Page 1

INSTALLATION & OPERATING

INSTRUCTIONS

CATALOG NO. 1000.53H Effective: 09-19-08 Replaces: 11-16-07 P/N 241112 Rev. 9

WARNING: If these instructions are not followed exactly, a fire or explosion may

result causing property damage, personal injury or death

.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in another safe place for

future reference.

Models 122–322

Types H, WH & P

L

W

Page 2

2

Rev. 9 reflects the following: Changes to: The text in the BEFORE INSTALLATION section on page 5; the text in paragraph

one of the GENERAL SAFETY section on page 8; the text in paragraph one of the Outdoor Installations section on page

10; Table E on page 10; the wiring diagram on page 35.

Page 3

WARNINGS 4

Pay Attention to These Terms 4

BEFORE INSTALLATION 5

Product Receipt 5

Model Identification 5

Ratings and Certifications 5

Installations at Elevation 5

Component Locations 6

General Information 7

Time/Temperature Relationships in Scalds 8

GENERAL SAFETY 8

Clearances 9

Equipment Base 9

INSTALLATION 9

Installation Codes 9

Combustion and Ventilation Air 11

Conventional Combustion Air Supply 11

Water Piping 12

Hydronic Heating 13

Domestic Hot Water Piping 15

Pool Heating 17

Gas Supply 17

Electrical Power Connections 19

Venting 21

Outdoor Installation 32

High Limit (Manual Reset) 33

Flow Switch 33

CONTROLS 33

Ignition Control Module 33

Low Water Cut Off (Optional) 34

Operating Control 34

WIRING DIAGRAM—MODELS 122

–322 35

PRE-START-UP 36

Filling System-Heating Heaters 36

Domestic Hot Water Heaters 36

Inspect Venting System 36

For Your Safety Read Before Lighting 36

Pre-Start-Up Check 36

INITIAL START-UP 36

Tools Needed 36

Preparation for Start-Up 36

Start-Up 37

Main Burner Adjustment 37

Safety Inspection 37

Follow-Up 38

POST START-UP CHECK 38

OPERATION 38

Operating Instructions 38

To Turn Off Gas To Appliance 39

MAINTENANCE 39

Suggested Minimum Maintenance

Schedule 39

APPENDIX 40

Inside Combustion Air Contamination 40

CONTENTS

3

Page 4

DANGER:

Indicates the presence of immediate hazards which will cause severe

personal injury, death or substantial property damage if ignored.

WARNING:

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

CAUTION:

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

NOTE:

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

DANGER: Make sure the gas on which the heater

will operate is the same type as that specified on the

heater rating plate.

WARNING: Should overheating occur or the gas

supply valve fail to shut, do not turn off or disconnect

the electrical supply to the heater. Instead, shut off

the gas supply at a location external to the heater.

WARNING: Do not use this heater if any part has

been under water. Immediately call a qualified

service technician to inspect the heater and to

replace any part of the control system and any gas

control which has been under water.

WARNING: To minimize the possibility of improper

operation, serious personal injury, fire, or damage to

the heater:

• Always keep the area around the heater free of

combustible materials, gasoline, and other

flammable liquids and vapors.

• Heater should never be covered or have any

blockage to the flow of fresh air to the heater.

WARNING - CALIFORNIA PROPOSITION

65: This product contains chemicals known to the

State of California to cause cancer, birth defects or

other reproductive harm.

WARNING: Risk of electrical shock. More than one

disconnect switch may be required to deenergize the

equipment before servicing.

CAUTION: Operation of this heater in lowtemperature systems requires special piping.

Harmful internal condensation will occur if the inlet

water temperature does not exceed 105°F. Warranty

claims will be denied when condensation occurs.

CAUTION: If this heater is to be installed above

radiation level, it must be provided with a low water

cut-off device at the time of heater installation.

CAUTION: If this heater is to be installed in a

negative or positive pressure equipment room, there

are special installation requirements. Consult factory

for details.

WARNINGS - Pay Attention to These Terms

4

CAUTION: This heater requires forced water

circulation when the burner is operating. See

minimum and maximum flow rates. Severe damage

will occur if the heater is operated without proper

water flow circulation.

WARNING: This unit contains refractory ceramic

fiber (RCF) insulation in the combustion chamber.

RCF, as manufactured, does not contain respirable

crystalline silica. However, following sustained

exposure to very high temperatures (>2192F), the

RCF can transform into crystalline silica

(cristabolite). The International Agency for Research

on Cancer (IARC) has classified the inhalation of

crystalline silica (cristabolite) as carcinogenic to

humans.

When removing the burners or heat exchangers,

take precautions to avoid creating airborne dust and

avoid inhaling airborne fibers. When cleaning spills,

use wet sweeping or High Efficiency Particulate Air

(HEPA) filtered vacuum to minimize airborne dust.

Use feasible engineering controls such as local

exhaust ventilation or dust collecting systems to

minimize airborne dust. Wear appropriate personal

protective equipment including gloves, safety

glasses with side shields, and appropriate NIOSH

certified respiratory protection, to avoid inhalation of

airborne dust and airborne fiber particles.

Page 5

BEFORE INSTALLATION

Raypak strongly recommends that this manual be reviewed thoroughly before installing your Hi Delta

heater. Please review the General Safety information

before installing the heater. Factory warranty does not

apply to heaters that have been improperly installed or

operated (refer to the warranty at the back of this manual). Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

If, after reviewing this manual, you still have questions

which this manual does not answer, please contact

your local Raypak representative or visit our website at

www.raypak.com.

Thank you for purchasing a Raypak product. We hope

you will be satisfied with the high quality and durability

of our equipment.

Product Receipt

On receipt of your heater it is suggested that you visually check for external damage to the shipping crate. If

the crate is damaged, make a note to that effect on the

Bill of Lading when signing for the shipment. Next,

remove the heater from the shipping packaging.

Report any damage to the carrier immediately.

On occasion, items are shipped loose. Be sure that

you receive the correct number of packages as indicated on the Bill of Lading.

Claims for shortages and damages must be filed with

the carrier by consignee. Permission to return goods

must be received from the factory prior to shipping.

Goods returned to the factory without an authorized

Returned Goods Receipt number will not be accepted.

All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and

serial number of the heater. When ordering under warranty conditions, you must also specify the date of

installation.

Purchased parts are subject to replacement only

under the manufacturer’s warranty. Debits for defective replacement parts will not be accepted. Parts will

be replaced in kind only per Raypak’s standard warranties.

Model Identification

The model identification number and heater serial

number are found on the heater data plate located on

the left inside jacket of the heater. The model number

will have the form H3 0162 or similar depending on the

heater size and configuration. The first character of the

model number identifies application (H = Hydronic

Heating System, WH = Hot Water Supply System, P =

Pool Application). The second character identifies the

firing mode (3 - two stage firing, 4 - On/Off firing ). The

next four places identify the size of the heater.

Ratings and Certifications

Standards:

• Gas-Fired Low Pressure Steam and Hot Water

Heaters, ANSI Z21-13 • CSA 4.9 - latest edition

• Industrial and Commercial Gas-Fired Package

Heaters, CAN 3.1 - latest edition

• Gas-Fired Pool Heaters, ANSI Z21.56 • CSA 4.7 latest edition

• Gas Water Heaters, ANSI Z21.10.3 • CSA 4.3 - latest edition

All Raypak heaters are National Board Approved, and

design-certified and tested by the Canadian Standards

Association (CSA) for the U.S. and Canada. Each

heater is constructed in accordance with Section IV of

the American Society of Mechanical Engineers

(ASME) Heater Pressure Vessel Code and bears the

ASME stamp. The heater also complies with the latest

edition of ASHRAE 90.1 Standard.

Installations at Elevation

Rated inputs are suitable for up to 4500 feet elevation

without de-rate. Consult the Factory for installations at

any altitude in excess of 4500 feet.

WARNING: Altering any Raypak pressure vessel

by installing replacement heat exchangers, tube

bundle headers, or any ASME parts not

manufactured and/or approved by Raypak will

instantly void the ASME and CSA ratings of the

vessel and any Raypak warranty on the vessel.

Altering the ASME or CSA ratings of the vessel also

violates national, state, and local approval codes.

