Page 1

USER’S INFORMATION MANUAL

CATALOG NO. 2100.51L Effective: 09-19-08 Replaces: 04-10-08 P/N 240490 Rev. 13

Models

0042B, 0066B, 0090B, 0135B,

0180B—Type H

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Do not store or use gasoline or other flammable vapors and liquids or other

combustible materials in the vicinity of this or any other appliance. To do so may

result in an explosion or fire.

Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

Gas Fired Residential

Heating Boilers

Page 2

2

Introduction

This User's Information Manual is provided with the

necessary information for the proper operation and

maintenance of these Raypak boilers. Please review

and follow these procedures carefully. Keep this manual in a safe and accessible place for easy reference

in the future.

Blocked Vent Shut-Off System

This boiler is equipped with a blocked vent shut-off

system designed to shut off main burner gas in the

event the venting system is totally blocked. In the

event the blocked vent shut-off system is actuated, do

not attempt to place the boiler in operation, contact a

qualified service agency.

Flame Roll-Out Safety Shut-Off

System

This boiler is equipped with a flame roll-out safety

shutoff system designed to shut-off the main burner

gas in the event of sustained flame roll-out. In the

event the flame roll-out safety system is actuated, do

not attempt to place the boiler in operation, contact a

qualified service agency.

Lighting Instructions For

Standing Pilot Models

Some safety information you need to read and understand before operating the boiler.

A. This boiler has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions

exactly.

B. BEFORE LIGHTING Smell all around the boiler

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch;

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach you gas supplier, call the fire

department.

C. Use only your hand to push in, move or turn the gas

control knob or lever. Never use tools. If the knob or

lever will not push in, move or turn by hand, don't try to

repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this boiler if any part has been under

water. Immediately call a qualified service technician

to inspect the boiler and to replace any part of the control system and any gas control which has been under

water.

For Standing Pilot Models with

Robertshaw Gas Valve, 2-Stage

Operation. (Models 90, 135 & 180)

5. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow "B" in the safety information

above in this manual. If your don't smell gas, go to

the next step.

6. Locate pilot mounted on the right side of the burner drawer, and right of first burner.

WARNING: Improper care and maintenance of flue

and venting system can cause a hazardous

condition which may result in injury, property

damage or loss of life.

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

NOTE: Lever cannot be moved from "ON" to "OFF"

unless lever is pushed in slightly. Do not force.

