Page 1

G-Series

Systems

Installation and

Commissioning

Instructions

Page 2

Page 3

G-Series System

Installation & Commissioning Instructions

Document Number:87070_1

Date: June 2007

Page 4

G-Series Installation & Commissioning 4

Trademarks and registered trademarks

Autohelm, HSB, Raymarine, RayTech, Sail Pilot, SeaTalk and Sportpilot are registered trademarks of Raymarine Limited. Apelco is a registered trademark of Raymarine Holdings Limited (Registered in all major marketing territories).

AST, Autoadapt, Auto GST, Autoseastate, Autotrim, Bidata, Marine Intelligence, Maxiview, On Board, Raychart, Raynav, Raypilot, Raystar,

ST40, ST60, Seaclutter, Smart Route, Tridata and Waypoint Navigation are trademarks of Raymarine Limited.

Maptech is a registered trademark of Maptech.

All other product names mentioned are trademarks or registered trademarks (if applicable) of their respective companies

© Raymarine plc 2007

Page 5

5

Contents

Chapter 1: Introduction .....................................11

1.1 Handbook information ..............................................12

1.2 Plan your installation ................................................12

1.3 Install your system ...................................................12

1.4 Commissioning ........................................................13

Chapter 2: Typical systems ..............................15

Chapter 3: Packs and contents .........................23

3.1 GPM400 processor ..................................................24

3.2 GVM400 video module ............................................25

3.3 G-Series Keyboard ..................................................26

3.4 Keyboard wireless upgrade kit .................................27

3.5 SeaTalk

ng

wireless basestation ...............................28

3.6 Marine monitors ................................... ... .................28

3.7 Alarm buzzer ........................................ ... .................29

Chapter 4: Cables and connections .................31

4.1 General instructions .................................................32

4.3 GPM400 processor ..................................................37

4.4 Monitor connections .................................................38

4.5 Keyboard connections .............................................40

4.6 Video and Entertainment .........................................43

4.7 SeaTalk

hs

network ...................................................47

4.8 GPS Connection ......................................................49

4.9 SeaTalk & Alarm connection ....................................50

4.10 NMEA 0183 connections .......................................51

4.11 SeaTalk

ng

connections ..........................................54

4.12 NMEA 2000 connections .......................................55

Chapter 5: Installation and mounting ................57

5.1 General instructions .................................................58

5.2 GPM400 Processor module .....................................59

5.3 G-Series Keyboard ...................................................60

5.4 G-Series Monitors ....................................................65

5.5 GVM400 Video Module ............................................66

5.6 Alarm buzzer ............................................................67

Chapter 6: Initial test .........................................69

6.1 Power up test ...........................................................70

Chapter 7: Initial Setup .....................................73

7.1 Power up the system ................................................74

7.2 First time configuration .............................................74

7.3 Select Master GPM ..................................................75

7.4 Configure Nav Stations ............................................77

7.5 Assign Keyboards ....................................................78

Chapter 8: Commissioning ................................81

8.1 Language setting ......................................................82

8.2 Compass heading setup ...........................................82

8.3 Radar setup ..............................................................83

8.4 GPS checks ..............................................................85

8.5 Fishfinder checks ....................................................86

8.6 Set up video .............................................................87

8.7 NMEA 0183 ..............................................................88

8.8 Data checks ..............................................................89

Chapter 9: Troubleshooting ..............................91

9.1 Troubleshooting ........................................................92

Appendix ATechnical specification..........................103

Appendix B - Nav Station schematic.......................109

Appendix C - Spares and accessories....................117

Index .......................................................................121

Page 6

G-Series Installation & Commissioning 6

Page 7

7

Warnings and cautions

EMC installation guidelines

Raymarine equipment and accessories conform to the appropriate

Electromagnetic Compatibility (EMC) regulations. This minimizes

electromagnetic interference between equipment, which could otherwise affect the performance of your system.

Correct installation is required to ensure that EMC performance is

not compromised.

For optimum EMC performance, we recommend that:

• Raymarine equipment and the cables connected to it are:

Product installation

This equipment must be installed and operated in

accordance with the Raymarine instructions

provided. Failure to do so could result in poor

product performance, personal injury, and/or

damage to your boat.

Potential ignition sources

The equipment in these instructions is NOT

approved for use in hazardous/flammable atmospheres such as an engine room.

Switch off power supply

Make sure you have set the boat’s power supply

to OFF before you start installing this product.

Unless otherwise stated connect and disconnect

equipment only with the power supply switched

OFF.

High voltage

Equipment contains high voltages.

Unless otherwise instructed within these

instructions do not remove the cove rs or attempt

to access the internal components.

Grounding requirements

This display is not intended for use on “positive”

ground boats. The power input cable earth

screen connections must be connected directly

to the boats ground.

Radar

The radar scanner transmits electromagnetic

energy. Ensure all personnel are clear of the

scanner before switching to Tx (transmit mode)

Navigation aid

Raymarine equipment is intended for use only as

an aid to navigation. You must still ensure that a

properly qualified person is acting as navigator

at all times and that all applicable maritime regulations are adhered to. You must also ensure that

all proper judgements and actions are taken to

ensure a safe passage. Always maintain a permanent watch

Service and Main tenance

This product contains no user serviceable

components. Please refer all maintenance and

repair to authorized Raymarine dealers.

Unauthorized repair may affect your warranty.

Sun covers

To provide protection against the damaging

effects of ultra violet (UV) light, use the sun

covers when equipment is not in use.

Cleaning

DO NOT use acid, ammonia based or abrasive

products.

DO NOT use commercial high pressure washing

(jet wash) equipment.

Page 8

G-Series Installation & Commissioning 8

i. At least 3 ft. (1 m) from any equipment transmitting or cables

carrying radio signals e.g. VHF radios, cables and

antennas. In the case of SSB radios, the distance should be

increased to 7 ft. (2 m).

ii. More than 7 ft. (2 m) from the path of a radar beam. A radar

beam can normally be assumed to spread 20 degrees

above and below the radiating element.

• The product is supplied from a separate battery from that used

for engine start. This is important to prevent erratic behavior

and data loss which can occur if the engine start does not have

a separate battery.

• Raymarine specified cables are used.

• Cables are not cut or extended unless doing so is detailed in the

installation manual.

Remember

Where constraints on the installation prevent any of the above

recommendations:

• Always allow the maximum separation possible between different items of electrical equipment. This will provide the best

conditions for EMC performance for the installation.

Suppression ferrites

Raymarine cables may be fitted with suppression ferrites. These

are important for correct EMC performance. Any ferrite removed to

facilitate installation must be replaced in the original position immediately installation is complete.

• Use only ferrites of the correct type, supplied by Raymarine authorized dealers.

Connections to other equipment

If Raymarine equipment is to be connected to other equipment

using a cable not supplied by Raymarine, a Raymarine suppression ferrite MUST always be attached to the cable near the

Raymarine unit.

Waste Electrical and Electronic Equipment Directive

The Waste Electrical and Electronic Equipment (WEEE)

Directive requires the recycling of waste electrical and

electronic equipment. Whilst the WEEE Directive does not

apply to some of Raymarine’s products, we support its policy and ask you to be aware of how to dispose of this

product.

The crossed out wheeled bin symbol, illustrated above, and found

on our products signifies that this product should not be disposed of

in general waste or landfill.

Please contact your local dealer, national distributor or Raymarine

Technical Services for information on product disposal.

Water ingress

As it exceeds the water proof rating capacity outlined by standards

CFR46 / IPX7, subjecting any Raymarine equipment to commercial

high pressure washing equipment may cause subsequent water

intrusion and failure of the equipment. Raymarine will not warranty

equipment subjected to high pressure washing

Warranty

T o register your new Raymarine product, please take a few minutes

to fill out the warranty card included in the box or go to:

www.raymarine.com

It is important that you complete the owner information and return

the card to receive full warranty benefits, including notification of

software updates if they are required.

Page 9

9

Disclaimer

The technical and graphical information contained in this handbook, to the best of our knowledge, was correct as it went to press.

However, our policy of continuous improvement and updating may

change product specifications without prior notice. As a result,

unavoidable differences between the product and handbook may

occur from time to time. Raymarine cannot accept responsibility for

any inaccuracies or omissions it may contain. For the latest product

information visit our website - www.raymarine.com

Page 10

G-Series Installation & Commissioning 10

Page 11

1

Chapter 1: Introduction

This guide provides information to help you plan, install and commission your G-Series system.

Chapter contents

• 1.1 Handbook information on page 12.

• 1.2 Plan your installation on page 12.

• 1.3 Install your system on page 12.

• 1.4 Commissioning on page 13.

See also

You may require additional information when planning or installing your system.

• Spares and accessories.

Lists of spares, accessories and cables can be found in Appendix C - Spares and accessories.

• Raymarine handbooks and manuals.

All additional documents referred to in this manual can be downloaded from the Raymarine website.

wwww.raymarine.com/handbooks

.

Page 12

G-Series Installation & Commissioning 12

1.1 Handbook information

This document is part of a series of books associated with the GSeries system

All documents can be downloaded from:

www.raymarine.com/handbooks

.

G-Series handbooks

Additional handbooks

You may also refer to separate instructions provided with the associated ancillary equipment.

1.2 Plan your installation

Prior to installing your G-Series system you will need to plan carefully. Use the information in this guide to assist you.

1.3 Install your system

Once you have completed the planning stage, proceed with the

installation:

Title Part number

Installation and commissioning instructions 87070

Operating guide 86126

User reference guide 81276

Tick Planning for Installation instructions

Overall system Chapter 2: Typical systems

Chapter 3: Packs and contents

Equipment location Chapter 5: Installation and mounting

Power, supply and

distribution

Chapter 4: Cables and connections

Connections and cables Chapter 4: Cables and connections

Nav Station details Appendix B - Nav Station schematic

We strongly recommend that you produce a complete schematic diagram for

your G-Series installation. See Appendix B - Nav Station schematic.

Tick Installation task Installation instructions

Ensure you have all

required equipment,

accessories and cables.

Chapter 3: Packs and contents

Chapter 4: Cables and connections

Appendix C - Spares and accessories

Site all equipment. Chapter 5:Installation and mounting

Route all cables. Chapter 4: Cables and connections

Drill cable and mounting

holes.

Chapter 5: Installation and mounting

Make all connections into

equipment.

Chapter 4: Cables and connections

Power on test the system. Chapter 6: Initial test

Secure all equipment in

place.

Chapter 5: Installation and mounting

Page 13

13 Chapter 1: Introduction

1.4 Commissioning

Once you have completed the installation, proceed with the commissioning of the system:

Tick

Commissioning

task

Installation instructions

Assign master GPM Chapter 7: Initial Setup

Set up Nav Stations Chapter 7: Initial Setup

Assign keyboards Chapter 7: Initial Setup

Commission ancillary

equipment

Chapter 8: Commissioning

Complete warranty cards

for equipment installed

Refer to separate warranty booklets

supplied with equipment.

Page 14

G-Series Installation & Commissioning 14

Page 15

2

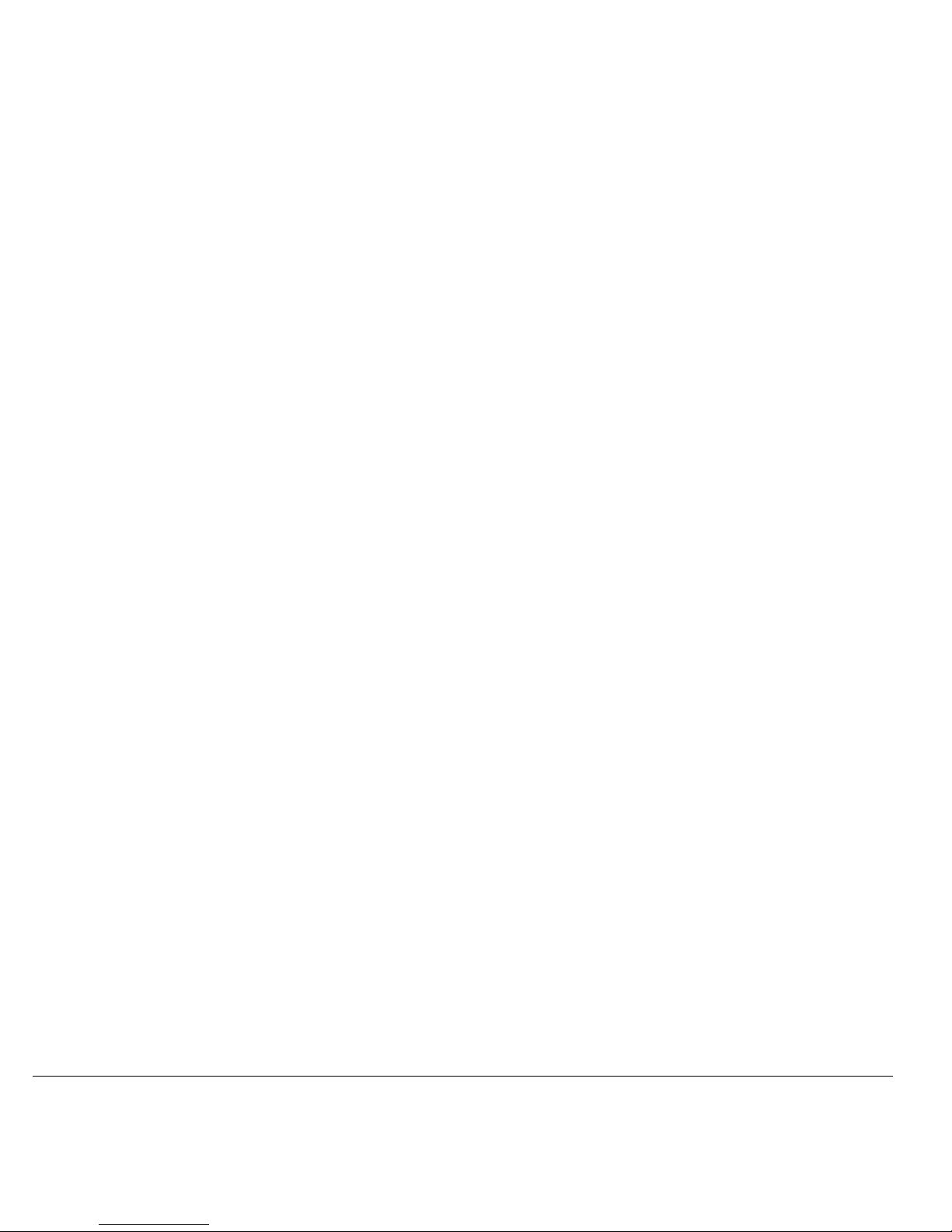

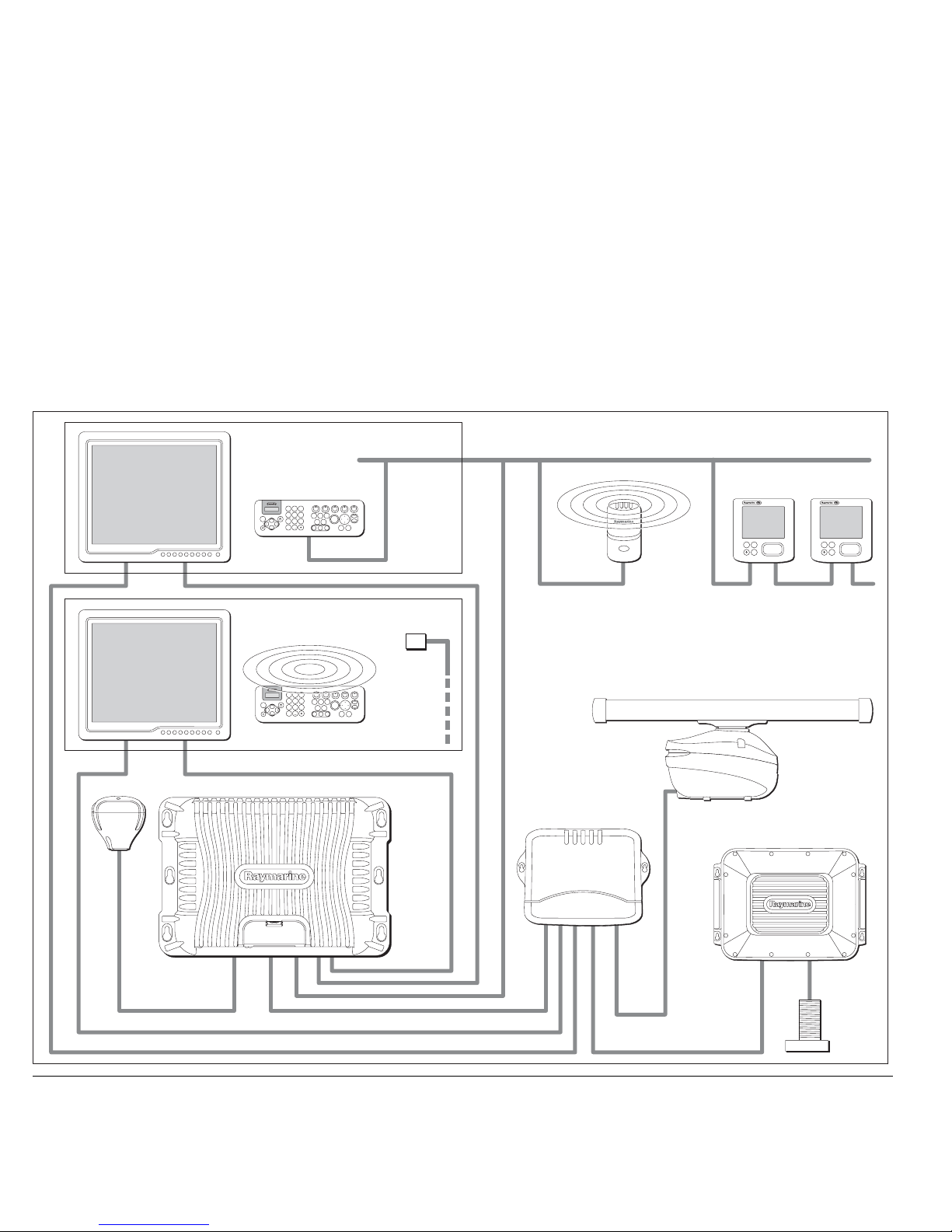

Chapter 2: Typical systems

This section provides an overview of typical G-Series systems and ancillary equipment.

