Page 1

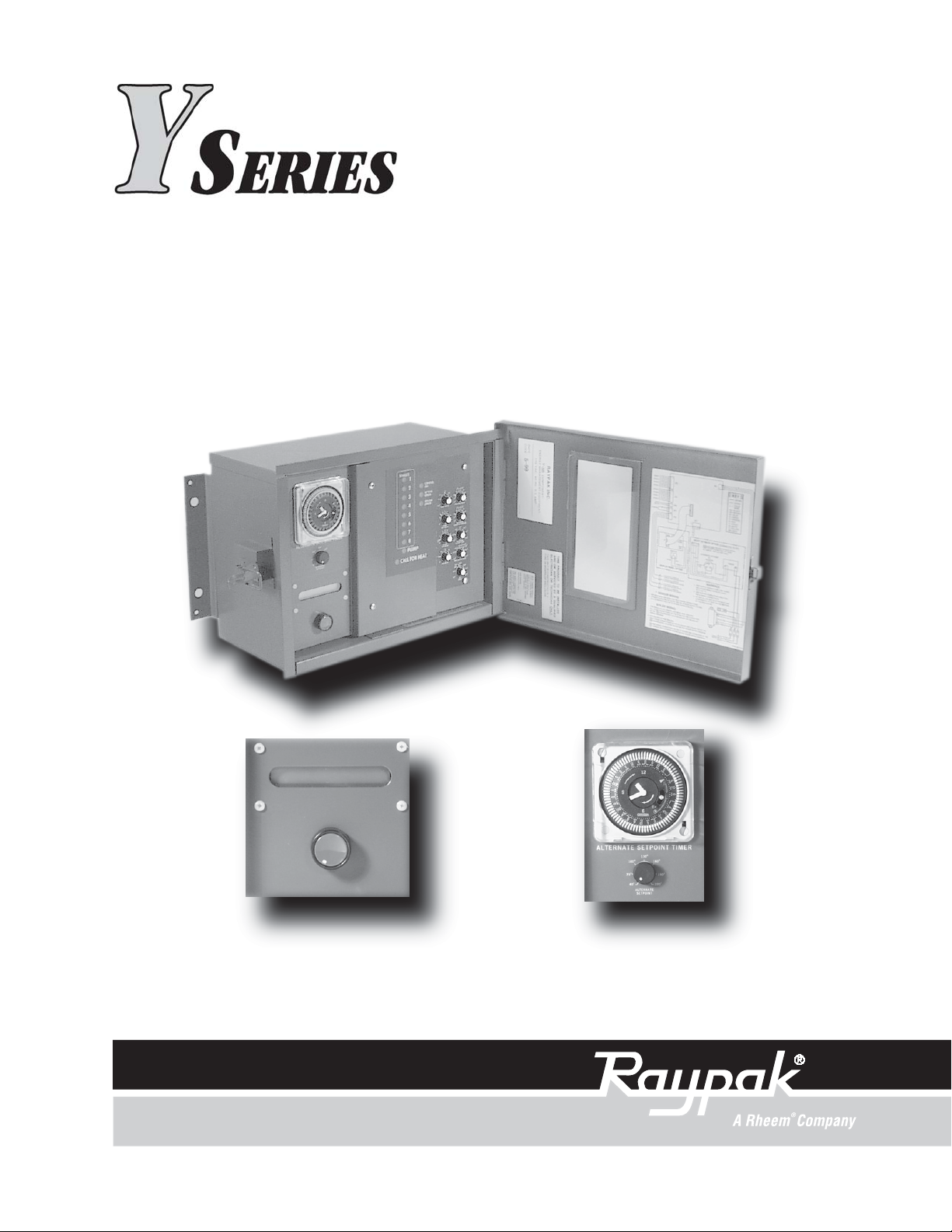

ELECTRONIC BOILER

SEQUENCER & OUTDOOR

RESET CONTROLLER

Catalog No: 5000.54H

Effective: 06-19-07

Replaces: 02-01-04

Installation and Operating Instructions

PN 240692 Rev . 9

Page 2

Y–SERIES ELECTRONIC BOILER CONTROL

Installation and Operating Instructions

is a registered trademark of Underwriters Laboratories Inc.®

is a registered trademark of Underwriters Laboratories-Canada Inc. ®

Before operating this product, please read these instructions completely.

2

Page 3

TABLE OF CONTENTS

Contents Page

Basics 4

Important Safety Instructions 4

Introduction 5

Concept of Operation 5

Optional Configurations 5

Control Features 6

Installation and Mounting 7

Mechanical Installation 7

Electrical Installation 7

Wiring: Power to Controller 8

Air Temperature Sensor 9

Water Temperature Sensor Installation 10

Hydronic Installations 10

Domestic Hot Water Installations 11

Pool Heating Installations 12

Field Wiring 13

Power Test 14

Control Familiarization 15

Sequence of Operation 16

Manual Override 16

Indicator Lights 18

Control Functions 19

Reset Ratio Chart 19

Circuit Board 23

Interior Jumper & Switches 24

Optional Controls 26

Replacement Parts List 27

System Start-Up Settings 28

Troubleshooting Guide 29

Warranty 30

Page 4

BASICS

Contents

Item Quantity

Y–Series Boiler Control, Installed on Boiler(s) As Ordered

Outdoor T emperature Sensor Assembly 1

Water Temperature Sensor Assembly 1

Optional Equipment As Ordered

Check packaging for damaged or missing components.

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT NOTICE: These instructions are intended for use by qualified personnel who are

specifically trained and experienced in the installation of this type of equipment and related system

components. Installation and service personnel may be required by some states to be licensed. If your

state requires certification, be sure your contractor bears the appropriate license. Only qualified persons

shall attempt to repair this equipment. Repair must be according to these instructions.

WARNING: Improper installation, adjustment, alteration, service or maintenance may damage the

equipment, create a hazard resulting in asphyxiation, explosion, fire, electric shock, personal injury or

property damage, and will void the warranty .

CAUTION: MORE THAN ONE (1) SUPPLY SOURCE. THIS APPLIANCE HAS PROVISIONS

TO BE CONNECTED TO MORE THAN ONE (1) SUPPLY SOURCE. TO REDUCE THE RISK

OF ELECTRIC SHOCK, DISCONNECT ALL SUCH CONNECTIONS BEFORE SERVICING.

CAUTION: RISK OF ELECTRIC SHOCK. MORE THAN ONE (1) DISCONNECT SWITCH

MAY BE REQUIRED TO DE-ENERGIZE THE EQUIPMENT BEFORE SERVICING.

4

Page 5

Thank you for selecting the Raypak Y–Series Electronic Boiler Control. It is our sincere hope that you will enjoy its

outstanding design, ease of use and energy saving features.

INTRODUCTION

The Y-Series Electronic Boiler Control (controller) is a microprocessor-based energy management system designed to

control either single or multiple stage-fired boilers. Ideally suited for use in hydronic heating and domestic hot water

supply applications, the Y-Series has been engineered with the flexibility and raw power to tame the most demanding

control situations. Utilizing a state-of-the-art PID control algorithm, the Y-Series minimizes operating costs by maximizing energy efficiency.

