Rayence RY1417WHD User Manual

1417WGC/WCC

User & Installation Manual

R-USM-020/021

Date: 2017-04-19

Preface

Please note that this information is for proper use and safety of the equipment. The following

symbols may indicate a hazardous situation in which, if not heeded, may result in serious injury

or even death to the user or others, or damage to the equipment.

WARNING

CAUTION

Used to emphasize essential i nf orm atio n.

Be sure to read this information to avoid incorrect operation.

Indicates warning and safety instructions. If not adhered to, it could result in death or

serious injury to the user or others.

Indicates a hazardous situation which, if not heeded, may result in minor or moderate

injury to the user or others, or damage to the equipment.

Preface

For users in the United States:

United State federal law restricts this equipment to be used by or on the order of a

physician.

Since the X-ray exposure condition can be changed depending on the age, gender and

bone density of the patient, in case of Pediatric, X-ra y exposur e condit io n can be c hange d

by expert’s judge. For further information, please refer to FDA Pediatric X-ray Imaging

webpage.

http://www.fda.gov/radiationemittingproducts/radiationemittingproductsandprocedures/medicalimaging/ucm298899.htm

For users in other countries:

This equipment is to be used by or on the order of a licensed person under the related laws

for each country.

Intended use:

Digital Flat Panel X-Ray Detector is indicated for digital imaging solution designed for general

radiographic system for human anatomy. It is intended to replace film or screen based

radiographic systems in all general purpose diagnostic procedures. Not to be used for

mammography.

VATECH Dental Manufacturing Ltd.

Chancery House, St. Nicholas Way, Sutton, SM1 1JB, United Kingdom

Tel : +44 208 652 1990, Fax : +44 208 652 1909

Rayence Co., Ltd.