5

Page 6

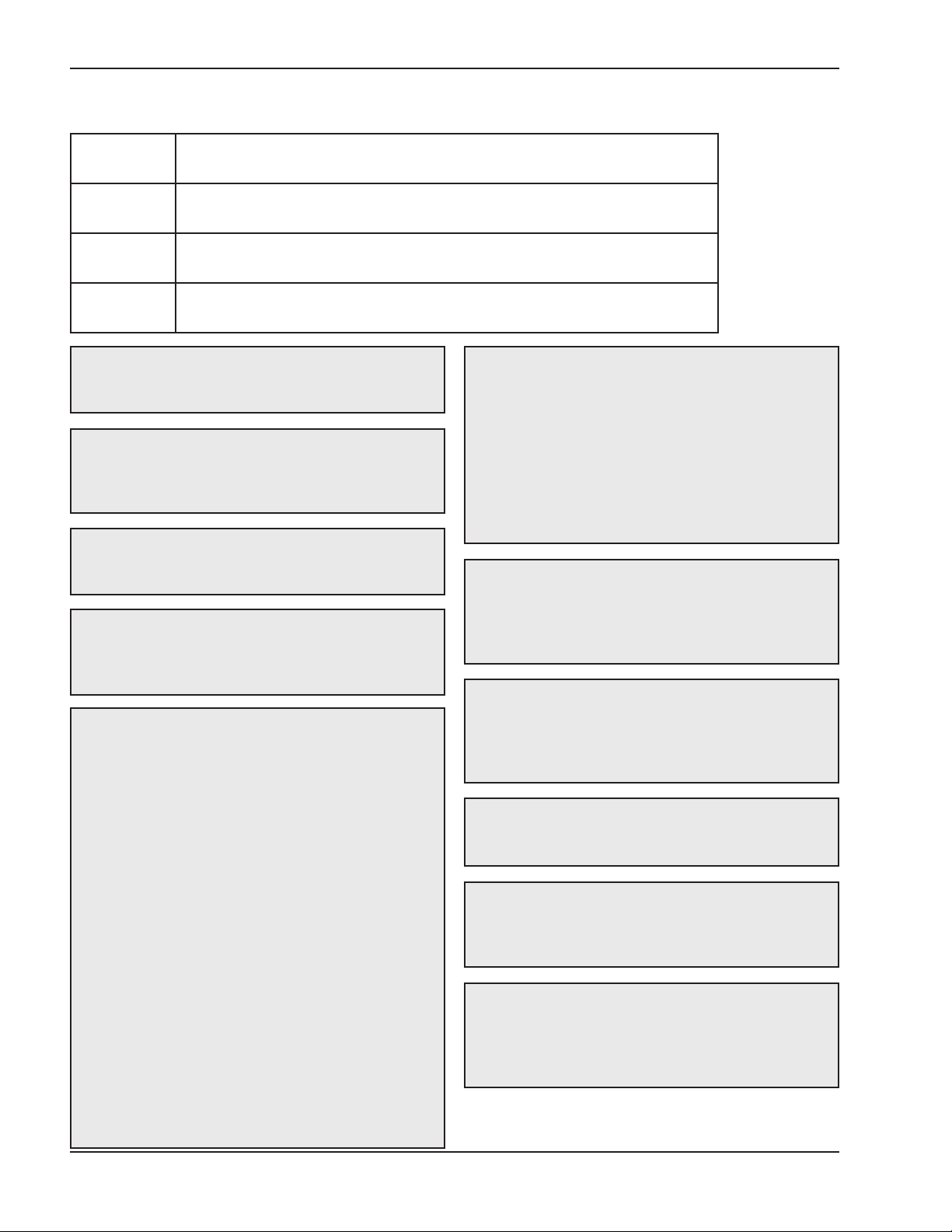

Component Locations

Fig. 1: Component Locations—Back

Fig. 2: Component Locations—Left Side

Panels removed for clarity

Fig. 3: Component Locations—Front

6

HI LIMITS

FLUE EXHAUST

PRESSURE RELIEF

CONNECTION

COMBUSTION AIR

INTAKE

HI-LIMITS

WATER OUTLET

GAS CONNECTION

WATER INLET

VIEW PORT

Fig# 9399

Page 7

General Information

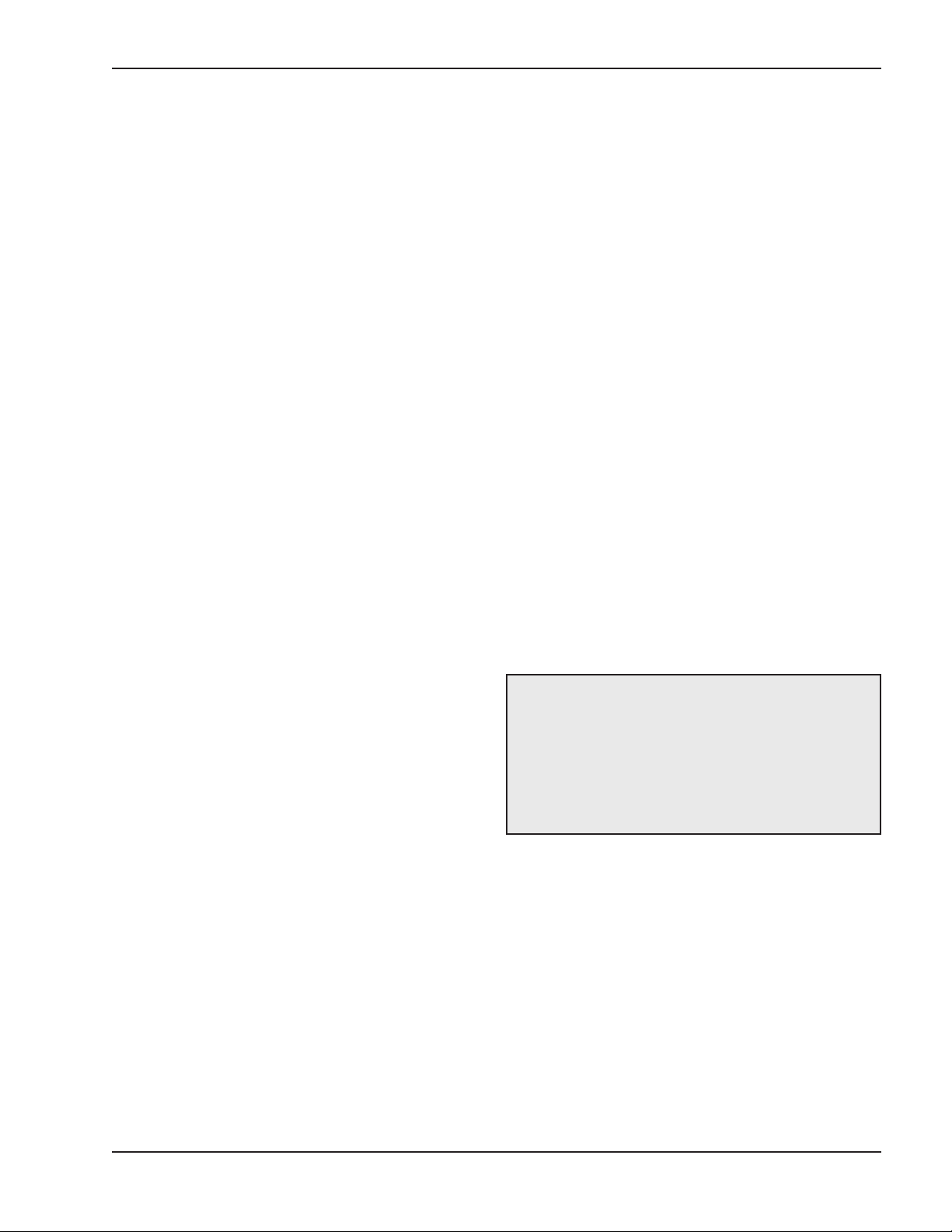

Table A: Basic Data

Table B: Manifold Data

Model

No.

Quantity of Vent Size (in.)

Burners Gas Valves Blowers Flue Intake

122 3 2* 1 4 5

162 4 2* 1 5 5

202 5 2* 1 5 5

242 6 2* 1 5 5

322 8 2* 1 6 5

Model

No.

Burners per Valve Stages % Fire at Stage

A B 1 2 1 2

122 2 1 A AB 66 100

162 3 1 A AB 75 100

202 3 2 A AB 60 100

242 4 2 A AB 66 100

322 5 3 A AB 63 100

7

*Second valve located inside air plenum

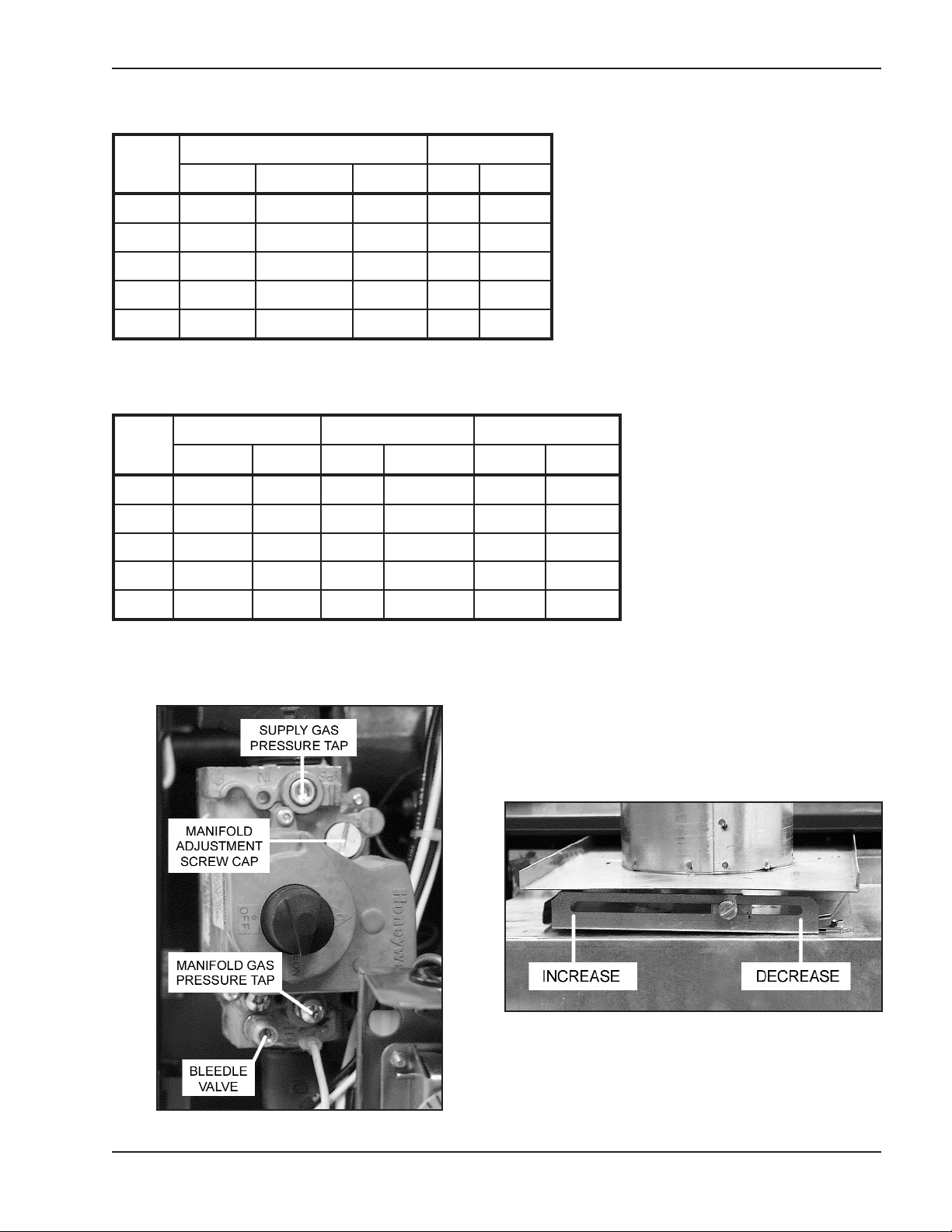

Fig. 4: Gas Valve Detail

Fig. 5: Air Shutter Adjustment

Page 8

GENERAL SAFETY

To meet commercial hot water use needs, the high

limit safety control on this water heater will shut off the

main gas valve before the outlet temperature reaches

210°F. However, water temperatures over 125°F can

cause instant severe burns or death from scalds.

When supplying general purpose hot water, the recommended initial setting for the temperature control is

125°F.

Safety and energy conservation are factors to be considered when setting the water temperature on the

thermostat. The most energy-efficient operation will

result when the temperature setting is the lowest that

satisfies the needs of the application.

Water temperature over 125°F can cause instant

severe burns or death from scalds. Children, disabled

and elderly are at highest risk of being scalded.

• Feel water before bathing or showering.

• Temperature limiting valves are available.

Maximum water temperatures occur just after the

heater’s burner has shut off. To determine the water

temperature being delivered, turn on a hot water

faucet and place a thermometer in the hot water

stream and read the thermometer.

NOTE: When this water heater is supplying general

purpose hot water for use by individuals, a

thermostatically controlled mixing valve for reducing

point of use water temperature is recommended to

reduce the risk of scald injury. Contact a licensed

plumber or the local plumbing authority for further

information.

