Raypak CHX-1000-10 Installation Manual

INSTALLATION & OPERATING

L

W

INSTRUCTIONS

Condensing Heat Exchanger (CHX)

Models 500, 750, 1000, & 1500

FFoorr HHii DDeellttaa MMooddeellss

440022BB––22000022BB

WARNING: If the information in these instructions are not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

CATALOG NO. 1000.56C Effective: 02-19-10 Replaces: 09-28-07 P/N 241007 Rev. 4

Rev. 4 reflects the following:

Changes to: Figures 3-8 on pages 8-11, Figures 11-19 on pages 15-19, Table D on page 20, Table E on page 24, Table F

on page 30.

Additions: California low-lead requirements on page 6, Replacement Parts information on pages 34 and 35.

2

CONTENTS

WARNINGS 4

GENERAL SAFETY 5

Time/Temperature Relationships in

Scalds 5

INTRODUCTION 6

Unpacking 6

INSTALLATION 6

Installation Codes 6

Equipment Base 6

Clearances 7

Combustion and Ventilation Air 7

CONNECTING THE CHX 7

VENTING CONNECTIONS 12

Appliance Categories 12

Support of Vent Stack 13

Vent Terminal Location 13

U.S. Installations 14

Installations in Canada 14

Venting Installation Tips 14

Venting Configurations 14

CONTROLS 19

Optional CHX Flow Switch 20

PVC/CPVC Vent Switch 20

WATER CONNECTIONS 20

Relief Valve Piping 21

Hydrostatic Test 21

Hydronic Heating 21

Domestic Hot Water 24

POOL HEATING 26

Automatic Chlorinators and Chemical

Feeders 26

Winterizing Your Heater 26

Pool and Spa Water Chemistry 27

OPERATION 29

Pre Start-Up 29

Start-Up 29

Post Start-Up Check 30

MAINTENANCE 30

Daily 30

Monthly 30

Periodically 31

Yearly 31

Cleaning the CHX Heating Surface 31

APPENDIX 33

Inside Air Contamination 33

REPLACEMENT PARTS 34

3

WARNINGS

Pay Attention to These Terms

ndicates the presence of immediate hazards which will cause severe

DANGER:

I

personal injury, death or substantial property damage if ignored.

WARNING:

CAUTION:

NOTE:

WARNING: Do not use this heater that this CHX is

attached to if any part has been under water.

Immediately call a qualified service technician to

inspect the heater and to replace any part of the

control system and any gas control which has been

under water.

WARNING: To minimize the possibility of improper

operation, serious personal injury, fire, or damage to

the heater:

• Heater should never be covered or have any

blockage to the flow of fresh air to the heater.

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

CAUTION: If this heater is to be installed above

radiation level, it must be provided with a low water

cut-off device at the time of heater installation.

