Page 1

INSTALLATION

AND OPERATING

INSTRUCTIONS

RAYTHERM™

HEATING BOILERS

Type H

Models 0133-4001

CATALOG NO. 2000.50Z

Effective: 03-15-04

Replaces: 06-15-03

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids or other combustible

materials in the vicinity of this or any other appliance. To do so may result in an explosion

or fire.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or loss of life. Refer to this manual. Installation and service

must be performed by a qualified installer, service agency or the gas supplier.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

*Do not try to light any appliance.

*Do not touch any electrical switch; do not use any phone in your building.

*Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

*If you cannot reach your gas supplier, call the fire department.

This manual should be maintained in legible

condition and kept adjacent to the boiler or kept

in a safe place for future reference.

P/N 240035

Page 2

MODEL IDENTIFICATION

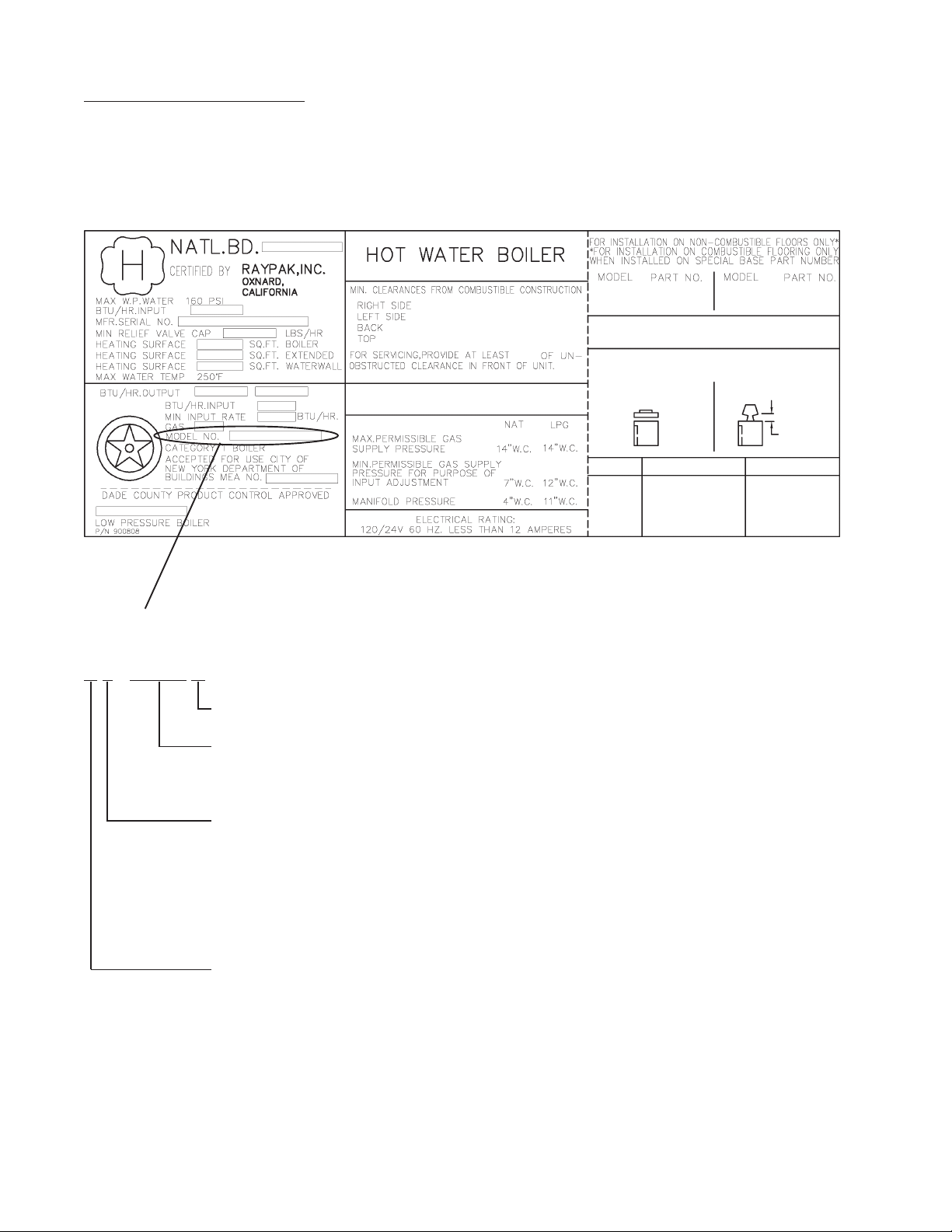

The model number of a boiler can be found on the Sales Order and the boiler's rating plate. The example below

identifies what the characters of the model number represent.

Boiler rating plate showing model number

MODEL NUMBER EXAMPLE:

H 3 - 0 5 1 4 A

Series

Model Size

Representative of approximate MBTUH input

(Model 0514 has input of 511,500 BTUH)

Firing Mode

1 Mechanical Modulation

2 Motorized Modulation

3 2-Stage Firing / 4-Stage Firing Option

4 On-Off Firing

5 Low Temperature Mechanical Modulation

6 Motorized Modulation w/Electronic Outdoor Reset B6000

Application

H = Heating Boiler

Page 3

TABLE OF CONTENTS

MODEL IDENTIFICATION........................................................................................2

RECEIVING EQUIPMENT........................................................................................ 4

CERTIFICATIONS.................................................................................................... 4

BOILER TYPES........................................................................................................ 4

CALIFORNIA PROPOSITION 65 WARNING.......................................................... 4

INSTALLATION........................................................................................................ 5

Installation Codes............................................................................................... 5

Installation Base................................................................................................. 5

Clearances......................................................................................................... 6

Combustion and Ventilation Air..........................................................................7

Venting................................................................................................................8

Plumbing.............................................................................................................15

CONTROLS.............................................................................................................. 21

Economaster Controls........................................................................................21

Electronic Ignition............................................................................................... 21

Operating Controls............................................................................................. 21

Limit Controls......................................................................................................22

ELECTRICAL CONNECTIONS................................................................................ 24

START-UP................................................................................................................ 25

Before Start-up................................................................................................... 25

Lighting Instructions........................................................................................... 26

After Start-up...................................................................................................... 28

Inspections......................................................................................................... 29

LOW NOx BOILERS.................................................................................................30

Operation............................................................................................................30

Start-up...............................................................................................................30

Burner Adjustment............................................................................................. 30

Visual Inspection................................................................................................ 30

Electrical............................................................................................................. 30

Flame Roll-out Safety Switch.............................................................................30

Service................................................................................................................31

TROUBLESHOOTING..............................................................................................32

Electrical............................................................................................................. 32

Mechanical......................................................................................................... 35

SERVICE.................................................................................................................. 36

Tube Cleaning Procedure..................................................................................36

Burner Tray Removal......................................................................................... 37

Gas Valve Removal........................................................................................... 37

Main Burner and Orifice Removal..................................................................... 37

Pilot Removal and Cleaning.............................................................................. 37

High Limit or Tankstat Removal........................................................................ 37

Heat Exchanger Removal..................................................................................37

Combustion Chamber Removal........................................................................ 38

Control Well Replacement.................................................................................39

Tube Replacement Procedure...........................................................................39

Cleaning Flue Gas Passageways......................................................................39

REPLACEMENT PARTS..........................................................................................3 9

WARRANTY............................................................................................................. 40

3

Page 4

RECEIVING EQUIPMENT

BOILER TYPES

On receipt of the equipment, visually check for

external damage to the carton or the shipping crate. If

either is damaged, make a note on the Bill of Lading

and report the damage to the Carrier immediately.

Remove the boiler from the carton or the shipping

crate.

On occasion, items are shipped loose. Be sure

that you receive the number of packages indicated on

the Bill of Lading.

When ordering parts, you must specify the Model

and Serial Number of the boiler. When ordering under

warranty conditions, you must also specify the date of

installation.

Raypak recommends that this manual be

reviewed thoroughly before installing your Raypak

boiler. If there are any questions which this manual

does not answer, please contact the factory or your

local Raypak representative.

Claims for shortages and damages must be filed

with carrier by consignee. Permission to return goods

must be factory authorized and are subject to a

stocking charge.

Purchased parts are subject to replacement only

under the manufacturer's warranty. Debits for

defective replacement parts will not be accepted and

will be replaced in kind only per our standard

warranties.

CERTIFICATIONS

The Raypak hydronic boilers are design certified

and tested under the latest requirements of the

American National Standard, ANSI Z21.13 - latest

edition. Each boiler has been constructed and

pressure tested in accordance with the requirements

of Setion IV of the American Society of Mechanical

Engineers Code, and factory fire tested.

All models are National Board approved.

Temperature and pressure gauge is standard.

Model 0133 has a 4-pass heat exchanger, 1 tube

per pass.

Models 0181-1826 have 2-pass heat exchangers,

5 tubes first pass, 4 tubes second pass.

Models 2100-4001 have 2-pass heat exchangers,

9 tubes per pass.

Models 926-4001 have optional single-pass heat

exchangers with cast iron headers only.

TYPE H1 - MECHANICAL MODULATING

Central heating boiler with 150°-210°F

mechanical modulating gas valves and pressure relief

valve. Standard on models 133-1826.

TYPE H2 - MOTORIZED MODULATING

Central heating boiler with a motorized

modulating gas valve. Standard on models 2100-

4001. Available as option on models 514-1826.

Modulating controller provided.

TYPE H3 - 2-STAGE CONTROLS

Central heating boiler with single two-stage gas

valve . Available as option on Models 183-4001. Twostage controller provided. Available with Y-1

sequencing option.

TYPE H4 - ON-OFF CONTROLS

Central heating boiler with on-off firing. Available

as option on Models 181-4001.

TYPE H5 - MECHANICAL MODULATING

Central heating boiler with 110°-170°F

mechanical modulating gas valves and pressure relief

valve. Standard on Models 133-1826.

TYPE H6 - B6000 SYSTEM CONTROL

Central heating boiler for use with the B6000

boiler management system. Available for Models

514-4001.

TYPE H9 - 4-STAGE

Central heating boiler for use with 4-stage firing.

Controller optional. Available option on Models 514-

4001.

CALIFORNIA PROPOSITION 65

WARNING:

This product contains chemicals known to the State

of California to cause cancer, birth defects or other

reproductive harm.

4

Page 5

INSTALLATION

INSTALLATION CODES

The installation must conform with these instructions and the latest editions of the ANSI National Fuel Gas

Code Z223.1, the National Electric Code ANSI/NFPA 70 and local codes. All boiler installations must conform

to ASME boiler code. Hot water pipes must be installed with minimum clearances to combustible material as

required by code.

