Page 1

Transducers

for

Fishfinders

Owner’s

Handbook

Document number: 81196_2

Date: Augu st 2002

Page 2

Page 3

Transducers for Fishfinders iii

T ransducers for Fishfinders Owners Handbook

August 2002

Intended Use

The transducer units detailed in this handbook are used in conjunction with Raymarine fishfinders and are intended for recreational marine depth, speed, and/or temperature measurement

purposes.

Safety Notice

This equipmentmust be installed and operated in accordance with

the instructions contained in this manual. Failure to do so can

result in personal injury and/or navigational inaccuracies.

Raymarine products are supported by a network of Authorized

Service Representatives. For information on Raymarine products

and services, contact either of the following:

United StatesRaymarine, Inc.

22 Cotton Road, Unit D

Nashua, NH 03063-4219

USA

Telephone 603-881-5200

Fax 603-864-4756

www.raymarine.com

EuropeRaymarine Ltd

Anchorage Park

Portsmouth

Hampshire PO3 5TD

England

Telephone +44 (0)23 9269 3611

Fax +44 (0)23 9269 4642

www.raymarine.com

© Raymarine, Inc. 2002

Page 4

iv Transducers for Fishfinders

Preface

This handbook describes the transducers that are required for use

with Raymarine fishfinders. A list of currently available fishfinder transducers appears on page 4.

The handbook contains very important information on the installation and operation of your new equipment. In order to obtain the

best results in operation and performance, please read this handbook thoroughly.

Raymarine’s Product Support representatives or your local dealer

will be available to answer any questions you may have.

The technical and graphical information contained in this handbook, to the best of our k nowledge, was correct as it went to press.

However,the Raymarine policy of continuous improvement and

updating may change product specifications without prior notice.

As a result, unavoidable differences between the product and

handbook may occur from time to time, for which liability cannot

be accepted by Raymarine.

Raymarine is a registered trademark of Raymarine Limited.

SeaTalk is a registered trademark of Raymarine Limited.

2

hsb

is a trademark of Raymarine Limited.

Warranty

Your transducer ownership warranty is registered when you fill

out the warranty registration card included with your Raymarine

Fishfinder Owner’s Handbook. It is very important that you complete the owner information and return the card to the factory in

order to receive full warranty benefits.

EMC Conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

The design and manufacture of Raymarine equipment and accessories conform to the appropriate Electromagnetic Compatib ility

(EMC) standards, but correct installation is required to ensure that

performance is not compromised.

Page 5

Contents v

Contents

Chapter 1: Overview ............................................... ............................. ...1

1.1 In troduction....................................................................... 1

General .............................................................................. 1

EMC Installation Guidelines ............................................2

1.2 TheFishfinder System ...................................................... 3

Selecting the Correct Typeof Transducer .........................4

Planning the Installation ...................................................5

1.3 U npackingand Inspecting the Components .....................6

1.4 S electingthe EquipmentLocation .................................... 6

TransducerMountingLocation ........................................6

TransomMountTransducer..............................................7

1.5 C ableRuns ......................................................................12

TransducerCable ............................................................ 12

Chapter 2: Installation ...................... ............................ ....................... .15

2.1 In stallingthe TransomMountTransducer ......................15

Preparation ......................................................................15

Installation ...................................................................... 16

2.2 In stallingthe Thru-hullTransducer ................................17

T oo lsand Material Needed ............................................. 17

Preparation ......................................................................17

Installation ...................................................................... 22

Installationin a CoredFiberglassHull ............................29

Checkfor Leaks .............................................................. 30

2.3 In stallingthe In-hullTransducer .....................................31

T oo lsand Material Needed ............................................. 31

T estingthe SelectedMounting Location ........................31

Installation ...................................................................... 34

Installationin a CoredFiberglassHull ............................37

2.4 Transducer Cable Connections ....................................... 39

Chapter 3: Maintenance .......................................................... .............43

Cleaning Instructions ...................................................... 43

Servicing and Safety .......................................................43

Problem Solving .............................................................44

CommonProblems and Their Solutions .........................44

Howto Contact Raymarine .............................................45

Worldwide Support .........................................................47

Index.................................................. ............................ ...... 49

Page 6

vi Transducers for Fishfinders

Page 7

Chapter 1: Overview 1

Chapter 1:Overview

1.1 Introduction

Thishandbookprovides instructions to assist you intheinstallation

andset up of thevarioustransducers for Raymarine fishfinders.See

Table 1-1 on page4for a list ofthe different sensor,material and

mountingtypes available.

General

Raymarinefishfindersrequire a transducer,either thru-hull, in-hull,

ortransom-mount.

Transducerscan measure water depth,temperature, distance

traveled,and/or speed. It is important to position yourtransducer

correctly,as described in Section 1.4,Selectingthe Equipment

Location.

Note:If speed andtemperaturearebeing input via SeaTalk, these

valuesare displayed instead of thespeed and temperature inputs

from the transducer.

Thishandbook is divided into threechaptersas follows:

Chapter One providesan overview of the transducerinstallation.It

includessectionson Unpacking and InspectingtheComponents,

SelectingtheTransducerSiteand a description of theCableRuns.

Chapter Twoprovidesdetailed instructionson how to mountand

connecteach type oftransducer.

ChapterThreeprovidesinformation on maintenanceandwhattodo

ifyou have problems.

Page 8

2 Transducers for Fishfinders

EMC Installation Guidelines

All Raymarine equipment and accessoriesare designed tothebest

industrystandardsfor use in the leisuremarineenvironment.

Theirdesign and manufactureconformsto the appropriate

Electromagnetic Compatibility (EMC) standards, but correct

installationis required to ensure thatperformanceis not

compromised.Althoughevery effort has been takentoensure that

theywill perform under all conditions,itisimportant to understand

whatfactors could affect the operationofthe product.

TheguidelinesgivenheredescribetheconditionsforoptimumEMC

performance,but it is recognizedthatit may not bepossibleto meet

allof these conditions in allsituations.Toensure the bestpossible

conditionsforEMC performance within theconstraintsimposed by

any location, always ensure themaximumseparationpossible

betweendifferent items of electricalequipment.

For optimum EMC performance, itis recommended that wherever

possible:

• Raymarineequipmentandcables connected toit are:

• Atleast1 m (3 ft)from any equipment transmitting or cables

carrying radio signals, e.g., VHFradios, cables and antennas.

In the case ofSSBradios, the distanceshould be increasedto

2 m(7 ft).

• Morethan 2m (7 ft) fromthe path of a radarbeam. A radar

beamcan normally be assumedtospread 20 degrees above

andbelowtheradiatingelement.

• Theequipment issuppliedfroma separate battery from thatused

forengine start. Voltage drops below 10 V (20Vfor 10 kW open

arrayscanners) in the power supplytoour products, and starter

motortransients,can cause theequipmenttoreset. This will not

damagethe equipment, but may causetheloss of some informationand may change theoperating mode.

• Raymarinespecifiedcables are used atall times. Cuttingand

rejoiningthesecablescancompromiseEMCperformanceandso

mustbe avoided unless doing soisdetailedin the documentation.

• Ifasuppressionferriteis attachedtoacable,this ferriteshouldnot

beremoved. If the ferrite needstoberemoved during installation

itmust be reassembled in thesameposition.

Page 9

Chapter 1: Overview 3

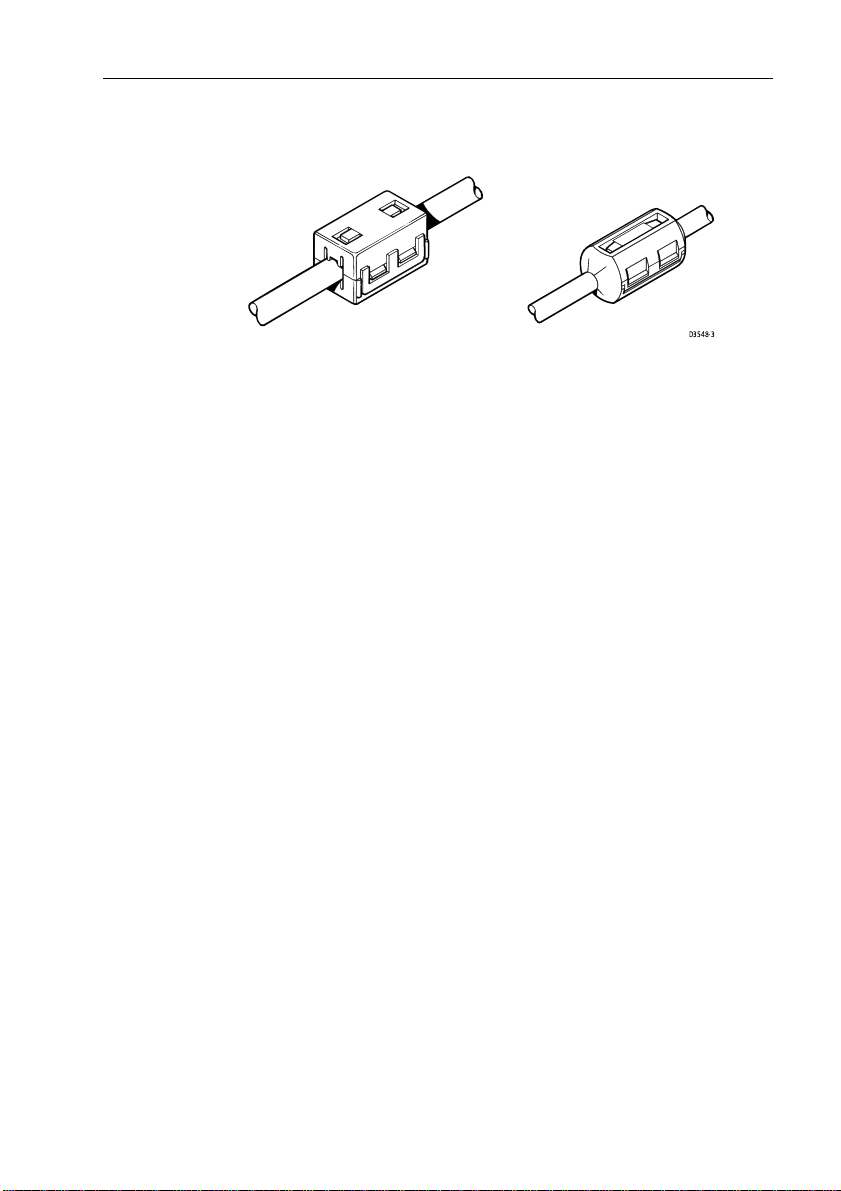

Thefollowingillustrationshows a typical range ofsuppression

ferrites fitted to Raymarine equipment.