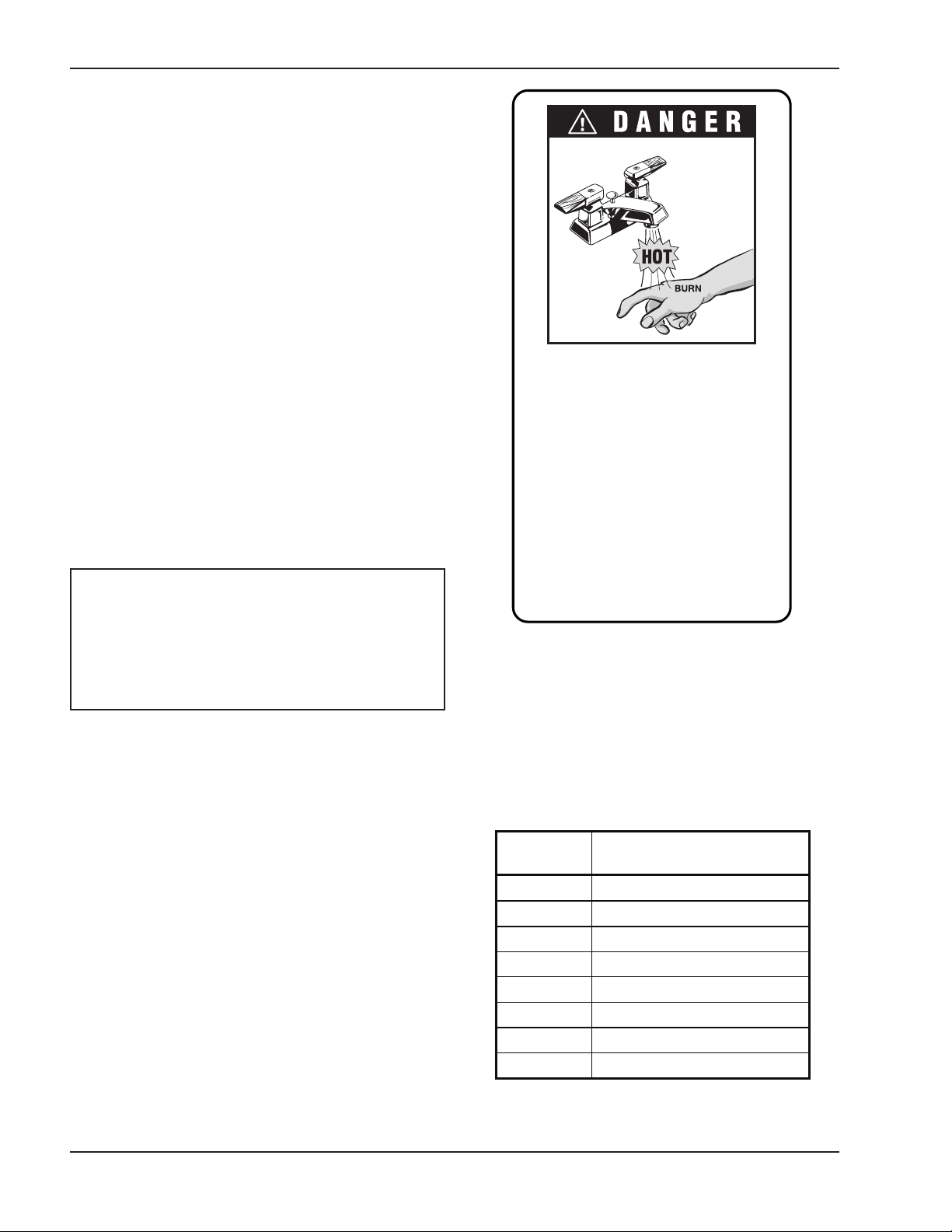

Time/Temperature

Relationships in Scalds

The following chart details the relationship of water

temperature and time with regard to scald injury and

may be used as a guide in determining the safest

water temperature for your applications.

Table C: Time to Produce Serious Burn

8

Water temperature over 125°F can

cause instant severe burns or death

from scalds.

Children, disabled, and elderly are

at highest risk of being scalded.

See instruction manual before setting temperature at water heater.

Feel water before bathing or showering.

Temperature limiting valves are

available, see manual.

Water

Temp.

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table courtesy of The Shriners Burn Institute

Time to Produce Serious

Burn

Page 9

INSTALLATION

INSTALLATION

Installation Codes

Installations must follow these codes:

· Local, state, provincial, and national codes, laws,

regulations and ordinances.

· National Fuel Gas Code, ANSI Z223.1- latest edition (NFGC).

· National Electrical Code, ANSI/NFPA 70 - latest

edition (NEC).

· Standard for Controls and Safety Devices for

Automatically Fired Heaters, ANSI/ASME CSD-1,

when required (CSD-1).

· For Canada only: CAN/CGA B149 Installation

Code (B149) and C.S.A. C22. 1 C.E.C. Part 1

(C22. 1).

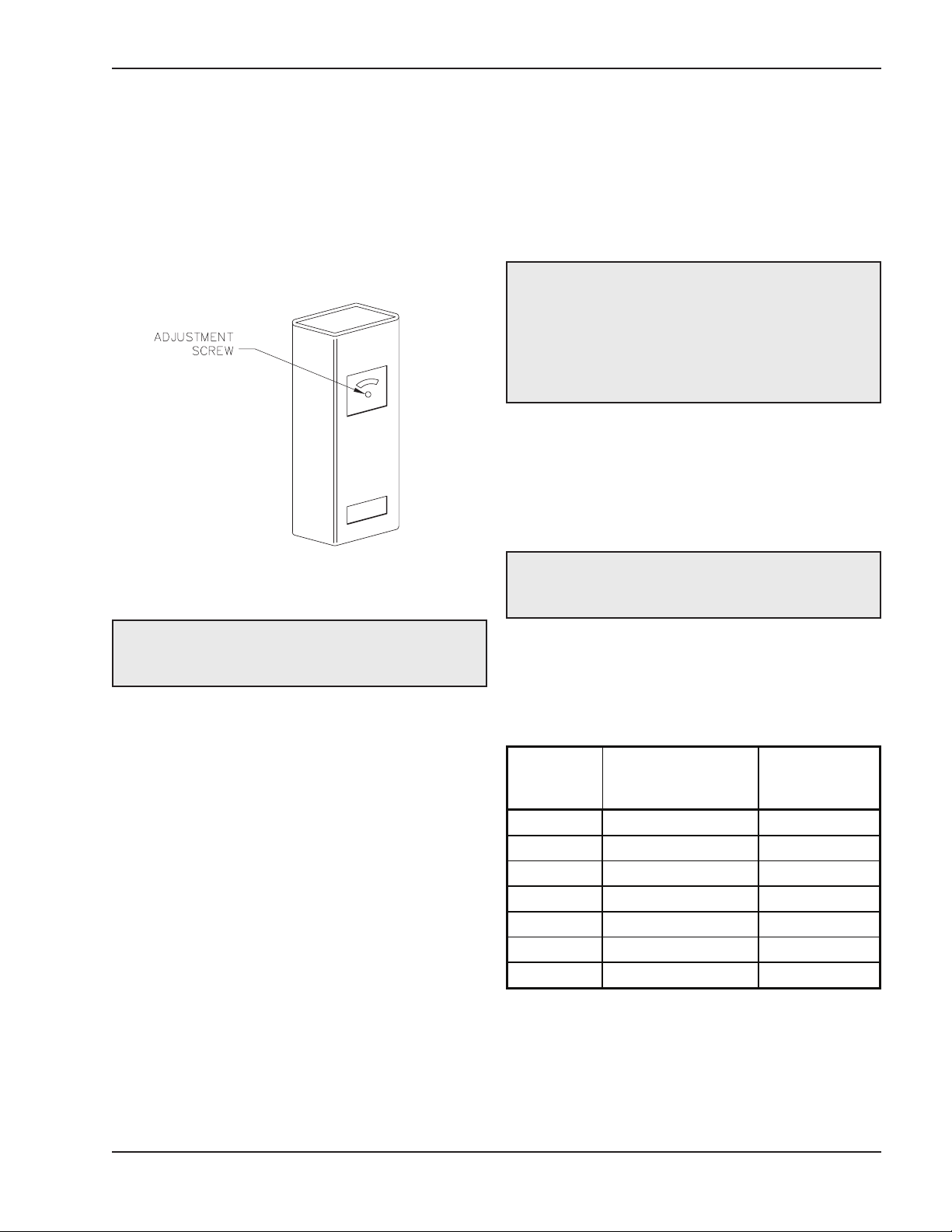

The temperature of the water in the heater can be regulated by using the temperature control. To comply

with safety regulations, the temperature control is set

at the lowest setting when shipped from the factory.

To adjust the water temperature, insert a small straight

screwdriver into the adjustment screw on the front of

temperature control and turn the wheel to the desired

setting (See Fig. 6).

CAUTION: Hotter water increases the risk of scalding! There is a hot water scald potential if the

thermostat is set too high.

Fig. 6: Temperature Control

Equipment Base

The heater should be mounted on a level, structurally

sound surface. The heater is approved for installation

on a combustible surface but must NEVER be

installed on carpeting. Gas-fueled equipment installed

in enclosed parking garages must be located at least

18 in. above the floor.

CAUTION: The heater should be located in an area

where water leakage will not result in damage to the

area adjacent to the appliance or to the structure.

When such locations cannot be avoided, it is

recommended that a suitable catch pan, adequately

drained, be installed under the appliance. The pan

must not restrict air flow.

9

In addition, the heater shall be installed such that the

gas ignition system components are protected from

water (dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

WARNING: This product must be installed by a

licensed plumber or gas fitter when installed within

the Commonweatlh of Massachusetts.

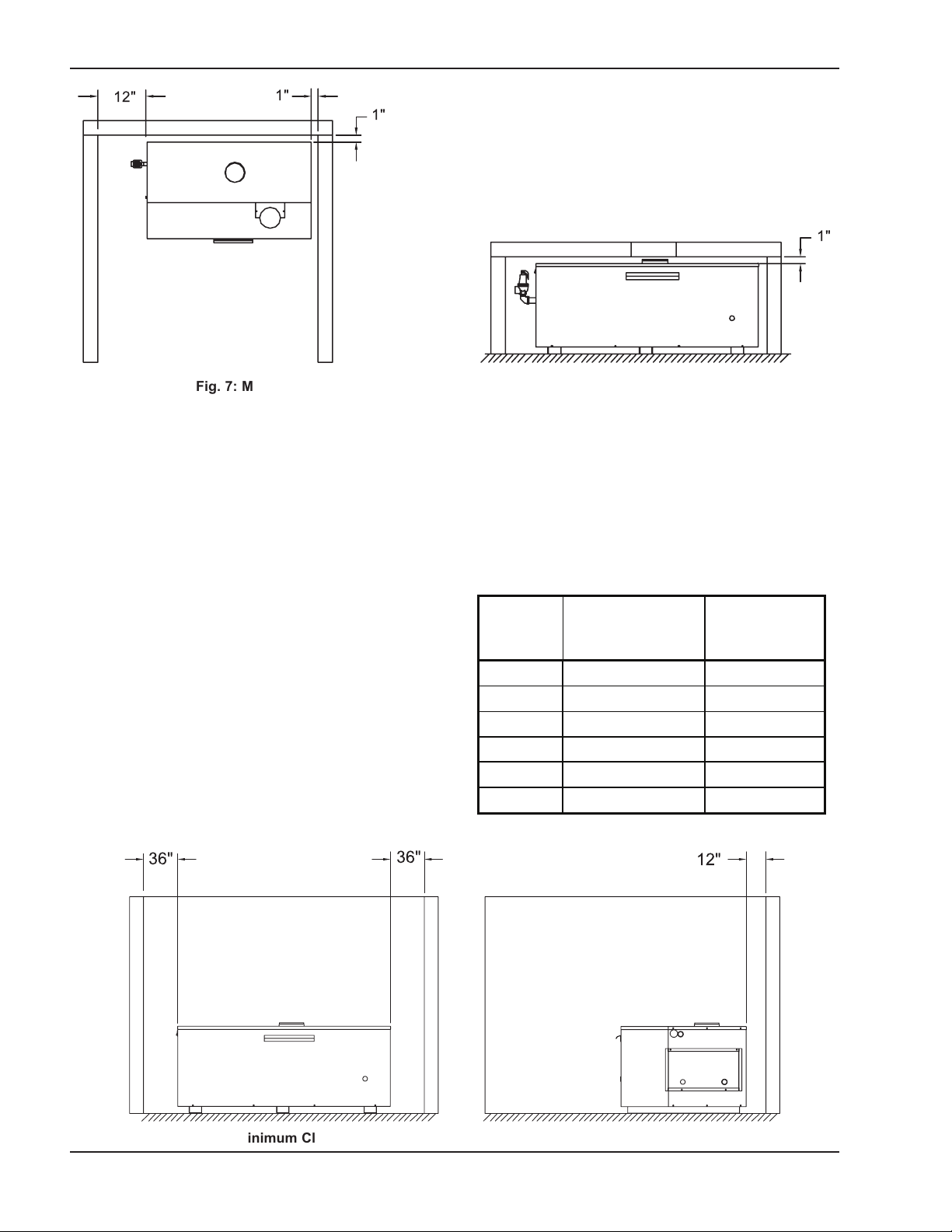

Clearances

Indoor Installations

Table D: Clearances – Indoor Installations

* DO NOT install on carpeting.

