Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

Installation & Operating Handbook

Nautech Limiied, Anchorage Park, Portsmouth

Telephone (0705) 693611, Telex 86384 NAUTEC G.

Hampshire, PO3

STO,

England.

Page 3

CONTENTS

Page

1. General Description

1.1.1 Course Computer

1.1.2

Control Unit

1.1.3 Fluxgate Compass

1 .1.4 RuddepReference Transducer

1.1.5

Auxiliary Alarm

1 .1.6 Radio Navigation Interface

Hydraulic Drive Units

1.2

1.2.1 Type 0 Hydraulic Drive

1.2.2 Type 1 Hydraulic Drive

2. Installation

2.1 .l Course Computer

2.1.2 Control Units and Radio

Navigation Interface

2.1.3 Fluxgate Compass

2.1.4 Rudder Reference Transducer

2.1.5

Accessories

Hydraulic Drive Unit

2.2

2.2.1 Type 0 Installation

2.2.2 Type 1 Installation

2.3 Cabling and Power Supplies

2.3.1 Signal Cabling

2.3.2 DC Power Supplies

3. Operation

3.1

Basic Principles

3.2 Controls

3.2.1 Fixed Control Unit

3.2.2 Hand Held Control Unit

3.2.3 Operating Mode Indication

and Course Display

3.2.4

Off-Course Alarm

Functional Test Procedures

3.3

3.3.1 Setting Up

3.3.2 Functional Test Procedure

3.3.3 Drive Unit Test Procedures

10

11

12

13

13

14

14

15

17

2

3

3

3

4 8.

4

4

5

5

10.

5

6

7

7

9

17

18

18

19

20

21

21

21

21

22

6.

Maintenance

Fault Location Procedure 27

7.

Warranty, After Sales

Service

U.K. Service Centres 30

9.

Overseas Representatives 31

26

28

4.

Sea Trials

First Sea Trials

4.1

Rudder Control Adjustment

4.2

5. Operating Hints

5.1

Unsatisfactory Steering

Performance

23

23

24

25

25

Page 4

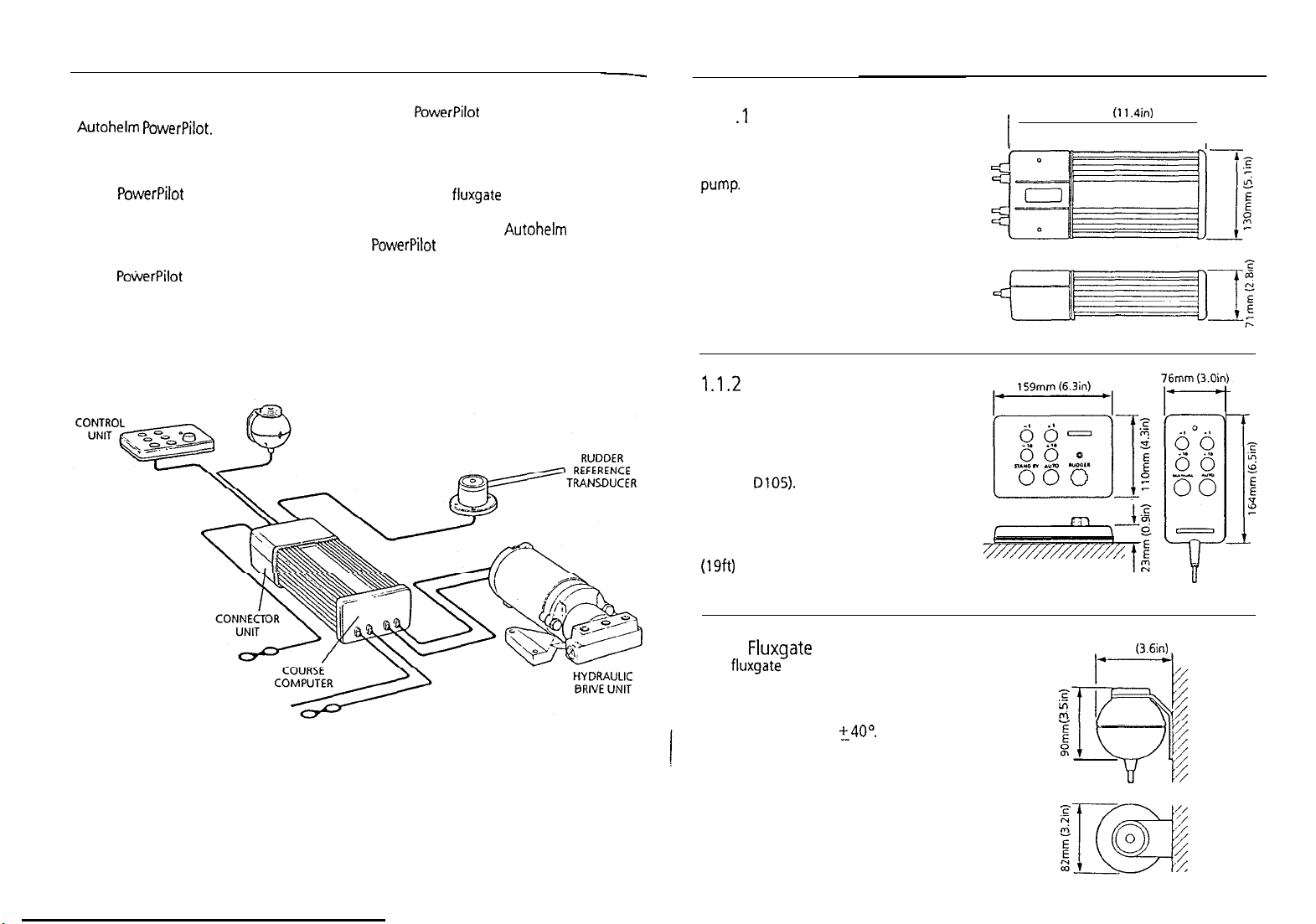

1. GENERAL DESCRIPTION

Congratulations on choosing the

Autohelm

outstanding self steering capability for a

wide range of modern powercraft

equipped with hydraulic steering.

The PowerPilot uses microprocessor

based technology and easy to use control

pads to give you total command under

autopilot control without the need for

constant adjustments.

The

world’s largest producer of Marine

autopilots with Technical Advice, Service

and Support ready to help you get the

most from your Autohelm.

PowerPilot.

PotierPilot

It offers

is manufactured by the

FLUX GATE

The PowerPilot is modular and designed

for easy installation with flexibility to cope

with the variation of individual craft and

owner specifications. It is supplied as

standard with the course computer, one

control unit, fluxgate compass, hydraulic

drive unit, and rudder reference

transducer. The basic

PowerPilot can be extended to suit

individual requirements. The basic system

is illustrated below in Figure 1.

Autohelm

1.1 .l Course Computer

The course computer houses the

microprocessor, electronic control circuitry

and power amplifier to drive the hydraulic

pump.

The course computer is splash proof

only and must be mounted in a dry and

protected position.

1 .1.2

Control Unit

The six button control unit is fully

waterproof and is mounted close to the

steering position. It is designed for surface

mounting, or alternatively can be bracket

mounted if required (bracket mounting kit

Cat. No. D105).