4

GENERAL SAFETY

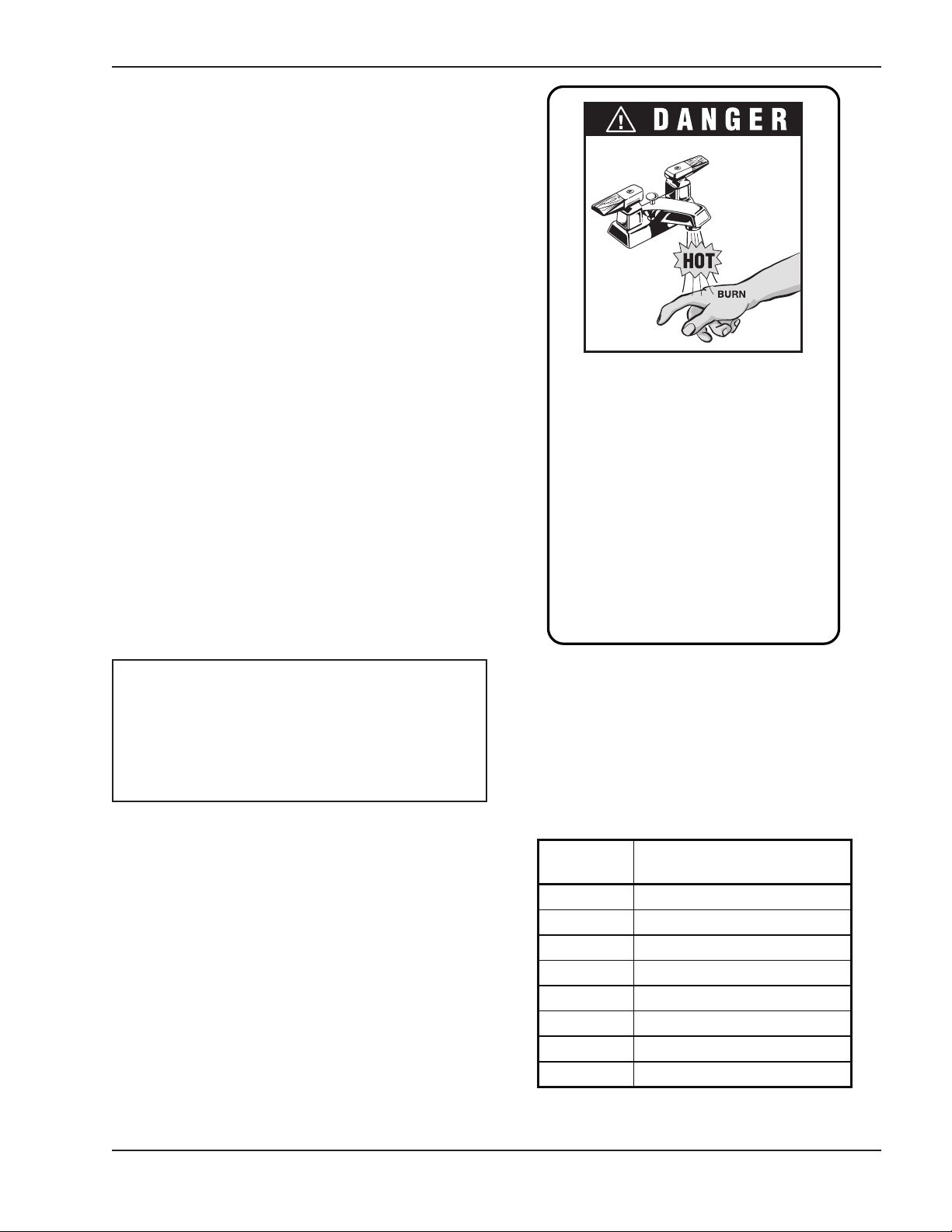

Water temperature over 125°F can

cause instant severe burns or death

from scalds.

Children, disabled, and elderly are

at highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are

available, see manual.

Water

Temp.

Time to Produce Serious

Burn

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table courtesy of The Shriners Burn Institute

To meet commercial hot water use needs, the high

limit safety control on this water heater is adjustable up

to 210°F. However, water temperatures over 125°F

can cause instant severe burns or death from scalds.

When supplying general purpose hot water, the recommended initial setting for the temperature control is

125°F.

This section applies to Hot Water Supply Boilers and

Hot Water Heaters ONLY. For sanitary rinse applications where outlet temperatures of 180°F to 195°F are

required, a boiler is recommended since the 210°F

limit on water heaters will NOT allow the heater to

maintain these desired sanitary rinse temperatures.

Safety and energy conservation are factors to be considered when setting the water temperature on the

thermostat. The most energy-efficient operation will

result when the temperature setting is the lowest that

satisfies the needs of the application.

Water temperature over 125°F can cause instant

severe burns or death from scalds. Children, disabled

and elderly are at highest risk of being scalded.

• Feel water before bathing or showering.

• Temperature limiting valves are available.

NOTE: When this water heater is supplying general

purpose hot water for use by individuals, a

thermostatically controlled mixing valve for reducing

point of use water temperature is recommended to

reduce the risk of scald injury. Contact a licensed

plumber or the local plumbing authority for further

information.

Maximum water temperatures occur just after the

heater’s burner has shut off. To determine the water

temperature being delivered, turn on a hot water

faucet and place a thermometer in the hot water

stream and read the thermometer. Consult the Hi

Delta Installation and Operation Instructions (Catalog

Numbers 1000.501 or 1000.511) for control and hot

water requirements.

Time/Temperature

Relationships in Scalds

The following chart details the relationship of water

temperature and time with regard to scald injury and

may be used as a guide in determining the safest

water temperature for your applications.

Table A: Time to Produce Serious Burn

5

INTRODUCTION

anties. Altering the agency ratings of the vessel also

r

violates national, state, and local approval codes.

Raypak strongly recommends that this manual be

reviewed thoroughly before installing your Raypak

heater. Please review the Safety section before

installing the heater. The factory warranty does not

apply to heaters that have been improperly installed or

operated; refer to the Warranty section.

Installation and service must be performed by a qualified installer, service agency, or gas supplier. If, after

reviewing this manual, you still have questions which

this manual does not answer, please contact your local

Raypak representative or Raypak corporate headquarters.

Thank you for purchasing a Raypak product. We hope

you will be pleased with the high quality and durability

of our equipment.

This manual applies only to CHX systems in conjunction with a Hi Delta heater, sizes 402B-2002B. It does

not cover either the installation or operation of a Hi

Delta heater that is not CHX-equipped. For those units

refer to the manual shipped with the heater.

INSTALLATION

WARNING: Improper installation, adjustment,

alteration, service or maintenance may damage the

equipment, create a hazard resulting in

asphyxiation, explosion or fire, and will void the

warranty.

These instructions are intended only for use by qualified personnel, specifically trained and experienced in

the installation of this type of heating equipment and

related system components. Installation and service

personnel may be required by some states to be

licensed. If your state is such, be sure your contractor

bears the appropriate license.

Persons not qualified shall not attempt to fix this equipment nor attempt repairs according to these

instructions.

Installation Codes

Unpacking

On receipt of your CHX it is suggested that you visually check for external damage to the shipping crate. If

the crate is damaged, make a note to that effect on the

Bill of Lading when signing for the shipment. Remove

the CHX from the shipping packaging. Report any

damage to the carrier immediately.

On occasion, items are shipped loose. Be sure that

you receive the correct number of packages as indicated on the Bill of Lading.