CONCEPT OF OPERATION

This controller is an outdoor reset control that is perfect for managing hydronic heating systems. Two temperature

sensors are used to control system response. One sensor is used to monitor the outdoor temperature, the other sensor is

used to regulate the temperature of the system water. By varying the temperature of the heating medium in response to

changes in the outdoor temperature, the Y-Series provides the ultimate in personal comfort and efficiency of operation.

The Y-Series controller is also well adapted to domestic hot water supply duty. By disabling the outdoor reset function, the

Y-Series behaves as an energy-wise boiler sequencer. With the ability to control up to eight firing stages, and such

features as a revolutionary "First-On, First-Off" lead-lag protocol, the Y-Series redefines "controlability" in domestic

water applications.

The controller is equipped with an energy-saving warm weather shutdown capability. When the outdoor temperature

rises above an adjustable "Outdoor Cutoff Temperature," the system automatically transitions to a dormant state. This

prevents the system from wasting energy trying to heat a building that is already at a comfortable temperature. Once the

outside temperature has fallen to the point that the system requires heat input to maintain the building temperature, the YSeries is reactivated and will hold the system temperature at the required point.

The Y-Series can also be equipped with an optional clocked alternate setpoint package. The alternate setpoint allows

control operation at an independent setpoint temperature and can be used either for night setback or preoccupancy boost.

An electromechanical 7-day timer switches the control between regular and alternate setpoint modes and can be set at two

hour activation intervals. See the section on the optional clocked alternate setpoint for details.

OPTIONAL CONFIGURATIONS

Y-2B BASIC UNIT, NO OPTIONS

Y-3B BASIC UNIT PLUS DIGITAL DISPLAY

Y-4B BASIC UNIT PLUS NIGHT SETBACK OPTION

Y-5B BASIC UNIT PLUS NIGHT SETBACK AND DIGITAL DISPLAY OPTIONS

PLEASE REGISTER

Before proceeding any further, please t ake a moment to complete the enclosed user registration form and mail a

copy to Raypak, Inc., Department Y–Series, 2151 Eastman Avenue, Oxnard, CA 93030

5

Page 6

CONTROL FEATURES

The Y-Series sequence panel includes:

• Standard Indicator Lights:

Stages 1 to 8: Red, indicates which stages are turned on.

Pump: Green, indicates that the pump circuit is energized.

Call for Heat: Green, indicates that a call for heat signal is present.

Control On: Green, indicates outdoor temperature is below the Outdoor Cutoff Temperature

potentiometer setting and that the boiler will respond to a call for heat.

Setting Error: Red, indicates one or more of the on-board settings is incorrect.

Sensor Error: Red, indicates that the Water or Outdoor Temperature Sensor has an out-of-range reading.

• Adjustment Knobs:

Reset Ratio: 0.12:1 to 8:1; determines how much the micro-controller calculated T arget

Temperature will change for a given outdoor temperature change.

Control Band: 1°F to 10°F; the temperature above or below the Target Temperature at which the boiler

turns off and on.

Pump Off Delay: 0 to 10 min.; determines when the pump shuts off after entering Outdoor Cutoff mode.

. Outdoor Cutoff 32°F to 200°F; a warm weather shutdown feature. When the outdoor temperature

Temperature: exceeds this setting, the boiler will not fire unless placed in manual override mode.

Outdoor Cutoff 1°F to 10°F; the number of degrees below the Outdoor Cutoff (O/C)

Deadband: Temperature which causes the O/C to reset.

Boiler On Delay: 0 to 5 min.; sets the time interval between sequential boiler start ups.

Stage On Delay: 0 to 60 sec.; determines the time delay between stages turning on.

Max. Water Temp.: 70°F to 235°F; the maximum value that the Target Temperature is allowed to reach.

Set Point: 40°F to 220°F; the system output temperature desired when the outdoor temperature is

70°F or, in domestic water applications, the desired water temperature.

• Logic T est Button, Jumper and Switches:

System Test Button (S1): initiates micro self test which causes the status indicator lights to blink 5 times

indicating the micro-controller is functioning properly.

Last Stage Jumper (J2): selects the last active stage used for boiler control.

First Stage #1 Selector (S2): designates the first stage of each boiler in a multi-boiler system. Switch

position #1 should always be on.

Mode Selector (S3): switch #1 selects either Manual or Auto Lead-Lag Mode. Switch #2 provides an

Outdoor Reset defeat. Switch #3 configures the Y–Series for Master/Slave ganged

operation. Switch #4 allows the Set Point to be set below 105°F.

Bypass Switches (S5): allows user to turn on any stage(s) regardless of current settings and

conditions if, and only if, the pump relay is already activated.

6

Page 7

INSTALLATION AND MOUNTING

If the Y–Series Electronic Boiler Control was not mounted on the boiler by the factory, care should be taken to select a

suitable mounting location. The control should be mounted on a solid and permanent base. The control enclosure is

NEMA 3R rated, rainproof and sleet resistant, and can be mounted outdoors if required. The unit should be readily

accessible for maintenance and installation purposes, and should be mounted so that the indicating lights are at a height

and location convenient for viewing.

MECHANICAL INSTALLA TION

Install the control within 10 feet of the boiler(s). The control must be mounted vertically with the conduit holes facing

downward. The conduit holes are sized to accommodate standard conduit fittings. If additional or larger conduit fittings

are required, the holes should be located on the bottom of the module.

Mount the control using the mounting bracket and appropriate 3/8” or 1/4” hardware in four (4) places.

A minimum of eighteen (18) inches clearance from the front, and six (6) inches clearance on all other sides is required for

service access. The hinged right side of the box should be installed with sufficient clearance (minimum 3” from the bolt

holes on the right side) to open the cover.

An electrical distribution sub-panel containing appropriate disconnect switches and surge suppressors is required at or near

the equipment location(s).

To access the control board, remove the interior front panel by unscrewing the four (4) decal panel fasteners.

INSTALL CONDUIT AS APPROPRIATE.

NOTE #1 : Shielded 18 gauge cable must be used to connect the sensors to the Boiler Control Module. The shielded

cable should be protected by conduit whenever possible.

NOTE #2 : 18 AWG - Stranded wire must be used for all connections to printed circuit board (PCB). Solid conductors

should not be used because solid wire conductors can cause excessive tension on contact pointS.

ELECTRICAL INSTALLATION

ELECTRICAL CHARACTERISTICS: 120 VAC, 60 Hz, 0.5A

120 V AC FEEDER CIRCUITS

Install a surge protection device sized appropriately for your installation at each module.

Install a separate disconnect means for each load. Use appropriately sized wire for equipment as defined by NEC and/or

local code. All primary wiring should be 125% of minimum rating.

It is strongly recommended that the Y-Series Electronic Control Module and the boiler(s) be supplied from the same power

source.