A second control unit (Cat. No. 2054)

and a hand held control unit (Cat. No.

2056) can be added to the system. The

hand held control unit is fitted with a 6m

(19ft) wander lead and plugs into a

bulkhead mounted waterproof socket.

288mm

(11.4in)

I

II

Fig. 1 BASIC SYSTEM

2

1.1.3 Fluxgate Compass

The fluxgate compass has been especially

developed for marine application. The

compass contains a gimbal mechanism to

permit accurate readings with pitch and

roll movements up to

is bulkhead mounted below decks and

connects directly to the course computer.

t40°.

The compass

92mm

(3.6in)

z

”

”

3

Page 5

1.1.4 Rudder Reference

Transducer

The rudder reference transducer provides

the course computer with a precise

rudder position. It is mounted on a

suitable base adjacent to the rudder

stock. The interconnecting cable connects

directly to the course computer connector

unit.

1.1.5 Auxiliary Alarm (Cat. No. 2035)

The autopilot is provided with an

automatic off course alarm system which

sounds from all control units and provides

sufficient audible warning under most

conditions. In cases where a high power

alarm is necessary, an auxiliary alarm can

be fitted. The auxiliary alarm is connected

to the main connector unit via a two

core cable.

1.1.6 Radio Navigation Interface

(Cat. No. 2057)

The PowerPilot can be interfaced to any

Loran, Decca or Satellite Navigation

receiver having a suitable cross track error

output to NMEA0180/0182/0183. The

radio navigation interface computes the

course adjustments to enable the

PowerPilot to steer to a selected waypoint.

The unit is waterproof and designed for

surface mounting (normally adjacent to

the Loran/Satellite Navigation receiver). If

required the unit can be bracket mounted

using the bracket mounting kit

(Cat. No. D104).

4

-1

82Smm

(3.2%)

213mm (8.37in)

1.2 HYDRAULIC DRIVE UNITS

The PowerPilot is available with one of

two hydraulic drive units, depending on

the size of the vessel and the

displacement of the ram.

The vessel size and displacement

recommendations given below apply to

directly driven steering systems. When a

power steering system is fitted the vessel

1.2.2 Type 1 Hydraulic Drive

The hydraulic drive unit consists of a

precision gear pump with integral valve

block driven by a continuously rated servo

motor. The pump drive motor is connected

directly to the course computer which also

regulates peak pump pressure and

eliminates the need for end stroke limit

switches.

size and displacement recommendations

can be ignored.

1.2.1 Type 0 Hydraulic Drive

The type 0 hydraulic drive unit consists of

a twin cylinder piston pump powered by a

small but powerful reversing electric

motor.

The high volumetric efficiency of the

piston pump provides precise control,

with the twin pistons offering smoother

and quieter operation than would be

found with a single cylinder design.

Descriotion Size

Maximum Vessel Size 8m

Maximum Vessel

Displacement 3000 Kq (6600

Maximum Ram Capacity

Minimum Ram Capacity

Regulated Peak Pressure

Peak Flow Rate (Unloaded) 490cdmin (30inYmin1

Power Consumption

(Typical Averaqe)

km

Type

Double Ended (Balanced)

(26ft)

13Occ (8.0ina)

5Occ (3in’)

30 bar (450lb

1.5-2.5 amps

Ibs)

in?)

Description Size

Maximum Vessel Size 1 lm (36f~)

Maximum Vessel

Displacement 5500 Kg (12000

Maximum Ram Caoacitv 23Occ (14in’)

Minimum Ram Capacity

Reaulated Peak Pressure

Peak Flow Rate

(Unloaded)

Poher Consumption

(Typical Average)

Ram Type

I-

13Occ (8inj)

50 bar (75ODs.i)

11

OOcdmin)

(67inYmin

3.5-6 amps

Single or Double Ended

(unbalanced or balanced)

190mm (7.5in)

Ibs)

w

Page 6

2.

INSTALMTION

WARNING

The Autohelm PowerPilot requires correct

installation if it is to provide accurate safe

self steering. Whilst designed for simple

installation we strongly recommend that

the system should be installed

professionally or alternatively professional

advice be obtained if you intend to install

the system yourself.

The manufacturers can accept no

liability for any claims arising from

incorrect installation or product useage.

2.1.1 Course Computer

Mounting Position - Below Deck

The course computer should be positioned

in use we strongly recommend the use of a

protective cover (optional extra

Cat. No.

in a dry protected area of the vessel free

from high operating temperatures and

excessive vibration. It can be mounted in

any attitude. Care must be taken to allow

at least

15mm

(6in) clearance all round to

aid heat dissipation from the power

amplifier in the unit. Do not mount in the

engine room.

WARNING

Safe operation of the PowerPilot requires

that the control unit be mounted within

easy reach of the helmsman when in the

normal steering position. Position the

control unit to ensure this requirement is

met.

DO NOT position the course computer

so that it will:

l

Receive any direct water splash/spray

(from Bilge/Hatch etc).

l

Be liable to physical damage from heavy

items.

0

Be covered by other equipment or

Mounting Instructions

The unit is attached with reusable positive

locking pads. In most cases, the pads may

be stuck directly onto the mounting

surface.

l

onboard gear.

l

Be close to major sources of

transmitted energy (Generators/S%

radios, Aerial Cables etc).

Mounting Instructions

l

Remove Terminal box lid (Fig. 2).

l

Unscrew two internal thumb retaining

l

nuts (Fig. 2).

l

Unplug terminal box and mounting

spine.

l

Position terminal box and mounting

spine in correct location, mark off and

pilot drill for the 5 self tapping screws

supplied (Fig. 3).

l

Screw terminal box and mounting spine

into place.

l

Plug course computer unit to terminal

box. Retighten thumb retaining screws.

The course computer is now ready for

wiring (see 2.3).

DlOl).

Using the template supplied, select the

control unit position, mark off and drill

the

17mm (5/8in)

hole for the

interconnect cable.

Attach the positive-lock pads to the rear

of the control unit (Fig. 4).

2.1.2 Control Units

Mounting Position

be mounted close to the steering stations.

The unit is fully water-proof and suitable

for external location. If the control unit is

permanently exposed when the boat is not

-

Control units must

l

Thoroughly clean the mounting surface

with alcohol (or equivalent) and allow

to dry.

7

Page 7

Instructions

l

Thread the interconnect cable through

the

17mm

(518in) hole, peel off the

l Using the template supplied mark off

backing from the pads (Fig. 5).

l

Press the unit onto the mounting

surface maintaining pressure for 30

l

seconds to ensure a strong bond.

The control unit interconnect cable is

l

now ready for connection to the course

computer (See 2.3).

l Note An additional foam seal must be

Where the control unit is to be mounted

to a painted, varnished or untreated wood

l Carefully align the control unit with the

surface the carriers supplied should be

used to provide a sound bonding surface

for the

mounting

pads.

(Fig. 6).

and drill the 17mm

(518in)

hole and

mark off and pilot drill the fixing holes

for the carriers.

Screw the holders

inio

position using

the self tapping screwS provided.

Clean the holder surface with alcohol

(oiequivalent) and stick the positive

lock pads into place (Fig. 6).

used in this method to provide sealing.

holders and press firmly into place to

secure a positive attachment.