Claims for shortages and damages must be filed with

the carrier by consignee. Permission to return goods

must be received from the factory prior to shipping.

Goods returned to the factory without an authorized

Returned Goods Receipt number will not be accepted.

All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and

serial number of the heater. When ordering under warranty conditions, you must also specify the date of

installation.

Purchased parts are subject only to replacement

under the manufacturer’s warranty. Debits for defective replacement parts will not be accepted and will

only be replaced in kind per Raypak’s standard war-

Installations must follow these codes:

• Local, state, provincial, and national codes, laws,

regulations and ordinances

• National Fuel Gas Code (NFGC), ANSI Z223.1latest edition

• For Canada only: CAN/CGA B149.1 and .2

Installation Code and C.S.A. C22. 1 C.E.C. Part 1

• CSA verified compliance with California AB1953

and Vermont Legislative Act 193 requirements.

Equipment Base

The CHX should be mounted on a level, structurally

sound surface. The CHX is approved for and can be

installed on a combustible surface but must NEVER

be installed on carpeting. Gas-fueled equipment

installed in enclosed parking garages must be located

at least 18 in. above the floor.

CAUTION: The cap should be located in an area

where water leakage will not result in damage to the

area adjacent to the heater or to the structure. when

such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the CHX.

The CHX must be mounted on a rack for connection to

the Hi Delta heaters. The following racks will allow

6

nstallation of the CHX either directly behind the Hi

i

Delta heater OR above the Hi Delta heater. These

racks are shown throughout this manual.

009528 - CHX Rack Kit for 402B - 902B Hi Delta

•

• 009529 - CHX Rack Kit for 992B - 2002B Hi Deltas

NOTE: The CHX does not require air for

combustion. Consult the Hi Delta Installation and

Operation Instructions (Catalog Number 1000.501 or

1000.511) for combustion air requirements for the

eater itself.

h

In addition to the racks noted above, an integral rack

is available factory-mounted to the appropriate CHX.

These are available using the following part numbers:

• 011640 - CHX/Rack Kit Short 402B/502B

• 011641 - CHX/Rack Kit Short 652B

• 011642 - CHX/Rack Kit Short 752B/902B

• 011643 - CHX/Rack Kit Short 992B

• 011644 - CHX/Rack Kit Short 1262B

• 011645 - CHX/Rack Kit Short 1532B

• 011646 - CHX/Rack Kit Short 1802B/2002B

Dimensional data for the CHX can be found on the

submittal sheets, Cat. No. 1000.81.

