Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

: WCOLOR

ECHO SOUNDER

+OPERATlON

MANUAL

Page 3

COLOR ECHOSOUNDER

OPERATION MANUAL

PURPOSE

This manual contains very important information on the installation,

operation, and maintenance of your new equipment. In order td get the best

results in operation and performance, please take the time to read this

manual thoroughly.

**-**

This

device is only an aid to

jlktors

improper handling or use. It is the

prudence andnavi@ionaljudgment, and thisdevice shouldnot be relied upon

as a

including

substUejb,r

IMPORTANT NOTICE

navigation.

equipmentfre

such prudence and judgment.

Its accumcy can be

ordeficts, environmental conditions, and

user’s nzsponsibility

*******

a&ted

to

e.wcise

FIRST EDITION

April, 1993

by

common

many

Page 4

RAYTHEON MARINE COMPANY products are supported by a network of Authorized Service Representatives. For information on Raytheon

products and services, contact any of the following regional offices:

UNITED

STATES . . . . . . . . . . . .

Raytheon Marine Company

46 River Road

Hudson NH. 03051

Telephone: (603) 881-5200

Raytheon Marine Company

1521 So. 92nd Place

Seattle, Wa. 98108

Telephone: (206) 763-7500

EUROPE . . . . . . . . . . . . . . . . . . .

Raytheon Marine Sales & Service

Elizabeth Way,

The Pinnacles,

Harlow,

Essex CM19 5AZ.

United Kingdom.

Telephone:

44-

(0) 279 444 244

Page 5

Table of Contents

INTRODUCTION

1 .lGENERAL

1 .2ABOUT THIS MANUAL..

1.3

ECHO

1 .4GPS GENERAL

INFORMATION..

SOUNDING

INFORMATION..

GENERAL

INSTALLATION

2.1 GENERAL . . . . . . . .

2.2

UNPACKING AND INSPECTION

2.2.1

2.2.2

2.3

INSTALLING THE

2.3.1

2.3.2

2.4

CONNECTIONS..

2.4.1

2.4.2 Data Input/Outputs..

2.4.3

2.4.4

2.4.5

2.4.6

Equipment Supplied..

Accessories&Options..

Standard

Console

Power Input

GPS

Sensor(Option).

SeaTalk

Video

Grounding The Echosounder..

Interface

Output..

.._.......................................................................

DISPLAY

Mounting

Mounting

......................................................................

...................................................................

...............................................................

.........................................................

............................................................

INFORMATION

..................................................

...................................................

........................................................

...................................................

UNIT

.........................................................

..........................................................

........................................................

.......................................................

............................................................

...............................................

...........................................

................................ .3

.l

.2

.5

9

.9

10

1 1

1

1

.l 1

14

14

15

.17

19

.19

19

9

2.5

TRANSDUCER INSTALLATION

2.5.1

2.5.2

2.5.3 252BL Lexan Transducer Installation

2.5.4 252BB Bronze Thru-Hull Transducer..

General

General

Mounting

2.5.3.1

2.5.3.2

2.5.3.3 Preparation 3- The Location

2.5.3.4 Transducer

2.5.3.5 Inside Hull Installations

2.5.3.6 Steel Hull Installations

2.5.4.1 Locating the 252BB .............................................

Information..

Mounting Considerations..

Location-

Preparation

Preparation2- The

.................................................

......................................................

Displacement

1- The

Installation

Stuffing Tube..

Fairing

...................................

Hulls

......................................

.......................................

.........................................

............................

................................. 24

........................

Block..

.........................

...............................

...............................

.20

.20

.21

.22

.24

.24

.25

..2 6

.30

.30

.34

.34

Page 6

2.5.5

2.5.4.2 Preparing the Installation

Installing

SpeedfTemperature

the

OPERATION

....................................

Unit..

...........................

.35

.38

3.1 GETTING STARTED

3.1 .lThe Keyboard

3.2 THE BASIC CONTROLS

3.2.1 The Power Control Keys

3.2.2

3.3 DISPLAY MODES..

3.3.1 STD

3.3.2

3.3.3

3.3.4 STDlBTM Display..

3.3.5 CRUISE DISPLAY..

3.3.6 PLOT/TEMP Mode..

3.3.7 NAVIGATION

Brilliance

3.2.2.1

FishFinder

3.3.1 .l Fishfinder/A-Scope

3.3.1.2 Frequency.. ..........................................

3.3.1 .3

3.3.1 .4 Using the

3.3.1.5 Selecting Range Scales

3.3.1 .6 Setting

3.3.1.7 Setting the Gain

3.3.1.8 Setting the STC

3.3.1.9 Controlling the Chart Speed

3.3.1.10 Setting and Using Alarms

3.3.1 .l 1 Noise Suppression/Interference Reduction

STDISTD

STD/ZOOM

3.3.5.1 CRUISE Operations.

3.3.5.2 NAV Alarms - The Set Alarm Menu .....................

3.3.6.1 Operations for Plot.Mode

3.3.6.2 Selecting

3.3.6.3 Navigating to Waypoints

3.3.6.4 Using EVENT Marks

3.3.6.5 Re-centering Own Ship

3.3.6.6 The TEMP

3.3.7.1 Navigation

.................................................................

...............................................................

Control..

Backlighting

..................................................................

Mode

Saving

Mode

Mode

Display

3.3.7.1.1

3.3.7.1.2

3.3.7.1

...........................................................

.............................................

..........................................................

the

Keypad..

.....................................................

..............................................

Events..

Shift..

..............................................................

Plot Scales

.3

..................................................

VRM

..................................................

....................................................

...............................................

................................................

...........................................................

..........................................................

.........................................................

............................................

........................................................

Graph

Operations..

GOT0 a Selected Waypoint: ...............

Store

Route

...............................................

.....................................................

an

Following Operations ................

....................................

..........

.._

.......................................

.................................

..................................

...........

....................................

..........................................

.....................................

...........................................

.........

......................................

EVENT..

..............................

....

.41

.42

.44

.44

.45

.45

.45

.46

47

48

.48

.49

.49

.50

.52

.53

.53

.54

.57

58

.59

.60

.60

.61

.62

.67

.68

.68

.68

.69

69

.70

.72

.73

.73

.73

.73

Page 7

3.3.8

3.4

MENU

3.4.1

3.4.2

3.4.3 NAVIGATION Menu

3.4.4

The CUSTOM

Key

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

FISHFINDING

3.4.1.1

3.4.1.2 Auto Gain

3.4.1.3

3.4.1 .4 Screen Colors

PLOTFEMP

3.4.2.1

3.4.2.2 PLOT DISPLAY

3.4.2.3

3.4.2.4 TRIP LOG Reset .

3.4.3.1 NAVIGATE SETUP Menu .

3.4.3.2

ROUTE

3.4.4.1

White

Simulator Mode

TRACK CONTROL

RTE

3.4.3.1 .lMagnetic

3.4.3.1 .2Display Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.4.3.1

STORE

3.4.3.2.1

3.4.3.2.2

3.4.3.2.3

3.4.3.2.4 SAVE Operations - WAYPOINT LIST . . . . . . . 89

PLANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ROUTE

3.4.4.1 .l

3.4.4.1.2

3.4.4.1 .3Listing

3.4.4.1 .4Editing

Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Line

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

INPUT

WAYPOINTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

._.........._.......................................

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Menu . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

.._....._........................................

._.......................................................

Correction

.3 Loran-C

Naming

Store

WAYPOINT

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Selecting

Making Route

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Waypoints

Waypoint

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

LIST Operations . . . . . . . . . . . . . . . . . . 88

Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

.._...............................

.._.................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

75

76

79

79

80

81

3.5

GPS

3.5.1

3.5.2

MODE

Getting Started

3.5.1 .lEstimated

3.5.1.2Antenna

3.5.1

The SATELLITE STATUS Page . . . . . . . .

3.5.2.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

with GPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

.3 Entering

SATELLITE -SF

3.5.2.1.1

3.5.2.1.2 Search The Sky

3.5.2.1.3

3.5.2.1.4

3.5.2.1.5

3.5.2.1.6 4 L/L

3.5.2.1.7 Response

Date& Time

FixType

HDOP

POSITION

Geodetic System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

CORR.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

=L/L

.._._.._.._.......................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

=SPD . . . . . . . . . . . . . . . . . . . . . . . 105

99

102

Page 8

3.6 SYSTEM SETUPS.. ................................................................. 106

3.6.1 INPUT/OUTPUT ........................................................... 106

3.6.1.1 NavIn............................................................ 106

3.6.1.2 Data Out.. ....................................................... 106

3.6.1.3 Heading In.. ..................................................... 107

3.6.1 .4

3.6.2 UNITS ........................................................................ 107

3.6.2.1 Selecting

3.6.2.2 Changing Temperature Units.. ............................ 108

3.6.2.3 Changing Units of Speed..

3.6.2.4 Changing

3.6.3 CALIBRATE Menu.. ...................................................... 109

3.6.3.1 Calibrate Temperature.. ...................................... 109

3.6.3.2 Calibrate Speed.. .............................................. 109

3.6.3.3 Calibrate TX Frequency..

3.6.4 Master

SpeedIn......................................................... 107

UnitsofDepth ................................... 108

.;.

108

109

1 10

1 1 1

Reset

..............................

Language

...............................................................

..........................................

....................................

MAINTENANCE

4.1 GENERAL

4.1 .lPaddle Wheel Maintenance..

4.1 .2 Transducer Maintenance ................................................

4.2 ELECTRICAL..

4.2.1

4.2.2 Replacing the Batten/

4.2.3 Self Test Mode

4.2.4 Auto Temperature Calibrate Mode..

4.2.5

4.3

TROUBLE

4.4 SPARE PARTS

4.5

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..............................................................................

...........................................

........................................................................

Replacing

Service

4.2.3.1 Dis-assembly For Service....................................

4.2.3.2 Power

4.2.3.3

4.2.3.4 TX/Rx Adjustments ........................................... TBA

SHOOTING

the

Fuse

........................................................

.....................................................

.............................................................

.................................

Alignments.. ......................................................

Supply

Color

.............................................................................

Monitor Adjustments..

CHART .......................................................

Adjustments.................................

............................... TBA

113

1 13

1 14

1

14

1 14

115

1 15

1 16

TBA

TBA

TBA

Page 9

SECTION I

INTRODUCTION

1.1 GENERAL INFORMATION

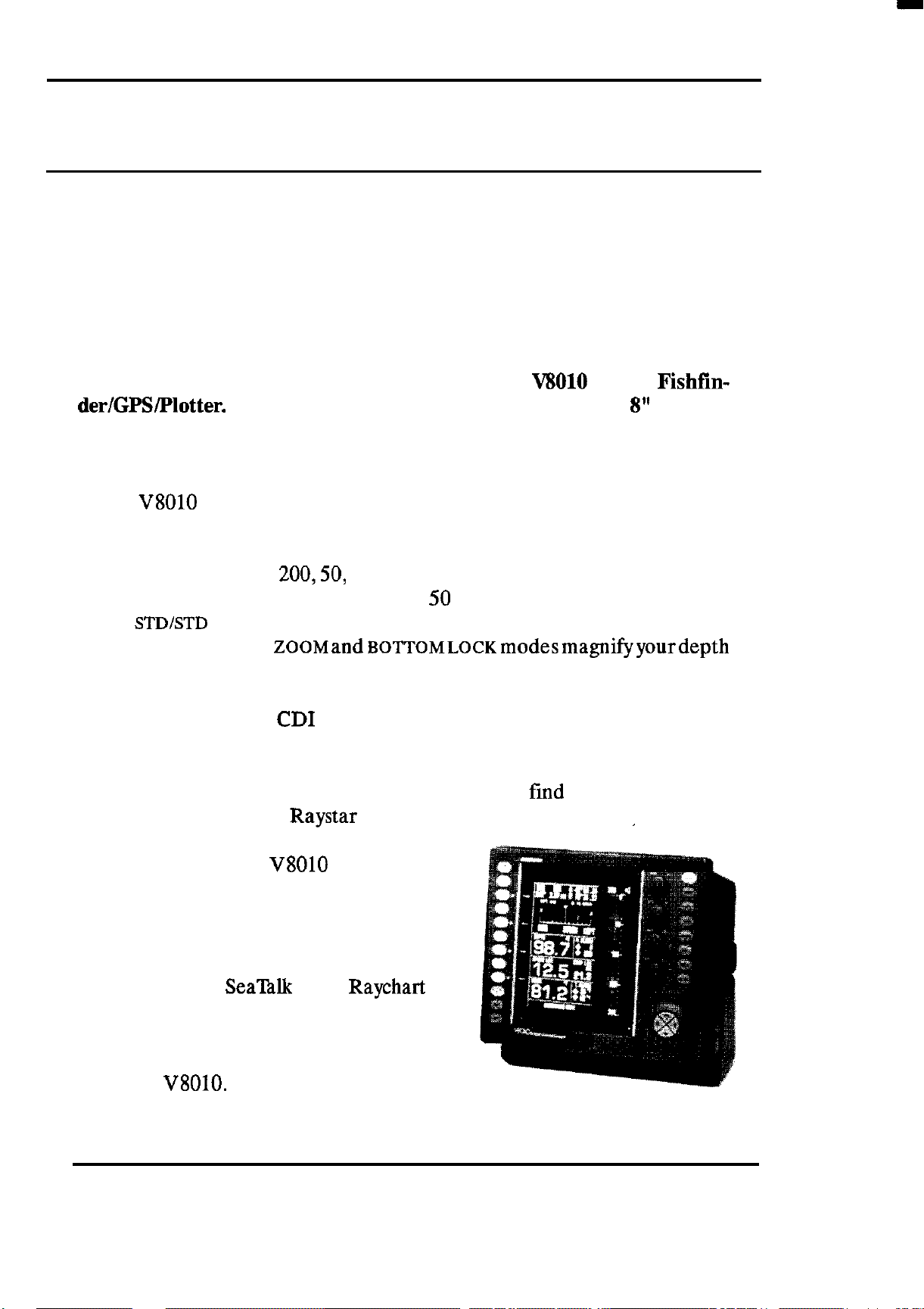

Congratulations on the purchase of your new

der/GPS/Plotter.

which combines the most useful fishing display modes in 8 or 16 bright

colors together with GPS or other external Navaid data.

The V8010 provides simple and direct access to your navigation and

fishfindingdata using simple on-screen menus and one -button operations.