Removing a Control Unit

l

Using a flat lever gently unlock the

securing pads starting at one corner.

l

Do not use excessive force.

0

The unit may be re-attached by

pressing

it’back

onto the security pads.

fluxgate

(2ft6in)

compass in order to avoid deviation of

both compasses. The

be positioned as far away as possible from

large iron masses, such as the engine and

2.1.3 Fluxgate Compass

The

fluxgate

a convenient bulkhead using the self

tapping screws provided. Unscrew the top

cap to release the compass housing from

the mounting bracket (Fig. 7). Screw the

bracket to the bulkhead using the self

tapping screws provided and finally

attach’the compass body to the mounting

bracket.

Correct positioning of the fluxgate is

crucial if ultimate performance from the

autopilot installation is to be achieved.

The

compass may be attached to

fluxgate

should ideally be positioned

re-

other magnetic devices which may cause

deviation and reduce the sensitivity of the

sensor. If any doubt exists over magnetic

suitability of the chosen site, the position

may be surveyed using a simple hand

bearing compass. The hand bearing

compass should be fixed in the chosen

position and the vessel swung through

360°. Relative differences in reading

between the hand bearing compass and

the vessel’s main steering compass should

ideally not exceed 5O on any heading.

Fig.

as near as possible to the pitch and roll

centre of the vessel in order to minimise

gimbal disturbance (Fig. 8).

Fig. 7

It is very important to ensure that the

is positioned at least 0.8m

away from the vessel’s steering

fluxgate

must also

8

.

0.3c to 0.5L

.

-I

L

I

+i

Fig.

6

When the installation is complete the

fluxgate

compass should be

approximately aligned with the vessel’s

centre line by rotating the body until the

arrows on the joint line face the bows

(Fig. 9).

8

9

Page 8

Fig. 9

the rudder reference unit arm and tiller

arm. If it is more convenient, the rudder

reference unit may be mounted upside

down (label downwards), but if this is

done, the red and green wires must be

reversed in the connector unit.

It is important to ensure that

dimensions A and B (fig. 11) are the same

at both points and that when the rudder

is amidships the unit arm is opposite the

cable gland and makes an angle of

90°

with the connecting bar.

2.1.5 Accessories

The most comprehensive installation is

illustrated below in

Fig.

12

CONTROL

fle

Fioure

=c5

12.

FLUX GATE

-

”

RADIO NAVIGATION

INTERFACE

RUDDER

Fig. 11

Installation Precautions

Correct installation of the course

computer and fluxgate compass is vital to

the successful performance of the

Autohelm Pow&Pilot. The installation

A

precautions must be heeded if poor

performance or even failure of the

autopilot is to be avoided.

2.1.4 Rudder Reference

Transducer

The rudder reference unit must be

mounted on a suitable base adjacent to

the rudder stock (Fig. 10) using the self

tapping screws provided. The base height

must ensure correct vertical alignment of

Fig.

10

TILLER

AR,M

8

I

I

B

y-

.

I

I

I

e

/

-

r-l

A

400

Having selected a suitable position

(Fig.

lo),

the interconnecting link A may

be cut to length and the linkage fastened

ensuring that the locking nuts B are

secure. The tiller arm should be tapped

M6 to a depth of

2Omm

(13/l 6in) or

through drilled to accept the ball joint

supplied. The rudder should then be

moved from side to side to ensure the

linkage is free from any obstruction,

Radio Navigation Interface

(Cat. No. 2057)

This is installed using the same procedure

as given for the control unit. (See 2.1.2).

Auxiliary Alarm (Cat. No. 2035)

The auxiliary alarm unit is waterproof and

may therefore be mounted in any

position. The alarm unit is supplied with a

terminal block to connect a two core

Remote Control Unit

The remote control socket is pre-wired

with the interconnecting cable. A 22mm

(7/8in) diameter hole should be bored

through the mounting panel and the

interconnection cable to the course

computer. A 22mm

bored through the mounting panel/deck

to pass through the two way connector

block and interconnecting cable (Fig. 14).

socket screwed into position using the

four self tapping screws provided (Fig. 13).

screwed into position using the four self

tapping screws provided. A foam seal on

the alarm mounting flange will ensure a

watertight joint to the mounting surface.

Fig. 14

HYDRAULIC

DRIVE UNIT

(718in)

hole

should.be

Finally, the alarm unit should be

11

Page 9

2.2 HYDRAULIC DRIVE UNIT

General guidelines

The hydraulic drive unit should be

mounted clear of spray and the possibility

of immersion in water. It should be

located as near as possible to the

hydraulic steering cylinder. It is important

to bolt the hydraulic drive unit securely to

a substantial member to avoid any

possibility of vibration that could damage

the inter-connecting pipework.

There are three basic types of hydraulic

steering system, and these are illustrated

in Fig. 15. Typical connection points for

the drive unit are shown in each case. In

all cases it is strongly recommended that

the steering gear manufacturer be

consulted.

Minimisation of hydraulic fluid loss

during connection of the drive unit will

help to reduce the time and effort

required later to bleed the system of

trapped air. Absolute cleanliness is

essential since even the smallest particle

of foreign matter could interfere with the

correct function of precision check valves

in the steering system.

Fig. 15

:

T.40 Line

System

%

RESERVOIR

completed the hydraulic pump may be

operated by switching the control unit to

Auto and operating the +

course change buttons. Greater motor

movements will be obtained if the rudder

control is set to maximum.

bled according to the manufacturer’s

instructions. From time to time during the

bleeding process the drive unit should be

run in both directions to clear trapped air

from the pump and inter-connecting pipe

work.

steering will feel spongy particularly when

the wheel is rotated to the hardover

position. Trapped air will severely impair

correct operation of the autopilot and the

steering system and must be removed.

has not been necessary to keep track of

the connection sense to the hydraulic

steering circuit since operating sense of

the autopilot can be corrected if necessary

by reversing the pobrity of the pump drive

motor connections (see section 3.3.1).

When the installation has been

10”

and - 10’

The hydraulic steering system should be

If the air is left in the system the

During the installation of the system it

r(

2.2.1 Type 0 Installation

The Type 0 pump must be mounted

vertically with the mounting flange bolted

to a suitable horizontal surface using four

6mm

(114in)

All ports are tapped

1/8in B.S.P. to 1/4in

included to convert to

bolts.

1/8in B.S.P.

N.PT.

adaptors are

N.PT.

where

Three

required. The sealing washers supplied

should be placed between the fitting and

the pump (Fig. 16).

It is recommended that

1/4in

fittings or

larger are used throughout to minimise

transmission losses.

Fig. 16

’

STEERING

CYLINDER PORTS

l/h B.S.P.

SEALING

The two cylinder ports are positioned

opposite one another on the pump body.

The reservoir port is marked R and is at

45“.

All connections to the pump should

be made with flexible hose.

Important Note

All connections in the reservoir line

must be sound as any air introduced

to this line will seriously degrade

pump performance.

Bleeding

The type 0 pump is sensitive to trapped

air, and care must be taken during

installation and commissioning to remove

it. Before connecting the hoses to the

pump:

bleed the system, turn the helm pump in

opposition. This will help any air expelled

from the hydraulic pump rise to the helm

pump reservoir.