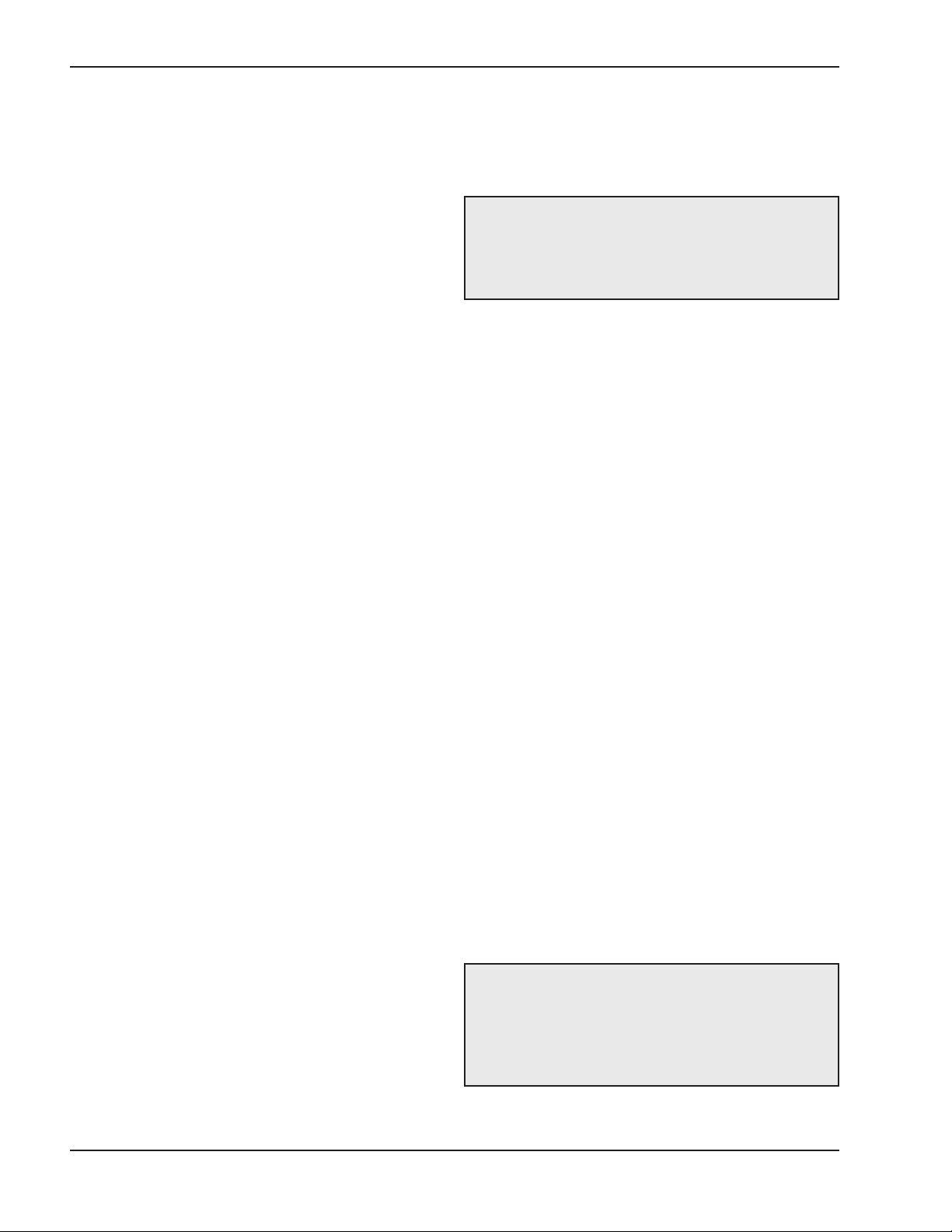

Clearances

Heater Side Min. Clearance

from Combustible

Surfaces

Floor* 0" 0"

Rear 0" 0"

Right

(Water Inlet)

Left (Water

Outlet)

Top 0" 36"

Vent 1" 1"

0" 12"

0" 12"

Recommended

Service

Clearance

and equipment ventilation. All installations must comply with the requirements of the NFGC (U.S.) and

B149 (Canada), and all local codes.

NOTE: In calculating free area, the required size of

openings for combustion, ventilation, and dilution air

shall be based on net free area of each opening. If

the free area through a design of louver or grill is

known, it shall be used in calculating the size

opening required to provide the free area specified.

For additional information, refer to the latest NFGC

requirements.

CONNECTING THE CHX

NOTE: Connect the vent before connecting the

water piping.

Install unions on water inlet and outlet of CHX for ease

of maintenance. The CHX requires cleaning as often

as once per year.

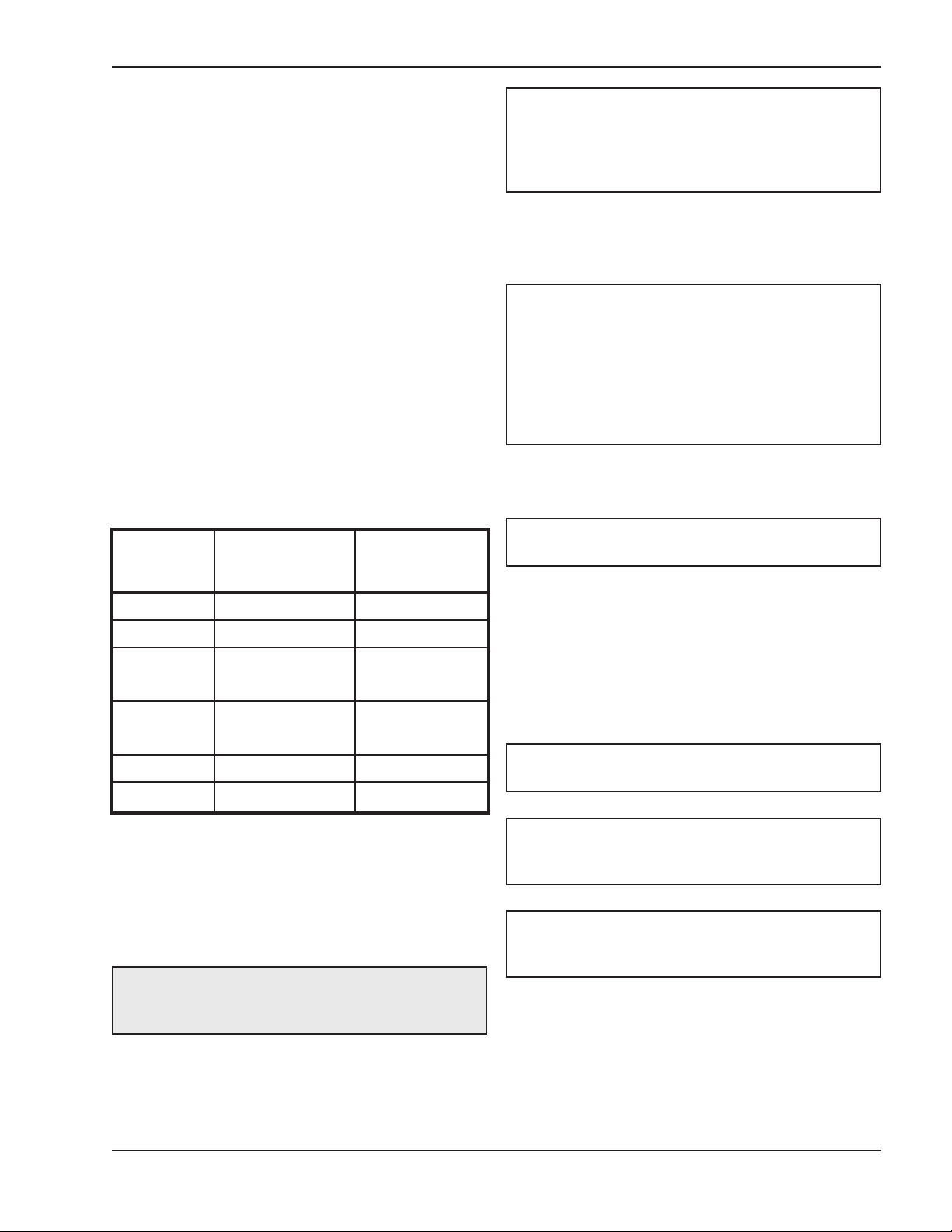

Typical Hi Delta connections to CHX are shown in

Figures 1 through 8. Hi Temp RTV (GE 106 or equivalent) is required to seal the vents as shown in Figures

9 and 10.

