Page 1

Tiller Drive

Installation Guide

Document numbe r: 870 612

Date: Oct 2006

Page 2

Page 3

Tiller Drive 3

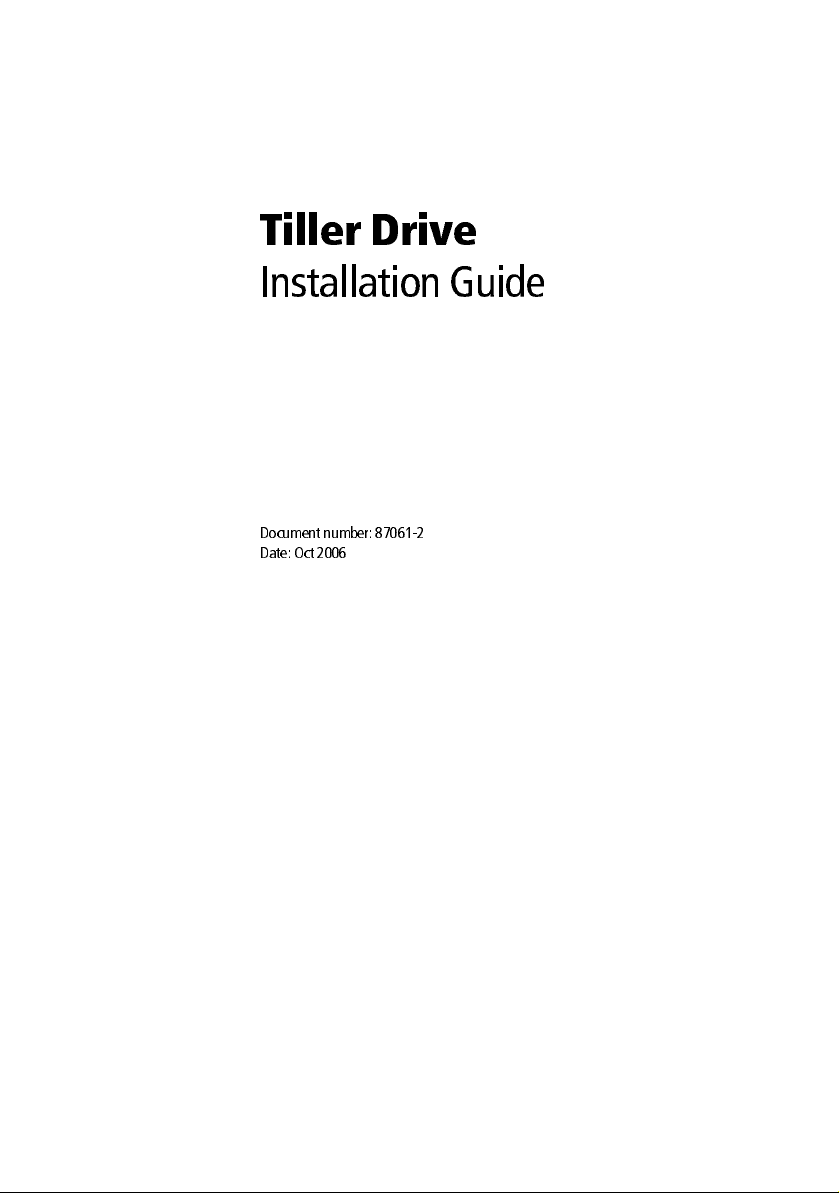

System layout

Tiller drive

Fluxgate compass

Control unit

Course computer

Boat's electrical

distribution panel