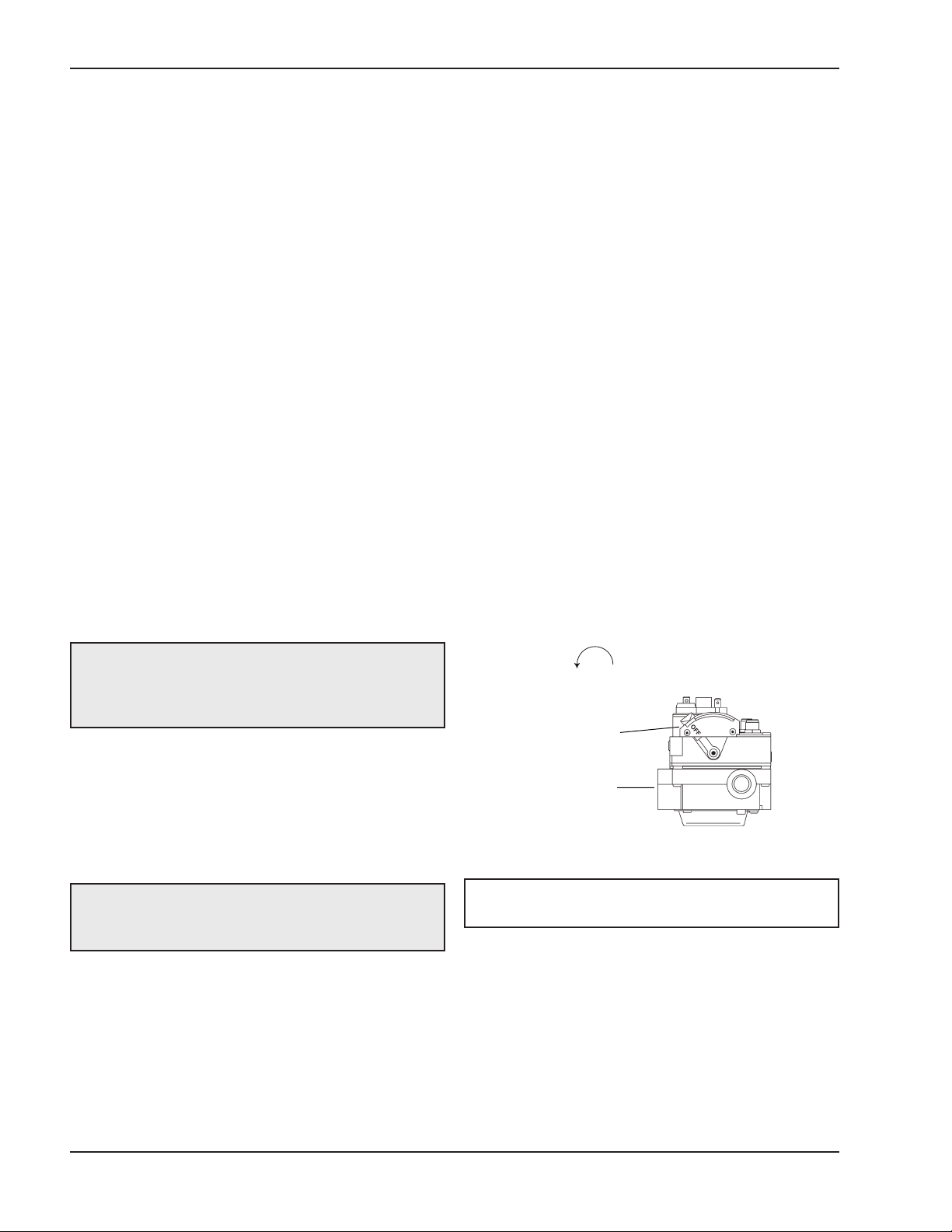

Fig. 1: Gas Control Lever

1. STOP! Read the safety information.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. Push in and move gas control lever counterclockwise to "OFF" position.

GAS CONTROL

LEVER SHOWN

IN "OFF" POSITION

GAS INLET

Page 3

3

Lighting Instructions For

Automatic Ignition Models

Please read carefully and understand the following

safety information before operating the boiler.

A. This boiler does not have a pilot. It is equipped with

a hot surface ignition device which automatically lights

the burners. Do not try to light the burners by hand.

B. BEFORE OPERATING smell all around the boiler

area for gas. Be sure to smell next to the floor because

some gases are heavier than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electric switch;

* Do not use any phone in your building.

* Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

* If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in, move or turn the gas

control knob or lever. Never use tools. If the knob or

lever will not push in, move or turn by hand, don't try to

repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this boiler if any part has been under

water. Immediately call a qualified service technician

to inspect the boiler and to replace any part of the control system and any gas control which has been

underwater.

For Intermittent Ignition (IID) with

Honeywell or Robertshaw Gas Valve

(For All Models)

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. This boiler is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

THERMOCOUPLE THERMOCOUPLE

Fig. 2: Pilots

To Turn Off Gas to the Boiler

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

Fig. 3: Honeywell Gas Valve

ROBERTSHAW PILOT HONEYWELL PILOT

7. Move control lever clockwise to "SET"

position and immediately light pilot with a match.

8. Hold lever in "SET" position for 1/2 minute after

pilot is lit. Release lever, and it will spring back to

"PILOT" position Pilot should remain lit. If it goes

out, repeat steps 4 through 8.

*If lever does not spring back to "PILOT" position

when released, stop and immediately call your

service technician or gas supplier.

*If the pilot does not stay lit after several tries, move

the gas control lever to "OFF" and call your service

technician or gas supplier.

9. Stand to the side of the heater and move the gas

control lever counter-clockwise to "ON".

10. Turn on all electric power to the appliance.

11. Set the thermostat to the desired setting.

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance.

3. Push in and move gas control lever counter-

clockwise to "OFF" position. Do not

force.

GAS CONTROL

KNOB SHOWN

IN "ON" POSITION

GAS INLET

HONEYWELL

(Models 30 - 90)

Page 4

4

8. Turn on all electric power to the boiler.

9. Set thermostat to desired setting.

10. If the boiler will not operate, follow the instruction

"To Turn Off Gas To Boiler" and call your service

technician or gas supplier.