Chapter contents

• System overview on page 16

• Single processor system on page 17

• Dual Nav station (single processor) on page 18

• Network system, Single Nav station (Dual processor) on page 19

• Dual Nav station (Dual processor 2) on page 20

• Entertainment system on page 21

• System limits on page 22

See also

• Cables and connections on page 31

Page 16

G-Series Installation & Commissioning 16

System overview

Note: Where 2 displays are connected to a sin g l e processor, both will displa y th e same information.

D9985-1

ENTERCANCEL

MENU

ENTERCANCEL

MENU

Navstation 1 (e.g. Flybridge)

Navstation 2 (e.g. Bridge)

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

ENTERCANCEL

MENU

ENTERCANCEL

MENU

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

I

N

ENTER

Keyboard

Monitor

SeaTalk

Alarm

sounder

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

SeaTalk

hs

network devices

SeaTalk

ng

DVI or VGA

DVI or VGA

NMEA 0183 or SeaTalk

GPS

SeaTalk

hs

switch

and/or

SeaTalk instruments/pilot

Keyboard

GPM 400

Digital radar

Video module

Video/audio

sources

OR

DSM digital sounder

(or other compatible

digital server)

Monitor

SeaTalk

ng

instruments/pilot

Page 17

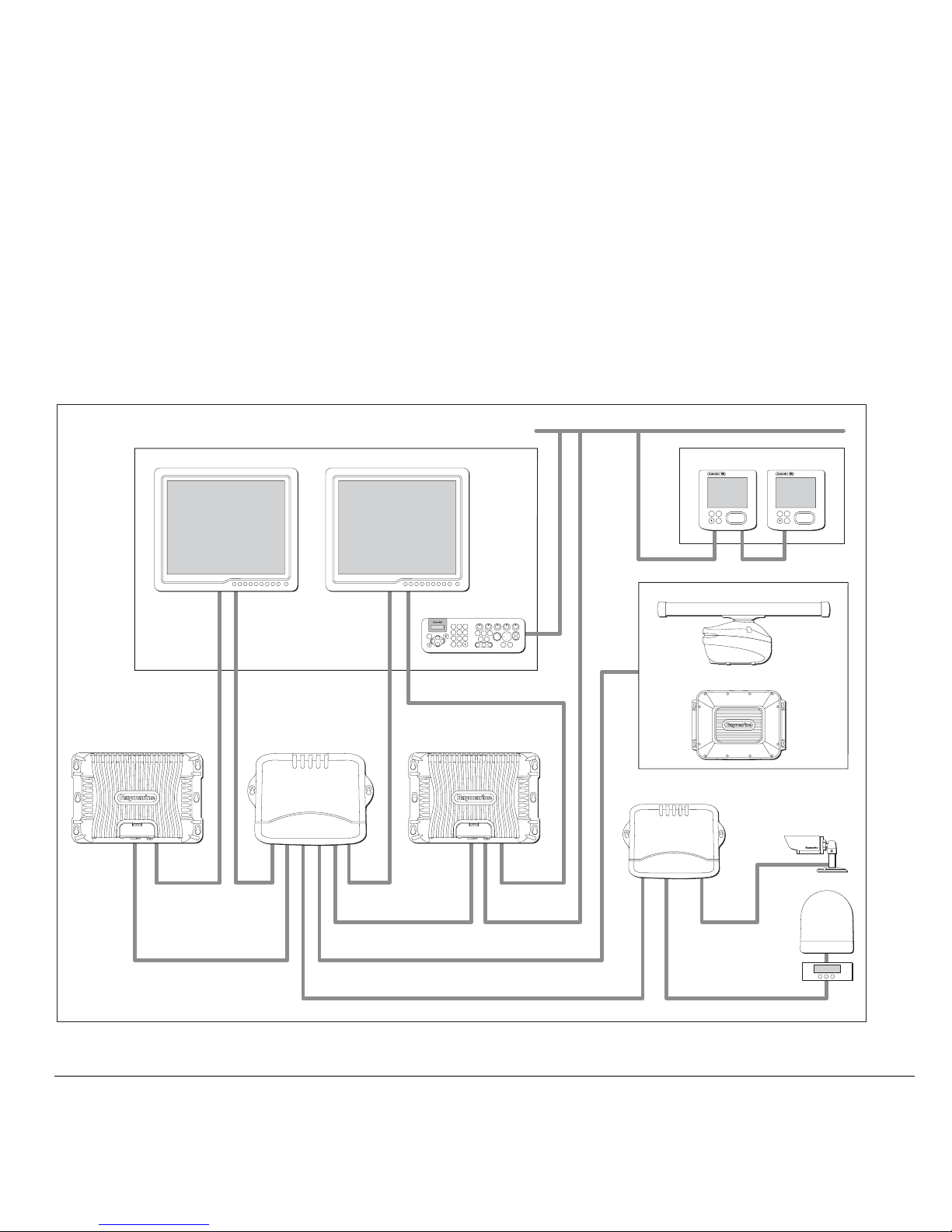

17 Chapter 2: Typical systems

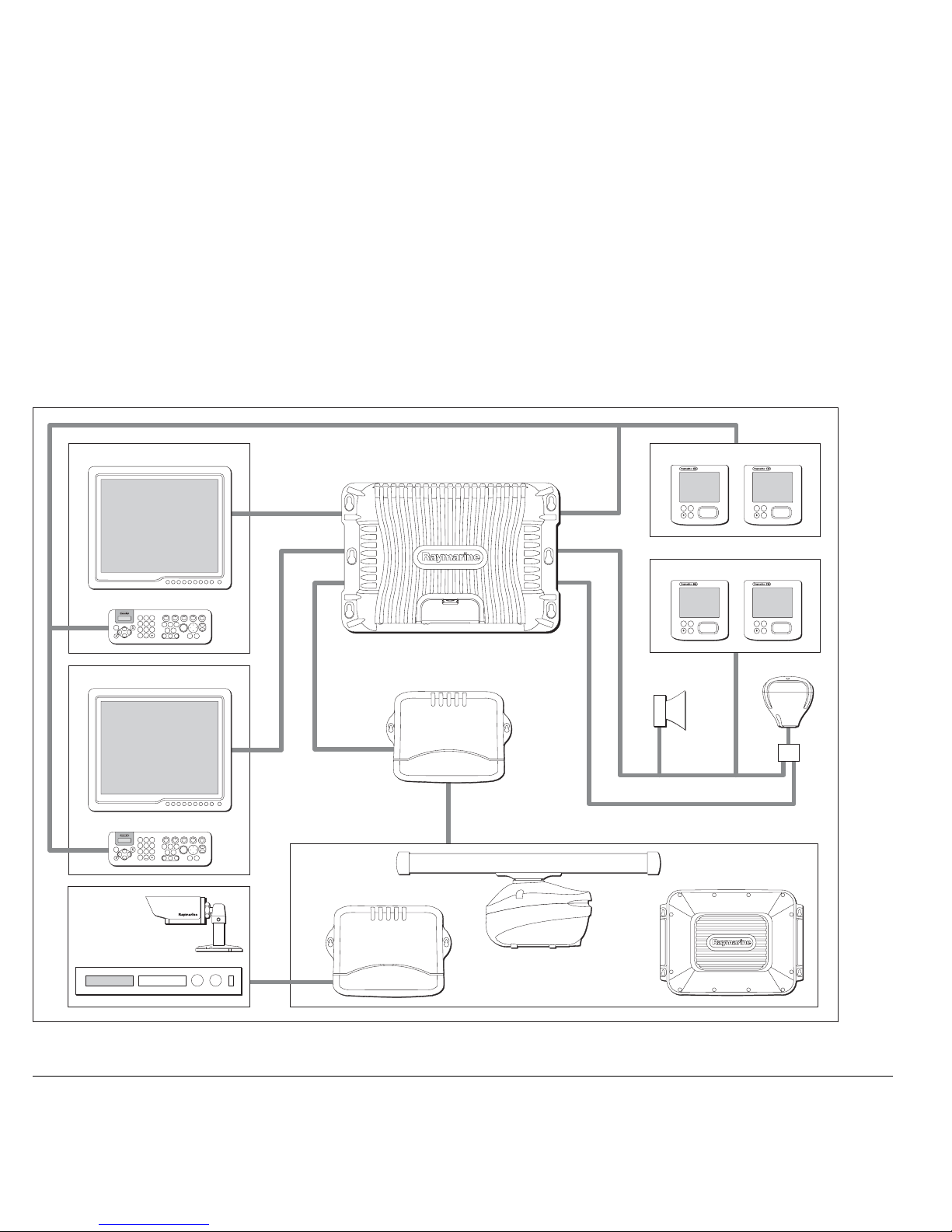

Single processor system

ENTERCANCEL

MENU

ENTERCANCEL

MENU

C/lines for plugs/sockets

Navstation

Monitor

Transducer

Digital radar

Pilot Instrument

Alarm

sounder

GPS

SeaTalk

hs

switch

GPM 400 (Central processor)

Audio OUT

(to ship's

audio system)

D9987-1

SeaTalk

ng

backbone

DVI or VGA

SeaTalk/Alarm output

SeaTalk

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

DSM digital sounder

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

Keyboard

SeaTalk

ng

Page 18

G-Series Installation & Commissioning 18

Dual Nav station (single processor)

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

ENTERCANCEL

MENU

ENTERCANCEL

MENU

C/lines for plugs/sockets

Keyboard

Wireless

keyboard

Monitor

Monitor

Wireless

base station

InstrumentPilot

GPS

SeaTalk

hs

switch

DVI or VGA

DVI or VGA

DVI or VGA

SeaTalk

or NMEA 0183

GPM 400

D9988-1

Transducer

DSM digital sounder

Digital radar

Charger

point

SeaTalk

ng

backbone

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

SeaTalk

ng

SeaTalk

ng

To SeaTa lk

ng

SeaTalk

ng

Navstation, (e.g. Bridge)

Navstation, (e.g. Flyridge)

Page 19

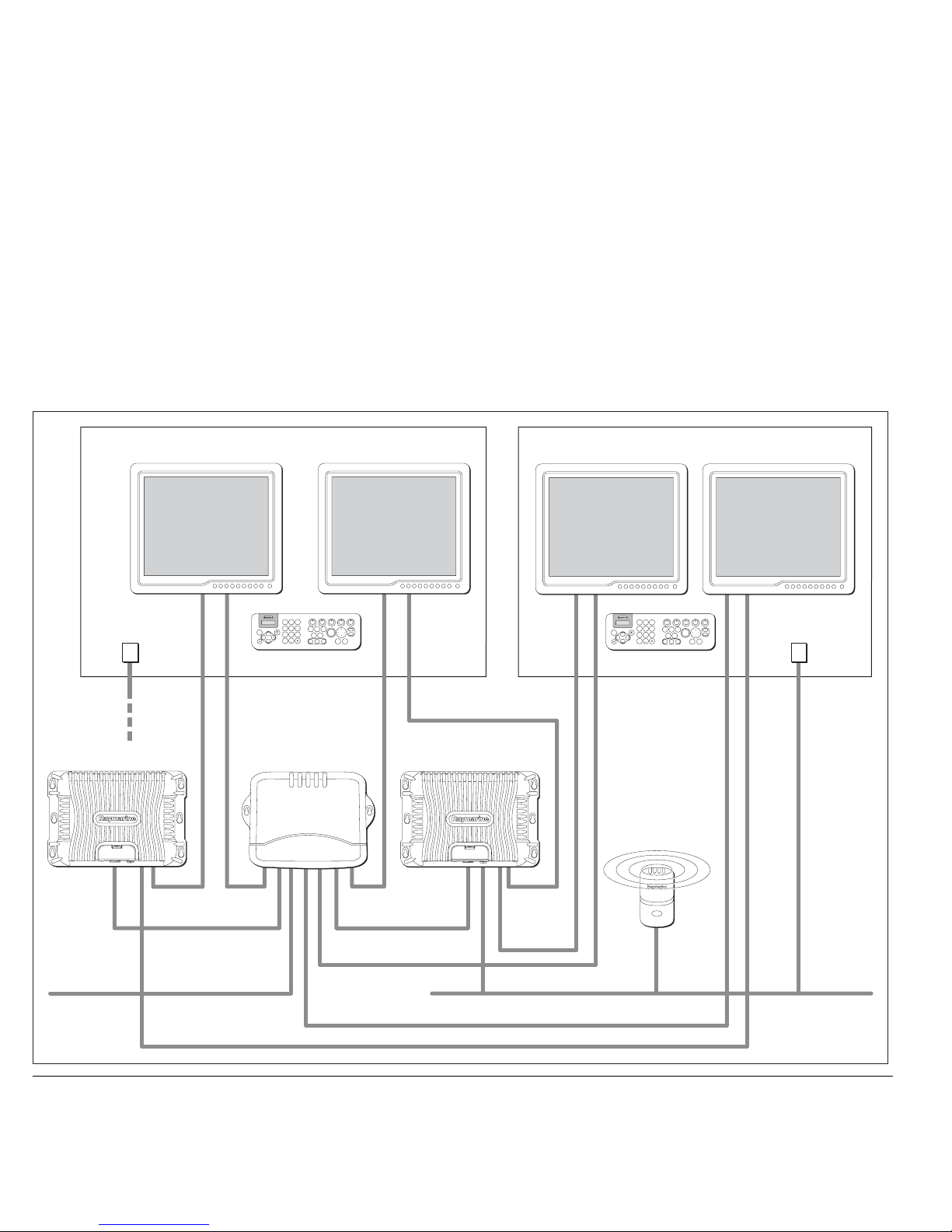

19 Chapter 2: Typical systems

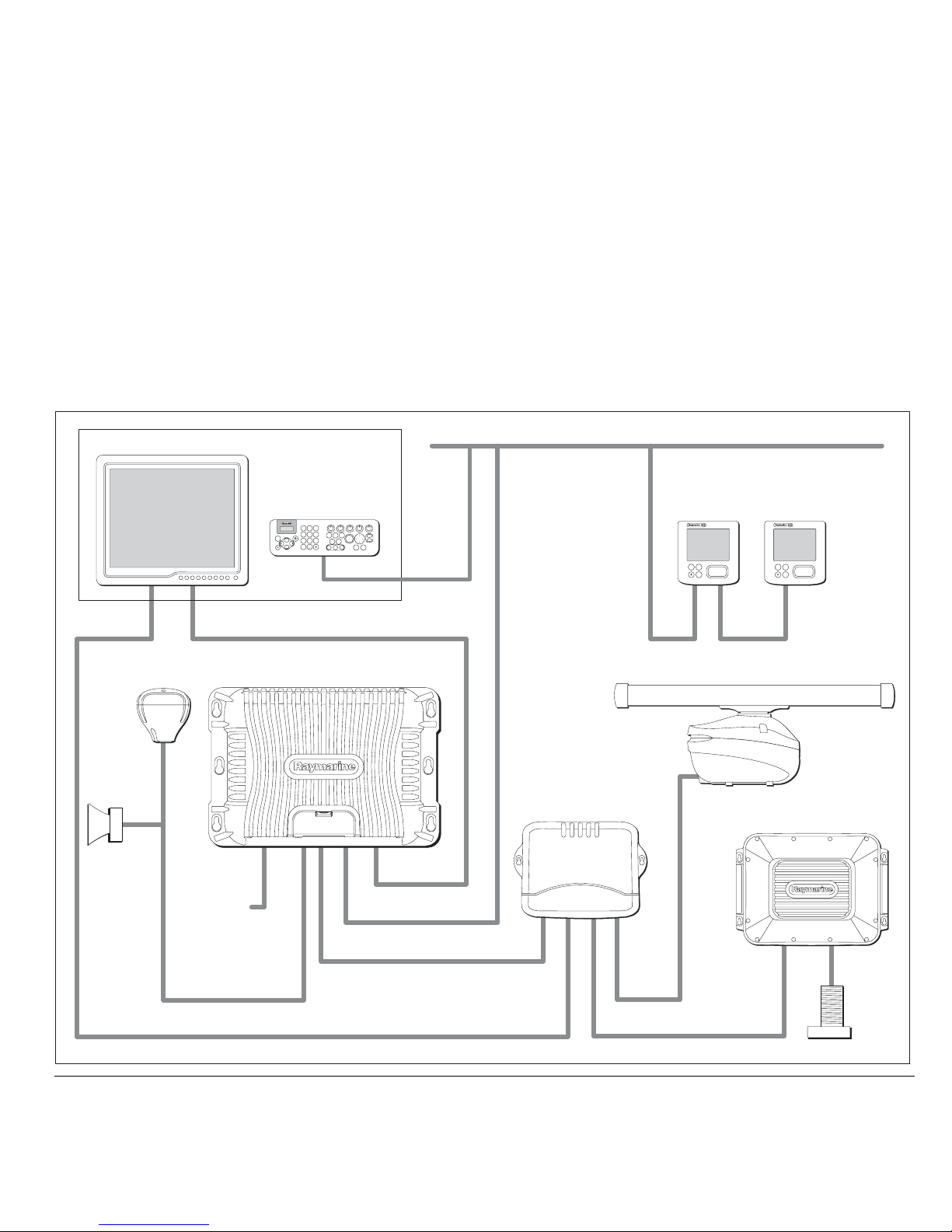

Network system, Single Nav station (Dual processor)

Note: Each display at a Nav station must be connected to a different GPM400. DIsplays sharing a GPM will both display identical

information.