14, Samsung 1-ro 1-gil, Hwaseong-si, Gyeonggi-do, Korea

www.rayence.com

1417WGC/WCC 3

Contents

Contents

PART I. User & Installation Manual 5

1. Safety Information ......................................................................................... 6

1.1 Safety Stand ar d .................................................................................... 6

1.2 Symbols .............................................................................................. 12

1.3 Warning .............................................................................................. 14

1.4 Caution ............................................................................................... 16

1.5 Safety Information ............................................................................... 20

1.6 Label and Location of Attachment ......................................................... 22

1.7 Summary of usability specifications ....................................................... 22

2. Product Introduction and Specification ........................................................... 23

2.1 Product Features .................................................................................. 23

2.2 Product Components ............................................................................ 24

2.3 Part Names and Functions .................................................................... 24

2.4 Part Specifications ................................................................................ 32

2.5 Environmental Requirements ................................................................ 36

2.6 Dimensions (Unit: mm) ........................................................................ 37

3. Installation and Calibration ............................................................................ 42

3.1 Installation .......................................................................................... 42

3.2 Calibration ........................................................................................... 91

4. Usage ........................................................................................................... 97

4.1 Set Up ................................................................................................. 97

4.2 Image Acquisition ................................................................................ 99

4.3 View Images ...................................................................................... 101

4.4 Additional Function ............................................................................. 103

5. Maintenance ............................................................................................... 114

5.1 Cleaning ............................................................................................ 114

5.2 Inspection ......................................................................................... 114

5.3 Replaceable Parts and Instruction of Replacement ............................... 115

5.4 Disposal or Recycling .......................................................................... 116

6. Warranty .................................................................................................... 117

6.1 Warranty ........................................................................................... 117

4 1417WGC/WCC

PART II. Service Manual

PART I. User & Installation Manual

1. Safety Information………….…………………….8

2. Product Introduction and Specification……25

3. Installation and Calibration…………………..44

4. Usage……………………………...………………..99

5. Maintenance………………………...…………..116

6. Warranty………………………..…………..……119

1417WGC/WCC 5

PART II. Service Manual

1. Safety Information

1.1 Safety Standard

1.1.1 Medical Device Classification

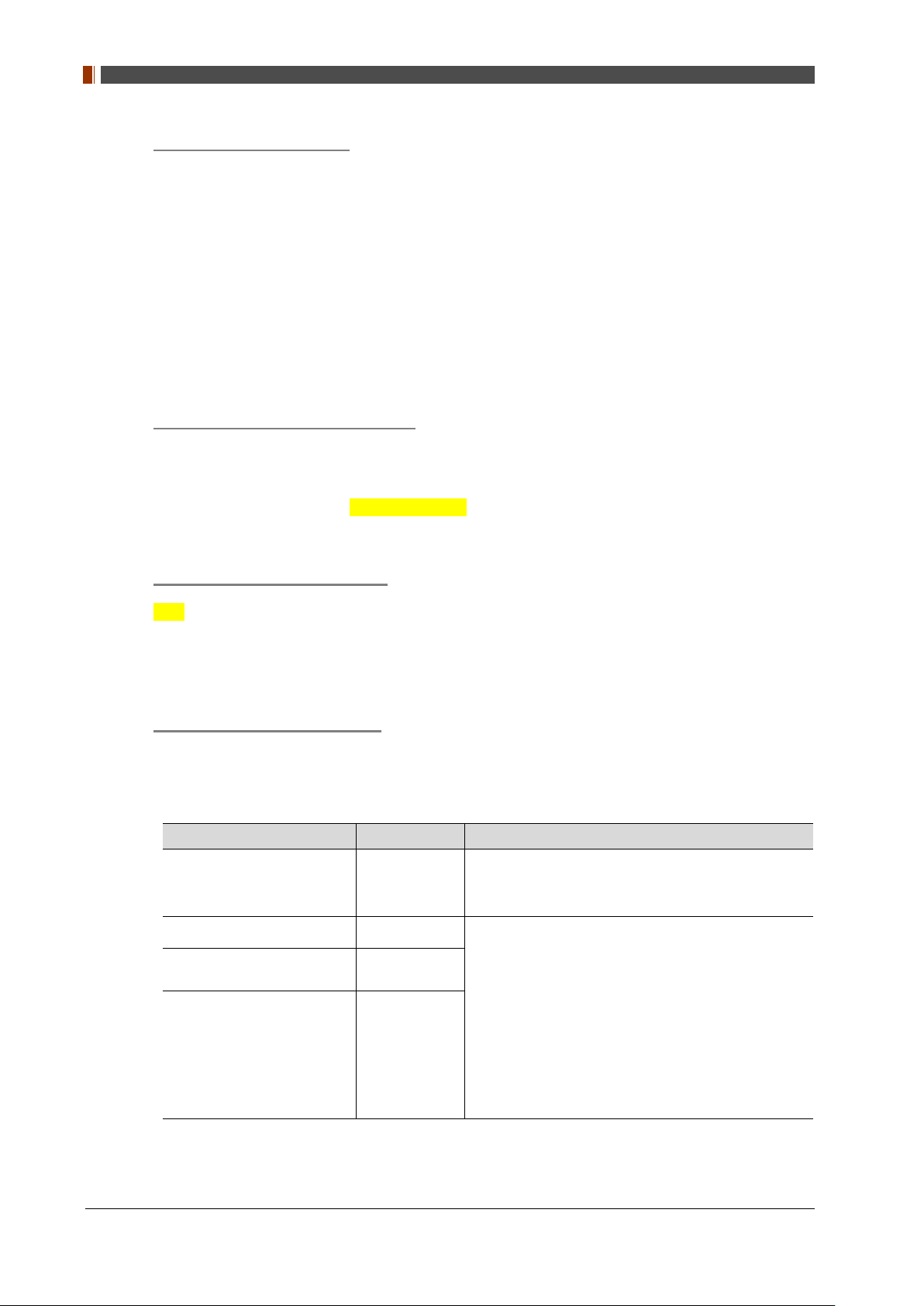

Item Description

Classification by protection type against Electric

Shock

Classification according to the degree of

protection against ingress of water

Mode of operation Continuous Operation

Environment of Use

1.1.2 Regulations

Class I or Internally Powered Equipment

IP53

This equipment is not suitable for use in the

presence of flammable anesthetic or oxygen.

1. Safety and Electromagnetic Compatibility Information

Item Description

IEC/EN/UL 60601-1

IEC/EN 60601-1-2

This equipment has been tested and found to comply with the limits for medical devices in IEC

60601-1-2. These limits are designed to provide reasonable protection against harmful

interference in a typical medical installation.

This equipment generates, uses and can radiate radio frequency energy. If not installed and

used in accordance with the instructions, it may cause harmful interference to other devices in

the vicinity. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to other devices, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures.

Reorient or relocate the equipment.

Increase the separation between the equipment.

Connect the equipment into an outlet on a circuit different from that to which the other

devices are connected.

Medical electrical equipment

Part 1: General requirements for safety

Medical electrical equipment

Part 2: Electromagnetic compatibility-requirements and tests

Contact Rayence Customer Service team or authorized agent for help.

1417WGC/WCC 6

2. Radio Frequency compliance

FCC (For USA)

• FCC ID: QIIRY1417WHD

• 5.15- 5.25 GHz band is restricted to indoor operations only.

• Host device of the approved module shall be marked with the following item:

• Compliance with FCC requirement 15.407(c)

Data transmission is always initiated by software, which is the passed down through the

MAC, through the digital and analog baseband, and finally to the RF chip. Several special

packets are initiated by the MAC. These are the only ways the digital baseband portion will

turn on the RF transmitter, which it then turns off at the end of the packet. Therefore, the

transmitter will be on only while one of the aforementioned packets is being transmitted. In

other words, this device automatically discontinues transmission in case of either absence

of information to transmit or operational failure.

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

PART II. Service Manual

FCC CAUTION

Changes or modifications not expressly approved by the party responsible for compliance

could void the user ’s authority to operate the equipment. This transmitter must not be colocated or operated in conjunction with any other antenna or transmitter.