NOTE: Assembly instructions for racks are included

with rack kits.

*Do not install on carpeting.

Table B: Clearances - Indoor, Alcove and Outdoor

Installations.

Raypak CHXs are design certified by ANSI/CSA for

outdoor installation. Roof water drainage must be

diverted away from heaters installed under overhangs.

WARNING: Do not install the CHX outdoors if

freezing conditions are typical. The condensate will

freeze and back up the flue system.

Combustion and Ventilation Air

This heater must be supplied with sufficient quantities

of non-contaminated air to support proper combustion

NOTE: It is reccomended that the vent adapters be

preassembled without RTV to ensure proper

orientation and fit.

NOTE: Refer to the Heatfab Saf-T Vent CI Plus

Installation and Maintenance Instructions (PI-CCINS

020607) for specific vent assembly instructions.

Connecting the CHX to the heater:

1. Apply a bead of high temp RTV within approximately 1/4 in. of the edge of the CHX Vent Inlet

Adapter, then assemble it to the Heater Vent

Outlet Adapter ensuring that the band clamp tabs

are aligned (see Fig. 1). Attach and tighten the

band clamp.

7

Apply RTV

Here

Band Clamp Tabs

(D-27)

(D-28)

NOTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

NOTE 3 - NOT APPROVED FOR SYSTEMS WITH RETURN TEMPERATURES

BETWEEN 120°F AND 140°F.

(SEE NOTE 2)

(SEE NOTES 1 & 3)

CHX/Heater Vent

dapter Assembly

A

(D-27/D-28)

Hi Delta Exhaust

utlet

O

Apply RTV

Here

Fig. 1: Connect the CHX Vent Inlet Adapter to the

Heater Vent Outlet Adapter

2. Apply a bead of high temp RTV within approximately 1/4 inch of the edge of the CHX Exhaust

Inlet. Install the CHX/Heater Vent Adapter

Assembly, created in step 1, onto the CHX

Exhaust Inlet (vent adapter must overlap onto

exhaust inlet/outlet by at least 1/2 in.) and secure

by tightening the hose clamp provided. Refer to

the bottom of Fig. 2.

3. Position the CHX so that the CHX/Heater Vent

Adapter Assembly aligns with the Hi Delta Exhaust

Outlet and install as described in step 2. See top

of Fig. 2.

CHX Outlet Vent

dapter (D-18)

A

CHX/Heater Vent

Adapter Assembly

(D-27/D-28)

Apply RTV

Here

Fig. 2: Proper Orientation of Vent Adapters for

Installation, Hi Delta Exhaust Outlet (Top) and CHX

Inlet/Outlet (Bottom)