2.2.2 Type 1 Installation

The Type 1 pump should be mounted on a

suitable horizontal surface.

114in B.S.P.

included to convert to

required (Fig. 17). The sealing washers

supplied should be placed between the

fitting and the pump (Fig. 18).

l

Ensure all hoses are filled with oil

l

Prime the pump ports with oil

When operating the hydraulic pump to

All ports are tapped 1/4in

to

114in N.PT.

Fig. 17

B.S.P.

Three

adaptors are

N.PT.

where

l/din N.P.T. FirriNG

N.PT. ADAPTOR

SEALING WASHER

Page 10

.

I

2.3 CABLING AND POWER

SUPPLIES

2.3.1 Signal Cabling

Cable interconnections between all sub

system modules are shown schematically

(in Figs 1 and 12). All peripheral units

connect to the connector unit where they

are permanently hard wired to

coded connector blocks situated on a

central printed circuit board (Fig. 19).

fitted with ten blanking discs (Fig. 20).

which are easily pressed out and replaced

with each peripheral unit fixing kit

/T

-----T

colour

The end face of the connector unit is

by the special rubber grommets supplied

_

,

_

Fig.

21

KEY

40mm

0 WHlTE

0

YELLOW

0

GREEN

@RED

e

BROWN

(Fig. 2 1). After cutting the

interconnecting cable to length (Fig. 21),

it may be passed through the inserted

rubber grommet and prepared for

connection to the relevant connector

block (Fig. 19).

Each connector block is clearly

identified on the printed circuit board and

each wire position is identified by

coloured

dots which match the individual

wire colours. The cable screen should be

connected to terminals identified by a

white dot.

Each peripheral unit is supplied with 6m

(20ft) of interconnecting cable. Additional

cabling can be supplied in

lengths as

Cat. No.

DO06

(Two

DO87

flhree core screened)

DO88

(Four core screened)

follows:-

core unscreened)

12m (4Oft)

Used On

Alarm, Electronic

power supply and

Clutch

Control

units,

Radio Navigation

Interface

Fluxgate Compass

and

cut

The total length of screened core cable

connected to the serial bus (connectors

Al

-A5)

should not exceed 30m (1

OOft).

Similarly, the total length of

interconnecting cable to the

fluxgate

should not exceed 2Om (60ft). If it is

necessary to exceed the above maximum

length recommendations, please consult

Nautech’s Product Support Department

for specific advice. In general the length

of interconnecting cables should be kept

to an absolute minimum to reduce the

possibility of interference by other

electronic equipment.

All cables should be run at least 1 m

(3ft) from existing cables carrying radio

frequency or pulsed signals, and should

be clamped at

0.5m

(1 .Sft) intervals.

2.3.2 DC Power Supplies

(Fig. 22).

Flexible connection tails fitted with

insulated spade connectors are

with the course computer to connect

main power

supply

(Blue and Brown) and

drive unit motor connections (Red

Black).

All four flexible wire tails are

preconnected to a four-way heavy duty

terminal block for connection to the main

power cabling. Similarly, the drive Ullil

supplied with flexible tails for the motor

power connection (Red and Black).

Before commencing power cabling,

interconnecting terminal blocks should be

screwed into a position where they

remain dry and protected. When pl,~nning

the position of the course computer

(ref.2.1.1).

it is important to reduce

overall length of heavy power cable

between the drive unit and the vessel’s

central power distribution panel to a

minimum.

Excessive lengths will generate losses in

the cable and will reduce system

performance. In addition, the cable

between the course computer and drive

unit must be less than 5m (16ft).

Having sited the course computer,

measure the total cable length between

the drive unit and the vessel’s central

distribution panel and select the

appropriate cable size from the table

below.

Total

Cable

Length

Up to 7m

Up to 1

Up to 16m 8410.3

Cable

Type

5010.25

Om 5610.3

Copper

2.5mm’

4.0mmz

6.0mml

Area

SUpplicd

a111j

will

the

Cable

Gauge

14 f’!J’srG

12

lOAWG

ttle

iS

all

length

AV’&

Page 11

3. OPERATION

The power supply must be led from the

main distribution panel and protected by

means of a 25 amp fuse or current

overload trip switch. A separate 5 amp

fuse must be fitted in the electronic

power supply cable.

Fig.

22

CIRCUIT BREAKER

25AMP- 12V

HEAVY

DUTY

POWER SUPPLY

OUTPUT

TO MOTOR

It is very important that both the

electronic and heavy duty power supplies

are isolated by a switch in the positive

supply line.

When connecting the power supplies to

the main distribution panel and to the

course computer spade connectors, it is

essential that the polarity is correct

(Brown positive, Blue negative).

ELECTRONIC

POWER

SUPPLY

3.1 BASIC PRINCIPLES

The following description of the

Autohelm

operation will help you to fully understand

its controls.

1

J

Deviation from course is continuously

monitored by a sensitive

and corrective rudder is applied by the

drive unit to return the vessel to course.

The applied rudder is proportional to

course error at any time and thus when

the course is restored the rudder will be

neutralised.

applied for a given off-course error must

match both the steering characteristics of

the vessel and speed through the water. A

vessel with a small rudder for example,

will require more corrective helm than a

similar sized vessel with a larger rudder.

Similarly, a high speed power boat will

require considerably less corrective helm

at planing speeds than it will at lower

displacement speeds.

When changes in vessel trim occur due

to variations in wind pressure or engine

throttle setting the course can only be

maintained by the application of

permanent rudder.off-set (standing helm)

to restore balance. If permanent rudder

off-set is not applied to restore balance

the vessel will bear on to a new heading.

Under these circumstances the

PowerPilot detects that the original course

is not being restoredand continues to

apply additional rudder off-set in the

appropriate direction until the vessel

returns to the original heading. Automatic

trimming capability ensures that the

originally set course is held irrespective of

any changes in balance that may occur

during the course of a passage.

computer also continuously monitors the

pattern of applied rudder correction and

can distinguish unnecessary repetitive

corrections caused by pitch and roll of the

PowerPilot’s

Autohelm

principle of

fluxgate

The amount of rudder

Autohelm

PowerPilot’s

central

compass

vessel from those necessary to maintain

the selected heading. If unnecessary

repetitive corrections continue the

computer will automatically neglect them

so that autopilot activity and power

consumption is continuously optimised at

minimum levels.

The high degree of control automation

made possible by the system’s central

micro computer simplifies user control to

a series of push button operations.

16

17

Page 12

3.2.3 Operating Mode indication

and Course Display

The operating mode of the autopilot is

indicated by a flashing red LED, as

summarised below:-

OPERATING MODE

STAND BY

Autopilot switched on but

not engaged

AU-t-0

Autopilot engaged to steer

compass heading

MANUAL

Hand held control power

steering in operation

ii@

ON

20

0

OFF SECONDS ’ ! : : : :

LED FLASHING CODE

)j

~~@j~fzJjj@

y?J

l

3.2.4 Off-Course Alarm

When the autopilot is set to Auto mode a

built in off-course alarm is automatically

set up. The off-course alarm will sound

from all control units when the vessel

deviates for any reason from the original

course by more than

seconds. If an auxiliary alarm is fitted this

will also be sounded after a one minute

delay to allow the watchkeeper to take

corrective action.