The Fishfinding modes include STANDARD displays of fish and the bottom

profile using either the 200,50, or 28Khz 1000 watt transmitters. There’s a

split-screen display of both the 200, and 50 (or 28) Khz frequencies together

called

trackingtogether.The

presentations for a better look at the fish in mid-water or on the sea bottom.

Plot tracker records your vessel’s track to destinations so you can trace the

path back home again. The Plot Tracer cursor helps spot the surface

temperature break points on the plotter so you can

and the fish. When the Raystar 100 GPS sensor is connected. automatic

satellite acquisition and tracking lets the

GPS mode turn the

navigation system

STDISTD

Graphic plotting and

We think you’ll appreciate the unit’s large 8” display

mode which provides best views of fish detection and bottm

ZOOMand~~TT~~~~~~modesmagnifyyourdepth

CD1

displays steer you to waypoints efficiently. The

V8010

into a full

Vii010

find

Color Fishfin-

the warm currents

Although we could go on describing

the exciting new features such as Multi-

color

Electronic Charting option, we’re sure

that you will enjoy will discovering and

using the many new features found in

your new

A-SCOPE,

V8010.

SeaTalk or the

Raychart

INTRODUCTION 1

Page 10

1.2 ABOUT THIS MANUAL

This manual contains important information to help you get the best

operation and performance from your new

V8010.

Although the unit is

pretty simple to master, please take the necessary time to read through the

each section.

In the event that you are using a GPS or a fishtinder for the first time, this

Introduction contains a brief discussion on the general principles of

finding and, if you’ve added the

V8010

system, a brief description of how the GPS satellite system works is

Raystar

100 GPS sensor option to your

included.

Section 2 contains very important information on the proper installation

of your new

V8010

Color Fishlinder/Plotter/Navigator. Although the typical installation might seem straight forward and simple, we highly recommend that this section be read

thoroughly

and the guidelines for installation

be closely followed to obtain trouble-free and efficient operation of your

new unit.

fish-

Section 3 contains the operating instructions for the

V8010

Color

Echosounder and will guide you through the unit’s operating controls and

display layouts. To more easily recognize how to enable the various operations, the names of keys that must be pressed to corn lete the described

operation are enclosed in boxes, such as

I-,

or

RANGE

rf

. In most cases,

pictures, showing the correct displays for the desired entry, are included

next to each function.

Some of the functions appear on the screen in temporary menus or boxes

whenever the blue keys such as

m

or

ml

are pressed. Numeric

values appearing in the boxes can be changed by pressing the UP or DOWN

direction keys. Other menu functions are enabled when the corresponding

‘softkey” is pressed.

The best way to learn about your

V8010

is to dive right in. You can’t

damage the unit by randomly pressing keys. So don’t be afraid to experiment. If at any time the results appear confusing, just push

themkey

and start again.

Section 4 contains some technical information on the Basic Care and

Maintenance for your unit. In the event that your

V8010

should ever

INTRODUCTION 2

Page 11

experience an operational failure, it is recommended that all repair services

be provided by an authorized Raytheon service dealer or by the Raytheon

Factory Service Center.

Before proceeding, please take a few moments to fill out the Warranty

Registration Card located behind the front cover of this manual. Then

return the card to Raytheon Marine Company. No postage is required

card is mailed in the U.S.A.. This card must be returned to assure the

registration of the warranty for your unit.

1.3

ECHO SOUNDING GENERAL INFORMATION

An echo sounder is a device which transmits an ultrasonic energy wave into the

water; listens for echoes from that ultra-

-:

TRANSDUCER

sonic wave and then displays the returning

echoes onto the LCD panel or CRT video

display. The elapsed time that it takes for

ENERGY WAVE

the pulse energy to travel down through

the water and be reflected back as echoes

can be measured and converted into units

of depth in the echo sounder.

ifthe

The frequency of this “ultrasonic” wave, the beam angle at which it is

transmitted, and the power at which it is sent will all

play

an important part

in determining the appearance of the echoes on the display.

The normal components of an echo sounder are a display unit containing

the electronic circuits, and a transducer for sending and receiving the sonic

energy. The echo sounder is one of the most useful pieces of electronic

equipment aboard a boat. In addition to indicating the depth of the water,

it can indicate whether the bottom is hard or soft, smooth or irregular in

contour and

whether

fish are present below the boat.

Echo returns from the bottom, from fish or fish schools, seaweed, grass,

bubbles, or plankton are received by the echo sounder in various echo

strengths. The bottom echo is usually the strongest echo return while

returns from fish are generally very weak. In color echo sounders, such as

the

V8010,

these different echoes are displayed in distinct colors (up to 16

colors can be used) for easy recognition by the operator. Whether fish

INTRODUCTION 3

Page 12

echoes are displayed on the echo sounder (or not) can depend on several

factors including:

*The type or species of the fish

l

Number and sires of the fish

l

Depth of fish below the boat

l

Gain control setting

*Transmitter Power and frequency

l

Transducer beam angle

l

Speed of the boat

l

Turbulence in the water

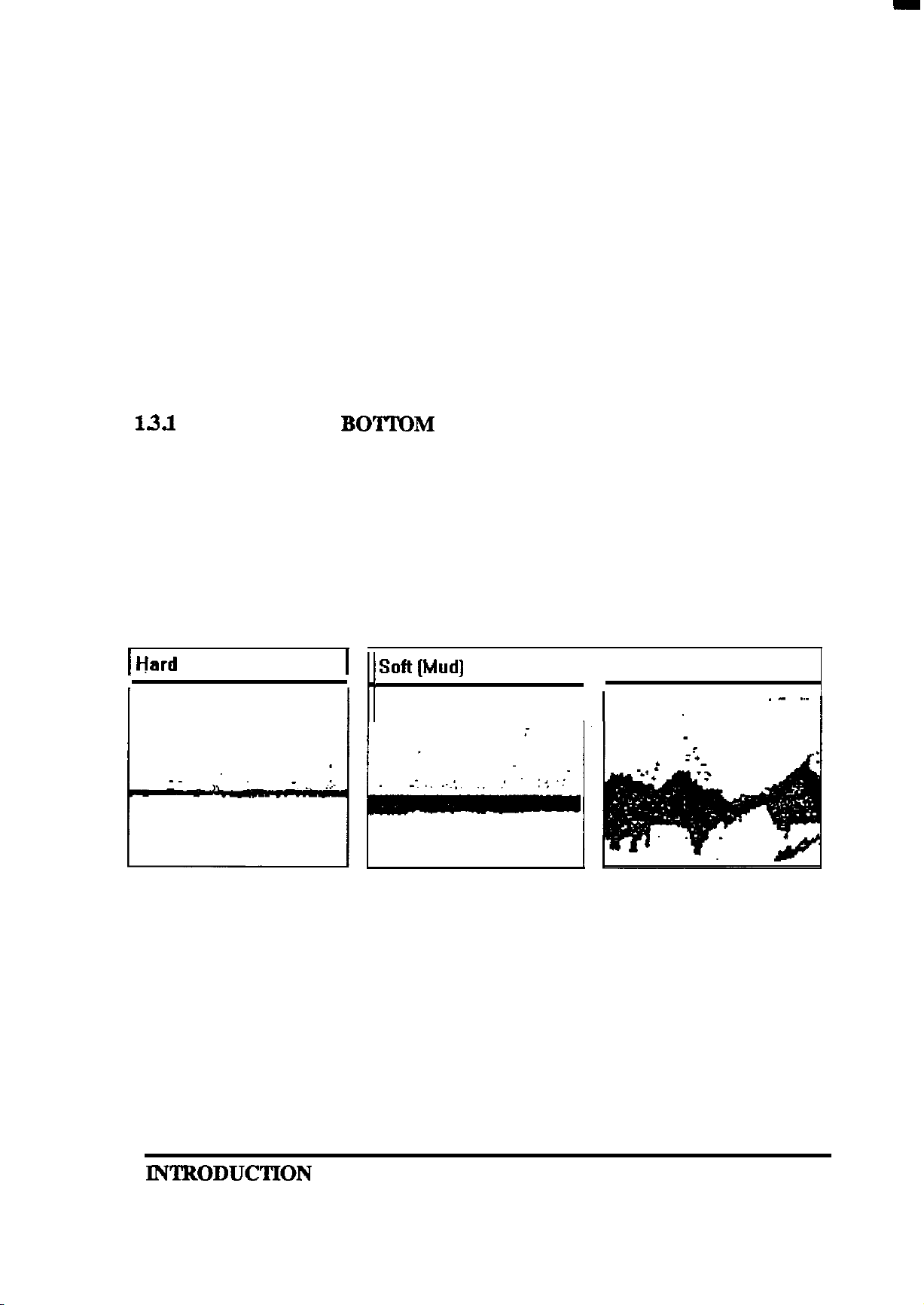

1.3.l

DETERMINING

To understand how bottom conditions affect the bottom echo’s appearance on the display, consider the signal transmitted from the transducer as

a cone-shaped beam of approximately 10 degrees. If the sea bottom were

as hard and flat as a mirror, only the signal directly under the transducer

would be reflected back to the transducer, and there would be a narrow

bottom echo line printed on the display screen.

BOTTOM

CONDITIONS

1 Hard

Bottom (Sand]

.

1

1

Soft(Mud] Bottom

/

_,

Rock

[Live]

Bottom

H

This type of echo line is typical characteristic of hard sandy sea bottoms.

Sometimes when the depth is shallow and the bottom is

echo can appear at exactly double the depth of the true bottom echo.

If the sea bottom is softer (sea grasses or muddy), the echo bottom line

would print thicker on the screen. This is because the echo consists not only

of that weaker echo reflected from the top surface of the grass or mud, but

very hard

,a second

IN’I’BODUCTION

4

Page 13

includes some energy that penetrates into the grass

, soft

sand, or mud and

then reflects back to the transducer slightly delayed in time. Under some

conditions, the sonic energy is strong enough to penetrate the soft bottom

and show a harder sub-botton such as an oyster beds or ledges.

If the sea bottom is made up of coral beds, wrecks, or rock piles, the

irregular surfaces of the bottom structures provide a series of closely spaced

echo returns from the various angles of the bottom. On screen, the bottom

line appears irregular with long tails as shown in the “Live Bottom”

figure.

Generally, these bottom conditions provide an ideal habitat for locating

fish.

On your display the echoes are printed on the CRT screen beginning at

the right edge adjacent to the range scale marks. Each time the echo

sounder transmits and receives, the new echoes replace the old echoes at

the right edge and the picture is

shifted

to the left. You can see the received

echoes even more clearly when you turn on the A-Scope feature of the

V8010.

that you have passed over

Eventually a historical

lYll

picture of the bottom contour

the screen.

and

fish echoes

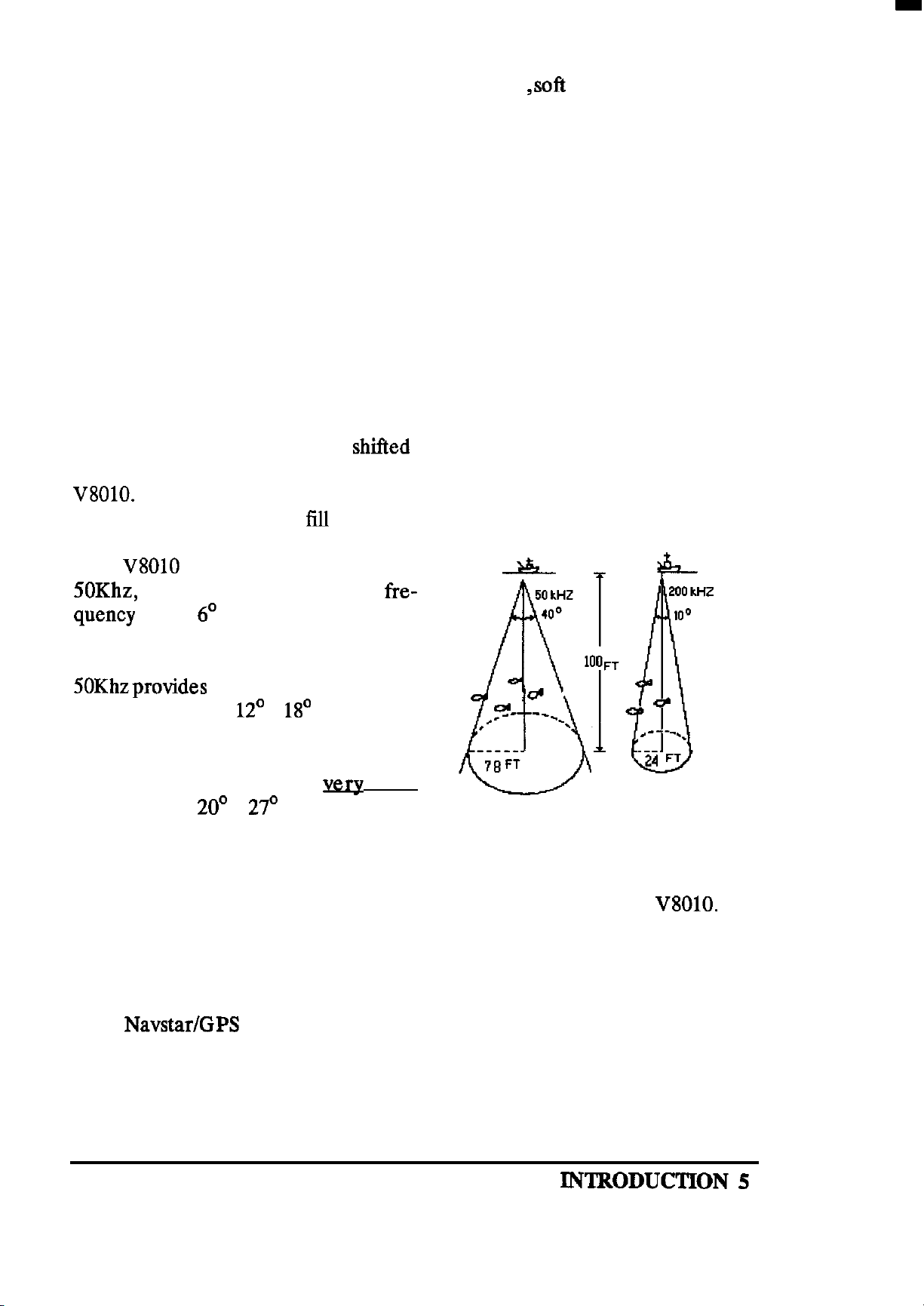

The

V8010

SOKhz,

quency

operates at either 200 Khz,

or 28Khz. The 200 Khz fre-

uses a 6O beam angle to provide

excellent detection of small fish and

high resolution of bottom detail. The

SOKhzprovides

tern with its wider

a larger fish search pat-

12’

x

18’

beam angle

and deeper depth bottom tracking. The

28Khz frequency is best for fish search

and bottom detection in

water using a 20’ x

27’

beam.

very

deep

The Operation section describes how the various controls can be set for

optimum performance. So, please take the time to read the Operation

section thoroughly so you can always get the best results from the

1.4 GPS GENERAL INFORMATION

V8010.