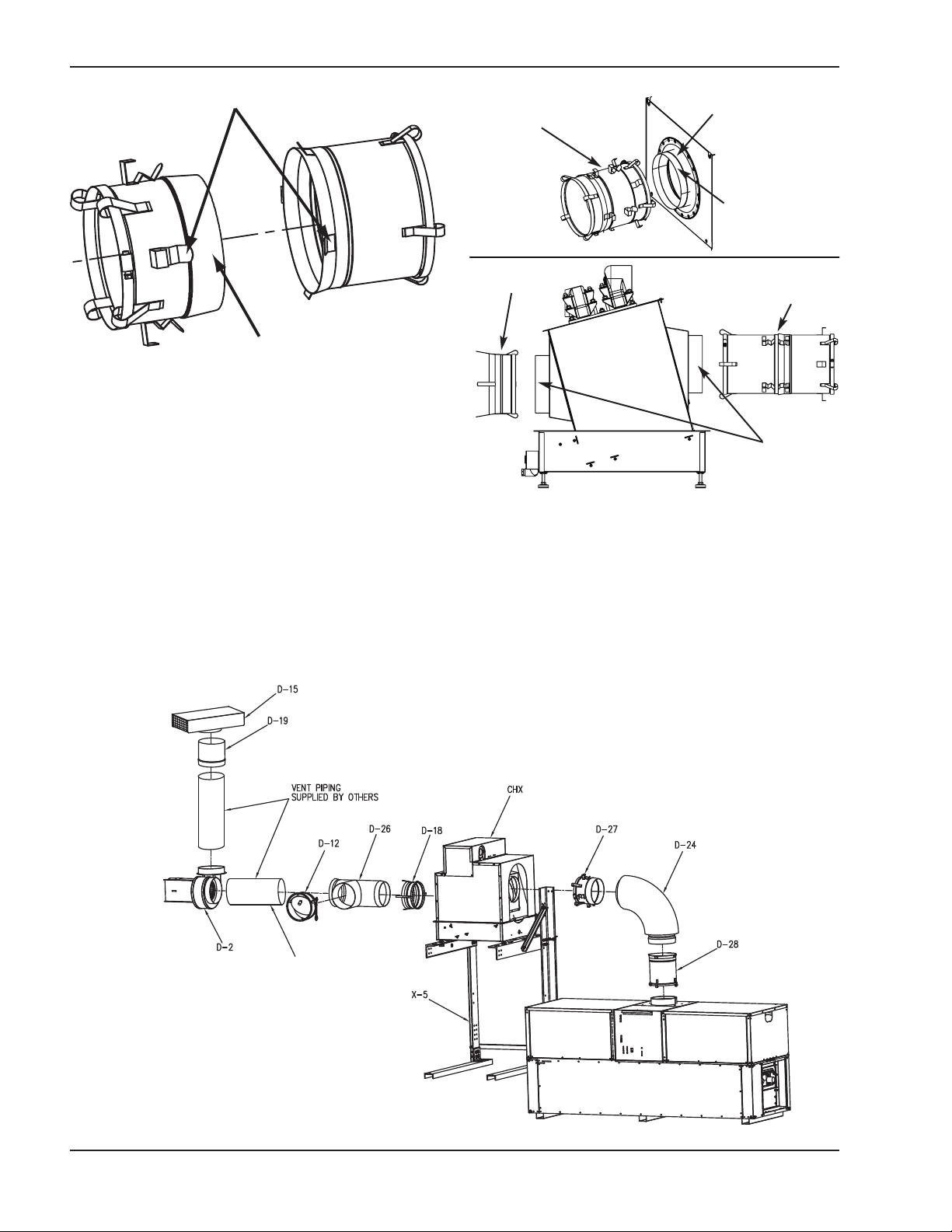

4. Install the CHX Outlet Vent Adapter (see Fig. 2)

and then install venting and water piping according to your installation. See Fig. 3 through 10 for

more information about various CHX configurations. Refer to the following sections for specific

information about venting and water piping.