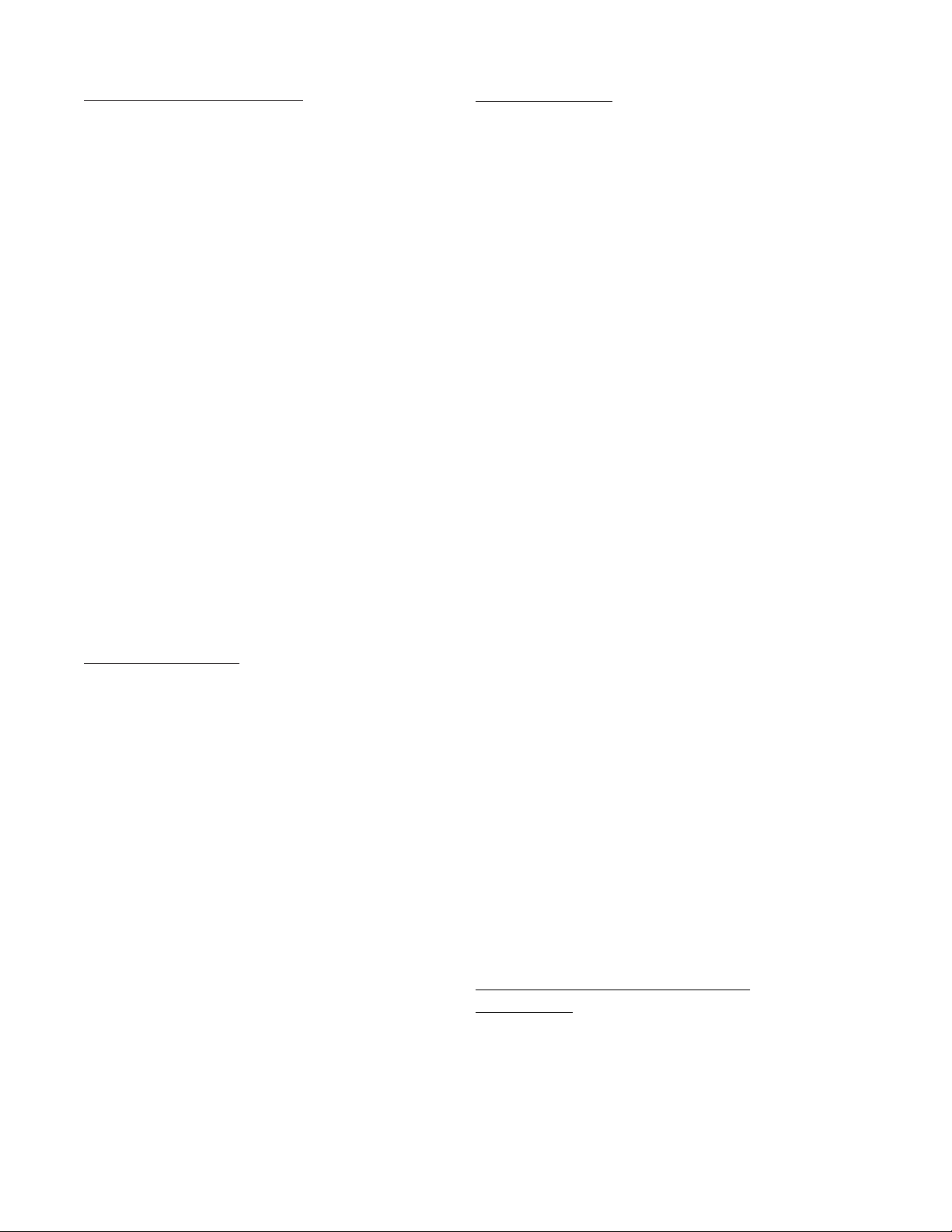

INSTALLATION BASE

The boiler should be mounted on a level, non-combustible surface. Boiler must not be installed on carpeting.

The boiler can be installed on a combustible surface only when a suitable floor shield base is provided. Raypak

offers an optional floor shield base which can be factory installed on all indoor models except Model 133; the

Model 133 floor shield base is shipped loose and must be installed by the contractor.

Do NOT use the shipping crate base as an installation base.

NOTE: The boiler should be located in an area where water leakage will not result in damage to the area adjacent

to the appliance or to the structure. When such locations cannot be avoided, it is recommended that a suitable

drain pan, adequately drained, be installed under the appliance. The pan must not restrict air flow.

In addition, the boiler shall be installed such that the gas ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance operation and service (circulator replacement, control

replacement, etc.).

Combustible Floor Shield ordering information:

Boiler Model No. Base Part No. Boiler Model No. Base Part No.

133

182/181

260/261

330/331

400/401

514

624

724

824

* Models with factory-installed floor shield as standard.

BOLD type indicates Low NOx models.

ALTERNATE METHOD FOR PROVIDING A NON-COMBUSTIBLE BASE

001749

058313

058314

058315

058316

056199

056200

056201

056202

926*

1083*

1178*

1287*

1414*

1571*

1758*

962

1125

1223

1336

1468

1631

1826

054597

054598

054599

054600

054601

058378

058379

059233

059234

059235

059236

059237

059238

059239

Fig. #8148.1

5

Page 6

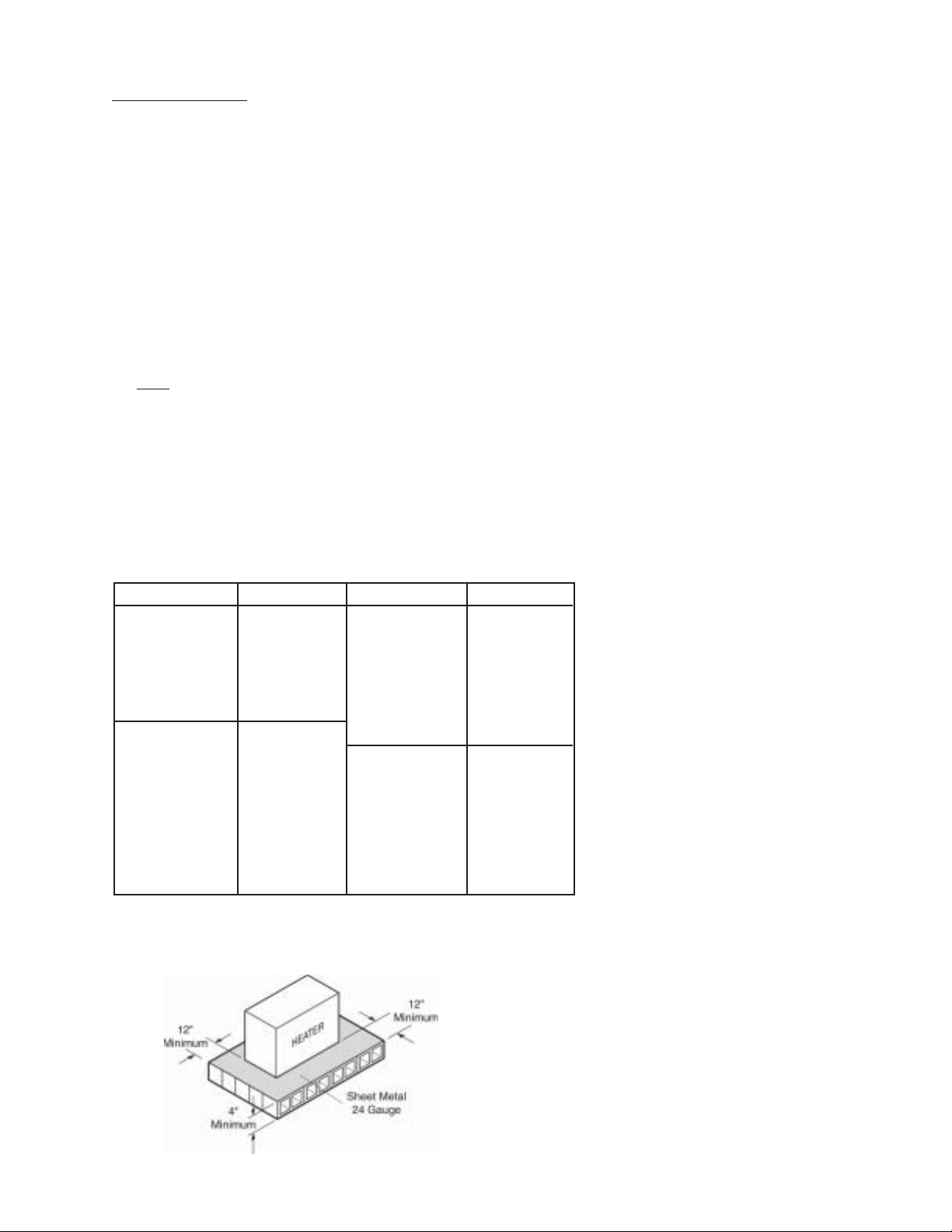

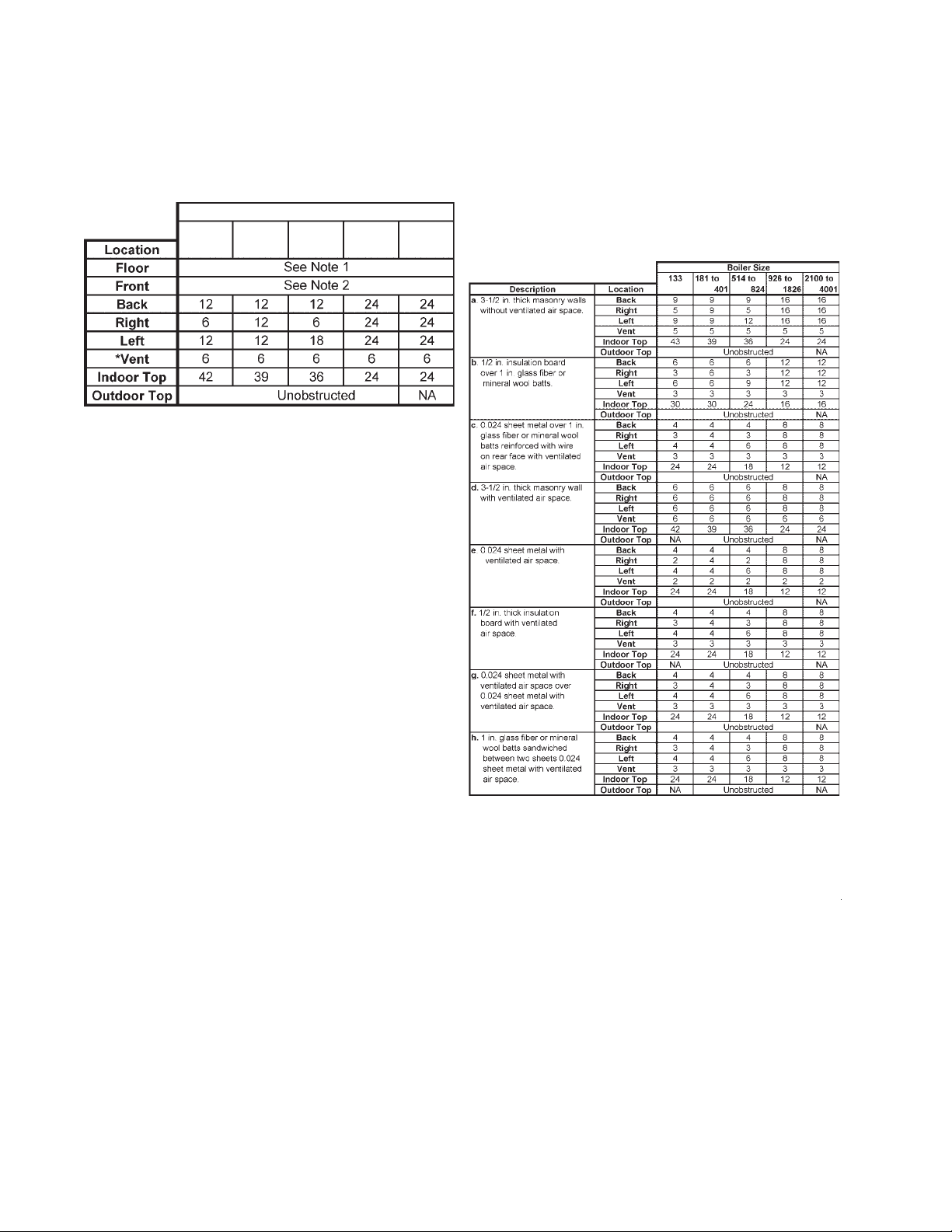

CLEARANCES

REDUCTION OF CLEARANCES TO PROTECTED

SURFACES

CLEARANCES FROM COMBUSTIBLE SURFACES

(All dimensions are in inches)

MODEL

181 to

133

401

Derived from National Fuel Gas Code, Table 6.2.3(a)

514 to

824

926 to

1826

2100 to

4001

Note 1:

Combustible floor shield is required when boiler is to be

installed on a combustible surface. (See ordering information on pg. 4.)

Note 2:

Servicing Clearances: Provide at least 24" (Models

133-1826), 48" (Models 2100-4001) in front of unit for

removal and servicing of the Controls & Burner Tray.

Provide at least 18" on side opposite water connections

for deliming of Heat Exchanger Tubes.

Note: The boiler shall be installed in a space large in

comparison to the size of the boiler. Large space is

defined as having a volume at least sixteen (16) times

the total volume of the boiler.

*Vent includes factory-supplied drafthood and does not

include field-supplied vent systems above the drafthood. On Models 2100-4001 drafthood is built into

boiler.