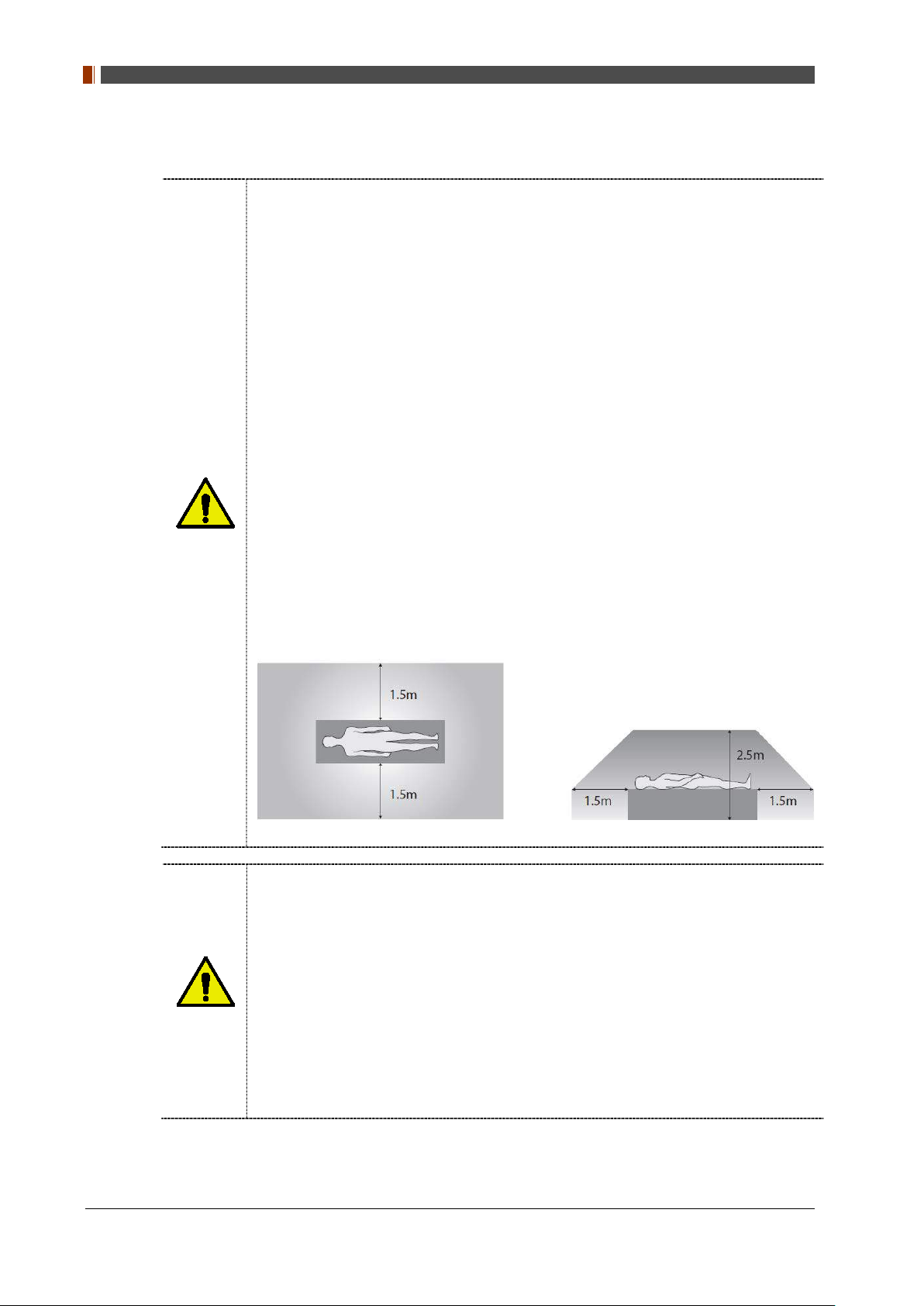

When installing it in a mobile equipment

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment and meets the FCC radio frequency (RF) Exposure Guidelines in CFR

§2.1093.

When you use the detector with wire mode, the wireless function is automatically off.

• 5150-5250 MHz band is restricted to indoor operations only.

< Note >

The front with touch configuration was only tested since only the front is touched to human

body in normal operation of this device

The highest reported SAR values for head & body are: 1.18 W/kg & 1.06 W/kg respectively.

1417WGC/WCC 7

PART II. Service Manual

IC Notice (For CANADA)

IC: 10742A-1417WHD

This Class A digital apparatus complies with Canadian ICES-003

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause undesired

operation of the device.

Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisee aux deux conditions suivantes: (1)

l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioelectrique subi, meme si le brouillage est susceptible d'en

compromettre le fonctionnement.

R&TTE Notice (European Union)

The product compliance to the Directive 1999/5/EC as radio equipment and telecommunications

terminal equipment.

Authorized by Notified Body (code no. : 0678)

5150-5250 MHz band is restricted to indoor operations only.

Japan Ratio Raw (For Japan)

Type Certification No. : 011-170018

3. Electro-Magnetic Compatibility Information

Electro-Magnetic Emissions

This 1417WCC/WGC is intended for use in the electromagnetic environment specified below.

The customer or the user of the 1417WCC/WGC should assure that it is used in such an

environment.

Immunity Test Compliance Electromagnetic Environment – Guidance

The 1417WCC/WGC uses RF energy only for its

RF Emissions CISPR 11 Group 1

RF Emissions CISPR 11 Class A

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations / Flicker

emissions IEC 61000-3-3

Class A

Complies

internal function. Therefore, its RF emissions are very

low and are not likely to cause any interference in

nearby electronic equipment.

The 1417WCC/WGC is suitable for use in all

establishments, including domestic establishments

and those directly connected to the public low-voltage

power supply network that supplies buildings used for

domestic purposes. provided the following warning is

heeded:

Warning: This equitpment/system is intended for use

by healthcare professionals only, This

equipment/system may cause radio inter fer e nce or

may disrupt the operation of nearby equipment. It

may be necessary to take mitigation measures, such

as re-orenting or relocating the 1717WCC/WGC or

shielding the location.

1417WGC/WCC 8

PART II. Service Manual

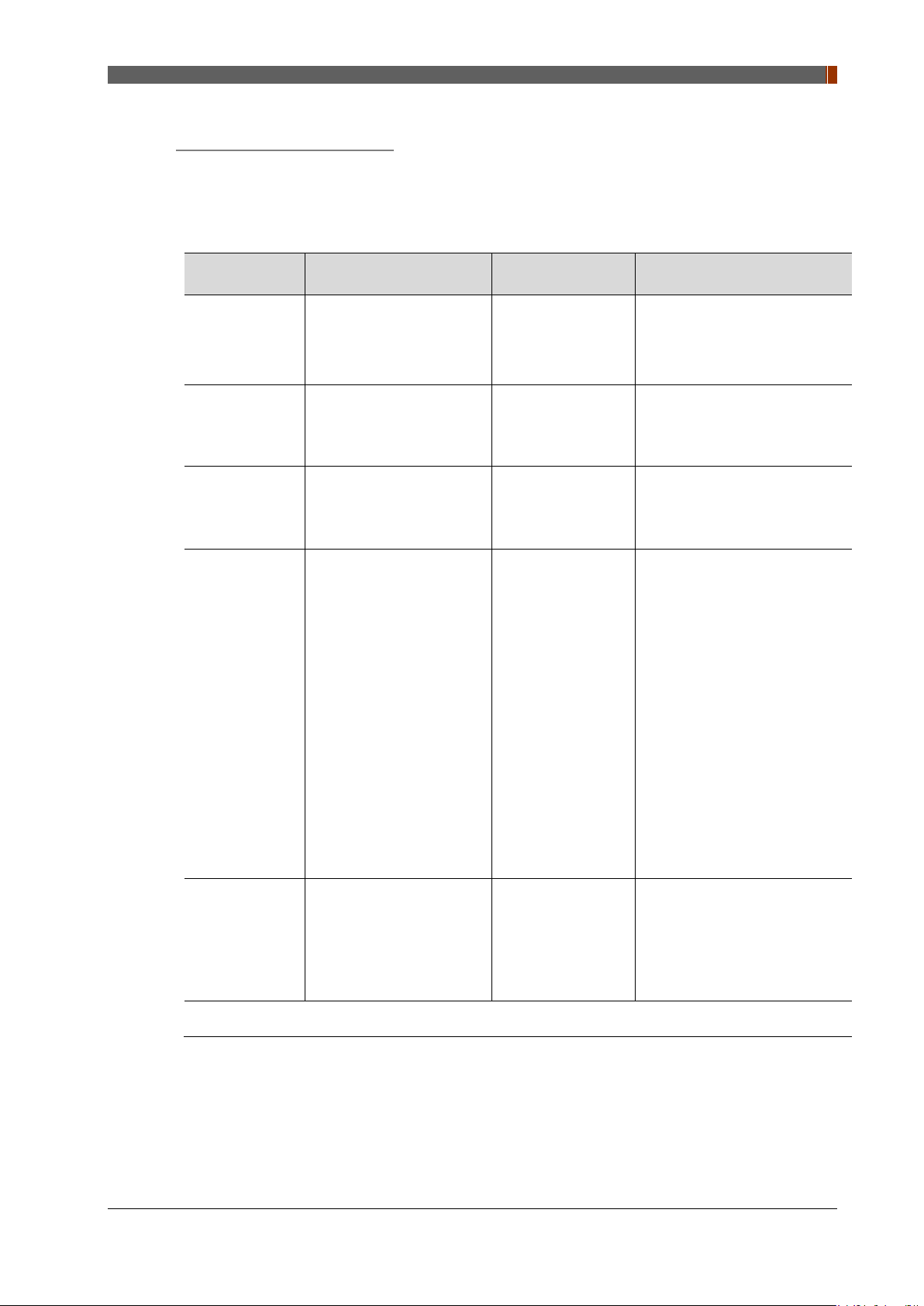

Electro-Magnetic Immunity

This 1417WCC/WGC is intended for use in the electromagnetic environment specified below.

