjected to a pressure test. These requirements

are generally not intended to apply to the pool equipment.

However, if the WARNING cannot be followed and pressure testing of the complete system must be

done, follow the following guidelines:

1. RELEASE ALL AIR in the system before testing.

2. Water pressure for the test must NOT EXCEED 35 PSI.

3. Water temperature for the test must NOT EXCEED 100° F (38° C).

4. Limit the test to 24 hours. After the test, visually check the system to be sure it is ready for operation.

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR CHECK FOR LEAKS.

11

Page 12

4 Operation

Start Up Guide

CAUTION: Never run the pump without water. Running the pump “dry“ for any length of time can cause

severe damage to both the pump and the motor and will void the warranty.

If this is a new pool installation, make sure all piping is clear of construction debris and has been properly

pressure tested. The lter should be checked for proper installation, verifying that all connections and

clamps are secure according to the manufacturer’s recommendations.

WARNING: To avoid risk of property damage, severe personal injury or death, verify that all power is

turned off before starting this procedure.

1. Depending on the location of the pump, do one of the following:

If the pump is located below the water level of the pool, open the lter pressure valve to prime

the pump with water. Once all the air has left the lter, close the lter pressure release valve.

If the pump is located above the water level of the pool, remove the lid and ll the basket with water

before starting the pump.

2. Prior to replacing the lid, check for debris around the lid o-ring seat. Debris around the lid o-ring seat

will make it difcult to prime the pump.

3. Hand-tighten the lid to make an air tight seal. Do not use any tools to tighten the lid: hand-tighten

only. Make sure all valves are open and the unions are tight.

4. Restore power to the system.

5. Pressing the START key will start the motor based on the factory default schedule. (See Table 2.0)

Table 2.0 - Factory Default Schedule

Button Speed (RPM) Duration (Hours)

STEP 1 1100 12

STEP 2 0 0

STEP 3 0 0

OVERRIDE 3450 2

Note: Motor will always run the PRIMING sequence when starting from 0 speed, Stop position, or OFF

power. The factory priming settings are 3450 RPM for 3 minutes.

6. (Self Priming Pump) Open the lter pressure relief valve until all air has escaped and then close.

7. If the pump does not prime and all instructions to this point have been followed, check for a suction

leak. Repeat steps 2-7.

8. For technical assistance, call Technical Support at 1-877-213-3726.

12

Page 13

Start Up Guide - continued

NOTE: If power goes off to the motor and the user did not press the STOP key, then the motor will

automatically start and run the programmed schedule. This will ensure that the motor will re-start in the

case of a power outage.

Energy Savings Operation - PS165VSP Pump Speed Optimization

The PS165VSP pumps come with factory defaults of STEP 1 set for 1100 RPM for 12 hours duration and

the OVERRIDE set for 3450 RPM for 2 hours duration. The remainder of the 24 hour day, the pump will

be OFF.

These speeds and durations can be programmed on site for each specic pool installation to support

specic pool parameters and equipment.

In order to maximize Energy Savings from pump operation, follow the steps below to optimize the pool

pump speeds to take full advantage of these savings opportunities.

1. Push the OVERRIDE button directly from the pump control, adjust the pump speed to determine the

proper operation rpm of the pump for each device intended for use on the pool (lter, vacuum, HPPH,

gas pool heater, etc.).

2. Use the UP (+) or DOWN (-) buttons on the pump control to increase/decrease the pump speed while

in the OVERRIDE mode (NOTE: The light over the OVERRIDE button will be lit when in OVERRIDE

mode).

3. Record the lowest RPM that allows each pool device to work properly and save for future reference

and use later in these instructions.

4. STEP 1 is primarily used to circulate the pump for a sufcient period each day to ensure proper turn

over of the pool water and ltration. Adjust the pump speed and duration for STEP 1 as determined for

proper operation of the ltration system (proper number of turns per day).

5. STEP 2 and STEP 3 can be used and set for other equipment operation.

6. OVERRIDE is used by the HPPH for heater operation. Adjust the ow rate so that it is just sufcient

for the unit to operate. This is the lowest setting for heat pump operation and will result in the greatest

energy savings.

7. OVERRIDE may also be used for other pool service tasks. If it is adjusted for any other purpose,

please remember to readjust when completed to the preset value as the HPPH uses this RPM for proper

heating/cooling operation.

8. Once all pump speeds have been determined, you can adjust the programs in the pump accordingly,

See the Programming Section on page 14.

NOTE: It is best to use a speed slightly above the minimum speed determined in the steps above to

ensure proper operation under dirty lter or clogged strainer baskets, etc. Example, if the heater operation

requires a setting of 1600 RPM – use 1850 RPM. This still maximizes pump energy cost savings, but

also reduces the probability of nuisance issues with the pool equipment not operating properly because

of insufcient water ow.

