Page 1

Page 2

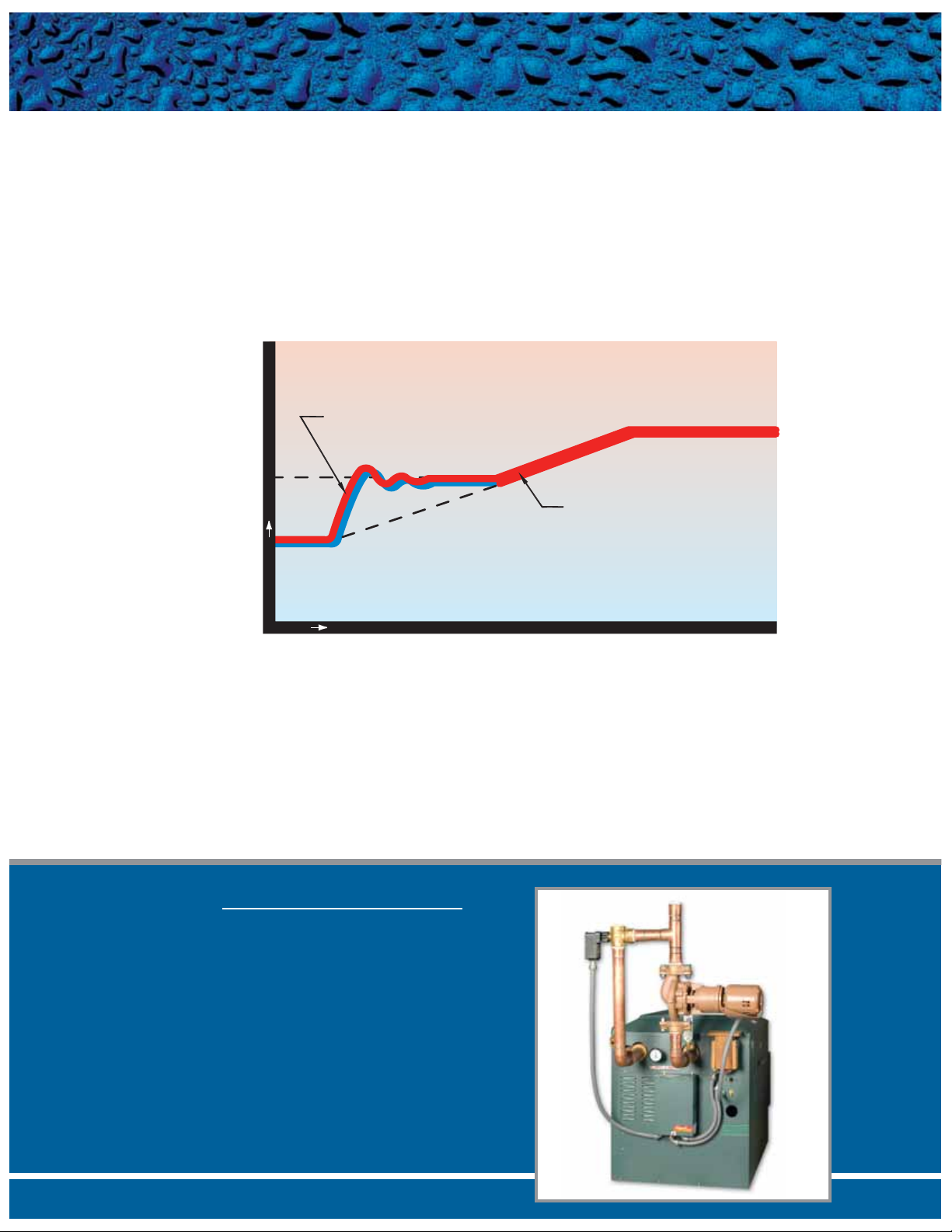

It is commonly known that prolonged internal condensation will dramatically shorten the life of standard boilers and

water heaters.While Raypak boilers and water heaters can operate without harmful condensation at lower inlet water

temperatures than the competition, there are still applications that require reliable protection against harmful condensation caused by frequent,extended,cold water start-ups.Raypak’s Cold Water Start protection system utilizes a proportional three-way valve to bypass water from the boiler outlet to the inlet during start-up, when the system return

water temperature is below the minimum acceptable level.