SeaTalk

ng

backbone

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

ENTERCANCEL

MENU

ENTERCANCEL

MENU

D9989-1

Digital radar

InstrumentInstrument

SeaTalk

hs

switch

S-video

AV

Video module

Camera

Sat

TV

GPM400

GPM400 Data Master

Monitor Monitor

Keyboard

DVI or VGA DVI or VGA

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

SeaTalk

ng

SeaTalk

ng

SeaTalk

ng

DSM digital sounder

Page 20

G-Series Installation & Commissioning 20

Dual Nav station (Dual processor 2)

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

D9990-1

SeaTalk

hs

switch

GPM400

GPM400 (data master)

Monitor Monitor

Monitor Monitor

SeaTalk

ng

devices

DVI or VGA

DVI or VGA

DVI or VGA

DVI or VGA

DVI or VGA

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

SeaTalk

hs

SeaTalk

hs

Keyboard

charge point

Keyboard

charge point

Wireless

Base station

Other SeaTalk

hs

equipment

(radar,DSM)

SeaTalk

ng

backbone

Navstation 1 (e.g. Bridge) Navstation 2 (e.g. Flybridge)

To SeaTalk

ng

Page 21

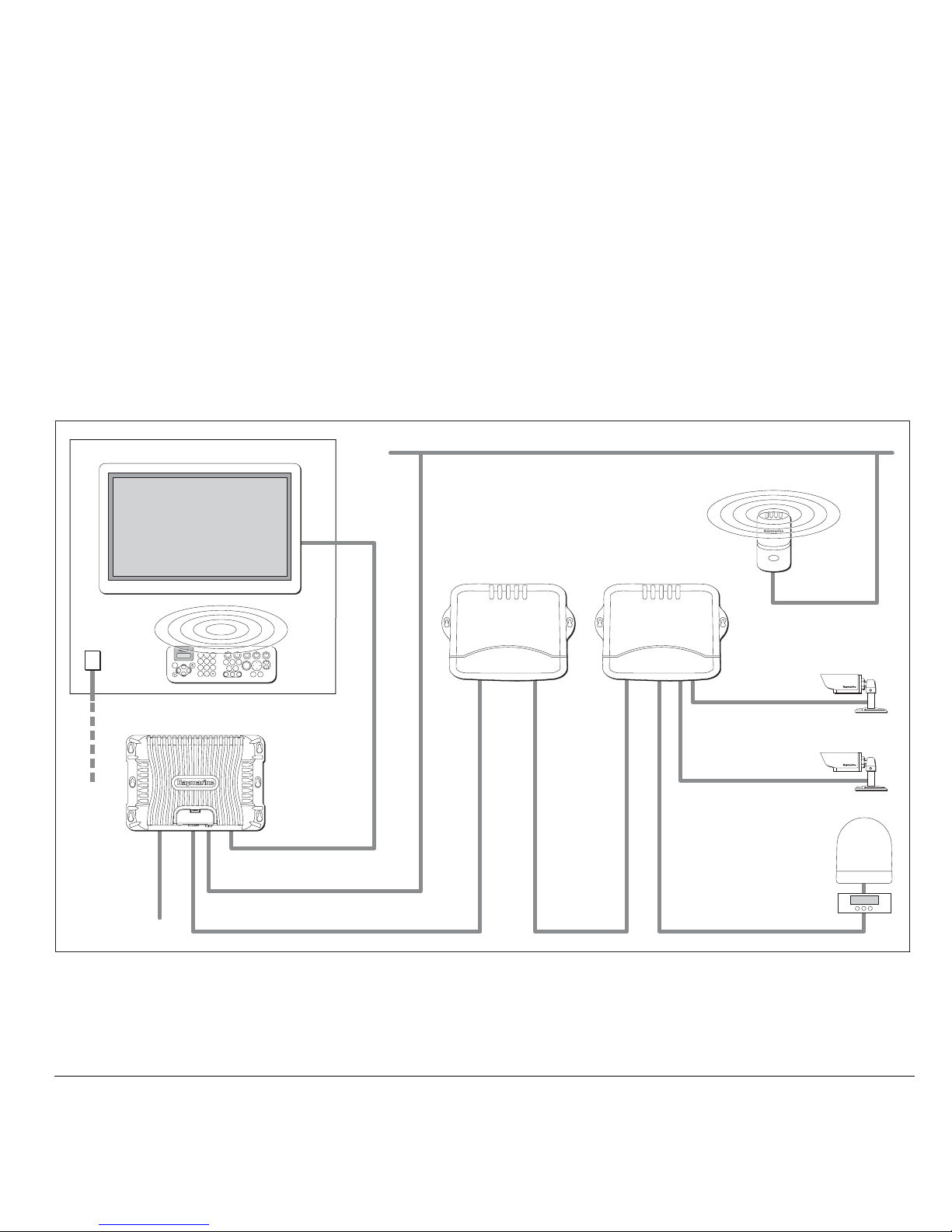

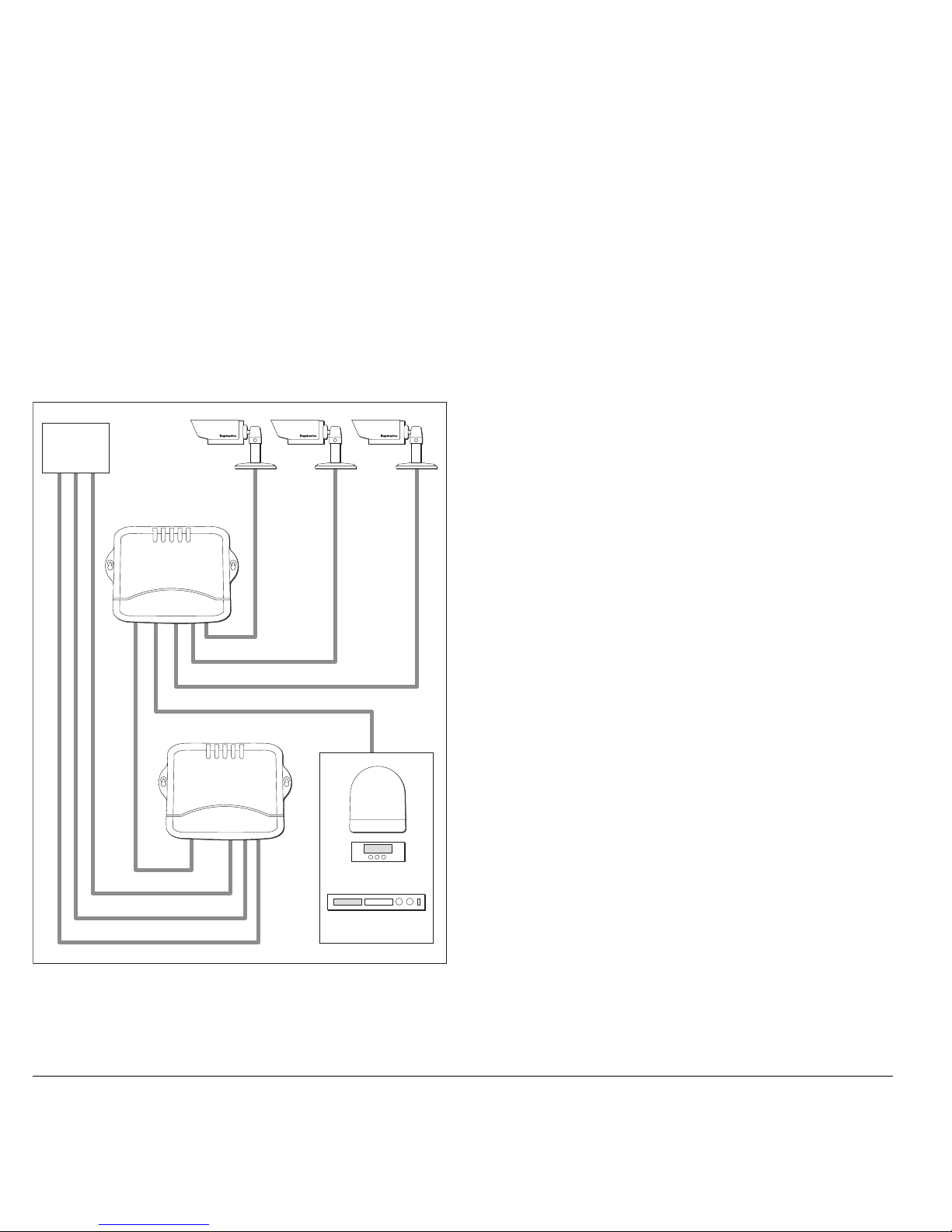

21 Chapter 2: Typical systems

Entertainment system

Note: The system may include up to 2 Video modules to provide additional video capacity.

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

D9991-1

SeaTalk

hs

switch

S-video

AV

AV

Video module

Audio out

Camera

Camera

Sat

TV

GPM 400 (Central processor)

Plasma Television

Basestation

Wireless

Keyboard

SeaTalk

hs

SeaTalk

hs

SeaTalk

ng

SeaTalk

ng

To SeaTalk

ng

DVI or VGA

Keyboard

charge point

SeaTalk

ng

backbone

Page 22

G-Series Installation & Commissioning 22

System limits

The following quantities of G-Series components may be

connected within a single system:

See also

For limitations associated with ancilliary components and systems,

refer to the separate manufacturer’s documentation.

G-Series component Max. number on system

GPM400 processor module 4

(of which 1 must be set as master

GPM)

Monitors 8

(2 per GPM400 processor)

Keyboards 8

GVM400 video module 2

DSM digital sounder 1

Digital radar scanner 2

Page 23

3

Chapter 3: Packs and contents

This section contains details of pack contents for the G-Series system components.

Chapter contents

• 3.1 GPM400 processor on page 24

• 3.2 GVM400 video module on page 25

• 3.3 G-Series Keyboard on page 26

• 3.4 Keyboard wireless upgrade kit on page 27

• 3.5 SeaTalk

ng

wireless basestation on page 28

• 3.6 Marine monitors on page 28

• 3.7 Alarm buzzer on page 29

See also

• For peripheral components (e.g. GPS antenna) refer to the separate instructions supplied with the

equipment.

Page 24

G-Series Installation & Commissioning 24

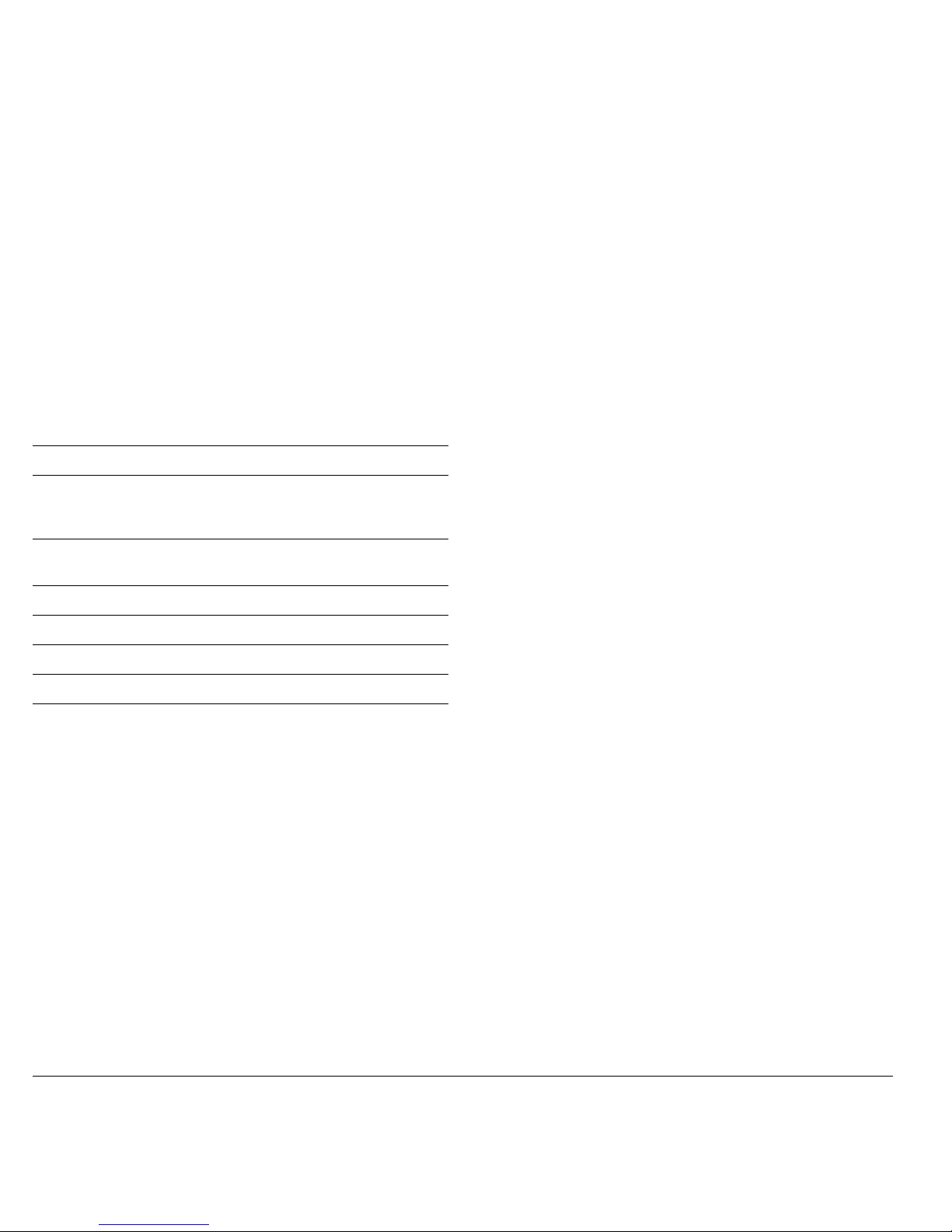

3.1 GPM400 processor

Pack items

SeaTalkng spur cable

D10062-1

GPM400 NMEA cable

GPM400 Power cable

GPM400 Audio cable

GPM400 SeaTalk/Alarm cable

GPM400

Processor Module

Handbook/documentation

Description Part No.