Heater

Side

Floor* 0” 0”

Rear 1” 24”

Water Side 12” 24”

Other Side 1” 24”

Top 1” 1”

Front Open 24”

Vent 2” 2”

Minimum Clearance

from Combustible

Surfaces

Recommended

Service

Clearance

Page 10

10

Fig. 7: Minimum Clearances from Combustible Surfaces—Indoor Installations

When installed according to the listed minimum clearances from combustible construction, these heaters

can still be serviced without removing permanent

structural construction around the heater. However, for

ease of servicing, we recommend a clearance of at

least 24 in. in front, and at least 36 in. on the water

connection side. This will allow the heater to be serviced in its installed location without movement or

removal of the heater.

Service clearances less than the minimums may

require removal of the heater to service either the heat

exchanger or the burner tray. In either case, the heater

must be installed in a manner that will enable the

heater to be serviced without removing any structure

around the heater.

Table E: Clearances – Outdoor Installations

TOP VIEW

FRONT VIEW

Fig. 8: Minimum Clearances from Combustible Surfaces—Outdoor Installations

Outdoor Installations

These heaters are design-certified for outdoor installation. Heaters must not be installed under an overhang

unless clearances are in accordance with local installation codes and the requirements of the gas supplier.

Three sides must be open in the area under the overhang. Roof water drainage must be diverted away

from heaters installed under overhangs.

!$

!$

Heater

Side

Front Open 24”

Rear 12” 24”

Water Side 36” 36”

Other Side 36” 36”

Top Unobstructed 36”

Vent N/A N/A

Min. Clearance

from Combustible

Surfaces

Recommended

Service

Clearance

Page 11

11

a motorized sealed damper to prevent the circulation of cold air through the heater during the

non-operating hours.

Conventional Combustion Air

Supply

U.S. Installations

All Air from Inside the Building

The confined space shall be provided with two permanent openings communicating directly with an

additional room(s) of sufficient volume so that the combined volume of all spaces meets the criteria for an

unconfined space. The total input of all gas utilization

equipment installed in the combined space shall be

considered in making this determination. Each opening shall have a minimum free area of 1 square inch

per 1,000 Btu per hour (22 cm² per kW) of the total

input rating of all gas utilization equipment in the confined space, but not less than 100 in.² (645 cm²). One

opening shall commence within 12 in. (30 cm) of the

top, and one opening shall commence within 12 in. (30

cm) of the bottom, of the enclosure. The minimum

dimension of air openings shall be not less than 3 in.

(8 cm) in any direction.

All Air from Outdoors

The confined space shall communicate with the outdoors in accordance with methods 1 or 2. The

minimum dimension of air openings shall not be less

than 3 in. (8 cm) in any direction. Where ducts are

used, they shall be of the same cross-sectional area

as the free area of the openings to which they connect.

1. Two permanent openings, one commencing within 12 in. (30 cm) of the top, and one commencing

within 12 in. (30 cm) of the bottom, of the enclosure shall be provided. The openings shall

communicate directly, or by ducts, with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

a. Where directly communicating with the out-

doors or where communicating to the

outdoors through vertical ducts, each opening

shall have a minimum free area of 1 sq in. per

4000 Btu per hr (5.5 cm

2

per kW) of total input

rating of all equipment in the enclosure.

b. Where communicating with the outdoors

through horizontal ducts, each opening shall

have a minimum free area of 1 sq in. per 2000

Combustion and Ventilation Air

Indoor Units

The heater must be supplied with sufficient quantities

of non-contaminated air to support proper combustion

and equipment ventilation. Combustion air can be supplied via conventional means where combustion air is

drawn from the area immediately surrounding the

heater, or via direct vent, where combustion air is

drawn directly from outside. All installations must comply with the requirements of the NFGC (U.S.) and

B149 (Canada), and all local codes.

Direct Combustion Air

If outside air is drawn through the intake pipe directly

to the unit for combustion:

1. Install combustion air direct vent in accordance

with the venting section of this manual.

2. Provide adequate ventilation of the space occupied by the heater(s) by an opening(s) for

ventilation air at the highest practical point communicating with the outdoors. The total

cross-sectional area shall be at least 1 in.

2

of free

area per 20,000 BTUH (111 mm2per kW) of total

input rating of all equipment in the room when the

opening is communicating directly with the outdoors or through vertical duct(s). The total

cross-sectional area shall be at least 1 in.

2

of free

area per 10,000 BTUH (222 mm

2

per kW) of total

input rating of all equipment in the room when the

opening is communicating with the outdoors

through horizontal duct(s).

3. In cold climates, and to mitigate potential freezeup, Raypak highly recommends the installation of

CAUTION: Combustion air must not be

contaminated by corrosive chemical fumes which

can damage the heater and void the warranty. (See

the Appendix.)

These clearances are required when the outdoor

vent cap is used. If installing the heater outdoors

with a vent stack, the indoor clearances may be

utilized.

The combustion air intake hood MUST be used for

outdoor installations. The hood is shipped loose and

installed on the side of the heater over the filter box at

the job site.

Page 12

12

WARNING: Do not use one permanent opening

method if the equipment room is under negative

pressure conditions or the equipment is common

vented with other gas-fired appliances.

1. Ventilation of the space occupied by the heater

shall be provided by an opening(s) for ventilation

air at the highest practical point communicating

with outdoors. The total cross-sectional area of

such an opening(s) shall be at least 10% of the

area required in (2) and (3), but in no case shall

the cross-sectional area be less than 10 sq. in.

(6500 sq. mm.).

2. For heaters using a barometric damper in the vent

system, and when air supply is provided by natural air flow from the outdoors for natural draft,

partial fan assisted, fan-assisted or power draftassisted burners, there shall be a permanent air

supply opening(s) having a cross section area of

not less than 1 sq. in. per 7000 BTUH (310 sq. mm

per kW) up to and including 1 million BTUH, plus

1 sq. in. per 14000 BTUH (155 sq. mm per kW) in

excess of 1 million BTUH. This opening(s) shall be

either located at or ducted to a point neither more

CAUTION: All combustion air must be drawn from

the air outside of the building; the mechanical equipment room must communicate directly with the

outdoors.

Canadian Installations

Water Piping

General

The heater should be located so that any water leaks

will not cause damage to the adjacent area or structures.

Relief Valve Piping

than 18 in. (450 mm) nor less than 6 in. (150 mm)

above the floor level. The duct can also "Goose

Neck" through the roof. The duct is preferred

straight down 18” from floor, but do not place near

piping. This air supply opening requirement shall

be in addition to the air opening for ventilation air

required in (1).

3. For heaters not using a barometric damper in the

vent system, and when air supply is provided by

natural air flow from outdoors for a power burner

and there is no draft regulator, drafthood or similar

flue gas dilution device installed in the same

space, in addition to the opening for ventilation air

required in (1), there shall be a permanent air supply opening(s) having a total cross-sectional area

of not less than 1 sq. in. for each 30,000 BTUH (70

sq. mm per kW) of total rated input of the burner(s), and the location of the opening(s) shall not

interfere with the intended purpose of the opening(s) for ventilation air referred to (1). This

opening(s) can be ducted to a point neither more

than 18 in. (450 mm) nor less than 6 in. (150 mm)

above the floor level. The duct can also "Goose

Neck" through the roof. The duct is preferred to be

straight down 18” from floor, but do not place near

piping.

4. Refer to the latest version of the B149 for additional information.

CAUTION: This heater requires forced water

circulation when the burner is operating. See Table F

and Table G for minimum and maximum flow rates

and water pump selection. The pump must be

interlocked with the heater to prevent heater

operation without water circulation.

WARNING: Pressure relief valve discharge piping

must be piped near the floor and close to a drain to

eliminate the potential of severe burns. Do not pipe

to any area where freezing could occur. Refer to

local codes.

Btu per hr (11 cm2per kW) of total input rating

of all equipment in the enclosure.

2. One permanent opening, commencing within 12

in. (30 cm) of the top of the enclosure, shall be

permitted where the equipment has clearances of

at least 1 in. (2.5 cm) from the sides and back and

6 in. (16 cm) from the front of the appliance. The

opening shall directly communicate with the outdoors or shall communicate through a vertical or

horizontal duct to the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors,

and shall have a minimum free area of:

a. 1 sq in. per 3000 Btu per hr (7 cm

2

per kW) of

the total input rating of all equipment located in

the enclosure, and

b. Not less than the sum of the areas of all vent

connectors in the confined space.

Page 13

13

Low Temperature System

Heater requires minimum inlet temperature of 105°F.

Consult the following sections for piping details.

Temperature & Pressure Gauge

The temperature and pressure gauge is factorymounted in the in/out header.

Hydronic Heating

Pump Selection

In order to ensure proper performance of your boiler

system, you must install a properly sized pump.

Raypak recommends using a 20°F Delta T as design

Delta T. (Delta T is the temperature difference between

the inlet and outlet water when the heater is firing at

full rate). If a Delta T larger than 20°F is necessary,

see Table F for minimum flow rate requirements.

Pressure Drop in Feet of Head

Feedwater Regulator

Raypak recommends that a feedwater regulator be

installed and set at 12 PSIG minimum pressure at the

highest point of system. Install a check valve or back

flow device upstream of the regulator, with a manual

shut off valve as required by local codes.

Model

No.