NMEA

instrument

or navigator

D8922-1

Page 4

4 Tiller Drive

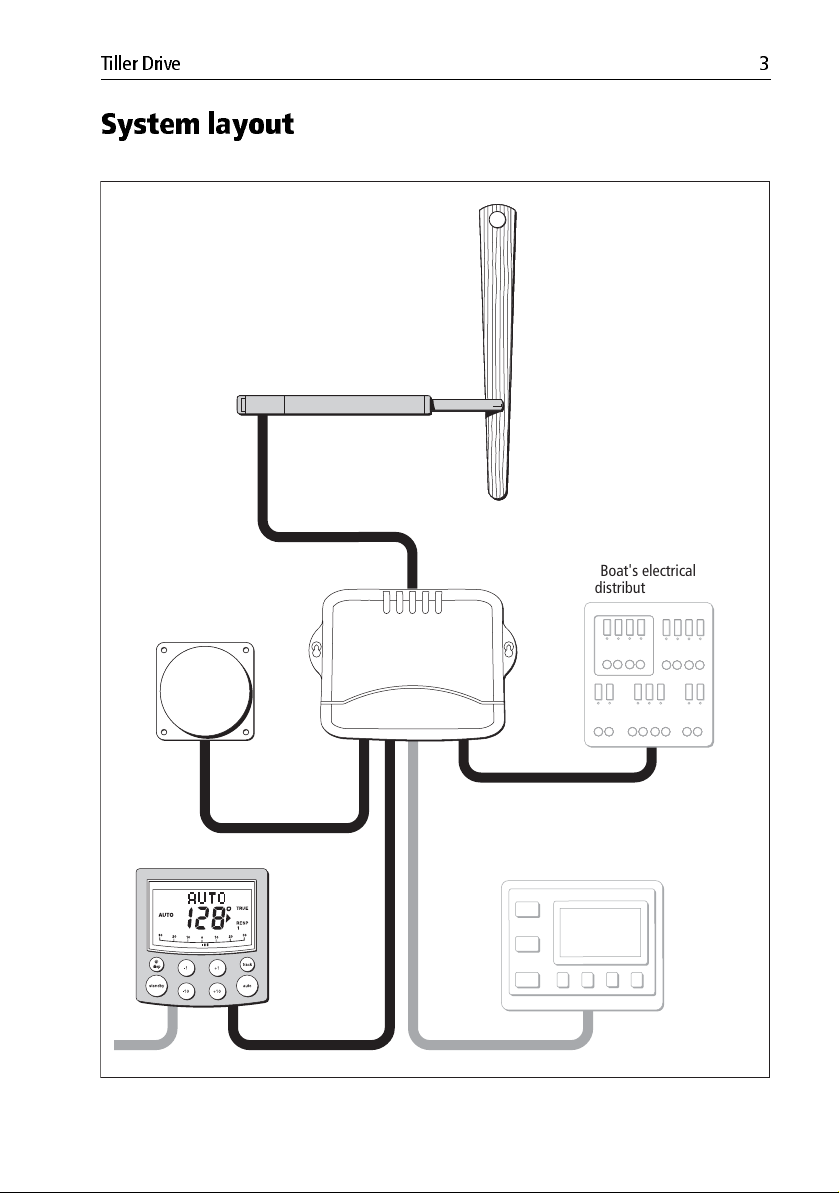

Parts supplied

Tiller drive parts

Plug

Cable clip

and screw,

No 6 x 1/2 in

Mounting

socket

Tiller drive

Tiller

pin

Socket

Socket screw

No 4 x 3/4 in (x2)