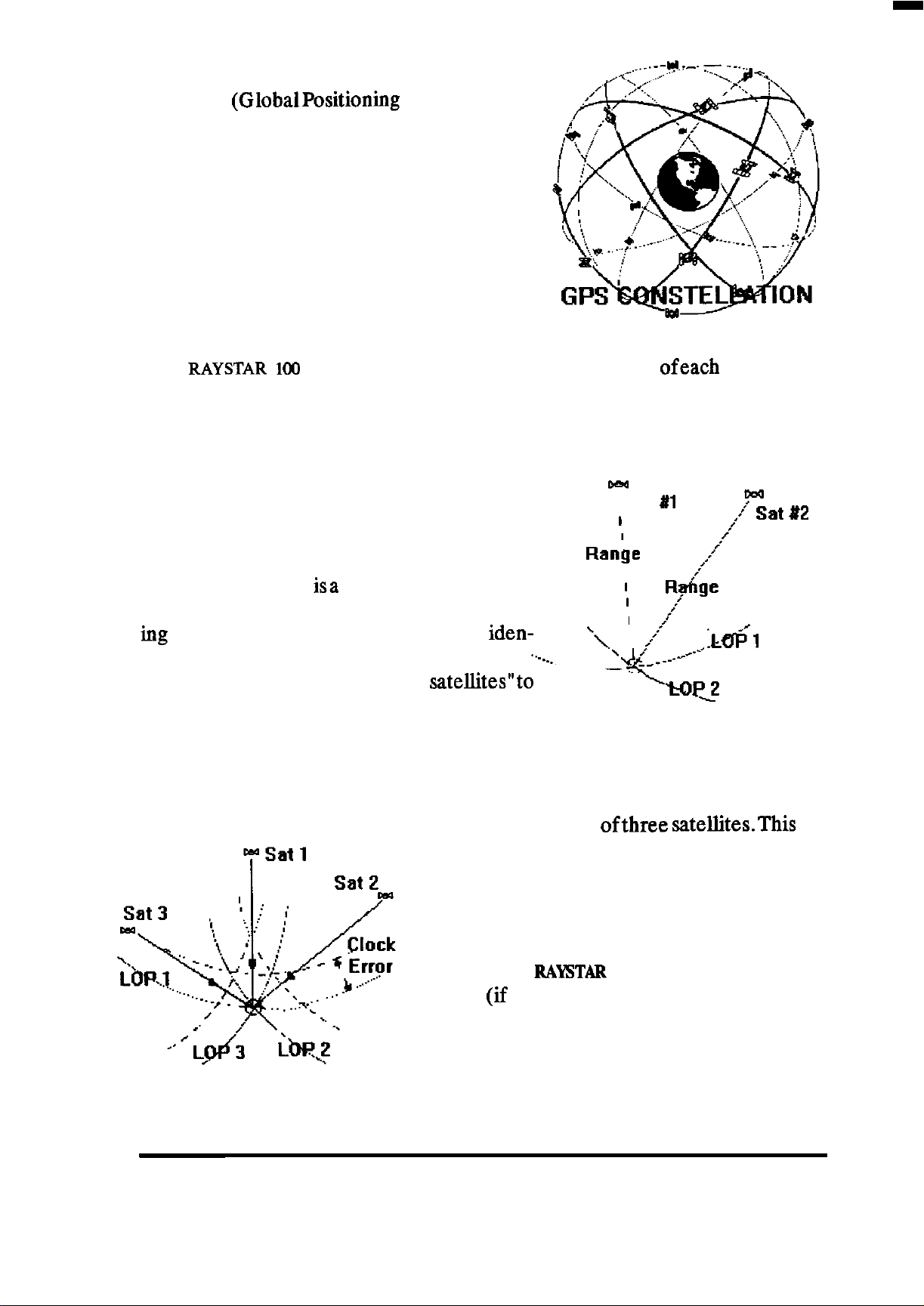

The Navstar/GPS system is a satellite-based radio navigation system de-

signed to provide global, continuous 24 hour-per-day all weather, accurate

position data for navigators worldwide.

KNTRODUCTION 5

Page 14

The GPS (GlobalPositioning System) is based

on a GPS receiver’s ability to accurately measure the propagation time of signals transmitted

from orbiting satellites.

These satellites transmit accurately timed signals along with a navigation message containing

the satellite’s position, precise time correction

signals, as well as almanac data for all of the

satellites in the constellation.

The

RAYSTAR

100

GPS sensor measures the time-of-arrival ofeach satellite

signal and calculates the range to each tracked satellite. If the range to the

satellites is known, the position of your vessel can be determined by

triangulation of the range data of the satellites in view, and presented in

Latitude and Longitude.

cna

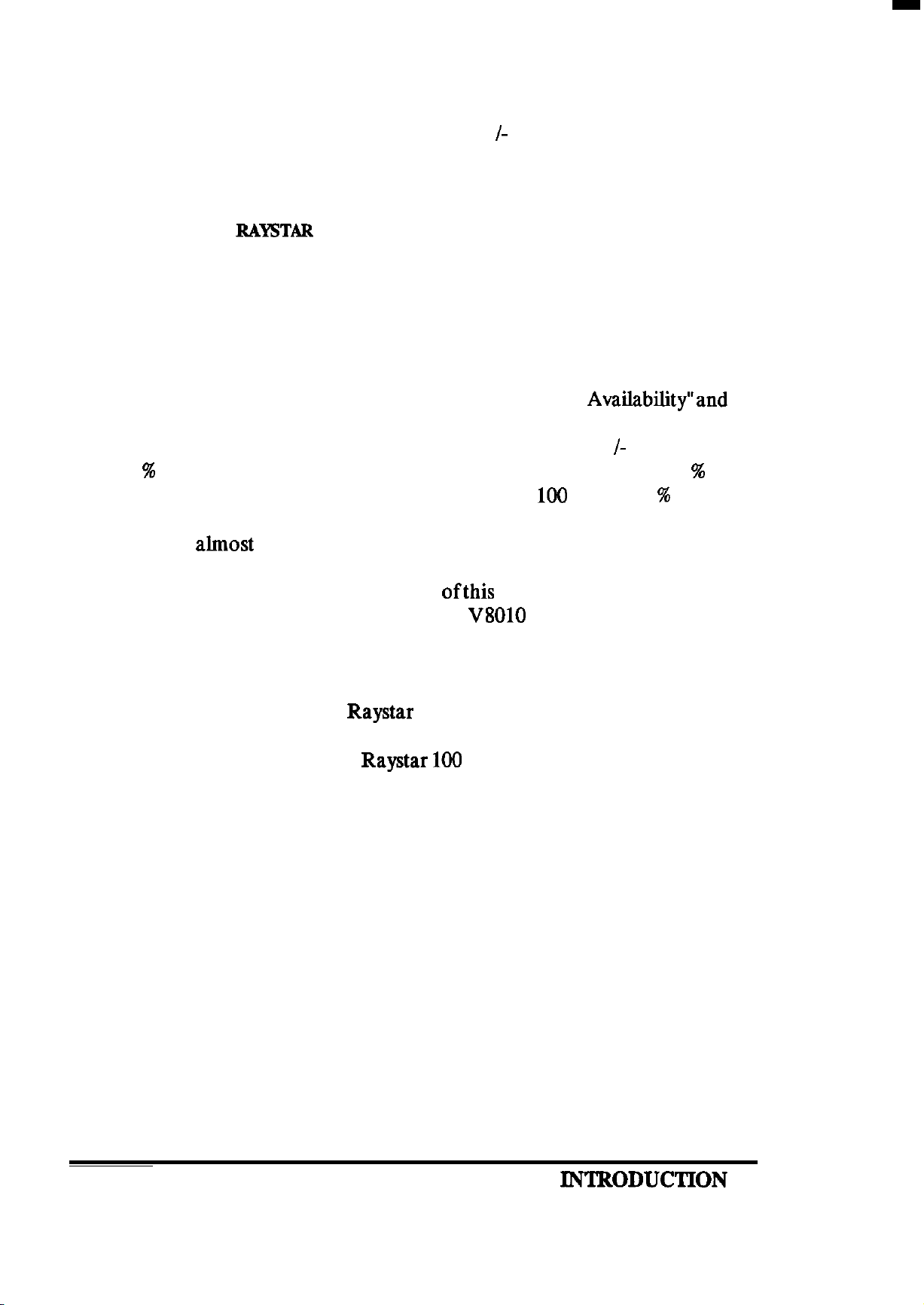

The satellites continuously broadcast their

navigation messages at a

frequency

of

1575.42

Mhz (for civilian use). Superimposed on the

navigation message

isa

high rate C/A (Coarse

Acquisition) code used for precise position-

ing

measurements and positive satellite iden-

tification. The C/A ID code permits the user

..-...~

to determine and select the ‘best satellites”to

Ranbe

,

‘\

__ _

t1

1

1

I

I

l&c

\

/’

,

,./

_J&“__------‘”

\

lzQP,2

:%t

/’

/

2

ii361

n2

I sat

use in position calculations.

If it were possible to measure true satellite ranges directly, it would only

be necessary to track data from any two satellites to obtain a vessel’s

latitude/longitude. In actual practice, for marine navigation the receiver

must trackaminimum

ofthree

satellites.This

is necessaryto resolve timing errors including

the receiver’s own internal clock timing bias

error which must be factored into the various

range calculations.

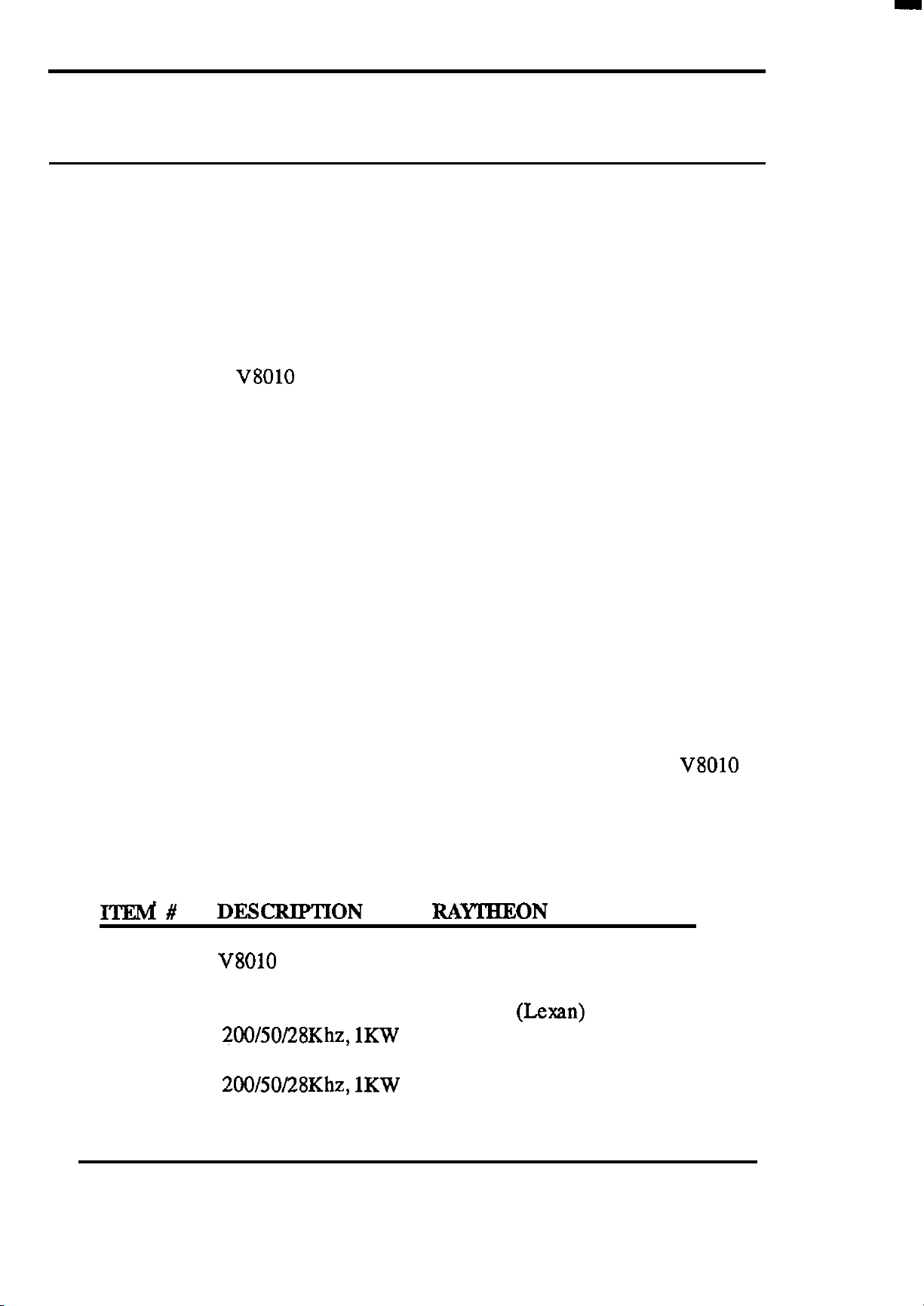

Normally, the

satellites

(if

RAYSTAR

visible)

100

tracks up to five

and uses the best four of

the five for calculating position fixes. By using four satellites, the processor can determine the amount of clock error in each range

INTRODUCTION 6

Page 15

calculation. The receiver subtracts the error bias equally from each range

solution until the LOP’s intersect. Theoretically, this process can produce

highly accurate position fixes for navigation. (+ I- 15M rms).

Continuous tracking of each satellite signal allows the receiver to perform

this timing adjustment process and to calculate accurate measurements to

the satellites. The

RAYSTAR

100

uses high-speed multiplexed scanning in a

single channel receiver. This receiver design method provides fast efficient

acquisition and accurate position updating, while saving in overall unit size

and weight, cost, and power consumption.