10°F ΔT 20°F ΔT 30°F ΔT Min. Flow Max. Flow

gpm ΔP (ft) gpm ΔP (ft) gpm ΔP (ft) gpm ΔP (ft) ΔT gpm ΔP (ft) ΔT

122 20 2.5 10 <1.0 10* <1.0 20 30 5.3 7

162 27 4.5 13 1.10 10 <1.0 27 30 5.4 9

202 34 7.2 17 1.85 11 <1.0 10 <1.0 34 30 5.5 11

242 40 10.0 20 2.65 14 1.3 10 <1.0 40 44 11.8 9

322 27 4.70 18 2.2 14 1.4 40 44 12.2 12

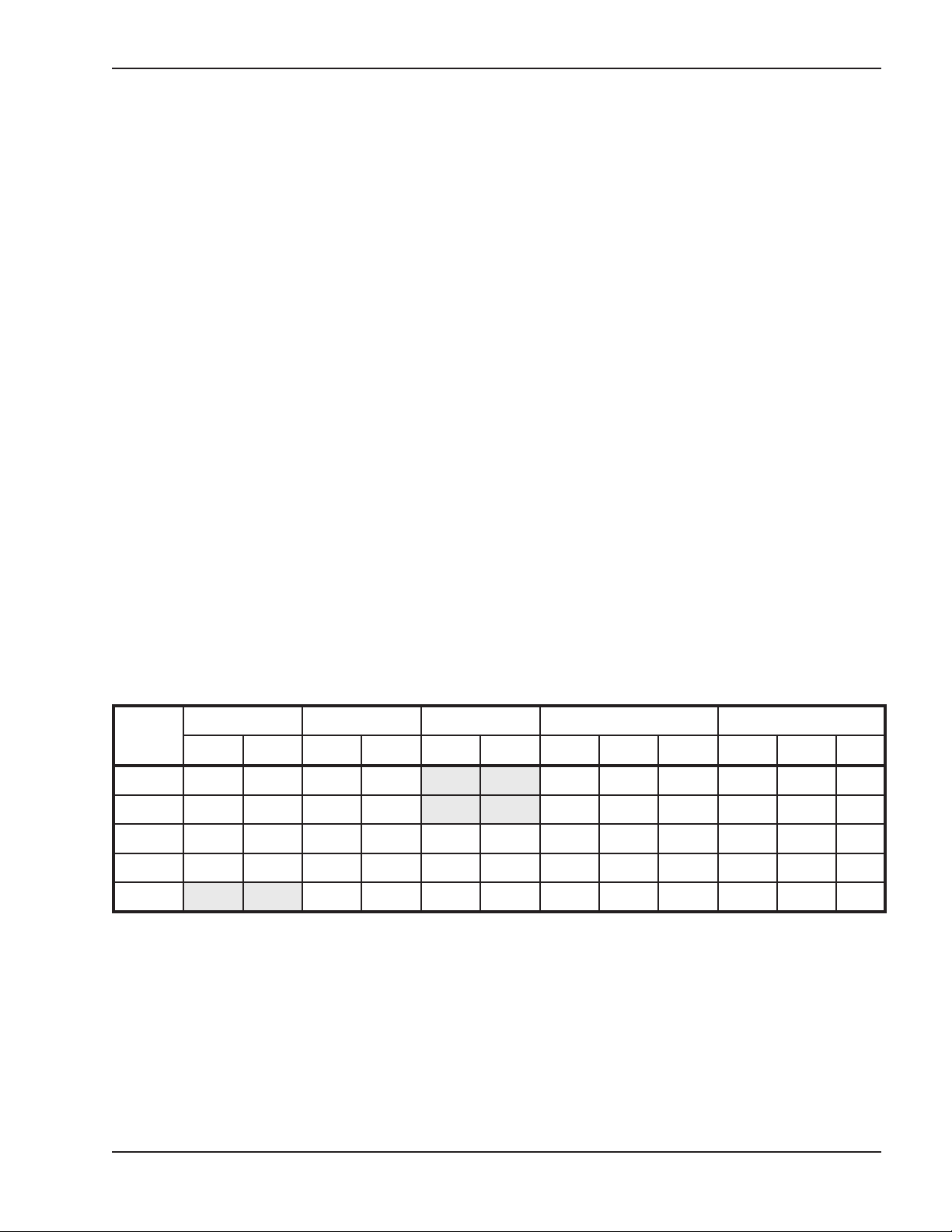

Table F: Heater Rates of Flow and Pressure Drops

* Flow switch (when used) will not activate at less than 12 gpm.

NOTE: Basis for minimum flow - 10 gpm or 40° Delta T

maximum flow - 44 gpm, except for 1.25” header.

Hydrostatic Test

Unlike many other types of heaters, Raypak heaters

do not require hydrostatic testing prior to being placed

in operation. The heat exchanger has already been

factory-tested and is rated for 160 PSI maximum operating pressure. However, Raypak does recommend

hydrostatically testing the piping connections to the

heater and the rest of the system prior to operation.

This is particularly true for hydronic systems using

expensive glycol-based antifreeze. Raypak recommends conducting the hydrostatic test before

connecting gas piping or electrical supply.

Leaks must be repaired at once to prevent damage to

the heater. NEVER use petroleum-based stop-leak

compounds.

1. Connect fill water supply. Fill heater with water (be

sure bleed valve is open). When water flows from

bleed valve, shut off water. Close bleed valve.

Carefully fill the rest of the system, being sure to

eliminate any entrapped air by using high point

vents. Close feed valve. Test at standard operating

pressure for at least 24 hours.

2. Make sure constant gauge pressure has been

maintained throughout test.

3. Check for leaks. Repair if found.

Page 14

14

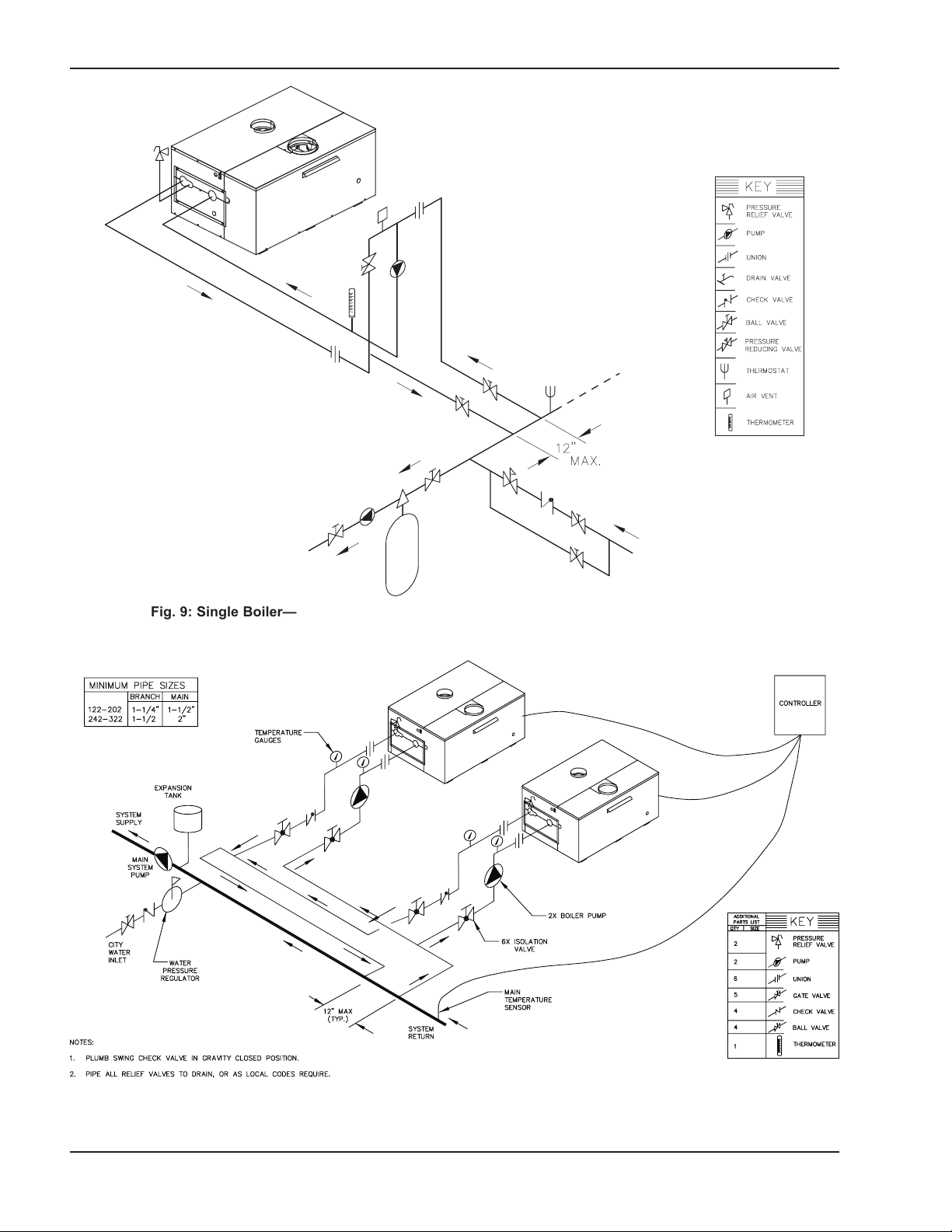

Fig. 9: Single Boiler—Low Temperature Application (Heat Pump) Primary/Secondary Piping

Fig. 10: Dual Boiler—Primary/Secondary Piping

Page 15

15

Table G: Domestic Water Heater Flow Rate Requirements

ΔT = Temperature rise, °F.

ΔP = Pressure drop through heat exchanger, ft.

SHL = System head loss, ft. (System head loss is based on the heater and tank placed no more than 5 feet apart and 25 feet equivalent length of

pipe and fittings.)

gpm = Gallons per minute, flow rate.)

MTS = Minimum tubing size.

*Must utilize optional cupro-nickel tubes.

**With Hard Water (16-25 grains per gallon), the operating control must be set no higher than 130F for scale free operation. For operating temperatures above 130F, a water softener must be utilized.

Model

No.

Soft (0–4 grains per gallon) Medium (5–15 grains per gallon) Hard* (16–25** grains per gallon)

ΔT gpm ΔP MTS SHL ΔT gpm ΔP MTS SHL ΔT gpm ΔP MTS SHL

122 10 20 2.5 1-1/4 4.9 8 26 4.0 1-1/4 7.8 7 30 5.3 1-1/4 10.3

162 14 20 2.5 1-1/4 4.9 11 26 4.1 1-1/4 7.9 9 30 5.4 1-1/4 10.4

202 17 20 2.6 1-1/4 5.0 13 26 4.2 1-1/4 8.0 11 30 5.5 1-1/4 10.5

242 21 20 2.6 1-1/2 3.5 16 26 4.3 1-1/2 5.9 9 44 11.8 1-1/2 16.1

322 27 20 2.7 1-1/2 3.6 20 27 4.8 1-1/2 6.6 12 44 12.2 1-1/2 16.5

Piping—Heating Boilers

All high points should be vented. Purge valves and a

bypass valve should be installed. A boiler installed

above radiation level must be provided with a low

water cut-off device. The boiler, when used in connection with a refrigeration system, must be installed so

the chilled medium is piped in parallel with the boiler

with appropriate valves to prevent the chilled medium

from entering the boiler.

The boiler piping system of a hot water heating boiler

connected to heating coils located in air handling units

where they may be exposed to circulating refrigerated

air, must be equipped with flow control valves or other

automatic means to prevent gravity circulation of the

boiler water during the cooling cycle. It is highly recommended that the piping be insulated.

Air-Separation/Expansion Tank

All boilers should be equipped with a properly sized

expansion tank and air separator fitting as shown in

the diagrams.

Three-Way Valves

Valves designed to blend water temperatures or

reduce water circulation through the boiler should not

be used. Raypak boilers are high recovery low mass

boilers not subject to thermal shock. Raypak offers a

full line of electric sequencers that produce direct reset

of boiler water temperature. Refer to the Controls

Section in our Complete Catalog.

Domestic Hot Water Piping

When designing the water piping system for domestic

water applications, water hardness should be considered. Table G indicates the suggested flow rates for

soft, medium and hard water. Hardness is specified as

grains per gallon.