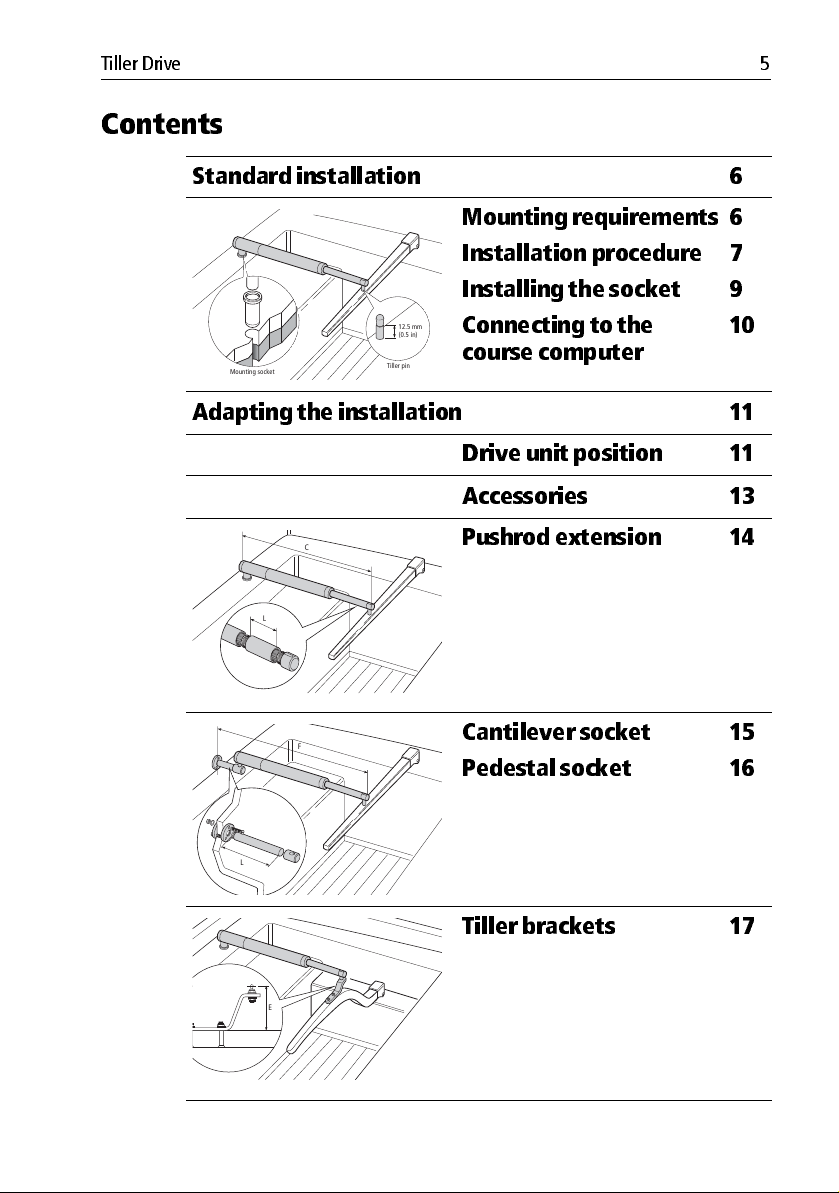

To ols requir ed

1. Drill

2. 2.5 mm (

3. Two part epoxy (Araldite) adh esive

4. Crosshead/po zidrive screwdriver

5. Slottedhead sc rewdriver

3

