Page 1

INSTALLATION INSTRUCTIONS

Flow Switch

&

Temperature/

Pressure

Gauge

For Atmospheric

Models C-R206AE-406AE

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids or other

combustible materials in the vicinity of this or any other appliance. To do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

NOTE: Not for use with millivolt units.

Models C-R207AE-407AE

For Low NOx

Catalog No. 6000.59.1B Effective: 03-08-12 Replaces: 03-28-07 P/N 241309 Rev. 3

Page 2

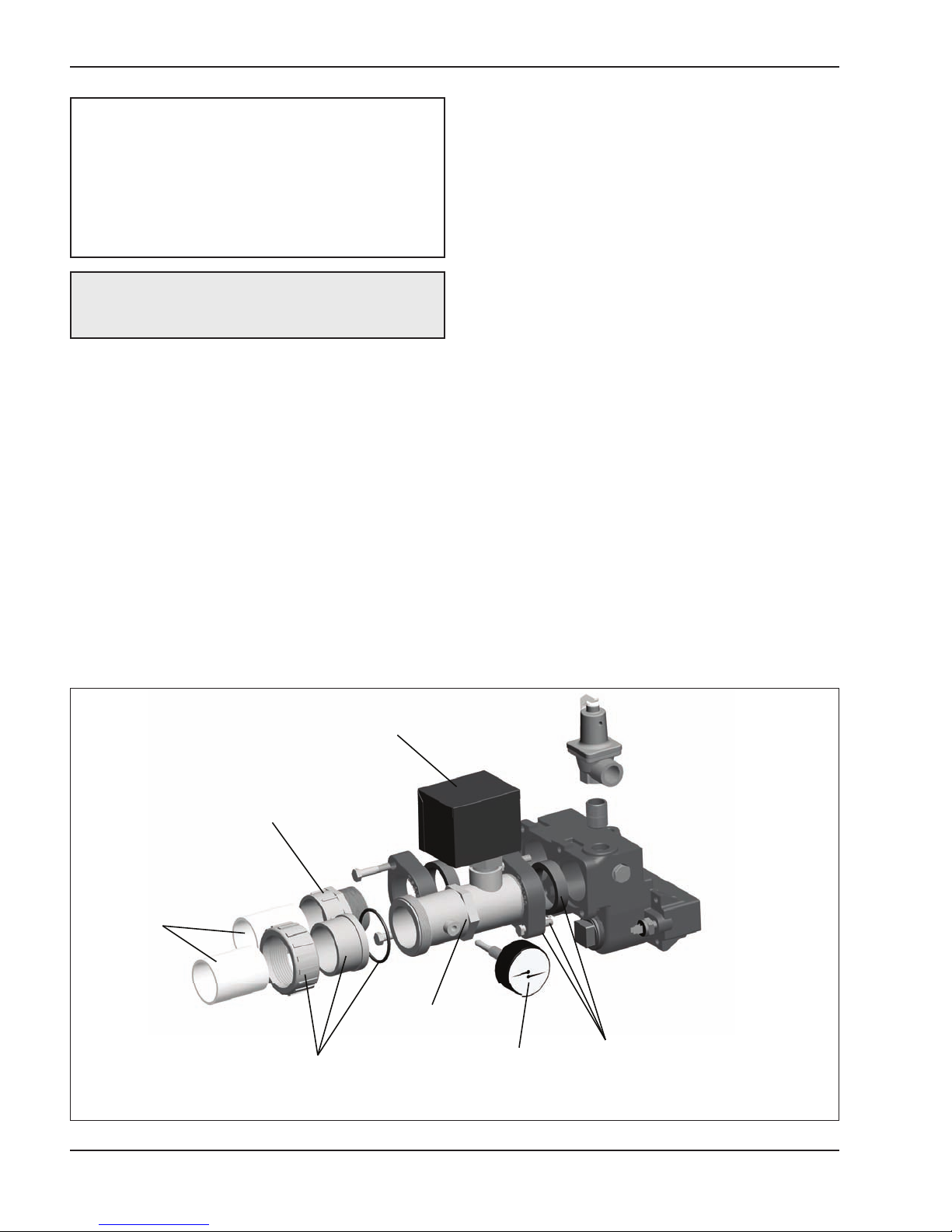

NOTE: These instructions are intended primarily for

PLUMBING

CPVC TAILPIECE

O-RING & RING NUT

(SUPPLIED)