13

Page 14

Programming

Operates on a 24 hour cycle that begins from the time the START button is pushed. To start the cycle at

a specic time, See the Schedule Advance Section on page 17.

Programmable Speed Settings:

3450, 3100, 2850, 2600, 2350, 2100, 1850, 1600, 1350, 1100, 850, 600, 0

NOTE: 0 is a programmable speed (RPM) and can be set for a specic duration.

Programmable Duration Settings (Hours)

24, 22, 20, 18, 16, 14, 12, 10, 8, 6, 4, 2, 0

Note: Up to three separate speeds with duration may be set. The sum of the three durations combined

must not exceed 24 hours. If the three combined exceed 24 hours, the pump will keep the current step

and re-write the remaining two steps to zero.

User can change the program duration and speed of STEP 1, STEP 2, STEP 3 & OVERRIDE keys.

Note: Pump must be OFF for programming speed and duration of the STEP 1, 2, 3 keys. Override speed

and duration can be programmed when the motor is either OFF or running.

Four programmable buttons lay across the top of the Keypad (overlay). (See Figure 4 - shows the speed

being set at 3100 RPM.) The LED directly above each button when lit indicates it is in operation or active.

To create a custom schedule and change the factory defaults settings, follow these steps:

1. Place the pump in the stop position (Press STOP Button).

2. Press the STEP 1 button. The LED above it will illuminate. The LED above the SPEED column will

illuminate.

3. Using the UP (+) or DOWN (-) arrows, toggle to the desired speed. The Bar graph will show the setting

as you toggle up and down. (See Figure 4 - shows the speed being set at 3100 RPM.)

4. Press the STEP 1 button again. The LED above the duration column will be lit.

5. Using the UP (+) or DOWN (-) arrows, toggle to the desired duration that you want this speed to run in

hours. The Bar graph will show the setting as you toggle up and down. (See Figure 5 - shows the duration

being set at 10 hours.)

6. Press any of the other STEP or the OVERRIDE button to save these settings for STEP 1.

7. To exit the system and not save these settings, press the STOP button.

8. Press STEP 2, STEP 3, or OVERRIDE key. Repeat steps 3-6 to program the corresponding speed and

duration for each button.

14

Page 15

Programming - continued

Figure 4 Figure 5

Restore Factory Defaults:

Press and hold the STOP and OVERRIDE key for 3 seconds. When the reset has been recognized the

Bar graph will blink three times.

Menu Structure

1. STEP 1 (Set Schedule) a. Speed and Duration

2. STEP 2 (Set Schedule) a. Speed and Duration

3. STEP 3 (Set Schedule) a. Speed and Duration

4. OVERRIDE (Settings) a. Speed and Duration

5. START

Press START to run the pump based on the programmed 24 hour schedule. The schedule is based on a

24 hour cycle and will repeat each day of the week.

During operation the LED lights above the “SPEED” and “DURATION” will ip back and forth every three

seconds. When lit, the graph below will show the active programmed speed or duration in progress.

Note: The START button must be pressed for the pump to operate. The START LED will illuminate after

the button has been pressed.

Note: If the schedule times combined are less than 24 hours, the remaining time for the 24 hour cycle will

be lled with the motor stopped.

15

Page 16

Menu Structure - continued

Schedule Table

Use these tables to enter a personalized operating schedule. By writing down the planned schedule, it

will make the programming process easier and will help the user to remember the user’s settings in case

the programming is inadvertently lost. The User Interface will not allow the user to program an overlap

between different steps of the schedule. The STEP currently being set will always take priority of any

older settings. Therefore, the duration for the other two (2) STEPs not currently being set will be cleared

to 0 hours and have to be programmed again by the user. It is always a good idea to double check your

programmed settings once you have completed the programming process.

Setup #1

STEP 1 STEP 2 STEP 3 OVERRIDE

Speed (RPM)

Duration (Hours)

Keypad Lock

The Keypad has a “key lockout” feature to prevent

unwanted changes to the settings. To lock the keys,

hold down the STEP 1, 2, and 3 buttons all at the

same time for more than 3 seconds. The “active step

LEDs” for STEP 1, 2 and 3 will blink for 30 seconds

indicating that the keypad is locked. (See Figure 6)

The user can unlock the keys by holding down the

same buttons for more than 3 seconds. The “active

step LEDs” for STEP 1, 2 and 3 will illuminate

continuously indicating the keypad is unlocked.

Figure 6

Motor Pause

Allows for temporary turn off of the motor.

1. Press and hold the START button for three seconds while the motor is running. The motor will turn off

and the START and OVERRIDE LED’s will blink.