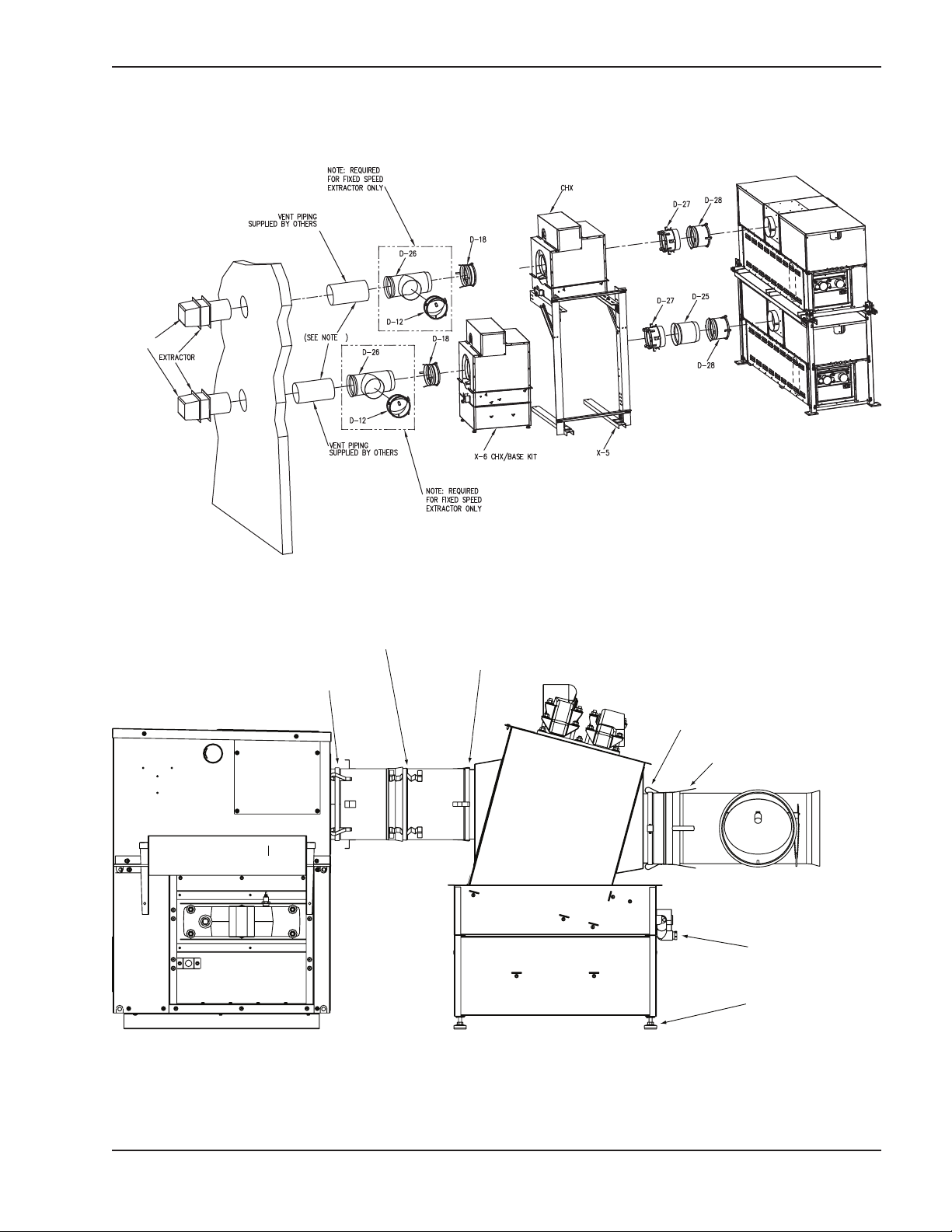

Fig. 3: Hi Delta with Top-Mounted CHX and Power Venter

8

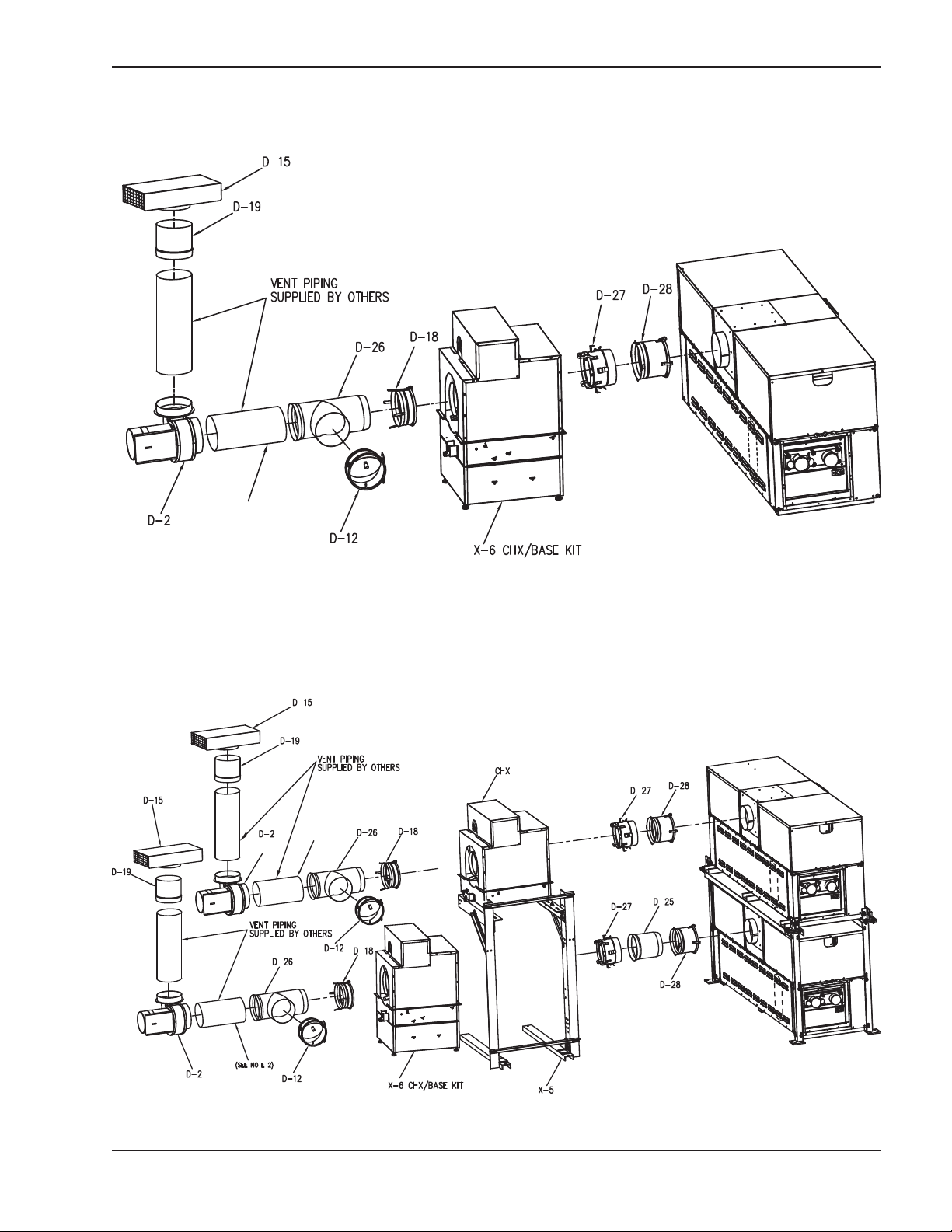

N

OTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

NOTE 3 - NOT APPROVED FOR SYSTEMS WITH RETURN TEMPERATURES

BETWEEN 120°F AND 140°F.

(SEE NOTE 2)

(SEE NOTES 1 & 3)

Fig. 4: Hi Delta with Rear-Mounted CHX and Power Venter

NOTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

NOTE 3 - NOT APPROVED FOR SYSTEMS WITH RETURN TEMPERATURES

BETWEEN 120°F AND 140°F.