The customer or the user of the 1417WCC/WGC should assure that it is used in such an

environment.

Immunity Test IEC 60601-1-2 Test Level Compliance Level

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips,

short

interruption, and

voltage

variations on

power supply

input lines

IEC 60601-4-11

± 6 kV contact

± 8 kV air

± 2 kV for power supply

lines

± 1 kV for input/output lines

± 1 kV line(s) to lines(s)

± 2 kV line(s) to earth

<5% Uт

for 0.5cycle

40% Uт

for 5, 6 cycles

70% Uт

for 25, 30 cycles

IEC 60601-1-2 Test

level

IEC 60601-1-2 Test

level

IEC 60601-1-2 Test

level

IEC 60601-1-2 Te st

level

Electromagnetic environment

– guidance

Floors should be wood,

concrete or ceramic tiles. If

floors are covered with synthetic

material, relative humidity

should be at least 30%.

Mains power quality should be

that of a typical commercial or

hospital environment.

Mains power quality should be

that of a typical commercial or

hospital environment.

Mains power quality should be

that of a typical commercial or

hospital environment. If the user

of the 1417WCC/WGC requires

continued operation during

power mains interruptions, it is

recommended that the

1417WCC/WGC be powered

from an uninterruptible power

source or battery.

<5% Uт

for 5s

Power

frequency

(50/60 Hz)

IEC 61000-4-8

NOTE UT is the a.c mains voltage prior to application of the test level.

3.0 A/m

IEC 60601-1-2 Test

level

Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical commercial

or hospital environment.

1417WGC/WCC 9

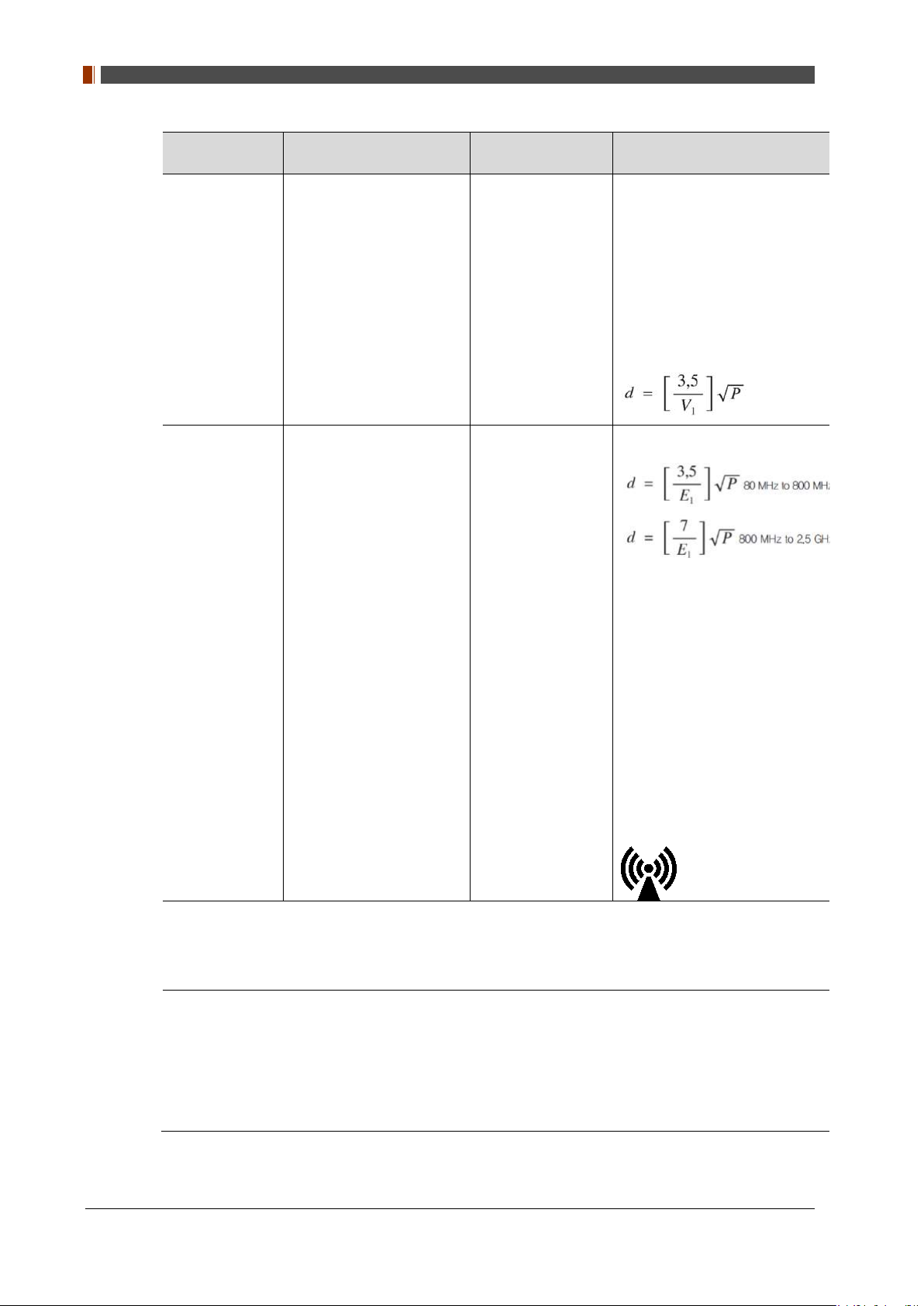

PART II. Service Manual

Recommended separation

(a) Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones

Immunity Test IEC 60601-1-2 Test Level Compliance Level

Conducted RF

IEC61000-4-6

Radiated RF

IEC61000-4-3

3 Vrms

150 kHz to 80MHz

3 V/m

80 MHz to 2.5GHz

3 Vrms

3 V/m

Electromagnetic environment

– guidance

Portable and mobile RF

communications equipment

should be used no closer to any

part of the 1417WCC/WGC,

including cables, than the

recommended separation

distance calculated from the

equation applicable to the

frequency of the transmitter.