D3548-3

Connections to Other Equipment

Ifyour Raymarine equipment is tobe connected to other equipment

usinga cablenotsuppliedbyRaymarine,asuppressionferriteMUST

always be attached tothe cable nearto the Raymarine unit.

1.2 The Fishfinder System

Transducersenablefishfinders to displaydepth, water temperature

and/orspeed, depending on thetypeof transducer(s) installed.

Beforeyou start the installation, check thatyouhave the correct

transducerfor your application, as described belowin Selecting the

CorrectTypeofTransducer.

Page 10

4 Transducers for Fishfinders

Selecting the Correct T ype of Tr ansducer

RaymarineFishfinderscan be used with anyofthe following

transducers:

T able 1-1:Transducer Types

1

Sensor

Type

Depth,

Speed, T emp

Depth,

Speed, T emp

Speed, T emp

Material

steel

Bronze Thru-Hull 600 W

Bronze Thru-Hull

Plastic Transom 600W

Part No.

E66008 Depth Plastic In-Hull 600 W

E66013 Depth Plastic Thru-Hull 600 W

E66014 Depth Bronze Thru-Hull 600 W

E66015 Depth Stainless

E66018 Speed, T emp Bronze Thru-Hull 600 W

E66019 Speed, T emp Plastic Transom 600 W

E66020

E66024 Depth, T emp Bronze T hru-Hull (high

E66029 1

E66030 Speed, T emp Plastic Thru-Hull 600 W

E66033 Depth, T emp Bronze Thru-Hull 600 W or

E66035 Depth, T emp Bronze Thru-Hull 600W

E66038 Depth,

Mounting

Method

Thru-Hull 600 W

performance)

(long stem)

Max.

Power

600 W or

1000 W

600 W

1000 W

E66043 1

1

E66020, E66029 and E66043 thru-hull transducers must be installed with a high-

speed fairing.

Depth,

Speed, T emp

Stainless

steel

Thru-Hull 600W

Note:Thisinformationwas currentasofthedatethishandbook was

printed.Newtransducer models are constantly becomingavailable.

Checkwith your dealer for themostcurrentlist.

Page 11

Chapter 1: Overview 5

WARNING:

IftheE66020,E66029 and E66043 thru-hull transducers are not

carefully installedand fitted to theshape of the hull, thevessel

maytake on water. Toensureproper alignment anda secure fit,

these transducermodels MUSTbe installed with afairing. In

additionto improving fishfinderperformance atallspeeds, the

fairingallowsbetterfittingto the hullanddramaticallyincreases

thesealing surface.

Applicatio ns

Plastichousingsare recommended for fiberglassor metalhulls.

Bronze housings arerecommendedfor wood or fiberglasshulls.

• Installa tionof a bronze housing in a metal hull requiresusing of a

fairing,available from your Raymarine dealer .

• Neverinstallametal housing in a vesselwitha positive ground

system.

Transom Mount Transducersare recommended for personal

watercraftand powerboats with outboard, inboard-outboard and jet

drives.They are NOT recommendedforlargeor twin screw inboard

boats.

• Adjuststo transomanglesfrom 3° – 16°.Forangles greater than

16

°, a tapered plastic, wood or metal shim will be needed.

• Designedfor operation from5–58 m.p.h. (4 – 50knots).

Thru-HullTransducersare recommended for boatswithstraightshaftinboard engines.

In-Hull transducers arerecommendedforfiberglasshulls,especially

inhigh speed power boatsandracingsailboats.

Planning the Installation

Beforeyou install your system, plan theinstallation,considering:

• Locationof thetransducerand fishfinder,as described in

Section 1.4

• CableRuns,includingcablesforanintegratedsystem(to provide

heading and position data,etc.), as described inSection 1.5.

Page 12

6 Transducers for Fishfinders

1.3 Unpacking and Inspecting the Components

Unpackyour system carefully,toprevent damage to theequipment.

Savethe carton and packing,in case you needtoreturn a unit for

service.

Checkthat you have allthe correct system components. These

dependon your system package, asfollows:

T able 1-2:Parts and Accessories

Part

Item

Transducer (

Transducer cable, 10 ft (3 m) extension

Transducer cable, 18 ft (5 m) extension

Transducer Y Cable

High Speed Fairing

see T able 1- 1 on page 4)

1

E66023 fairings are required for installing E66020 and E66029 bronze thru-hull

transducers.

2

E66045 fairings are required for installing E66043 stainless steel thru-hull

transducers.

No.

— — All

E66009

E66010

E66022

E66023

E66045

E66025

E66034

E26017

Supplied

with:

—

—

Speed/Temp

Transducers

1

—

2

—

—

—

—

Note:Thisinformationwas currentasofthedatethishandbook was

printed.Check with your dealer forthe most current list ofpartsand

accessories.

1.4 Selecting the Equipment Loca tion

T ransducer Mounting Location

Option

for:

All

All

All others

E66020, E66029

E66043

E66024

E66033

E66035

Itis very important thatyoumount the transducer correctly.The

transducerprovidesthe most reliable readings ifitlooksinto water

thatis smooth and undisturbed.

Page 13

Chapter 1: Overview 7

Acousticnoiseisalwayspresentandthesesoundwavescaninterfere

withthe operation of the transducer .Ambient (background) noise

fromsources such aswaves, fish, rainand other vessels cannotbe

controlled.Carefully selecting thetransducer’smounting location

can minimize noise generated by the vessel’spropeller(s), shaft(s),

machinery, andotherecho sounders. The lowerthe noise level, the

higherthe echo soundergainthat can be used,andthe better the

Fishfinder’sperformance.

CAUTION:

To ensureaccurate readings,DO NOT mount the transducerin

anareaof turbulence or bubbles:

• near waterintakeor discharge openings

• behindstrakes, fittings orhullirregularities

• behinderoding paint(an indication of turbulence)

Choosea location where:

• Thewaterflowingacrossthehullissmoothestwitha minimumof

turbulenceand bubbles (especially at highspeeds).

• Thetransducer willbecontinuously covered by waterwhen the

boatis moving. If thetransduceris mounted near the sideofthe

boat,it may be exposedwhenthe boat is turning.

• Thetransducer beamis unobstructed by the keelorpropeller

shaft.

• Thereis aminimum deadrise angle.

• Thereis adequate headroom inside the vessel for the height of the

thru-hullhousing,tighteningthenuts, and removing the valve

assembly insert.