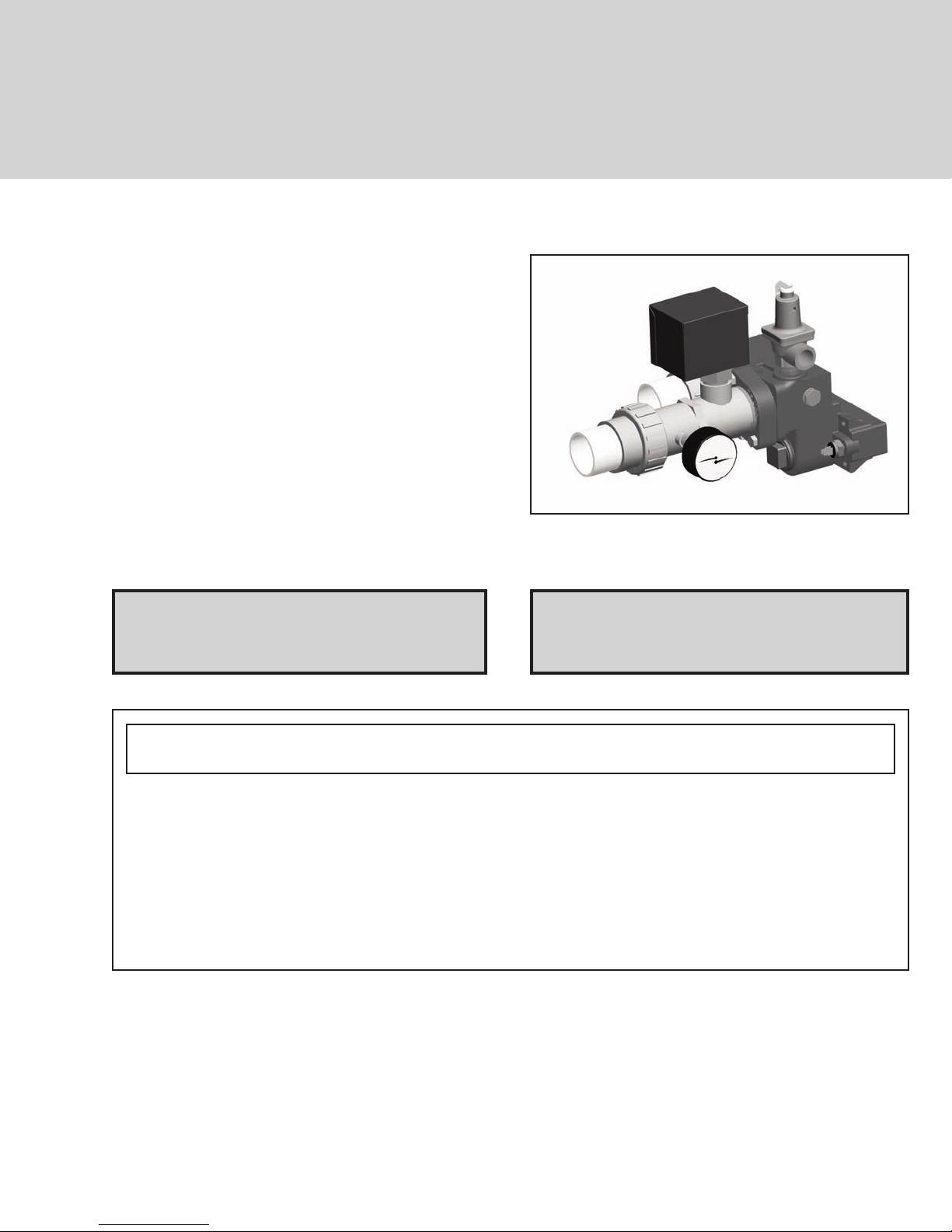

CPVC MANIFOLD

(SUPPLIED)

T&P GAUGE

(SUPPLIED)

GASKETS, FLANGES

& BOLTS

(WITH ORIGINAL EQUIPMENT)

FLOW SWITCH COVER

(SUPPLIED)

MALE CPVC CONNECTOR

(WITH ORIGINAL EQUIPMENT)

use by qualified personnel specifically trained and

experienced in the installation of this type of heating

equipment and related system components.