Derived from National Fuel Gas Code, Table 6.2.3(b)

6

Page 7

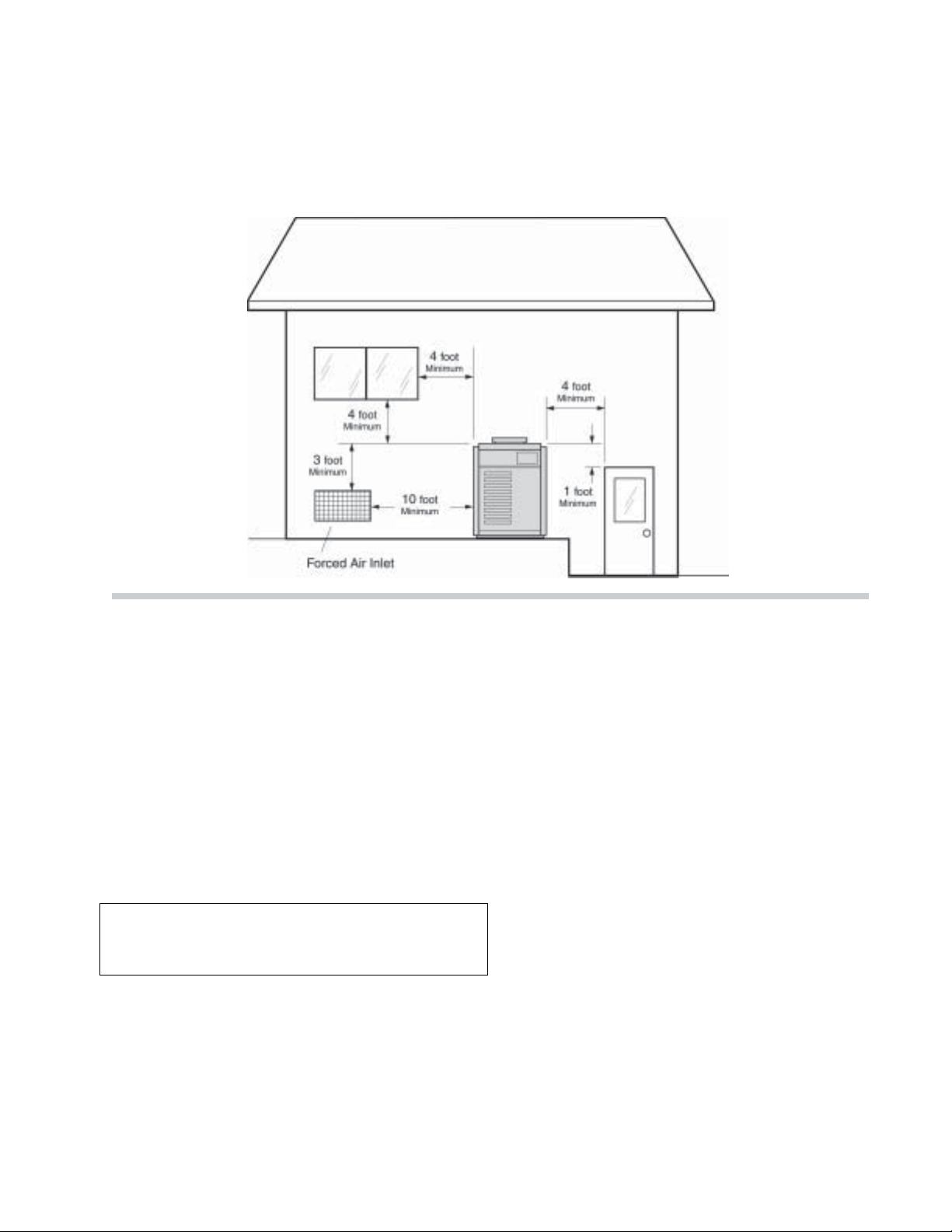

OUTDOOR BOILERS

These boilers are designed certified for outdoor installation. Boilers must not be installed under an

overhang within three (3) feet from the top on the boiler. Three (3) sides must be open in the area under the

overhang. Roof water drainage must be diverted away from the boilers with the use of gutters.

The point from where the flue products exit the boiler must be a minimum of four (4) feet below, four (4) feet

horizontally from or one (1) foot above any door, window or gravity inlet to a building. The top surface of the boiler

shall be at least three (3) feet above any forced air inlet, or intake ducts located within ten (10) feet horizontally.

HIGH-WIND CONDITIONS (Outdoor Units Only)

In areas where high winds are frequent, it may be

necessary to locate the boiler a minimum of 3' from

high vertical walls, or install a wind break so the boiler

is not in direct wind current.

COMBUSTION AND VENTILATION AIR

(Indoor Units Only)

The boiler must have both combustion and ventilation air. Minimum requirements for net free air supply

openings are 12 inches from ceiling for ventilation and

12 inches from the floor for combustion air as outlined

in Z223.1 - latest edition and any local codes that may

have jurisdiction.

CAUTION: Combustion air must not be contaminated

by corrosive chemical fumes which can damage the

boiler and void the warranty.

a. All Air From Inside The Building:

Each opening shall have a minimum net free

square inches as noted:

Fig. #8245

Model Square Inches Model Square Inches

133 136 1125 1125

182/181 181 1223 1223

260/261 264 1336 1337

330/331 334 1468 1467

400/401 399 1631 1630

514 512 1826 1826

624 627 2100 2100

724 726 2500 2499

824 825 3001 3000

962 962 3500 3500

4001 4000

b. All Air From Outdoors:

When air is supplied directly from outside of building, each opening shall have a minimum net free

square inches as noted:

Model Square Inches Model Square Inches

133 34 1125 282

182/181 46 1223 306

260/261 66 1336 335

330/331 84 1468 367

400/401 100 1631 408

514 128 1826 457

624 157 2100 525

724 182 2500 625

824 207 3001 750

962 241 3500 875

4001 1000

7

Page 8

VENTING

OUTDOOR INSTALLATIONS

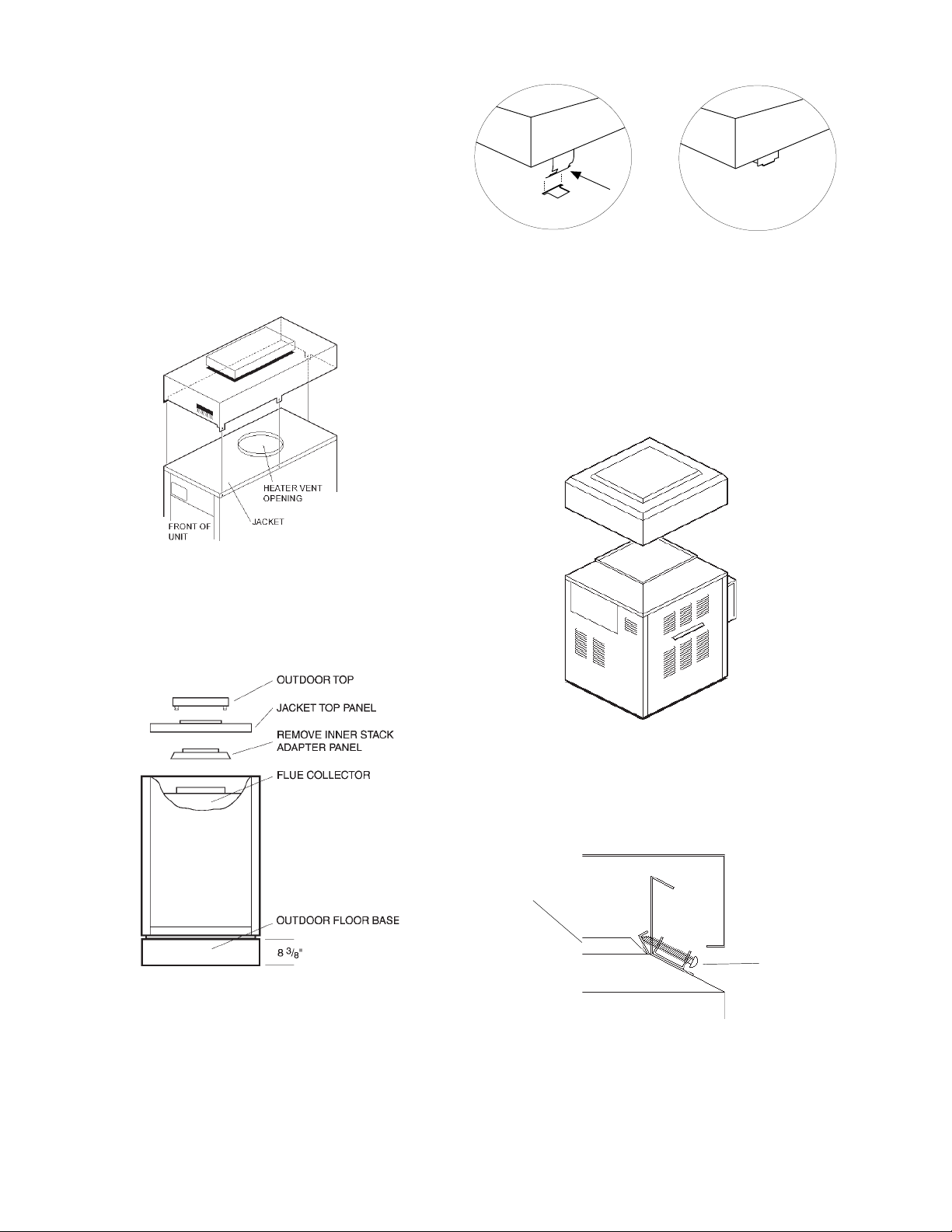

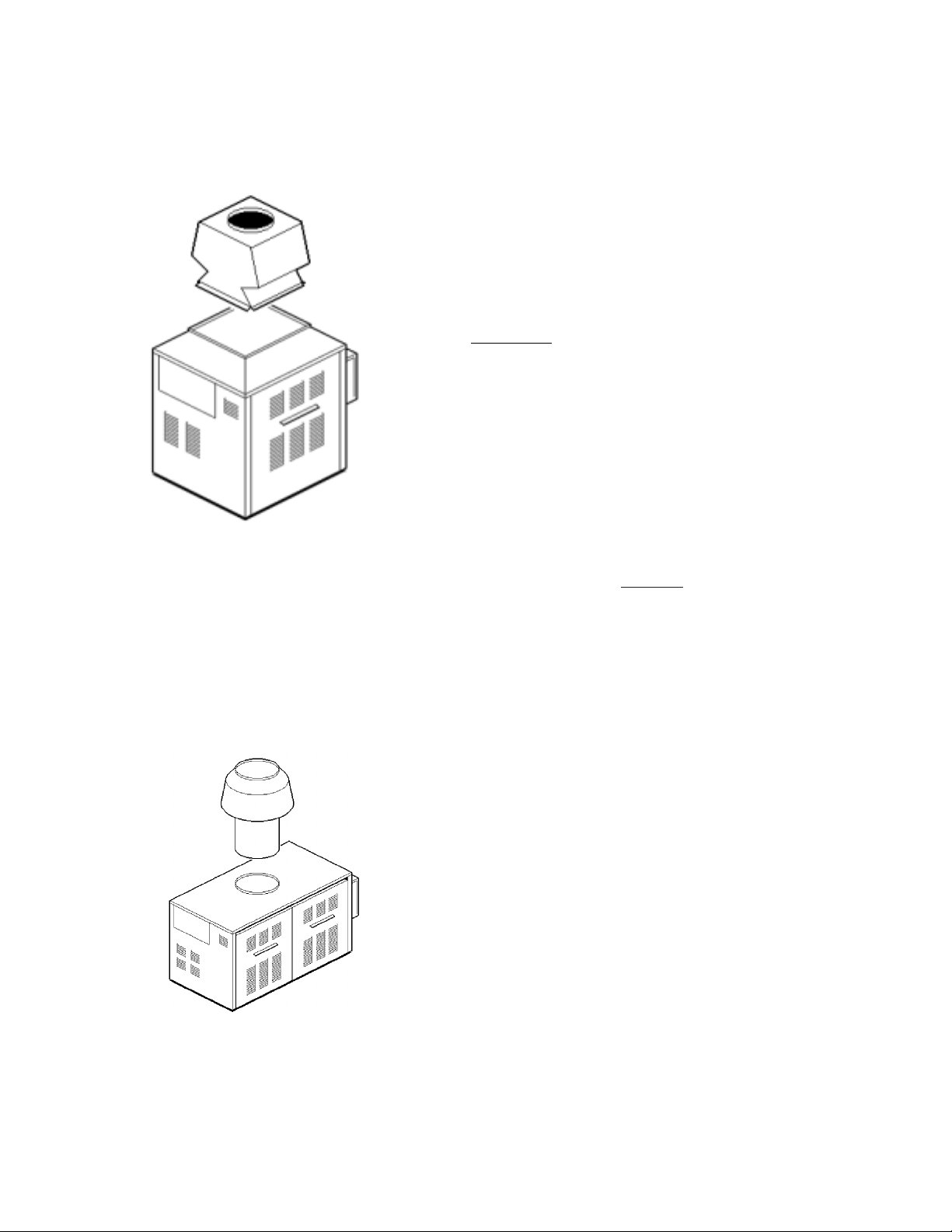

MODEL 133

Step 1: Remove the front (4) screws.