T ransom Mount Tr ansducer

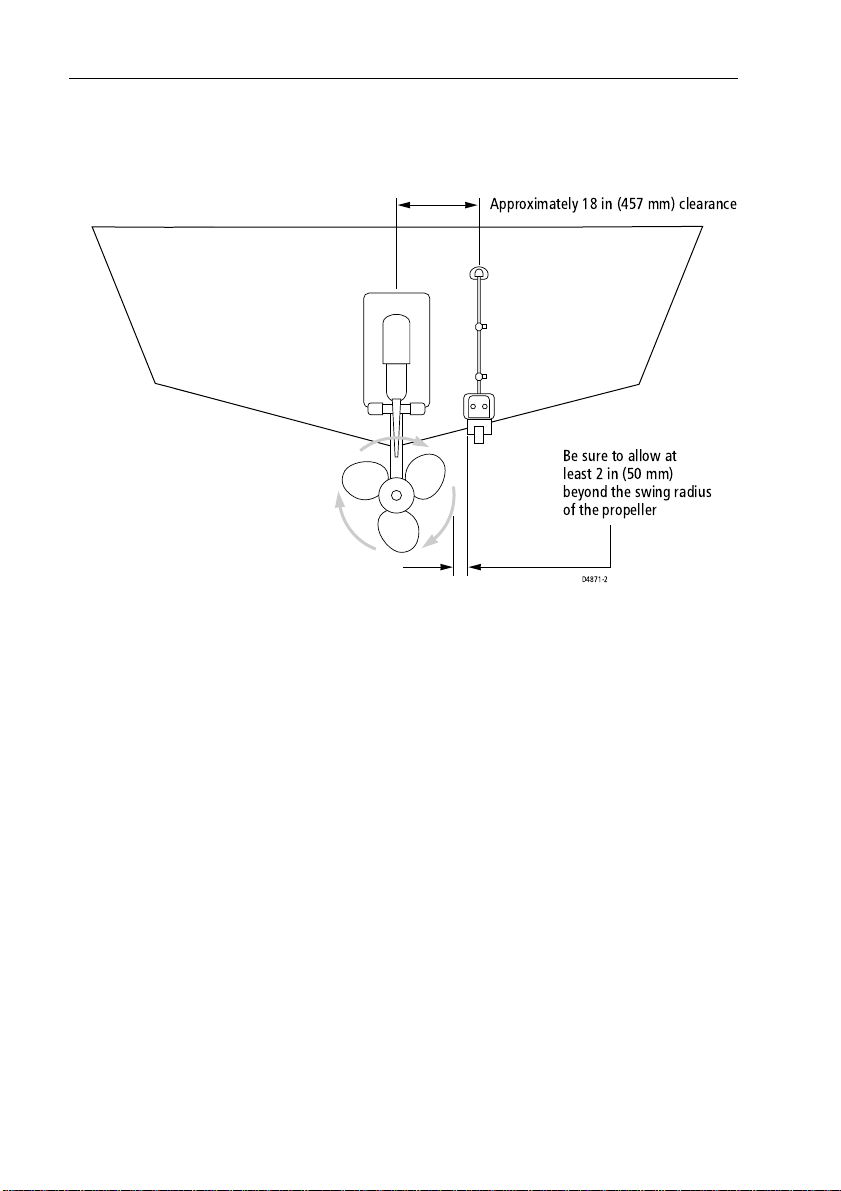

• Single drive boat -Referto Figure 1-1 . If yourboathas one pro-

peller(outboardor inboard),mountthetransducerabout 18"(455

mm)tothesideoftheboat’s centerline. To reduce anyinterfer-

encecaused by air bubbles,choosethesideon the downstroke of

thepropeller (usually the starboardside).

• Twin drive boat- If yourboathas twin propellers (outboard or

inboard-outboard),mount the transducerbetween thedrivesnear

the centerline of the boat. If the boat will be operated at high

speeds,thetransducermay be mounted closer to thecenterlineof

the hull.

Page 14

8 Transducers for Fishfinders

• Ifthe propellercanbeturnedtosteerthe boat, allow at least 2" (50

mm)beyond the swing radius ofthe propeller.Thiswillprevent

thepropeller from damagingthetransducer when itis turned.

Approximately 18 in (457 mm) clearance

Be sure to allow at

least 2 in (50 mm)

beyond the swing radius

of the propeller

D4871-2

Figure 1-1: T ransom Mount Transducer Location

• DoNotmount the transducer behind any hullfittings,intakesor

otherparts extending from the hullthatmay cause turbulence or

airbubbles.

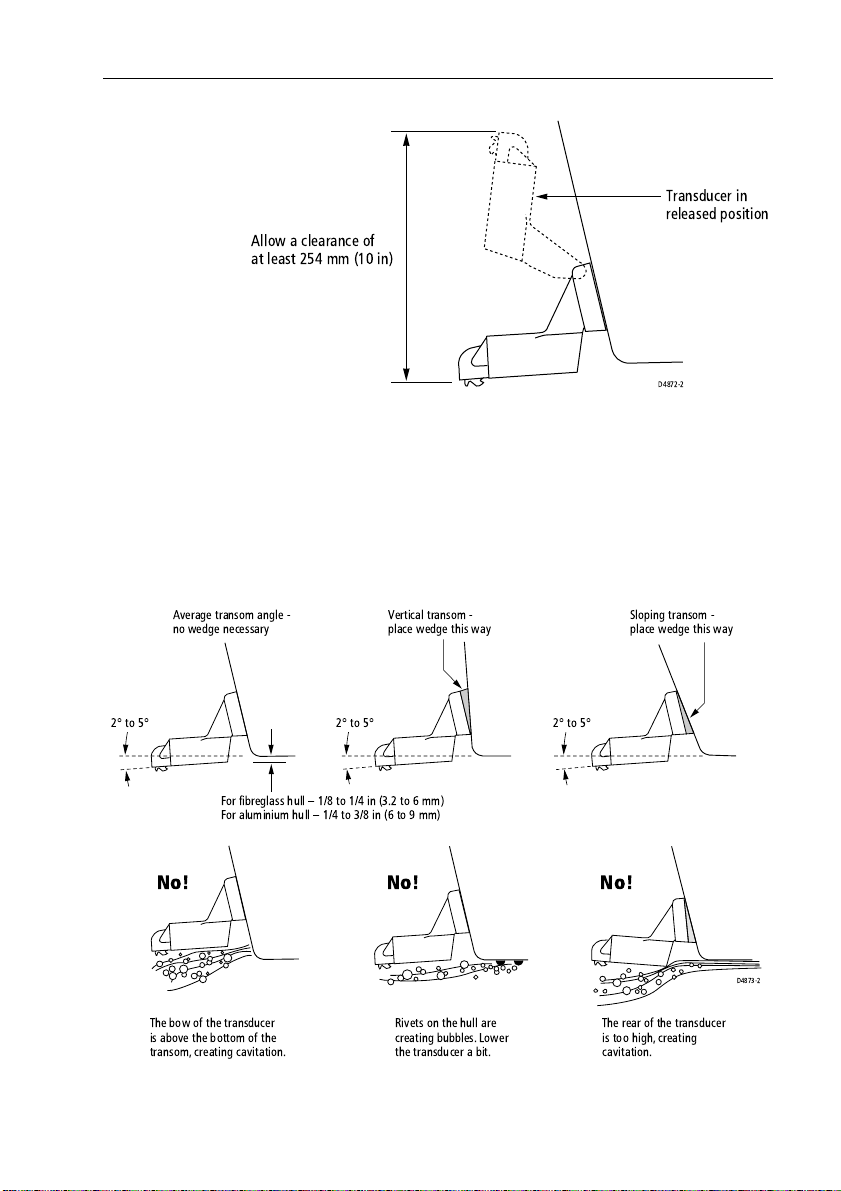

• Thebrackethas a quick-releasemechanism, shown Figure1-2 .

This allows the transducer to flip upif it hits anydebris or thebottom.Allowenoughclearanceabovethetransducerforitto swing

upwardscompletely– thisisabout10"(254mm), measured from

the bottom ofthe transom.

Page 15

Chapter 1: Overview 9

Transducer in

released position

Allow a clearance of

at least 254 mm (10 in)

D4872-2

Figure 1-2: T ransom Mount T ransducer - Quick-release Bracket

• Onaboatwithafiberglasshull, theleadingedgeofthetransducer

shouldextend1/8" (3.2 mm) to1/4"(6 mm) below the bottom

edgeofthe hull asshowninFigure1-3.Onanaluminum hull, the

transducershould extend abit more – 1/4"(6mm) to 3/8" (9 mm)

• Ifthe boat willbe trailered, besure the transducer will nothit any

rollers,bunksor fittings on the trailer.

Average transom angle -

no wedge necessary

2° to 5°

The bow of the transducer

is above the bottom of the

transom, creating cavitation.

Vertical transom -

place wedge this way

2° to 5°

For fibreglass hull 1/8 to 1/4 in (3.2 to 6 mm)

For aluminium hull 1/4 to 3/8 in (6 to 9 mm)

2° to 5°

No!No!No!

Rivets on the hull are

creating bubbles.Lower

the transducer a bit.

The rear of the transducer

is too high, creating

cavitation.

Figure 1-3: T ransom Mount T ransducer - Vertical P osition

Sloping transom -

place wedge this way

D4873-2

Page 16

10 Transducers for Fishfinders

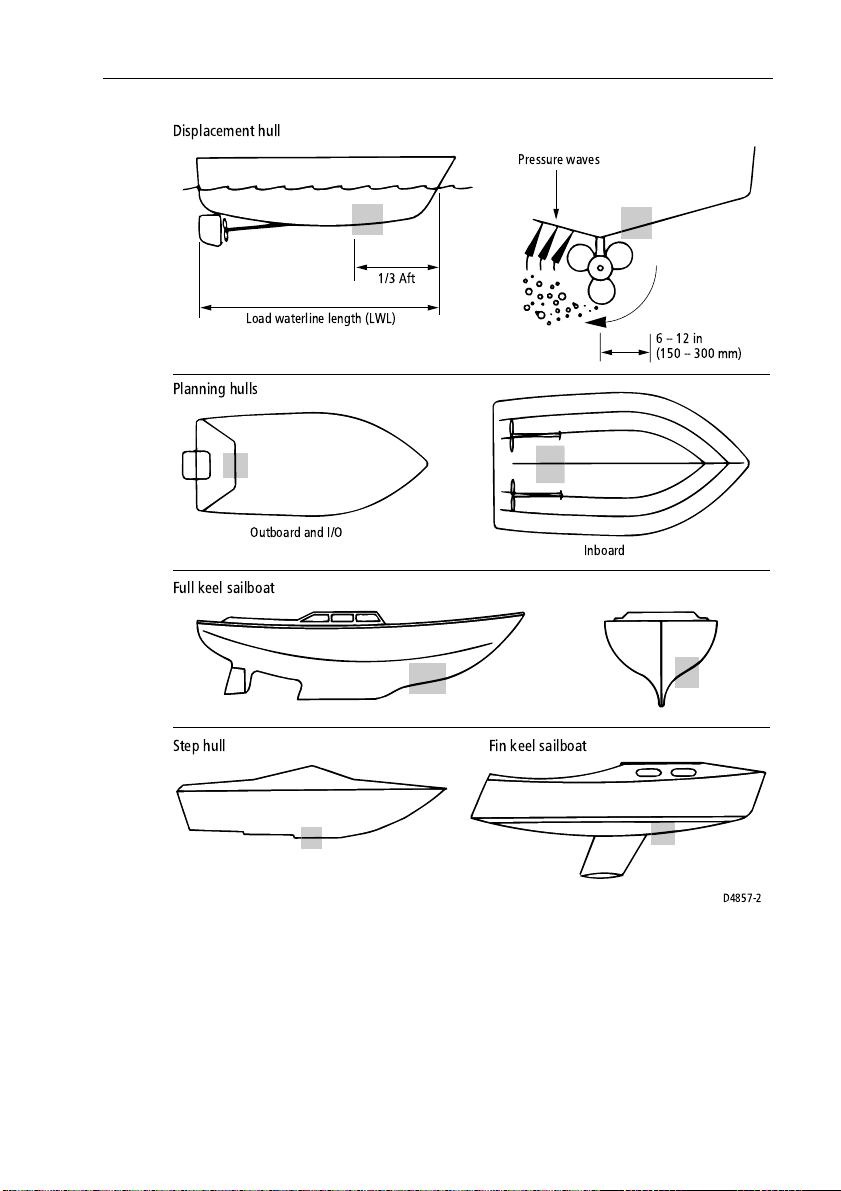

Thru-hull T ransducer and In-hull Tr ansducer

Similarconsiderationshouldbegiventothe locationof thru-hulland

in-hulltransducers.Figure1-4 shows thebesttransducerlocation for

differenthulltypes.