7

Page 8

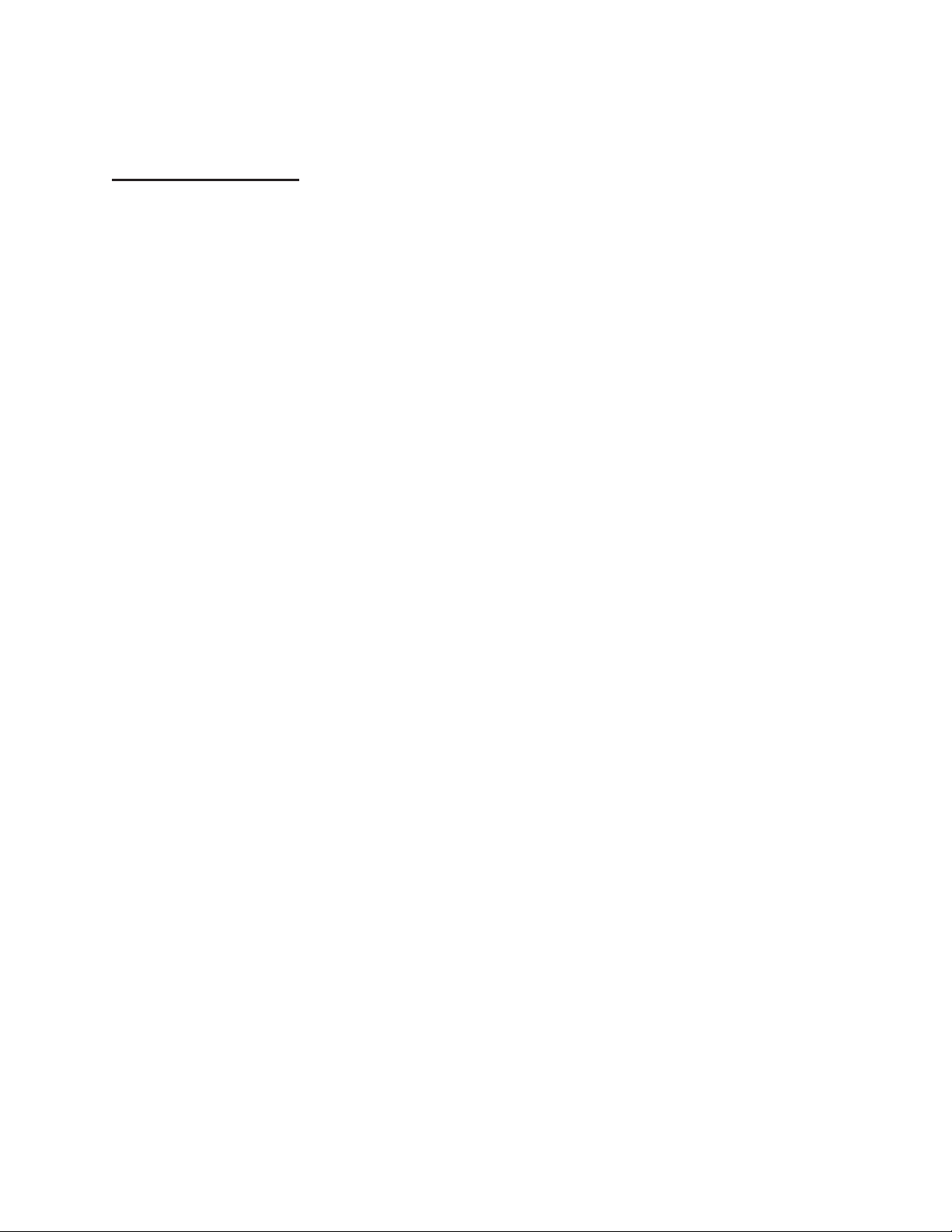

CHECK YOUR POWER SOURCE

Using a volt-ohm meter, check the following voltages at the circuit breaker panel:

BLACK

CIRCUIT

BREAKER

WHITE

GREEN

GROUND

ABC

AC = 108 Volts AC Minimum, 132 Volts MAX

AB = 108 Volts AC Minimum, 132 Volts MAX

BC = Must be less than 1.0 Volts AC

VOLT-OHM

METER

WIRING: POWER SOURCE TO CONTROLLER

• Observe polarity.

• Observe proper wire colors while making electrical connections.

• Provide an external surge suppressor capable of maintaining system integrity.

• Provide overload protection and a disconnect means for equipment serviceability as required by local and state

code.

• Conduit cannot be used as the ground. (There must be a “WIRED” ground.)

• Very Important: A grounding electrode conductor shall be used to connect the equipment grounding

conductors, the equipment enclosures, and where the system is grounded, the grounded service

conductor to the grounding electrode.