Step 2: Line up outdoor top vent opening over heater

vent opening.

Step 3: Lower outdoor top onto unit lining up slots in

the outdoor top with screws holes in jacket top.

Step 4: Reinstall (5) screws to secure jacket top and

outdoor top to unit.

Fig. #8114

Fig. #RP8280.1

Detail A Detail B

Outdoor Top

(Shipped Loose with Heater)

MODELS 514 - 824

Step 1: Lower outdoor top onto unit. Position top so it

is centered on unit from side to side and front

to rear.

MODELS 181-401 and 182-400

Outdoor Top Installation

(Part of heater)

Fig. # 9389

Step 1: Remove jacket top panel.

Step 2: Remove and discard inner stack adapter

panel.

Step 3: Install jacket top panel.

Step 4: Insert tabs of outdoor top into keyholes located

on jacket top panel (4 places). See Detail A

Step 5: Snap tabs on outdoor top into the locked

postion of the keyhole so the top will not pull

out. See Detail B

Fig. # 8166.1

Step 2: Tighten the (4) screws (Shown below) until

they come in contact with the unit jacket top,

then evenly tighten all (4) screws to secure to

unit.

JACKET TOP

FASTENING

SCREW

Fig. # 8233

MODELS 926-1758

Boilers are shipped with outdoor vent terminal

factory installed.

8

Page 9

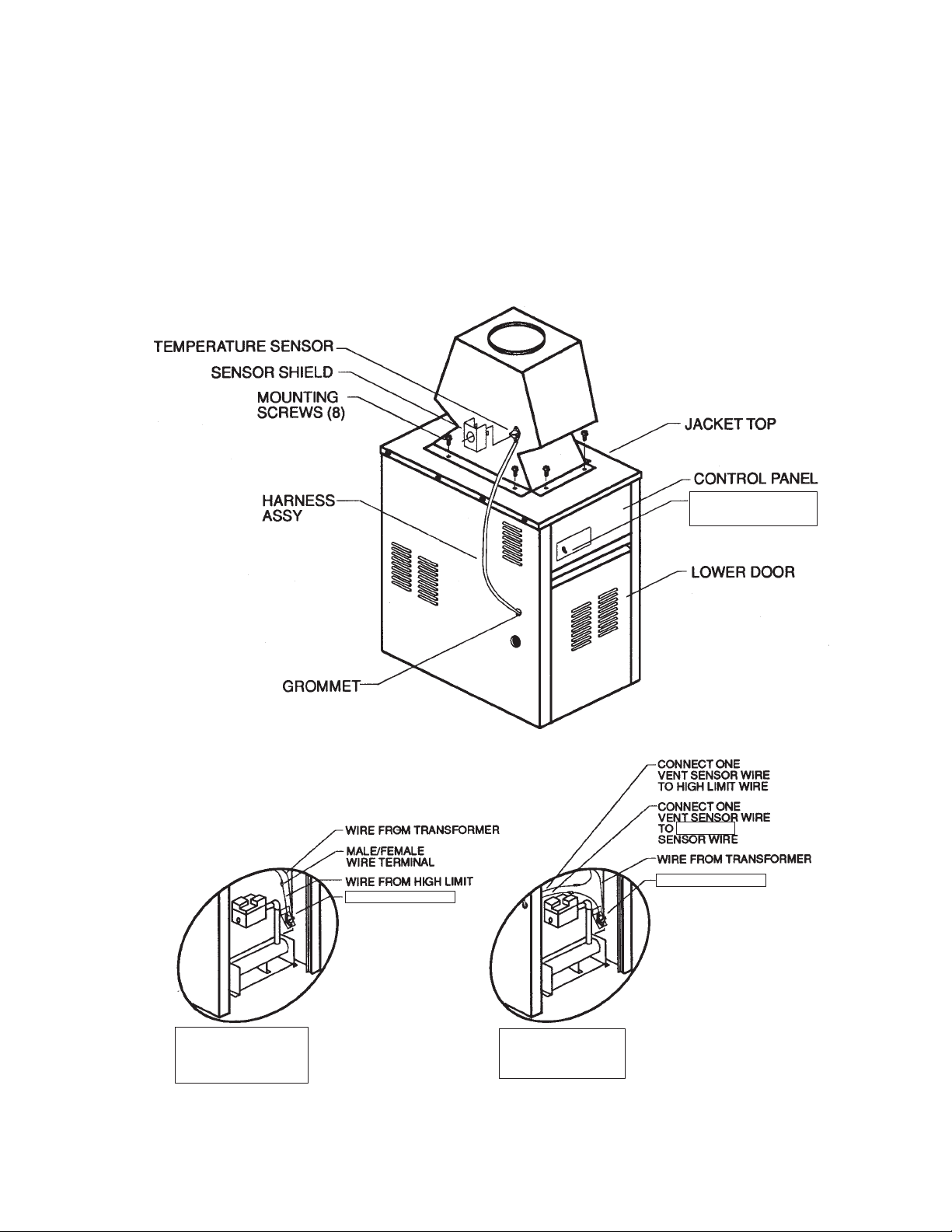

INDOOR INSTALLATIONS

MODEL 133

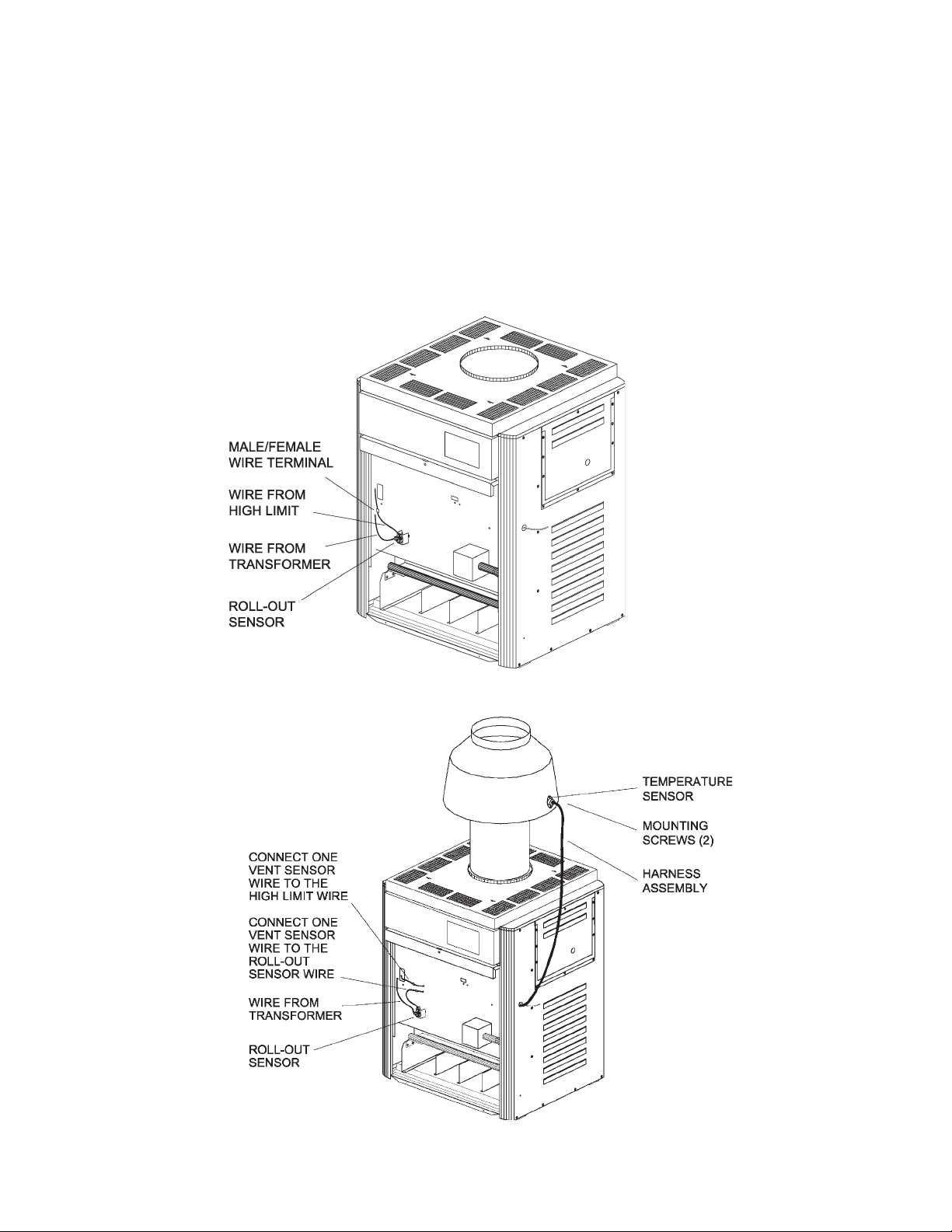

Step 1. Shut-off main electrical power switch to boiler.

Step 2. Turn heater manual switch located in upper control panel to the "OFF" position.

Step 3. Shut-off gas supply and water supply to the boiler.

Step 4. Mount drafthood on boiler and attach with the 4 sheet metal screws provided. Drafthood should be

positioned with the vent sensor located on the front left side as shown below.

Step 5. Remove plastic plug from left side of boiler jacket and install the plastic grommet provided.

Step 6. Route flue sensor wire harness through the grommet installed in Step 5.

BOILER ON/OFF

SWITCH

Fig. #8946

Step 7. Remove door and locate wire from roll-out sensor to high limit with the male/female connector.

ROLL-OUT

ROLL-OUT SENSOR

ROLL-OUT SENSOR

BEFORE

INSTALLATION

OF DRAFTHOOD

AFTER

INSTALLATION

OF DRAFTHOOD

Fig. #8947

Step 8. Disconnect male/female connector and attach to the 2 wires from drafthood vent sensor harness.

9

Page 10

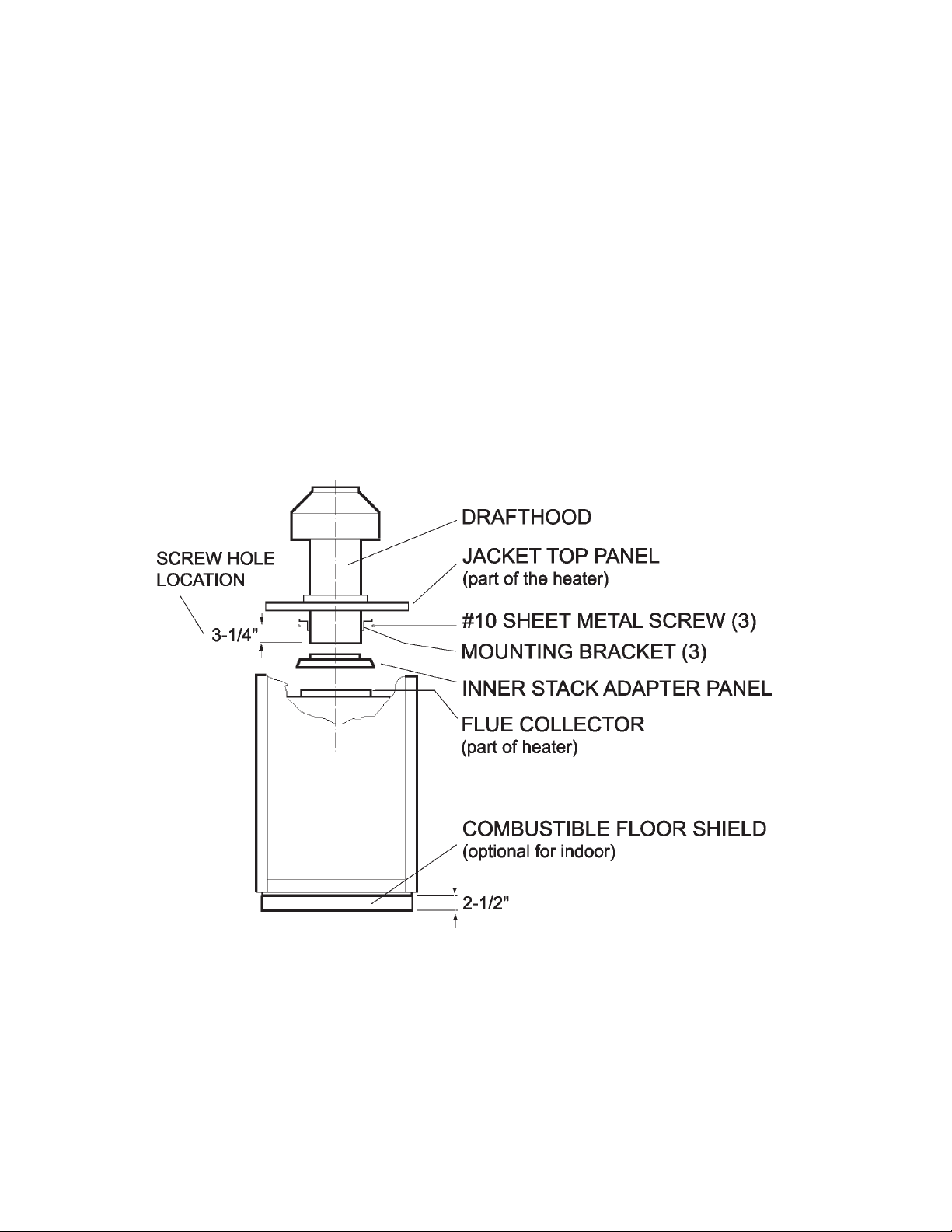

MODELS 181-401 and 182-400

INDOOR STACK INSTALLATION

1. Remove the louvered jacket top by removing

four (4) #10 flathead screws.