• Displacementhullpowerboat –Locateat 1/3 aftload waterline

length(L WL)and 6 -12" (150-300 mm) off the centerlineonthe

sideof the hull where thepropeller is moving downward.

• Planin ghull powerboat–Mountwell aft, on or nearthe center-

line, and wellinboard ofthe first set of lifting strakes to ensure

that it is in contactwiththe water at high speeds.Mounton the

sideof the hull where thepropeller is moving downward.

OutboardandI/O – Mount just forwardofthe engine(s).

Inboard–mount well forward ofthepropeller(s)andshaft(s).

Step-hull – Mount just aheadofthe first step.

Boatscapableof speeds above 25kn(29 m.p.h.) – Review

transducer location and operating results of similar boats before

proceeding.

• Finkeelsailboats– Mount to theside of the centerlineand for-

wardof the fin keel1- 2 ft (300-600mm).

• Fullkeelsailboats–Locate amidships and away from the keel at

thepoint of minimum deadrise angle.

• FiberglassHulls – Since thehullabsorbs acoustic energy,trans-

mittingthroughthe hull reduces the sensor’sperformance. Fiberglasshullsare often reinforcedinplacesforadded strength.These

coredareascontain balsa woodorstructuralfoam,which are poor

soundconductors.If you cannot avoidlocatingthesensor over

coring,followthe instructions for Installation in aCoredFiber-

glassHullon page 29.

• Thru-hullTransducer Headroom–Allowadequate headroom

insidethe vesselfortheheight ofthethru-hullhousing,tightening

thenuts and removing the insert.Theminimum headrooms are:

Withfairing:10"(254mm)

Withoutfairing: 12" (305mm)

• In-hullT ransducer–Find a location wherethe fiberglass is

solid:

Thereare no air bubblestrappedin the fiberglass resin.

Thereis no coring,flotation material,or dead airspace sandwichedbetween the inside skinandthe outer skin of thehull.

Page 17

Chapter 1: Overview 11

Displacement hull

Pressure waves

1/3 Aft

Load waterline length (LWL)

Planning hulls

Outboard and I/O

Full keel sailboat

Step hull Fin keel sailboat

Figure 1-4: Best Location for T hru Hull Transducer

Inboard

6--12in

(150 -- 300 mm)

D4857-2

Page 18

12 Transducers for Fishfinders

1.5 Cable Runs

Consider the following beforeinstalling the system cables:

• Youneed to attachthe power cableand the transducer cable.

Additionalcables will be required ifyouare installing an integrated system.

• Allcables should be adequatelysecured,protected fromphysical

damageand protected from exposuretoheat. Avoidrunning

cablesthroughbilges or doorways, or closetomoving or hot

objects.

• Acutebends mustbeavoided

• Wherea cablepassesthrough an exposed bulkheadordeckhead,

awatertightfeed-through should be used.

• Securecablesin place using tie-wraps or lacingtwine. Coil any

extra cable andtie it outof the way .

T ransducer Cable

A30 ft (10m) cableis supplied with the transducer. The transducer

cablemaybeextendeduptoamaximumof60ft(20m)using

optionalextensioncables.

Thetransducercable connector hasanutthathas been removed toaid

installation. Toallowyouto complete the installation withoutcutting

thecable, ensure that anyholesyou drill are largeenoughto accept

theconnector,withthe nut removed.

Afterthe cable has beenrunthroughthe holes, this nutmustbe

attached before the cablecan be connected,as described in

Trans ducerCable Connections onpage 39.

CAUTION:

Donot cut thetransducer cable orremovethe connector.Donot

tryto shorten orsplice the cable.If the cableis cut, itcannotbe

repaired.Cuttingthecable will alsovoidthewarranty.

• ForaTransommountinstallation–routethecable upandoverthe

top edge of the transom as shown in Figure 1-5 . Secure the cable

usingcable clamps (available fromyourlocal marine equipment

supplier).

Page 19

Chapter 1: Overview 13

Ifyou do not wantto expose the cable ondeck, you may drill a

hole13/16"(21 mm)throughthetransomforthe cable(withconnector attached). Toseal the opening, useafeed-thru cap where

thecable passes through the transom.

• Foreithertype ofinstallation –runthecablethrough the interior

oftheboat.

• Ifthe 30ft (10 m) cable isnotlong enough, extension cables are

availablefrom your Raymarine dealer.See Table 1-2 on page 6.

Total cablelength fromthetransducer tothe fishfinder must

notexceed60 ft (20 m). Whenyouattachthe extension cable, be

surethat the connections are watertight.UseDow Corning DC-4

oran equivalent sealing compound toprotectthe connector

assemblies.

Cable cover

Cable clamps

2 in (50 mm)

Figure 1-5: Installing the Cable on a Transom Mount T ransducer

D5033-2

Page 20

14 Transducers for Fishfinders

Page 21

Chapter 2: Installation 15

Chapter 2:Installation

Thischapter gives details onhowto install your transducer .

Instructionsare divided intothe following sections:

• TransomMount Transducers- recommended for personal

watercraftand powerboats with outboard, inboard-outboardand

jetdrives.

• Thru-HullTransducers -recommended for boats with straight-

shaftinboard engines.

• In-Hulltransducers- recommended for fiberglasshulls,espe-

cially in high speedpower boats andracing sailboats.

2.1 Installing the Transom Mount T ransducer

Preparation

Tr ansducer Mounting Bracket

Wheninstalled, the lower surfaceofthe transducer should tilt down

toward the rear ata slight angle (2°to 5°). The mounting bracket

includesa wedge; depending on theangleof the transom on your

boat,you may need toinstallthis wedge to getthecorrect transducer

angle.

1. T oattach thetransducer to the bracket,insert the transducer

mountinglugsinto the slot in thebracketas shown in Figure2-1 .

Correct Incorrect

Attach the two parts Bracket is installed

upside down

Lower the transducer and

snap in the release clip

Figure 2-1: Fitting the T ransducer to the Brack et

D4874-2

Page 22

16 Transducers for Fishfinders

2. Lookingatthe rear of the boat, be surethebracketis vertical (perpendiculartothewaterline) and holdthebracket(plusthe wedge,

ifused)againstthe transom.

Tracethepositionof the screw slots,then mark the screwpositionsasshown in Figure 2-2 . Theoutertwo screws should be

placed about 1/4" (6 mm) upfromthe bottom of eachslot, the

centerscrew should be placedabout 1/4" (6 mm)downfrom the

top.This will allow the brackettobe adjusted up ordown.

Remove the bracket.

Correct alignment

Insert screws 1 and 3, 6.4 mm (1/4 in)

from the bottom of the slots,and

screw 2, 6.4 mm (1/4 in) from the top

the slot to allow room for adjustment.

Incorrect alignment

If screws are inserted this way it

won't be possible to make the

height adjustment.

1

23

123

D4875-2

Figure 2-2: Position of Screws in Mounting Bracket

Installation

1. Ona fiberglass hull, to minimize surface cracking of thegelcoat:

Before drilling the pilot holes, usea 1/4" (6 mm) drill bit to drill a

shallowhole (chamfer) ateach location about 1/16"(1.5mm)

deep.

Drill pilot holes3/4" (19 mm) deep using a 9/64"(3.6 mm) drill

bit.

T opreventdrillingtoodeeply,wrapmaskingtapearoundthe drill

bitabout7/8"(22mm)fromthetip.Drillinonlyasfaras the tape.

2. Applya good quality marine sealanttothe pilot holes to protect

thehull from water penetration.

3. Attach the bracket tothe hull using the panhead screwswith flat

washers. Do notcompletely tighten thescrewsyet.

4. Movethe bracketupordown sotheleadingedgeofthetransducer

hasthe clearance showninFigure1-3.