GRN

WHT

BLK

120VAC

SUPPLY

HOT

RTN

GND

GRN

SPG

SINGLE POINT

GROUND

WHT

BLK

8

Page 9

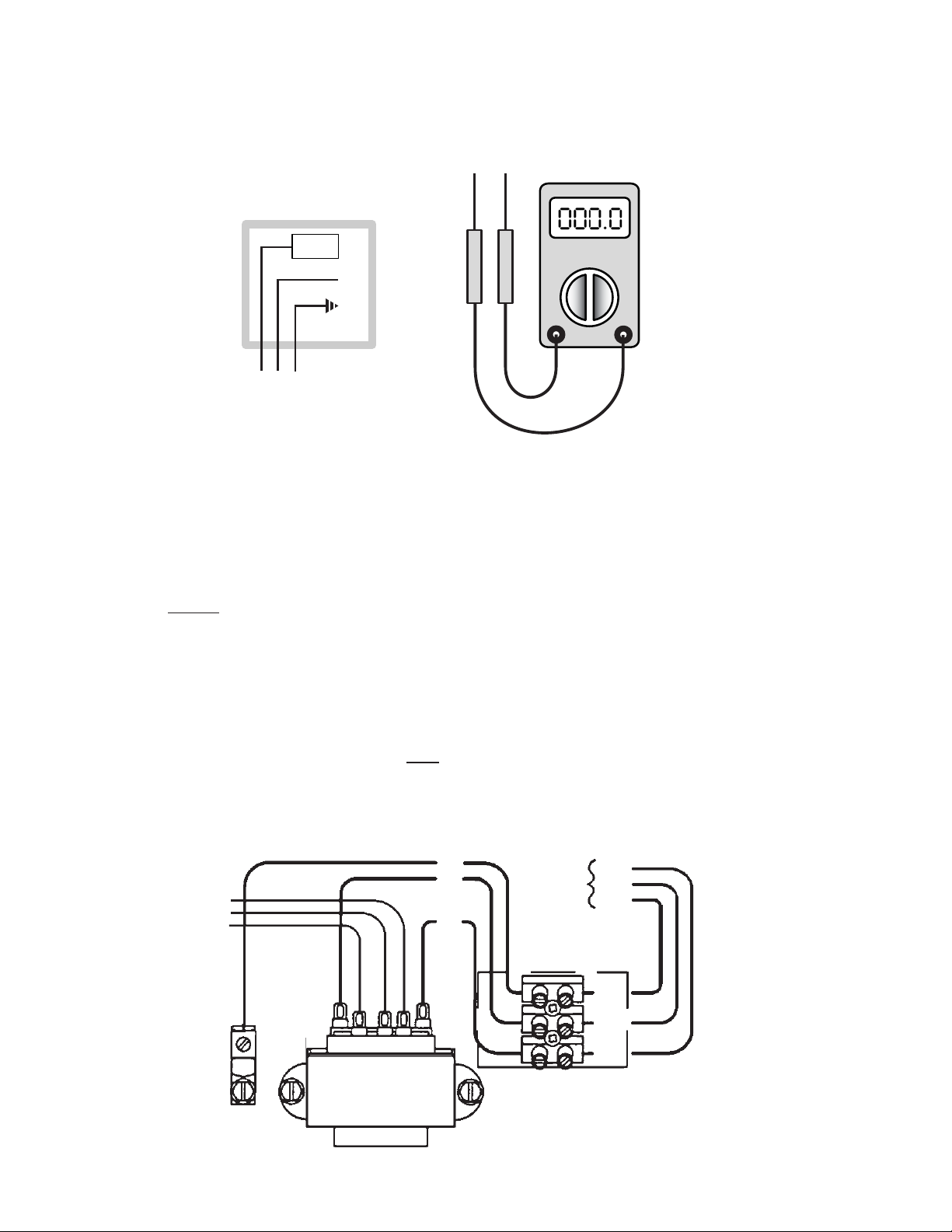

AIR TEMPERA TURE SENSOR

Red (spare)

Red (connect)

Black (connect)

Fig. #9040

OUTDOOR AIR TEMPERATURE SENSOR

Outdoor Air Temperature Sensor Installation Notes:

• Locate the sensor on the coldest side of building, usually the North or West side.

• Install the sensor in a shaded area, out of direct sunlight.

• Locate no higher than 2/3 up the side of the building, or between the 2nd and 3rd floor if the building is more than

three stories tall.

• Do not locate under an overhang, near wall corners, near drafts from stacks, air-moving devices, windows, doors, or

balconies.

• Shielded cable length run is not to exceed 300 feet.

• Install with properly-sized conduit that contains no other wiring.

• Observe proper wire colors.

• The outdoor air temperature and water temperature sensors are identical and interchangeable. Both are equipped

with dual sensing elements. Connect only one red wire and the black wire to the sensor connecting points. The

second element is an installed spare.

9

Page 10

W A TER TEMPERATURE SENSOR INST ALLA TION

HYDRONIC INSTALLATIONS

Fig. #9496

TYPICAL WATER SENSOR

• The water sensor should be installed in the system supply.

• Locate the water temperature sensor in the system piping just prior to the first boiler connections, on the

upstream side of the System Supply Loop.

• Cable length must not exceed 300 feet.

• Install in shielded conduit with no other wiring.

• Observe wire colors.

10

Page 11

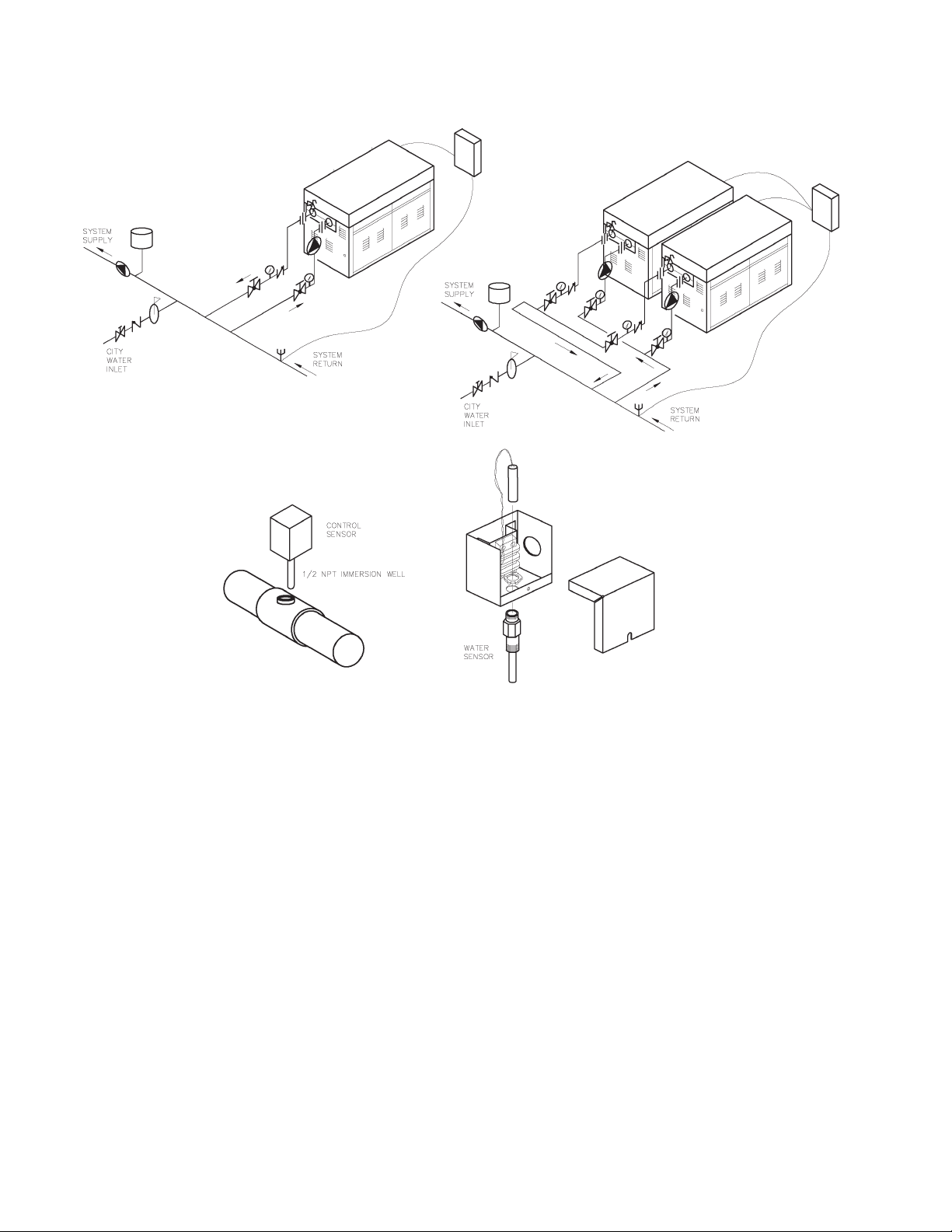

WATER TEMPERATURE SENSOR INSTALLATION

DOMESTIC HOT WATER INSTALLATIONS

Y -Series Controller

Fig. # 9497.1

Air temperature sensor must be installed across air temperature sensor contacts. The sensor is not activated and can be

left stored in controller enclosure.

DOMESTIC HOT WATER APPLICATION SETUP PROCEDURE

1 . Install a 10,000 Ohm, 1/8 W att resistor between pins 1 and 2 on P2 connector (see pg. 13), in place of

the Outdoor Air T emperature Sensor . The Outdoor Air Temperature will appear to be about 77°F.

2 . Set switch #2 (Outdoor Reset) to ON - 70°F Defeat, on S3. (See pg.s 15 and 23-24.)