2. If originally installed, remove outdoor top

from the louvered jacket top.

3. Place the inner stack adapter panel over the

flue collector inside the heater. Make sure

the flanged side of the flue opening is up.

4. Turn the stack (drafthood) upside

down and set it down bottom side up.

5. Turn the jacket top panel (removed in step 1)

upside down and place it through the stack.

6. Attach the three (3) mounting brackets to the

stack using the screws provided and the holes

that are pre-drilled in the stack. Make sure the

brackets are positioned with the flange near the

top side of the stack (see illustration).

Caution must be taken not to over tighten and

strip the screw threads.

7. Turn the assembled stack and jacket top, rightside up. The jacket top will be trapped between the

brackets and the top of the stack. Place the stack

over the inner stack adapter panel flanged hole

and lower the louvered jacket top panel back into

its original position. Reinstall the four (4) #10

flathead screws removed in step 1 above.

Fig. #8246.5

10

Page 11

MODELS 181-401 and 182-400

Step 1. Shut-off main electrical power switch to boiler.

Step 2. Turn heater manual switch located in upper control panel to the "OFF" position.

Step 3. Shut-off gas supply and water supply to the boiler.

Step 4. Mount drafthood on top of boiler as shown on page 8. Drafthood should be positioned with the vent

sensor located on the front right side as shown.

Step 5. Remove plastic plug from left side of boiler jacket and install plastic grommet provided.

Step 6. Route flue sensor wire harness through the grommet installed in Step 5.

Step 7. Remove door and locate wire from roll-out sensor to high limit with the male/female connector.

Step 8. Disconnect male/female connector and attach to the 2 wires from drafthood vent sensor harness.

BOILER BEFORE

DRAFTHOOD

INSTALLATION

Fig# 9349

BOILER AFTER

DRAFTHOOD

INSTALLATION

11

Fig# 9351

Page 12

MODELS 514-824

MODELS 2100-4001

Locate and assemble as shown below. Secure with

screws supplied in envelope in carton.

Fig. # 8167.0

MODELS 962-1826

Locate and assemble as shown below. Secure with

screws supplied in envelope in carton.

These models have built-in drafthoods. For proper

operation, the drafthood outlet must be connected to

the venting system.

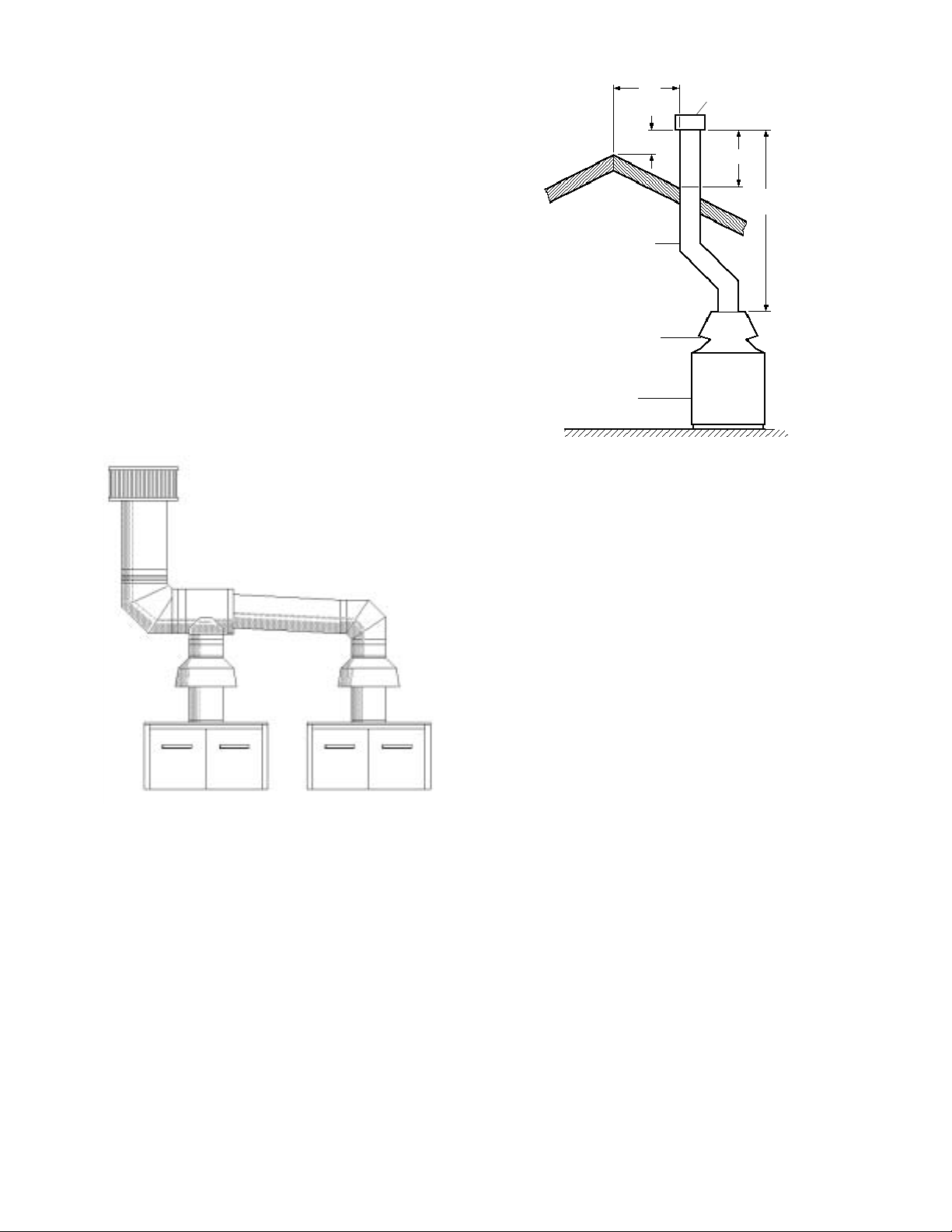

VENT PIPING

WARNING: Indoor boilers require a drafthood that

must be connected to a vent pipe and properly vented

to the outside. Failure to follow this procedure can

cause fire or fatal carbon monoxide poisoning.

Vent piping the same size or larger than the

drafthood outlet is recommended, however, when the

total vent height is at least 10 ft. (drafthood relief

opening to vent terminal), the vent pipe size may be

reduced as specified in Chapter 10 of the latest edition

of the National Fuel Gas Code, ANSI Z223.1. As much

as possible avoid long horizontal runs of vent pipe and

too many elbows. If installation requires horizontal

non-vertical runs, the vent pipe must have a minimum

of 1/4 inch per foot rise and should be supported at not

more than 5 ft. intervals. Plumbers tape, criss-crossed,

will serve to space both horizontal and vertical piping.

Gas vents supported only by the flashing and extending above the roof more than 5 ft. should be securely

guyed or braced to withstand snow and wind loads. We

recommend the use of insulated vent pipe spacers

through the roof and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a vent cap which complies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1.

The discharge opening must be a minimum of 2 ft.

vertically from the roof surface and at least 2 ft. higher

than any part of the building within 10 ft.

Fig. # 8165.0

12

Page 13

Vent stack shall be at least 5 ft. in vertical height

above the drafthood outlet. The vent cap location shall

have a minimum clearance of 4 feet horizontally from,

and in no case above or below, unless a 4-foot horizontal distance is maintained, from electric meters, gas

meters regulators and relief equipment.

The weight of the vent stack or chimney must not rest

on boiler drafthood. Support must be provided in compliance with applicable codes. The boiler top and

drafthood must be readily removable for maintenance

and inspection. Vent pipe should be adequately supported to maintain proper clearances from combustible

construction.

Type "B" double-wall or equivalent vent pipe is recommended. However single-wall metal vent pipe may

be used as specified in the latest edition of the National

Flue Gas Code ANSI Z223.1.

10' or less

Vent Cap

2' min.

2' min.

5' min.

Vent Pipe

Drafthood

Heater

Manifolds that connect more than one

boiler to a common chimney must be

sized to handle the combined load. Consult available guides for proper sizing of

the manifold and the chimney. At no time

should the area be less than the area of

the largest outlet.

Fig. #7043.1

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected to the common venting system are not in

operation.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and make sure there is no

blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces

of the building. Turn on clothes dryers and any

Fig. #8119.0

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

(d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

(e) Test for spillage at the drafthood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

(f) After it has been determined that each appliance

remaining connected to the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to

their previous conditions of use.

(g) Any improper operation of the common venting

system should be corrected so that the installation

conforms with the latest edition of the National Fuel

Gas Code, ANSI Z223.1. When re-sizing any

portion of the common venting system, the common venting system should be re-sized to

approach the minimum size as determined using

the appropriate tables in Part 11 of the National

Fuel Gas Code, ANSI Z223.1.

For special venting applications that require reduced

vent sizes and through-the-wall venting, the Type D

Induced Draft Assembly can be used. Consult the

factory or your local Raypak representative.

13

Page 14

VENT DAMPER INSTALLATION

D808

(MODELS 133 THROUGH 261)

WHERE REQUIRED

LOCATION

The vent damper must be located in the vent so

that it serves only the appliance for which it is intended.

If improperly installed, a hazardous condition, such

as an explosion or carbon monoxide poisoning, could

result. Make certain that it is mounted in an accessible

location at least 6 inches from any combustible material or the heat exchanger, and that the position indicator is in a visible location.

The vent damper must be installed after the appli-

ance drafthood, as close to the drafthood as practicable, and without modification of the drafthood.

Note: Model 133 drafthood shown.

Fig. # 8182.0

WARNING: Do not use thermally actuated vent dampers on a modulating boiler. To do so, may result in

asphyxiation. Use only a mechanically actuated vent damper device that is electrically interlocked with the

modulating boiler operation.

On vertical vents, the vent damper may be mounted with the actuator in any position. On horizontal vents,

do not mount the actuator either directly above or directly below the vent pipe; mount the vent damper actuator

to the side of the vent.

The vent damper is set up for a continuous pilot system. If the vent damper is installed on an Intermittent

Pilot or Direct Spark Ignition equipped system, the energy savings of the vent damper can be improved by

plugging the hole in the vent damper blade using the knockout plug, Part No. 105612R, provided in the parts

envelope.

DO NOT plug the hole if installing the vent damper on a continuous pilot system as this will create a hazard.

HORIZONTAL INSTALLATION

VERTICAL

INSTALLATION

FLOW >

D808

TO CHIMNEYTO BOILER

TO CHIMNEY

D808

TO BOILER

YES

ACTUATOR MAY BE

INSTALLED IN ANY

POSITION ON

VERTICAL PIPE.

NO

NO

INSTALL VENT

DAMPER WITH

ACTUATOR TO

SIDES OF VENT

ONLY. DO NOT

MOUNT ABOVE OR

BELOW VENT.

Fig. # 8183.0

YES

N.O. N.C.

End

Switch

C.

1K3

12345

Black Orange Red

1

Power supply provide disconnect me ans an overload protection as requ ired.

Power supply provide disconnect means an overload protection as required.