The alarm will be silenced if the vessel

returns to within 1 So of the original

course. If the vessel does not return within

course limits the alarm can only be

silenced by disengaging the autopilot and

resetting a new course.

f$j

3.3 FUNCTIONAL TEST

15“

for over 20

PROCEDURES

The following functional tests and set up

procedures must be carried out before

sea trials are attempted.

3.3.1 Setting Up

Switch On

Switch on the electrical supply from the

main panel. All control units will emit a

short beep tone to indicate that the

computer is now active. The autopilot will

start up in Stand By mode.

L;

Operating Sense

The operating sense of the autopilot can

be checked as follows:-

* Select Auto

l

Select + 10 which should move the

rudder a few degrees to produce a turn

to starboard.

If this does not occur, correct operating

sense can be restored as follows:-

* If the rudder immediately drives hard

over to starboard, the red and green

wires of the rudder reference

transducer should be reversed in the

connector unit.

If the rudder immediately drives hard

over to port, the motor connections

between the course computer and

drive unit should be reversed.

l

If the rudder drives a few degrees to

port, reverse the motor connections,

and reverse the red and green wires of

the rudder reference transducer.

N.B. Reversal of the motor connections

should be permanently made at one of

the main terminal blocks and not by

reversing the spade connector flying leads

to the course computer.

3.3.2 Functional Test Procedure

l

Switch on and note that all control

units are live and signalling Stand by

mode.

0 Key Auto on any fixed control unit and

note that Auto mode is indicated on

all control units.

l

Key course change commands from all

control units noting that

corresponding helm movements occur.

0 Key Manual on the hand held control

unit (if fitted) and note that Manual

mode is signalled from all control units.

l

Key power steer commands via the

course control keys of the hand held

control unit and note that

corresponding incremental helm

movements occur.

l

Key Stand by

The automatic trimming capability of

the autopilot can be observed by the

following test:

Key Auto followed by a 1 O” course

change to starboard. This effectively

simulates a condition where the need for

standing helm has developed and the

vessel is not returning to course. You will

notice that an initial fixed helm movement

is applied and that after a short interval

the drive unit will continue to apply

further incremental helm movements. If

21

Page 13

4. SEA TRIALS

left in this condition the rudder will

l

eventually be driven hard over. If, however,

the vessel were moving through the

water, the progressive application of

0 Check that all unions are tight and

additional helm would eventually return

the vessel to the correct course with the

necessary standing helm applied. Return

to course can be simulated by keying

-

10

(to return to the current heading). The

progressive application of standing helm

will cease when the fluxgate senses that

the course error has been removed.

Current Limit and Cutout

When the rudder is driven onto end stops

drive to the hydraulic pump may cut out

after a few seconds. This is normal. Drive

will only be restored if the rudder moves

away from the end stop or if drive is

required in the opposite direction.

3.3.3 Drive Unit Test Procedures

Before attempting sea trials it is important

to check that the vital link with the

steering system provided by the hydraulic

pump and rudder reference transducer

are free from obstruction and operating

correctly.

Warning

When the steering system is being moved

manually or under drive from the

autopilot do not touch any part of the

system. The forces exerted are

considerable and could cause injury.

With an assistant to turn the main

steering wheel get into a position where

the tiller and rudder reference transducer

can be seen.

l With the autopilot in Stand by turn

the sheering wheel from hard over to

hard over.

l

Check that the rudder reference

transducer and linkage do not foul any

part of the steering mechanism or

vessel’s structure.

0 Select Auto and use the + 10 button

to drive the rudder hard over (use’

maximum rudder setting).

l Use the

-

10 button to drive the

rudder hard over in the opposite

direction.

22

PowerPilot will only reach the designed

levels if the installation of the hydraulic

pump and rudder reference transducer is

correctly engineered and adjusted. It is

strongly advised that these be checked

before sea trials.

Check that the steering ram moves

smoothly and that there is no excessive

play.

there is no seepage of hydraulic fluid.

The performance of the

Autohelm

Initial sea trials should be carried out in

calm conditions with plenty of sea room.

The previously conducted functional test

will have verified that the autopilot is

operating correctly and that you are

During the first minute of operation, it will

be noticed that repetitive movements of

the vessel are gradually neglected until

finally the autopilot will respond only to

true variations in course.

familiar with all of its controls.

Set the rudder control on all control

units to minimum.

Initial sea trials on fast planing vessels

the sea state control is automatically reset

whenever a 1 O0 course change is

selected.

should be conducted at no more than half

engine speed. Minimum setting of the

rudder control should provide stable

steering performance.

Fine setting of the rudder control is

Automatic Trim Control

The Autohelm

corrects for trim. No adjustment of the

pilot is necessary.

discussed later (4.2).

Automatic Trim is cancelled and the

4.1 FIRST SEA TRIALS

During first sea trials, the vessel will be

constanfly changing heading, and it is,

therefore, very important to maintain a

constant look-out. The following initial

trial procedure is recommended:@ Steer on to a compass heading and

hold the course steady.

0 Press Auto to lock on to the current

heading. In calm

perfectly constant heading will be

sea

conditions a

Autohelm

correct trim for the new heading. This

process takes approximately one second

per degree of course change. It should be

noted that if a large course change is

keyed in (greater than 60°) the pilot will

not assume the final selected course

immediately. The vessel will come to

within say

will only settle onto course when the

Automatic Trim has been fully established.

maintained.

0 Alter course to port or starboard in

multiple increments of 1 and 10

degrees from any control unit. Course

changes should be prompt and

without any sign of overshooting.

l

If a hand held control unit is fitted key

procedure is adopted for large course

changes.

l

l

l

0

Manual to change over to remote

power steering. Practice power

l

steering using the four course control

keys..

0 Press Stand by to disengage the

autopilot for return to hand steering.

course changes only whilst steering

manually. In this way any obstructions or

other vessels may be cleared properly and

Automatic Sea State Control

During the sea trial, the operation of the

automatic sea state control can be

due account taken of the changed wind

and sea conditions on.the new heading

prior to engaging the pilot.

observed. When the autopilot is initially

engaged in Auto mode the autopilot will

respond to all pitch and roll movements.

To ensure precise course adjustments

PowerPilot

automatically

After each course change the

PowerPilot

10”

will re-establish the

of the desired course and

It is recommended the following

Note required new heading

Select Stand by and steer manually

Bring vessel onto new heading

Select Auto and let vessel settle onto

course

Bring to final course with 1

0

increments.

It is sound seamanship to make major

23

Page 14

5. OPERATING HINTS

4.2 RUDDER CONTROL

ADJUSTMENT

The rudder control setting recommended

on page 22 will provide stable control for

initial sea trials. However, power craft can

vary widely in their response to the helm

and further adjustment of the rudder

control setting may improve the

Autohelm’s steering characteristics.

An excessively high rudder control

setting results in

recognised by the vessel swinging from

side to side of the automatic heading

accompanied by excessive rudder

movement. In addition, distinct overshoot

will

be observed when the course is

oversteer

which can be

higher speed craft and when it occurs can

be corrected by reducing the rudder

control setting. In excess of 30 knots, a

reduction by at least two positions can

often be required within 45“ of North.