Recommended separation

distance

distance

Where P is the maximum output

power rating of the transmitter in

watts (W) according to the

transmitter manufacturer and d

is the recommended separation

distance in meters (m).

Field strengths from fixed RF

transmitters, as deter-mined by

an electromagnetic site survey,

(a) Should be less than the

compliance level in each

frequency range (b).

Interference may occur in the

vicinity of equipment marked

with the

following symbol:

Note 1) Uт is the A.C. mains voltage prior to application of the test level.

Note 2) At 80 MHz and 800 MHz, the higher frequency range applies.

Note 3) These guidelines may not apply in all situations. Electromagnetic propagation is affected by

and land mobile rad io s, a mat e ur radi o, AM and FM radio broadcast and TV broadcast cannot be pred ict ed

theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength the location in which the

1417WCC/WGC is used exceeds the applicable RF compliance level above, the 1417WCC/WGC should

be observed to verify normal operation. I f abn ormal p erfor mance i s observ ed, ad ditiona l measure s may be

necessary, such as re-orienting or relocating the 1417WCC/WGC.

(b) Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V / m.

absorption and reflection from structures, objects and people.

1417WGC/WCC 10

PART II. Service Manual

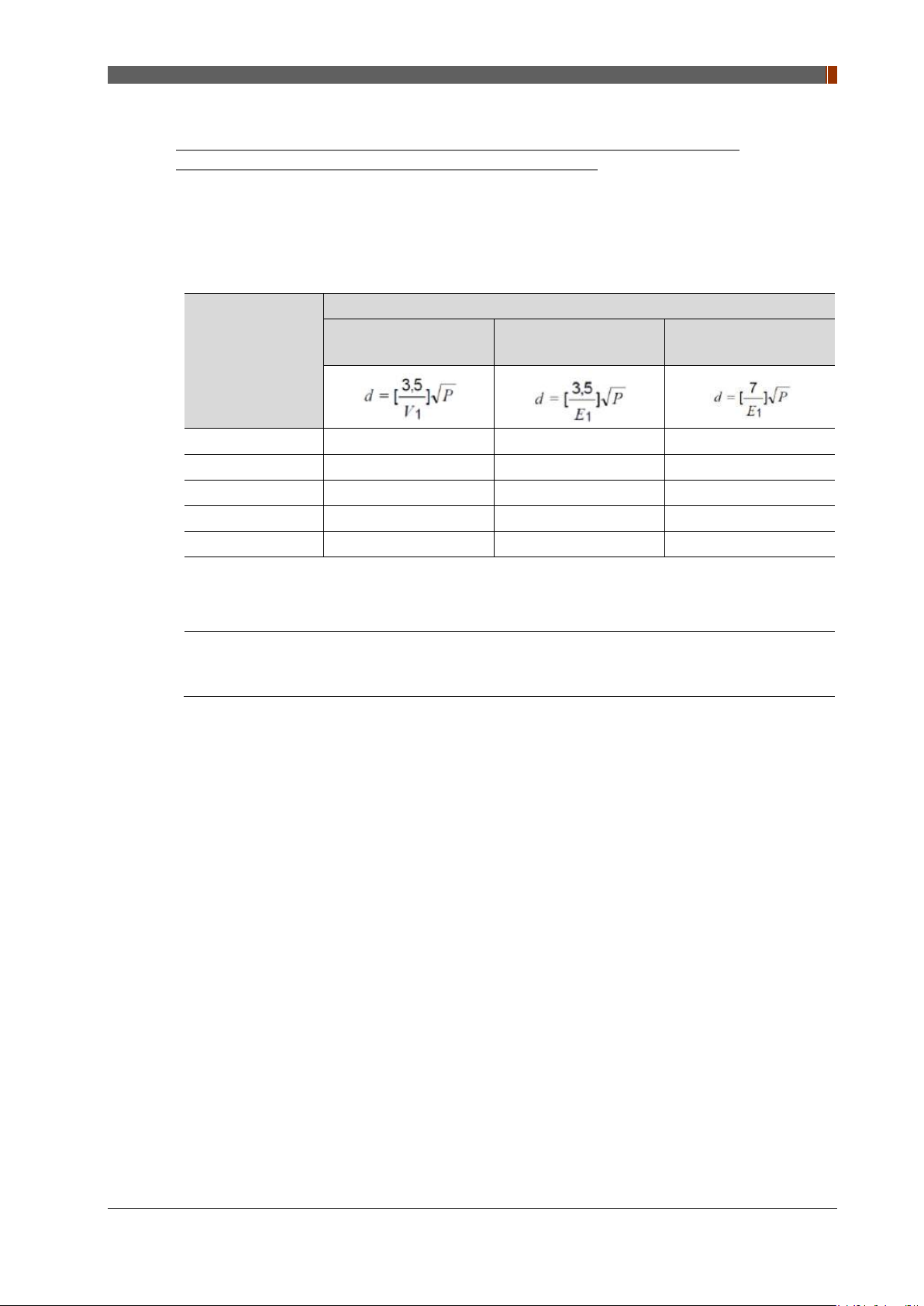

Recommended separation distance between portable and mobile RF

communications equipment and the 1417WCC/WGC

The 1417WCC/WGC is intended for use in an electromagnetic environment in which radiated

RF disturbances are controlled. The user of the 1417WCC/WGC can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile

RF communications equipment (transmitters) and the 1417WCC/WGC as recommended below,

according to the maximum output power of the communications equipment.

Separation distance (m) according to frequency of transmitter

Rated maximum

output power (W)

of transmitter

150kHz to 80MHz

80MHz to 800MHz 800MH z to 2.5GHz

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation

distance (d) in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to

the transmitter manufacturer.

Note 1) At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

Note 2) These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects, and people.