Page 16

16

Fig. 11: Single Heater—Domestic Hot Water with One Storage Tank

Page 17

17

Gas Supply

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shut-off valve located outside the heater jacket. A pounds to inches

regulator must be installed to reduce to gas supply

pressure to under 10.5 in. WC. The regulator should

be placed a minimum distance of 10 times the pipe

diameter upstream of the heater gas controls. All gas

piping must be tested after installation in accordance

with local codes. The heater and its gas connection

must be leak-tested before placing it in operation.

DANGER: Make sure the gas on which the heater

will operate is the same type as specified on the

heater’s rating plate.

Pool Heating

The Hi Delta pool heater is equipped with an external

pump and bypass arrangement that blends outlet

water with the inlet to increase the inlet water temperature, thereby reducing the likelihood of condensation

forming on the heat exchanger. The pump also serves

to circulate water through the heater from the main

system piping.

To complete the installation of the pool heater, the pool

thermostat needs to be installed in the main return

water line. This will ensure that the heater will be energized at the right time. If the main water line is too far

away from the heater and the capillary bulb will not

reach it, locate the pool thermostat adjacent to the

main line and run wires back to the heater.

Adjustment of the bypass valve is critical to proper

operation of the heater. The bypass valve should be

adjusted to achieve a minimum inlet water temperature of 105°F and an outlet water temperature

between 120°F and 140°F. When starting with a cold

pool, make initial adjustments. Make final adjustments

when pool water approaches desired temperature.

Automatic Chlorinators and

Chemical Feeders

All chemicals must be introduced and completely diluted into the pool or spa water before being circulated

through the heater. Do not place chlorine tablets or

bromine sticks in the skimmer. High chemical concentrations will result when the pump is not running (i.e.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical

backup into the heater when the pump is shut off.

CAUTION: Power to the heater should be

interlocked with the main system pump to make sure

the heater does not fire without the main system

pump in operation. Improper flow control can

damage the heater. Uncontrolled flow (too high) or

restricted flow (too low) can seriously damage the

heater. Follow these instructions to make sure your

heater is properly installed.

Winterizing Your Heater

When heaters installed outdoors in freezing climate

areas are to be shut down for the winter, please

observe the following procedure:

Heaters installed outdoors in freezing climate areas

should be shut down for the winter. To shut down

heater, turn off manual main gas valve and main gas

shut-off. Close isolation valves and remove water piping from the in/out header of the heater. Drain the

heater and any piping of all water that may experience

below freezing temperatures.

Pool and Spa Water Chemistry

NOTE: Chemical imbalance can cause severe

damage to your heater and associated equipment.

Maintain your water pH between 7.4 and 7.8 and

total alkalinity between 100 and 150 ppm. If the

mineral content and dissolved solids in the water

become too high, scale forms inside the heat

exchanger tubes, reducing heater efficiency and also

damaging the heater. If the pH drops below 7.2, the

heater will be severely damaged.

NOTE: Heat exchanger damage resulting from

chemical imbalance and/or scaling is not covered

under the warranty.

NOTE: High chemical concentrates from feeders

and chlorinators that are out of adjustment will cause

very rapid corrosion to the heat exchanger in the

heater. Such damage is not covered under the

warranty.

Page 18

18

Fig. 12: Sediment Trap Orientation

GAS

Gas Supply Connection Gas Supply Pressure

A minimum of 7 in. WC and a maximum of 10.5 in. WC

upstream gas pressure is required under load and no

load conditions for natural gas. A minimum of 11 in.

WC and a maximum of 13 in. WC is required for

propane gas. The gas pressure regulator supplied on

the heater is for low pressure service. If upstream

pressure exceeds 14 in. WC, an intermediate gas

pressure regulator, of the lockup type, must be

installed.

When connecting additional gas utilization equipment

to the gas piping system, the existing piping must be

checked to determine if it has adequate capacity.

Gas Pressure Regulator

The gas valve pressure regulator(s) on the heater are

nominally preset at 3.5 in. WC for natural gas, and

10.5 in. WC for propane gas manifold pressure. The

pressure at the gas valve outlet tap, measured with a

manometer,while in operation should be 3.5 ± 0.1 in.

WC for natural gas and 10.5 in. ± 0.1 in. WC for

propane gas. If an adjustment is needed, turn the

adjustment screw clockwise to increase pressure or

counter-clockwise to decrease pressure.

CAUTION: The heater and its manual shutoff valve

must be disconnected from the gas supply during

any pressure testing of the gas supply system at test

pressures in excess of 1/2 PSIG (3.45 kPa). The

heater must be isolated from the gas supply piping

system by closing the manual shutoff valve during

any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG.

Relieve test pressure in the gas supply line before

reconnecting the heater and its manual shut off valve

to the gas supply line. FAILURE TO FOLLOW THIS

PROCEDURE MAY DAMAGE THE GAS VALVES.

Over pressurized gas valves are not covered by

warranty. The heater and its gas connections shall

be leak tested before placing the appliance in

operation. Use soapy water for leak test: DO NOT

use open flame.

CAUTION: Do not use Teflon tape on gas line pipe

thread. A pipe compound rated for use with gas

systems is recommended. Apply sparingly only on

male pipe ends.

CAUTION: Support gas supply piping with

hangers, not by the heater or its accessories. Ensure

the gas piping is protected from physical damage

and freezing where required.

FLOW

MANUAL

SHUT OFF

VALVE

SUPPLIED

BY OTHERS

SEDIMENT TRAP

EXTENTS OF

UNIT ENCLOSURE

MANUAL

SHUT OFF

VALVE

SEDIMENT

TRAP

GAS

FLOW

SUPPLIED

BY OTHERS

EXTENTS OF

UNIT ENCLOSURE

TO BURNERS

UNION

TO BURNERS

Page 19

19

Electrical Power Connections

Installations must follow these codes:

· National Electrical Code and any other national,

state, provincial or local codes or regulations having jurisdiction

· Safety wiring must be N.E.C. Class 1

· Heater must be electrically grounded as required

by N.E.C.

· In Canada, C22.1

The heater is wired for 120 VAC, 12 AMPS. The voltage is indicated on the tie-in leads. Consult the wiring

diagram shipped with the heater in the instruction

packet. The remote tank control stat, thermostat, or

electronic heater control as applicable, may be connected to stage selector terminal (See wiring diagram).

24 Volts are supplied to this connection through the

heater transformer. DO NOT attach line voltage to the

“TH” leads. Before starting the heater check to ensure

proper voltage to the heater and pump.

Install a separate disconnect means for each load.

Use appropriate-sized wire as defined by NEC, CSA

and/or local code. All primary wiring should be 125% of

minimum rating.

It is strongly recommended that all individually-powered control modules and the heater should be

supplied from the same power source.

Surge Protection

Microprocessor-based and solid state controls are vulnerable to damage from voltage and amperage

fluctuations in the power supply. All sensitive control

components should be protected by a suitable commercial-grade surge protection device.

If any of the original wire as supplied with the heater

must be replaced, it must be replaced with 105°C wire

or its equivalent.

Check the Power Source

AC = 108 Volts AC Minimum, 132 Volts AC MAX

AB = 108 Volts AC Minimum, 132 Volts AC MAX

BC = < 1 Volt AC

Making the Electrical Connections

Refer to Fig. 14 Wiring Connection, and the Wiring

Diagram.

1. Verify circuit breaker is properly sized by referring

to heater rating plate. A dedicated circuit breaker

should be provided.

2. Turn off all power to the heater. Verify that power

has been turned off by testing with a volt-ohm

meter prior to working with any electrical connections or components.

3. Observe proper wire colors while making electrical

connections. Many electronic controls are polarity

sensitive. Components damaged by improper

electrical installation are not covered by warranty.

4. Provide an external surge suppressor capable of

maintaining system integrity.

5. Provide overload protection and a disconnect

means for equipment serviceability as required by

local and state code.

6. Install heater controls, thermostats, or building

management systems in accordance with the

applicable manufacturer’s instructions.

7. Conduit should not be used as the ground. There

must be a solidly wired ground.

Fig. 13: Check Power Source

NOTE: A grounding electrode conductor shall be

used to connect the equipment grounding

conductors, the equipment enclosures, and the

grounded service conductor to the grounding

electrode.

WARNING: Using a volt-ohm meter (VOM), check

the following voltages at the terminal block inside the

unit. Make sure proper polarity is followed and house

ground is proven.

Page 20

20

Fig. 14: Single Stage and 2-Stage Tankstat

Electrical Connections—Domestic

Hot Water

Installer action is required to electrically enable your Hi

Delta heater to operate after making the power connections. You must make a connection on Terminal

Block #3 for temperature control connections. This will

be done based on the controller option selected with

your heater order.

1. For Pool and Closed Loop Water Source Heat

Pump applications, your heater should be configured to operate in an ON/OFF firing mode. This

means that you will connect a single-pole control

to stage one of stage selector (Terminals 4 & 5).

Then jumper the remaining firing stages. For

example, if your heater is a 162, you will jumper

stage two. Then your heater will either be on at full

fire, or it will be off.

2. For multi-stage controller connections, connect

each stage of the control to the corresponding

stage selector terminal block in the heater. Stage

1 of the heater to stage 1 of the control. Stage 2 of

the heater to stage 2 of the control, and so on. Set

the operating control at the setpoint in which you

want the heater to maintain. Ensure that the sensing bulb of the control is at the point in the system

that will best maintain the temperature you want.

For example, when you are heating a tank of

water, you want the operating control sensor bulb

in the tank.

Consult the wiring diagram shipped with the heater in

the instruction packet. The Stage 1 connections are for

the remote tank control through the heaters 24 volt

transformer. DO NOT attach line voltage to the Stage

1 connection. Before starting heater, check to ensure

proper voltage to heater and pump.

CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

DANGER—SHOCK HAZARD: Make sure

electrical power to the heater is disconnected to

avoid potential serious injury or damage to

components.

NOTE: Minimum 18 AWG, 105°C, stranded wire

must be used for all low voltage (less than 30 volts)

external connections to the unit. Solid conductors

should not be used because they can cause

excessive tension on contact points. Install conduit

as appropriate. All high voltage wires must be the

same size (105°C, stranded wire) as the ones on the

unit or larger.

Page 21

21

SINGLE

Fig. 15: Single Stage Tankstat

Fig. 16: 2-Stage Tankstat

Heater must be electrically grounded in accordance

with NEC and C22.1(in Canada).

NOTES:

1. Field installed ground to inside of junction box.

2. If any of the original wire as supplied with the

heater must be replaced, it must be replaced with

105°C wire or its equivalent.

Venting

General

Definition of Appliance Categories

Heaters are divided into four categories based on the

pressure produced in the exhaust and the likelihood of

condensate production in the vent.

Category I. A heater which operates with a non-positive vent static pressure and with a vent gas

temperature that avoids excessive condensate production in the vent.

Category II. A heater which operates with a non-positive vent static pressure and with a vent gas

temperature that may cause excessive condensate

production in the vent.

Category III. A heater which operates with a positive

vent pressure and with a vent gas temperature that

avoids excessive condensate production in the vent.

Category IV. A heater which operates with a positive

vent pressure and with a vent gas temperature that

may cause excessive condensate production in the

vent.

See Table H for appliance category requirements for

the Hi Delta.

Determination of Appliance

Category for Venting Purposes and

Venting Arrangements

CAUTION: Proper installation of flue venting is criti-

cal for the safe and efficient operation of the heater.