2. To resume running, hold the START button for three seconds.

Power Outage

If there is a power outage and the user does not press the STOP key, upon power being restored,

the pump will automatically start and run the schedule starting with STEP 1. This feature ensures that

the motor will re-start in the event of a power outage. The Priming sequence precedes STEP 1. All

programming is retained.

16

Page 17

Schedule Advance

The Schedule Advance Feature allows you to program the pump yet start the 24 hour cycle at a different

time of day.

The following steps should be followed to set the Schedule Advance:

1. With the motor stopped, press the START Key and hold for more than three seconds. The Start LED

will blink. The Duration LED and Bar Graph will illuminate.

2. Press the UP (+) or DOWN (-) arrows to set the desired schedule cycle start time. The schedule

advance mode will automatically start after the desired delay time is selected. This mode can be cancelled

by pressing the STOP key.

Note: During the Schedule Advance if a user presses the STEP 1, STEP 2, STEP 3, OVERRIDE, or the

START key, the system will start the normal schedule and the Schedule Advance will be cancelled.

Note: If power is lost during the Schedule Advance, then the 24 hour schedule will automatically start

when power is restored.

Using an Existing or New 24 hour timer to start the pump controller program

The PS165VSP operates on a 24 hour cycle. Once the controller is programmed, it only requires the

START button to be pressed to start the 24 hour cycle. Once the START button is pressed, power cycled

(such as a temporary power failure) to the pump would result in the 24 hour cycle restarting at the

beginning of STEP 1. Using or adding a “24 hour timer” will allow you to start the “24 hour cycle” at any

time during the day.

Note: The pump must be programmed and the Start Key pressed in order to operate.

Optional PS165VSP-RM Controller

This optional controller uses the RS485 connectors. (See Table 3.0)

Note: Verify that Dip switch 1 is ON and Dip switch 5 is OFF.

Note: The +12V and GND can also be used to supply 12V for the Digital Inputs when Dip switch 1 is ON.

The benets of the PS165VSP-RM:

1. Ability to view fault-codes and troubleshoot.

2. Ability to set a pump running schedule based on a real-time clock setting.

3. Ability to remotely mount the PS165VSP-RM.

4. Ability to congure Prime Speed and Prime Duration.

5. Ability to congure Freeze Protection temperature.

6. Ability to view speed and power of the motor in real-time.

7. Ability to adjust motor speed in 25 RPM increments.

8. Battery backup to keep stored settings and time.

17

Page 18

Freeze Protection

Freeze Protection will run the motor at 2600 RPM for eight (8) hours if the ambient temperature drops

below 39° F. Once this eight (8) hour duration has elapsed, the motor control will check the ambient

temperature again. If the temperature is still below the 39° F threshold, the motor will run for an additional

eight (8) hours. If the temperature is above the threshold, the motor will automatically return to the 24

hour based schedule.

NOTE: The freeze protection function will NOT operate if the START button is not pressed. This can be

conrmed by verifying that the START LED is illuminated.

Override

The pump is equipped with an OVERRIDE feature, which can be engaged to temporarily run at higher or

lower speeds between 600 to 3450 RPM. Once override duration has elapsed, the motor will automatically

return to programmed schedule.

1. Pressing the OVERRIDE key; while the motor is running; will cause the motor to start running in the

OVERRIDE mode at the programmed Speed and Duration. The “active step LED” for OVERRIDE will

illuminate. The speed and duration settings LED along with its respective bar graph LED of OVERRIDE

shall blink back and forth at three (3) seconds.

2. The UP (+) / DOWN (-) arrows allow the user to congure Speed and Duration. These settings can be

changed while the motor is running. These settings are stored each time the UP (+) / DOWN (-) arrows

are pressed.

NOTE: When the OVERRIDE duration ends, the motor resumes the 24 hour duration cycle and will start

in the corresponding STEP. The OVERRIDE duration will not affect the start or stop times of the 24 hour

cycle.

NOTE: Pressing/Holding OVERRIDE key for more than three (3) seconds will cancel OVERRIDE mode.

NOTE: During the OVERRIDE mode, the motor will not start with the priming sequence.

NOTE: Pressing STOP at any time turns the motor OFF and clears the start time for the 24 hour schedule.

Communication

Control with Digital Inputs

The user can run the motor at the programmed STEP 1, 2, 3, or OVERRIDE speeds by utilizing the four

(4) digital inputs. STEP 1, 2, 3, or OVERRIDE are equivalent to Digital Input 1, 2, 3, or 4 respectively.

The controller is rated to accept digital inputs of 18V-30V AC (24V AC+/- 20%) and 9-30V DC (12/24 V

DC +/- 20%).