GPM400 Processor module - US version

GPM400 Processor module - EU version

GPM400 Processor module - ROW version

E02042

E02047

E02048

1.5 m (4.9 ft) Power cable R08003

1.5 m (4.9 ft) NMEA 0183 cable R08004

1 m (3.3 ft) SeaTalk

ng

spur cable A06039

1.5 m (4.9 ft) SeaT alk/Alarm Out cable E55054

3 m (9.8 ft) G-Series Audio out cable R08266

Install pack R08295

User documentation CD 47018

Commissioning and installation guide 87070

Quick reference guide 86126

Warranty booklet 80017

Page 25

25 Chapter 3: Packs and contents

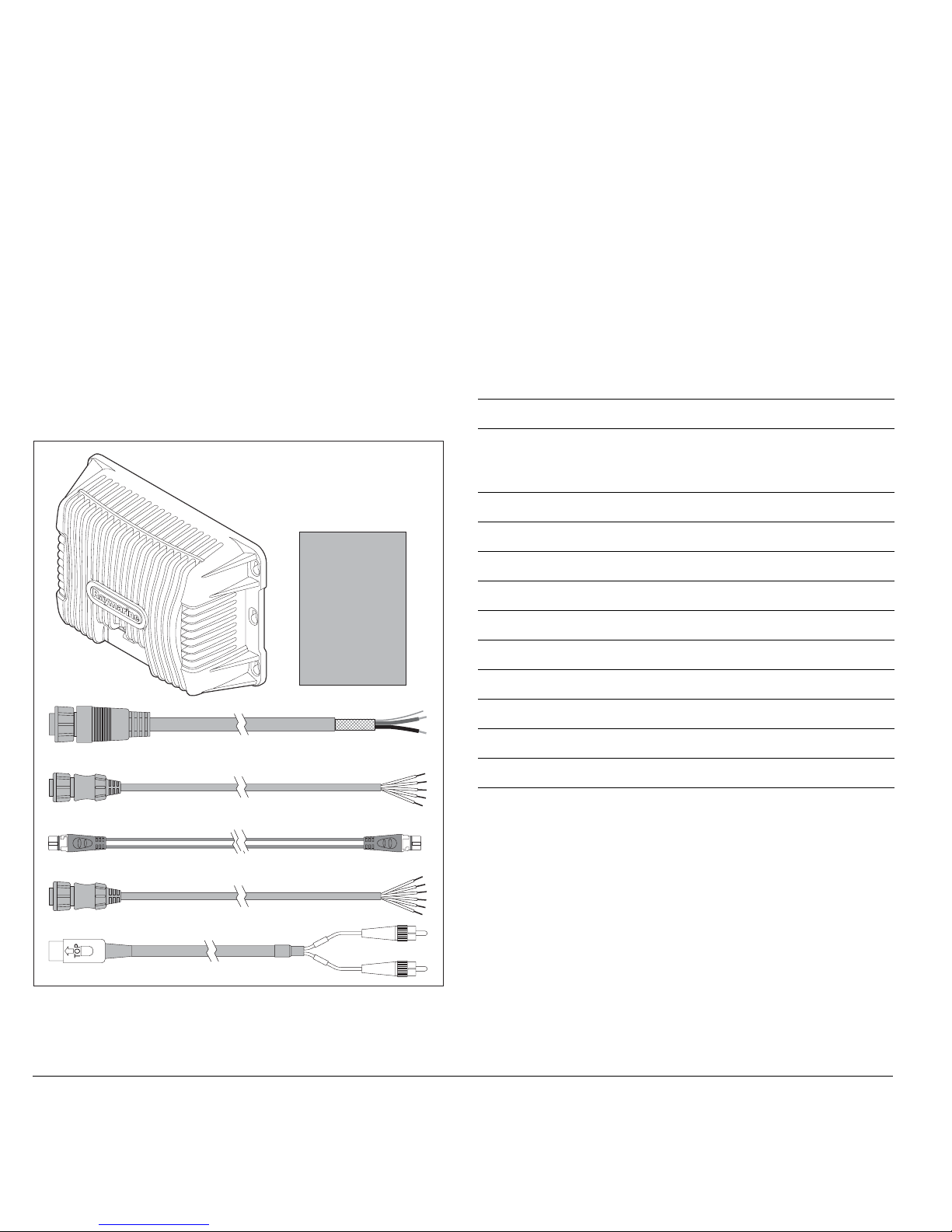

3.2 GVM400 video module

Pack items

GVM400 S-video cable

GVM400 audio cable

D10063-1

GVM400

Audio/Visual server unit

Description Part No.

GVM400 Video Module E02043

1.5 m (4.9 ft) S-Video cable R08274

1.5 m (4.9 ft) Audio cable R08275

Install pack R08318

Installation sheet 87068

Warranty booklet 80017

Page 26

G-Series Installation & Commissioning 26

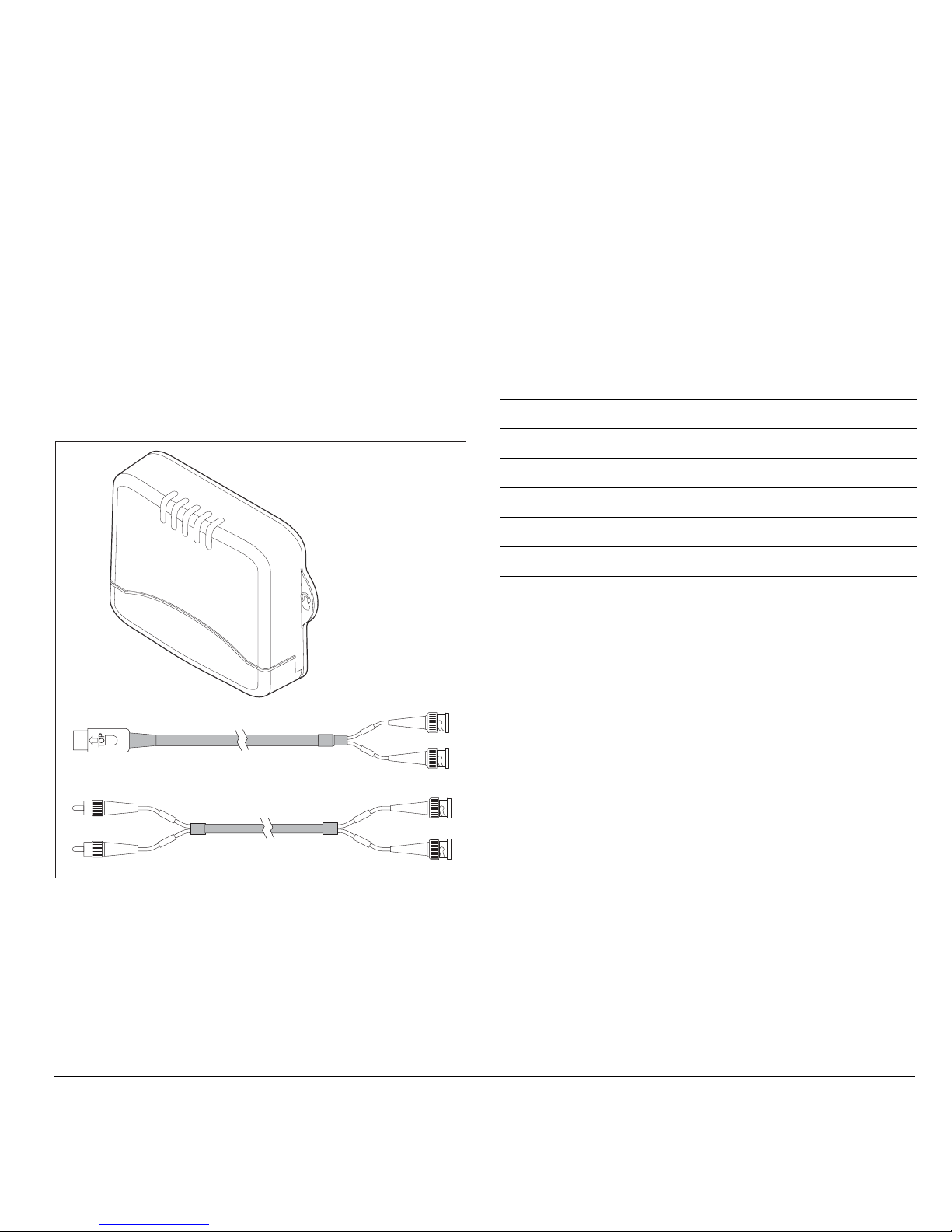

3.3 G-Series Keyboard

Pack items

D10065-1

Suncover

Handbook/

Documentation

Command

center keyboard

Panel seal

Stud (x4)

Finger

nut (x4)

Rear clamp

assembly

SeaTalkng backbone cable

SeaTalk

ng

spur cable

SeaTalk

ng

T connector

Description Part No.