5. Once the bracketis in thecorrect position tighten thescrews.

Page 23

Chapter 2: Installation 17

2.2 Installing the Thru-hull T ra nsducer

Tools and Material Needed

Water-based antifoulingpaint (mandatory for boatskeptinsalt

water)

Safetygoggles

Dustmask

Electric drill

Drillbit:1/8" (3 mm)

Holesaw:

Drill

Fiberglassorwood2"(51 mm)

Aluminium or steel hull 2-1/8" (54mm)

Sandpaper

File (for installation in a metal hull)

Mild household detergent or weak solvent(alcohol)

Marine sealant

Slip-joint pliers

Siliconegreaseor petroleum jelly

Tie-wraps

Coredfiberglasshull installation:

Holesaw for hull interior2-3/8" (60mm)

Cylinder,wax, tapeandcasting epoxy

Fairing(required with E66020, E66029 and E66043transducers;

optionalforE66024, E66033 and E66035

Level and protractor (installation with a fairing)

Band saw or handsaw (installation witha fairing)

Rasp(installationwitha fairing)

Preparation

Fairing

Mostvessels have a deadriseangleat the transducer’smounting

location. If thetransducer ismounted directly to the hull, thesonar

beam will be tiltedoff-vertical at the sameangle as the deadrise.To

offsetthis deadrise angle, youcan install a transducerfairing.

Differentfairings are available to fit various transducers.Fairingsare

requiredforinstallingthe E66020, E66029 and E66043 thru-hull

transducers.

Page 24

18 Transducers for Fishfinders

WARNING:

IftheE66020,E66029 and E66043 thru-hull transducers are not

carefullyinstalled andfitted tothe shape ofthe hull, the vessel

maytakeon water.Toensureproper alignment and asecurefit,

these transducer models MUST beinstalled witha fairing.In

additiontoimprovingfishfinderperformanceat all speeds, the

fairingallowsbetter fittingtothehullanddramaticallyincreases

thesealing surface.

Fairingsarealso strongly recommended for usewithother high

performancetransducers. See the table thatfollows.

Thefairing is used to:

• Verticallyorientthe sound beam bymountingthe transducer parallel to the watersurface

• Minimizeaeratedwater flowing over thetransducer’sfaceby

mountingit in deeper water

• Reducedrag bydirectingthe water around the multisensor

Thefairingis madeofhighimpact urethanewithan integratedcutting

guide.It can be shapedto accommodate a deadriseangleof up to 25°

and a range of hullthicknessesas follows:

Fairing No.

E26017 E66035

E66023 E66020

E66023 E66029

E66025 E66024

E66034 E66033

E66045 E66043

Used with

Transducer No.

Max. Hull Thickness

with Fa iring

2" (50mm)

1" (26mm)

3-3/4" (87mm)

1-3/4" (45mm)

1-3/4" (45mm)

1/2" (14mm)

Page 25

Chapter 2: Installation 19

Aft View

Backing block

minimum fairing

thickness

D5568-1

Hull

Slope of hull

Deadrise angle

Parallel to

water surface

Fairing

Isolation sleeve

Figure 2-3: Deadrise Angle and Fairing Thickness

Backing Block

Abacking block isused inside the hulltoprovide a level surface for

thehull nut to seatagainst (see Figure2-3). After cutting the fairing,

usetheremaining section with the cuttingguideasthebacking block

(see Figure 2-4 ).

⇐

BOW

Triangular recess

for anti-rotation bolt

Cutting guide

D5567-1

Figure 2-4: T ransducer Fairing E66023

Cutting the Fairi ng

1. Measure the deadrise angleofthe hull at theselected location

usinga digital level, or bubbleleveland protractor (see Figure2-

3).

2. Tilttheband saw tabletothe measured angleand secure the cutting fence (see Figur e2-5 ).

Page 26

20 Transducers for Fishfinders

Band saw table

Deadrise

angle

Bow end for

installation

on port side

D4860-2

Figure 2-5: Cutting the Fairing

CAUTION:

Thearrowonthefairingalwayspoints forwardtowardsthebow.

Besuretoorient the fairing on thebandsaw so the angle cut

matchesthe intendedside of the hull.

3. Place the fairingon the tableso the cutting guide restsagainst the

fence.The arrow/blunt end willpoint toward you for installation

on the port side andaway from you forinstallation on the starboardsideof the boat.

WARNING:

Alwayswearsafetygoggles and a dustmaskwhendrilling.

Cutting guide

Fence

4. Rechecksteps 1 through 3, thencut the fairing.

5. Shapethefairingtothehull as precisely as possible with a rasp or

powertool.

Antifouling P aint

Marinegrowth can accumulate rapidlyonthe transducer’s surface,

reducingperformancein weeks. Surfaces exposedtosalt water must

becoated with antifoulingpaint.

Page 27

Chapter 2: Installation 21

Usewater-basedantifoulingpaintonly.

Neveruse ketone-based paintsinceketones can attack many

plastics,possiblydamagingthetransducer.

Reapplypaint every sixmonths or at thebeginning of each boating

season.

It is easier to apply antifouling paint beforeinstallation, but allow

sufficientdryingtime.Asillustrated in Figure2-6 paint thefollowing

surfaces:

Exposedarea of the housing, including the acousticwindow

Boreof the housing up to1¼"(30mm)

Outside wall belowlower O-ring

Exposedendof the paddle wheelinsert

Paddlewheel cavity

Paddlewheel

Blankingplug below the lower O-ringandthe exposed end

Housing Paddlewheel

Paint exposed housing

and bore up to 1.1/4" (30 mm)

Figure 2-6: Applying Antifouling Paint

insert

Lower

'O' ring

Paint outside wall below the lower 'O' ring including

exposed end, paddlewheel cavity and paddlewheel

D4859-2

Page 28

22 Transducers for Fishfinders

Installation

Note:To install the thru-hull transducer in acored fiberglass hull,

follow the instructions in Installation in a Cored Fiberglass Hull on

page 29.

Drilling Holes

WARNING:

Alwayswearsafetygoggles and a dustmaskwhendrilling.

1. Drilla1/8"(3mm)pilot hole perpendicular tothewaterlinefrom

insidethehull(see Figure2-3 ).

Ifthere is a ribor strut near themountinglocation,drill from the

outside.

Ifthepilothole is drilled in thewronglocation, drill a secondhole

ina better location. Applymaskingtape to the outsideofthe hull

overthe incorrect hole andfill it with epoxy.

2. Cuta hole from outside the hull:

Fiberglassorwoodhull– Use a2"(51 mm) hole saw.

Aluminium orsteel hull– Use a 21/8"(54 mm) hole sawto

accommodatethe isolation sleeveused to preventcontact

between the stainless steelhousingand the metal hull.

3. Sandand clean the areaaroundthe hole, inside and outside,to

ensure that thesealant willadhere properly to thehull. If thereis

anypetroleumresidue inside thehull,removeitwitheitheramild

householddetergentora weak solvent(alcohol)before sanding.

4. Removeone safetyring,theretaining pin,thecapnut,and thehull

nutfrom the transducer (see Figure2-7 ).

Page 29

Chapter 2: Installation 23

Retaining pin

Safety ring

Cap nut

Stem

Hull nut

Backing

block

Hull

Fairing

D5566-1

Marine

sealant

Figure 2-7: Seating

Dry Fit for F airing

WARNING:

Ifa fairing is used, the anti-rotationbolt mustbeinstalled to

preventthefairingfromrotatingwhentheboatis underway.

1. Dry fit the transducer tolocate the hole for the anti-rotation bolt.

2. Threadthe transducer cable through thelargeholein the fairing

andthrough the mounting hole inthehull.Seat the transducer

firmly in therecess in the fairing.

Note:The transducer must beflushwith the fairing. If itisrecessed

morethan1/64" (0.5mm) inside the fairing,youmaycarefullyfile or

sandthefairingflush with the transducer.

WARNING:

Alwayswearsafetygogglesanda dust mask.

3. Attachthe drill bit to yourdrillappropriatefor your fairing:

Fairing Used with Tr ansducer Drill Size

E26017 E66035

E66023 E66020, E66029

E66025 E66024

E66034 E66033

E66045 E66043

3/8" (10mm)

3/8" (10mm)

1/2" (13mm)

1/2" (13mm)

3/8" (10mm)

Page 30

24 Transducers for Fishfinders

4. Slidethetransducer’sstem with the fairing inplace into the

mountinghole.Besurethe triangularrecessinthefairingis pointing forward toward the bow.

5. Whileholding the assembly in placeandusingtheboltholeinthe

fairingasyourguide,drill a hole through the hull for theanti-rotation bolt.

6. Removethe assembly and cable from themountinghole.

7. Sandand clean the areaaroundthe hole, inside and outside,to

ensure that thesealant willadhere properly to thehull.

Metalhull-Remove any burrsaroundboth holes with a fileand

sandpaper .

BOW

Anti-rotation

bolt

⇐

Nut and

washer

Triangular plug

with curved surface

facing outward

Backing

block

D5565-1

Fairing

Figure 2-8: Using a Fairing and Backing Block

Seating

1. Remove the transducer from the fairing, if used.

2. Stainlesssteeltransducer in metalhull - Slidethe appropriate

sizeisolation sleeveover the cableandonto the stemof the transduceras far down aspossible(see Figure2-3 ). Be sure thetopof

theisolation sleeve will be belowthe top of the backingblockto

preventthe sleeving from interfering withtighteningthehull nut.

WARNING:

To prevent electrolyticcorrosion,neverallow direct contact

betweena stainlesssteel transducerand a metal hull.

Page 31

Chapter 2: Installation 25

3. Applya 1/16" (2mm) thick layerofmarine sealant to thesidesof

thetransducerthatwillcontactthefairing, ifused,andup thestem

1/4"(6mm) higher than thecombined thickness of the fairing,

hull,backing block, andhullnut. This will ensurethere is marine

sealantinthethreads to seal the hullandholdthehullnut securely

in place (see Figure2-7 ).

Stainlesssteel transducerinmetalhull - Apply the marine sealantto the outside of thesleevinginsteadof the stem itself.