Planing Craft

On

wide speed range, the rudder control

setting often requires reduction at higher

speeds where steering effectiveness is

increased. Oversteer can be extremely

violent at planing speeds and it is

recommended that the rudder control

setting is reduced before opening the

throttle.

changed. This condition can be corrected

by reducing the rudder control setting

(rotating rudder control anticlockwise).

Similarly, an insufficient rudder control

setting results in

understeer

which gives

sluggish steering performance and is

particularly apparent when’changing

course. This is corrected by increasing the

rudder control setting (rotating rudder

control clockwise). These tendencies are

most easily recognised in calm sea

conditions where wave action does not

mask basic steering performance. The

rudder control setting is not over critical

and should be set to the lowest setting

consistent with accurate course keeping.

This will minimise actuator movements

and hence reduce power consumption.

It may be noticed that the autopilot

tends to be a little less stable on northerly

headings in the higher latitudes of the

northern hemisphere (and converse!y

southerly headings in the southern

hemisphere). This is caused by the

increasing angle of dip of the earth’s

magnetic field at higher latitudes which

has the effect of amplifying rudder

response on northerly. headings. The

tendency towards northerly heading

instability is usually more .obvious in

24

fast planing craft which operate over a

Autohelm

PowerPilot’s central course

computer continuously optimises

automatic steering performance

l

eliminating the need for operator

supervision.

It is, however, very important to

understand the effect of sudden trim

0

changes on steering performance.

At planing speeds, where only a small

proportion of the hull is in contact with

the water, variations in wind speed and

direction can produce significant changes

in trim. Similarly, variations in vessel

attitude and engine settings also produce

trim changes. When a change in trim

l

l

l

l

occurs the automatic trim compensation

system requires at least 120 seconds to

l

apply the necessary rudder off-set to

restore the automatic heading. In gusting

conditions, therefore, particularly when

the wind is forward of the beam, the

If vessel wanders under pilot control

l

course may tend to wander slightly.

Passage making under automatic pilot

l

is a very pleasant experience which can

lead to the temptation of relaxing

permanent watch. This must always be

l

avoided no matter how clear the sea may

appear to be.

5.1 UNSATISFACTORY STEERING

PERFORMANCE

If the

Autohelm

correctly specified, installed in accordance

with the instructions and adjusted

correctly it will provide outstandingly

good steering precision over a very wide

range of wind and sea conditions.

If the performance falls below your

expectations and the pilot appears to be

working correctly the fault will normally

be found by carrying out the simple

checks outlined below. Before reporting

your difficulties to an

please check the following:-

* Have the test procedures and

adjustments detailed in Section 3.3

PowerPilot has been

Autohelm

specialist,

been carried out correctly? Check

again.

Has the

fluxgate

compass been

installed in an area free from large

magnetic deviation? If in doubt use a

hand bearing compass to check.

If performance has changed recently

has a magnetic influence been

introduced near the

-

anchor/chain/radio equipment/

fluxgate

compass?

loudspeaker/tools/AC. generator, etc.

Is battery voltage correct?

12~.

Are fuses intact and of correct rating?

Are circuit breakers engaged?

Is wiring of correct diameter and are

screw connectors firmly tight?

If pilot fails to hold course - check

rudder setting at control units.

Verity that hydraulic pump is correct for

size and type of vessel.

Check steering ram and actuator are of

compatible type and bleed system to

remove air.

Check rudder reference transducer

linkages for security and correct

alignment.

25

Page 15

6. MAINTENANCE

7. FAULT LOCATION PROCEDURE

The autopilot is one of the most used and

hardest working items of equipment on

board, and therefore must receive its fair

share of attention and routine

maintenance.

Regular inspection of the installation is

recommended in the following areas

where applicable.

1. Check that Hydraulic Steering systems

are free from leaks and trapped air.

Bleed when necessary to remove air

from the system.

2. Check that all inter-connecting cable

terminals are fully tightened and

corrosion free.

3. Check that external waterproof sockets

are capped when not in use and

periodically spray with

similar) to protect from corrosion.

4. Check that the heavy power supply

cable connections are tight and free

from corrosion.

WD40

(or

Autohelm PowerPilot has been designed

to achieve very high standards of reliability

combined with ease of servicing.

If a fault should appear, please double

check that all connections in the

connector unit are sound and that the

heavy power cable connections are tight

and free from corrosion. If you are

satisfied that all connections are sound,

the simple check procedure tabulated

below will assist you to locate the most

likely fault area.

Since the course computer houses the

majority of the electronic control system

there is a high probability that if an

electronic fault has occured it will be

INSTALLATION

HAVE ONLY ONE

DO RED KEYS

EMIT BEEP TONES

WHEN PRESSED?

located in this area. The course computer

unplugs easily for servicing (Section

2.1.1).

suitable lever to separate the pads starting

at one corner. Do not use excessive force.

Disconnect from the connector unit and

withdraw the interconnecting cable

(Section 2.1.2).

returned to your nearest service agent.

Nautech’s Product Support Department in

the U.K. or your own National distributor

who will also be able to provide expert

assistance.

Control units are removed using a

The faulty unit should be removed and

If any difficulties arise, please consult

FAULT OCCUR

IN ONE CONTROL

26

27

Page 16

8. WARRANTY, AFTER SALES SERVICE

LIMITED WARRANTY

Nautech or its appointed Distributors or

Service Centres will, subject to the

conditions below, rectify any failures in

this product due to faulty manufacture

which becomes apparent within twelve

months of its purchase date.

Equipment used in the country of

purchase should be sent directly to the

authorised Distributor for that country or

its appointed Service Centres. The product

will then be service free of charge and

returned promptly direct to the sender.

Equipment used outside the country of

purchase can be either:-

a. Returned to the Distributor or Dealer in

whose country of from whom the

equipment was originally purchased -it

will then be serviced free of charge

and promptly returned direct to the

sender, or

b. The product can be returned freight

pre-paid to the authorised Distributor

or its appointed Service Centres in the

country in which the product is being

used. It will then be serviced and

returned direct to the sender on the

basis that the Distributor or Service

Centre will supply any parts used free

of charge but the sender will be

invoiced for the necessary labour and

return shipment at the local rate.

CONDITIONS

The warranty is invalid if:-

a. The product has been misused,

installed or operated not in accordance

with the standards defined in this

manual.

b. Repairs have been attempted by

persons other than Nautech approved

Service personnel.

FULL INTERNATIONAL

WARRANTY

Nautech or its appointed Distributors or

Service Centres will, subject to the

conditions below, rectify any failures in

this product due to faulty manufacture

which become apparent within twelve

months of its purchase date wherever the

vessel and the product may be operated.

CONDITIONS

1. The product must be installed aboard

2. The product must be installed in

3. The installation must be carried out by

4. The Warranty Registration Card must

5. The Full International Warranty is

CLAIM PROCEDURE

1.

the vessel in the country of purchase.

accordance with the recommendations

issued by Nautech Ltd.

an installer approved by Nautech:

alternatively the installation must have

been inspected and approved by

Nautech or its approved installer.

be completed by:-

0

The Owner or User

l

The Dealer supplying the product

0

The Installer

invalid if:(a) The product has been misused, or

installed or operated not in

accordance with standards defined

in this handbook.