G-Series command center keyboard E02044

Sun cover R08307

1 m (3.3 ft) SeaTalk

ng

/NMEA2000 cable A06039

400 mm (15.75 in) SeaTalk

ng

backbone cable A06033

SeaTalk

ng

T-piece connector A06028

Rear cover / mounting bracket R08308

Screw pack R08309

Installation sheet 87084

Warranty booklet 80017

Page 27

27 Chapter 3: Packs and contents

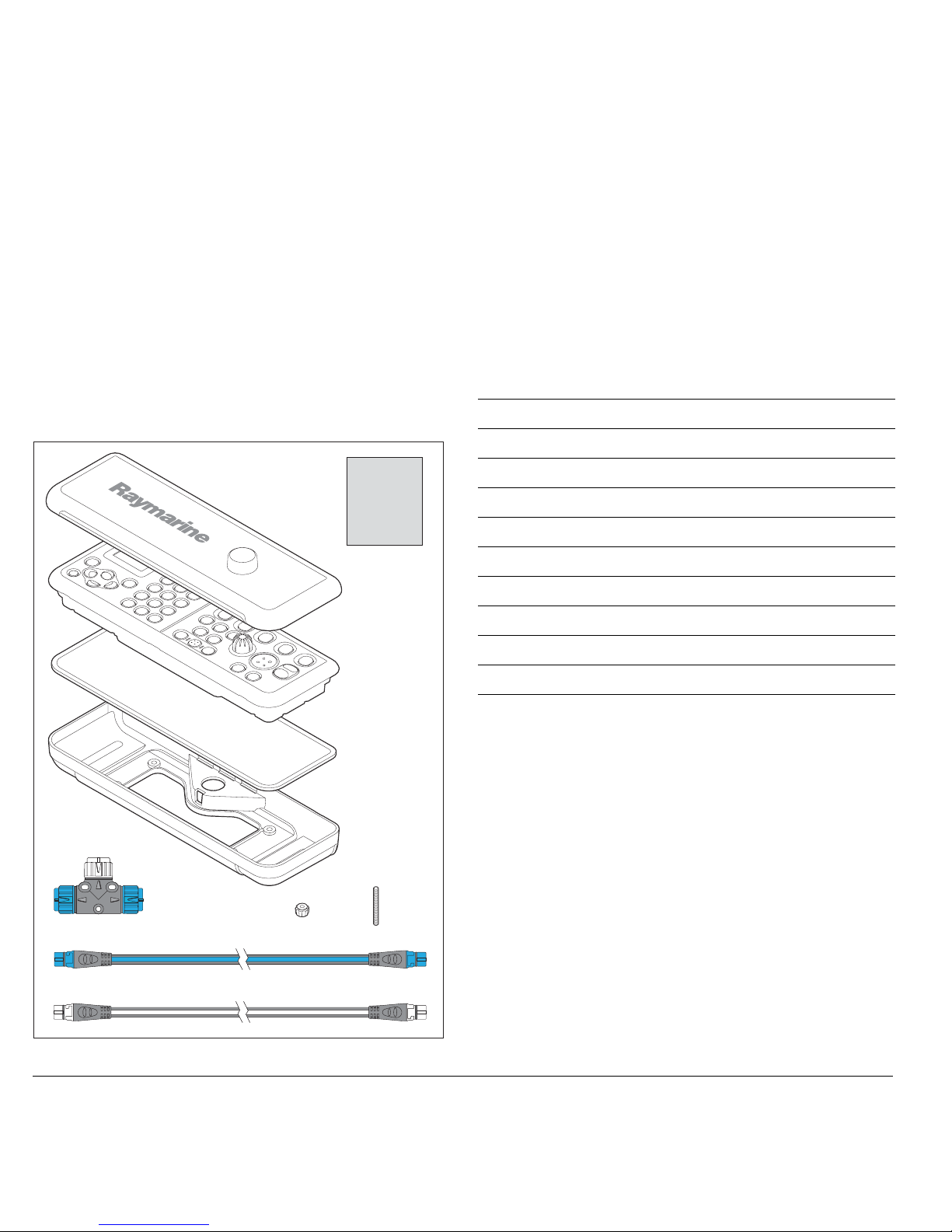

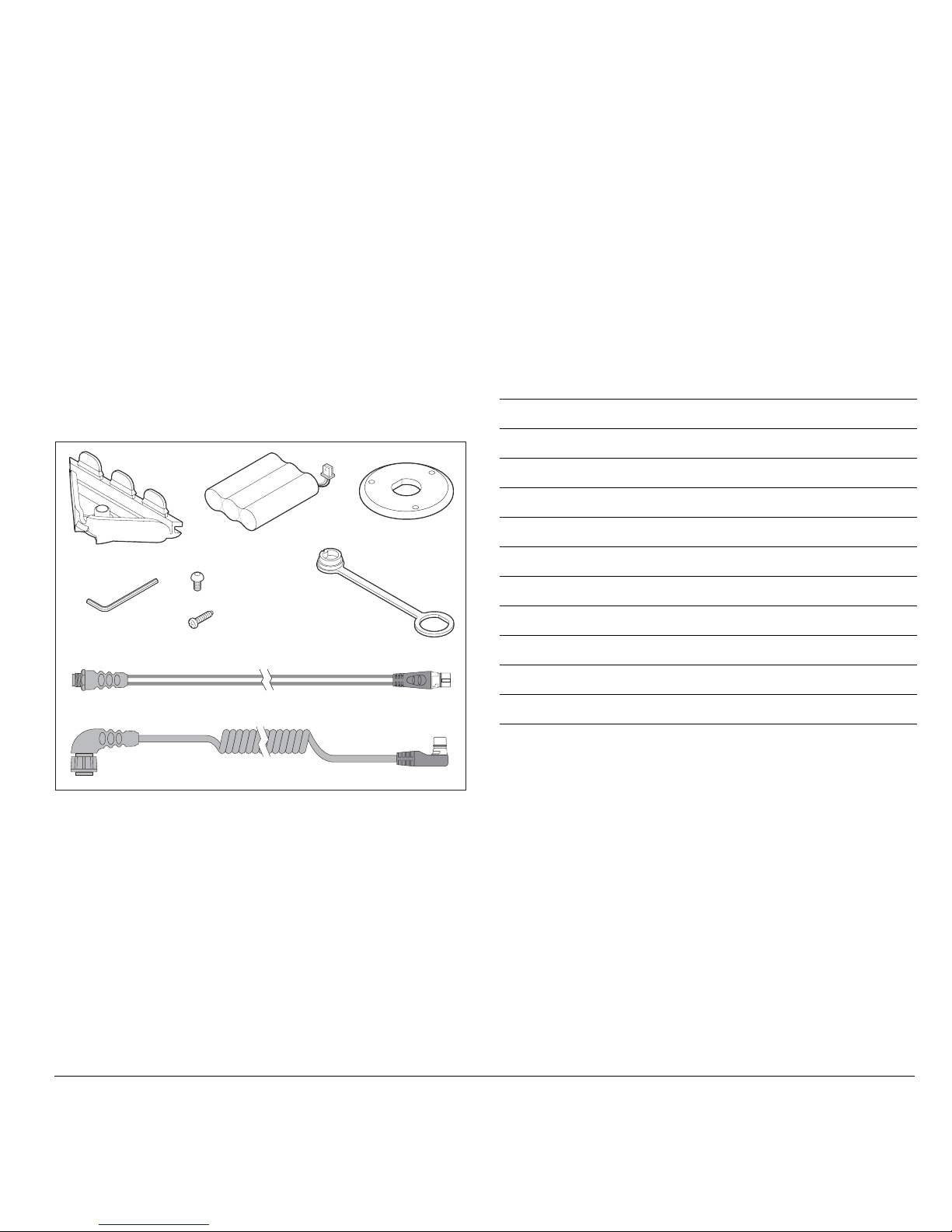

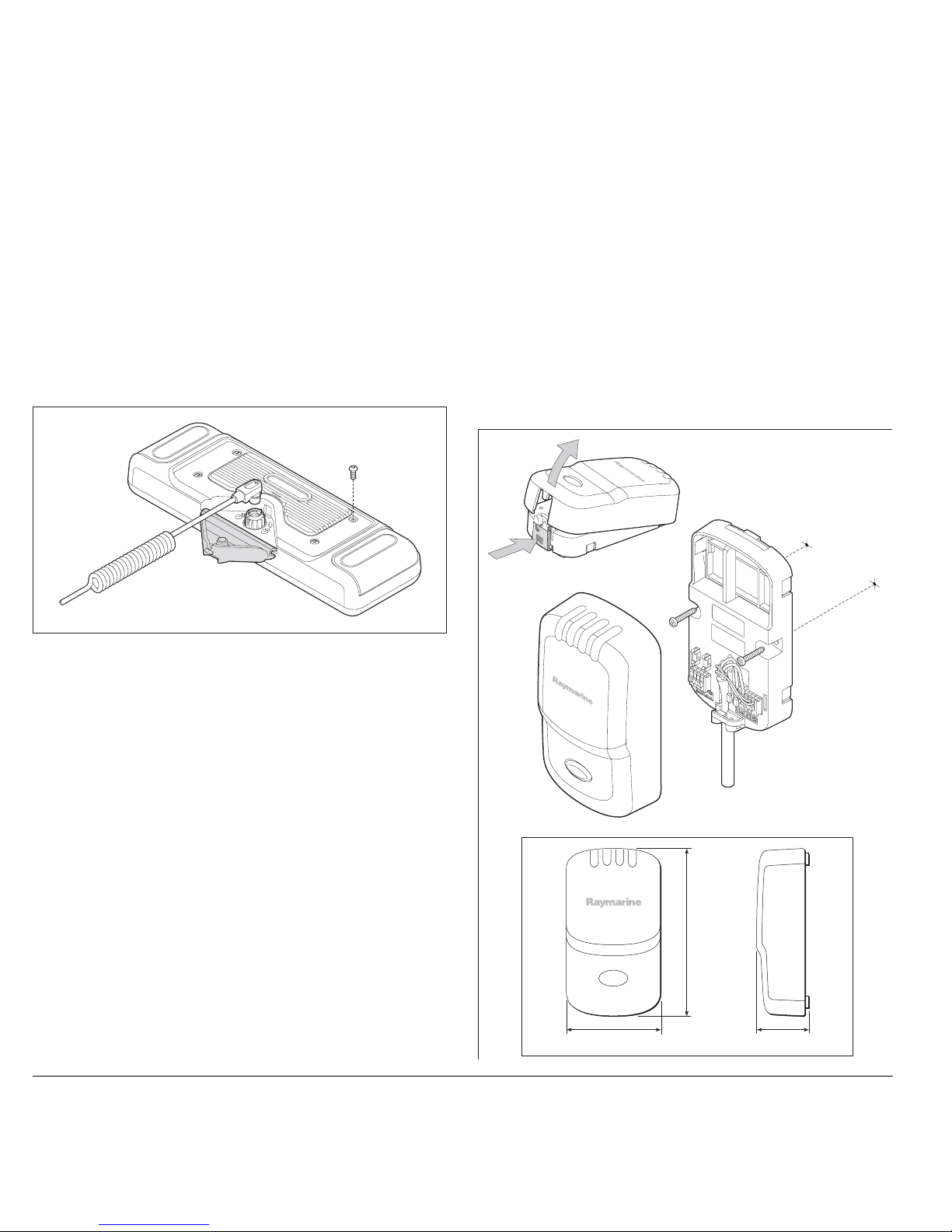

3.4 Keyboard wireless upgrade kit

Pack items

Battery pack

Connector cover

D10066-1

Handset dust cover

Allen head screw (x4)

Screw (x3)

Mounting plate

SeaTalk

ng

bulkhead mounting cable

SeaTalk

ng

Command Center charge cable

Allen key

Description Part No.

SeaTalk

ng

bulkhead mounting cable R08311

2.5 m (8.2 ft) keyboard charge cable R08310

Battery pack R08312

4 x allen head M3 screws R08313

Mounting plate R08314

Connector cover R08315

Mounting screws (self tapping) x 3 R08316

Dust cap (covers dash mount cnx) R08317

Allen key R08338

Installation Sheet 87085

Page 28

G-Series Installation & Commissioning 28

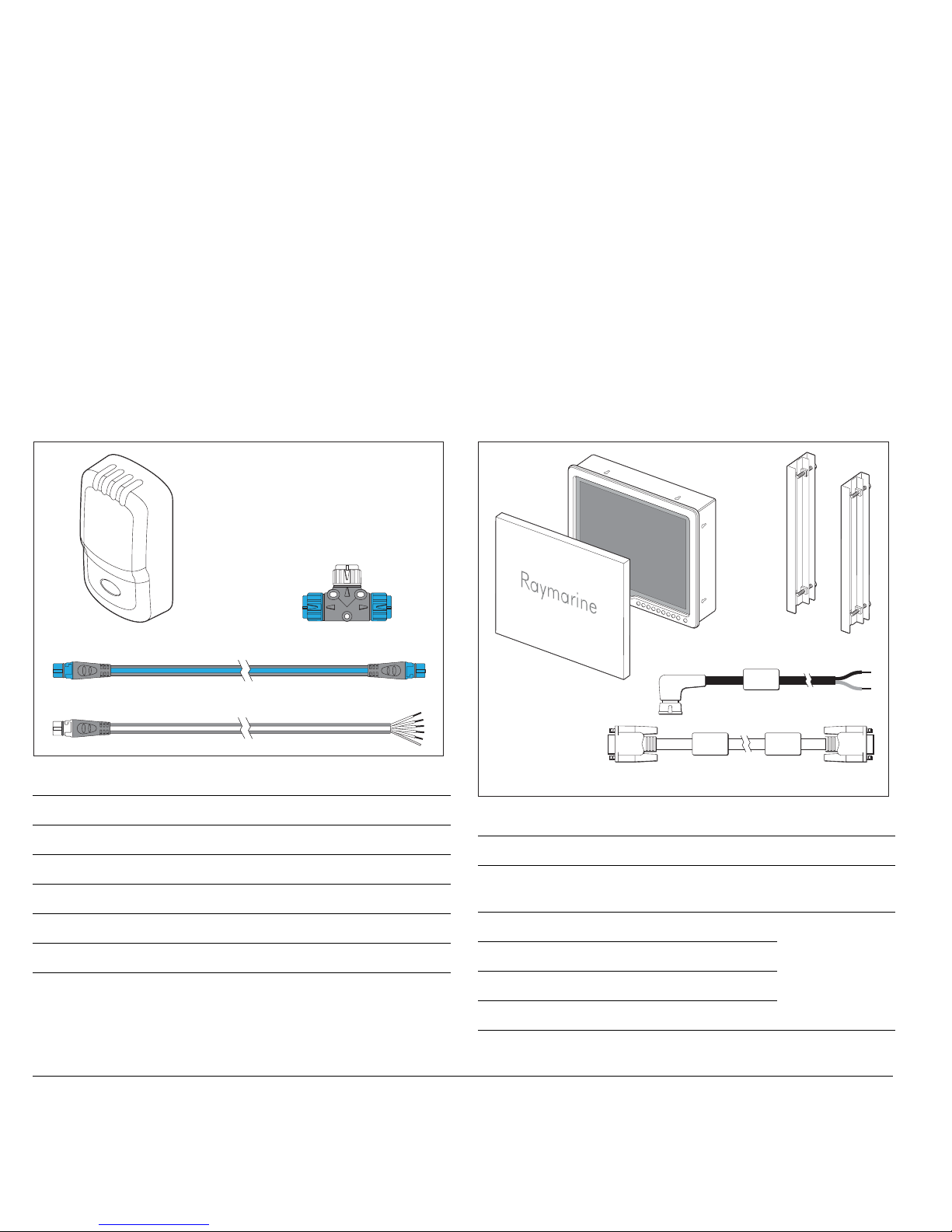

3.5 SeaTalkng wireless basestation

Pack items

3.6 Marine monitors

Pack items

Description Part No.

Wireless basestation E02045

1 m (3.3 ft) SeaTalk NG spur cable - stripped ends A06043

400 mm (15.75 in) SeaTalk

ng

backbone cable A06033

SeaTalk NG T-connector A06028

Installation instructions 87086

SeaTalkng backbone cable

SeaTalk

ng

spur cable

SeaTalk T connector

D10067-1

SeaTalk

ng

wireless basestation

Description Part No.

17” Marine Display

19” Marine Display

E02036

E02037

Sun cover Part numbers

depend on the

display model.

Refer to your

display handbook

for details

2 x mounting brackets

5 m (16.4 ft) VGA cable

1.5 m (4.9 ft) Power cable

Marine

display

Sun cover

1.5 meter Power Cable

5 meter VGA cable assembly

Mounting brackets x 2

D10363-1

Page 29

29 Chapter 3: Packs and contents

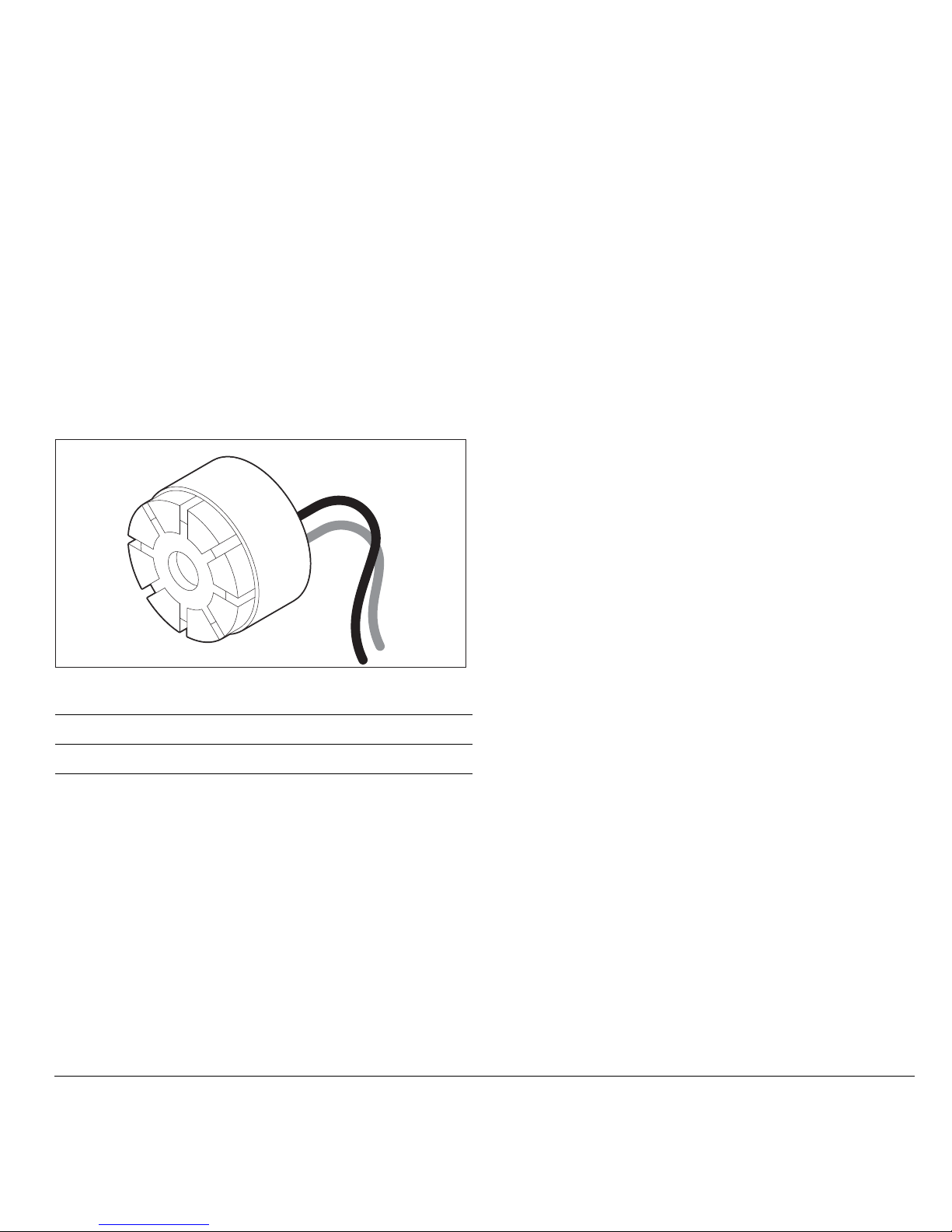

3.7 Alarm buzzer

Pack items

Description Part No.

Alarm buzzer E26033

D10363-1

Page 30

G-Series Installation & Commissioning 30

Page 31

4

Chapter 4: Cables and connections

This section contains details of cables and connections. Use it to plan your system wiring and ensure that you

have the necessary cables available.

Chapter contents

• 4.1 General instructions on page 32

• 4.2 Power distribution on page33

• 4.3 GPM400 processor on page 37

• 4.4 Monitor connections on page 38

• 4.5 Keyboard connections on page 40

• 4.6 Video and Entertainment on page 43

• 4.7 SeaTalk

hs

network on page 47

• 4.8 GPS Connection on page 49

• 4.9 SeaTalk & Alarm connection on page 50

• 4.10 NMEA 0183 connections on page 51

• 4.11 SeaTalk

ng

connections on page 54

• 4.12 NMEA 2000 connections on page 55

Page 32

G-Series Installation & Commissioning 32

4.1 General instructions

Cable types and length

• Follow the guidelines given in this section to determine appropriate cable types and length.

• Unless otherwise stated use only standard cables of the correct

type, supplied by Raymarine.

• Ensure that any non-Raymarine cables are of the correct quality

and gauge. For example, longer power cable runs may require

larger wire gauges to minimize any voltage drop in a cable.

Routing cables

• No acute bends. Minimum bend radius of 100mm.

• Protect all cables from physical damage and exposure to heat.

Use trunking or conduit where possible. Avoid running cables

through bilges or doorways, or close to moving or hot objects.

• Secure cables in place using tie-wraps or lacing twine. Coil any

extra cable and tie it out of the way.

• Where a cable passes through an exposed bulkhead or deckhead, a watertight feed-through should be used.

You should always route data cables:

• as far apart from other equipment and cables as possible,

• as far away from high current carrying AC and DC power lines

as possible,

• as far away from antennas as possible.

Strain relief

• Ensure adequate strain relief is provided. Protect connectors

from strain and ensure they will not pull out under extreme sea

conditions.

Circuit isolation

For installations using both AC and DC current:

• Always use isolating transformers or a separate power-inverter

to run PC’s, processors, displays and other sensitive electronic

instruments or devices.

• Always use an isolating transformer with Weather FAX audio

cables.

• Always use and RS232/NMEA converter with optical isolation

on the signal lines.

• Always make sure that PC’s or other sensitive electronic devices have a dedicated power circuit.

Cable shielding

Ensure that all data cables are properly shielded that the cable

shielding is intact (e.g. hasn’t been scraped off by being squeezed

through a tight area).

Schematic diagram

When planning your connections and cabling, produce a schematic

diagram to assist you.

EMC installation guidelines

Raymarine equipment and accessories conform to the appropriate

Electromagnetic Compatibility (EMC) regulations. This minimizes

electromagnetic interference between equipment, which could otherwise affect the performance of your system.

Correct installation is required to ensure that EMC performance is

not compromised.

Ensure you comply with the EMC guidelines detailed on page 58

D10596-1

Minimum bend of cable

100 mm (4 in) radius

Minimum bend

200 mm (8 in)

diameter

Page 33

33 Chapter 4: Cables and connections

4.2 Power distribution

Typical distribution

D10145-1

DSM 400

GPSRadar

GPM400 GPM400

+VE bar

Circuit breaker

All GPM400 processors must be

powered from a single breaker.

In line fuse protection must be provided

for each individual power circuit.

-VE bar

GPM400 GPM400

Distribution Panel

Monitor Monitor

Fuses

Page 34

G-Series Installation & Commissioning 34

Power distribution notes:

• Raymarine recommend that you have a dedicated distribution

panel for your G-Series system.

• All GPM400 processor units must be powered from a single

breaker or switch, with appropriate circuit protection.

• All monitors and ancillary equipment should where possible be

wired to individual breakers.

Sharing a breaker

Where more than 1 piece of equipment shares a breaker you must

provide protection for the individual circuits. E.g. an in-line fuse for

each power circuit

The fuse must be of an appropriate type and rating for the load to

be protected.

Circuit grounding

Grounding notes

• Use a dedicated earthing plate (e.g. dynaplate) in contact with

the water.

• Ground cables may be routed to a common point (e.g. within

the switch panel. With a single (appropriately rated) copper

braid connecting to the earthing plate.

• Use flat tinned copper braid, 30 A rating (1/4 inch) or greater.

Equivalent stranded wire diameter 4mm or greater.

• Keep the length of the earth braid as short as possible.

• Installations using both AC and DC current should have a separate ground circuit for each. See Circuit isolation on page 32.