1417WGC/WCC 11

PART II. Service Manual

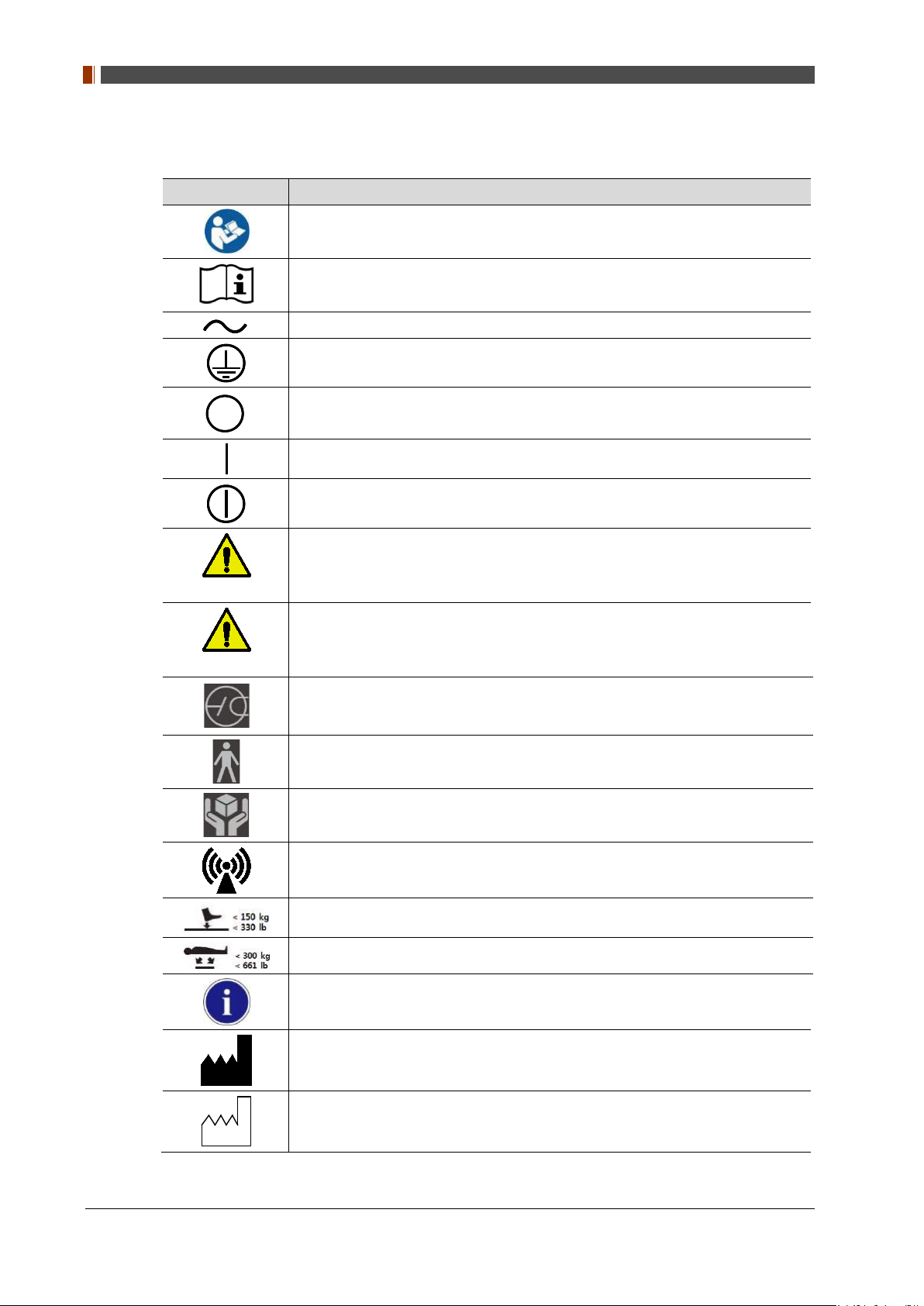

1.2 Symbols

Symbols Descriptions

Refer to instruction manual / booklet

Consult instructions for use

Alternate current

Protective earth (Ground)

Off (power : disconnect from the main switch)

On (power : connect from the main switch)

On / Off (button type)

WARNING

CAUTION

Warning

Caution

To indicate a reference to the X-ray tube, for example to identify the surface of a

component such as a focused ant scatter grid, that has to be oriented towards the

X-ray tube.

This is a Type B applied part according to UL 60601-1 and IEC 60601-1.