NOTE: For additional information on appliance

categorization, see appropriate ANSI Z21 Standard

and the NFGC (U.S.), or B149 (Canada), or

applicable provisions of local building codes.

WARNING: Contact the manufacturer of the vent

material if there is any question about the appliance

categorization and suitability of a vent material for

application on a Category III or IV vent system.

Using improper venting materials can result in

personal injury, death or property damage.

STAGE

TANKSTAT

STAGE 1

CONNECTION

ATTACH STAGE 1 CONNECTIONS

ON HEATER TO THE SINGLE STAGE

TANKSTAT AS SHOWN IN THE DIAGRAM ABOVE.

2-STAGE

TANKSTAT

STAGE 1

CONNECTION

ATTACH STAGE 1 CONNECTIONS ON HEATER

TO STAGE 1 CONNECTION ON TANKSTAT.

ATTACH STAGE 2 CONNECTIONS OR

STAGE 1 CONNECTION OF HEATER 2

TO STAGE 2 CONNECTIONON TANKSTAT

AS SHOWN IN THE DIAGRAM.

STAGE 2 CONNECTION OR

STAGE 1 CONNECTION

OF HEATER 2

Page 22

22

Table H: Venting Category Requirements

Combustion Air

Supply

Exhaust

Configuration

Venting Category

Certified

Appliance Material

Combustion Air

Inlet Material

From Inside

Building (Non-Direct

Venting)

Vertical Natural

Draft Venting

I

Type B or and

Category I Venting

System*

Horizontal

Thru-wall

Venting

III

Stainless Steel

(Gas Tight)

From Outside

Building (Direct

Venting)

Vertical Venting I

Type B or and

Category I Venting

System*

Galvanized Steel

PVC

ABS

CPVC

Horizontal

Thru-wall

Venting

III

Stainless Steel

(Gas Tight)

*As defined in the latest edition of the NFGC, or in Canada, the B149.

Barometric Damper

A barometric damper may be required when vent

heights exceed 25 feet or when the draft is greater

than -0.08 in. WC. In these installations, a barometric

damper (single acting) is recommended.

The damper should be installed NO CLOSER than 18

in. from the discharge of the unit and no closer than 18

in. from a combustible ceiling. The damper can be

installed in horizontal or vertical runs of vent pipe as

necessary. Installation in a bull-head tee is acceptable

as shown in the NFGC.

The weights on the damper should be adjusted per the

damper manufacturer’s instructions for proper operation.

Support of Vent Stack

The weight of the vent stack or chimney must not rest

on the heater vent connection. Support must be provided in compliance with applicable codes. The vent

should also be supported to maintain proper clearances from combustible materials.

Use insulated vent pipe spacers where the vent passes through combustible roofs and walls.

Vent Terminal Location

General

Give special attention to the location of the vent termination to avoid possibility of property damage or

personal injury.

a) Gases may form a white vapor plume in winter.

The plume could obstruct a window view if the termination is installed in close proximity to windows.

b) Prevailing winds could cause freezing of conden-

sate and water/ice build-up on building, plants or

roof.

c) The bottom of the vent terminal and the air intake

shall be located at least 12 in. above grade.

d) Un-insulated single-wall metal vent pipe shall not

be used outdoors on cold climates for venting gas

utilization equipment.

e) Through-the-wall vents for Category II and IV

appliances and non-categorized condensing appliances shall not terminate over public walkways or

NOTE: During winter months check the vent cap

and make sure no blockage occurs from build up of

snow. Condensate can freeze on the vent cap.

Frozen condensate on the vent cap can result in a

blocked flue condition.

Page 23

23

Fig. 17: Minimum Clearances from Vent/Air Inlet Terminations – Indoor and Outdoor Installations

Table I: Vent/Air Inlet Termination Clearances

U.S. Installations

Clearance above grade, veranda, porch,

A

deck, or balcony

Clearance to window or door that may be

B

opened

4 ft (1.2m) below or to side

1 ft (30 cm) 1 ft (30 cm)

of opening; 1 foot (30 cm)

above opening

1

Canadian Installations

3 ft (91 cm)

2

C Clearance to permanently closed window **

Vertical clearance to ventilated soffit located

above the terminal within a horizontal dis-

D

tance of 2 ft (61cm) from the centerline of the

5 ft (1.5m) *

terminal

E Clearance to unventilated soffit **

F Clearance to outside corner **

G Clearance to inside corner 6 ft (1.83m) *

Clearance to each side of center line ex-

H

tended above meter/regulator assembly

*

3 ft (91 cm) within a height

15 ft above the me-

ter/regulator assembly

I Clearance to service regulator vent outlet * 6 ft (1.83m)

Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any

J

other appliance

K Clearance to mechanical air supply inlet

Clearance above paved sidewalk or paved

L

driveway located on public property

Clearance under veranda, porch, deck or

M

balcony

1

In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Code

2

In accordance with the current CAN/CGA-B149 Installation Codes

t Vent terminal shall not terminate directly above sidewalk or paved driveway located between 2 single family dwellings that serves

both dwellings

TT Permitted only if veranda, porc h, deck, or balcony is fully open on a mini mum of two sides beneath the floor and top of terminal and

underside of ver anda, porch, deck or balcony is greater than 1 ft (30cm)

* Clearances in accordance with local installation codes and the requirements of the gas supplier

4 ft (1.2m) below or to side

of opening; 1 ft (30 cm)

above opening

3 ft (91 cm) above if within

10 ft (3m) horizontally

7 ft (2.13m)

* 12 in. (30 cm) TT

3 ft (91 cm)

6 ft (1.83m)

7 ft (2.13m) t

Page 24

24

over an area where condensate or vapor could

create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or

other equipment. Where local experience indicates that condensate is a problem with Category

I and III appliances, this provision shall also apply.

f) Locate and guard vent termination to prevent acci-

dental contact by people or pets.

g) DO NOT terminate vent in window well, stairwell,

alcove, courtyard or other recessed area, unless

previously approved by local authority.

h) DO NOT terminate above any door, window, or

gravity air intake. Condensate can freeze, causing

ice formations.

i) Locate or guard vent to prevent condensate from

damaging exterior finishes. Use a 2’ x 2’ rust

resistant sheet metal backing plate against brick

or masonry surfaces.

j) DO NOT extend exposed vent pipe outside of

building. Condensate could freeze and block vent

pipe.

US Installations

Refer to latest edition of NFGC.

Vent termination requirements are as follows:

a) Vent must terminate at least four (4) feet below,

four (4) feet horizontally, or one (1) foot above any

door, window or gravity air inlet to the building.

b) The vent must not be less than seven (7) feet

above grade when located adjacent to public walkways.

c) Terminate vent at least three (3) feet above any

forced air inlet located within ten (10) feet.

d) Vent must terminate at least four (4) feet horizon-

tally, and in no case above or below unless four (4)

feet horizontal distance is maintained, from electric meters, gas meters, regulators, and relief

equipment.

e) Terminate vent at least six (6) feet away from adja-

cent walls.

f) DO NOT terminate vent closer than five (5) feet

below roof overhang.

g) The vent terminal of a direct vent appliance with

an input over 50,000 Btu per hour shall require a

12-inch vent terminal clearance.

h) Terminate vent at least one (1) foot above grade,

including normal snow line.

i) Multiple direct vent installations require a four (4)

foot clearance between vent caps.

Canada Installations

Refer to latest edition of CAN/CGA-B149.

A vent shall not terminate:

a) Directly above a paved sidewalk or driveway

which is located between two single family

dwellings and serves both dwellings

b) Less than 7 ft.(2.13m)above a paved sidewalk or

paved driveway located on public property

c) Within 6 ft(1.8m) of a mechanical air supply inlet to

any building

d) Above a meter/regulator assembly within 3

ft(900mm) horizontally of the vertical centre-line of

the regulator

e) Within 6 ft.(1.8m) of any gas service regulator vent

outlet

f) Less than 1 ft.(300mm) above grade level

g) Within the 3 ft.(1m) of a window or door which can

be opened in any building, any non-mechanical air

supply inlet to any building or the combustion air

inlet of any other appliance

h) Underneath a verandah, porch or deck, unless

(i) the verandah, porch or deck is fully open on a

minimum of two sides beneath the floor, and

(ii) the distance between the top of the vent termi-

nation and the underside of the verandah,

porch or deck is greater than 1 ft (30 cm).

Page 25

25

Venting Installation Tips

Support piping:

· horizontal runs- at least every five (5) feet.

· vertical runs - use braces:

· under or near elbows

Follow items listed below to avoid personal injury or

property damage.

· Cut nonmetallic intake pipe with fine-toothed hacksaw.

· Do not use nonmetallic intake pipe or fittings that

are cracked or damaged.

· Do not use nonmetallic intake fittings if they are

cut or altered.

· Do not drill holes, or use screws or rivets, in nonmetallic intake pipe or fittings.

To make metallic vent joints:

· Do not install seams of vent pipe on bottom of

runs.

· 100% Seal all joints and seams with high temperature silicone sealant.

Venting Configurations

For heaters connected to gas vents or chimneys, vent

installations shall be in accordance with the section

on, Venting of Equipment, of the latest edition of

NFGC, or in Canada, B149 Installation Code for Gas

Burning Appliances and Equipment, or applicable provisions of local building codes.

WARNING: Examine the venting system at least

once a year. Check all joints and vent pipe

connections for tightness, corrosion or deterioration.

NOTE: The words "Flue Exhaust", "Flue" and

"Exhaust Vent" are used interchangeably.

Fig. 18: Natural Draft Vertical Venting (Category I)

Model

No.

Appliance

Category

Certified

Venting

Material

Minimum

Recommended

Vent Size (inches)

Min./Max. Venting

Length without

Barometric

Damper (feet)**

122

I

Type B or

Equivalent

4

5/25

162

202

242

5

322 6

**Vent lengths are based on a lateral length of 2 feet. Refer to the latest edition of the NFGC for further details. (ANSI Z223.1)

Table J: Natural Draft Vertical Venting

10 FEET

OR LESS

VENT CAP

2' MIN.

2' MIN.

VENT PIPE

COMBUSTION AIR

FILTER

BOILER

UNIT

Page 26

26

Natural Draft Vertical Venting

System Installation

Natural draft venting uses the natural buoyancy of the

heated flue products to create a thermal driving head

that expels the exhaust gases from the flue. The negative draft must be within the range of -.01 in. to -.08

in. WC as measured 12 in. from the appliance flue outlet to ensure proper operation. Vent material must be

listed by a nationally recognized test agency.

The maximum and minimum venting length for

Category I appliance shall be determined per the latest edition of the NFGC (U.S.) or B149 Installation

Code (Canada).

The diameter of vent flue pipe should be sized according to Part 11 of the latest edition of the NFGC (U.S.)

and part 7 and appendix B of the B149 Installation

Code (Canada). The minimum flue pipe diameter for

conventional negative draft venting using double-wall

B type vent is 4” for 122, 5” for 162, 202 and 242, 6”

for 322.

The connection from the appliance vent to the stack

must be as direct as possible and shall be the same

diameter as, or larger than the vent outlet. The horizontal breaching of a vent must have an upward slope

of not less than 1/4 inch per linear foot from the heater

to the vent terminal. The horizontal portions of the vent

shall also be supported for the design and weight of

the material employed to maintain clearances and to

prevent physical damage or separation of joints.