4. Ifafairing is used, thread thetransducercable through the fairing

andseat the transducerfirmly within the recessin the fairing.

5. Applya 1/16" (2mm) thick layerof marine sealant to thesurface

ofthe fairing thatwill contact thehull, if used.

Attaching the Transducer

1. Fromoutside thehull,threadthecable throughthemountinghole.

2. Push the stem ofthe transducer(with thefairing in place)into the

mountingholeusinga twisting motiontosqueezeoutexcesssealant.

3. Frominsidethe hull, slide the backingblockonto the transducer

cable and stem, seating itfirmly against the hull (Figure2-9 ).

CAUTION:

Be careful toavoid cross threading the cap nut.

4. Screwthe hull nut in placeandtightenit with slip-joint pliers.

Stainlesssteeltransducer in metalhull - Be sure the top of the

isolation sleeve is belowthe top of thebacking block to prevent

thesleeving from interfering with tighteningthehull nut.

5. Applya 1/16" (2mm) thick layerofmarine sealant to theantirotationbolt,1/4" (6mm) higher than thecombinedthicknessof

thefairing, hull, backing block, washer,and nut. Thiswillensure

thatthere is marine sealant on thethreads to seal thehull and hold

thenut securely inplace (see Figure 2-8 ).

6. Pushthebolt through the fairing, if used,andintothe hull.

7. Frominside the hull,slidethewasher and nutontothebolt.Screw

the nut in place and tighten it withslip-joint pliers.

Wood hull - Allow for thewood to swell.

Page 32

26 Transducers for Fishfinders

Cable

Safety chain

Pull ring

Safety ring

Cap nut

Stem

Backing block

D4863-2

Figure 2-9: Fore View of Transducer Installation

8. Ifa fairing is used,apply marine sealantto the flat sideofthetri-

angularplug. Push the plugintothe triangular recess in thefairing.Thetriangularplugfitsonewayonly.Besurethecurved

sideof the plug is exposed,matchingthecurve on the outsideof

thefairing. Tapit into place with a mallet.

CAUTION:

Forsmoothwater flow over thetransducer’ssensor,besurethat

theexternalsurfaceof the installedtriangularplugisFLUSH

withthe external curvedsurfaceof the fairing.

9. Beingsurethe valve assembly is seatedfirmlyinthe housing,

carefullyscrew the capnut in place.Hand tighten itonly; do not

over tighten.

10. Remove any excesssealanton the outside of thehullto ensure

smoothwater flow over thetransducer .

Retaining pin

Safety wire

Hull nut

Hull

Fairing

Transducer

Page 33

Chapter 2: Installation 27

11. After thesealant cures, inspect andlubricate the O-rings onthe

paddlewheel insert with silicone greaseorpetroleum jelly (see

Figure2-10 ).

12. Slide the paddle wheelinsert into the valve assembly with the

arrowonthetop pointing forward untilitisfullyseated(the insert

fitsone way only).

Take care nottorotate the outer housinganddisturbthe sealant.

13. Slide the centerring of the safetychainonto the cable. Slidethe

retaining pin inplace and reattach thesafety ring (Figure2-9 ).

WARNING:

Alwaysattach the safety wiretopreventthe insert from backing

outin the unlikelyevent that thecap nut failsor is screwedon

incorrectly.

14. Wrapone end of thesafety wire tightly around thestemof the

housingandtwist it together withthelong end. Lead thewire

straightup and throughoneeyeinthecapnut,then throughoneof

thesafety rings. Loop the wire throughthepullring and twist it

securely to itself.

15. Route the cabletothe transducer,being careful not totearthe

cablejacket when passing itthroughthebulkhead(s) and other

partsof the boat.

16. Attach the connectornutto the cable per instructionsinTrans-

ducerCable Connections on page 39.

17. Attach theassembledconnector cable tothetransducer.

18. Routetheotherend ofthecabletothefishfinder,being careful not

to tear the cablejacket when passingit through the bulkhead(s)

andother parts of theboat.Toreduce electricalinterference, separatethe transducer cablefromother electrical wiringand the

engine.

19. Coil any excess cable and secure it in placeusingtie-wrapstoprevent damage.

Page 34

28 Transducers for Fishfinders

Top view of

paddlewheel

insert

Paddlewheel

insert

BOW

Paddlewheel detail

Notches

Pull ring

Flat side of

paddlewheel

blade faces bow

'O' rings

Housing

and valve

assembly

Cable

Key (2)

Valve assembly

Cap nut

Housing

D4864-2

Figure 2-10: Servicing the Paddle Wheel Insert and Valve Assembly

Page 35

Chapter 2: Installation 29

Installation in a Cored Fiberglass Hull

Thecore (wood or foam)mustbe cut andsealedcarefully.Thecore

mustbeprotectedfromwaterseepageand the hull mustbereinforced

topreventitfromcrushing under thehullnut,allowingthe housing to

becomeloose.

WARNING:

Alwayswearsafetygogglesand a dustmaskwhendrilling.

1. Drill a 1/8" (3mm) pilot hole perpendicular to thewaterline from

inside the hull.If there is a ribor strutnear the selected mounting

location,drill from the outside (seeFigure2-10).If the hole is

drilledinthe wrong location, drill asecondhole in a betterlocation.Applymaskingtape to the outsideofthehullover the incorrecthole and fill itwithepoxy.

2. Usinga 2" (51 mm) holesaw,cut a holefrom outsidethe hull

through the outerskinonly.

3. Usingthe 2 3/8"(60mm)holesaw,cut throughtheinnerskinand

mostof the core from insidethehull.The core material can be

verysoft.Apply only light pressure to thehole saw after cutting

throughthe inner skin toavoid accidentally cuttingthe outer skin

Note:The optimal interior hole diameterisaffected by the hull’s

thicknessand deadrise angle. It must be largeenoughin diameter to

allow the coreto be completely sealed.

4. Removethe plug of core materialsotheinside of the outer skin

andinner core of the hullis fully exposed. Clean and/or sandthe

innerskin,core, and the outerskinaround the hole.

CAUTION:

Completelysealthehull to prevent water seepage intothecore.

5. Coat a hollow orsolid cylinder of the correct diameter with wax

andtapeitinplace.Fillthegapbetweenthecylinderandhull with

castingepoxy.After theepoxy has set, removethecylinder (see

Figure2-11).

Page 36

30 Transducers for Fishfinders

Dimension equal to the thickness of the hull's

outer skin to ensure adequate clearance

Casting epoxy

Hull

Figure 2-11: Preparing a Cored Fiberglass Hull

6. Sandand clean the areaaroundthe hole, inside and outside,to

ensure that thesealant willadhere properly to thehull. If thereis

anypetroleum residue inside the hull,removeit with either mild

householddetergentora weak solvent(alcohol)before sanding.

7. Proceedwith Seating on page 24 and AttachingtheTransducer

onpage 25.

Check for Leaks

WARNING:

Never installa thru-hull transducer andleave theboat

unchecked for severaldays.

1. When the boatis placed inthe water, immediatelycheck around

thethru-hull transducer for leaks.Note that verysmall leaks may

notbe readily observed. Do not to leavethe boat inthe water for

morethan3 hours before checkingitagain.Ifthere is asmallleak,

theremay be considerablebilgewater accumulationafter 24

hours(probablynot enough to causewaterdamage). If a leakis

observed,repeat Seating on page 24 and Attachingthe Trans-

ducer on page 25 immediately.

D4865-2

Inner skin

Core

Outer skin

Solid or

hollow

cylinder

Page 37

Chapter 2: Installation 31

2.3 Installing the In-hull T ra nsducer

Tools and Material Needed

Tape

Pole

Detergent

Weak solvent (alcohol)

Safetygoggles

Dust mask

Disc sander

Thin, sealable plastic bag (optional)

T wist-tie

Petroleum jelly (Vaseline®)

Leveland protractor

Carpenter’ssquare

Pencil

Adhesive(Loctite#5699 or 3M #4200)

Screwdriver

Siliconegrease (optional)

Mineraloil 2.4 fl oz.(71mil)

Cored fiberglass hull installation:

Drill

Holesaw for hull interior4"(100 mm)

Miniaturedisk sander

Castingepoxy(polyproxy#7035/7040)or resin

Papercup

Stirrer

Testing the Selected Mounting Location

Establishing a Performance Baseline

The results of thistest are used todetermine the bestin-hulllocation

fora transducer.

1. Take the boat to the maximum depth for which yourinstrumentis

rated,or the maximum depth inwhichyou will operate thefishfinder.

2. Connectthe transducer to thefishfinder.Refer to Transducer

CableConnections on page 39.

Page 38

32 Transducers for Fishfinders

3. Tape the transducertoa pole with thecable side up. Hold itover

theside of the boatwiththe active face submergedinthewater

(seeFigure2-12). Keep the activeface of the transducerparallel

to the surface ofthe water.

4. Observethe Fishfinder’sperformance and depth reading.

D5000-2

Figure 2-12: Establishing a Performance Baseline

Testi ng the Mounting Loc ation

Whiletheboat is moving aroundthesame site (and depth ofwater),

testthe transducer at your selectedmountinglocation inside the hull.

Useone of the methodsbelow:

1. Thismethodisrecommendedifthesensorwillbelocatednearthe

stern and the boat hasa minimum deadrise angle.

i. Clean away any largebuild-upof dirt and/or greaseusing

detergentor a weak solventsuch as alcohol.

ii. Placethe sensor against the hull andallowbilgewatertocover

thesurface where theytouch (see Figure 2-13 A).

WARNING:

Alwayswearsafetygoggles and a dustmask.