NOTE: The motor will detect either a 50/60Hz for AC input or an active low signal for DC digital inputs.

The items below describe the functionality of the digital inputs: (See Figure 7)

1. If the user provides any one of the 4 digital inputs, then the DURATION LED will blink every one (1)

second to indicate the Digital Input is functioning properly.

2. The motor will illuminate the corresponding “active step LED” and the respective bar graph LED. The

START LED will be OFF when a digital input is present.

18

Page 19

Communication - continued

NOTE: There is no schedule for digital inputs. The timing for each speed is controlled directly by the

digital inputs.

NOTE: The digital inputs have the highest priority amongst all the inputs (i.e. Keypad, Serial and Digital

Inputs). Therefore, the serial commands as well as the Overlay Keypad inputs will be ignored when a

digital input is present.

NOTE: If more than one digital input (switch) is present, then the motor will give priority to the highest

number digital input. Therefore, OVERRIDE has highest priority followed by STEP 3, then STEP 2, then

STEP 1.

NOTE: If no digital input is detected, the motor will automatically start the 24 hour schedule if the START

key was pressed prior to the application of the digital input.

Figure 7

Table 3.0 - Communication Connection Table (RS485)

Pin# Wire Color Description

J201-1 Red + 12V

J201-2 Green RS485 - A

J201-3 Black RS485 - B

J201-4 Yellow Isolated Ground

19

Page 20

3rd Party Controllers (Wiring)

Wiring Diagram for ProLogic with PS165VSP

Note: 12V from the RS485 can be wired

to the Line In of each Aux. Load Out will

be the input for each digital signal. Verify

Dip switch 1 on pump is ON.

12V - Pin1

L2NL1

DI-2

DI-1

DI-3

DI-4

Figure 8

L1 (Black)

L1 (Black)

L2 (Red or White)

L2 (Red or White)

208-230V

Power Source

Earth

Earth

Earth

Earth

20

Page 21

g

y

3rd Party Controllers (Wiring)

Wiring Diagram for AquaLink RS with PS165VSP

R e d

B la ck

G r e e n

Ye ll o w

G r e e n

B la ck

R e d

W hit e

B row n

S o la r

S e n s or

W a t e r Te mp .

S e n sor

B lu e

R e d

N o t U se d

B la ck

N o t U se d

R e d

B la ck

R e tu rn

JVA

In t a k e

Lo w Vo lt a g e

H e a t e r

JVA

C lea ne r

J VA

S o lar

JVA

S o lar

P u m p

E le ct.

H e a t e r

D ip S w i tc h S e ttings

F a c to ry S et

#

O F F

1

A u x 1

2

1 s p d p u m p

3

A u x 3

4

C o o l D ow n

5

S e e M an u al

6

N o t U se d

7

S e e M an u al

8

G a s H e ate r

O p tio n al S et

O N

C l e a ne r

2 s p d p u m p

S p a S p illo ve r

D i s a ble d

S e e M an u al

N o t U se d

S e e M an u al

H e a t P um p

F il te r P u mp R e lay

A u x . 1 R e lay

4 3 2 1 6 5 4 3 2 1

To C on tr o lle r

(r e d te rm . b a r)

R e la y S o c k e ts (2 4 V D C o u tp u t)

F.P um p A u x . 1 A u x . 2 A ux . 3

To R em ote

(b row n te rm . ba r)

A u x . 3 R e lay

A u x . 2 R e lay

To S en sor s, e tc.

(g ree n t e rm . b ar)

R e la y S o c k e ts (2 4 V D C o u tp u t)

O p t io na l R elay

R S 6 or R S8

O p t io na l R elay

R S 6 or R S8

JVA Soc k e ts

(2 4 V A C ou tp ut)

A u x . 7A u x . 6A u x . 5A ux . 4

R e la y S o c k e ts

(2 4 V DC o u tp u t)

O p t io na l R elay

R S 8

O p t io na l R elay

R S 8

B a t ter

(9 Volt )

L o w Vo lt a g e R ac e wa y ( d o n o t r u n hig h vo lt a g e w ire in th is co mp artm en t)

Lin e On e

12V - Pin1

Lin e Tw o

Lo a d O ne

Lo a d Tw o

DI-4

DI-1

DI-2

Note: Dip Switch 1 on pump must be in the ON position for this

conguration.

Note: Filter Pump Relay must be connected to DI-4 for the Spa mode

feature to function properly.

Figure 9

G r o u n din

DI-3

B ar

L1 (Black)

S y s te m Po w er

W ire N u t to

12 0 VA C P o we r

L2 (Red or White)

208-230V

Power Source

Earth

Earth

21

Page 22

3rd Party Controllers (Wiring) - continued

Wiring Diagram for Multiwave with PS165VSP

Make sure that voltage selector switch is in 120V position

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

Single pole

Breaker

before applying power to Terminals 1 & 2.