(b) Repairs have been attempted by

persons other than Nautech

*approved Service personnel.

(c) The warranty card has not been

completed correctly or is not

accompanied by proof of purchase.

The product should be sent direct to

Nautech or its appointed Distributor or

Service Centre nearest to the vessel.

The completed Warranty Card and

proof of purchase must accompany

the claim. The product will then be

serviced free of charge and returned

promptly direct to the sender.

2.

Nautech,‘its

Centres, are not liable for any charges

arising from visits to the vessel not to

attend to the product, whether under

warranty or not, nor for sea trials or

any other work associated with the

installation. The right is reserved to

charge for any such services at the

local rate.

Distributors and Service

AFTER SALES SERVICE

Your

Autohelm

give you long service and reliable

performance wherever you sail. To’ensure

that you can always receive prompt and

expert attention in case of any difficulty,

Nautech has established a worldwide

network of AUTOHELM SERVICE

CENTRES.

Please contact your nearest Service

Centre for assistance.

ready:-

* Your Warranty Card

l Proof of Purchase

PowerPilot is designed to

Always

have

28

29

Page 17

9. SERUICECENTRES - UK,Eireand Channel Islands

10. OVERSEASREPRESENTATIVES

Ponsmo;th

Hdmphwe

0705 693611

PortsmouthlChichester

Harbour

Greenham Marine Ltd

EmrwonhYacht Harbour

Thaney Road

Emsworth

Hampshire

0243378314

Chlchesrer Marina

Chichester

vuest Surseex

0243 511070

Hamble Rlverl

Southampton Water

a K Electra Marine

Ft,; ;;ard

WaMsh

Hampshire

o4a952170

Hudson Marine Electronics

MercuryYa~ht Harbour

Sdtchell Lane

Hamble

liampd-lire

0703455129

Lecmar Marine Electronics

Arcalta Marine

COWS

low

0983293996

&

Lymlngton/Poolr

Greenham Marine Ltd

Klog Saltems Lane

Lymmgton

Hampshire

0590 75771

Danlea

Electronics

Cobk Quay

PO&

DOnet

0202673880

Greenham

Quay West Mama

z&y

Quay Road

DO&et

0202676363

aumin

Marine Electronics

OS4

8&i

3321

MarineLtd

Greenham Marine Ltd

COXKk

Pfymwth

0752 228114

Marine Electronics

Putiige

auckfdnd

arwer

aideford

Norlh

Own

0805

22870

Ocean Marine Servicer

43 afetonride

Pfymwth

0752 23922

Quay

Electrfcs

The Sail Loh

Pump seeet

arixham

080

Mylor

Falmouth

Cornwall

0326

Sevrrn & Bristol Channel

AN D Electronics

Dene Road

Severnrlde

Avonmouth

arw0l

0272 821441

Dale Sailing Co Ltd

Ddk

Havedord West

DY+d

064

&No”h&WestWa~es

i\ Rowlands

Electronics Ltd

The Outer Harbour

RNllheli

0758613193

Sailtronic Marine

Church Street

Glan Conv.vn

chffl a&

Clwyd

0492 $a 536

Merseyride

Robbins Marine Radio Servicer

Norfh East Cobwg Dock

Lwerpool

OS1

(Teignmouth) Ltd

45 3030

Marine Electronics

74001

Trading Estate

6.5 349

Marine

709 5431

Sflemr

190 Dock Street

Fleefwocd

03917 5241

Northern Ireland

Belfast Lough Marine Electronics

55

aelfan

Road

Cnickfergur

Co Antrim

0960365565

Dublin 11

0001342590

Rider Services

Glenbrook

Passage west

Co Cork

010353

2184

1176

Steampacket Building

East Quay

RansPf

Isle of

Man

0624

812583

S/W Scotland

Boat Elect&

Ayrshire

0292315355

western Scotland

Jeff Rutherford

Yacht Electrical and

Electronic Services

targr Yacht Haven

lrvme

Largr

AyEhire

0475 686091

Northern Scotland

a P ln~rument~t~onLtd

Greenbank Road

East

Aberdeen

0224874003

scalloway

Shetland

059 588 645

.fi

S/E

Fonh Area Marine Electronics

Electronics

PoR

South Queensferry

Edinburgh

0313314343

Road

T”llOS

Scotland

Centre

Edgar

h Electronic

Humberside

i/&m

Electronicc Marine Ltd

&‘WM

Wrlghl0cck.s

Hull

0482 25163

,&& &;i;;‘%$e

Grkgewalk

Wroxham

Norfolk

06053 2238

R

6 J Marine Electronics

2

alrch

Avenue

Dcwxoun ady

Harwlch

0255 502819

R 6 J Marine Electronics

c/o Suffolk Yacht Hdrbour

Levington

Iprwich

047

388

.A

dff

dbKent

.iq

r’?>Cartle

*. $1

737

Essex

Mantrbrite htarine Electronics

19d

Spatal

Road

Maldon

ESSex

0621 53003

Heron Marine Services

129 aroddway

Herne say

Kent

0227 361255

Channel lrlands

aoatworkr +

Emplacement

Peter

POR

GWfWY

0481 26071

Jersey Marine Electronics

umt 2

La we

St n&r

kSey

0534 21603

Mainbrayce Ltd

Inner t4arbour

ar.+e

Alderney

0481822772

Ltd

Argentina

Trimer S.A.

Fray J.5 M. de Ore 2030/40

1425

Buenos

Argrntma

Tel: (010 54 I) 774

Telex:

Australia

Solo Marine Pty Ltd

RwerbyNSW2212

AUSl&

T&(01061 2)7745255

Telex:

FIX:

Werner Ober-Yachtelektronik

A-6890 Lusrenau

Relchrstrasx 38

Austria

Tel: (0104315577 2419

Fax: (010 43) 5577 24195

C.O. Williams Electrical Co. Ltd

Wa,,elW

St Mkherl

Barbddor

Tel:(0101809)4252250

Telex:

Fax: (010

Belgium

West Diep Yachting Centre SPRL

a.a450

Louisweg 2

Belgium

Tel: (0103258) 234061

fa.~:(01032 sajsa23924a

Bermuda

Marine Communications

72 Pntr Bay Road

Pembroke HM 06

Bermuda

T~I:

Telex: 007 290 3795 MARCO aA

Fax: (010 1

Fast Yachts

Control S A.

lndurtro E. Comerico

sao Paub -

Telex: CO7 38 11 24612 CNTO RR

Cay Electronics

TOr7&

Tel:

7&x:

63~. (010 i

Aires

3728/4470

007

33 23653 TRMER AR

11 Green Street

M)7

71 127045 SOLMAR AA

(010 61 2) 7745291

Barbados

007

392 2366 COW Wa

1809)

424 0374

N~euwwon

010 i

809) 295.0558

809)

Brazil

P.0 Box 12700

ardril

Tel:~01055)115211944

Fax:

British Virgin Islands

P.O. aor 345

Road Town

arbtlrh

292 co79

SP

(010 55) 11 5482070

Wrgin Islands

(010 1a09

49) 42400

007 255

510 1006891

a09

49) 44707

Tom Taylor Co. Ltd

72 Fraser Avenue

Toronto M6K 3El

Ontario

Canada

Tel.