3 . Set the Outdoor Cutoff T emperature to 200°F . (See pg. 21.)

4 . Adjust the Set Point to desired domestic hot water temperature. Controller will track the Set Point

T emperature. (See pg. 22.)

NOTE: The Outdoor Air Temperature sensor can be used as a replacement for the Water Temperature Sensor. Both

sensors are identical.

11

Page 12

WATER TEMPERATURE SENSOR INSTALLATION

POOL HEATING INSTALLATIONS

Fig. # 9498

Fig. # 9499

1. Install the air temperature sensor across the air temperature sensor contacts (P2, pins 1 and 2; see the field

wiring diagram on pg. 13).

2 . On the mode selector switch (S3), set switch #2 (Outdoor Reset) to ON to disable the outdoor reset function.

(See pg.s 15 and 23).

3 . Set the Outdoor Cutoff T emperature to 200°F . (See pg. 21.)

4 . Adjust the setpoint to desired pool temperature. Thereafter, the controller will track the setpoint and fire

heater stages as necessary.

NOTE: The Outdoor Air Temperature sensor can be used as a replacement for the Water Temperature Sensor , as both

sensors are indicated.

12

Page 13

FIELD WIRING

Single-Stage (On/Off) Boilers

- All stage connections on the control

board are connected at the {TH}

(Thermostat) location on the

boiler wiring diagram.

Stage 1

Stage 2

Stage 3

Stage 4

P5

1

2

3

4

5

6

7

8

Multiple-Stage Boilers

- First stage connections on the

control board are connected at

the {TH} (Thermostat) location

on the boiler wiring diagram.

- Second (or third, etc.) stage

connections on the control

board are connected at the

locations shown on the

boiler wiring diagram.

Utilize Shielded Cable

Outdoor Air Temperature

Sensor (see NOTE 4)

Water Temperature

Sensor

Stage 5

Stage 6

Stage 7

Stage 8

Pump Relay

Pilot Duty Only

2.5 Amp Max

250V Max

Thermostat

(Jumpered) or

Building Management System

Outdoor T emp

Water Temp

1

2

3

4

5

6

7

8

P6

1

2

P4

1

2

3

P1

1

2

3

4

P2

Notes:

1. Tighten terminal strip clamping screws to 4 in-lbs. Breakage from over torquing is not covered under warranty.

2. Use copper conductors only.

3. For supply connections, use wires sized on the basis of 60°C (140°F) ampacity and rated a min. 90°C (194°F).

4. The outdoor sensor must be connected, otherwise a sensor error will be displayed.

13

Page 14

INST ALLATION VERIFICATION PROCEDURE

REGISTER

Before proceeding any further, please verify that the user registration form has been completed and mailed.

MECHANICAL INST ALLATION

Verify that the mechanical installation has been completed in accordance with the instructions.

OUTDOOR AIR TEMPERA TURE SENSOR

Verify that all Outdoor Air Temperature Sensor installation parameters have been met.

WATER TEMPERATURE SENSOR

Verify that the Water Temperature Sensor installation parameters have been met.

SYSTEM MODULE INST ALLATION

Verify electrical power wiring connections.

Verify electrical connection torque requirements.

Verify Outdoor Air Temperature Sensor wiring.

Verify Water T emperature Sensor wiring.

Verify Power Test has been completed successfully.

POWER TEST

Utilizing a Volt-Ohm-Meter (VOM) monitor the following on the controller for proper voltage levels. Check at

Terminal Block TB-1.

POWER TEST TABLE

From: To: Indication

TB pin 1 TB pin 2 108 VAC to 132 VAC

TB pin 1 Single Point Ground 108 VAC to 132 VAC

TB pin 2 Single Point Ground less than 1 VAC

14

Page 15

CONTROL FAMILIARIZATION

The System is configured using the circuit board jumpers and switches, and the front panel control potentiometers.

Open the front cover of the Boiler Control Box for access to the front panel. Remove the front panel to gain access to the

jumpers and switches on the Y-Series Electronic Boiler Control circuit board.

Refer to the Interior Jumper and Switches section of this manual (pg. 24) for detailed configuration instructions.

1. Last Stage Selector. Install the jumper pot (J2) shunt bar in the position that corresponds to the total

number of stages to be controlled.

2 . First Stage Selector . Switch (S2); Place switches in the ON position corresponding to the first stage

of each boiler in the system. Switch position #1 should always be in the ON position.

3. Mode Selector. Switch (S3) determines the following:

A. Switch #1, R/M

OFF - Manual Lead-Lag selection

ON - Automatic Lead-Lag selection

B. Switch #2, 70°F OFF

OFF - Outdoor Reset Enabled

ON - 70°F Defeat Enabled, Outdoor Reset Disabled-used for domestic water installations.

C. Switches #3 Master/Slave Option

OFF - Designates the Y-Series as a Master Control (Normal)

ON - Designates the unit as a slave (used for ganged Y-Series controls controlling 9 to 24 firing stages)

D. Switch #4, No Min Set Point Switch

OFF - Minimum allowable Set Point of 105°F to reduce potential of condensing the boiler.

ON - Set Point can be reduced to 40°F for special applications (i.e. water source heat pumps, etc.)

E. Switch #5 (reserved)

F. Switch #6 (reserved)

G. Switch #7 (reserved)

H. Switch #8 (reserved)

4. Lead-Lag Selector, Rotary switch (S4) selects the lead stage for stage sequencing. (Applies only in manual

lead-lag mode when Mode Selector Switch (S3) Switch #1, is OFF) switch should point to first stage in multi

stage applications.

5 . Output Over-Ride Switch (S5) provides Manual Override of the system control. Switches #1 through #8 turn

on the corresponding relay and stage. Switch #9 turns on the pump circuit. The other stages are interlocked with Switch #9 and will not fire unless the pump is on. Switch #10 is not used.

6 . System T est Switch (S1) is a momentary switch which will cause status indicators to blink five times

then revert to normal indications. This tests the functions status of the micro-controller.

Reinstall the panel above indicator lights that cover the Y-Series Electronic Boiler Control Circuit board.

Refer to the CONTROL POTENTIOMETERS (KNOBS) section of this manual to set the initial system operating parameters. Set knobs to default values and fine tune if necessary.

15

Page 16

SEQUENCE OF OPERATION

1. When the reset is enabled, the Y-Series Control continously monitors outdoor temperature using the outdoor

temperature sensor. When the outdoor temperature falls below the outdoor cutoff tempersture, the Control becomes

active and closes the primary pump relay, energizing the primary system circulating pump. The Control then monitors

the system supply water temperature. The microprocessor calculates an optimum target water temperature within

selectable limits of the control band, the setpoint, the reset ratio and the outdoor air temperature. If outdoor is reset is

disabled, the readings of the air sensor are not used in subsequent calculations. In either case, if the water temperature

falls below the the calculated target temperature the Control sends a call for heat to the lead unit (stage).