D10164-1

+VE bar

Circuit breaker

FuseFuse

Monitors and ancilliary equipment where

possible be wired to individual breakers.

Where this not possible an inline FUSE

can be used to provide additional portection.

-VE bar

Grounding

The power cable screen and all Ground terminals

MUST be connected to ship’s ground. Failure to

connect to ship’s ground may cause it, or other

on-board electronics to function incorrectly

.

No positive ground

The G-Series system is NOT intended for use on

“positive” ground boats. The power input cable

earth screen connections must be connected

directly to the boats ground.

No ground loops

Ground loops may cause galvanic corrosion.

Avoid using the ships structure (metal) as an

earth point, as this could result in ground loops.

Page 35

35 Chapter 4: Cables and connections

Circuit protection

GPM400 processor

All GPM400 processors must be switched via a single breaker.

General circuit protection

The following loads and protection ratings apply to G-Series displays and ancillary equipment:

Power cables

• Cable must be of a suitable gauge for the circuit load.

• Each unit should have its own dedicated power cable wired

back to the distribution panel.

• All GPM400 processors should be connected to the same

breaker.

• Power cable must include a separate screen wire.

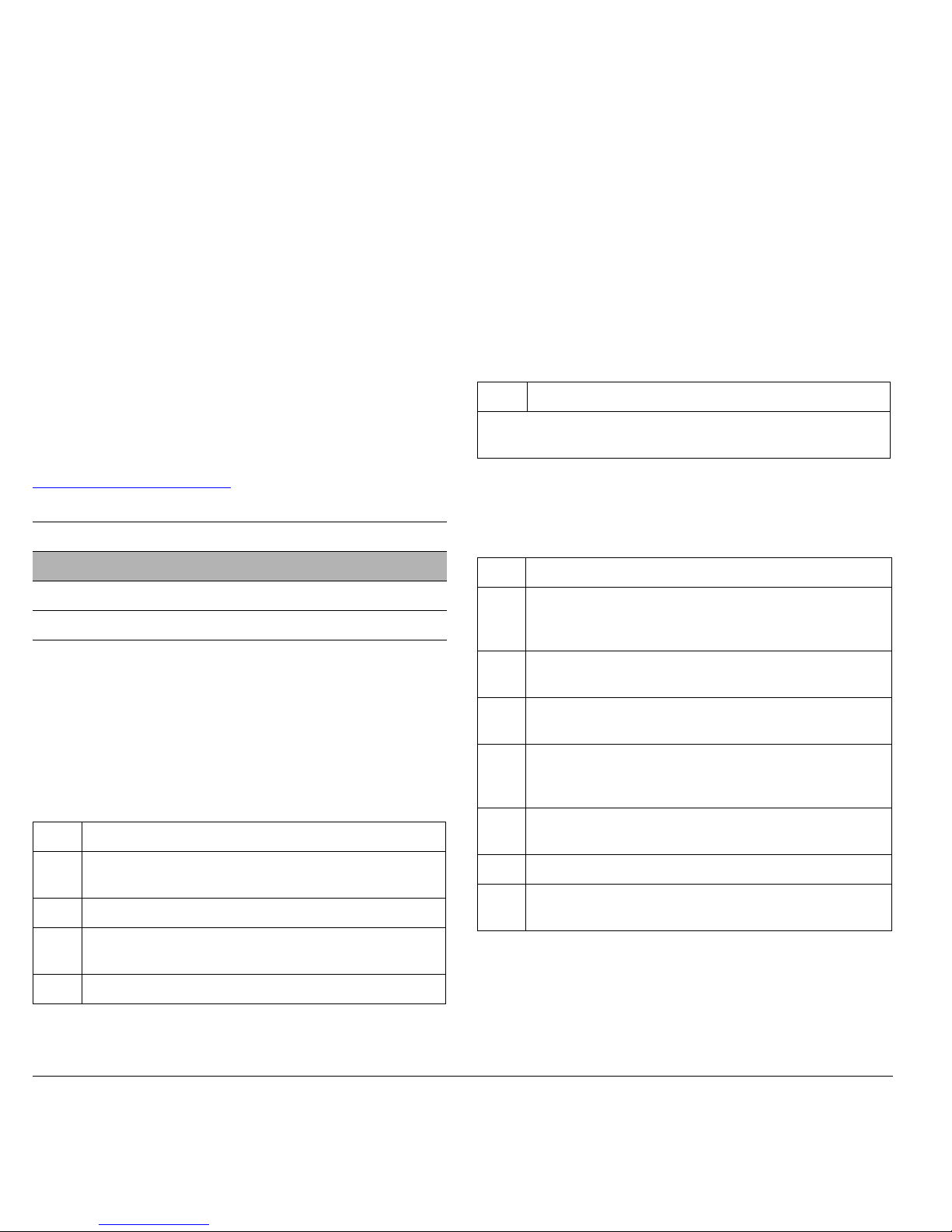

Number

of

GPM400

units

Supply

voltage

Thermal

breaker

(Overall)

Fuse

(Individual)

1 12 V 10 A 10 A

24 V 5 A 5 A

2 12 V 20 A 10 A

24 V 10 A 5 A

3 12 V 25 A 10 A

24 V 15 A 5 A

4 12 V 35 A 10 A

24 V 20 A 5 A

Equipment

Supply

voltage

Thermal

breaker

Fuse

G190 marine display 12 V 8 A 12 A

24 V 4 A 6 A

G170 marine display 12 V 8 A 12 A

24 V 4 A 6 A

GVM400 Video Module 12 V 1.2 A 2 A

24 V 1 A 1 A

For other ancillary equipment, refer to the separate installation instructions for

circuit loading and protection information.

Equipment

Supply

voltage

Thermal

breaker

Fuse

Page 36

G-Series Installation & Commissioning 36

GPM400 power cables

GVM400 Video Module power cables

G170/G190 Marine monitor power cables:

Length (max) Supply voltage

Cable gauge

(AWG)

0-5 m

(0-16.4 ft)

12 V 18

24 V 20

5-10 m

(16.4-32.8 ft)

12 V 14

24 V 18

10-15 m

(32.8-49.2 ft)

12 V 12

24 V 16

15-20 m

(49.2-65.6 ft)

12 V 12

24 V 14

Each unit should have its own dedicated power cable wired back to the distribution panel.

All GPM400 processors should be connected to the same breaker.

Power cable must include a separate screen.

Length (max) Supply voltage

Cable gauge

(AWG)

0-5 m

(0-16.4 ft)

12 V 20

24 V 20

5-10 m

(16.4-32.8 ft)

12 V 20

24 V 20

10-15 m

(32.8-49.2 ft)

12 V 20

24 V 20

15-20 m

(49.2-65.6 ft)

12 V 18

24 V 20

The GVM400 should have its own dedicated power cable wired back to the

distribution panel.

Power cable must include a separate screen.

Length (max) Supply voltage

Cable gauge

(AWG)

0-5 m

(0-16.4 ft)

12 V 12

24 V 12

5-10 m

(16.4-32.8 ft)

12 V 9

24 V 9

10-15 m

(32.8-49.2 ft)

12 V 7

24 V 7

15-20 m

(49.2-65.6 ft)

12 V 6

24 V 6

Monitor connection notes:

• Each monitor should have its own dedicated power cable.

• Equipment which is susceptible to noise (such as VHF radios) should not be

wired to the same distribution panel as the monitors. If in doubt the monitors

(or affected equipment) can be wired directly back to the battery/power

source via a dedicated breaker.

Refer to the separate monitor documentation for more details.

Length (max) Supply voltage

Cable gauge

(AWG)

Page 37

37 Chapter 4: Cables and connections

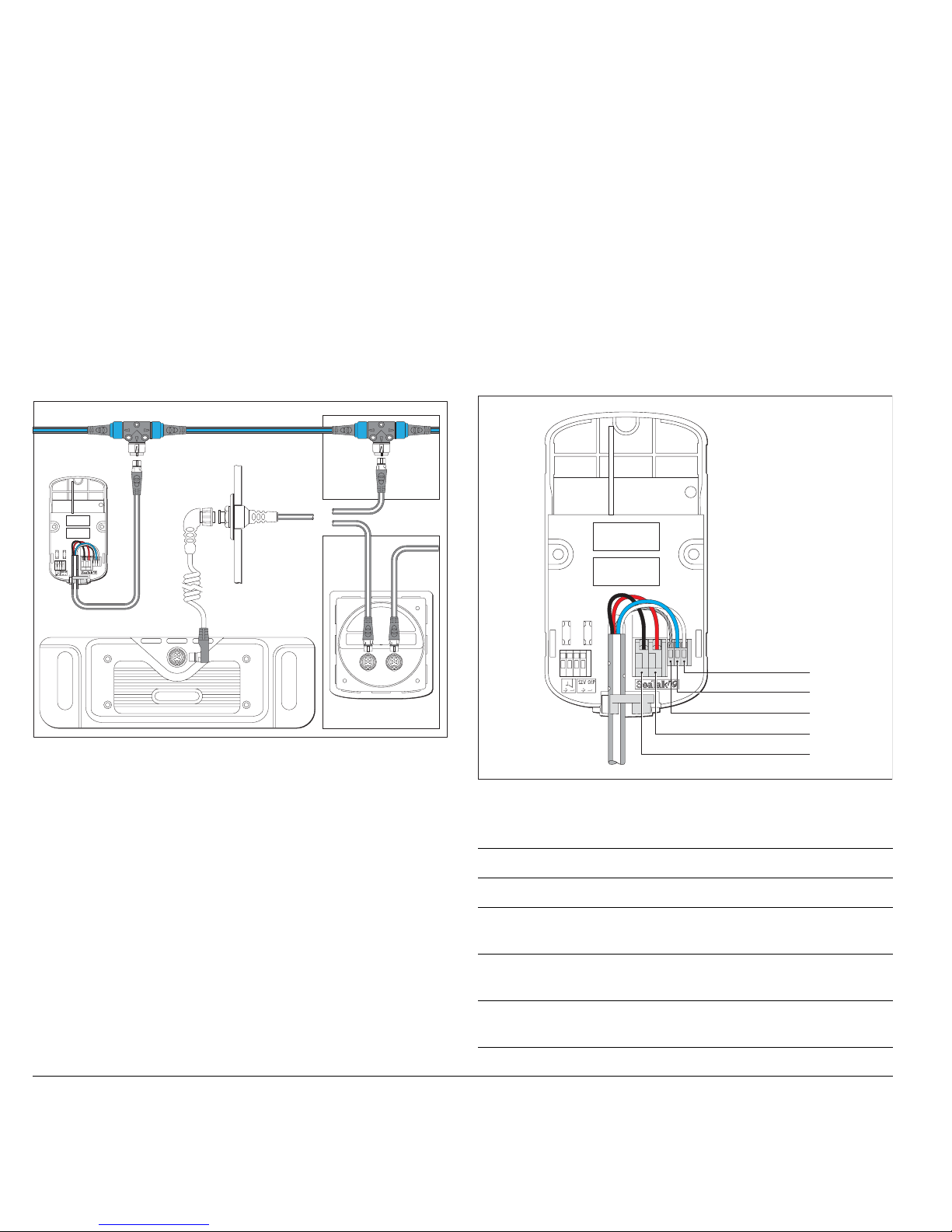

4.3 GPM400 processor

The GPM400 has the following connections:

1. 12/24V Power in (see page 33)

2. Status LED (see page 99)

3. SeaTalk / Alarm output (see page 50)

4. SeaTalk

ng

connection (see page 54)

5. DVI disp lay connection - repeater (see page 38)

6. DVI disp lay connection - master (see page 38)

7. USB connection (for chart and software upgrade only)

8. SeaTalk

hs

network connection (see page 47).

9. NMEA 0183 connection (see page 51)

10.NMEA 0183 connection (see page 51)

11.Audio output (see page 46)

Maximum quantity of GPM400 units

The G-Series system will support up to 4 GPM400 processors, of

which 1 must be set as the Master GPM.

Master GPM

On a system with more than one GPM400 you must designate one

them as a Master GPM. The SeaTalk and SeaTalk

ng

bus must be

connected to the Master GPM.

Note: The data is passed between multiple GPMs using the

SeaTalk

hs

network.

See also

• Ensure you record connections to the GPM400 on the schematic diagram. See Appendix B - Nav Station schematic .

• For a typical SeaTalk

hs

system see page 19.

• For information on SeaTalk

hs

cables and connections see

page 47.

D10163-1

S

E

A

T

A

L

K

H

I

G

H

S

P

E

E

D

N

M

E

A

0

1

8

3

2

S

E

A

T

A

L

K

/

A

L

A

R

M

O

U

T

P

O

W

E

R

N

M

E

A

0

1

8

3

1

S

E

A

T

A

L

K

N

G

A

U

D

I

O

MONITOR REPEATER

MONITOR MASTER

4351

67891011

2

Page 38

G-Series Installation & Commissioning 38

4.4 Monitor connections

Connect the G-Series marine displays to both the GPM400 processor and SeaTalk

hs

switch.

Monitors may be connected to the GPM400 using either VGA or

DVI cable.

Repeat displays

Repeat displays (if used) show the same information / page as the

master display. For this reason each display within a Nav Station

must be connected to a different GPM400.

Note: During start-up only the master display will show the boot

sequence and start-up information.

Maximum quantity of monitors

The G-Series system will support up to 8 monitors (2 per GPM400).

CameraCamera

Monitor

GPM 400

Repeat Monitor (optional)

DVI or VGA

DVI or VGA

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

D10074-1

SeaTalk

hs

switch

Composite video

Composite video

D10075-1

Power Cable

DVI

Input

SeaTalk

hs

SeaTalk

hs

VGA

Input

VGA

input

adaptor

cable

DVI

Input

VGA

Input

Network selector switch

(in UP position)

Monitor

HS switch

GPM 400

OR

Page 39

39 Chapter 4: Cables and connections

Screen resolution and aspect ratio

Each GPM will output the same screen resolution to all connected

displays.

Therefore where multiple displays are connected to a single GPM

they should have the same aspect ratio and screen resolution. For

example we recommend that wide screen televisions and standard

displays are connected to separate GPMs.

IP Address

When connecting a display to the processor, note its IP address on

your system diagram. You will need to refer to this during the commissioning process. (See Appendix B for sample diagrams.)

Selector Switch

Raymarine G-Series displays have a selector switch located by the

SeaTalk

hs

connector. This must be in the UP position for connec-

tion to the SeaTalk

hs

network.

3rd party displays

Ensure that any 3rd party (non-Raymarine) displays have electrical

isolation between the video connections and power supply (and

any other 0 V referenced connection). This is to avoid 0 V loops

which can cause interference issues.

Marine display cables

The following cables can be used with marine displays:

Cable Part No Notes

DVI Connection To ensure optimum signal quality

use only Raymarine cables.

5 m (16.4 ft)

DVI to DVI (digital) cable

E06021

10 m (32.8 ft)

DVI to DVI (digital) cable

E06022

VGA T o ensure optimum signal quality

use only Raymarine cables.

500 mm (19.69 in)

DVI-VGA converter

E06053 Required for any VGA connec-

tion to the GPM400.

1.5 m (4.9 ft)

VGA cable

R08130

5 m (16.4 ft)

VGA cable

R08174 Supplied with Raymarine

G-Series Marine Displays.

10 m (32.8 ft)

VGA cable

R08296

20 m (65.6 ft)

VGA cable

R08297

Display to SeaTalk

hs

Required for keyboard control of

display functions.

1.5 m (4.9 ft)

SeaTalk

hs

cable

E55049

5 m (16.4 ft)

SeaTalk

hs

cable

E55050

10 m (32.8 ft)

SeaTalk

hs

cable

E55051

20 m (65.6 ft)

SeaTalk

hs

cable

E55052

Power

1.5 m (4.9 ft)

Power cable

R08173 Supplied with product

Cable Part No Notes

Page 40

G-Series Installation & Commissioning 40

See also

• For more detailed installation information refer to the separate

users guide supplied with the display.

• Ensure you record connections to the GPM400 on the schematic diagram. See Appendix B - Nav Station schematic .

4.5 Keyboard connections

The G-Series Keyboard communicates using the SeaTalk

ng

system. It may be connected directly to the backbone (wired) or use a

remote basestation (wireless).

Note: You should have at least one permanently wired keyboard.

In the event that any wireless keyboards are lost, the wired

keyboard can be used to control the system.

Maximum quantity of Keyboards

The G-Series system will support up to 8 keyboards.

Schematic diagram

When connecting a keyboard to the system, record its details on

your system/schematic diagram. You will need this information during commissioning. (See Appendix B for sample diagrams.)

Wired keyboard system

Power cable extension Not supplied You may extend the power cable

if required. See page 35.