Unfortunately, the Department of Defense has included a special mode

into the GPS satellite system design which introduces variable timing errors

into the satellite signals. This mode is known as “Selective

Availability”and

when it is enabled, it is designed to provide less accurate fixes for all users

(except authorized military users). Accuracy in the order of + /- 100 meters

rms 95 % of the time is obtained when SA is ON. This means that 95 % of

the time the actual position will be within a radius of

100

meters; 5 % of the

time it will be outside of this 100 meter circle. Selective Availability has

been enabled

almost

continuously since early 1991.

Please continue reading the next section

with the installation and operation of the

ofthis

V8010

manual before proceeding

unit. There are some

important recommendations regarding successful installation practices for

obtaining the best echo sounder performance.

If you have elected to add the Raystar 100 GPS sensor option to your new

video sounder system, specific installation information for installing the

GPS sensor will be found in the Raystar

100

GPS Sensor manual.

IN’IRODUCTION

7

Page 16

1

q

i

z

%

INTRODUCTION 8

Page 17

2.1 GENERAL

SECTION2

INSTALLATION

Although your

performance, it can best attain those standards only when it has been

properly installed. This section provides the user with practical guidelines

to assist in the planning and installation of the echo sounder unit aboard

your vessel.

2.2 UNPACKING AND INSPECTION

Use care when unpacking the unit from it’s shipping carton to prevent

damage to the contents. It is also good practice to save the carton and the

interior packing material until the unit has been satisfactorily installed on

the vessel. The original packing material should be used in the unlikely

event that it is necessary to return the unit to the factory.

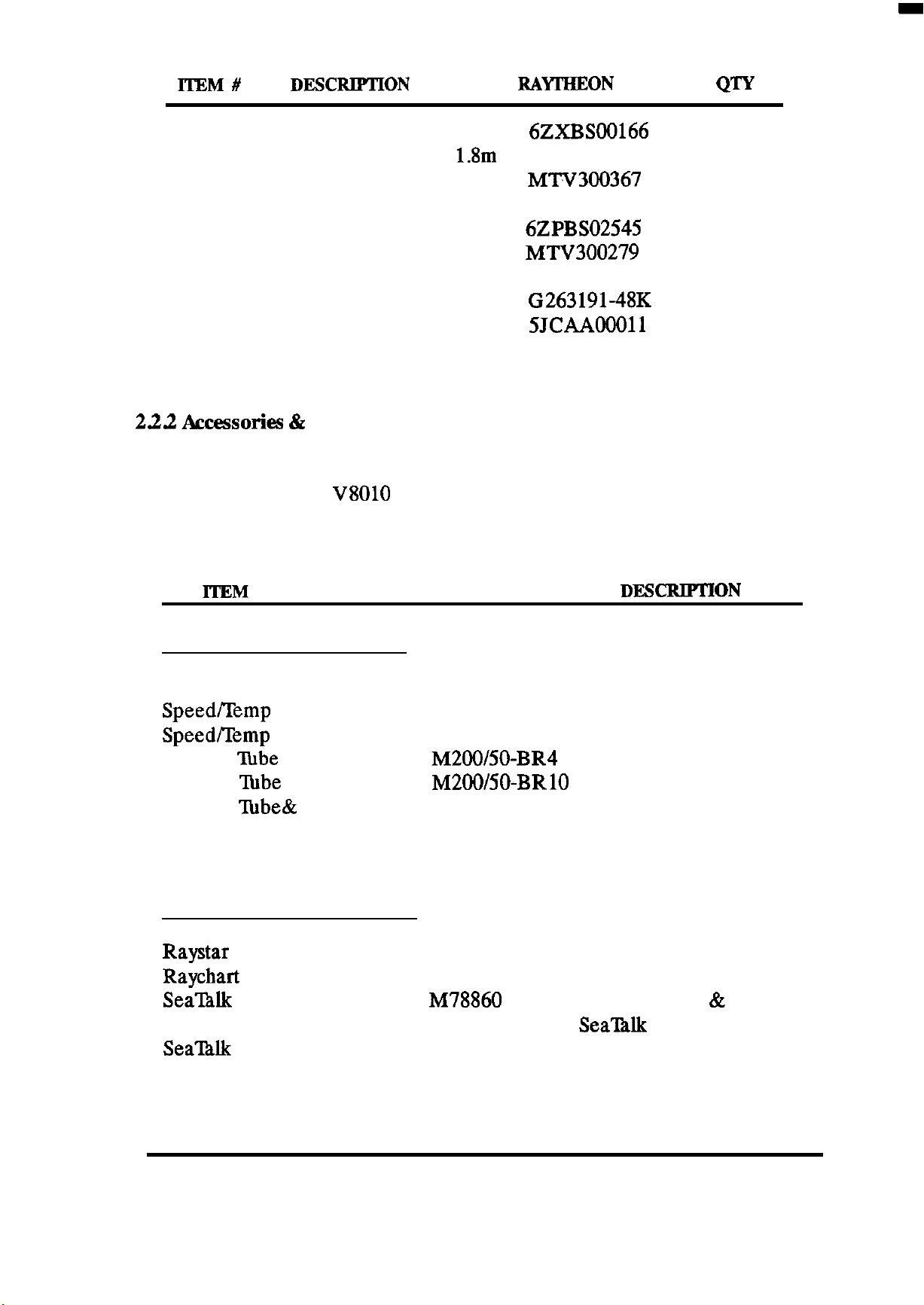

22.1 Equipment Supplied

The following items should be included in the carton with your

echo sounder unit. If an item is missing, please contact your Raytheon

dealer immediately for assistance.

V8010

is designed to the highest levels of quality and

V8010

Table 2.1 Equipment Supplied

ITEM#

1

2

or

DEXXIPTION

V8010

Transducer, Type 2528L M78858

200/50/28Khz, 1KW

Transducer, Type 2528B M78859 (Bronze)

200/50/28Khz, 1KW

Color Echo Sounder

RAYTHKON

(Lexan)

PA’ QTY

1

1

1

INSTALLATION 9

Page 18

ITEM#

DJZSCRIPTION

RAITHEON

P/N

QW

3

4

5

6

7

8

9

10

11

Spare Parts Kit

Power Cable Assy

1.8m

Sun Cover

Dust Cover

Instruction Manual

Hood

Mounting Screws

Connector, 6 pin (Data)

Connector, 5 pm,

6ZXBSOO166

CFQ-4598

MTV300367

MPXP30132

6ZPBSO2545

MT%‘300279

MPTG02024

G263191-48K

5JcAA00011

1

1

1

1

1

1

3

1

1

(Transducer)

12

Connector, 7 pm, (Video)

222 Accessories 82

TBA

Options

1

The following items are available to aid in the installation or to enhance

the operation of the

V8010

Color echo sounder unit. Please contact your

Authorized Raytheon dealer for information on obtaining any of these

items.

lTEM

PRODUCT NUMBER

INSTALLATION ITEMS:

Console Mounting Kit

Speed/Temp

Speed/Temp

Stuffing

Stuffmg

Stuffing

Sensor

Sensor SST

lube

4” Bronze

Abbe

10”Bronze

l’hbe&

Adapter Plate M78695

M78692

M78662

M78696

M200/50-BR4

M200/50-BRlO

Fairing Block M78693

Fairing Block

OPERATION ENHANCEMENTS:

Raystar 100 GPS Sensor

Raychart

Sea’Btlk

Sea’Ihlk

610ES Chart System M95990

Interface Kit

Y Cable

M78694

M95984

M78860

M81172

DJZSCRlPTION

For flush mounting

Bronze, TH Sensor

SST TH Sensor

For fiberglass boats

For fiberglass boats

For metal hull boats

For mounting 2528L

For mounting 2528B

Adds GPS Nav functions

Adds Electronic Charting

Interface PCB & kit for

Sea’IUk

network.

INSTALLATION

10

Page 19

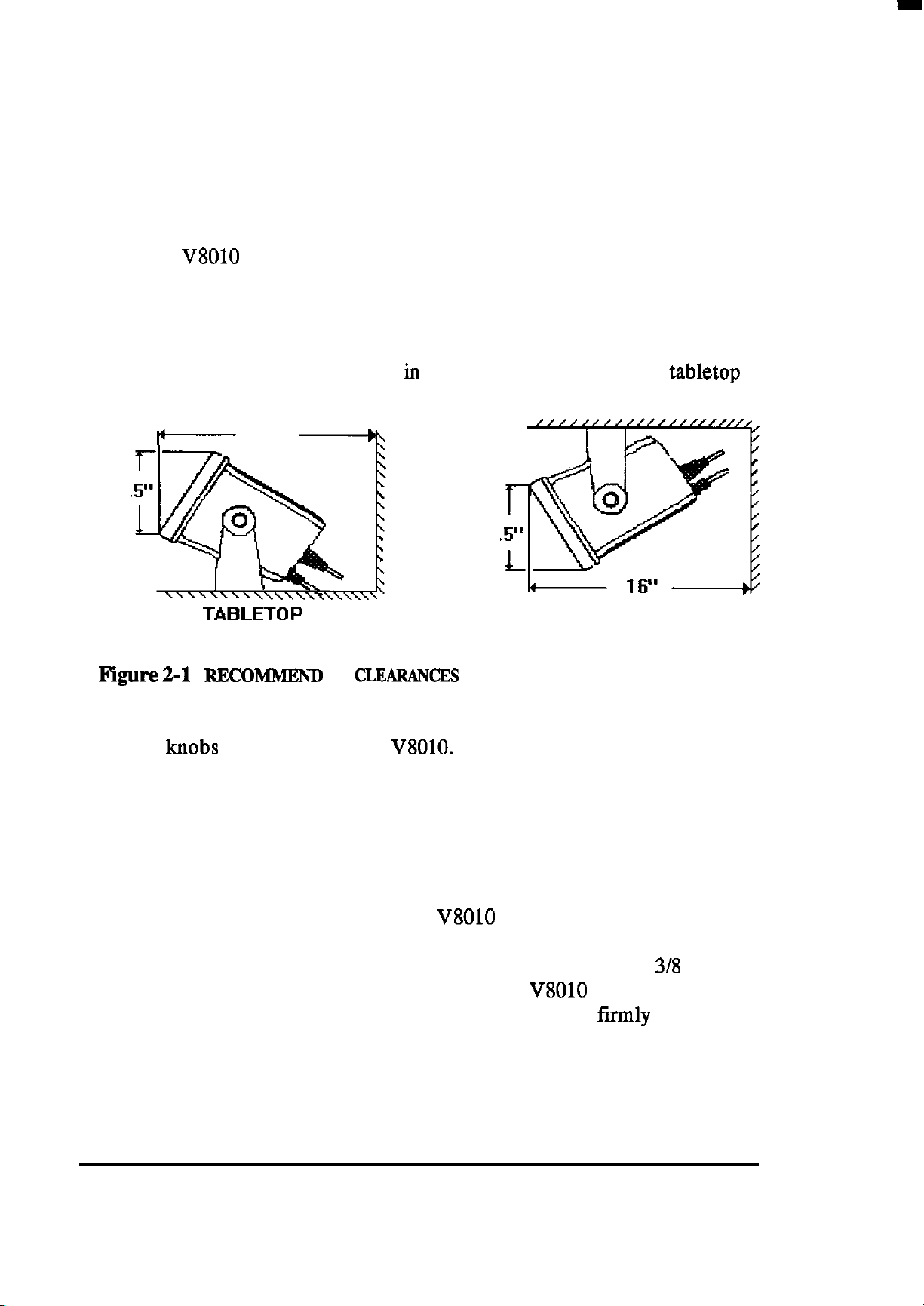

2.3 INSTALLING THE DISPLAY UNIT

23.1 Standard Mounting

The two most important considerations, when deciding on where to

mount the

l

V8010

Color echo sounder unit will be:

To choose the best location for operating and viewing.

*Best protection afforded to the unit from the environment.

Typically, the unit can be mounted iu its yoke assembly to a chart tabletop

or suspended from an overhead location,

I‘-

16”

-6

8.

8.

TABLETOP

FIgure2-1 REcoMMEND

ED

CLEARAh’CES

FOR YORE MOUNTING

OVERHEAD

To mount the unit, remove the mounting yoke from the unit by loosening

the yoke

knobs

on each side of the

V8010.

Attach the bracket to the desired

mounting surface with appropriate screws. ( included in the kit). Once the

bracket has been mounted, slide the unit back into its yoke. Secure the unit

with the yoke knobs at the desired viewing position.