1K2

Motor

1R

Thermostat or

Controller

Dual Valve

Combination Gas

Control or

Ignition System

1K1

R

Yellow Blue

Transformer

Optional Limit

LocationLimit

Fig. # 8615.0

VENT DAMPER INSTALLATION VENT DAMPER GENERAL WIRING DIAGRAM

(Hot)

L1

L2

1

14

Page 15

INSTALL THE VENT DAMPER TO SERVICE ONLY THE SINGLE APPLIANCE FOR WHICH IT IS INTENDED. IF

IMPROPERLY INSTALLED, A HAZARDOUS CONDITION, SUCH AS AN EXPLOSION OR CARBON MONOXIDE

POISONING, COULD RESULT.

VENT DAMPER

NORMAL OPERATION SUMMARY

For safe, efficient operation, the vent damper and all flue product carrying areas of the appliance must be

checked annually, with particular attention given to deterioration from corrosion or other sources. Check vent

damper operation as follows:

1. When the boiler is off, check that the vent damper

position indicator points to the closed position.

(See figure below.)

EFFIKAL® RVGP

2. Turn the thermostat or controller up to call for heat

and check that the vent damper indicator points to

the open position. (See figure below.)

3. Turn the thermostat or controller down again and

check that the vent damper position indicator

returns to the closed position.

THE VENT DAMPER MUST BE INSPECTED AT LEAST

ONCE A YEAR BY A TRAINED, EXPERIENCED

SERVICE TECHNICIAN. THE NAME OF THE PERSON

WHO ORIGINALLY INSTALLED YOUR VENT DAMPER

IS SHOWN ON THE INSTALLATION LABEL. DAMPER

MUST BE IN OPEN POSITION WHEN BOILER MAIN

BURNERS ARE OPERATING.

Damper Position

Indicator

Damper Position

Indicator

Fig. # 8181.0

DAMPER OPEN DAMPER CLOSED

VENT DAMPER POSITON INDICATOR

PLUMBING

Fig. # 8090.1

CONNECTION DIAGRAM FOR EFFIKAL

VENT DAMPER

GAS SUPPLY CONNECTIONS

Gas piping must have a sediment trap ahead of the

boiler gas controls, and a manual shut-off valve located

outside the heater jacket. All gas piping should be

tested after installation in accordance with local codes.

CAUTION: The boiler and its manual shut-off valve must

be disconnected from the gas supply during any pressure

testing of that system at test pressures in excess of

1/2 PSIG. Dissipate test pressure in the gas supply line

before reconnecting the boiler and its manual shut-off

valve to gas supply line. FAILURE TO FOLLOW THIS

PROCEDURE MAY DAMAGE THE GAS VALVE. OVER

PRESSURED GAS VALVES ARE NOT COVERED BY

WARRANTY. The boiler and its gas connections shall be

leak tested before placing the appliance in operation. Use

soapy water for leak test do NOT use open flame.

NOTE: Do not use teflon tape on gas line pipe thread.

A flexible sealant is recommended.

15

®

Page 16

A minimum of 7" W.C. and a maximum of 10.5" W.C. upstream pressure, under load and no-load conditions,

must be provided for natural gas, or a minimum of 12" W.C. and a maximum of 13" for propane.

*Low NOx units not available for propane.

GAS PRESSURE REGULATOR

The gas pressure regulator is preset nominally at 4" W.C. for natural gas, and 11" W.C. for propane. Between

the gas valve and the burners is a 1/8" pipe plug. The pressure at this point, taken with a manometer, should

be about 3.7" W.C. for natural gas and 10.5" W.C. for propane. Low NOx models should be 3.9" W.C., natural

gas only. If an adjustment is needed, turn adjustment screw clockwise to increase pressure, or counter-clockwise

to decrease pressure.

For boilers with mechanical modulation gas valves (Type H1 and H5) or two-stage gas valves (Type H3),

the gas pressure regulator is preset and sealed, and not field adjustable. Pressure tap is provided on the outlet

side of the gas valve for measurement of gas pressure in the manifold.

VENTING OF DIAPHRAGM GAS COMPONENTS

Gas valves that are equipped with a gas bleed must be vented to the outdoors as required by the National

Fuel Gas Code. Under NO circumstances shall bleed lines terminate in the gas utilization equipment flue or

exhaust system.

Bleed Line Connection

Fig. # 8185.2

GENERAL

Boiler should be located so that any water leaks will not cause damage to any adjacent areas or structures.

See piping diagrams for proper water connections for the type of boiler and system.

16

Page 17

PUMP SELECTION

In order to ensure proper hydraulics in your

hydronic heating system, adequate pump size must be

selected. We recommend that the pump be sized for

20°F Delta T. (Delta T is the temperature difference

between the inlet and outlet water when the boiler is

firing at full rate). For some boilers, the Delta T is more

than 20°F (22°-33°F) at the recommended flow rates.

RECOMMENDED PURGE MANIFOLDS FOR

TYPICAL HYDRONIC SYSTEM HOOKUPS

The boiler piping system of a hot water heating

boiler connected to heating coils located in air handling

units where they may be exposed to refrigerated air

circulating, must be equipped with flow control valves

or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle.

FEEDWATER REGULATOR

We recommend that a feedwater regulator be

installed and set at 12 PSIG minimum pressure. Install

a check valve or back flow device upstream of the

regulator, with a manual shut-off valve. Leave the

valve open.

PIPING - HEATING BOILERS

We recommend that all high points be vented and

that purge valves and a bypass valve be installed. A

boiler installed above radiation level must be provided

with a low water cut-off device. The boiler, when used

in conjunction with a refrigeration system, must be

installed so that the chilled medium is piped in parallel

with the boiler with appropriate valves to prevent the

chilled medium from entering the boiler.

TEMPERATURE & PRESSURE GAUGE

The temperature & pressure gauge is standard

equipment on all hydronic heating and hot water supply

boilers. All temperature & pressure gauges are factory

mounted in the in/out header except for residential

boilers, Models 133 and 181-401. On these models the

temperature & pressure gauge is shipped loose for

field installation, and located in the outlet water

connection. All fittings required to mount gauge to

piping system are supplied by others.

17

Page 18

PIPING DIAGRAMS

DIAPHRAGM TANK SYSTEM

7024e

NOTE: Expansion tanks (supplied by others) should be

installed per manufacturer's instructions.

18

Page 19

MULTI-ZONE HEATING SYSTEMS

MODELS 133 TO 4001

Fig.# 7027.1e

NOTE: Expansion tanks (supplied by others) should

be installed per manufacturer's instructions.

Fig.# 7024.1e

NOTE: Expansion tanks (supplied by others) should

be installed per manufacturer's instructions.

19

Page 20

MULTIPLE-BOILER– REVERSE RETURN HOOK-UP

MODELS 133 TO 4001

Fig. #9495

REVERSE RETURN PIPING IS A PROPER METHOD OF MANIFOLDING MULTIPLE BOILER HOOK-UPS TO

ENSURE BALANCED FLOW THROUGH EACH BOILER. VALVES ON SUPPLY AND RETURN ARE NEEDED

TO ISOLATE ANY BOILER, AS REQUIRED.

20

Page 21

CONTROLS

OPERATING CONTROLS

ECONOMASTER CONTROLS

The Raytemp Economaster II is an electronic device that allows the operator to set the desired time for

the pump to run after the boiler shuts off. The time is

factory-set at 7 minutes and it can be re-adjusted in the

field anywhere from 3 to 10 minutes.

In a conventional system, when the aquastat is

satisfied, the main gas valve closes, but the pump

continues operating. With the new energy-conserving

Economaster II the boiler pump is programmed to

continue running for an optimum period of time in order

to absorb the residual heat from the combustion chamber and use it in the system. The pump then shuts off

until the next call for heat is received from the aquastat.

NOTE: Pump will come on when power is first applied

to boiler.

3/4

Models 133-1826 with mechanical modulating

controls have one or more Robertshaw Unitrol 7000

Series hydraulic snap-on thermostatic combination

gas valves. These valves have the pressure regulator

and 24 volt operator built-in. The hydraulic actuator

will throttle the boiler input to adjust the firing rate and

meet the required load. This, in effect, prevents costly

fuel consumption, as compared to an on-off cycling

boiler. The valve has a remote capillary bulb immersed in a well, at the header outlet, to maintain a

constant outlet water temperature. When multiple

valves are furnished, they can be staged to give

greater flexibility of control. Standard factory setting is

at position 5. Consult the dial setting tag attached to

the control for your desired temperature. See sample

tag drawings below.

ACAD: ECONO. DWG.

ELECTRONIC IGNITION

The intermittent ignition device conserves energy

by automatically extinguishing the pilot when desired

temperature is reached. When additional heat is

needed, the pilot re-ignites electrically, eliminating the

fuel costs of maintaining a constant pilot. To ensure

safe operation, the gas valve cannot open until the pilot

relights and is proven.

All units are shipped with lockout ignition module

as standard.

Fig. #8645.1

LOW TEMP. RANGE HIGH TEMP. RANGE

IGNITION MODULE

ELECTRONIC SAFETY

Fig. #8645 Fig. # 8929.1

21

Page 22

MODULATING VALVES

W/ BUILT-IN REGULATOR

MODULATING VALVE LOCATION

LIMIT CONTROLS

HIGH LIMIT

The boiler is equipped with a manual reset high

limit. Push the reset button and set the limit(s) to 3040 °F above desired operating temperature.

Fig. #8643

THERMOSTAT CONTROL

rupted. Pilot flame is automatically lit when the device

is powered. Unit performs its own safety check and

opens the main valve only after the pilot is proven to be

lit.

FLOW SWITCH

This dual purpose control shuts off the boiler in the

case of a pump failure or low water condition. It is

mounted and wired in series to the main gas valve.

Standard on all models except the 133.

NOTE: Flow switch will not operate if flow is less than

12 GPM.

100% PILOT SAFETY

All standard boiler models 514-4001 employ elec-

tronic devices which close the main gas valve within

8/10 of a second whenever the pilot flame is inter-

MANUAL RESET HIGH LIMIT FLOW SWITCH

LOW WATER CUT-OFF (OPTIONAL)

The low water cut-off automatically shuts down

burner whenever water level drops below probe. 90second time delay prevents premature lockout due to

temporary conditions such as power failure or air

pockets. Flush float type devices at beginning of each

heating season.

HIGH AND LOW GAS PRESSURE SWITCHES

These switches sense either high or low gas pressures and automatically shut down burners if abnormal

pressures exist.

Fig. #8644 Fig. 9317

22

Page 23

FLOW SWITCH CUTTING MODULATING VALVE

Fig. #8925 Fig. #8995

LOW WATER CUT-OFF GAS PRESSURE SWITCH

Fig. #8236Fig. #8996

23

Page 24

ELECTRICAL CONNECTIONS

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after

servicing.

DANGER - SHOCK HAZARD

Make sure electrical power to the heater is disconnected to avoid potential serious injury or damage to

components.

The boiler is normally wired for 120 Volts. The

voltage is indicated on the tie-in leads. Consult the

wiring diagram shipped with the boiler in the instruction

packet. The "TH" leads are for the remote tank control

connection. 24 Volts are supplied to this connection

through the boiler transformer. DO NOT attach line

voltage to the "TH" leads on models 133-1826. Before

starting boiler check to ensure proper voltage to boiler

and pump.

Boiler must be electrically grounded in accordance

with National Electrical Code ANSI/NFPA No 70.

Fig. #9138.1

NOTES:

1. Field install ground to inside of junction box.

2. If any of the original wire as supplied with the boiler

must be replaced, it must be replaced with 105°C

wire or its equivalent.

-

Fig. #9138.2

24

Page 25

START-UP

HIGH LIMIT

BEFORE START-UP

Safe lighting and other performance criteria were

met with the gas manifold and control assembly provided on the boiler when the boiler underwent tests

specified in the latest edition of ANSI-Z21.13 Standard.

GENERAL

Before lighting up a new installation, water should

be flowing through the boiler. Regulator should be set

to minimum 12 PSI.

CAUTION:

Liquefied petroleum gas is heavier than air and

sinks to the ground. Exercise extreme care in lighting

boiler in confined areas.

FILLING SYSTEM - HEATING BOILERS

Fill system with water. Purge all air from the system

using purge valve sequence. After system is purged of

air, lower system pressure. Open valves for normal

system operation. Fill system through feed pressure.

Manually open air vent on the compression tank until

water appears, then close vent.