(SEE NOTE 2)

(SEE NOTES

1 & 3)

(SEE NOTES 1 & 3)

Fig. 5: Stacked Hi Deltas with Rear-Mounted CHXs and Power Venters

9

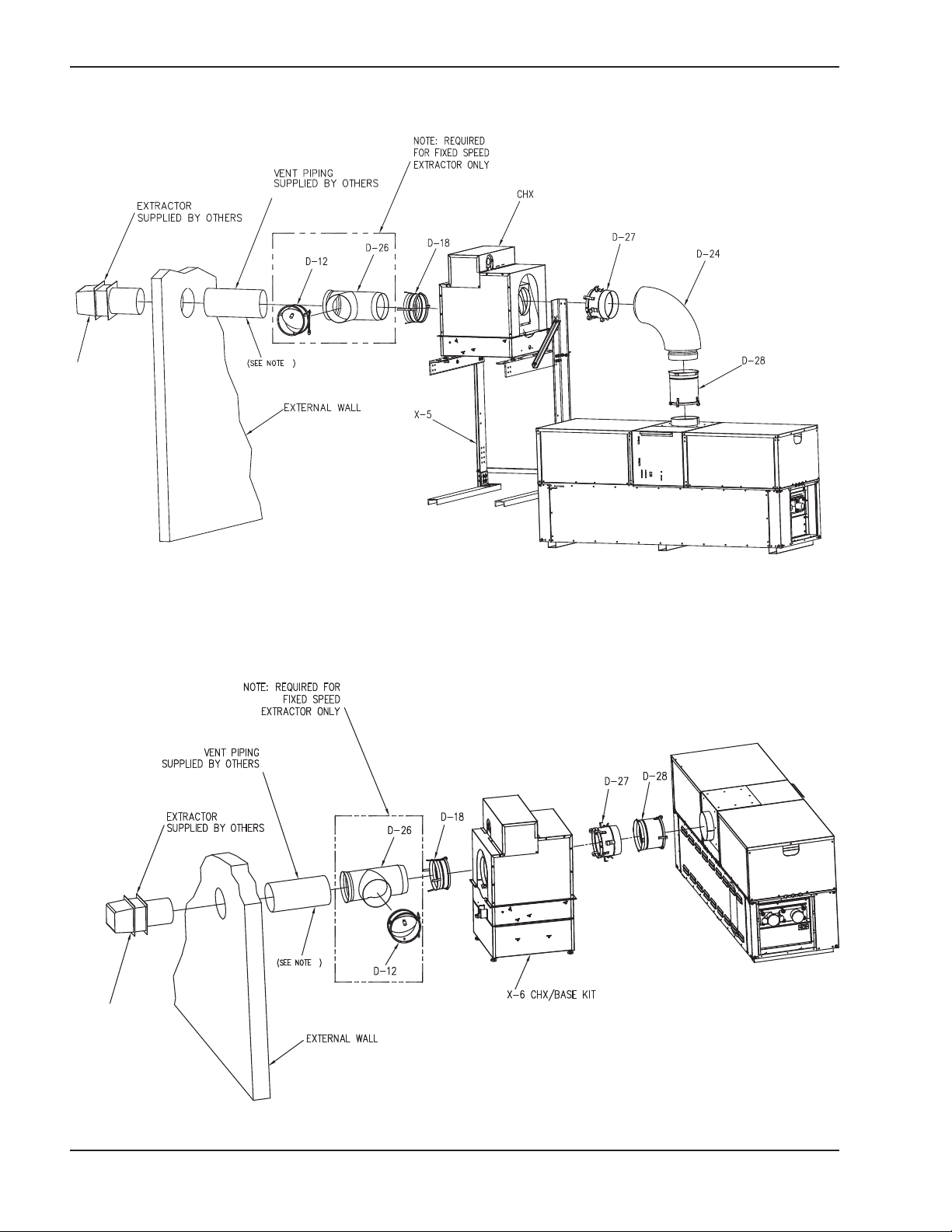

1

NOTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

(SEE NOTE 2)

1

NOTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

(SEE NOTE 2)

Fig. 6: Hi Delta with Top-Mounted CHX and Extractor

Fig. 7: Hi Delta with Rear-Mounted CHX and Extractor

10

1

NOTE 1 - FIELD-SUPPLIED TRANSITION ADAPTER MAY BE REQUIRED

NOTE 2 - LOCKABLE BALANCING OR BLAST BAFFLE MAY BE REQUIRED

BETWEEN THE BAROMETRIC DAMPER AND POWER VENTER/EXTRACTOR

TO CONTROL EXCESS DRAFT.

(SEE NOTE 2)

Fig. 8: Stacked Hi Deltas with Rear-Mounted CHXs and Extractors

CONDENSATE DRAIN

ADJUST AS NECESSARY

HI TEMP RTV THIS JOINT

HI TEMP RTV THIS JOINT

HI TEMP RTV THIS JOINT

TIGHTEN LOCKING STRAP

FOLD FLAPS

NOTE: CHX flue in/out may be different for different models based on:

• Vertical location

• General appearance

• With or without added extensions

Fig. 9: Sealing Rear-Mounted CHX on the Hi Delta

11

Loading...

Loading...