2. Upon a call for the heat the control closes the lead unit's thermostat (TH) circuit, which the energizes the lead unit's

circulating pump. After the flow switch has confirmed adequate flow, the ignition sequence is initiated and the unit

ignites at stage 1. The Control then sequences the units/stages in response to changes in the system to target differen

tial temperature, time away from target temperature, and temperature rate-of-change parameter as determined by the

P+I+D algorithems.

3. Additional stages (and units) are activated or deactivated as required in order to maintain or restore target system

water temperature. This Control uses "first on, last off" logic. As the system water temperature increases and begins to

approach target temperature, the Control deactivates the stages and heaters in reverse order of firing until the first

unit/stage fired is turned off. After the final stage of a given unit has been turned off, that unit's Economaster pump

control will continue to power the unit's circulating pump until a user-adjustable time delay has elapsed, thereby

extracting all available residual heat.

4. The Control stores firing command and system response data in the last five memory registers of the microprocessor.

On the next call for heat, the Control will modify the stored P+I+D data to optimize its own responses.

5. When the outdoor temperature exceeds the outdoor cutoff temperature, the Control enters warm weather shut-down

mode. The primary pump is turned off after a user-adjustable time delay, and the Control becomes dormant, until

outdoor temperatures again fall below the outdoor cutoff temperature.

MANUAL OVERRIDE

Internal Switch (S5) Output Override can be used to manually override the Micro-controller control as long as the

Electronic Boiler Control circuit board has 24 VAC power. See Output Over-Ride Switch (S5) above.

16

Page 17

Y–SERIES ELECTRONIC BOILER CONTROL MODULE

Night Setpoint

Option

Digital Display

Option

Panel with Clock & LCD

Y-5 Configuration Shown

17

Page 18

STAGES

INDICA T OR LIGHTS

PUMP

1

2

STAGE INDICATORS

The pump driver and each of the output stages' drivers has its own LED indicator. Each of

these LEDs is lit whenever the corresponding output relay is energized.

3

4

5

6

7

8

PUMP INDICA T OR

The Pump Indicator is illuminated whenever the pump circuit and pump relay are energized.

CALL FOR HEAT

CONTROL

ON

SETTING

ERROR

SENSOR

ERROR

CALL FOR HEA T INDICATOR

The Call For Heat Indicator is illuminated whenever a call for heat signal is present. In

most applications the thermostat connections on the control board (pg. 13) will be jumpered,

which will generate a continuous call for heat signal. The thermostat leads may also be

connected to a building management system which will produce the call for heat signal as

required.

CONTROL ON INDICA T OR

The Control On Indicator illuminates if all settings and system conditions are such that the

control can function properly, and outdoor temperature cutoff temperature setting is less

than or equal to the outdoor temperature.

SETTING ERROR INDICA TOR

The Setting Error Indicator is illuminated if there is a potentiometer, switch setting or jumper

placement error. Refer toTroubleshooting Guide "Setting Error LED Is On".

SENSOR ERROR INDICA TOR

The Sensor Error Indicator is illuminated if either temperature sensor is out of range.

Steady on represents outdoor sensor failure, blinking represents water temperature sensor

error. See "Sensor Error LED On" in the Troubleshooting Guide (pg. 29).

18

Page 19

CONTROL FUNCTIONS

RESET RATIO

The Reset Ratio setting determines how much the Target Temperature will increase as the

outdoor temperature drops. The Reset Ratio is expressed in the following manner:

The first number in the ratio refers to the change in outdoor temperature in degrees Fahrenheit below outdoor cutoff while the second refers to the change in the computed Target

Temperature in degrees Fahrenheit. A Reset Ratio of 2:1 means that for every 2°F drop in

outdoor temperature from 70°F, the Target Temperature will increase 1°F.

For example:

Assume a Reset Ratio setting of 2:1 and a Set Point of 120°F .

When the outdoor temperature drops from 70°F to 20°F, the Target Temperature will increase from 120°F to 145°F. (With an outdoor to target ratio of 2:1, a 50°F outdoor temperature decrease results in a 25°F Target Temperature increase). See Reset Ratio Chart

(pg. 20) for more information.

The Reset Ratio is adjustable from 0.12:1 to 8.0:1.

Recommended Initial Setting for Reset Ratio is 1:1.

X:Y X - change in outdoor temperature

Y - change in Target Temperature

Suggested Settings

Typical Reset Ratio Setpoint at Design Temp:

RADIATION

Standing 190 105 0.3:1 0.6:1 0.8:1 1.1:1

Convection or

Baseboard

Fan Coil - Heating 190 105 0.3:1 0.6:1 0.8:1 1.1:1

Fan Coil - Heat & Cool 140 105 0.9:1 1.4:1 2.0:1 2.6:1

Radiant Floor 120 105 2.0:1 3.3:1 4.7:1 6.0:1

Radiant Ceiling 120 105 2.0:1 3.3:1 4.7:1 6.0:1

The selection of the correct ratio is dependent on the initial temperature Set Point and the desired system water temperature. If the building

is too cold, move the ratio knob counter-clockwise one setting. After a change is made to the ratio, wait several days and evaluate the

comfort level before making another change.

Temp @

Design Cond.

200 105 0.3:1 0.5:1 0.7:1 0.9:1

Temp. @

70°F

40°F 20°F 0°F - 20°F

19

Page 20

RESET RATIO CHART

PUMP TURN-OFF DELAY

The Pump Turnoff Delay works in conjunction with the Outdoor Cutoff Temperature.

The Pump Turnoff Delay sets the delay between the time when the Outdoor Cutoff

Temperature is reached and the time when the pump is turned off.

The Pump Turnoff Delay is adjustable from 0 to 10 min.

Recommended Initial Setting for Pump Off Delay is 3 min

20

Page 21

BOILER TURN-ON DELA Y

In a multiple boiler system:

The Boiler Turn-On Delay sets the time delay before each additional boiler is turned on in

response to a call for heat. This delay starts when the preceding boiler is turned on.

The Boiler Turn-On Delay range is from 0 to 5 min.

Recommended Initial Setting for Boiler Turn-On Delay is 30 sec.

ST AGE TURN-ON DELAY

The Stage Turn-On Delay sets the time delay before a new stage in a multistage boiler

configuration is turned on. This delay starts when the stage or boiler preceding the next

stage is turned on.

The Stage Turn-On Delay range is from 0 to 60 sec.

Recommended Initial Setting Stage for Turn-On Delay is 10 sec.

CONTROL BAND

The Control Band sets the maximum temperature above or below the Target Temperature

(which is determined by the embedded micro-controller) between which the system temperature may deviate. This provides a control deadband that limits the boiler from shortcycling.

The Control Band range is from 1°F to 10°F.

Recommended Initial Setting for Control Band is 3°F.

OUTDOOR CUTOFF DEADBAND

The Outdoor Cutoff Deadband sets the number of degrees below the Outdoor Cutoff where

the Outdoor Cutoff reset occurs.

The Outdoor Cutoff Deadband range is from 1°F to 10°F.

Recommended Initial Setting for Outdoor Cutoff Deadband is 3°F.