Installation and service personnel must be licensed

in some states. Persons not qualified shall not

attempt to install this equipment nor attempt repairs

according to these instructions.

Before Starting

1) Turn off power to the heater at the circuit breaker.

2) Turn off gas supply.

3) Shut off the water supply to the heater.

DANGER - SHOCK HAZARD: Make sure electrical power to the heater is disconnected to avoid

potential serious injury or damage to components.

Kit Contents

Each kit includes:

(1) Temperature and Pressure gauge

(1) Pre-wired Flow Switch with outdoor cover

(2) Paddles

(1) Screw, #6-32 x 3/16

(1) 2” CPVC Tailpiece Connector

(1) 2” CPVC Manifold Adapter

(1) O-Ring

(2) Female spade terminals

(1) Ring nut

This kit is primarily intended for jurisdictions requiring

the addition of a flow switch and/or temperature and

pressure gauge on pool heaters.

4) Allow heater to cool down before attempting work.

INSTALLATION

1. Remove main front panel door and set aside.

2. Remove the front control panel screws (2 each

located at the ends of the panel). Lower front

panel to expose the main circuit board.

3. Remove transformer cover located on either the

upper right or left side.

4. Locate conduit opening above power conduit

opening on the waterside of the heater.

5. Locate the Inlet/Outlet header.

6. Install 2” flanges to header ports, if not already

installed.

Fig. 1: Flow Switch and Temperature and Pressure Gauge

2

Page 3

7. Locate and install the 2” CPVC manifold adapter

CONDUIT ENTRANCE

(Longer paddle)

(Shorter paddle)

Models Models

Paddle

Size

1.88” LG 1.8” LG

206, 207

266, 267

366, 367

406, 407

Paddle

ID

“F” “A”

CUT THE WHITE JUMPER LABELED “SPARE”

onto the Outlet side (see Fig.1). Careful not to strip

the threads on the manifold adapter.

8. Locate the flow switch, (2) paddles and (1) #6-32

screw.

9. Using a Phillips screw driver, install the correct

paddle size to the flow switch.

10. Install flow switch onto manifold adapter.

11. Be sure to verify the flow switch is positioned correctly to sense the proper direction of the water

flow, out of the heater.

a. The arrow on the flow switch indicates the

direction of flow.

12. Locate and install the flow switch cover, if not

already installed.

13. Locate and install the T&P gauge on the side of

the manifold adapter (see Fig.1).

14. Use the CPVC tailpiece, o-ring and ring nut to connect to your outlet plumbing.

15. Using the original equipment male CPVC connector, install your inlet plumbing.

16. Locate the pre-wired hard conduit off the flow

switch and route through the upper control panel

as indicated in Fig 2.

17. Cut the white “spare” jumper located on the back

of the circuit board in the upper control panel. See

Fig. 3.

18. Strip 1/4" of insulation from each end of the white

“spare” jumper cut in the previous step. Install and

crimp a female spade connector (supplied in kit)

on each stripped end.

a. Ensure the connectors being crimped are of

the proper size and shape to accept the connectors on the end of the wire harness.

b. Ensure the crimp is tight.

Fig 2: Transformer Box

Fig 3: Cutting the Jumper Wire

3

Page 4

19. Plug the connectors from the flow switch wire har-

www.raypak.com

FLOW SWITCH WIRES

CONNECTED TO “SPARE” JUMPER

ness into the connectors just installed on the white

“spare” jumper. See Fig. 4.

20. Reinstall the sheet metal transformer cover.

21. Close front control panel and reinstall the four

screws (two at each end).

22. Reinstall front main panel door onto the heater.

23. Turn water on to the heater and check for leaks.

a. If leaks are found, repair immediately.

24. Turn on gas to the heater.

25. Turn on power to the heater.

26. Cycle the heater a few times to verify flow switch

operation.

Fig 5: Completed Assembly

Fig 4: “Spare” Jumper Connections

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

4

Loading...

Loading...