COLD WATER START

Raypak’s Cold Water Start system:

• Continuously monitors and adjusts inlet water temperature to prevent condensation

• Regulates minimum inlet water temperature during system start-up

• Shuts down boiler if the minimum inlet water temperature is not achieved

• Eliminates job site set-up with proprietary self-tuning controller and system-matched components

• Utilizes proportional three-way valve to achieve bypass

• Allows high-temperature system operation without cycling on high-limit

• Activates alarm if shutdown occurs (option)

CCoommmmeerrcciiaall HHyyddrroonniicc HHeeaattiinngg

Office Buildings •

Factories/Warehouses •

Greenhouses •

DDoommeessttiicc HHoott WWaatteerr SSuuppppllyy

Restaurants •

Weekend Shut-down •

(e.g. 6-day/week shopping center)

Dump Loads •

87% Hot Water Supply Boiler •

Intermittent Industrial Process •

AAPPPPLLIICCAATTIIOONNSS

Boiler Start-Up Cycle

MIN INLET

TEMP SETTING

START-UP

TEMP

TEMPERATURE

TIME

BLENDED BOILER

INLET TEMP

SYSTEM RETURN

SYSTEM RETURN NOW AT

OR ABOVE MINIMUM INLET

SETTING. BYPASS CLOSED,

FULL SYSTEM FLOW

STABLE SYSTEM TEMP

Page 3

For the same reason stated for Cold Water Starts,it is even more important to provide protection against condensation

from cold inlet water on systems where the return water temperature to the boiler will always be below the acceptable

minimum. Raypak’s Cold Water Run system utilizes a variable-speed pump to inject just the right amount of water

from the main system loop into the boiler to maintain the optimum inlet temperature.This approach allows the full

capacity of the boiler to be utilized to meet the system load,while at the same time continuously maintaining the optimum inlet water temperature to prevent condensation.

COLD WATER RUN

Raypak’s Cold Water Run system:

• Continuously monitors and adjusts inlet water temperature to prevent condensation

• Regulates minimum inlet water temperature regardless of system temperature

• Shuts down boiler if the minimum inlet water temperature is not achieved

• Protects boiler from constant low return water temperatures with its proprietary self-tuning controller

• Utilizes variable-speed injector pump to control boiler loop temperature

• Activates alarm if shutdown occurs (option)

• Pool Heating

• Low-temperature Industrial Process

• Very Low-temperature Return Water

(e.g. convalescent hospital domestic

hot water)