OUTDOOR CUTOFF TEMPERATURE

The Outdoor Cutoff sets the maximum outdoor temperature at which heat is desired. This

control sets the outdoor temperature above which the boiler bank is disabled. If the outdoor temperature increases beyond the Outdoor Cutoff setting, the Control ON LED turns

off and if there is no call for heat, the pump turn-off delay starts turning off the pump. If

the outdoor temperature falls below the Outdoor Cutoff minus the Outdoor Cutoff Deadband

the boiler bank will again be enabled.

The Outdoor Cutoff Temperature is from 32°F to 200°F.

Recommended Initial Setting for Outdoor Cutoff Temperature is 65°F.

21

Page 22

MAXIMUM WA TER TEMPERATURE

The Maximum Output Temperature is the system output high limit. This potentiometer

sets the maximum value the Target Temperature is allowed to reach regardless of other

operational settings or conditions.

The Maximum Water Temperature range is from 70°F to 235°F.

Recommended Initial Setting for Maximum Water Temperature is 180°F.

SET POINT

The Set Point is the system output temperature desired when the outdoor temperature is

70°F. This potentiometer may be set to any temperature from 40°F to 220°F, and is the

base-line setting for all operations. Note: Set Point cannot be below 105°F in normal

operation unless the No Min Set Point switch is in the ON position. (See Mode Selector

Switch). In domestic water supply applications, Set Point determines the water temperature maintained by the control.

The Set Point range is from 40°F to 220°F .

Recommended Initial Setting Set for Point is 120°F.

CAUTION: Setting the Set Point below 105°F may cause the boiler to condense which

will damage the boiler.

22

Page 23

CIRCUIT BOARD

S5 MANUAL BYPASS

SWITCH

S4 MANUAL LEAD/

LAG

SELECTOR

SWITCH

J2 LAST STAGE

SELECTOR

JUMPER

S3 MODE

SELECTOR

MAINTENANCE

PLUG TEST

S1 SYSTEM

TEST

23

S2 FIRST STAGE

SELECTOR I.D.

Page 24

INTERIOR JUMPER & SWITCHES

J-2

The Last Stage Selector Jumper (J2) is comprised of an eight (8) position jumper block. A shunt

bar jumper is placed in the position corresponding to the last active stage or boiler number. See

table below for examples of Jumper (J2) settings.

Fig # 9242

S-2

The First Stage Selector (Stage #1 ID) (S2) Switch is an eight (8) position switch, each switch

position corresponds to a Y-Series output stage. Turn ON the switch(s) that correspond(s) to

the FIRST stage of EACH boiler . Turn OFF the switch(s) that correspond(s) to the second (or

subsequent) stage(s), of EACH boiler.

(Switch #1 should always be on.) See the table below for examples.

S-3

Fig # 9245

The Mode Selector Switch (S3) is comprised of an eight (8) position dip switch with the

following functions:

AUTO

Sw #1 - Manual/Auto Lead-lag Selection Off - Manual lead-lag selection

On - Automatic lead-lag selection

OD off

Sw #2 - Outdoor Reset Off - Outdoor Reset Enabled

"OD off" On - Outdoor Reset Disabled. Use this setting

for applications like Domestic Hot Water

where outdoor air sensing is not required.

Fig # 9246

Note: The outdoor sensor must be connected in all modes, otherwise a sensor error will be

displayed.

24

Page 25

S-4

SLA VE

Sw #3 - Master/Slave Off - Designates the Y-Series as a Master Control

(Normal)

On - Designates the unit as a slave (used for

ganged Y-Series' controlling 9 to 24 firing stages)

DHW

Sw #4 - Outdoor Reset Off - Minimum allowable Set Point of 105°F

reduces potential of condensensing the boiler.

On - Set Point can be reduced to 40°F for special

applications (e.g. water source heat pumps, etc.)

Sw #5 - 8 - Reserved Reserved for future use.

MANUAL LEAD-LAG

The Lead-lag Selector Switch (S4) is a ten (10) position rotary switch. Switch positions

0 and 9 are not used. In manual lead-lag selection, the Lead-lag Selector is used to select

the lead boiler (stage). This is normally shipped from the factory set at position 1. If

auto lead-lag is used, do not adjust this switch.

Fig # 9244

S-5

S-1

OUTPUT OVERRIDE

The Bypass Switches: Switch (S5) is a ten (10) position dip switch. Switch position

10 is not used. The Bypass Switch enables the user to turn on any of the outputs

regardless of the current settings and conditions. Switch position 9 will turn on the

pump and the remaining eight switches will each override one of the output stages.

The pump switch and the output stages switches are interlocked such that the output

stages can only be turned on if the pump is on.

Fig # 9243

SYSTEM TEST

The System Test Switch (S1) is comprised of a single momentary push button switch.

When depressed it should cause the Status Indicators to blink five times. This test

sequence is an indication of the functioning status of the embedded micro-controller.

The Status Indicators revert back to their original indications after the test sequence is

completed.

Fig # 9247

25

Page 26

OPTIONAL CONTROLS

Operational

Override Switch

Clock

Alternate

Setpoint Adjustment

Digital Display

OPTIONAL ALTERNA TE SETPOINT OPERATION

The Optional Alternate Setpoint can be used to establish an independent second set point for setback or

temperature boost requirements.

Front Panel with Optional Alternate Setpoint

TRIPPERS

The electro-mechanical timer consists of 84 small switches called "Trippers" and a 7-day mechanical

clock. Each tripper represents a two-hour interval which determines set point selection as shown:

Tripper Pushed In = Normal Setpoint Operation

Tripper Pushed Out = Alternate Setpoint Operation

OPERATION OVERRIDE SWITCH

The Operation Override Switch is a three-position switch that determines if the trippers select the Setpoint,

of if either the normal Setpoint or Alternate Setpoint is continuously selected. The Operation Override

Switch can be set as follows

I - Alternate Setpoint selected continuously

L - Trippers determine selected set point

O - Normal Setpoint select continuously

NIGHT SETBACK OPTION:

MECHANICAL CLOCK (7-DAY)

Set to the appropriate local time.

Note: Turn the numbered dial clockwise to set time.

ALTERNATE SET POINT

Works independently of normal Setpoint. See discussion of Setpoint for details. Set to appropriate

setback or boost temperature. Turn the knob in the night setback option to the desired alternate setpoint.

DIGITAL DISPLAY OPTION:

LCD DISPLAY PANEL

The optional LCD display will indicate all values plus calculated target temperature and actual air and

water temperature.