2. Thismethod can be usedat all hull locations.

i. Ifthe hull surface is notsmooth,grind it with a discsander.

ii. Partiallyfill a thinplastic bag with water, place the sensor

inside the bagand close it tightly with atwist-tie.

iii. Wetthesurface of the hull and pressthesensor face againstit

throughthe bag (see Figure 2-13 B).

Page 39

Chapter 2: Installation 33

WARNING:

Alwayswearsafetygogglesanda dust mask.

3. Thisis the leastdesirable testing method,as it may be difficult to

removealltracesof the petroleumjellybeforebondingthebaseto

the hull.

i. Ifthe hull surface is notsmooth,grindit with a discsander.

ii. Coatthe face of the sensor with petroleum jelly.

iii. Press it against the hull with a twisting motion (see Figure2-

13C).

ABC

D5001-2

Figure 2-13: T esting the Transducer at the Selected Location

Observe the Fishfinder’sperformance and compare it to the baseline.

Lookfor astabledepthreadingthat issimilartothebaseline,compare

thethickness and intensity ofthe bottom trace.

Ifthe performance is closeto the baseline, thisisa good mounting

location.Remember,someenergyis lost transmitting through the

hull.

Ifthetestreadingdiffersmarkedlyfromthebaseline,youneedtofind

anotherlocation to install the transducer.

Ifthereis no reading oritiserratic, the sensormaybepositioned over

coringwhich is absorbing the acoustic energy. Choose another

location.If no other spotisavailable, check with theboat

manufacturer to becertain coring is presentbefore proceeding

with Installationin a Cored FiberglassHullon page 37.

Page 40

34 Transducers for Fishfinders

Installation

1. Measurethe deadrise angle of thehullat the selected location

usingalevelandprotractor (see Figure2-14). Measurecarefully ,

sincethe installed transducer must be within5° of vertical.

WARNING:

Alwayswear safetygogglesand a dustmask.

2. Thehullsurfacetobebondedmustbesmoothand free of paint or

anyother finish. If the surfaceisrough, use a discsanderto

smoothan area 4" (100 mm) indiameter.

3. Remove any dust, grease oroil with a weak solvent, such asalcohol,to ensure a good bond.Cleanand dry both theselectedarea

andthe underside of the base.

4. Usinga carpenter’ssquare, draw alineon the hull perpendicular

tothe keel through thecenter of the mounting location.Thiswill

beused as a guidelineto orient the base.

Hull

Flange

Deadrise angle

D5002-2

Guideline

perpendicular

to keel

Parallel to waterline

Base

Figure 2-14: Deadrise Angle

5. Thenumbers on the flange ofthebase represent deadrise angles.

Identifythenumberthatmostcloselycorrespondstothedeadrise

angleof your hull. Find itsmatchon the opposite side of the

flange.Keeping the keel directionarrowson the side ofthebase

nearest the keel, alignthetwo raised marksindicating your

deadriseanglewiththe guideline drawn on the hull (see Figure2-

15).

Page 41

Chapter 2: Installation 35

CAUTION:

Thebasemustbeliquid-tight.

6. When you are satisfiedthat the locationofthe transducer isoptimaland the orientation of thebase corresponds to the deadrise

angleof your boat, apply abead of adhesive to thebottomof the

baseflange.(Followtheadhesive manufacturer’sinstructionsfor

use).

Pressthe flange firmly in placeto form a liquid-tight seal and

allow the adhesive to cure.

Keel

Keel direction arrow

Keel direction arrow

D5003-2

Figure 2-15: Aligning the Base Flange with 4–12° Deadrise Angle

7. Slidethetransducer housing into the locking ring.T urnthe housinguntil the rib thatmost closely corresponds to thedeadrise

angleof your hull is alignedwiththeangle indicator on thelockingring.Tosecure thehousingto the locking ring, inserttwo

screws(see Figure2-16 ). Do notovertighten the screws.

Page 42

36 Transducers for Fishfinders

Transducer

housing

Locking

ring

10° deadrise

angle shown

Angle

indicator

Ribs

D5004-2

Figure 2-16: Joining the Transducer Housin g to the Locking Ring

8. LubricatetheO-ring withsiliconegreaseor petroleum jelly.Slide

theO-ring onto the transducerassembly(see Figure2-17 ).

Transducer

housing

Locking

ring

Front view Side view

'O' ring

D5005-2

Figure 2-17: Installing the O-ring

9. Whentheadhesive on the base has cured,pour2.4fl. oz. (71 mil)

of mineral oilinto the base.

10. Lock the transducerassemblyintothe base by insertingthekeys

onthe locking ring in thenotches in the base. Pressdownand

rotate clockwise until seated(see Figure2-16 ).

11. Route thecable to the transducer,being carefulnotto tear the

cablejacket when passing it throughthebulkhead(s) and other

partsof the boat.

Page 43

Chapter 2: Installation 37

12. Attach the connectornutto the cable per instructionsinTransducerCable Connections on page 39.

13. Attach theassembledconnector cable tothetransducer.

14. Routetheotherend ofthecabletothefishfinder,being careful not

to tear the cablejacket when passingit through the bulkhead(s)

andother parts of theboat.Toreduce electricalinterference, separatethe transducer cablefromother electrical wiringand the

engine.

15. Coil any excess cable and secure it in placeusingtie-wrapstoprevent damage.

Note:Ifyouareusing an extension cable, besuretolocatethemated

3-pinconnectors wellabovethebilge waterline.Tofacilitatethis, use

cableclamps on either side oftheconnection.

Installation in a Cored Fiberglass Hull

Installationina cored hull is difficult.The objectiveis to bond the

sensortotheinsidesurfaceofthehull’souterskin whilepreventing

anymoisture from penetratingthe core.

CAUTION:

Thereisnowayto determine iftheouterskinis solid (no trapped

airbubbles inthe fiberglass)at the selected location before

cuttingthe inner skin.

WARNING:

Alwayswearsafetygogglesanda dust mask.

1. Usinga4"(100 mm)hole saw,cutthroughtheinner skin and the

coreat the selected location (see Figure2-18).Thecorematerial

canbe very soft. Applyonlylightpressure to the holesawafter

cuttingthroughthe inner skin toavoid accidentally cutting the

outer hull.

2. Removethe plug of core material,sotheinner core of the hullis

fullyexposed.Sand the inside surfaceof the outer skin using a

miniaturediscsander.Slightlyundercutthe surrounding coringif

possible.

3. Cleanand dry both theinside surface of theouter skin and the

housingwithaweaksolvent,suchasalcohol,toremoveanydust,

greaseoroil.

Page 44

38 Transducers for Fishfinders

CAUTION:

Donotproceedif thehulltemperatureisbelow60°F(15°C)since

thecuretimeofthecastingepoxywillbegreatlyextended.

4. Ifthe hull temperature is above60°F(15°C),mix a half cupof

castingepoxystirringcarefully to avoid trappingairinthe mixture.

Pourthis around the housing until the cavityisfull.Allow the

castingepoxyto set foratleast1 hour.

100 mm(4 in)

Transducer assembly

Hull thickness

Inner skin

Core

Outer skin

Fill with casting epoxy

D5006-2

Figure 2-18: Installation in a Cored Fiberglass Hull

5. Proceed with step7 of Installa tion on page 34.

Page 45

Chapter 2: Installation 39

2.4 Tr ansducer Cable Connections

Thetransducer cable connector (andY-connector,if supplied) has a

nutthat has been removedto aid installation. To allow youto

completethe installation withoutcutting the cable, ensurethat any

holesyou drill are largeenoughto accept the connector,with the nut

removed(approximately13/16" or 21mm).

Beforeattaching the transducer cable, you willneed to attach the

connectornutand split ring. These items,plusa wedge tool, are

included in the transducer packaging.

Connector/cable

Protrusion

Mounting groove

Nut

Split

Split ring

Wedge tool

Figure 2-19: Assembling the T ransducer Connector

CAUTION:

Takecarenottopullonthecable–this can damage the

transducer wires.

D5256-1

Page 46

40 Transducers for Fishfinders

➤ Toattach thetransducer cable connector:

1. Slipthe nut over the connectorcableend. Push it pasttheconnectorand over thecable.

2. Insertthewedge tool into thegrooveinthe split of the splitring

andslide the wedge tool untilitssquared end is flush with the

largeredge of the split ring.

3. Slipthe split ring and wedgetool over the connector bodyuntil

alignedwith the mounting groove ontheconnector.

4. Removethe wedge tool and seatthesplit ring in themounting

groove,making sure the connector protrusionfallsintothe split.

5. Slipthenut forward until it stops.Twist until the protrusions on

theinside of the nut alignwiththe grooves on the splitring.

6. Slipthe nut forward andsnapinto place.

Thetransducer cable isattached to the 7pin male connectormarked

TRANSDUCERonthefishfinder.How you connect thecableto theunit

dependson the type of transduceryou have installed:

• Combined depth/speed/temptransducershave a 7 pinfemale

connector.Attach the transducer cable connectordirectly to the

fishfinder.

• Combinedspeed/temperature transducers havea 3 pinfemale

connectorthat requires the use ofan additional Y -shapedcable

(RaymarinepartnumberE66022)toattachtothe 7 pin connector

on the fishfinder.ThisY-cable is included withyour speed/temperaturetransducer.

Attachthe7 pin female connector on the Y-cableto the fishfinder

unitthen attach the transducercable to the 3pinmale connector

on the Y-cable.

• Depth-onlytransducers have a 7pinfemale connector.