Natural Draft Vertical Vent

Termination

The vent terminal should be vertical and should terminate outside the building at least two (2) feet above the

highest point of the roof that is within 10 feet. The vent

cap should have a minimum clearance of four (4) feet

horizontally from and in no case above or below

(unless a four (4) foot horizontal distance is maintained) electric meters, gas meters, regulators and

relief equipment. The distance of the vent terminal

from adjacent public walkways, adjacent buildings,

open windows and building openings must be consistent with the NFGC, or in Canada, the B149

Installation Code for Gas Burning Appliances and

Equipment. Gas vents supported only by flashing and

extended above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads.

Natural Draft Vertical Venting with

Common Venting System, Category I

Appliance Only

Manifolds that connect more than one heater to a common chimney must be sized to handle the combined

load. Consult available guides for proper sizing of the

manifold and the chimney. At no time should the area

of the vent be less than the area of the largest heater

exhaust outlet.

Common venting systems may be too large when an

existing unit is removed. At the time of removal of an

existing appliance, the following steps must be followed with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation.

a) Seal any unused opening in the common venting

system.

b) Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion or other

unsafe condition.

c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common vent system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate summer

exhaust fan. Close fireplace dampers.

d) Place in operation the appliances being inspected.

Follow the manufacturers instructions for lighting

NOTE: Vent Adapter will have to be used to connect

B vent to the unit.

CAUTION: Listed vent cap terminal must be used

and sized adequately to evacuate the flue products

from the heaters.

WARNING: Vent connectors serving appliances

vented by natural draft shall not be connected into

any portion of mechanical draft systems operating

under a positive pressure.

CAUTION: Vent connectors for natural draft

venting systems must be type “B” vent or better.

Page 27

27

each appliance. Adjust thermostat so appliance

will operate continuously.

e) Check the pressure at a pressure tap located 12

in. above the bottom joint of the first vertical vent

pipe. Pressure should be anywhere between -.01

to -.08 in. WC.

f) After it has been determined that each appliance

remaining connected to the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and other gas burning appliances to their

previous conditions of use.

COMBUSTION

Fig. 19: Horizontal Thru-Wall Venting (Category III)

g) Any improper operation of the common venting

system should be corrected so that the installation

conforms with the latest edition of the NFGC (US)

and the B149 Installation Code (Canada). When

re-sizing any portion of the common venting system, the common venting system should be

re-sized to approach the minimum size as determined using the appropriate tables in Appendix G

in the NFGC (US) and Appendix B of the B149

Installation Code (Canada).

Model

No.

Appliance

Category

Certified

Venting

Material

Vent Size

(inches)

Max. Venting

Length (feet)

122

III

Stainless

Steel

(Gas Tight)

4

70

Subtract 10 ft per

elbow, maximum

three elbows

162

202

242

5

322 6

Table K: Horizontal Thru-Wall Venting (Category III)

AIR FILTER

BOILER

UNIT

INSULATED

EXHAUST

VENTING

12"

MIN

FLUE EXHAUST

VENT CAP

12" MIN

Page 28

28

Horizontal Thru-wall Venting

System (Category III) Installation

These installations utilize the heater-mounted blower

to vent the combustion products to the outdoors.

Combustion air is taken from inside the room and the

vent is installed horizontally through the wall to the outdoors. Adequate combustion and ventilation air must

be supplied to the mechanical room in accordance

with the NFGC or, in Canada, the B149 Installation

Code.

The total length of the horizontal thru-wall exhaust

vent system should not exceed seventy (70) feet in

length. If horizontal run exceeds 70 feet, an appropriately sized extractor must be used. To maintain proper

operation pressure reading must be between -.01 to .08 in. WC as measured 12 in. from the appliance flue

outlet. Each elbow used is equal to ten (10) feet of

straight pipe. This will allow installation in one of the

four following combinations.

· 70’ of straight flue pipe.

· 60' of straight flue pipe and one elbow.

· 50' of straight flue pipe and two elbows.

· 40' of straight pipe and three elbows.

The vent cap is not considered in the overall length of

the venting system.

The vent must be installed to prevent the flue gas leakage. Care must be taken during assembly to ensure

that all joints are sealed properly and are airtight.

The vent must be installed to prevent the potential

accumulation of condensate in the vent pipes. It is recommended that:

a) The vent be installed with a slight downward slope

of not more than 1/4" per foot of horizontal run to

the vent terminal.

b) The vent be insulated through the length of the

horizontal run.

For appliances installed in extreme cold climate, it is

recommended that:

a) The vent be installed with a slight upward slope of

not more than 1/4" per foot of horizontal run to the

vent terminal. In this case, an approved condensate trap must be installed per applicable codes.

b) The vent be insulated through the length of the

horizontal run.

Horizontal Thru-wall Direct Vent

Termination

The flue exhaust direct vent cap MUST be mounted on

the exterior of the building. The direct vent cap cannot

be installed in a well or below grade. The direct vent

cap must be installed at least one (1) foot above

ground level and above normal snow levels. The

Raypak supplied flue exhaust direct vent cap must be

utilized.

The Stainless Steel direct vent cap must be furnished by the heater manufacturer in accordance

with its listing.

Use only the special gas vent pipes listed for use with

category III gas burning heaters, such as the stainless

steel vent by Heat Fab Inc (800-772-0739), Protech

Systems, Inc. (800-766-3473) or Z-Flex (800-654-

5600). Pipe joints must be positively sealed. Follow

carefully the vent manufacturers installation instructions.

WARNING: No substitutions of flue pipe or vent

cap material are allowed. Such substitutions would

jeopardize the safety and health of inhabitants.

Page 29

29

Fig. 20: Direct Vent Horizontal Thru-Wall Venting (Category III)

12"

Model

No.

Appliance

Category

Certified

Venting

Material

Vent Size

(inches)

Max.

Venting

Length

(feet)

Combustion

Air Intake

Pipe

Material

Air Inlet

Size

(inches)

Max. Air

Intake

Length

(feet)

122

III

Stainless

Steel

(Gas Tight)

4

40

Subtract 10

ft per

elbow,

Max. two

elbows

Galvanized

Steel

PVC

ABS

CPVC

5

40

Subtract 10

ft per

elbow,

Max. two

elbows

162

202

242

5

322 6

Table L: Horizontal Thru-Wall Venting

INTAKE

VENT

COMBUSTION AIR

FILTER

BOILER

UNIT

VENT PIPE

6"

VENT CAP

36" MIN.

INTAKE

VENT

12" MIN.

Page 30

30

Horizontal Thru-wall Direct Vent

System (Category III) Installation

These installations utilize the heater mounted blower

to draw combustion air from outdoors and vent combustion products to the outdoors.

The total length of the thru-wall exhaust vent cannot

exceed forty (40) feet in length for the flue outlet. Each

elbow used is equal to ten (10) feet of straight pipe.

This will allow installation in one of the three following

combinations.

· 40’ of straight flue pipe.

· 30' of straight flue pipe and one elbow.

· 20' of straight flue pipe and two elbows.

The total length air supply pipe cannot exceed forty

(40) feet in length for the combustion air inlet. Each

elbow used is equal to ten (10) feet of straight pipe.

This will allow installation in one of the three following

combinations.

· 40’ of straight combustion air pipe

· 30' of straight combustion air pipe and one elbow.

· 20' of straight combustion air pipe and two elbows.

The flue exhaust direct vent cap is not considered in

the overall length of the venting system.

Care must be taken during assembly that all joints are

sealed properly and are airtight.

The vent must be installed to prevent the potential

accumulation of condensate in the vent pipes. It is recommended that:

a) The vent be installed with a slight downward slope

of not more than 1/4" per foot of horizontal run to

the vent terminal.

b) The vent be insulated through the length of the

horizontal run.

For appliances installed in extreme cold climate, it is

recommended that:

a) The vent be installed with a slight upward slope of

not more than 1/4" per foot of horizontal run to the

vent terminal. In this case, an approved condensate trap must be installed per applicable codes.

b) The vent be insulated through the length of the

horizontal run.

Horizontal Thru-wall Direct Vent

Termination

The flue exhaust direct vent cap MUST be mounted on

the exterior of the building. The direct vent cap cannot

be installed in a well or below grade. The direct vent

cap must be installed at least one (1) foot above

ground level and above normal snow levels.

Multiple direct vent caps MUST NOT be installed with

one combustion air inlet directly above a direct vent

cap. This vertical spacing would allow the flue products from the direct vent cap to be pulled into the

combustion air intake installed above. This type of

installation can cause non warrantable problems with

components and poor operation of the unit due to the

recirculation of flue products. Multiple direct vent caps

should be installed in the same horizontal plane with a

three (3) foot clearance from the side of one vent cap

to the side of the adjacent vent cap(s).

Combustion air supplied from outdoors must be free of

particulate and chemical contaminants. To avoid a

blocked flue condition, keep the vent cap clear of

snow, ice, leaves, debris, etc.

The Stainless Steel flue exhaust direct vent cap

must be furnished by the heater manufacturer in

accordance with its listing. Use only the special gas

vent pipes listed for use with category III gas burning

heaters, such as the stainless steel vent by Heat Fab

Inc (800-772-0739), Protech Systems, Inc. (800-766-

3473) or Z-Flex (800-654-5600). Pipe joints must be

positively sealed. Follow carefully the vent manufacturers installation instructions.

WARNING: No substitutions of flue pipe or vent

cap material are allowed. Such substitutions would

jeopardize the safety and health of inhabitants.

Page 31

31

12" MIN.

Model

No.

Appliance

Category

Certified

Venting

Material

Vent Size

(inches)

Min./Max.

Vertical

Venting

Height

(feet)

Combustion

Air Intake

Pipe

Material

Air Inlet

Size

(inches)

Max. Air

Intake

Length

(feet)

122

I

Type B

Equivalent

4

5/25

Galvanized

Steel

PVC

ABS

CPVC

5

40

Subtract 10

ft per

elbow,

Max. two

elbows

162

202

242

5

322 6

Table M: Vertical Venting

Fig. 21: Direct Vent—Vertical Venting (Category I)

INTAKE

VENT

36"

VENT CAP

36" MIN.

VENT PIPE

COMBUSTION

AIR FILTER

BOILER

UNIT

Page 32

32

Vertical Direct Vent System

Installation

These installations utilize the heater mounted blower

to draw combustion air from outdoors and uses the

natural buoyancy of the heated flue products to create

a thermal driving head that expels the exhaust gases

from the flue. The negative draft must be within the

range of -0.01 to -0.08 in. WC as measured 12 in. from

the appliance outlet to ensure proper operation. The

vent material must be in accordance with the above

instructions for vent materials. Vent material must be

listed by a nationally recognized test agency.

The maximum and minimum venting length for

Category I appliance shall be determined per the latest edition of the NFGC (U.S.) and B149 Installation

Code (Canada).

The connection from the appliance exhaust vent to the

stack must be as direct as possible and should be the

same as or larger than the vent outlet. The vent must

be installed to prevent accumulation of condensate

and, where necessary, have means provided for

drainage of condensate. The horizontal breaching of a

vent must have an upward slope of not less than 1/4

inch per linear foot from the heater to the vent terminal. The horizontal portions of the vent shall also be

supported for the design and weight of the material

employed to maintain clearances and to prevent physical damage or separation of joints.

Vertical Direct Vent Termination