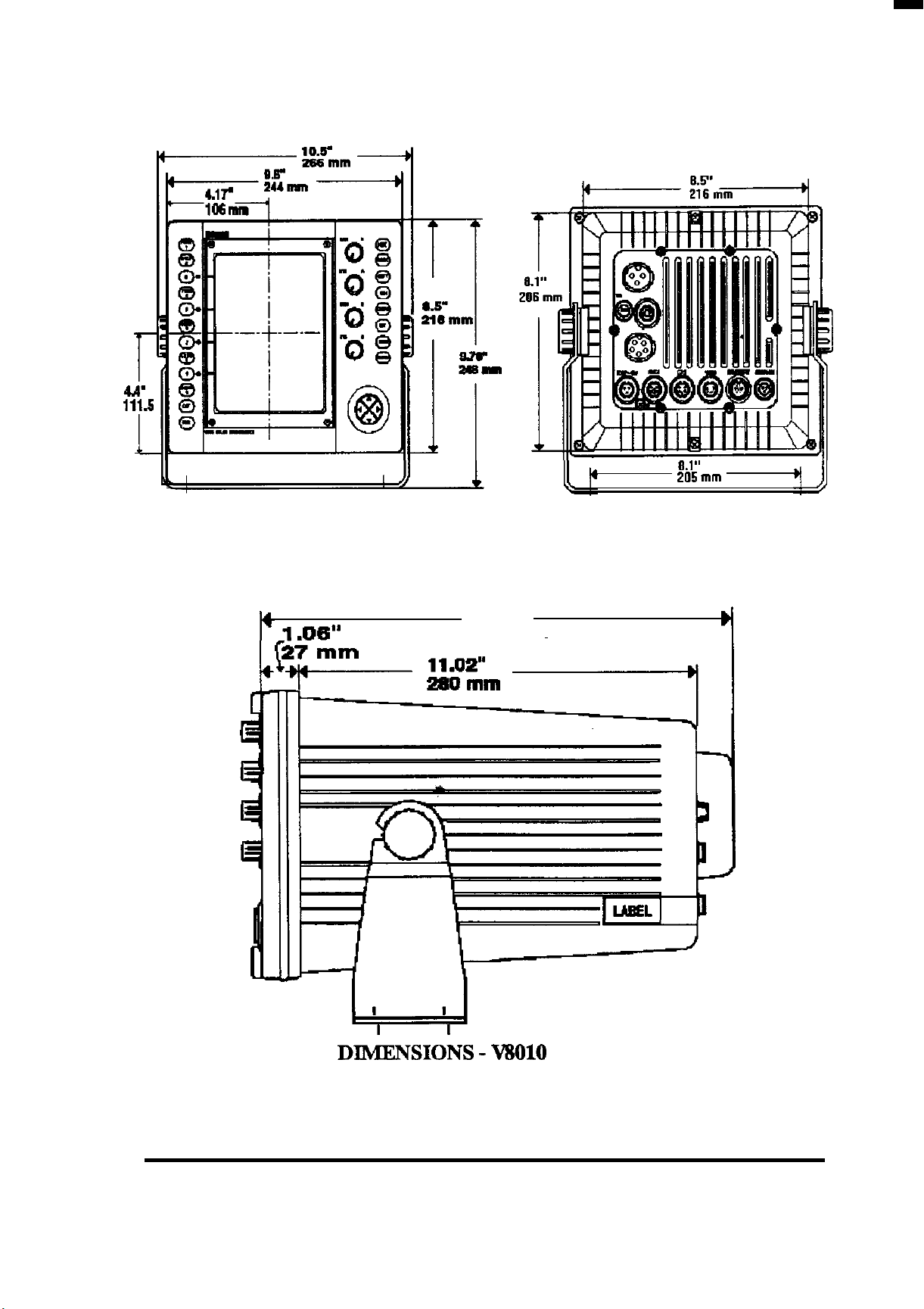

232 Console Mounting

You may choose to flush mount the

V8010

display using the optional

Console Mounting Kit M78692. The Console mounting kit contains the

necessary hardware for flush mounting the unit into panels up to

in thickness. The trim riug is designed to hold the

console cutout, but it is recommended that the unit also be

V8010

in position in the

tirmly

3/g

inches

supported

inside the console to protect the unit from excessive vibration or pounding

forces.

INSTALLATION 11

Page 20

_l .m-

13.07”

332

mm

8.1”

205 mm

Y

OUTLINE

INSTALLATION 12

DIdENS~O~S - MI010

ECHO SOUNDER

Page 21

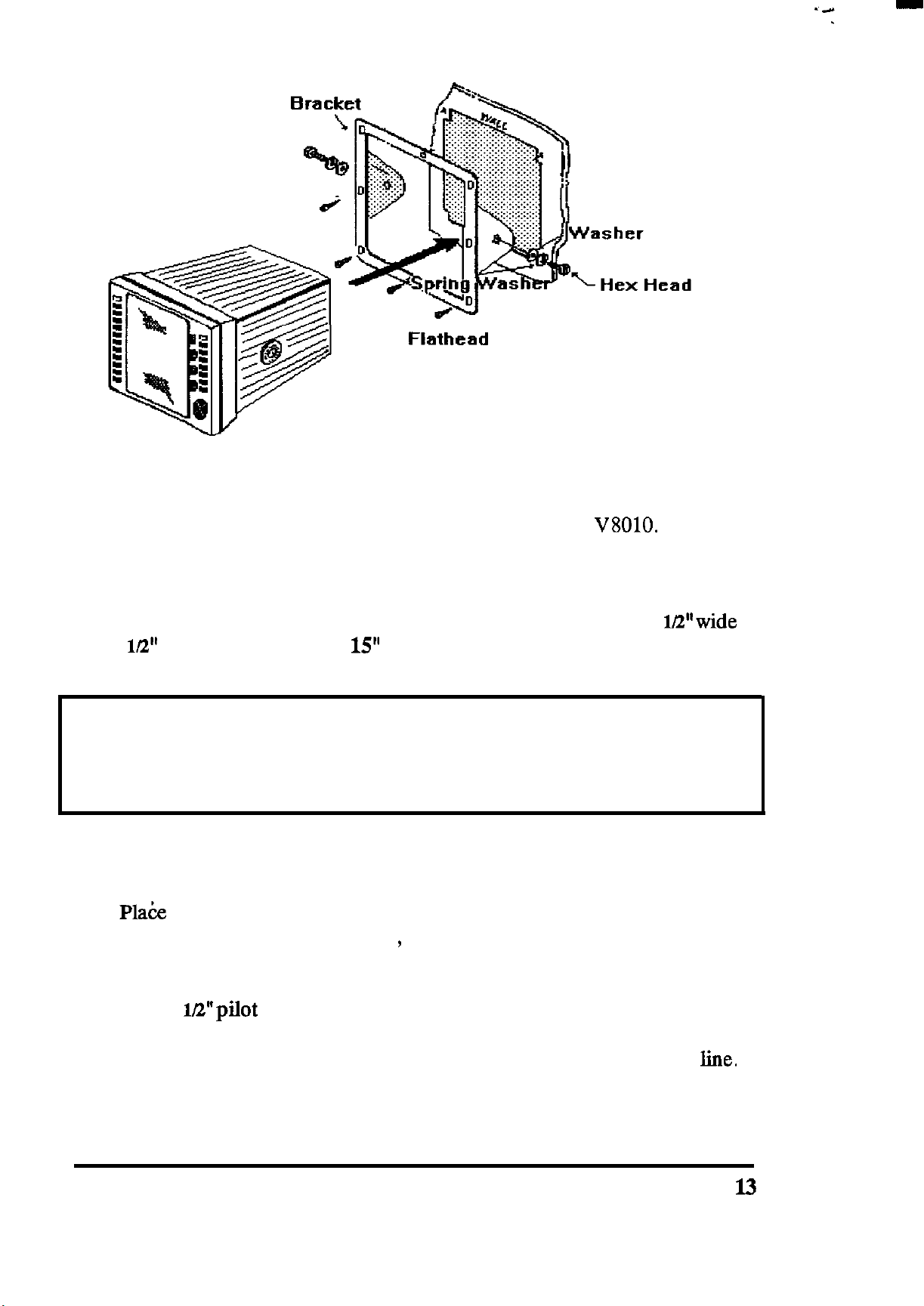

232.1 Console Mounting Instructions

Screw

Flathead

Screws

The procedure below can be used to console mount the

V8010.

Refer to

the console mounting figure above to see how the various hardware items

are arranged during assembly.

1. Select the location for the unit. A clear, flat area of at least 11

by 9

lL2”

high having at least

15”

of clearance depth behind the panel is

Wwide

required.

CAUTION

Make sure there are no hidden electrical wires or other items behind the

desired location before proceeding. Check that free access for mounting

and cabling is available.

2. Unpack the console mounting kit and confirm that all hardware is

present.

3.

Pla6e

the trim ring over the desired location on the panel. Using the

inside of the trim ring as guide , trace the perimeter for the cutout.

Remove the trim ring.

4. Drill a 1E’pilot hole in each opposing corners of the cut-out area.

5. Using an appropriate saw, cut along the outside edge of the cut-out

INSTALLATION

line.

l3

Page 22

6. Remove the yoke knobs, the yoke, and the rubber spacers from the

V8010

cabinet. Check that the unit will fit into the cut-out area.

7. Complete the installation of the DC power, transducer, data input,

ground, and any other accessory cables, into the console.

8. Slip the trim ring over the cabinet from the rear.Make sure the rounded

tabs on each side face the rear of the cabinet. Slide the unit into the

cutout of the panel. A suitable sealant may be used between the trim

ring and console panel to prevent moisture entry.

9. Use the clamps and hardware supplied in the kit to secure the unit in

the trim ring bracket. The trim ring should be then secured onto the

console with the countersunk

the unit rear panel.

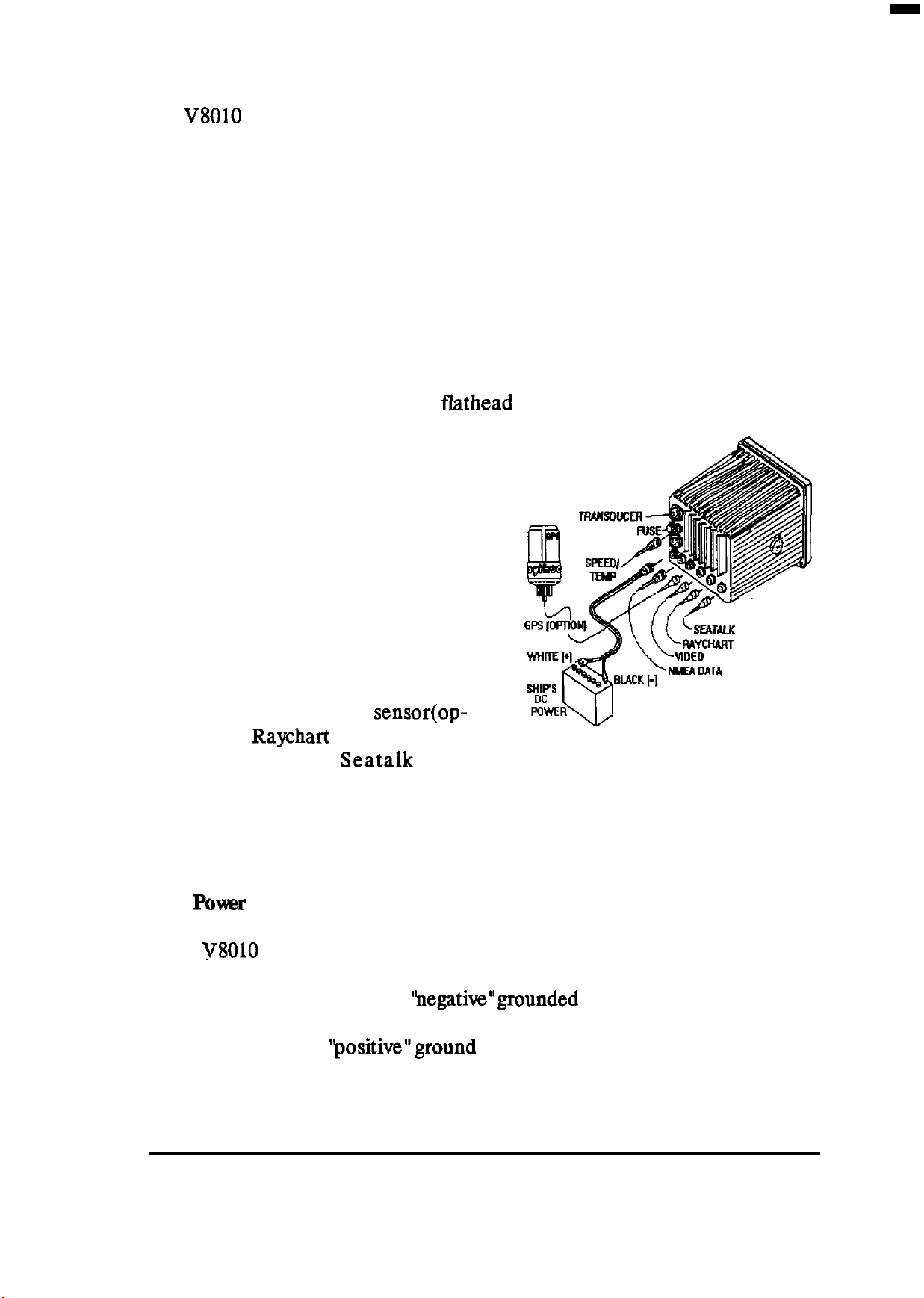

2.4 CONNECTIONS

flathead

screws. Connect all cables to

The drawing shows the basic rear

panel connections to the echo

sounder unit. In a simple installation, the connections at the left side

of the unit (power and transducer)

are used. The connectors along the

bottom provide input of NMEA

data, the GPS antenna

sensor(op-

tional), the Raychart 610ES controller (optional), or

Seatalk

data

(optional). A connector for an external RGB video output is also provided.

A grounding screw is provided to connect the echo sounder to the ship’s

RF ground system.

2.4.1

The

POWX

V8010

Input

is intended for use on vessels with DC power systems and can

operate as long as the DC supply is maintained between 10.8 to 41.3 VDC.

The DC power system can be

‘hegative”grounded

or have both positive and

negative supply lines “floating” above ground. The echo sounder is not

intended for use on ‘positive”ground vessels.

INSTALLATION 14

Page 23

A6footpowercableassemblyissuppliedwithyourunit and,inmanycases,

will be adequate to reach to the source of DC power. The 3 pin watertight

connector plugs into the rear panel receptacle in the lower left comer of

the unit marked DC 12-40V.

The power leads should normally be routed to the ship’s DC power

distribution panel on larger boats. The unit requires 5 amps of current; is

fused at 10 amps. So connection to a 10 amp or (maximum of) 15 amp circuit

breaker is recommended. On smaller vessels, the power leads may be

connected directly to the main battery isolation switch or breaker. For best

noise immunity from the other shipboard electronics avoid grouping the

unit’s power connections together with the radar, radio, or other navaids,

such as loran or GPS on the same circuit breaker. The power leads should

be separated as much as possible from other devices.

Although the unit’s power consumption is approximately50 watts, if the

power cable leads need to be extended more than 10 feet, the gauge of the

wire leads should be increased accordingly to minimize line losses. For

runs of

20-35

feet # 12 AWG is recommended.

Confirm the power leads are connected to the correct terminal polarity!

The WHITE wire should be connected to the Positive (+ ) source terminal;

the BLACK wire should be connected to the Negative (-) source terminal.

If the power leads are accidentally reversed, the rear panel fuse will blow.

If this happens, recheck the polarity of the power cord connections with a

voltmeter (VOM) and, if necessary, reverse the leads for a proper polarity

connection. Replace the fuse.