Attach the transducercable connector directlyto the fishfinder.

or

• Ifbeing installedinconjunction with a speed/temperaturetransducer,attach the 7pinfemaleconnectorontheY-cableto the fishfinderthenattachthetransducercabletothe7pinmaleconnector

on the Y-cable.

Note:If your system requires both a Y-cable and a transducer exten-

sioncable, ensure that you connecttheY-cable to the fishfinder and

theextension cable to thetransducer.

Page 47

Chapter 2: Installation 41

CAUTION:

Donot cut thetransducer cable orremovethe connector.Donot

tryto shorten orsplice the cable.Ifthe cable iscut, it cannotbe

repaired.Cuttingthe cable will alsovoidthe warranty.

Page 48

42 Transducers for Fishfinders

Page 49

Chapter 3: Maintenance 43

Chapter 3:Maintenance

Cleaning Instructions

Cleaning the Transducer

Seagrowth can collect quicklyonthe bottom of the transducer,this

canreducethe performance in justa few weeks. Topreventthebuildupof sea growth, coatthetransducer with a thinlayerof paint. Use

onlya water-based antifouling paint, orawater-basedpaint

specificallydesigned for transducers. Apply thepaint with a brush.

Ifyour transducer becomes fouled orstopsworking because of sand

orsea growth, use a stiffbrushtoclean it. Youmay sandthe surface

witha fine-grit wet ordry sandpaper (#320 grade orfiner),but this

will affect the performance ofthe unit when theboat is moving at

higherspeeds.

Thepaddle wheel mechanismmaybecome jammed bydirt,grit or

barnacles. Workthis out ofthe mechanism, then clean the unit with

soapand water oralcohol.

Cleaning the Hull

Usecautionwhen sanding or cleaning theoutsideofthehull near the

transducer.

CAUTION:

Harshcleaningsolventssuch as acetone maydamagethe

transducer.

Servicing and Safety

• Raymarineequipment shouldbe serviced only by authorized

Raymarineservice technicians. They will ensurethatservice proceduresand replacement partsusedwill not affect performance.

Thereare no user serviceableparts in any Raymarineproduct.

• Someproducts generate high voltages, so neverhandlethe

cables/connectorswhen power is beingsuppliedtothe equipment.

• Whenpowered,all electrical equipmentproduceselectromagnetic fields. These cancause adjacent pieces of electrical equipmentto interact with oneanother,with aconsequentadverse

effecton operation.

Page 50

44 Transducers for Fishfinders

• Inordertominimize these effects and enableyouto get the best

possibleperformancefrom your Raymarine equipment, guidelinesare given in the installationinstructions,toenableyouto

ensureminimum interaction betweendifferentitems of equipment, i.e., ensureoptimum Electromagnetic Compatibility

(EMC).

• Alwaysreport anyEMC-relatedproblemto your nearest Raymarinedealer.We use suchinformation to improve ourquality standards.

• Insome installations,it maynotbe possible to prevent theequipmentfrom being affectedbyexternal influences. In generalthis

willnotdamagetheequipmentbutitcanlead tospuriousresetting

action, or momentarily may result in faulty operation.

Problem Solving

Common Problems and Their Solutions

T able 3-1:Common T ransducer Problems

Problem Correction

Fishfinder display

“freezes”

Fishfind er does

not see bottom or

fish

Fishfind er does

not display fish

Fishfinder is unreliable at high boat

speeds

Fishfinder displays

a lot of background noi se

Fishfind er speed

or log readings are

wrong

Check the transducer cable for damage. If damaged, the c able and t ransduce r must be re placed

as a unit.

1. If you have a transom-mount transducer , check

that the transducer hasn’t kicked-up on hitting an

object.

2. Check that the transducer is within 10° of vertical.

3. Check that the transducer face is not covered or

fouled. If necessary clean the transducer .

Ensure the t ransducer is within 10 ° of vertical.

Turbulence around the transducer may be confusing the unit.

Check that the transducer is mounted correctly

and is clean.

Check that the transducer paddle wheel is clean.

Page 51

Chapter 3: Maintenance 45

How to Contact Raymarine

On the Intern et

Vi si tthe RaymarineWorld WideW ebsite forthelatestinformation

onRaymarine electronic equipment and systemsat:

www .r aymarine.com

Customer Support

Navigate to theCustomer Support page for links to:

• FindingFactoryService locations andAuthorized Dealers near

you

• Registeringyour Raymarineproducts

• Accessinghandbooks in AdobeAcrobatformat

• DownloadingRayTech software updates

• Accessingthe Raymarinesolutiondatabase

ClickingtheFind Answers linkroutesyou to our solutiondatabase.

Searchquestionsand answers by product,category, keywords,or

phrases.If the answer you areseeking is not available,clickthe Ask

Raymarinetab to submit yourownquestiontoourtechnicalsupport

staff, who reply to youby e-mail.

In the US

Accessories and Parts

Many Raymarine accessory itemsand parts canbe obtained directly

fromyourauthorized Raymarine dealer. However, if you arein need

ofan item notavailablefrom the retailer,pleasecontact Raymarine

T echnicalServicesat:

800-539-5539ext.2333,or

603-881-5200.

T echni calService isavailableMondaythrough Friday 4:00 AM to

6:00 PM Eastern Time.

PleasehavetheRaymarineitemorpartnumberreadywhencallingif

placinganorder.Ifyou arenotsurewhich item isappropriateforyour

unit, you should firstcontact the TechnicalSupport Department to

verifyyour requirements.

Page 52

46 Transducers for Fishfinders

Technical Suppo rt

For technical support,call:

800-539-5539ext.2444,or

603-881-5200.

OurTechnicalSupport Specialistsareavailable to answer questions

aboutinstalling,operating and trouble-shooting all Raymarine

products.

Questionscan be sent directly toourTechnicalSupport Department

viatheInternet.Point your browsertowww.raymari ne.comandclick

onthe Customer Support link. Fromthere, select Find Answers

and click the Ask Raymarine tab.

Product Repair and Service

IntheunlikelyeventyourRaymarineunitshoulddevelopaproblem,

please contact your authorizedRaymarine dealer for assistance.The

dealeris best equipped tohandleyour service requirements andcan

offertimesaving help in gettingthe equipment back intonormal

operation.

In the event that repairscan not be obtained conveniently, product

servicemay also be obtained by returningtheunitto:

Raymarine, Inc.

ProductRepair Center

22CottonRoad, Unit D

Nashua,NH03063-4219

TheProductRepairCenterisopenMondaythroughFriday8:15a.m.

to5:00 p.m. Eastern Time.Allproductsreturned to the Repair Center

areregistered upon receipt. Aconfirmationletter will be sentto you

acknowledgingtherepair status and theproduct’s referencenumber.

Shouldyouwishtoinquireaboutthe repairstatusofyourunit,contact

theProduct Repair Center at:

800-539-5539

Please have the product referencenumber,orunitserial number,

readywhen you call. We will doeverythingpossibleto make the

repairand return your unitasquickly as possible.

Page 53

Chapter 3: Maintenance 47

In Europe

InEurope, Raymarine support, service and accessoriesmay be

obtainedfrom your authorized dealer,or contact:

Raymarine Ltd

AnchoragePark

Portsmouth,Hampshire

EnglandPO3 5TD

Tel +44 (0)239269 3611

Fax+44 (0) 23 9269 4642

Technical Support

TheTechnicalServices Departmenthandlesinquiries concerning

installation,operation,faultdiagnosisand repair.Fortechnical

helpdesk contact:

Tel:+44 (0) 2392714713

Fax:+44(0) 23 9266 1228

Questionscan be sent directlytoour TechnicalSupportDepartment

viatheInternet.Point your browsertowww .raym ar ine.comand click

on the CustomerSupport link. From there,select FindAnswers

andclick the AskRaymarinetab.

Accessories and Parts

Raymarineaccessory items andparts are available throughyour

authorized Raymarine dealer .Please referto the lists of component

partnumbers and optional accessoriesin the Installation chapterof

thismanual, and have theRaymarine part number readywhen

speaking with your dealer.

Ifyou are uncertain aboutwhat item to chooseforyourRaymarine

unit, please contact ourCustomer Services Department prior to

placingyour order.

Worldwide Support

Pleasecontact the authorized distributor in thecountry.A listof

worldwidedistributorsissuppliedwith your system.

Page 54

48 Transducers for Fishfinders

Page 55

Index 49

Index

A

Accessories 6

B

Backing Block 19

C

Cable Runs 12

Installation Considerations 5

Cleaning Instructions 43

Connections

Transducer 39

Cored Fiberglass Hull - Transducer Installation 29, 37

E

EMC iv

Conformance iv

Installation Guidelines 2

F

Fairing 6, 17

H

Help from Raymarine 45

I

In-hull Transducer 1

Installation 31

Cored Fiberglass hull 37

Location 10

Installation

Cable Runs 5, 12

EMC Guidelines 6

In-hull Transducer 31

Location 5

Thru-hull Transducer 17

Transom Mount Transducer 15

L

Location

In-hull Transducer 10

Transducer 6

M

Maintenance 43

P

Problem Solving 44

S

Safety

and Servicing 43

EMC Guidelines 6

Servicing 43

T

Thru-hull Transducer 1

Installation 17

Location 10

Transducer

Applications 5

Cable 12

Connections 39

In-hull 1

Installation 15, 17, 31

Cored Fiberglass Hull 29, 37

Location 6

Thru-hull 1

Transom Mount 1, 7

Transducer Types 4

Transom Mount Transducer 1, 7

Installation 15

Cored Fiberglass hull 29

W

Warranty iv

Page 56

50 Transducers for Fishfinders

Loading...

Loading...