Handle with care

Non-ionizing radiation

Partial Pressure Limit

Overall Pressure

Read carefully

Manufacturer

Date of manufacture

1417WGC/WCC 12

PART II. Service Manual

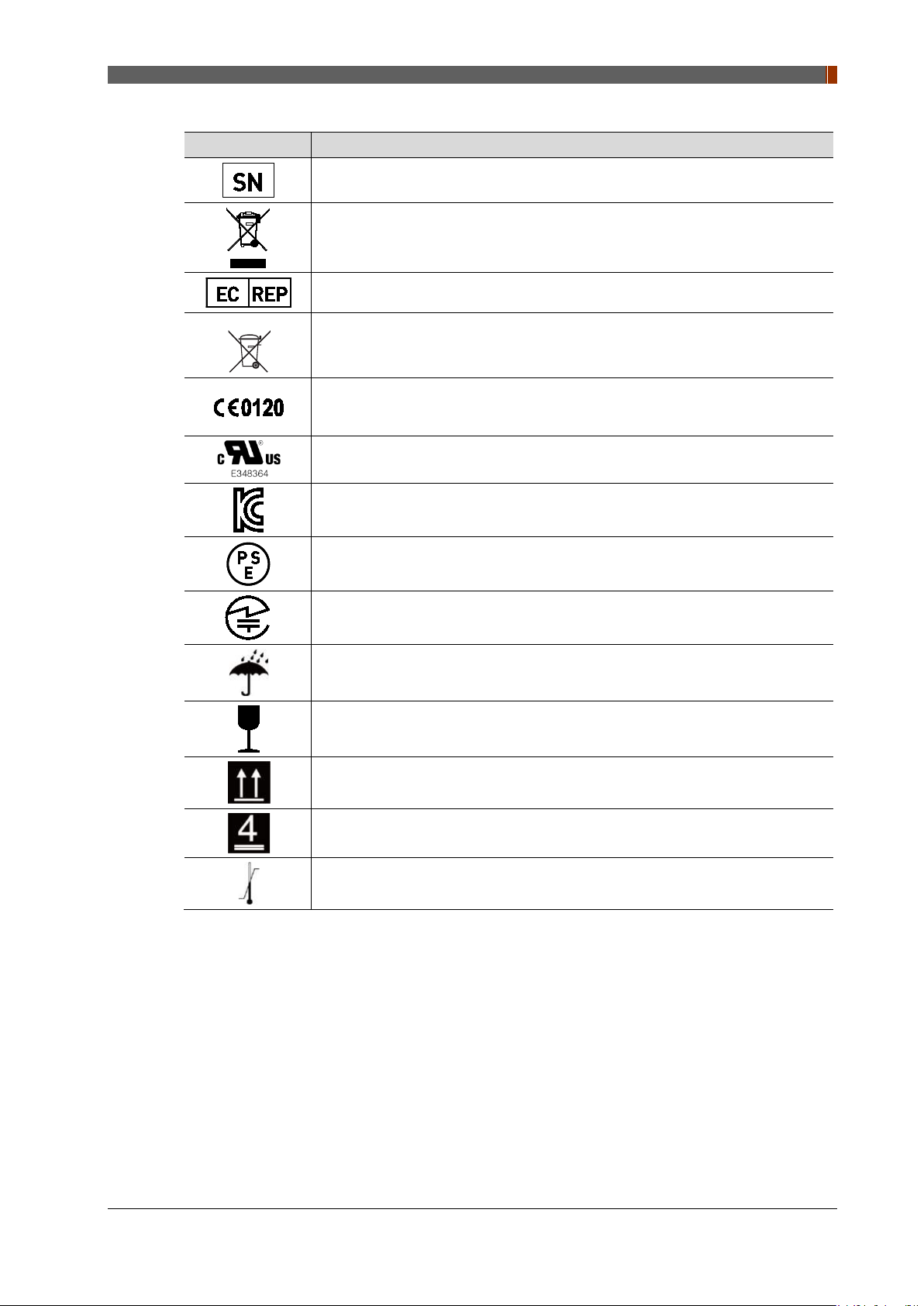

Symbols Descriptions

Serial number

WEEE : Waste Electrical and Electronic Equipment

Authorized representative in the European community.

Batteries Marking (Battery Directive 2006/66/EC)

CE symbol grants the equipment compliance to the European Directive for

Medical Devices 93/42/EEC as a class �a device and 1999/5/EC. Authorized by

Notified Body SGS (code no.:0120) of British

Recognized Component Mark for Canada and the United States

For Korea

Symbol for safety

For Japan

Product Safety of Electrical Appliance & Materials

For JAPAN

Japan Radio Law Certification

Keep dry

Fragile, handle with care

This side up

4 layer stacking

Temperature limit

1417WGC/WCC 13

PART II. Service Manual

1.3 Warning

WARNING

WARNING

WARNING

WARNING

Environment of Use and Storage

Follow the specif ied process of operational instructions written in this manual for the

safety of the users and patients.

Does not use or store the detector near any flammable chemicals such as thinner,

benzene, etc. Also, this detector is not a category AP or APG equipment. If chemicals

are spilled or evaporate, it may result in fire or electric shock through contact with

electric parts inside the detector. Also, some disinfectants are flammable. Be sure to

take care when using them.

Connection

Do not connect the detector with anything other than specified. Otherwise, it may result

in fire or electric shock.

To avoid the risk of electric shock, this detector must only be connected to supply

mains with protective earth.

Do not touch SIP/SOP and the patient simultaneously. There is a risk of electric shock

from current leakage.

Additional equipment connected to medical electrical equipment must comply with the

respective IEC or ISO standards (e.g. IEC 60950 for data processing equipment).

Furthermore all configurations shall comply with the requirements for medical electrical

systems (see IEC 60601-1-1 or clause 16 of the 3 Ed. of IEC 60601-1, respectively).

Anybody connecting additional equipment to medical electrical equipment configures a

medical system and is therefore responsible that the system complies with the

requirements for medical electrical systems. Attention is drawn to the fact that local

laws take priority over the above-mentioned requirements. If in doubt, contact Rayence

Customer Service team or authorized agent.

Equipment connected to the detector and in the patient envir onme nt must be pow ered

from a medically-isolated power source or must be a medically-isolated device.

Equipment powered from a non-isolated source can result in chassis leakage currents

exceeding safe levels. Chassis leakage current created by an accessory or devic e

connected to a non-isolated outlet may add to the chassis leakage current of the

detector.