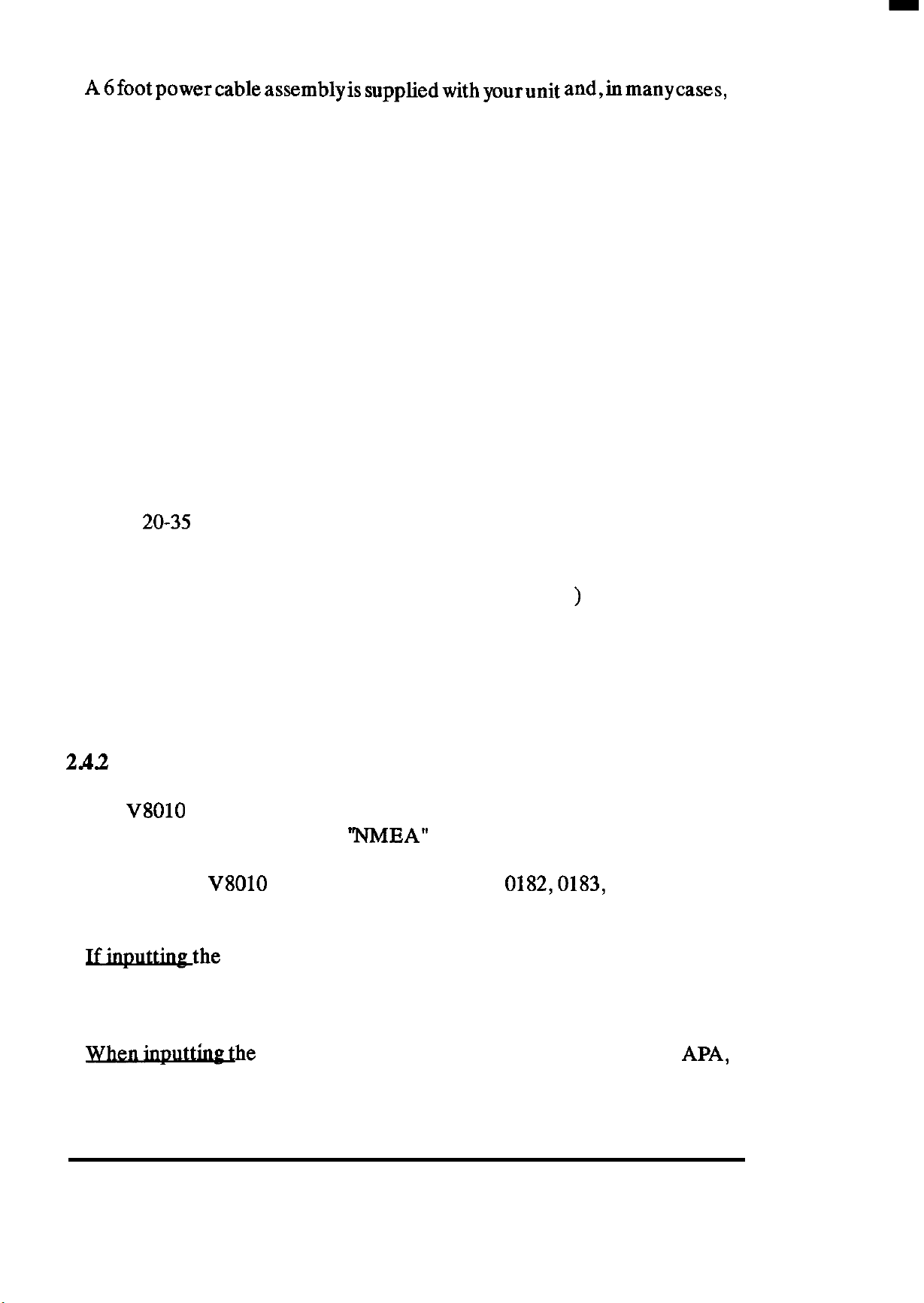

2.42

Data Input/Outputs

The

V8010

at the 6 pin connector marked

has one Data Input port and one Data Output port available

“NMEA”

located on the rear panel (next to

the Power connector). When an external navaid is connected to the Data

Input port, the

V8010

can recognize the NMEA

0182,0183,

or JRC serial

formats:

.

Ifthe

.

NMEA 0182 format, only the Latitude and Longitude of

the ship’s position will be supplied to the echo sounder to operate the

plotting mode.

.

Whenhe

.

NMEA 0183 format, the sentences GLL, GTD,

APB, VTG, BWC, RMA, RMC, and RMB can be read by the unit.

INSTALLATION 15

APA,

Page 24

The

V8010

has one

Datavia

the same 6 pin connector which

can provide data for up to 3 external navigation equipments connected in

parallel. So, be sure that all devices connected to this data output port

(autopilots, plotters, video sounders, radars) are programmed to use

NMEA 0183 data format.

When sending the NMEA 0183 Data Output from the

V8010,

the normal

data available includes the DBT (Depth) and MTW (water temperature)

sentences. When the optional Raystar 100 GPS sensor, Seatalk, or an other

extemalnavaidisinputto the video sounder,GLL,APA,APB,VTG,BWC,

RMA, RMB, or RMC sentences are available at the Data Output port.

2.42.1 Making Data Connections

A 6 pin watertight connector is supplied with the spare parts materials for

making the Data Input/output connections. The general instructions for

assembling this 6 pin connector can be found in section 2.422 of this

chapter. If planning to use both input and output ports it is recommended

that a cable containing two (2) pair of shielded twisted conductors be used

for the interface cable.

Connect the Input Data ( +

Data Return ( - ) to pin 2 of the connector. Pin 1 is marked by the raised

)to

pin 1 of the connector. Connect the Input

dot on the housing.

Connect the Output Data (+

)to

pin 4 of

LOCATING DOT

DATA OUT

the connector. Connect the Output Data

Return ( -

DATA IN

DATA IN RETURN

DATAOUT (+)

DATA

Pin 3 of the connector

cotme& &&i&l

Do NOT GROUND the Data Output or Data Out Return lines at any of

)

to pin 5 of the connector.

(+)

OUT RETURN

= PIN 1

= PIN 2

= PIN 4

= PIN 5

is

of the data output pair of wires.

Viewed

fkom

solder side

Pin 6 of the connector map be used

NOTE:

the external navigation equipments.

to

INSTALLATION 16

Page 25

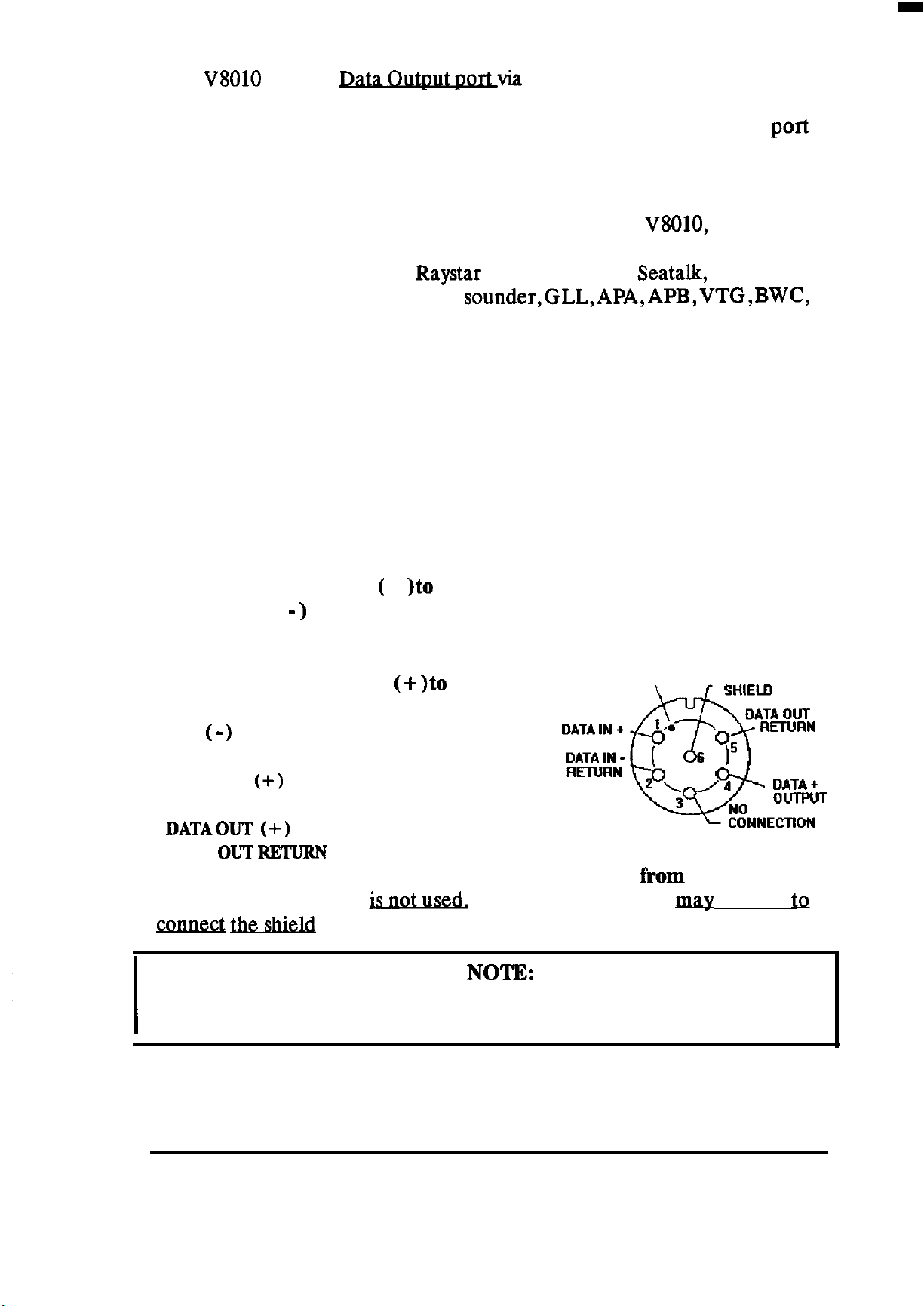

2AiU

Cormeetor

Assembly Instructions

This section describes the procedure to correctly assemble the various

watertight connectors used to connect accessories to the

V8010.

1. Feed the end of the cable through the backshell, rubber grommet and

coupling ring in the order and position shown.

BACKSHELL

GROMMET

COUPLING RING

PIN

CONNECTOR BODY

‘0 ’ RING

2. Strip cable as shown. Begin soldering con-

ductors to pins of the connector as shown in the

appropriate diagram for the NMEA, or

connectors. Verifythat each connection

Seatalk

is firmly

soldered and that no stray wires are shorting

adjacent pins.

3. Slide the coupling ring over the body of the connector and beyond the

locking projections on each side. If may be necessary to rotate the ring

slightly for it to pass by the locking tabs.

4. Push the rubber grommet forward as far as

possible~to

seat it snugly

against the connector body.

5.Push the backshell all the

way

forward. It must first compress the rubber

grommet, then be twisted over the (2) locking posts on the connector body.

This is a tight connection. For leverage, it may be helpful to first insert and

lock the connector into its mating plug on the

V8010

back panel.

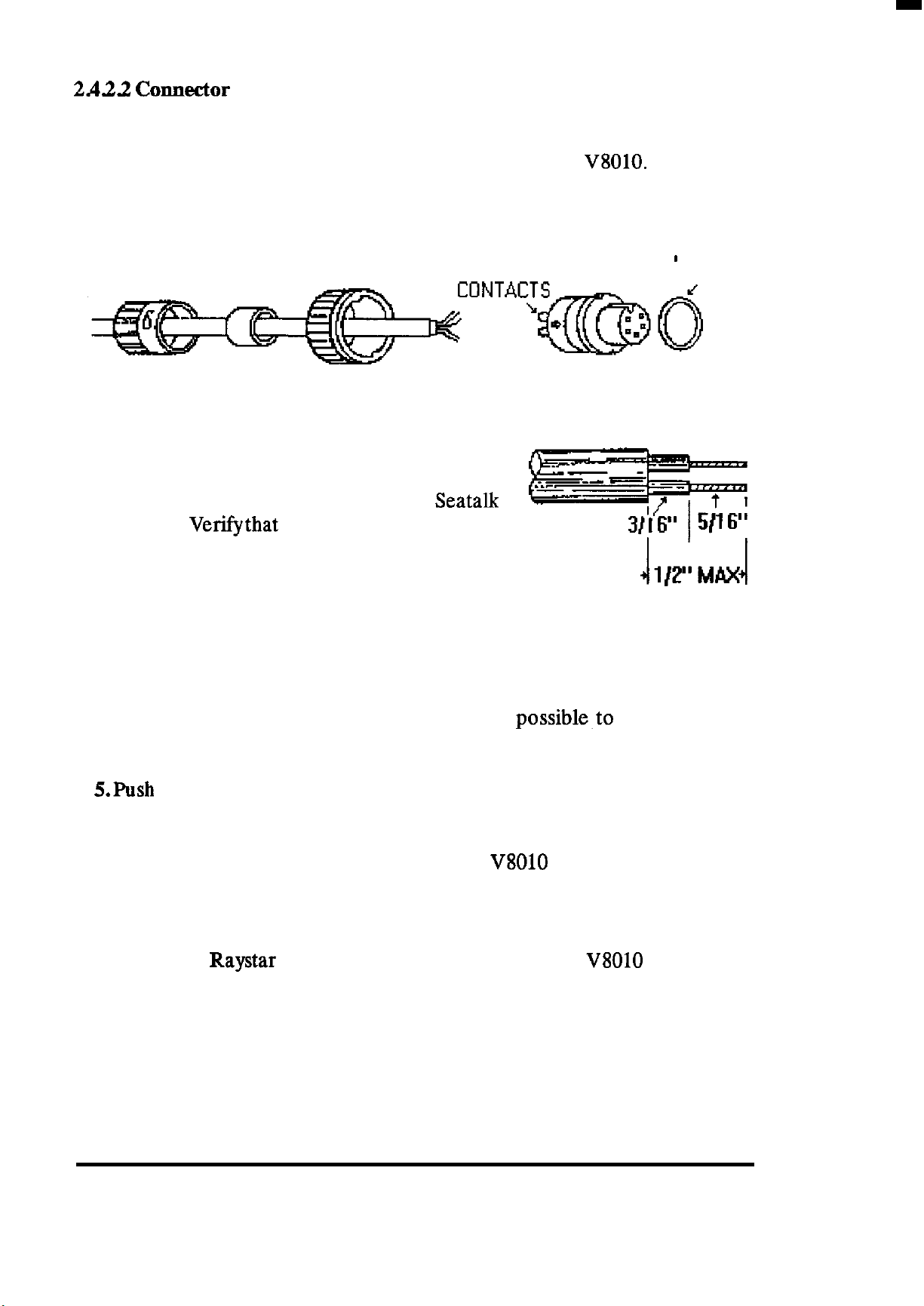

2 A3 GPS Sensor (Option)

The optional Raystar 100 GPS sensor unit used with the

V8010

is not only

a GPS antenna unit, but also contains the GPS receiver/processor. Normally, the sensor obtains its 12 VDC operating

sounder

display

unit

and can then proceed to locate and track satellites and

power

input from the echo

provide ship’s L/L position data on its own without other input require-

ments.