To Turn Off Gas to the Boiler

1. Set the thermostat at the lowest setting.

2. Turn off all the electric power to the boiler if service is to be performed.

Inspection and Maintenance

Procedures

It is a good practice to make a periodic inspection of

the boiler. It is recommended that the home owner or

user check the boiler after the first and third month of

operation, and then on an annual basis, or more often

if desired. It is also recommended to have a qualified

service agency check the boiler before each heating

season, or at anytime there may be an indication of a

problem.

Burner Inspection

Clean the main burners and air louvers of dust, lint and

debris. With burner in operation, make a visual check

of the burner flame and the pilot flame (when

equipped). Yellow flames indicate some restriction of

combustion air openings. A bright orange, luminous

flame is not normal and can cause sooting under prolonged operation. Should this condition be observed,

immediately contact a qualified service agency to correct the problem.

5. For Honeywell Valve: Turn gas control knob

Fig. 4: Robertshaw Gas Valve

Fig. 5: Honeywell Pilot

CAUTION: Should overheating occur or the gas

supply fail to shut off, DO NOT turn off or disconnect

the electrical supply to the pump. Instead, shut off

the gas supply at a location external to the

appliance. Failure to observe this precaution may

aggravate the overheated condition resulting in

possible damage to the boiler and injury to the user.

DANGER: Keep boiler area clear and free from

combustibles and flammable materials. Do not

obstruct the flow of combustion and ventilating air

into the boiler enclosure. Failure to observe these

safety precautions can cause fire, explosion, or

asphyxiation.

Fig. 6: Burner Flame

clockwise to "OFF".

For Robertshaw Valve: Push in and move gas

control lever to "OFF" position.

6. Wait 5 minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above

in this manual. If you don't smell gas, go to the next

step.

7. For Honeywell Valve: Turn gas control counter-

clockwise to "ON".

For Robertshaw Valve: Move gas control lever to

"ON" position.

PILOT

S

ON

GAS CONTROL

KNOB SHOWN

IN "OFF"

POSITION

GAS INLET

ROBERTSHAW

(All Models)

OFF

E

T

3. For Honeywell Valve:

Turn gas control knob clockwise to "OFF".

Make sure knob rest against stop.

For Robertshaw Valve:

Push in and move gas control lever to "OFF"

position.

BLUE FLAME

Page 5

5

Venting System Inspection

Visually inspect the venting system. Make sure the

vent connections are secure and have not become

disengaged. Look for any indication of corrosion, or

carbon (soot) streaks which could cause leakage of

products of combustion into the living space. Inspect

the vent terminal outside the building. Make sure it is

not damaged to cause blockage or restriction of the

flue gas. Look for any indication of soot. The presence

of soot accumulation in the vent terminal would indicate an abnormal operating condition. This should be

investigated and corrected by a qualified service

agency.

Circulator (Water Pump) Inspection

The circulator is permanently lubricated and thus, will

not require any lubrication. Inspect for evidence of

water leakage. This should be corrected to prevent

any possible damage to electrical components of the

boiler.

To prevent the potential freezing damage to the heating system, it is recommended that the following

system shut down procedure be performed.

System Shut Down Procedure

1. Set the room thermostat to "OFF" or the lowest

setting.

2. Turn off all electric switches to the boiler.

3. Turn off all gas valves supplying gas to the boiler.

Refer to operating instruction label on the boiler.

4. Shut off the water supply to the boiler piping system loop.

5. Open drain valve on the boiler to remove water

from the boiler and the piping circuits.

Service Assistance

If service is required on the boiler, contact your local

service agency or Raypak can refer you to the proper

qualified service agency. It is important and very often

will save time if you state the model number, serial

number and type of gas used. This information will be

found on the nameplate of the boiler.

Fig. 7: Inspect the Venting System

CAUTION: In case of a prolonged power failure

during freezing weather conditions, boiler and piping

system must be drained completely to avoid possible

damage to the heating system.

NOTE: It may be necessary to open the purge

valves and/or manual air vents to facilitate complete

drainage of water from the heating system.

SOOT

CORROSION

DISENGAGED

Page 6

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

Loading...

Loading...