RECEIVER

POWER

SUPPLY

120V

240V

Note: Dip Switch 1 on pump must be in the ON

position for this conguration.

Figure 10

12V - Pin1

DI-1

DI-2

DI-3

L1 (Black)

L2 (Red or White)

208-230V

Power Source

Earth

Earth

22

Page 23

3rd Party Controllers (Wiring) - continued

Wiring Diagram for IntelliTouch with PS165VSP

Figure 11

12V - Pin1

DI-1

DI-2

DI-3

DI-4

L1 (Black)

L1 (Black)

L2 (Red or White)

L2 (Red or White)

208-230V

Power Source

Earth

Earth

Earth

Earth

23

Page 24

Heat Pump Pool Heater Connections (Wiring)

The PS165VSP can be connected directly to single phase or 3-phase Raypak, Rheem, Ruud, Weatherking

and Perfectemp Heat Pump Pool Heaters (HPPH) without the need for any external sequencer or

control. The HPPHs will provide an OVERRIDE signal to the pump whenever there is a Call for Heat at

the HPPH if wired as shown in these instructions. The pump will continue to operate at this OVERRIDE

speed until the HPPH thermostat has been satised.

NOTE: This direct wiring is ONLY available for R-410A Digital HPPH models produced after August

2010. The HPPH control board revisions PH2.8 and PH2.8D are the only revisions that provide this

connectivity. Verify the HPPH control board revision as shown in Figure 12 before attempting to connect

this pump to an existing Digital HPPH.

The PS165VSP pump will also connect to all Analog HPPH models (both R-410A and R-22) when

connected as shown in these instructions.

24

Figure 12 - Digital HPPH Control Board Revision

Page 25

Heat Pump Pool Heater Connections (Wiring) - continued

Digital HPPH Wiring Connections

Field wiring to Digital HPPH products will be accomplished by connecting directly to the HPPH control

board as shown below in Figure 13. A ¼” spade connection is required to connect to the HPPH control

board at the terminals marked “PUMP” as noted below. Use 18 AWG insulated stranded wire for these

connections.

COMPRESSOR

POWER DEFROST

BL

R

BL

R

USE COPPER CONDUCTORS ONLY

C

R

o

USE 75

C 600 V WIRE

TORQUE SCREWS: 40 IN-LB

S

M

INSERT B

15

16

PD

INSERT B

HEAT/COOL

15

16

RS

BK

NC NO COM L1 L2 L2

VOLTAGE

MONITOR

R

BK

21

22

23

24

3

REMOTE CONTROL

FIELD CONNECTIONS

L1 L1

R

181920

C

S

P

L1

INSERT

POWER SUPPLY

208/230V-1 PHASE-60Hz

208V

BK

R

1

O

240V 240V

TRANSFORMER

12V 12V

2 AMP

FUSE

BL

1

2

3

BL

M

121317

Y Y

HPS

LPS

WPS

FR

A

BK

BK

MOTOR

4

5

WS DS AS PS

BR/P

BR/P

O

O/R

BK

FAN

COM

SPR1

HP

FR

RR

SPR2

LP

11

10 8 6

REV

FLO

9 7

O

BK

BR

BL

NC

NO

R

P/S

COMP

W

AC F1 F2 F3

12~0~12

PUMP

INSERT B

15

16

BL

POO/RBLBL

L2

BK (TO TRANSFORMER)

R

BL

BK

RT

BK

L2

R

BL

W

R

FIELD CONNECTIONS TO

RAYPAK PUMPS

W

P

Figure 13 - Digital HPPH Wiring Connections

25

Page 26

Heat Pump Pool Heater Connections (Wiring)

Analog HPPH Wiring Connections

Field wiring to Analog HPPH products will be accomplished by connecting directly to terminals #15 and

#16 on the terminal strip located in the HPPH junction box as shown below in Figure 14. Use 18 AWG

insulated stranded wire for these connections.

SPA / REMOTE / POOL

SWITCH

SHOWN IN POOL POSITION

BL

1

A

2

3

4

5

B

6

7

8

C

9

10

11

D

12

BK

COMPRESSOR

MOTOR

FAN

USE COPPER CONDUCTORS ONLY

C

S

R

O

BK

BR

o

C 600 V WIRE

USE 75

TORQUE SCREWS: 40 IN-LB

M

BK

FR

BK R

POWER SUPPLY

208/230V-1 PHASE-60Hz

208V

1

240V 240V

TRANSFORMER

BK

FUSE

2 AMP

R

4

SPA

T

1 2 3

R

4

POOL

T

1 2 3

13 12

111014

GY/BK

GY

GY

WATER SENSOR

2

Y

HPS

9

BK

R

R

1

BR/P BR/P

24V

BK/W

A C

BK

BK BK

F

BKBK

LPS

POT 1

POT 2

TEMP. CONTROL

BOARD

C

SEN

SEN

BK/R

7 5

5

8

BK/BL

24 VAC

HOT

N.O.