See Appendix C for other cables and accessories.

Cable Part No Notes

Monitor

Keyboard

D10068-1

SeaTalkng backbone

SeaTalk

ng

spur

SeaTalk

ng

spur

GPM 400

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

I

N

ENTER

Page 41

41 Chapter 4: Cables and connections

Wired keyboard connection details

For cable part numbers see page 42.

Wireless keyboard system

OR

SeaTalkng instrument, e.g. ST70

SeaTalk

ng

spur

SeaTalk

ng

spur

Keyboard

SeaTalk

ng

backbone

D10070-1

Monitor

Keyboard

SeaTalk

ng

backbone

SeaTalk

ng

spur

SeaTalk

ng

spur

SeaTalk

ng

spur

GPM400

D10069-1

SeaTalk

ng

charge cable

Basestation

Charge point

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

Page 42

G-Series Installation & Commissioning 42

Wireless keyboard connection details

Keyboard cables

The following cables can be used with the Keyboard:

OR

Wireless

basestation

Keyboard

SeaTalk

ng

backbone

Charge

point

SeaTalk

ng

bulkhead

mounting

SeaTalk

ng

spur

SeaTalk

ng

instrument

(e.g. ST70)

D10071-1

Cable Part No Notes

Keyboard to SeaTalk

ng

400 mm (15.75 in)

SeaTalkng spur cable

A06038

1 m (3.3 ft)

SeaTalk

ng

spur cable*

A06039* Suppled with the keyboard

3 m (9.8 ft)

SeaTalk

ng

spur cable

A06040

D10208-1

Black

Red

Blue

White

Wireless

basestation

SeaTalk

ng

connection

Screen

Page 43

43 Chapter 4: Cables and connections

See also

Ensure you record connections to the GPM400 on the schematic

diagram. See Appendix B - Nav Station schematic .

4.6 Video and Entertainment

Video and entertainment is connected and distributed to the

G-Series system using 2 system components:

• GVM400 Video Module

•SeaTalkhs switch.

Note: Video equipment may also be connected directly into the

displays, although this will not be distributed around the

system.

5 m (16.4 ft)

SeaTalk

ng

spur cable

A06041

Wireless basestation to SeaTalk

ng

1 m (3.3 ft)

SeaTalk

ng

spur cable

(bare ends)

A06043 Included with wireless

basestation.

3 m (9.8 ft)

SeaTalk

ng

spur cable

(bare ends)

A06044

Dashboard / Charging

2.5 m (8.2 ft)

charging cable

R08311 Included with the wireless

upgrade kit.

3 m (9.8 ft)

SeaTalk

ng

bulkhead

mounting cable

R08310

See Appendix C for other cables and accessories.

Cable Part No Notes

Page 44

G-Series Installation & Commissioning 44

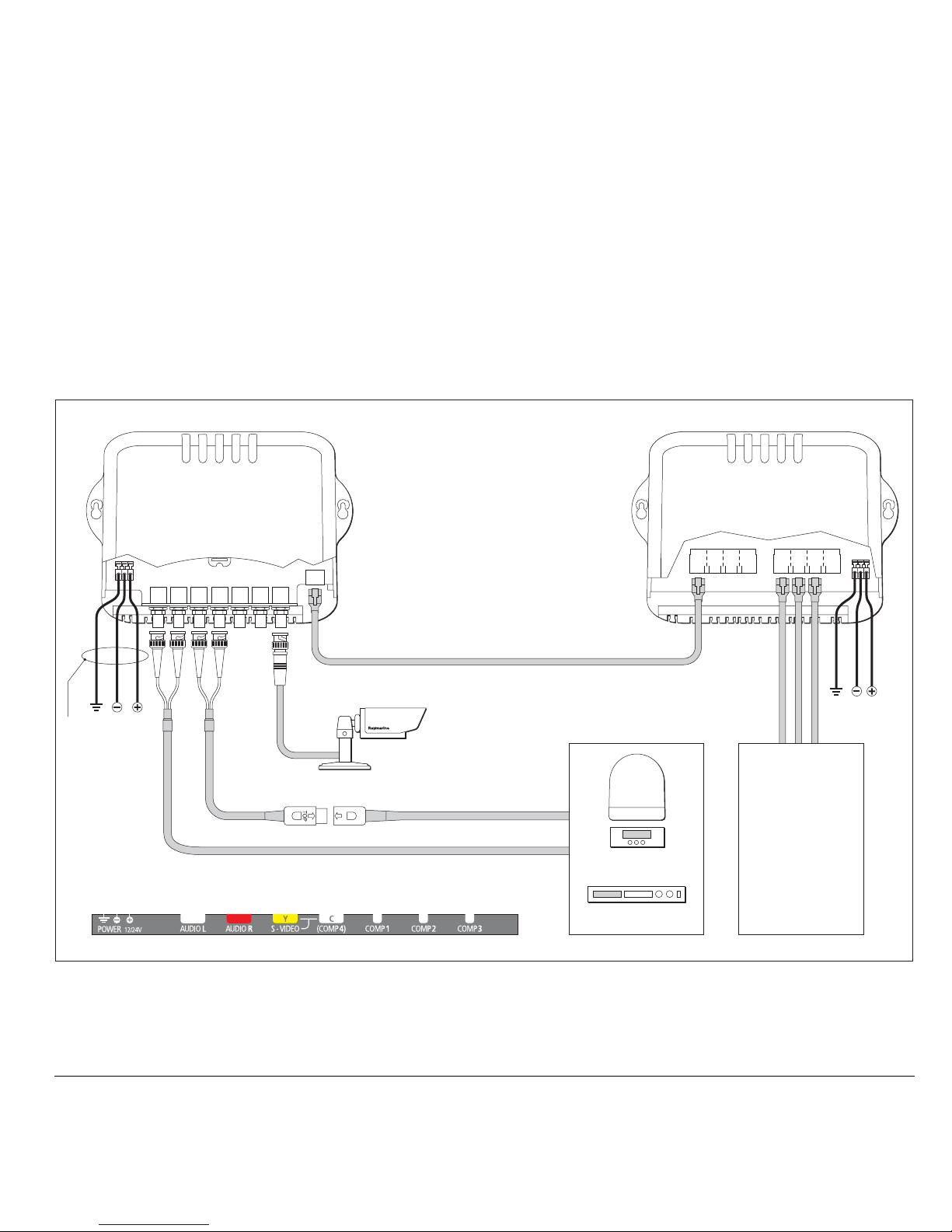

Typical video system

Maximum quantity of GVM400 video modules

The G-Series system will support up to 2 GVM400 video modules.

D10076-1

SeaTalk

hs

switch

S-Video and Audio

SeaTalk

hs

SeaTalk

hs

SeaTalk

hs

network

DVD

OR

Sat

TV

GVM400 video module

Composite

Composite

Composite

Page 45

45 Chapter 4: Cables and connections

Video / Entertainment connection details

D10077-1

Video module

SeaTalk

hs

switch

SeaTalk

hs

G-Series and

SeaTalk

hs

devices

DVD

OR

Audio

Video module connections

S-Video

Sat

TV

Screened

power cable

Power

supply

Earth

Page 46

G-Series Installation & Commissioning 46

Video/Entertainment system cables

The following cables are used to connect the GVM400 video

module:

Video output connection

The video output is obtained from the GPM400 processor using

DVI or VGA cables. See Monitor connections on page 38 for

details.

Audio output connection

G-Series audio output is obtained from the GPM400. The following

audio signals are obtained through this output.:

• Entertainment / Audio from the Video processor. (Associated

with the Comp4 or S-Video connection)

• Alarms and other system alerts.

Note: The audio output is line level only and must be connected to

a suitable 3rd party amplifier in order to be heard.

Audio cables

The following cables are available to connect to the audio output:

Cable Part No Notes

S-Video

1.5 m (4.9 ft)

adapter cable

R08274 Included with GVM400.

Audio

1.5 m (4.9 ft)

audio cable

R08275 Included with the GVM400

AV cables N/A Installer to supply suitable cables.

Video and audio equipment should be supplied with appropriate cables to

connect to the G-Series system.

SeaTalk

hs

Use SeaTalkhs Patch cables.

See page 47

Power Power cables are not included with GVM400.

You must supply appropriate power cables to

suit your system requirements (see page 35).

See Appendix C for other cables and accessories.

Cable Part No Notes

Audio

3 m (9.8 ft)

Audio out cable

R08266 Supplied with GPM400.

15 m (49.2 ft)

G-Series Audio out

cable

R08298

GPM 400

D10190-1

To ship's audio system

Page 47

47 Chapter 4: Cables and connections

4.7 SeaTalkhs network

The SeaTalkhs network has 2 main purposes:

• Connection of digital devices.

• Networking of G-Series equipment.

For a typical SeaTalk

hs

system see page 19.

SeaTalkhs devices

The following digital devices communicate via the SeaTalkhs

network:

• SeaTalk

hs

Switch

The hub of the network, this routes all network traffic.

• GPM400 processors

For sharing data over the network.

• GVM400 Video Module

For video distribution over the G-Series network. See page 43

• Digital radar

• Digital sounder (e.g. DSM400)

For fishfinding applications. Refer to the separate instructions

supplied with the sounder.

• G-Series marine displays (G190, G170 etc.)

To allow control of display functions at the G-Series keyboard.

See page 38

• SR100 Sirius weather/audio receiver (North America only.)

To receive sirius satellite weather and audio services.

See also

For a typical SeaTalk

hs

system see page 19.

For more details on the connections refer to the separate instructions supplied with the digital devices and the SeaTalk

hs

switch.

SeaTalkhs Network cables

All devices are wired individually back to the SeaTalkhs switch

using the following cables:

Cable Notes

SeaTalk

hs

network

1.5 m (4.9 ft)

SeaTalk

hs

network

cable

E55049 Network cables are used to connect

the GPM400 to the SeaTalkhs

switch.

5 m (16.4 ft)

SeaTalk

hs

network

cable

E55050

10 m (32.8 ft)

SeaTalk

hs

network

cable

E55051

15 m (49.2 ft)

SeaTalkhs network

cable

A62135

20 m (65.6 ft)

SeaTalk

hs

network

cable

E55052

SeaTalk

hs

patch

Page 48

G-Series Installation & Commissioning 48

Increasing network capacity

For increased capacity the network may contain multiple SeaTalkhs

switches, connected together using SeaTalk

hs

network patch

cables.

DSM digital sounder connection

The G-Series system can be used with the following DSM units:

•DSM300

•DSM400

The DSM connects to G-Series system via the SeaTalk

hs

switch.

Example: DSM400 connection

Maximum quantity of DSM sounders

The G-Series system will support 1 DSM sounder.

See also

For more information refer to the installation guide supplied with the

DSM unit.

1.5 m (4.9 ft)

SeaTalk

hs

patch cable

E06054 Patch cables are used to connect

the following devices to the

SeaTalkhs switch:

• GVM400 video module

•SeaTalk

hs

Switch (connecting to

other SeaTalk

hs

switches).

• G-Series marine displays.

5 m (16.4 ft)

SeaTalk

hs

patch cable

E06055

10 m (32.8 ft)

SeaTalk

hs

patch cable

E06056

15 m (49.2 ft)

SeaTalk

hs

patch cable

A62136

20 m (65.6 ft)

SeaTalk

hs

patch cable

E06057

Power Power cables are not included with the SeaTalk

hs

switch. You must supply appropriate power cables to

suit your system requirements (see page 35).

See Appendix C for other cables and accessories.

Cable Notes

D10201-1

HS switch

SeaTalk HS

DSM400

Page 49

49 Chapter 4: Cables and connections

Digital radar connection

The digital radar scanner connects to the SeaTalkhs switch using

dedicated digital radar cables

Maximum quantity of Radar scanners

The G-Series system will support up to 2 digital rader scanners.

Digital radar cables

The following cables are used to connect the digital radar scanner:

See also

For more information refer to the installation guide supplied with the

radar scanner.

4.8 GPS Connection

Depending upon your GPS type it may be either connected via

SeaTalk or NMEA 0183.

For SeaTalk connection refer to:

• SeaTalk & Alarm connection on page 50.

• Separate instructions supplied with your GPS unit.

For NMEA 0183 connection refer to:

• NMEA 0183 connections on page 51

• Separate instructions supplied with your GPS unit.

Cable Part No Notes

Digital cable

5 m (16.4 ft)

Digital cable

A55076

HS switch

Radar

D10202-1

Power

VCM100

10 m (32.8 ft)

Digital cable

A55077

15 m (49.2 ft)

Digital cable

A55078

25 m (82.0 ft)

Digital cable

A55079

Digital extension cable Required if you wish to extend

the cable distance.

5 m(16.4 ft)

extension cable

A5080

10 m (32.8 ft)

extension cable

A55081

The maximum cable length including all extensions is 55 m (180 ft)

Cable Part No Notes

Page 50

G-Series Installation & Commissioning 50

4.9 SeaTalk & Alarm connection

The alarm output and SeaTalk are combined into a single connector. This includes a 12 V fused power supply.

Alarm output

The alarm output is used to alert the operator to alarms and other

audible warnings.

Note: Alarms are global and as such will be sounded across all

audio and alarm outputs across the system.

SeaTalk connection

The SeaTalk connection allows the G-Series system to receive

data from Raymarine SeaTalk compatible devices such as:

• Autopilot

The G-Series can receive and display autopilot information and

act as a repeat controller. Refer to the separate reference guide

for operation details.

• Instruments

The G-Series can receive and display data received from instruments, such as wind, speed and depth.

• GPS

Required for chart applications.

Master GPM

The SeaTalk bus must be connected to the Master GPM (see

page 37).

Note: SeaTalk connection to other GPMs for the purposes of

redundancy is allowed.

12 V power supply

The SeaTalk connection provides a 12 V supply rated at 125 mA.

This is suitable to supply 1 sounder module.

Note: SeaTalk instruments will usually be powered from a sepa-

rate power supply, e.g from a Raymarine autopilot course

computer. You should not power a SeaTalk bus from more

than one supply.

Alarm

Alarm

Red

Black

Red

Black

No other SeaTalk

devices connected

Other SeaTalk

devices connected

Red

Black

Brown

White

White

Brown

Black

Red

Yellow

Drain

SeaTalk/Alarm

Drain

Yellow

Other

SeaTalk

devices

12v

supply

GPM 400

D10144-1

or

Page 51

51 Chapter 4: Cables and connections

SeaTalk / Alarm output cables

The following cable is used to connect the SeaTalk / Alarm output:

4.10 NMEA 0183 connections

The GPM400 processor has 2 NMEA 0183 connectors.

Dual speed: 38.4 or 4.8 Kbps as required.

These may be used for connection of NMEA compliant devices for

data such as:

• Fastheading, from an autopilot or fastheading sensor.

This is required for Radar target acquisition (MARPA). See

page 52 and your separate autopilot instructions.

• AIS information (for radar target identification).

See page 53 and your separate AIS receiver instructions.

• Other NMEA data (such as 3rd party GPS or autopilot systems).

For other NMEA device connections refer to the separate manufacturers instructions.

Multiple NMEA devices

You may connect NMEA devices to any GPM400 including the

master GPM. You should only connect 1 device of any particular

type to the G-Series system (including any connected databus or

networked electronics).

For example: Your system should have GPS connected to one

place only. Duplicated GPS data will produce erratic behavior

within the system.

Connection /

Cable

Part No Notes

Alarm / SeaTalk

1.5 m (4.9 ft)

SeaTalk/Alarm Out

cable

E55054 Supplied with GPM400

processor.

See Appendix C for other cables and accessories.

GPM 400

D10193-1

Green

-ve

IN

White

+ve

IN

Yellow

+ve

OUT

Brown

-ve

OUT

Screen

(not

connected)

NMEA DEVICE

-ve

OUT

+ve

OUT

+veIN-ve

IN

Page 52

G-Series Installation & Commissioning 52

NMEA 0183 connection cables

The following cables are used to connect to NMEA 0183 devices.

NMEA 0183 Raymarine cable cores:

Fastheading connection

Fastheading data required for radar target acquisition (MARPA)

may come from either the autopilot or a separate Raymarine Fastheading sensor.

Connection /

Cable

Part No Notes

1.5 m (4.9 ft)

NMEA 0183 cable

R08004 Supplied with GPM400

processor unit.

Other NMEA

connections

N/A Installer to supply suitable data

cable.

Use a shielded twisted pair cable to minimise interference.

See Appendix C for other cables and accessories.

Function

(at GPM400 processor)

Color Pin no.

NMEA Input (-ve) common Green 1

NMEA Input (+ve) White 2

NMEA Output (+ve) Yellow 3

NMEA Output (-ve) common Brown 4

Not connected Screen 5

Note: Input and outputs are crossed.