/32"), 6 mm(1/4"), 12.5 mm (1/2"), 18 mm (23/32") drill bits

D5437-2

Page 5

Tiller Drive 5

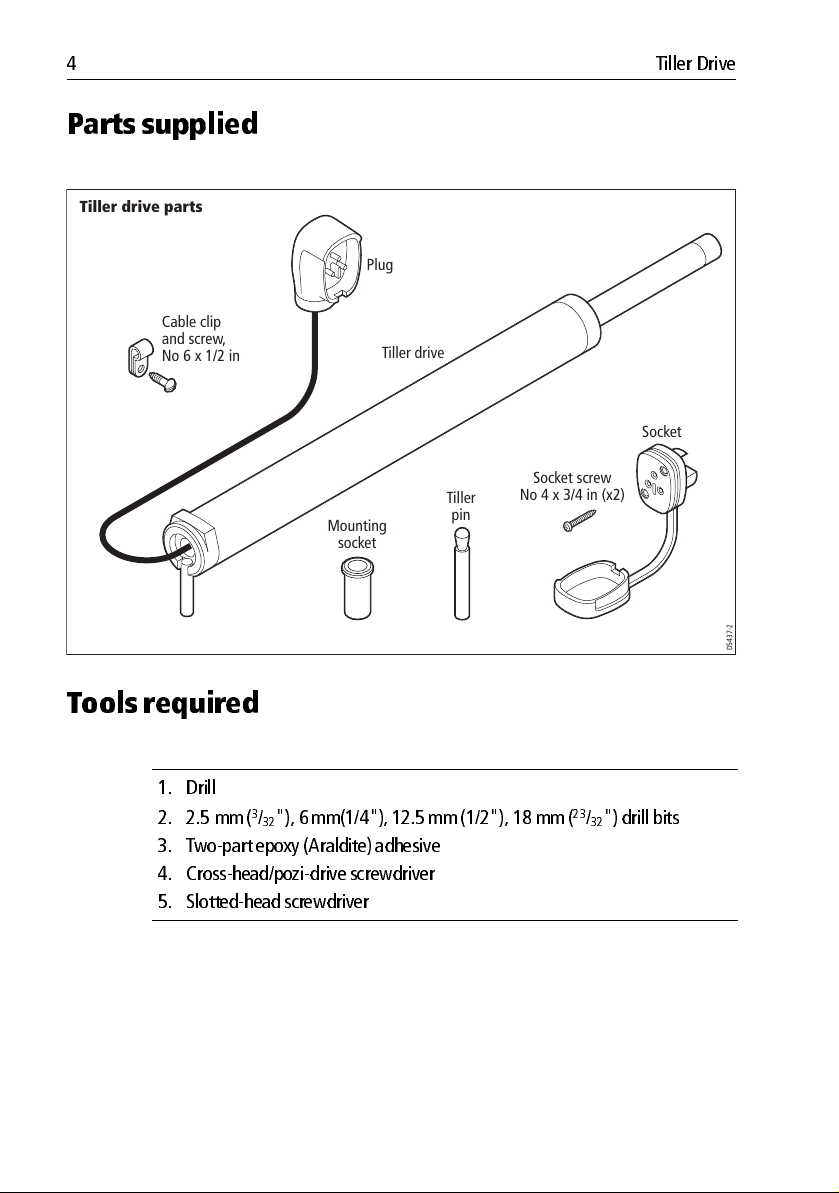

Contents

Standard installation 6

Mounting socket

Tiller pin

12.5 mm

(0.5 in)