24 VAC

COM

N.C.

BK BK

O/R

W

W

4

BK

WPS

BL

W

W

B

W

26

GY

T

3

REMOTE CONTROL

FIELD CONNECTIONS TO

RAYPAK PUMPS

21

22

23

24

FIELD CONNECTIONS

24 Volts AC

R

C

R/BL

S

BL/R

P

16

15

BK/R

W

Figure 14 - Analog HPPH Wiring Connections

BK/GY

E

DEFROST

SWITCH

D

BK BKBK BK

Delay Timer

62 3

T

BK/GY

W

P/BKT/BK

P

FR

W

M

W

W

Page 27

Heat Pump Pool Heater Connections (Wiring) - continued

Wiring Connections to the PS165VSP Pump

Connect the 18AWG wires from the HPPH to the PS165VSP pump as show and described below.

It does not matter which wire is connected to the IO-4 terminal

or the IGND terminal for these 24 VAC connections. While the

24 VAC connections are polarity sensitive, the digital inputs on

the VSP pump are oating and look for a differential voltage

from IO-4 to IGND. Therefore, the wiring does not matter for an

AC input signal, but will matter for a DC input signal. However,

connections to the Analog and Digital HPPH are 24 VAC signals

and so this is not an issue.

The factory default speed setting for this OVERRIDE signal

is 3450 RPM. This is to ensure sufcient water ow to ensure

proper operation of the HPPH. If optimization of this pump speed

is desired as an energy savings measure, (Refer to the Energy

Savings Operation - PS165VSP Pump Speed Optimization

Section page 13.

Figure 15 - PS165VSP Wiring Connections

5 Service and Maintenance

Routine Maintenance

This pump requires little or no service other than reasonable care and periodic cleaning of the strainer

basket.

1. Inspect the pump basket for debris by looking through the clear pump lid.

2. Turn off the power to the pump. If the pump is located below the water level, close isolation valves on

the suction and discharge sides of the pump to prevent back ow of water.

3. Remove any debris, because as the debris accumulates, it will begin to block the ow of water through

the pump. Keep the basket clean and clear to improve the performance of the pump.

4. Turn the lid’s lock ring counter clockwise until it stops. Carefully remove the lid and lock ring.

5. Remove the basket and properly dispose of the debris into the trash and rinse out the basket. Check

basket for cracks, if crack is found replace basket.

6. Replace basket back into the pump, align the basket properly with the suction pipe. Then ll with water

up to the suction pipe. Clean clear cover, lid o-ring and sealing surface of the pump of any debris.

7. Replace lid with locking ring. Hand-tighten the lid to make an air-tight seal. Do not use any tools to

tighten the lid.

27

Page 28

Routine Maintenance - continued

8. Verify that all valves have been returned to the proper position for normal operation. Turn on the power

to the pump.

Winterizing

CAUTION: The pump must be protected when freezing temperatures are expected. Allowing the pump

to freeze will cause severe damage and void the warranty.

There are two options when winterizing the pump

Option 1:

1. Drain all the water from the pump, system equipment, and piping.

2. Remove drain plugs. Do not replace plugs. Store the plugs in the empty strainer basket for winter.

3. Keep the motor covered and dry.

Option 2:

1. Drain all the water from the pump, system equipment, and piping.

2. Remove the pump and motor from the plumbing and store indoors in a warm and dry location.

Note: When the winter season is over the pump will need to be primed prior to start. Refer to Section 4

Operation, Start Up Guide.

CAUTION: DO NOT run the pump dry. If the pump is run dry, the mechanical seal will be damaged and the

pump will start to leak at the seal. If this occurs, the mechanical seal will need to be replaced. ALWAYS

maintain the proper water level in your pool. Continued operation in this manner could cause a loss of

pressure, resulting in damage to the pump casing, impeller, and mechanical seal (voiding warranty).

6 Troubleshooting

Fault LED

WARNING: The pump must be serviced by a professional service technician qualied in pool/spa

installation. The following procedures must be followed exactly. Improper installation and/or operation

can create dangerous electrical hazards, which can cause high voltage to run through the electrical

system. This can cause property damage, serious personal injury, and/or death. Improper installation

and/or operation will void the warranty.