INSTALLATION 17

Page 26

In a typical installation the 5 pm an-

tenna connector is plugged into the

nectar labeled

‘FPS”

on the rear of the

con-

cabinet. Other external navigation

equipment requiring GPS position

in-

puts normally can obtain the required

NMEA 0183 data via the Data Output

connection of the

V8010

via the 6 pm

Data cable.

Viewed

from solder side

However, there may be an occasion

where it is desirable to operate the GPS sensor unit directly

with

other

navigation equipment capable of accepting GPS input data. In this case,

the GPS sensor cable could be terminated at a terminal strip outside of the

video sounder and cabled according to the configuration shown in the

drawing below. The GPS sensor provides GLL, VTG, RMC, and GGA

NMEA 0183 sentences in it’s output.

2

BLACK/SHIELD

In this installation the ship’s DC power is applied directly to the GPS

sensor through a circuit breaker and/or distribution switch.

sensor to be used even though the

The Sensor DATA OUTPUT is provided both to the

V8010

is turned OFF.

V8010

This permits

the

GPS connector

input and in parallel to the external navigation equipment. Please note that

the GPS sensor output is only guaranteed to drive 2 (two) devices directly.

Verify also that the data lines are not grounded at any of the external

equipment.

INSTALLATION 18

Page 27

The Sensor

DATA

INPUT wire (pin 5)

should also be connected to the GPS

connector so that the echo sounder can provide initializing data input to the

GPS sensor unit.

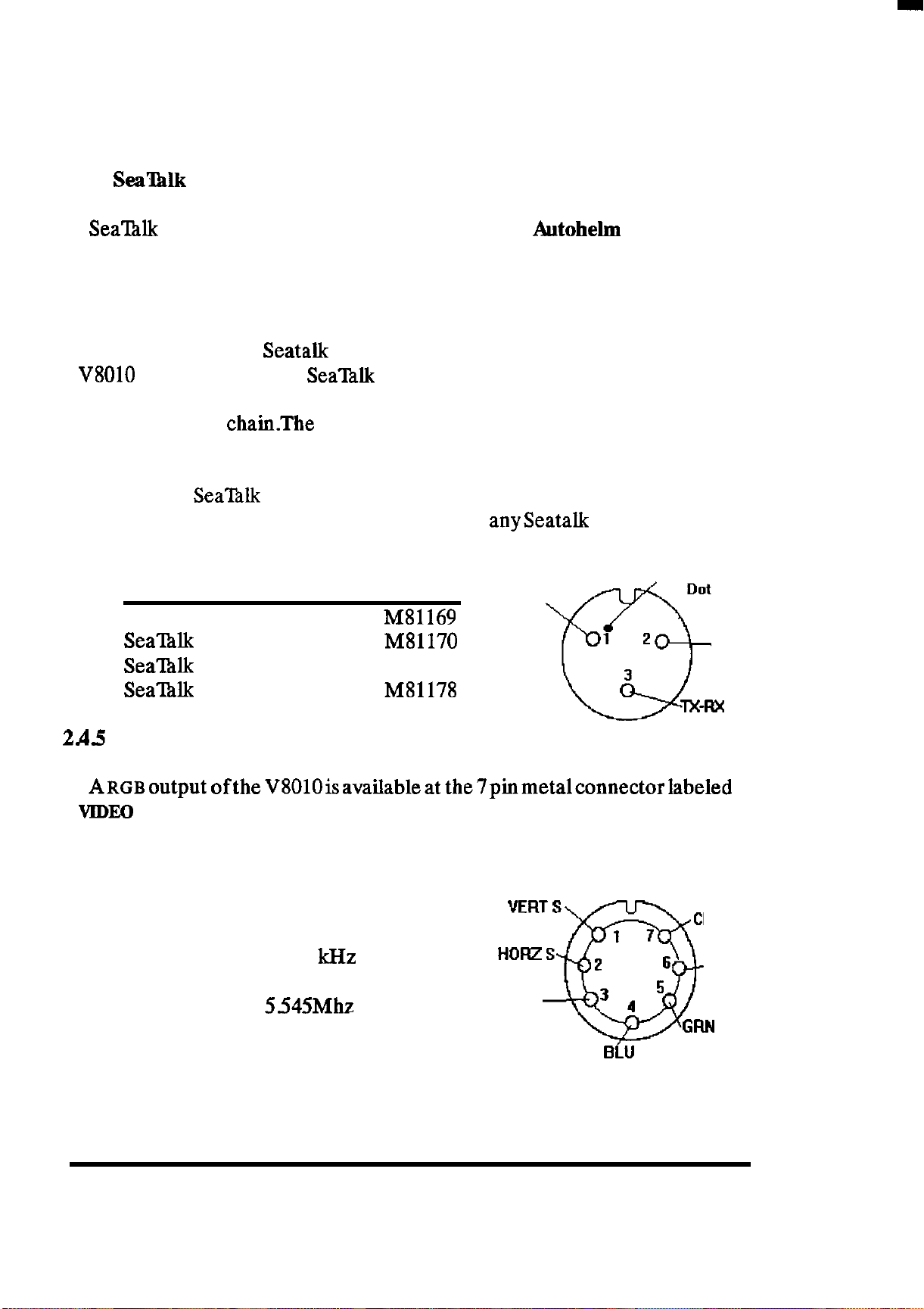

2.4.4

Sea%lk

Sea’ltilk

Interface

is a system of data interchange between

Autohelm

Instruments

and Autopilots and other Sealhlk compatible units. The system is linked

serially by a single cable containing three wires. The wires used are 1) 12

VDC supply, 2) a bi-directional data line, and 3) ground.

When the optional

V8010

is connected to the

Seatalk

SeaTalk

Interface Kit (M78860) is installed, and the

bus via the 3 pm micro connector on the

unit rear panel, the echo sounder will interface directly to the free end of

the Sealhlk data

chainThe

connections for the 3 pm connector are shown

in the diagram.

Convenient

Raytheon/ Autohehn dealers to help complete

Sea’l%lk

cable assemblies are available at various lengths from

anyseatalk

interconnection

requirements as follows:

Locating

Dot

TX-R%

Sealhlk Cable

SeaINk Cable

Sea’lhlk

Seal?&

2A5

Video Output

ITEM

LENGTH P/N

3 Foot

10 Foot M81170

Cable

30 Foot

Y Cable 1 Foot

MS1169

M81171

M81178

vcc

1 2

3

Q

[Solder Side]

View from solder side

A~~~output

VIDEO

OUT on the unit’s rear panel. This output can be used to operate a

ofthe V8010isavailableat the7pinmetalconnectorlabeled

separate remote RGB color display.

Gnd

Data

The picture will be portrait oriented on the

remote display.

Horizontal Sync = 15.75 kHz

Vertical Sync

Dot Clock

= 60Hz

=

5.545Mhz

VIDEO OUTPUT

VERT

S

1 7

HORZS

GND

0

2

32

6

BLU

View from solder side

INSTALLATION 19

CLOCK

RED

GFIN

Page 28

2 A.6

Grounding The Echo Sounder

One very important requirement in installation of shipboard electronics

is to obtain the cleanest, noise-free environment possible so each piece of

electronic equipment can work to its best performance levels. This requirement isaccomplished byassuringaproper connection from each equipment

to the ship’s RF ground system. The ground provides a drain for shipboard

noise transmission and pickup.

A separate ground wire of # 10 or # 12 AWG (# 10 recommended) should

be connected from the ground screw marked

“E”on

the rear of the unit to

the nearest connection point of the ship’s ground system.

Normally,on a steel hull

boa&a

good clean connection to the hullprovides

a sufficient ground. On a fiberglass or wood hull, connection to a ground

plate or to the engine block and other bonded groundwork should be

acceptable.

2.5 TRANSDUCER INSTALLATION

25.1 General Information

Each

‘B&frequency

ate at

(8Kw

The

V8010

200,50,

peak).

Lexan

Color Echo Sounder is provided with one of the new 2528

transducer assemblies. The ‘Iii-frequency transducers oper-

and 28Khz frequencies and are rated to

1Kw

ofaverage power

2528Lis intended for direct

hull mounting with thru-bolts and a

stuffing tube, while the 2528B bronze

transducer is used when the more traditional thrn-hull stem mounted style is

preferred. Stuffing tubes for the 2528L

for use in wood, fiberglass, or steel ves-

sels and fairing block assemblies suitable. for both transducers are available,

as options, from your Raytheon dealer

to simplify installations. (See Options

list)

INSTALLATION 20

Page 29

The transducer section of the manual begins with a general discussion of

transducer installation considerations for locating transducers on the ves-

sel. Detailed mounting instructions for the

follows this section.

-

2528L

transducer and the

2528B

The transducer element is that portion

of a sounder system that converts the elec-

tricalpulse from the sounder into a sound

wave which is transmitted downward to

the bottom and returned as an echo. This

TRANSDUCER

echo is picked up by the transducer and

sent to the sounder which, through time

comparison, converts the difference for

display on your

V8010.

ENERGY WAVE

The transducer, the heart of the Fishfin-

der, is a delicate instrument and although

it is designed to survive in the toughest

marine environment it should not be

dropped or manhandled during installation.

The transducer element assemblies are constructed into either molded

resin or bronze caste housings and covered with an epoxy window surface.

The epoxy “window” is the surface through which ultrasonic pulses must

travel. This epoxy surface must be kept as clean and smooth as possible so

the ultrasonic energy path is uninterrupted. Caution is advised when han-

dling the transducer to prevent any damage to the transducer face.

Also, when handling the transducer, avoid lifting or pulling on the

transducer by the cable. Although the cable appears thick and substantial,

the internal cable wiring could become damaged due to stress by the sheer

weight

ofthe

transducerunit and malfunctionat the most inopportune time.

252 General Mounting Considerations

In any transducer installation acoustic noise is always present. The noise

is usually a combination of “ambient” as well as “vessel generated” levels.

Ambient noise is often generated by waves and air bubbles, fish and mam-

mals, ram and hail on the surface, other nearby vessels or shore noises.

Sources of vessel generated noise include: propellers

&

propeller shaft

vibrations, machinery, main engines, generators & pumps, flow of water

INSTALLATION 21

Page 30

across the hull, boundary layer turbulence, and interference from other

onboard echo sounders.

While very little can be done to combat ambient noise, carefully selecting

the transducer mounting location can help to minimize the influence of the

“vessel generated” noise. Of course, the lower the acoustic noise level; the

better the signal-to-noise ratio and the higher the echo sounder gain setting

that can be used.

Mounting Location-Displacement Hulls

Study the shape of the vessel hull carefully to determine the best

transducer mounting location. To achieve optimal echo sounder system

operation, the transducer should be mounted in a spot which will minimize

acoustic noise reception and the chance that aerated water will flow across

the transducer’s acoustic window (transmitting surface).

One of the main sources of vessel generated noise is from the propeller.

It is very important to pick a mounting position to keep the transducer

clearly away from this noise source to minimize pickup.

As an additional precaution tilt

the transducer forward slightly so

that the transducer acoustic win-

dow is facing away from propeller

noise.

Generally

a

5’ forward tilt is

recommended. Any tilting is normally accomplished in the shaping

of the fairing block.

Mount the transducer on the side

of the hull where the propeller

blades are moving downwards.

The upward motion of the propeller generates pressure waves

which pushes air bubbles up

against the hull. By mounting the

transducer on the downward side,

the hull will tend to protect the

transducer from this effect.

INSTALLATION 22

Page 31

Aerated water can blind an echo sounder by reflecting the ultrasonic

energy. Water near the bow and water near the keel can become quite

aerated. Aeration occurring near the transducer can be minimized by

keeping the transducer mounted away from the keel, and by mounting the

transducer in the after

and water line, if possible.

2/3

of the vessel’s length midway between the keel

Generally, this provides the best compromise

between obtaining aeration-free water and minimizing propeller noise.

Keep in mind that the deeper the transducer protrudes into the water, the

less chance of aeration.

NOTE:

The transducer should not be mounted near any water discharge fittings.

Never position a transducer behind any struts or fittings that may cause

turbulence.

BOLT HOLES (2)

34’

(1Om)

0.40” dia.

39”

OUTLINE

DIMENSIONS

2528L

LEXAN TRANSDUCER

INSTALLATION 23

Page 32

2.53

2528L Lexan

Transducer Installation

253.1 Preparation 1 - The Stuffing

M200/50_BR4

M200/5O_BRlO

Other stuffing tubes can be used but special care must be taken to insure

these tubes will sealproperly to the

These instructions are written speciflcallyto facilitate installationsusingthe

Raytheon optional stuffing tubes.

10” Bronze

lbbe

Installation of the 2528L lexan

transducer requires a

of a material compatible with the

hull. Raytheon offers bronze stuffing tube kits for wood or fiberglass

(GRP) hulls as well as a stuffing

tube kit and adapterplate for steel

hull mounting. Stufling tubes for

wood or fiberglass hulls can be

ordered by the following numbers

from your Raytheon dealer:

4” Bronze Stuffing

Stufling ‘Inbe

0.40”cable

diameter

lltbe

ofthe

stufling

transducer.

tube

2532 Preparation 2 - The Fairlng Block

Nearly all vessels have some

location. If the transducer were mounted directly to the hull, the sound

beam will be tilted off from the vertical at the same angle as the deadrise.

A fairing block (usually constructed of wood such as mahogany or teak)

providing a level mounting

surface is strongly recommended. A Resin Fairing

Block (Product # M78693)

for use with the

transducer is available from

your Raytheon dealer for

convenient installation.

2528L

deadrise

angle at the transducer mounting

INSTALLATION 24

Page 33

To

reduce drag, best results are obtained with sharp vertical leading edge

fairings because their wedge shape helps to divert aerated water off to the

sides of the transducer and not over the acoustic window.

After the fairing block has been shaped to the

mm x 150 mm

(3”~

6’3 hole should be cut through the center of the fairing

deadrise

of the hull, a 77

block to allow for cable routing and service loop, and to make room for the

stuffing tube that leads the cable into the hull.

Backing blocks should be fabricated using the interior deadrise angle on

bottom of block and a level surface on the top of the block for mounting

hardware for each of the two rods that hold the transducer in place. Boat

yards are generally equipped to fabricate fairing and backing blocks.