Mounting requirements

Installation procedure

Installing the socket

Connecting to the

course computer

6

7

9

10

Adapting the installation 11

Drive unit position 11

Accessories 13

C

L

F

Pushrod extension 14

Cantilever socket

Pedestal socket

15

16

L

Tiller brackets 17

E

Page 6

6 Tiller Drive

Standard installation

Mounting requirements

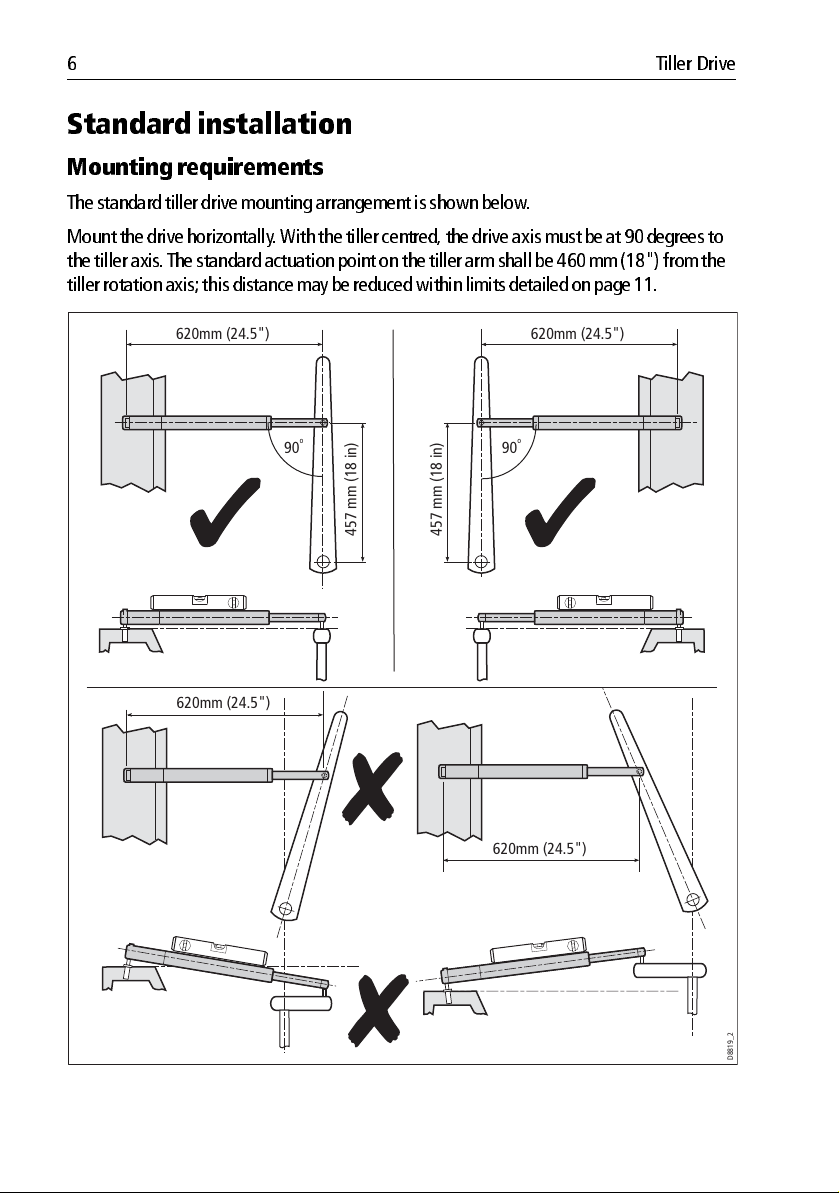

The standard tiller drive mounting arra ngement is shown below .

Mount the drive horizon tally . With the tiller cen tred, the drive axis must be at 90 deg rees to

the tiller axis. T he standard actu ation point on th e tiller arm shall be 460 mm (18") from the

tiller rotation axis; this di stance may be reduced with in limits detailed on p age 11.

620mm (24.5")620mm (24.5")

620mm (24.5")

o

90

457 mm (18 in)

457 mm (18 in)

o

90

620mm (24.5")

D8819_2

Page 7

Tiller Drive 7

The installat ion can be adapted to suit a wide variety of configu rations. See also:

•

Drive unit position page 11

•

Accessories page 13

Installation procedure

This proced ure can be followed when neith er accessories or adaption of the drive unit

position are required .

Install the tiller d rives as fo llows:

1. Securely clamp the tiller, mark the pin posit ion and drill the 6 mm (1/4”) hole .

2. Fix the pin in position using a twopart epoxy adhesive.

3. Check the shoulder heigh t of the pin.

1. 2.

Two part

457 mm (18 in)

6 mm

(0.25 in)

12.5 mm

(0.5 in)

3.

12.5 mm

(0.5 in)

Allow epoxy to fully harden

before applying load.

epoxy

adhesive

to fix tiller

pin in

place

4. Mark the sock et position and drill a 6 mm (1/4“) pilo t hole to con firm the thickness of th e

structure. If less than 25 mm, rei nforce with plywood and bond into position. Once cu red

open up the hole diam eter to 12.5 mm (1/ 2”).

5. Fix the sock et in position using a twopart epoxy adhesive .

D8818-2

Page 8

8 Tiller Drive

6. Once the epoxy has fully hardened, fit the tiller dri ve.

4.

620 mm (24.5 in)

457 mm (18 in)

12.5 mm

(1/2 in)

25mm

(1.0 in)

5.