Fig. #8991

ETHYLENE GLYCOL SYSTEMS HEATING BOILERS

Fill through filler opening on the top on the

Air-X Tank to solution desired. Always maintain solution level in sight glass.

INITIAL START-UP - PUMP AND MOTOR

Many pumps are now direct-drive. They have no

coupler or bearing assembly. These pumps do not

require lubrication. Others require SAE-30 non-detergent oil to lubricate both the motor and the bearing

assembly. Check pump motor for type before attempting to oil.

Clean dust and lint from pump and motor. Check

pump coupler and tighten if necessary.

Flush system before putting into operation to ensure that foreign material does not damage pump

seals.

CAUTION:

A. Pump must be off to check oil in bearing assembly.

B. Do not run pump without water in system.

25

Page 26

START-UP

LIGHTING INSTRUCTIONS FOR BOILERS WITH STANDING PILOT. For Models 133, 182, 260, 330 & 400

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted

by hand. When lighting the pilot, follow these

instructions exactly.

B. BEFORE LIGHTING smell all around the appli-

ance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and

will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on

this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. Remove boiler door panel.

5. Push in gas control knob slightly and turn

clockwise to “OFF”.

GAS CONTROL

KNOB SHOWN

IN "OFF"

POSITION

GAS CONTROL

KNOB SHOWN

IN "OFF"

POSITION

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, don’t try to repair it,

call a qualified service technician. Force or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

PILOT THERMO BURNER COUPLE

7. Locate pilot mounted

on the right side of the

burner tray, and right

of first burner.

8. Turn knob on gas control

counter-clockwise

to "PILOT"

9. Push in control knob all the way and hold in .

GAS INLET

Fig. # 8081.0

GAS INLET

Fig. # 8243.0

NOTE: Knob cannot be turned from “PILOT” to “OFF”

unless knob is pushed in slightly. Do not force.

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety information above on this label. If you don’t smell

gas, go to next step.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance.

3. Remove boiler door.

Immediately light the pilot with a match. Continue

to hold the control knob in for about one (1) minute

after the pilot is lit. Release knob and it will pop

back up. Pilot should remain lit. If it goes out, repeat steps 5 through 9.

• If knob does not pop up when released, stop

and immediately call your service technician

or gas supplier.

• If the pilot will not stay lit after several tries,

turn the gas control knob to “OFF” and call

your service technician or gas supplier.

10. Stand to the side of the boiler and turn the gas

control knob counter-clockwise to "ON".

11 Replace boiler door panel.

12. Turn on all electric power to the appliance.

13 Set the thermostat to the desired setting.

4. Push in gas control knob slightly and turn clockwise to “OFF”. Do not force.

5. Replace boiler door panel.

26

Page 27

LIGHTING INSTRUCTIONS FOR BOILERS WITH ELECTRONIC IGNITION (IID)

For Models with Manual Gas Valves

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

A. This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the pilot

by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electric switch; do not use any phone

in your building.

* Immediately call your gas supplier from your neighbor’s

phone. Follow the gas supplier’s instructions.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat on the lowest setting.

3. Turn off all electrical power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the pilot

by hand.

5. Remove boiler door panel.

6. For Robertshaw gas valve: Turn gas control knob

clockwise to “OFF”.

For Honeywell gas valve (all models except 40#):

Turn gas control knob clockwise to “OFF".

Make sure knob rest against stop.

For Honeywell gas valve (Models 40# only):

Push in gas control knob slightly and turn clockwise

to “OFF”. Knob cannot be turned to “OFF”

unless knob is pushed in slightly. Do not force.

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow “B” in the safety information above. If

you do not smell gas, go to the next step.

8. For Robertshaw gas valve: Turn gas control knob

counter-clockwise to “ON”.

ROBERTSHAW

GAS CONTROL

KNOB SHOWN

IN "ON" POSITION

GAS INLET

Fig. # 8080

* If you cannot reach your gas supplier, call the fire de-

partment.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

For Honeywell gas valve: Turn gas control knob

counter-clockwise from “OFF” until it

stops. Push in gas control knob and continue

rotating counter-clockwise to “ON”

position. Make sure knob rests against stop.

HONEYWELL

GAS CONTROL

KNOB SHOWN

IN "ON" POSITION

GAS INLET

Fig. # 8082

For Honeywell gas valve

(Models 40# only):

Turn gas control knob counter-clockwise to “ON”.

GAS CONTROL KNOB

SHOWN IN "ON"

POSITION

GAS INLET

9. Replace boiler door panel.

Fig. #8219

10. Turn on all electrical power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

“To Turn Off Gas To Appliance” and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to the lowest setting.

2. Turn off all the electrical power to the appliance if service

is to be performed.

3. Remove door panel.

4. For Robertshaw gas valve: Turn gas control knob

clockwise to “OFF”.

For Honeywell gas valve (all models except 40#):

Turn gas control knob clock-wise to “OFF”.

Make sure knob rests against stop.

For Honeywell gas valve

(Models 40# only):

Push in gas control knob slightly and turn clockwise

to “OFF”.

5. Replace heater door panel.

27

Page 28

FOR MODELS WITH AUTOMATIC GAS VALVES

LIGHTING INSTRUCTIONS

1. Close all gas valves. Turn off electrical power

supply. Wait five (5) minutes.

2. Open manual pilot valve. Turn on electrical

power. Pilot is automatically lighted.

PILOT

VALVE CONTROL

SHOWN IN THE MAIN GAS SHUT-OFF

"ON" POSITION VALVE SHOWN IN

THE "ON"

POSITION

GAS INLET

Fig. # 8220.0

3. Open main gas valve.

4. Set temperature controls to desired temperature.

TO SHUT DOWN

Close all manual gas valves. Turn off electrical

power.

IGNITION MODULE

Fig. # 8929.1

AFTER START-UP

STANDING PILOT CHECKOUT PROCEDURE

1. Turn on pilot gas supply, light pilot, and check

pilot tubing connections for leakage. With main

burner in operation, paint tubing connections

with a rich soap and water solution. Bubbles

indicate a gas leak.

2. Adjust pilot to obtain a normal flame enveloping

3/8 to 1/2 inch [9.5 to 12.5 mm] of the

thermcouple or generator tip.

3. Place system in operation, and:

a. Check for satisfactory ignition of main

burner.

b. Make certain the pilotstat "holds in", and

that shutdown occurs within 2-1/2 minutes

after the pilot flame is extinguished.

c. Observe operation for at least three cycles

to be sure the system is functioning normally.

PILOT FLAME SHOULD ENGULF THERMOCOUPLE

PILOT WITH

BURNER FLAME

INTERMITTENT PILOT SYSTEM CHECKOUT

(S8600)

1. Turn on power to the ignition systems and turn

gas supply off.

2. Check ignition module as follows:

a. Set the thermostat or controller above

room temperature to call for heat.

b. Watch for continuous spark at the pilot

burner.

c. Time the spark operation. Time must be

within the lockout timing period (15 or 90

seconds).

d. Turn thermostat down to end call for heat

and wait 60 seconds on lockout models

before beginning step 3.

3. Turn on gas supply.

4. Set thermostat or controller above room temperature to call for heat.

5. Systems should start as follows:

a. Spark will turn on and pilot gas valve will

open at once. Pilot burner should ignite

after gas reaches the pilot burner.

b. Spark ignition should cut-off when pilot

flame is established.

c. Main gas valve should open and main

burner should ignite after gas reaches the

burner port.

Fig. # 8186.1

STANDING PILOT

28

Page 29

INSPECTIONS

BURNERS

Clean main burners and air louvers of dust, lint and

debris. Keep boiler area clear and free from combustibles and flammable liquids. Do not obstruct the

flow of combustion and ventilation air. Make visual

check of burner and pilot flame. Yellow flame indicates

clogging of air openings. Lifting or blowing flame indicates high gas pressure. Low flame indicates low gas

pressure.

TYPICAL MAIN BURNER FLAME Fig. # 8144

NOTE: Modulating burner flame varies in height from

approximately 1/4" at low fire to approximately 4" at

high fire.

Fig #9336

PILOT BURNER FLAME (IID UNITS)

CONTROLS

Check all controls to see that they are operational.

To check electronic safety (IID Models), turn off main

burner. Observe pilot burner when shutting off pilot

gas. Ignition spark should go on. Main gas valve will

also drop out.

To check high limit switch, turn dial setting down to

a point slightly below the temperature of the water

leaving the heater. The reset button should snap out

and the burner should shut-off. Reset dial to 30°F to

40°F above desired operating temperature, and push

reset button. Burner should light.

SUGGESTED INSPECTION SCHEDULE

The boiler should be inspected on the first and third

months after initial start-up and then on an annual

basis. If problems are found, refer to Troubleshooting

Guide for additional directions.

1. Remove top of heater and inspect heat exchanger

for soot and examine venting system.

2. Remove rear header and inspect for scale depos-

its, and/or accelerated erosion.

*3. Inspect pilot and main burner flame and firing rate.

*4. Inspect and operate all controls and gas valve.

*5. Visually inspect system for water leaks.

*6. a. Oil pump motor and bearing assembly, if oil

cups are provided.

b. Disconnect pump from header and check

condition of pump impeller. Check condition

of bearing by attempting to move impeller

from side to side. Replace any parts showing

wear.

c. Check pump coupler for wear and vibration.

7. Check flow switch paddle.

8. Clean room air intake openings to ensure ad-

equate flow of combustion and ventilation air.

CAUTION: Combustion air must not be contaminated

by corrosive chemical fumes which can damage the

boiler and void the warranty.

9. Keep boiler area clear and free from combustible

materials, gasoline, and other flammable vapors

and liquids.

*Should be checked monthly. (Takes approximately

15 minutes).

PILOT BURNER FLAME

(STANDING PILOT UNITS)

Fig #8964.1

29

Page 30

LOW NOx BOILERS Models 181 to 401

The boilers are certified and tested under the latest

edition of the ANSI Z21.13 standards for hot water

boilers.

The boiler should be installed to meet the latest edition

of all local codes, the National Fuel Gas Code Z223.1

and the National Electrical Code, ANSI/NFPA 70.

BURNER ADJUSTMENT

This burner assembly does not require any primary air

adjustments.

VISUAL INSPECTION

Flame can be observed through the slot opening above

the plenum. Flame color is blue and evenly spread on

the top surface of the burner. At least every three

months a visual inspection should be made of the

burners. In case flame lifting is observed, check gas

pressure on manifold and static pressure in plenum.

Gas pressure in manifold should be 3.9" W.C. and

static pressure in plenum should be greater than 0.5"

W.C.

ELECTRICAL

Be sure that electrical service to the boiler has proper

overload fuse or circuit breaker protection and wire

size, and connections which comply with all applicable

codes.

Fig # 9361

OPERATION

On call for heat, the ignition system, consisting of an

electronic spark module, and gas pilot system is energized. Providing pilot is proven, blower will start

running, the main gas valve will open and the boiler will

operate. When the operating control is satisfied the

boiler will shut down.

START-UP (S8610B)

1.Turn on power to the boiler with gas supply off.

2.Check ignition module as follows:

a. Set the thermostat or controller to call for heat.

b. Watch for continuous spark at the pilot burner.

c. Check the ignition spark operation. Time must be

within the lockout timing period (15 or 90 seconds).

d. Turn control down to end call for heat and wait 60

seconds on lockout models before beginning step

3.

3.Turn on gas supply.

4.Set controller to call for heat.

5.System should start as follows:

a. Spark will turn on and pilot gas valve will open and

the blower will begin running.

b. Heater will operate until call for heat is satisfied.

FLAME ROLL-OUT SAFETY SWITCH

The boiler is equipped with a cut-off device to prevent

flame roll-out in the event the heat exchanger becomes

blocked. This is a "manual reset" type roll-out switch,

that must be reset by a service technician after any over

temperature conditions have been fixed. Excessive

restriction in the heat exchanger flue passage may

cause the switch to disable the boiler.

Fig. # 9412

30

Page 31

SERVICE

LOW NOx BURNER TRAY ASSEMBLY

6. Use a long ½” socket wrench to remove orifices

from the gas manifold.

7. Remove burners by raising the bracket on the back

end of the burners up and out of their slots.

8. Reverse above procedure to re-install.

Fig # 9363

Fig # 9362

IID PILOT

PILOT REMOVAL

BURNER TRAY REMOVAL

1. Shut-off main electrical power switch to heater.

2. Shut-off gas upstream of heater.

3. Remove front door.

4. Disconnect gas line from gas valve.

5. Remove (2) screws that mount burner tray to the

base of the unit, and (2) screws that secure gas

valve to jacket.