Place the transducer over the fairing block and mark the two transducer

mounting hold locations. Drill the two 10 mm

through the fairing block. Counterbore these holes to 39 mm (1

diameter, 10 mm

(13/32”)

deep, from the transducer side.

NUT, AND WASHERS

(13/32”)

LESS STEEL ROD

diameter holes

112”)

BOLTS SHOULD BE TORQUED

TO NOT MORE THAN

TRANSDUCER

TYPICAL LEXAN TRANSDUCER

2533 Preparation 3 -

The

Location.

FAMNG

RUBBER WASHER

INSTALLATION

BLOCK

(For Fiberglass or Wood Hull Installation)

(Safety Goggles and Dust Mask should be worn when drilling)

10

Ff/LBS

INSTALLATION 25

Page 34

A. Drill a

Gaugingwhere the transducer mountingrods

‘l&sting

Hole Location For The Stuffing

willgo,

lbbe.

see

ifthere

is a strake

or other hull irregularity near the hardware sites for rods and stuffing tube.

If no possible interference is apparent from inside the hull, or outside the

hull, drill a 3 mm

you mayhave to select another

(l/S”)

diameter pilot hole. If a restriction is encountered,

location.

Note that sometimes you may have

to drill from the outside of the hull.

B. Stuffing

Drill a 28 mm (1

the

stufling

‘lbbe

Hole Preparation:

l/S”)

hole perpendicular to the outside hull surface for

tube from the outside

ofthe hullat

pilot hole location. Remove

all burrs and clean the area around the hole, inside and outside, to ensure

that the caulking will seal. It is important that the circumference of the

flanged nut that secures a non-welded stuffing tube from inside the hull be

in contact with the hull surface. Shims may be required.

C.

‘Ikansducer

Drill two 10 mm

Mounting Hole Preparation:

(13/32”)

holes in the hull and in the backing blocks for

the transducer mounting rods. To reduce drag, care must be taken to ensure

that the two rod holes are drilled parallel to the keel to maintain the

alignment of the transducer fore and aft.

Note that the 2528L housing is

symmetrical and either end of the transducer could be positioned forward.

253.4 lkansducer Installation

The order of assembly for the transducer is to first mount the

stuffing

tube

into the hull. Follow by mounting the fairing block and backing blocks to

the hull with the two stainless steel rods provided. Finally the transducer

gets bolted onto the hull. Each step is

detailed in the following paragraphs.

1. Install The Stuffing

lbbe

First.

Remove the rubber bushing, washer

and packing nut from the stuffing tube.

Select a marine grade polysulfide, urethane or RTV bedding/caulking compound for sealing the units to the hull.

Following the recommendations of the

caulking compound manufacturer,apply

a 3 mm

the

(118’3

stuffing

thick layer of caulking on

tube flange that makes con-

tact with the outside of the hull, and up

INSTALLATION 26

db-

Packing Nut [Bmnze]

Washer

Rubber Bushing

Washer

Ftanged

Vessel Hull

Stuffing

[SSTj

ISSTJ

Nut @ronze]

wood

or

Fiberglass]

Tube @mnze]

Page 35

the threads of the stuffing tube to where the flanged nut will be, inside the

hull. This will seal and hold the flanged nut securely in place inside the hull

Push the stem of the stuffing tube through the hull and fasten the bronze

flanged nut from inside the hull. For a fiberglass hull, tighten this nut

securely.

NOTE:

If the hull is wood and has been out of the water for a prolonged period,

it is suggested that the stuffing tube nut be hand tightened only, since wood

will swell after the boat is in the water and exert considerable pressure on

the stuffing tube hardware. After the hull has expanded, the nut should be

tightened securely.

2. Install the

Faking

Block:

Slide a backing block, washer, and a nut onto each of the threaded rods.

Feed the rods down through the hull.

Cut a piece of tarred felt (not provided) as a gasket to fit between the hull

and the fairing block (see the figure below). Cut a hole in the center of the

felt for the cable to pass through.

Following the caulking manufacturer’s directions, apply 3 mm

(l/S”)

thick layer of caulking to the surface of the fairing block that fits against

the hull. Lay the tarred felt on top of the coated fairing block.

ST Threaded rod, nut

&

washer (2 sets]

ST Nut &washer

ubber

Leveling

ANOTHER LOOK AT A TYPICAL INSTALLATION

washer

Sealent

INSTALLATION 27

Page 36

From outside hull, slide fairing block up onto the threaded rods, and press

up against the hull. Verify that the length of the rods extending below the

flat face of fairing block is between 2.75” to 3” in length. If not, adjust by

tightening the nuts on the rods inside the hull to obtain this length.

Secure the fairing block to hull using a stainless steel washer and nut on

each rod as shown in the figure. Tighten the nuts with a torque wrench using

a force not exceeding 5

used, tighten the nuts only lightly. This will allow the fairing block to

in sea water and then the internal nuts at the backing blocks may be

tightened to 5

ft./lbs.

ft./lbs

(7 newton-meters). If a wood fairing block is

(7 newton-meters) for proper torque.

swell

3. Route Cable through the

Stuffing ‘Ibbe.

Uncoil and thread the transducer cable through the stuffing tube to the

inside of the hull. Make a service loop inside the cavity of the fairing block

so there will be no tension applied to the cable.

IMPORTANT

When handling the transducer and cable

msducer

m

by its cable because this may sever internal connections and

hold the transducer in place during transducer mounting by applying

NOTE

do

tension to the transducer cable.

4. Caulk the Fair-lug Block.

Following the manufacturer’s directions, apply

l/8”

(3 mm) thick layer of

caulking to the surface of the fairing block that will be in contact with the

transducer.

5. Mount the transducer.

While holding the transducer in position against the fairing block, slide a

rubber washer and a stainless steel washer (provided) onto each transducer

mounting rod. Apply some caulking to the mounting rod and then secure

the transducer with nuts provided. Tighten the nuts with a torque wrench

using a force not exceeding 5

minimum of 3 threads extending beyond the head

ft./lbs

(7 newton-meters). There should be a

ofthe

nut when tightened.

WARNING:

DO NOT USE SOLVENTS

Do not expose the 2528L resin transducer to any solvents while cleaning

away excess sealants. Strong solvents such as acetone and methylene

chloride will attack many types of plastics and can dramatically reduce the

strength of those materials. Accumulation of grease or grime should be

removed with a soft damp cloth and

mild detergents.

INSTALLATION 28

Page 37

6. Seal Cable in

Stuffing lbbe:

Slide the rubber compression bush-

ing, compression washers, and the

packing nut down the

to the

stuffing

tube (see Figure 5).

Make sure the rubber bushing fits

transducer

cable

se-

curelyinto the machined upperpart of

the

stufling

tube. Tighten the packing

nut. Clean up all excess sealant material inside the hull.

7. Plug the bolt holes.

To minimize turbulence on the

sur-

face of the transducers, a white Styrofoam plug material is supplied which

fits into the transducer mounting holes. Cut the Styrofoam to length so that,

when installed, each plug is recessed 5 to 7 mm

(3/16”

to

5/16”)

below the

surface of the housing. Push these Styrofoam plugs into the holes and

smooth out the surface using caulking. Level out and remove any excess

caulking to ensure smooth water flow over the transducer.

8. Route the cable to the echo sounder.

Be

very

careful

not to tear the cable jacket when passing the cable through

bulkheads, etc. To reduce electrical interference, keep the transducer cable

separated from electrical wiring and other sources of electrical interference. To prevent damage, secure the transducer cable in place using tywraps

or lacing twine.

9. Attaching the plug.

The wires of the cable must now be soldered to the 5 pin transducer

connector, packaged with the echo sounder using the color code shown in

the drawing.

10 05

’

20

0

(SOLDER SIDE)

04

30

=Qdii

TRANSDUCER

P/N

HS-21P-5.5 PIN

0

0

‘1;;:

:s:

:-:

<a:

z:

COLOR

YELLOW

BLUE

SHIELDS

BLACK

BROWN

s

-7

PIN

5JcAAooo11

1

;

4

5

.

-I”,‘,”

I

;rz

’

INSTALLATION 29

Page 38

The cable can be cut to the necessary length or extended as required. If

extending the cable, use the same type of cable and conductors to complete

the installation properly.

10. Checking for Leaks

When the boat is placed in the water, immediately check around the bolts

that fasten the transducer to the hull and around the

stuffmg

tube for leaks.

Note that very small leaks may not be readily observable, so it is best not to

leave the boat in the water unattended for more than 3 to 24 hours before

checking it again. If there is a small leak, there may be considerably water

accumulation after 8 to 24 hours. If a leak is observed, the installation

bedding procedure should be repeated to seal the leak. It is not prudent to

installa

transducer and leave a boat in the water

unchecked

for severaldays.

2535 Inside the

Hull

Installations (Fiberglass Hulls Only)

Generally, inside-hull mounting can be useful on fiberglass hulls when the

top speed of the boat is at least 25 knots and drag becomes a factor. Inside

mounting creates less turbulence and the transducer performance can

improve at speeds above 20 knots. However, inside hull mounting frequently results in ultrasonic energy losses of up to 50% or more. So the

transducer must be located where hull is solid fiberglass resin to minimize

sound transmission losses.

Generally its better to test selected areas of the hull

the transducer by

placing

the transducer face against the hull and operating

first

before installing

the echo sounder while checking for satisfactory echo returns. A coupling

medium, such as water, or gel, (Vaseline), should be used to transfer the

sonic energy to the hull more efficiently during the testing. Consult with the

boat dealer or vessel manufacturer if your not sure of the hull construction

or best locations.

Once a satisfactory location is found, always mount the transducer into a

liquid-filled box. Never bond the

25281,

resin housing directly to the hull.

253.6 Steel Hull Installations

For steel hulls Raytheon offers the optional transducer installation kit

M78695 consisting of:

INSTALLATION 30

1 each

2 each

1 each

Steel adapter plate

3/8”

(9 mm) x 1 l/2” (38 mm) SST bolts

SST

stuffing

tube assembly

Page 39

Compression Bushing

Washer, SST

Steel Hull

Weldment

Pr’ard

Weld all around

SST Packing Nut

SST Adapter Plate

Cable Service

Supplied)

LooP/~~&~

Weld all around

SST Nuts, welded

to plate. [4 Places)

TYPICAL STEEL HULL MOUNT WITH CONDUIT

Note:

Certain approval authorities require that the transducer cable be encased

in conduit. In such installations, the conduit is welded to the stuffing tube,

as shown in the figure above. In welded conduit installations, the stuffing

tube must have the packing nut tightened from outside the hull. The

stuffing tube supplied by Raytheon is “reversible”, allowing the compression bushing to be tightened from inside or outside of the hull.

Once the location for the transducer has been determined, it will be again

necessary to assure the transducer is angled to face the sea bottom directly.

On steel hulled

vesselsa

steel weldment must be fabricated

bythe

shipyard

or procured by the person installing the transducer. The exact dimensions

of the weldment are not specified, but the bottom of the weldment must be

parallel to the water surface, (slightly angled forward about

5’)

and must

be large enough to allow the mounting of the adapter plate.

The weldment should also have an access hole at least as large as the hole

in the adapter plate to allow feeding of the transducer cable up to and

through the stuffing tube. Any sharp edges on the weldment and any weld

spots should be ground smooth to minimize the chance of tearing or

abrading the transducer cable. The adapter plate can either be welded

directly to the weldment or bolted to the weldment at the four places drilled

in the adapter plate. The dimensions of the vertical sides of the weldment

will be determined by the

deadrise

of the hull at the location where the

INSTALLATION 31

Page 40

Weld all around

Stuffing Tube [Steel]

Weld all around

Sealant

Rubber washer

SST

3/8

Bolt

&

washer

Styrofoam Plug

Leveling Sealant

transducer will be installed and to allow clearance for the bolts used for

attaching the adapter plate.

253.6.l

1. Inspect

Installing the

Location:

Stuffing ‘Ihbe

Prior to drilling or cutting from the outside of the hull, the interior of the

hull should be inspected to ensure that there is proper clearance for the

stufting

drilling. The stuffing tube is 150 mm

thickness of the hull, will require at least

tube and that there are no cables or stakes to impede the cutting or

(6”)

in length and, depending on the

200

mm

(8”)

of clearance to

facilitate routing of the cable.

2. Drill the Hole:

Drill or cut (with a cutting torch) a 38 mm (1

installation of the

stuffing

tube. A fire watch should be stationed inside the

l/2”)

hole in the hull for

hull.

3. Install the

‘Abbe:

Remove the packing nut, compression bushing, and washers from the

stuffing tube. These will be necessary at a later time to seal the stuffing

tube, after the transducer cable is fed up into the hull. Insert the

stufling

tube into the hull and weld the stuffing tube in place (See Figure).

INSTALLATION 32

Page 41

Cable

SST Packing Nut

SST Washer

Rubber compression

bushing

SST Washer

Steel Hull

Weld all around

253.63 Installing the Adapter Plate &

1. Mounting the Plate:

‘ikausducer

Weld or Bolt the adapter plate to the leveling weldment. If the adapter

plate is bolted to the weldment, coat the adapter plate surface that will

contact the weldment with approximately a 3 mm

(l/S“)

thick coating of

caulking. Apply caulking to the four bolts (not supplied) and install the

adapter plate to the weldment. Remove excess caulking.

2. Mounting the

Uncoil the transducer cable and feed it up through the adapter plate, the

‘Ikausducer:

weldment, and stuffing tube into the inside of the hull. Never pull of carry

the transducer by its cable---this may damage internal connections. Do not

hold the transducer in place by applying tension to the transducer cable.

Apply a 3 mm

(l/8”)

thick layer of caulking to that surface of the transducer

which will contact the adapter plate. Slide the rubber washers (to reduce

stress concentration in the resin

housing

in

the bold hole area) ,and stainless

steel washer supplied with the transducer onto the transducer mounting

bolts and then apply caulking to the threads of the two

3/8”

x 1

l/2”

long

stainless steel mounting bolts. See the figure above for the correct orien-

tation of the washers.

Holding the transducer against the adapter plate, thread the mounting

bolts into the adapter plate. Tighten the bolts with a torque wrench to

ft./lbs.

(7 newton-meters). Remove excess caulking.

INSTALLATION 33

5

Page 42

To minimize turbulence on the surface of the transducers, a white

styro-

foam plug material has been provided which fits into the transducer mounting holes. Cut the styrofoam to length so that, when installed, each plug is

recessed 5 mm

(3/16”to 5/16”) belowthe