The fault LED will be solidly on if there is a fault in the controller portion of the electronics. This can

include over temperature, over current, over/under voltage, or an open phase of the motor. The fault

LED will blink if a fault has been detected in the user interface. The motor reads the fault status every

seven seconds. The motor will stop and remain off when a fault is present. Once the fault is cleared, if the

motor was previously running, it will automatically resume running the normal schedule. During the fault

condition, the Bar graph LEDs will turn off. However, the power LED and active STEP LED will remain

illuminated. When a fault is present, only the STOP key will function. Once the fault is cleared, the fault

LED will turn off automatically.

28

Page 29

General Pump Troubleshooting

Problem Possible Cause Solution

1. Pump will not prime. A. Suction air leak

Make sure see-through lid and o-rings

are clean and properly positioned.

Hand tighten see-through lid. Tighten

all pipes and ttings on suction side

of pump. Be sure water in pool is high

enough to ow through skimmer.

B. No water in pump.

C. Closed valves or blocked lines.

D. Low voltage to motor.

2. Motor Fails to Start A. No power to motor.

B. Pump jammed

C. Controller Dip switches not congured properly

3. Motor Runs then Stops A. Over temperature fault

B. Over current fault

Make sure strainer tank is full of water.

Open all valves in system. Clean

skimmer and strainer tank. Open pump

and check for clogging of impeller.

Check voltage at motor. If low, pump

will not come up to speed.

Check that all power switches are

on. Be sure fuse or circuit breaker is

properly set. Time set properly? Check

motor wiring at terminal.

With power off, turn shaft. It should

spin freely. If not, disassemble and

repair.

Verify that the Dip switches are in the

correct position.

Check the back of the motor is free

from dirt and debris.

Motor will automatically restart after

one minute.

4. Motor is noisy A. Debris in contact with fan

B. Debris in strainer basket

C. Loose mounting

5. Low ow A. Dirty lter

B. Suction Leak

Check that the back of the motor is

free from dirt and debris.

Clean strainer basket.

Check that the mounting bolts are tight.

Back wash lter when lter pressure is

high, or clean cartridges.

See Problem 1

Blocked Impeller

WARNING: Before servicing the pump, switch off the circuit breakers at the power source. Severe

personal injury or death may occur if the pump starts while your hand is inside the pump.

1. Turn off the pump. Switch off the circuit breaker to the pump motor.

2. Remove the pump lid and strainer basket.

3. Look inside pump for debris. Remove any debris found inside.

29

Page 30

Blocked Impeller - continued

WARNING: Before servicing the pump, switch off the circuit breakers at the power source. Severe

personal injury or death may occur if the pump starts while your hand is inside the pump.

1. Turn off the pump. Switch off the circuit breaker to the pump motor.

2. Remove the pump lid and strainer basket.

3. Look inside pump for debris. Remove any debris found inside.

4. Replace the strainer basket and lid.

5. Switch on the circuit breaker to the pump motor.

6. Turn on the pump, see if the problem is resolved.

7. If the impeller is still blocked with debris and it is not possible to remove the debris using Steps 2 - 4,

the pump will need to be disassembled in order to access the inlet and outlet of the impeller.

Removal and Replacement of the Impeller and/or Mechanical Seal

WARNING: Before servicing the pump, switch off the circuit breakers at the power source. Severe

personal injury or death may occur if the pump starts while your hand is inside the pump.

1. Turn off the pump. Switch off the circuit breaker to the pump motor. If you are not replacing the motor,

do not disconnect the electrical wiring.

2. Turn off any valves to prevent pool water from reaching the pump. Drain water from the pump by

loosening the unions or removing the drain plugs.

3. Remove the ten (10) screws connecting the pump casing to the ange.

4. Pull the motor, seal housing, ange out from the pump casing. Remove the pump casing o-ring. The

impeller is connected to the motor shaft.

5. Remove the diffuser by gently pulling the diffuser (the

diffuser is the cover over the impeller) horizontally until

the pins clear the seal housing.

6. Place a 5/16” Allen head wrench through the center

hole of the fan cover and into the recess on the end of

Impeller

Ceramic Ring

Shaft

Rubber Collar

motor shaft.

7. While holding the motor shaft, turn the impeller counter-

Spring

Assembly

Sealing

Surfaces

clockwise.

Figure 16

Pump Seal Housing

8. Gently pull the mechanical seal from the impeller shaft noting the way it was originally installed.

CAUTION: Do not damage the ceramic or carbon surfaces of the seal. If the surfaces are damaged,

leaks will occur.

9. Using water with a small amount of dish soap, brush the impeller shaft for ease of assembly.

30

Page 31

Removal and Replacement of the Impeller and/or Mechanical Seal - continued

10. With the carbon side up, push the mechanical seal onto the impeller shaft and wipe carbon surface

with a clean cloth.

CAUTION: Do not use grease or lube to install seal. It will damage the seal and cause failure.