AAPPPPLLIICCAATTIIOONNSS

Boiler Start-Up Cycle

BLENDED BOILER

INLET TEMP

MIN INLET

TEMP SETTING

SYSTEM RETURN

START-UP

TEMP

TEMPERATURE

TIME

Page 4

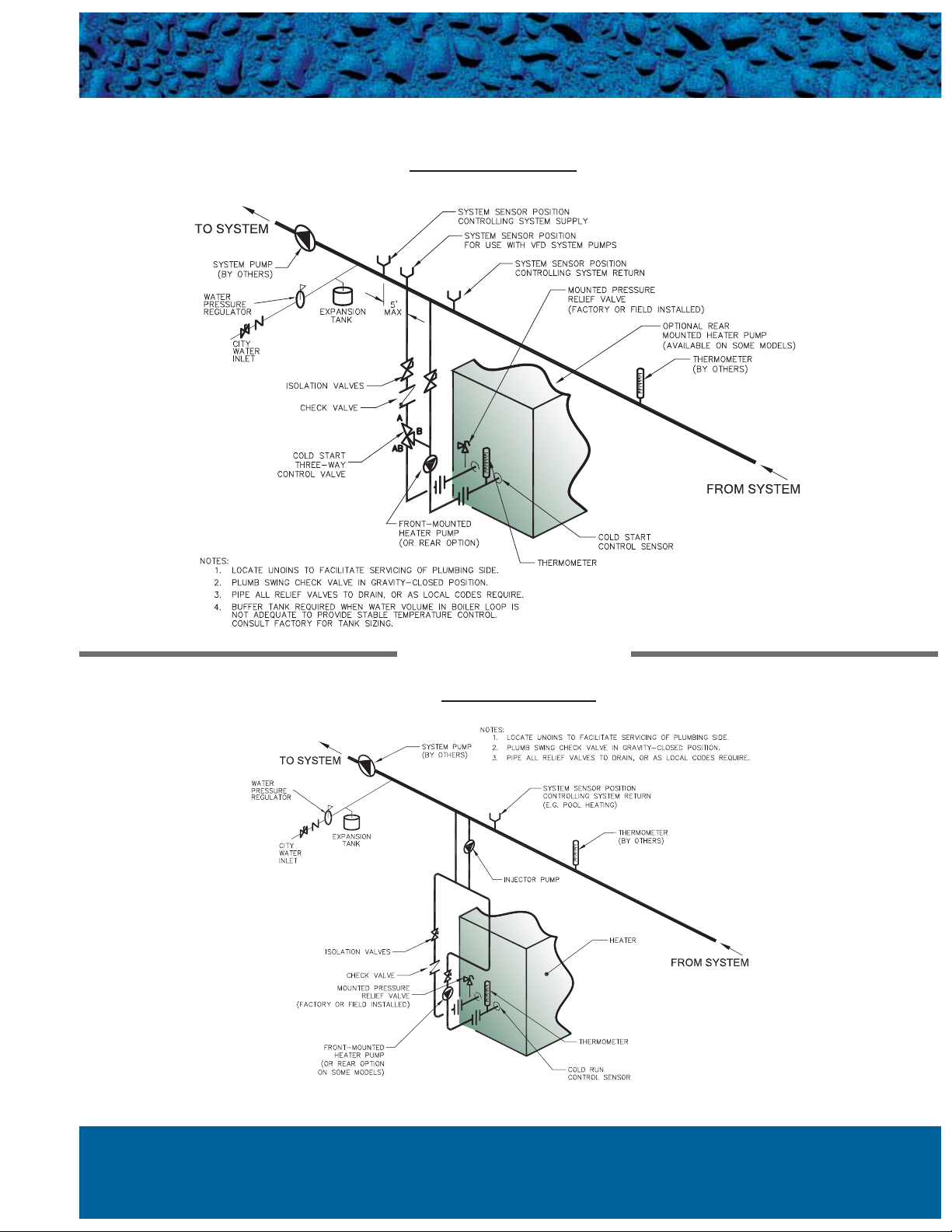

COLD WATER START

COLD WATER RUN

Cold Water Start J-Box Assembly Typical Cold Start Plumbing

Pictorial-Not to Scale

Cold Water Run J-Box Assembly Typical Cold RunPlumbing

Pictorial-Not to Scale

3-WAY

VALVE

BOILER

BOILER

PUMP

TO

SYSTEM

SYSTEM

PUMP

BOILER

BOILER

PUMP

FROM

SYSTEM

VARIABLE SPEED

INJECTOR PUMP

TO

SYSTEM

SYSTEM

PUMP

FROM

SYSTEM

Page 5

TECHNICAL DATA

COLD WATER START

COLD WATER RUN

* Items required for cold water operation are shown.

Other standard system components have been omitted for clarity.

* Items required for cold water operation are shown. Other standard system components have been omitted for clarity.

TYPICAL BOILER PIPING*

TYPICAL BOILER PIPING*

Page 6

Catalog No.: 1000.19C Effective: 06-15-08 Replaces: 01-01-07

Raypak Inc., 2151 Eastman Ave., Oxnard, CA 93030

(805) 278-5300 Fax (800) 872-9725

MULTIPLE UNIT COLD WATER START

Total System Load

(MBTUH)

Three-Way Diverting Valve Specifications

Valve Size Cv GPM

P

500-900 2” NPT 57 70 3.5’

901-1,800 2-1/2” NPT 74 100 4.2’

1,801-3,000 2-1/2” NPT 100 150 5.2’

3,001-4,000 4” Flange 152 220 4.8’

4,001-6,000 4” Flange 254 330 3.9’

6,001-8,000 4” Flange 327 440 4.2’

Notes:

1. Maximum of 4 boilers per system.

2. Many variables can impact the proper valve sizing for multiple boilers. This sizing is provided as a guide. When in doubt consult the factory.

3. Multi-unit system ALWAYS shipped loose- Not available mounted.

4. 4” flanges, bolts and gaskets supplied by others. Multi-units with 4” valves are to be used on hydronic heating only.The valve body is cast

iron.

TECHNICAL DATA

Loading...

Loading...