6.

Two part

epoxy adhesive

to fix mounting

socket in place

D8831_2

Page 9

Tiller Drive 9

Installing the socket

1. Cutout and tape the temp late to the bulkhead in the req uired position.

23

2. Drill a 18 mm (

3. Lift off the template remove burrs or shar p edges.

4. Pass th e cable through the bu lkhead and attach to th e socket, makin g sure you connect

each core to the correct pin .

Attach the sock et to the bulkhead usin g the two selftapping screws . Use cable clamps to

secure the drive cable at regular interv als.

/32”) clearance hole and two 2.5 mm (3/32”) pilot holes .

Rear of socket

Drive (blue)

3 stripe terminal

To the

control unit

Tiller drive - socket template

Drill 2.5 mm (3/32 inch)

diameter hole (2 positions)

Terminal

identification

stripes

Drive (brown)

2 stripe terminal

D8840-1

Drill 18 mm (23/32 inch)

diameter hole

D5411-2

Page 10

10 Tiller Drive

Connecting to the course computer

The tiller drive is supp lied with a cord and plug. T o connec t the drive and course computer , the

supplied sock et should be in stalled and a cable ro uted from the sock et to the course comp uter .

1. Measure the required leng th of cable and select the correc t gauge using the follo wing

table:

Cable le ngth Copper are a AWG

Up to 2 .5 m (8 ft)

Up to 4 .0 m (13 ft)

Up to 6 .0 m (22 ft)

1.0 mm

1.5 mm

2.5 mm

2. Route the cable from the so cket to the course co mputer .

Course computer

2

2

2

18

16

14

SEATALK

Brown

POWER IN

RF GND

Blue

D9446-1

Page 11

Tiller Drive 11

Adapting th e installatio n

Drive unit position

The tiller pin and drive pedestal can be mounted between 356 mm and 457 mm (14” 18”)

from the centre of the ru dder stock. 45 7 mm (18”) is the sta ndard distance fo r use on vessels

up to:

• 6 tonnes fully laden d isplacement for the standa rd tiller drive unit.

• 7.5 tonnes fully la den displacement for th e GP tiller drive unit.

Note:

Typically laden displacement is up to 20% greater than manufacturers’ disp lacement figures.

For lighter d isplacement vessels requiring faster turn rates it is possible to i nstall the tiller pin

and drive pedestal closer to the ru dder stock, to a minim um of 356 mm (14“).

Tiller Drive Unit Position Range

620mm (24.5")

90˚

356 mm to 457 mm (14 in to 18 in)

D9291_1

Page 12

12 Tiller Drive

The following table can be used to calcu late the required position .

Drive pin

distance from

rudder stock

457 mm (1 8”)

standard d istance

432 mm (17” ) 33º 8 º per second 79 kgf

406 mm (16” ) 35º 9 º per second 75 kgf

381 mm (15” ) 37º 9 º per second 70 kgf

356 mm (1 4”) 39 º 10 º per second 65 kgf

Max degre es of

helm (with pilot

engaged)

31º 8 º per second 84 kgf

Rate of helm

change Force a t rudder

Page 13

Tiller Drive 13

Accessories

The following accessories may be used to ad apt the tiller drive mountin g to suit different

installation requi rements.

Part Number Description

D003 Pushro d Extens ion 25mm (1")

D004 Pushro d Extens ion 51mm (2")

D005 Pushrod Ext ension 76 mm (3")

D006 Pushrod Extension 102 mm (4")

D007 Pushrod Extension 127 mm (5")

D009 Tiller Br acket 2 5 mm (1")

D010 Tiller Br acket 5 1 mm (2")

D011 Tiller Br acket 7 6 mm (3")

D159 Tiller Br acket 1 02 mm (4")

D160 Tiller Br acket 1 27 mm (5")

D031 Cantilever Sock et

D026 Pedes tal Sock et 38 mm (1.5")