11. The ceramic side of the seal can be pushed out from the rear of the seal housing. Please note its

position before removing.

12. Using water only, wet the ceramic side of the seal and using your thumbs push into the seal housing.

Clean surface with a clean cloth.

13. Wipe the motor shaft of all debris. Re-install the seal housing and apply a single drop of Loctite to

the motor shaft threads.

14. Install impeller by spinning it clockwise onto the motor shaft. Continue to turn clockwise until the

carbon and ceramic sides make contact and the seal spring slightly compresses.

15. Install the diffuser by aligning the diffuser pin with the holes in the seal housing and pressing together.

16. Make sure the diffuser and casing o-rings are in place and free of debris. Reassemble in reverse,

sliding the seal housing back into the casing.

17. Tighten (torque of 8 Nm or 70.8 in-lb.) the ten (10) screws using a cross pattern from side to side and

top to bottom.

CAUTION: Do not over-tighten or you will strip the casing threads.

Motor Replacement

WARNING: The pump must be serviced by a professional service technician qualied in pool/spa

installation. The following procedures must be followed exactly. Improper installation and/or operation

can create dangerous electrical hazards, which can cause high voltage to run through the electrical

system. This can cause property damage, serious personal injury, and/or death. Improper installation

and/or operation will void the warranty.

1. Disconnect the wiring from the side of the motor. (Refer to the Electrical Installation)

2. Remove the ten (10) screws holding the ange to the pump casing.

3. Slide the motor and ange from the casing.

4. Remove the diffuser by gently pulling the diffuser horizontally until the pins are clear from the seal

housing.

5. Place a 5/16” Allen head wrench through the center hole of the fan cover and into the recess on

the end of the motor shaft.

6. While holding the motor shaft, turn the impeller counter-clockwise.

7. After removal of the impeller, the seal housing will slide easily off the motor shaft.

8. Using a athead screwdriver, remove the four bolts and washers securing the ange to the motor.

31

Page 32

Motor Replacement - continued

9. Remove the motor ange from the face of the old motor and install on the new motor.

10. Clean the surfaces of the seal (Refer to the Removal and Replacement of the Impeller and/or

Mechanical Seal Section page 30-31 steps 9 -17). Reverse the process for installation.

7 Product Specications

Dimensional Drawing

27.1"

8.9"

Performance Curve

12.1"

16.6"

17.0"

3450 RPM

80

70

3100 RPM

60

2850 RPM

50

2600 RPM

40

2350 RPM

TOTAL HEAD IN FEET

30

2100 RPM

1850 RPM

20

1600 RPM

1350 RPM

10

1100 RPM

850 RPM

600 RPM

0

13.6"

4.3"

B

A C

20 40 60 80 100 120 140 160

GALLONS PER MINUTE

B, A, and C represent average system curves for pools

with the pipe diameter mentioned below.

1

/

2” Pipe A = 2” Pipe C = 2

B = 1

1

/

2” Pipe

6.8"

12.7"

0.4"

5.1"

6.9"

9.7"

32

Page 33

Replacement Parts and Exploded View

20

1

CLOSE

FERMER

ZU

AUF

OUVRIR

OPEN

2

3

5

4

6

7

5

6

14

15

7

8

9

16

10

12

11

17

13

19

18

KIT NUMBER CALL-OUT QTY DESCRIPTION

014329F 1 1 LID LOCK RING - DARK GRAY

014328F 2 1 LID - CLEAR

014330F 3 1 O-RING - LID 137 x 5mm

014331F 4 1 BASKET - WHITE ONE PIECE

014344F 5 NUT - UNION ABS

014354F 6 2

014355F 7 2 O-RING - UNION 68 X 3.5mm

014332F 8 1 CASING

014333F 9 1 DRAIN CAP - DARK GRAY (3/8”) WITH GASKET - CASING

014336F 10 1 O-RING - DIFFUSER 90 x 5mm

014337F 11

014338F 1 IMPELLER 1.65 HP 124 / 5.0mm

014339F 13 1 MECHANICAL SEAL (20mm) - COMPLETE

014340F 14 1 O-RING - CASING 206 x 6mm

014341F 15 1 SEAL HOUSING 49mm

014335F 16 10 SCREW - CASING 3/8 HEX/SLOT M7 x 48mm SS

014334F 17 3 LEGO SPACER

014342F 18 1 FLANGE

014343F 19 4 SCREW - 3/8 -16 X 2” SLOTTED

014345F 20

12

2

UNION END - 2” ABS

1 DIFFUSER

SPANNER - LID 1

33

Page 34

Notes

34

Page 35

Page 36

2999999292 - Rev 01/2013 v1

Loading...

Loading...