Input GPM400 is connected to output at NMEA device and vice versa.

D10191-1

ENTERCANCEL

MENU

GPM 400

NMEA0183

Autopilot

Pilot control head Fluxgate compass

Page 53

53 Chapter 4: Cables and connections

AIS connection

For more information refer to separate AIS instruction documents.

D10192-1

GPM 400

AIS receiver

VHF radio

VHF antenna

NMEA0183

4.8 (GPS data

to VHF radio)

NMEA0183 4.8

(fast heading)

NMEA0183 (38.4)

Page 54

G-Series Installation & Commissioning 54

4.11 SeaTalkng connections

The G-Series system will use SeaTalkng to communicate with:

•SeaTalkng instruments (e.g. ST70),

•SeaTalk

ng

autopilots (e.g. ST70 with SPX course computer),

• G-Series keyboard.

SeaTalkng cables

The SeaTalkng system uses the following cables and connections.

SeaTalkng power

The SeaTalkng bus requires a 12 V power supply. This may be

provided from:

• Raymarine equipment witha regulated 12 V supply. (e.g. a

SmartPilot course computer)

• Other suitable 12 V supply. (Note the grounding requirements

for the G-Series system, see page page 34.

Typical SeaTalkng system

Connection /

Cable

Notes

Backbone cables

(various lengths)

The main cable carrying data. Spurs from the backbone are used to connect SeaTalk

ng

devices.

T-piece connectors Used to make junctions in the backbone to which

devices can then be connected.

Terminators Required at either end of the backbone.

Spur cables Used to connect devices.

Devices may be daisy chained or connected directly

to the T-pieces.

For more information refer to the separate SeaTalk

ng

reference manual.

Keyboard

GPM 400

Autopilot (Course Computer)

12 V / 24 V dc 12 V dc + Data

D10195-1

ENTERCANCEL

MENU

ENTERCANCEL

MENU

Power Supply

9

WXYZ8TUV7PQRS

4

GHI5JKL6MNO

ACTIVE

WPTS

MOB

DATA

MENU

PAGE

.

0

2

ABC3DEF

1

CANCEL

STANDBY

DODGE PILOT OK

R

A

N

G

E

O

U

T

IN

ENTER

SeaTalk

ng

backbone

Page 55

55 Chapter 4: Cables and connections

4.12 NMEA 2000 connections

NMEA 2000 devices are connected using the SeaTalkng bus. The

G-Series system can display data received from NMEA 2000

devices (e.g. for displaying data from compatible engines).

You may connect NMEA 2000 compatible devices using appropriate adaptor cables.

NMEA 2000 cable

The following cable is used to connect the NMEA 2000 devices to

the SeaTalk

ng

bus:

See also

For more information refer to the separate SeaTalk

ng

reference

manual.

Connection /

Cable

Part No Notes

1.5 m (4.9 ft)

SeaTalk

ng

to DeviceNet

male

A06046

SeaTalk

ng

to DeviceNet cable

SeaTalk

ng

backbone

NMEA 2000

equipment

(e.g. engine via

appropriate

manufacturers

interface)

D10599-1

Page 56

G-Series Installation & Commissioning 56

Page 57

5

Chapter 5: Installation and mounting

This section gives details for installation and mounting of the core components of the G-Series system. Use

this information when planning and installing your system.

Chapter contents

• 5.1 General instructions. Page 58

• 5.2 GPM400 Processor module. Page 59

• 5.3 G-Series Keyboard. Page 60

• 5.5 GVM400 Video Module. Page 66

• 5.6 Alarm buzzer. Page 67

See also

• Monitor installation. Refer to the separate instructions supplied with the monitor.

• Peripheral equipment. Refer to the instructions supplied with the individual packs.

• Cabling and connections - Chapter 4: Cables and connections. Page 31.

Page 58

G-Series Installation & Commissioning 58

5.1 General instructions

Equipment location

When deciding on the location of system components, consider the

following:

• Ignition hazards

•Ventilation

• Mounting surface

• Cable entry

• EMC installation guidelines

Ignition hazards

Ventilation

To ensure adequate airflow:

• Ensure that equipment is mounted in a compartment of suitable

size.

• Ensure that ventilation holes are not obstructed.

• Allow adequate separation of equipment.

Any specific requirements for each system component are provided

later in this chapter.

Mounting surface

Ensure equipment is adequately supported on a secure surface.

Do not mount units or cut holes in places which may damage the

structure of the vessel.

Any specific requirements for each system component are provided

later in this chapter.

Cable entry

Ensure the unit is mounted in a location which allows proper routing

and connection of cables:

• Minimum bend radius of 100 mm (3.94 in).

• Use cable supports to prevent stress on connectors.

EMC installation guidelines

Raymarine equipment and accessories conform to the appropriate

Electromagnetic Compatibility (EMC) regulations. This minimizes

electromagnetic interference between equipment, which could otherwise affect the performance of your system.

Correct installation is required to ensure that EMC performance is

not compromised.

For optimum EMC performance, we recommend that:

• Raymarine equipment and the cables connected to it are:

i. At least 3 ft. (1 m) from any equipment transmitting or cables

carrying radio signals e.g. VHF radios, cables and

antennas. In the case of SSB radios, the distance should be

increased to 7 ft. (2 m).

ii. More than 7 ft. (2 m) from the path of a radar beam. A radar

beam can normally be assumed to spread 20 degrees

above and below the radiating element.

• The product is supplied from a separate battery from that used

for engine start. This is important to prevent erratic behavior

and data loss which can occur if the engine start does not have

a separate battery.

• Raymarine specified cables are used.

• Cables are not cut or extended unless doing so is detailed in the

installation manual.

Potential ignition sources

The equipment in these instructions is NOT

approved for use in hazardous/flammable atmospheres such as an engine room.

Page 59

59 Chapter 5: Installation and mounting

Remember

Where constraints on the installation prevent any of the above

recommendations:

• Always allow the maximum separation possible between different items of electrical equipment.

• This will provide the best conditions for EMC p erformance for

the installation.

Suppression ferrites

Raymarine cables may be fitted with suppression ferrites. These

are important for correct EMC performance. Any ferrite removed to

facilitate installation must be replaced in the original position immediately after the installation is complete.

• Use only ferrites of the correct type, supplied by Raymarine authorized dealers.

Connections to other equipment

If Raymarine equipment is to be connected to other equipment

using a cable not supplied by Raymarine, a Raymarine suppression ferrite MUST always be attached to the cable near the

Raymarine unit.

5.2 GPM400 Processor module

D10100-1

Minimum radius

bend of cable

(100mm)

Minimum ventilation

clearance of XXX mm

around total perimeter

Cable clip

Air vents

335 mm (13.2 in)

230 mm (9.0 in)

125 mm (4.92 in)

Page 60

G-Series Installation & Commissioning 60

Mounting and environment

The following conditions apply:

• Do NOT install near sources of heat or vibration (e.g. engine).

• The unit is NOT designed for use in a sealed enclosure. Access

to the unit is required, e.g. for chart updates.

• Must be mounted on a vertical surface. Sides and top must be

level.

• Mounting surface must be firm, secure and capable of supporting the weight of the unit.

• Install below decks in a dry area.

• Install the unit well away from potential sources of ignition.

Mounting clearances

Allow the following clearances from other equipment and surfaces.

Cables

• Minimum bend radius of 100 mm (3.94 in)

• All cables must be secured within 150 mm (5.91 in) of the unit.

This will prevent undue strain on the connectors.

See also

Ensure you record connections to the GPM400 on the schematic

diagram. See Appendix B - Nav Station schematic.

For connection details, see page 31.

5.3 G-Series Keyboard

The Keyboard can be installed for 2 different types of use:

• Wired operation (flush mounted).

• Wireless operation, using the wireless upgrade kit and

SeaTalk

ng

basestation.

Note: You should have at least one permanently wired keyboard.

In the event that any wireless keyboards are lost, the wired

keyboard can be used to control the system.

Side Distance

Top 100 mm (3.94 in)

Left 100 mm (3.94 in)

Right 100 mm (3.94 in)

Bottom To allow cable entry

Front 150 mm (5.91 in)

Page 61

61 Chapter 5: Installation and mounting

Wired operation - flush mounted

Mounting arrangement

Dimensions

Mounting and environment

• The keyboard is suitable for mounting both above and below

decks. It is waterproof to CFR-46 standard.

• Use the cutting template provided with the keyboard.

• Connect cable into keyboard before clamping in place.

The following conditions apply:

• Do NOT install near sources of heat. (e.g. engine).

• Install the unit well away from potential sources of ignition.

D10101-1

G-Series keyboard

Sun cover

Keyboard

Panel seal

(adhesive

side up)

SeaTalk NG

cable

Stud (x4)

Finger

nut (x4)

Rear clamp

assembly

D10226-1

297 mm (11.69 in)

98 mm (3.85 in)

35 mm (1.38 in)

59.8 mm (2.35 in)

minimum clearance

46 mm (1.81 in)

Page 62

G-Series Installation & Commissioning 62

Cables

• Minimum bend radius of 100 mm (3.94 in).

See also

Ensure you record your keyboard details on the schematic diagram. See Appendix B - Nav Station schematic.

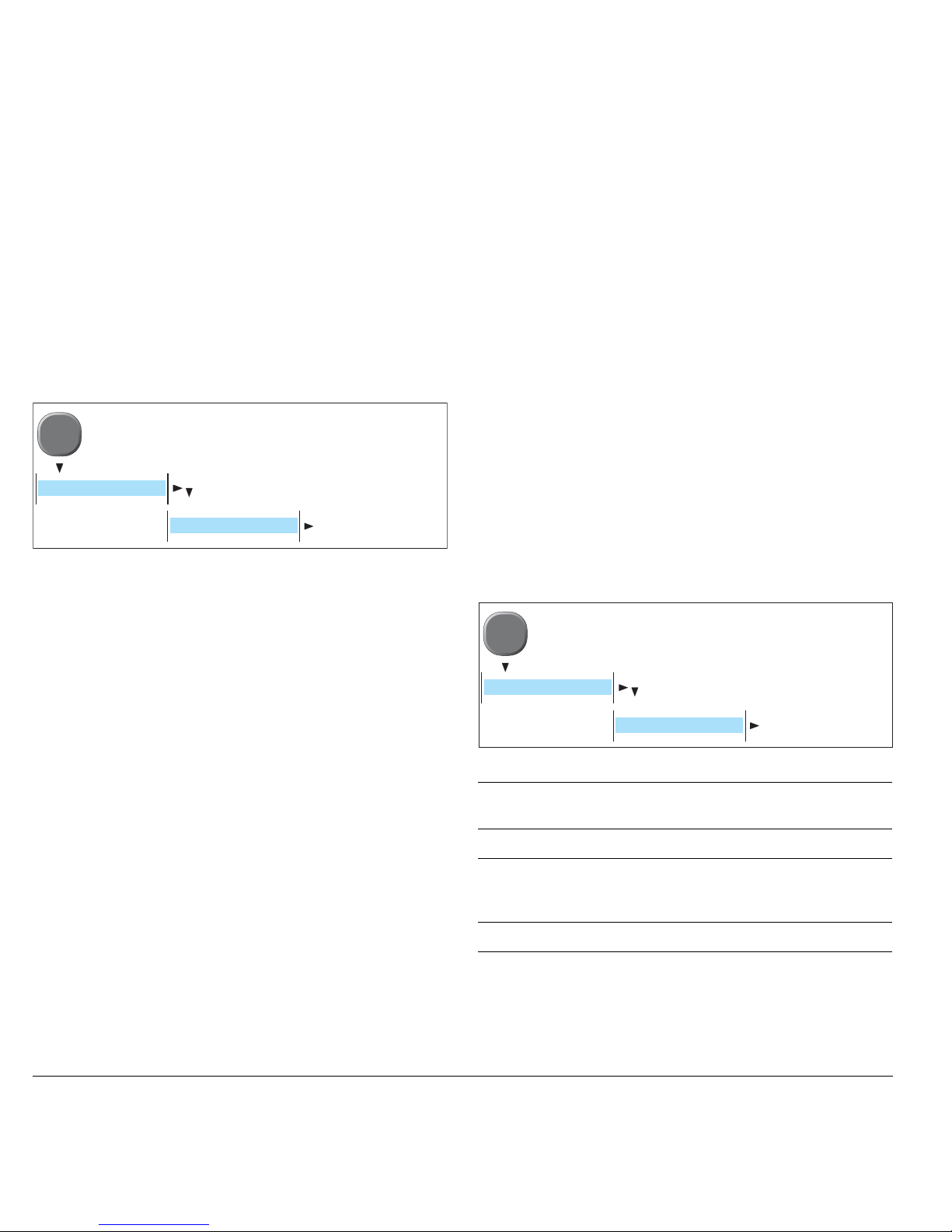

Wireless upgrade kit

Allows wireless operation of the keyboard.

Mounting and environment

• The should be within sight of G-series monitors. This will allow a

keyboard to operate the system whilst on charge.

1. Install charge point.

Ensure flat edge is located to

left side for correct orientation

Note: Remove protective cover

from each side of gasket

No.4 x 3/8"screw

Cut 25 mm

diameter hole

25 mm

diameter hole

D10161-1

25 mm

(1 in)

49 mm (2.6 in)

Page 63

63 Chapter 5: Installation and mounting

2. Fit splash cover. 3. F it the battery, taki ng care to avoid contamination of the cover

seal.

D10162-1

D10518-1

Page 64

G-Series Installation & Commissioning 64

4. Fit the rear cover.

5. For charging and wired operation use the cable provided

Note: The keyboard should be charged for 6 hours before use.

Wireless basestation

Required for wireless operation of the keyboard.

D10189-1

66 mm (2.6 in)

117 mm (4.61 in)

36 mm (1.42 in)

Page 65

65 Chapter 5: Installation and mounting

Mounting and environment

The following conditions apply:

• You must perform a site survey to find an appropriate location

and ensure good wireless reception around the boat.

• Do NOT install near sources of heat or vibration. (e.g. engine).

• Install in a dry area as high on the vessel as possible.

• Mount on a vertical surface.

• Install the unit well away from potential sources of ignition.

• Mount at least 1 m (3 ft) away from devices which may be af-

fected by radio transmission (e.g. compass)

Site survey (wireless coverage)

You will need to survey the wireless coverage to ensure that wireless devices can operate around the vessel.

Repeat basestation

A repeat basestation may be used to optimize wireless coverage.

Note: Only the master basestation is connected to SeaT alk

ng

. The

repeat basestation requires a power connection only.

5.4 G-Series Monitors

To install your monitor refer to the separate instructions provided.

See also

Ensure you record your monitor details on the schematic diagram.

See Appendix B - Nav Station schematic.

Fit Base Station as high up as possible, in a dry location

D10205-1

Note: Only the master basestation is connected to SeaTalkng.

The repeat basestation requires a power connection only.

D10207-1

Page 66

G-Series Installation & Commissioning 66

5.5 GVM400 Video Module

Mounting and environment

• Mount below decks in a dry area

• Install on a vertical surface.

• Do NOT mount near sources of heat or vibration. (e.g. engine)

• Install well away from potential sources of ignition.

Cables

• Minimum bend radius of 100 mm (3.94 in).

• Power cable should be fixed to the plastic case using the cable

tie provided.

• All video / data cables must be secured within 150 mm (5.91 in)

of the unit using a suitable cable clip. This will prevent undue

strain on the connectors.

D10197-1

Minimum

radius bend

of cable

(100mm)

Cable clip

170 mm (6.7 in)

237 mm (9.33 in)

56 mm

(2.2 in)

Page 67

67 Chapter 5: Installation and mounting

5.6 Alarm buzzer

The alarm is used to alert the operator to alarms and other audible

warnings.

Mounting and environment

• Mount below decks in a dry area

• Install on a vertical surface.

• Do NOT mount near sources of heat or vibration. (e.g. engine)

• Install well away from potential sources of ignition.

D10203-1

38 mm

(1.5 in)

60 mm (2.36 in) diameter

60 mm (2.5 in)

18 mm

(0.7 in)

Page 68

G-Series Installation & Commissioning 68

Page 69

6

Chapter 6: Initial test

This section gives details for the initial tests and checks to be carried out once installation is complete.

Chapter contents

• Turn on breakers on page 70

• Marine monitor checks on page 70

• Keyboard checks on page 70

• GPM400 processor checks on page 70

• GVM400 video processor checks on page 70

• SeaTalk

hs

switch on page 70

See also

For help with diagnosing and rectifying faults, refer to Chapter 9: Troubleshooting.

Before powering up

Before proceeding with the power on test of your system please ensure that:

• Radar and all ancillary equipment has been installed and connected in accordance with the manufacturers instructions.