26

Page 27

REPLACEMENT PARTS LIST

2-N

CALL OUT

1-C

2-C

3-C

1-S

2-S

3-S

4-S

5-S

6-S

1-N

2-N

1-N

DESCRIPTION

PC Board Standard

PC Board w/ Night Set Back

Programmed Eprom

Programmed Eprom W/ Night Set Back

Transformer

Door w/Window

Side Mount Bracket

Air Temperature Sensor Complete

Water Temperature Sensor Complete

Air/Water Temperature Sensor

Well Assembly

Timer

Alternate Setpoint Adjustment

PART NO

006039F

006034F

005764F

006031F

005657F

N/A

005654F

005700F

005701F

005299B

004821F

006033F

006032F

1-S

3-C

2-C

3-S

2-S

1-C

5-S

4-S

5-S

6-S

27

Page 28

SYSTEM START-UP SETTINGS

SYSTEM SETTING ENTERED ON DATE:

Front panel control potentiometers (knobs)

Reset Ratio: ______ Control Band: ______

Default Value: 1:1 Default Value: 3°F

Pump off Delay: ______ Outdoor Cutoff Deadband: ______

Default Value: 3 min. Default Value: 3°F

Boiler on Delay: ______ Outdoor Cutoff Temp.: ______

Default Value: 30 sec. Default Value: 65°F

Stage on Delay: ______ Max W ater Temp.: ______

Default Value: 10 sec. Default Value: 180°F

Set Point: ______

Default Value: 140°F

Optional Alternate Set Point ______

INTERIOR JUMPER & SWITCH SETTINGS:

Last Stage (J2) Output ON Switch (S2)

Mode Selector Switch (S3) Lead-Lag Switch (S4)

Bypass Switch (S5)

28

Page 29

TROUBLESHOOTING GUIDE

In normal operating conditions, the Status Indications should be observed as follows:

Control Enabled ON (lit)

Sensor Error OFF

Setting Error OFF

If the outdoor sensor fails and all other operating conditions remain the same, the control will remain on but it will

function as if the 70°F defeat mode is enabled. The following Status Indications should be observed:

Control Enabled ON (lit)

Sensor Error ON (lit)

Setting Error OFF

If a different LED status is observed other than those described above, use the following detailed descriptions as a

guide:

If Control Enabled LED is OFF

Possible Causes:

1. The output temperature sensor is out of range. The Sensor Error LED should be on. See below for details on the

Sensor Error LED.

2. There is a setting error. The Setting Error LED should be on. See below for details on the Setting Error LED.

3. The outdoor temperature is higher than or equal to the outdoor cutoff setting less the outdoor cutoff deadband

setting.

Sensor Error LED is ON or blinking ON/OFF once per second

Possible Causes:

LED ON steady: Outdoor (air) sensor is out of range.

LED blinking ON/OFF once per second: Output (water) sensor is out of range.

1 . Examine wiring, ensure continuity from Y -Series to sensor(s).

2. Use a multimeter, measure resistance of sensor(s) compare with table below:

SENSOR RESISTANCE AT VARIOUS TEMPERATURES

TEMP

Deg F 405060708090100110120

Resistance (K) 26.11 19.90 15.31 11.88 9.30 7.33 5.83 4.66 3.76

TEMP

Deg F 130 140 150 160 170 180 190 200 210

Resistance (K) 3.06 2.48 2.04 1.69 1.40 1.17 0.98 0.83 0.70

If all Okay, Replace Y-Series Boiler Control Board

3. If all okay, replace Y-Series Boiler Control Board.

Setting Error LED is ON

Possible Causes:

1. The Maximum Output Temperature setting is less than the Minimum Output Temperature setting.

2. The last stage selection is invalid. Either there is no stage selected or more than one stage is selected.

3. The first output stage is not selected as a stage #1. The first output stage should be set as a stage #1 in all cases.

4. In manual mode, the lead-lag selection is invalid (0 or 9).

5. In manual mode, the lead-lag selection is higher than the last stage.

6. In manual mode, the stage selected as the lead-lag is not set as a stage #1.

29

Page 30

LIMITED WARRANTY

B6000, Y-Series, E-4 & Accessories

SCOPE OF WARRANTY

Raypak, Inc. ("Raypak") warrants to the original owner the Control System to be free from defects in materials and workmanship under

normal use and service for the applicable warranty period. In accordance with the terms of this Limited Warranty, RAYPAK will furnish

a replacement or repair, at our option, any defective part which fails in normal use and service during the applicable warranty period. The

replacement or repair will be warranted for only the unexpired portion of the original Warranty Period.

APPLICABLE WARRANTY PERIOD

The effective date of warranty coverage is the date of original installation, of the Control System, by a qualified electrician or by a

RAYPAK authorized service technician. The Applicable Warranty Period is one (1) year from the effective date.

WARRANTY EXCLUSIONS

This Limited Warranty does not apply:

1. if the control system is not properly installed by a qualified technician in accordance with manufacturer's installation

instructions, applicable codes, ordinances and good trade practices,

2. to damage or malfunctions resulting from failure to properly install, operate or maintain the system in accordance

with the manufacturer's instructions;

3. if the rating plate(s) or serial number(s) are altered, defaced or removed;

4. if the System is modified in any way or used with any non-factory authorized accessories or components;

5. to damage or failure from abuse, accident, act of nature, fire, flood, freezing or the like;

6. to accessories, rubber or plastic parts, light bulbs or glass parts;

7. if the System is moved from its original installation site; or if the original owner no longer owns the site or the System.

LABOR AND SHIPPING COSTS

This Limited Warranty does not cover labor costs for service, removal or reinstallation of any part nor shipping charges to or from

RAYPAK'S designated repair center or to or from the installation site. All such costs are your responsibility.

HOW TO MAKE A WARRANTY CLAIM

To make a warranty claim, promptly ship (postage prepaid) or carry the defective part to a designated RAYPAK Service Dealer or Service

Station in the United States, supplying proof of purchase and date of installation and the model and serial numbers. If you cannot locate a

dealer, contact RAYPAK'S Service Department at the address/telephone listed below. Raypak reserves the right at all times to inspect the

claimed defect and verify warranty coverage at its factory.

EXCLUSIVE WARRANTY - LIMITATION OF LIABILITY

This is the only warranty given by RAYPAK. No one is authorized to make any other warranties on Raypak's behalf. ANY IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND

BEYOND THE APPLICABLE WARRANTY PERIOD SPECIFIED ABOVE. RAYPAK'S SOLE LIABILITY WITH RESPECT

TO ANY DEFECT SHALL BE AS SET FORTH IN THIS LIMITED WARRANTY. ANY CLAIMS FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING DAMAGE FROM WATER LEAKAGE) ARE EXCLUDED. Some states do not

allow limitations on how long an implied warranty lasts, or for the exclusion of incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

We suggest you immediately complete the information below and retain this Limited Warranty Certificate in case warranty service is

needed.

RAYPAK, INC. SERVICE DEPARTMENT

2151 Eastman Avenue, Oxnard, California 93030

Telephone: (805) 278-5300 FAX (805) 278-5468

The following information must be provided when you write or call:

________________________________________________ _______________________________________________

Original Owner Daytime Telephone Number

__________________________________________________________________________________________________

Complete Mailing Address

________________________________________________ _______________________________________________

City State Zip Code Installation Site

________________________________________________ _______________________________________________

Model Number Contractor/Installer

________________________________________________ _______________________________________________

Date of Installation Serial Number

Raypak, Inc., 2151 Eastman Ave, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468 Litho in U.S.A.

Page 31

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (800) 872-9725

Raypak Canada Limited, 2805 Slough St., Mississauga, Ontario, Canada L4T 1G2 (905) 677-7999 Fax (905) 677-8036

Litho in U.S.A.

Loading...

Loading...