Telex.

Fax: (010 I 416) 5304345

Canary Islands

Norden

us iuan

Santa

Canary

Tel.

Telex: W7 52 92230 CCKIN

Fa*:~0103422)287311

CYPNS

Mercury

53

Spyrou

P.O aor 469

Limarrd

Cyprus

Te~fO1035751)65492

Telex: W7 605 4976 MERCDNE

Finland

Oy Maritim Aa

Veneentek~~antie 1

:‘,-,12

;el:(010358)0673331

Telex. 037

Far:(010358)06927917

France

5.0.

Marine Electronique

17.25 Rue Barian

78500

France

Tef.(O1033)139146833

Telex:

Fax: (010 33) I 3913 3022

Gibraltar

Bond Innrument~tion

The

Gibraltar

Te~(OIO35Ol73701

I&<:

Fax: (010 350) 73726

Sale3

H. Sheppard 6 Co.

W.C3pXt

G,braltdr

Tel

Telex.

G,ee<e

Piraeur Electronic

46

ALU h4oursopoulou

hlarlnd Zear

la5

GWXe

T&(010301)4531027/41a

ESLUD

Telex:007601

Fax (olo301)4la

LO10 !416)53Olatl

007

2 1 06524332 TOMTAYCO TOR

awista

57

Cruz

de Tener,fe

lrldnds

(010

34 22) 26-t a71

Diven

Co. Limited

Araouzou Street

10 Helsinki

57 124788 MARJT SF

5anr0~~~11e

007

42

658347

SDMELEC

D&yard

007 405 2373 GlaREP GK

(010

350) 77183

007

405 2324 MARINA GK

36

plraeus

241219DORlGR

1091

E

0’

1797

Page 18

.

Holland

Bconwna’s

PO BorNr.50128

1305 AC Almere Have”

H&r!d

Tel- (01031 3240) 11524

Telex: 007

Far (010

Hong Kong

Far East Yacht Specialists limited

M2 floor

Earkervik House

22

Hong Kong

Tel:

Tele::

Iceland

&nco

Lagmula7

125 Reykjavik

kcland

Tel:

Teler 007

fax: (010 354029323

Brim Yacht I Marine Supply

Tel Am P.O.

Israel

Tel: (010

lelcr 265871

Italy

Deck Marine

Vdc

20151

IldfY

~4:

Telex: 007 43 353147 DECK I

Fax: (010 392) 301 3398

Japan

J.M.J. Limited

2F lnago

Hayama Mum

Kanagawa

Japan

Tel:

Telex:

Fas

RipardLawan 6 Ripard

Yachttviatia

Maka

Tel: 1010 356)

Telex: CQ7

Netherlands Antllles

Radi&+olland

P.O.

Phrlipburg

5,

Netheriandr Antilles

Tel. (010 599) 522583

la: (010

Handelmaatxhappij 8.V

44 70121 GEBONI

313240)

11519

Ice

HOuIe street

(010852)5 257015/5229394

007

802 65925 KREMA HX

Ltd

(0103541)8jO7?

SO1

2334

Box

33232

972)

320 259913284432

(Gu&eret

J37AlJR)MONREF G

Cerdosa 155

M4am

(010

392)

joa

7229

Bldg

370

bhli

(01081)46876

007

72 3852532 JMJJPN J

010 81468 76 1044

156 Ta’Xbier Seafront

3559)

406

934 YOTS

Caribbean NV

Box

146

thanen

599) 5-22589

BOLT-X

1511

MW

Switzerland

Yachting

Marine

torail

BP 648 Noumea

NewCole&&

Tel: IO10 687) 27 58 46

T&r 007

Fdx:

NewZealand

Lusty 6 Blundell limited

69 Wairau Road

Takamna

Auciland 10

New Zealand

T&(010649)4443675

Telex: W7 74 60324

fax: (010 64 9) 444 3738

Norway

Seatronic AIS

nardd

15w

Ncmay

Tel: (010

I5

Telex: 007 56 76542 SIRON N

Far:(01047)9274152

Portugal

A.

RuadcloreFakao 152.156

4ooo PortoCc&?*

Ponugal

Tek(o10351

Telex:

Far(010351 2)314169

Slngaporc

Co”%micatio”s

Engineering Pte Lld

67 Ayer Rajah Crescent 07.01

Smgapm 05

Tel. @lOSSI 77 65191

Telex: W7 07 23036 DEBEGPL

Fax:(01065)7766795

Souih Afrlcr

Central Boating Pty Limited

a I

Cape Tow”

South

Tel:

Teh: 007955

Fax~OlO2721)242564

SpaIn

Sit&

MuntanerM

Eartelona

Spain

Tel:1010343)3234315

Tekx:

Fw(OlO343)3235062

Axhtde 6 Hansson

Nya Vdw?l

5.421 71v:

SWfden

Tel:~OlO4631)291111

Telex: 007 54 21447 AXHAS

Fax:(0104631)292789

Pacifique

706 3 120 CONIPANS NM

1010 687) 27 66 43

LUST-Y

HaarldgrE54Jl

Moss

Percira

CO7 404 22308 JORDAO P

Brec

Africa

Ml0

007

s

47)9

2727331231272835

Jordao

2)209479

Syrtemr

I3

5seet

8Wl

27 21) 248026r7@

26712%

11

52 542 18

Frotunda

SITf

E

Far:(01041 I)2028064

Taiwan

Ing Hai Company Limited

PO

Tel: (010 88 6215312

NZ

Telex:

Fax: (010 88 62) 5376 531

Turkey

Turimpex

Telex: W7 230 643 804 IMI

Slemenrtras-se

West Germany

Tel.(010494101)301240

Telex:00741

Fax:(010494101)301214

Systems

General

Wdle

Slrarre

8002 Zurich Enge

Swuerland

Tel:

(01041 I)202 8044

Telex: 007 45 816598 YASH CH

Box

9-Y

007

M.

Burhanetlin Tekdag

Haydn Irk&i

80680

Etiktar

Istanbul

Tel:

(010) 16046881161 01 32

Telex: CO7 607 26613 TRIM

USA

SWVilX

Autohelm America

New Wh,tBeld Streel

;y;fmd,

CT 06437

%i:

CO10

I 203) 453 8753

Fax:(OlOl

west Gcrmdnv

Ferropilot

2064

R&we”

West lndln

The Signal Locker

Nelsoon~s

Dockyard

Antigua

W-1

India

Tel:(O101809)4631528

Telex:(CO7393)214212ll9

DYRDBHT AKNACHTS AK

Fax:(0101809)4631524

Yugorldvld

Mare Nostrum

Yachting Ccarulting

Eorur

CcirbSdin

M.Tira 85

Opdlljd

Yugcriavia

Tel:~0103851)713506

Telex: 007 62 24215 TEHRI YU

IO

068

785 13951 VIRAGO

Cad.

I-7

203)4536109

GM&

3s

2189160FERD

TR

32

4434312

Loading...

Loading...