D027 Pedes tal Sock et 51 mm (2")

D028 Pedes tal Sock et 64 mm (2.5")

D029 Pedes tal Sock et 76 mm (3")

D030 Pedes tal Sock et 89 mm (3.5")

D002 Mounting Socket (package of 5 )

D014 Small Thread T iller Pin (package of 5)

D001 Tiller P in (package o f 5)

D014 Small threaded tiller pin 25 mm (1")

D020 Extra leng th tiller pin 71mm (2.8 ”)

D021 Extra leng th thr eaded tiller p in 71mm (2.8” )

Page 14

14 Tiller Drive

Push rod extension

Use a pushrod extension if dimensi on C is greater than 620 mm (24.5”).

1. Select a pushrod extensio n with a length L nearest to C 62 0 mm (24.5”)

2. Unscrew the pushrod end cap

3. Screw on the pushro d extension

4. Screw the pushrod end cap onto the pushr od extension.

C

L

D8812_1

Page 15

Tiller Drive 15

Push rod mountin g

Cantilever socket

Use the cantilever socket if you need to attach the tiller drive to a vertical face (suc h as the

cockpit sidewall).

F

L

1

6_

1

8

8

D

1. Use a hacksaw to cut the rod to length L = F 635 mm (25”).

2. Assemble the mountin g ring, rod and socket.

3. With the drive horizonta l mark the location of the mo unting ring and its holes.

4. Drill three 6 mm (1/4”) diameter clearance holes at th e marked positi ons.

5. Apply a thin co at of silicone sealant to the base of th e mounting ring.

6. Use three 6 mm (1/4” ) diameter bolts , nuts an d washers to att ach the mount ing ring and

backing plate

7. Roughen the en d of the rod and inside of the sock et to provide a key . Then a pply twopart

epoxy adhesive to the rod end an d cap.

8. Place the cap over the rod end, making sure the hole faces upw ards. A llow the adhesive

to harden fully before ap plying a load.

Note:

Note: When the autop ilot is not in us e, you can unscrew the complete rod assembly to leave the

cockpit unobstructed

Page 16

16 Tiller Drive

Pedestal socket

Use the pedestal socket if yo u need to raise the height of the sock et to keep the tiller drive

horizontal.

L

G

1. Select a sock et assembly with a length L, nearest to G 38 mm (1.5” ).

2. With the drive assembled , and the sock et positioned 460 mm (24.5”) from the til ler axis

mark the location of the mounting rin g and holes .

3. Drill three 6 mm (1/4”) diameter clearanc e holes at the marked positions .

4. Apply a th in coat of silicone sealant to the base of the mounting ring.

5. Use three 6 mm (1/4”) diameter bo lts, nu ts and washers to attach the mo unting ring and

backing pla te

Note:

Note: When the autop ilot is not in us e, you can unscrew the complete rod assembly to leave the

cockpit unobst ructed

D8817_!

Page 17

Tiller Drive 17

Tiller brackets

If the tiller is h igher or lower than the mou nting sock et, you can use a til ler bracket to vary th e

tiller pin height so the d rive is horizontal.

D

D8813_1

E

1. If the drive is below the tiller; brack et size equals dimen sion D . If the drive is above the

tiller; brack et size equals dimension E 25 mm (1”).

D8814_1

Page 18

18 Tiller Drive

2. Place the tiller brac ket on the center lin e of the tiller (above or below) and establish the

correct positio n.

3. Mark the centers of the brack et mounting holes.

4. Drill two 6 mm (1/4”) diameter clearanc e holes through the center li ne of the tiller at the

positions ma rked.

5. Attach the tiller b racket using two 6 mm (1/4“) diam eter bolts, n uts and washers.

6. Fix th e bolts in position using twopart epoxy adhesive .

7. When the epoxy is com pletely hardened, fully tighten the nuts .

457 mm (18 in)

90 degrees

D8815_2

Loading...

Loading...