6. Disconnect wires that terminate at gas valve.

7. Unscrew (4) screws that secure the control box.

8. Disconnect pilot wire from the ignition module.

9. Disconnect wire harness from the combustion

blower.

10. Carefully slide out the burner tray assembly.

11. Reverse above procedure to re-install.

GAS VALVE REMOVAL

1. Remove burner tray. See Burner Tray Removal

procedure.

2. Disconnect, pilot tubing from gas valve.

3. Turn vertical gas pipe from manifold slightly and

unscrew gas valve.

4. Reverse above procedure to re-install.

1. Disconnect pilot tubing from gas valve.

2. Remove (4) screws from control box. Open the

control box.

3. Remove the pilot wire from the ignition wire.

4. Remove (2) screws that mount the pilot bracket

to the air manifold assembly.

5. Pull the pilot bracket slightly, then drop and pull

downwards and outwards.

6. Reverse above procedure to re-install. Make

sure the pilot bracket is all the way up on the

pilot side, see drawing below.

MAIN BURNER AND ORIFICE REMOVAL

1. Remove burner tray. See Burner Tray Removal

procedure.

2. Remove pilot. See Pilot Removal procedure.

3. Remove (8) total screws from the hold-down brackets, front and rear of tray.

4. Remove (8) total screws from the left and right

sides of the manifold assembly. Detach the manifold assembly from the burner tray assembly.

5. Remove burners by raising the bracket on the back

end of the burners up and out of their slots.

FOR HEATERS

MADE IN OR AFTER

AUGUST 2001

COMBUSTION FAN REMOVAL

1. Remove burner tray. See Burner Tray Removal

procedure.

2. Remove (4) screws that mount the combustion

blower to the manifold assembly.

3. Reverse above procedure to re-install.

31

Page 32

TROUBLESHOOTING

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

ELECTRICAL

ELECTRONIC IGNITION IID

Intermittent Pilot System

TROUBLESHOOTING HONEYWELL S8600

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

NOTE: Some heaters may be equipped with

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

an ignition module that shuts off pilot gas if

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

pilot fails to light. To reset, interrupt power

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

to heater.

For qualified technicians ONLY

WARNING

HIGH VOLTAGE

START

TURN GAS SUPPLY OFF.

TURN THERMOSTAT

(CONTROLLER) TO CALL

FOR HEAT

POWER TO MODULE

(24 V NOMINAL)

YES

SPARK ACROSS

IGNITER/SENSOR GAP

YES

TURN GAS SUPPLY ON

PILOT BURNER LIGHTS?

YES

SPARK STOPS WHEN

PILOT IS LIT?

YES

NO

NO

NO

NO

NOTE: Before troubleshooting, familiarize yourself with the start-up and checkout

procedure.

Check line voltage power, low voltage transformer, limit controller, thermostat

(controller) and wiring.

Pull ignition lead and check spark at module.

If spark Okay:

• Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

• Check boot of the ignition cable for signs of melting or buckling. Take protective

action to shield cable and boot from excessive temperatures.

If not, replace module.

• Check that all manual gas valves are open, supply tubing and pressures are

good, and pilot burner orifice is not blocked.

• Check electrical connections between module and pilot operator on gas control.

• Check for 24 Vac across PV-MV/PV terminals on module. If voltage is

okay, replace gas control; if not, replace module.

NOTE: If S8600H goes into lockout, reset system. Lockout is used on propane

models.

• Check continuity of ignition cable and ground wire.

• Clean flame rod.

• Check electrical connections between flame rod and module.

• Check for cracked ceramic flame rod insulator.

• Check that pilot flame covers flame rod and is steady and blue.

• Adjust pilot flame.

• If problem persists, replace module.

MAIN BURNER LIGHTS?

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS?

YES

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

YES

TROUBLESHOOTING

ENDS

NO

NO

NO

• Check for 24 Vac across MV-MV/PV terminals. If no voltage, replace module.

• Check electrical connections between module and gas control. If okay, replace

gas valve or gas control operator, i.e. pilot gas valve, flow switch, etc.

NOTE: IF S8600H goes into lockout, reset system.

• Check continuity of ignition cable and ground wire.

NOTE: If ground is poor or erratic, shutdowns may occur occasionally even though

operation is normal at the time of checkout.

• Check that pilot flame covers flame rod and is steady and blue.

• If checks are okay, replace module.

• Check for proper thermostat (controller) operation.

• Remove MV lead at module; if valve closes, re-check temperature

controller and wiring; if not, replace gas valve.

32

Page 33

ELECTRICAL

STANDING PILOT

For Service Technicians

START BOILER

IF PILOT BURNER LIGHTS IF PILOT BURNER

BUT MAIN BURNERS DO NOT DOES NOT LIGHT

CHECK FOR 24 V CHECK THERMOCOUPLE

AT GAS VALVE

IF NOT 24 V: IF 24 V: IF O.K. IF DEFECTIVE

CHECK TRANSFORMER OUPUT REPLACE

FOR 24 V GAS VALVE REPLACE REPLACE

GAS VALVE THERMOCOUPLE

IF NO IF 24 V:

24V:

REPLACE PROBLEM IN

TRANSFORMER LIMIT

CIRCUITS

WARNING

HIGH VOLTAGE

For Qulified Techinicians ONLY

33

Page 34

10

3/4

TYPICAL ON-OFF INTERMITTENT IGNITION

CONTROL WIRING DIAGRAM

34

Page 35

MECHANICAL PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

When boiler is turned on nothing

happens.

Thermostat in "ON" position causes

relay and pump to operate, but boiler

does not fire.

Continuous shut down of manual reset

high limit.

Pilot is not lit………………………………

No power to the boiler…………………...

Bad transformer………………………….

Inoperative thermostat…………………..

Inoperative toggle switch………………..

Inoperative relay………………………….

Main gas valve is closed……………….

Plugged bleed line on gas valve or

gas pressure regulator…………………..

Broken pump coupler……………………

Shutdown by low water cut-off,

caused by air……………………………..

Gas valve defective………………………

Temperature setting too low…………….

Low water flow……………………………

Interrupted pump operation……………..

Modulating control set too high………..

Mechanical modulating control…………

Light pilot. (Standing pilot models)

Check the circuit breaker, outdoor controller, etc., upstream of boiler.

If power to Leads L1 and L2 of transformer, but no power on 24V side, replace.

Jumper thermostat. Replace with new if

boiler fires.

If power to toggle switch, but not

through switch, replace.

If power to relay, but not operating,

replace.

Open valve.

Loosen bleed line and clean.

Replace coupler. Inspect bearing assembly, and if frozen, lubricate or replace.

Bleed air from system.

Check for power to gas valve. If valve

has power but will not open, check vent

tube for blockage. If clear, replace

valve.

Reset high limit to higher temperature.

Check system water pumps.

Check pump oil if necessary.

Reset modulator to a lower setting.

Check and replace if necessary.

Sooting

CAUTION-Soot may be combustible.

Wet down and exercise caution when

cleaning.

Continuous shut down of low water cutoff or flow switch.

Low flame.

Outer jacket very hot (blistered paint).

Air starvation……………………………..

Condensation……………………………..

Toxic fumes which cause a chemical

reaction with copper tubes or destroy

combustion……………………………….

Improper venting…………………………

Insufficient system flow………………….

Low water due to leaking………………..

Air in system………………………………

Line strainer dirty…………………………

Lime in heat exchanger…………………

Gas supply………………………………..

Insects or debris clogging burners..........

Burner intake ports low gas pressure….

Venting or combustion air……………….

Broken refractory…..…………………….

Refer to installation instructions regarding combustion air requirements.

Set bypass valve to prevent boiler inlet

temperature from dropping below

105 °F.

Remove all sources of fumes, such as

freon, chloride, or isolate the boiler.

Follow recommended vent installation

instructions.

Check pumps and piping.

Inspect for leakage and repair.

Inspect for leakage and repair. Install

an automatic air vent.

Clean.

Ream tubes.

Debris in gas line (pipe dope, rocks,

etc.). Gas line too small.

Improperly sized gas meter.

Gas regulator adjustment.

Clean burners.

Adjust gas pressure.

Refer to installation instructions regarding combustion air requirement.

Replace refractory panels.

35

Page 36

PUMPS

FAILURE TO PUMP

1. Pump not properly primed.

2. Wrong direction of rotation.

3. Speed too low.

4. Total head too high.

PUMP LOSES PRIME

1. Air leaks in suction line.

2. Excessive amount of air in water.

3. Water seal in stuffing box not functioning.

4. Excessive suction lift and pump operating too

near shut-off point.

REDUCED CAPACITY AND/OR HEAD

1. Air pockets or leaks in suction line.

2. Clogged impeller.

3. Foot valve strainer too small or clogged.

4. Excessive suction lift (over 15 ft.).

5. Insufficient positive suction head (for hot water).

6. Total head more than that for which pump is

intended.

7. Excessively worn impeller and wearing rings.

RAPID WEAR OF COUPLING

1. Misalignment or a bent shaft.

2. Sagging motor mounts (over-oiling).

OVERLOADED DRIVING UNIT

1. Head much lower than that for which pump is

designed.

2. Speed too high or higher than that contemplated.

MECHANICAL TROUBLES AND NOISE

1. Misalignment.

2. Excessive suction lift or vapor binding (hot

water).

3. Bent shaft and/or damaged bearings.

4. Suction and discharge piping not properly

supported and anchored.

SERVICE

RAYPAK TUBE CLEANING KIT

Extension Pieces (5) Auger with Carbide Tip Wire Brush

P/N 052871F - 5/8 DIA.

REPAIR SECTION

TUBE CLEANING PROCEDURE

Establish a regular inspection schedule, the frequency depending on the local water condition and

severity of service. Do not let the tubes clog up solidly.

Clean out deposits over 1/16" in thickness.

The boiler may be cleaned from the side opposite

the water connections as shown, without breaking pipe

connections. It is preferable, however, to remove both

Fig# 9310

Fig. # 8154

P/N 052870F - 7/8 DIA.

headers for better visibility through the tubes and to be

sure the residue does not get into the system.

Note that you do not remove the top pan or the heat

exchanger generally.

After reaming with the auger, mount the wire brush

and clean out the debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in noninhibited de-scale solvent.

36

Page 37

COMBINATION FLAME SENSOR/

IGNITER AND PILOT BURNER

TYPICAL BURNER TRAY ILLUSTRATED

BURNER TRAY REMOVAL

1. Shut-off power and gas supply to the boiler.

Disconnect union(s) and pilot tubing, then

loosen and remove burner hold-down screws.

2. Disconnect wires at gas valve and slide burner

tray out.

GAS VALVE REMOVAL

1. Shut-off gas supply to the boiler. Remove gas

piping to gas valve inlet.

2. Disconnect wires, pilot tubing and bleed line, if

required.

3. Turn vertical gas pipe from manifold slightly and

unscrew gas valve.

4. Reverse above procedure to re-install.

MAIN BURNER AND ORIFICE REMOVAL

1. Remove screws and burner hold-down bracket.

NOTE: If the heat exchanger is sooted badly, the

burner hold-down bracket and spacer can become

distorted from direct flame impingement and this usually necessitates replacement of these parts.

2. Lift burners from slotted spacer and slide from

orifices. Clean with a wire brush.

3. Clean orifice(s) as necessary.

PILOT REMOVAL AND CLEANING

1. Disconnect pilot tubing at pilot and sensor/igniter

wire. Remove screws holding pilot bracket to

burner tray.

2. Remove pilot and bracket, clean pilot of debris,

small bugs, etc., with wire or small brush.

3. Replace pilot, pilot tubing, sensor ignition wires

and check for leaks.

HIGH LIMIT OR TANKSTAT REMOVAL

1. Turn off electrical power.

2. Remove front inspection panel.

3. Remove wires to high limit and loosen screws

holding high limit to cabinet.

4. Remove wedge clip holding sensing bulb in

control well.

5. Remove high limit and install a new one.

6. Check control operation before leaving job.

HEAT EXCHANGER REMOVAL

1. Shut water, gas and electricity off, close valves

and relieve pressure, remove relief valve.

Remove side inspection panels.

2. Remove top holding screws.

3. Remove draft diverter, lift and remove top and

flue collector on stack type models. Remove