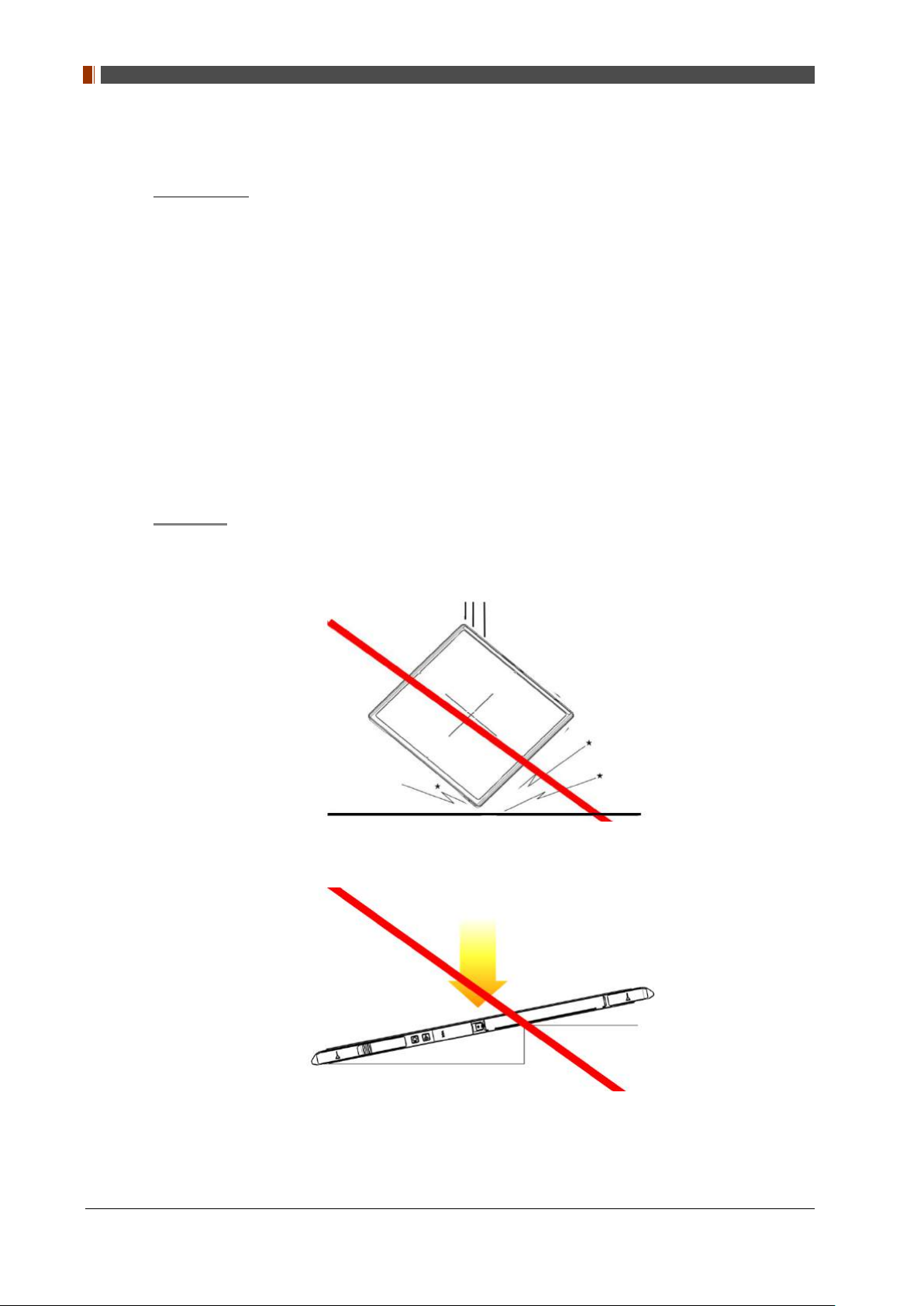

Handling

Always be sure to keep checking the condition of the system and the patient to ensure

they are normal during the use of the detector. If any problem is found, take

appropriate measures, such as stopping the operation of the detector, as required.

Never disassemble or modify the detector as it may result in fire or electric shock.

Also, since the detector incorporate s parts that may cause electric shocks and other

hazardous parts, touching them may cause death or serious injury.

Do not hit or drop the detector. The detector may be damaged if it receives a strong

jolt, which may result in fire or electric shock if the detector is used without being

repaired.

When Problem Occurs

Should any of the following occur, immediately turn OFF the power of each detector,

unplug the power supply cord from the AC outlet, and contact Rayence Customer Service

team or authorized agent.

When there is smoke, odd smell or abnormal sound.

When liquid has been spilled into the detector or a metal object has entered through an

opening.

When the detector has been dropped and it is damaged.

1417WGC/WCC 14

PART II. Service Manual

Maintenance and Inspection

For safety reasons, be sure to turn off the power of the detector when the following

inspections are going to be performed. Otherwise, it may result in electric shock.

When the detector is going to be cleaned, be sure to turn off the power of each

detector, and unplug the power cable from the AC outlet.

Do not use any type of solvent, such as benzene. Otherwise, fire or electric shock may

WARNING

result.

Wear waterproof gloves to protect your hands from direct contact with IPA (Isopropyl-

alcohol) or any other liquid.

Maintenance of the detector should be done by an authorized service provider. If

problem still cannot be corrected, it may result in fire or electric shock.

Wireless Connection

SSID & PSK value should match to Router’s setting. If these values are not matched

with Detector and Router, the connection is not allowed for security.

Avoid using co-channel or adjacent-channel with other wireless devices for high quality

wireless performance.

Transmitting omnidirectional radio wave and sending same information to different

WARNING

place at once is against the law.

Any service related to the human life safety cannot be supported since this wireless

detector has potential electric wave interference.

This wireless detector has potential electric wave interference during use.

1417WGC/WCC 15

PART II. Service Manual

1.4 Caution

CAUTION

Environment of Use and Storage

Do not install the detector in a location with the conditions listed below. Otherwise, it may

result in failure or malfunction, cause fire or inj ury.

Close to facilities where water is used.

Where it will be exposed to direct sunlight.

Close to air-conditioner or ventilation equipment.

Close to heat source suc h as a heater.

Prone to vibration

Insecure pla ce.

Dusty environment.

Saline or sulfurous environment.

High temperature or humidity.

Freezing or conde ns atio n.

Do not place the storage case in a location with the conditions listed below.

Where the cable of the detector unit will be strongly pulled when the detector is put into

the case, otherwise, the cable may be damaged, resulting in fire or el e ctr ic shock.

Where someone might get their foot caught in the cable of the detector.

Non-medical equipment such as the battery charger, access point cannot be used in

patient’s vicinity.

Handling

Applied part: CFRP (Carbon Fiber Reinforced Plastic) Applied part having contact with

the patient for a time “t”: 1 min ≤ t < 10 min

If contact over 24 hours on CFRP (Carbon Fiber Reinforced Plastic) of detector, it

could be cause skin irritation.

In order to prevent infection, please wipe the CFRP (Carbon Fiber Reinforced Plastic)

with a soft cloth moistened with IPA (Isopropyl-alcohol) liquid.

CAUTION

Wear waterproof gloves to protect your hands from direct contact with IPA or any other

liquid.

For safety reasons, be sure to turn off the power of each equipment when detector is

not used.

This detector is contraindicated for pregnant woman.

1417WGC/WCC 16

PART II. Service Manual

Location of Cables

Make sure all cables are located so that they cannot be stepped on, tripped over, or

CAUTION

otherwise subjected to damage or stress.

Maintenance and Inspection

For safety reasons, be sure to inspect the detector before using it. In addition, carry out

a regular inspection at least once a year.

If the detector is defective, do not disassemble the detector randomly. Maintenance of

CAUTION

the detector should be done by an authorized service provider. Please contact

Rayence Customer Service team or authorized agent.

Be sure to check the user’s manual for replaceable components.

Modifications

Any changes or modifications in construction of this detector which are not expressly

approved by the party responsible for compliance could void the user’s authority to

CAUTION

operate the detector.

Battery

Do not let the detector or battery come in contact with liquids. Liquids can get into the

detector’s circuits, leading to corrosion. Even when the detector appears to be dry and

appears to operate normally, the circuitry could slowly corrode and pose a safety

hazard. If the battery gets wet, have them checked by authorized agent or contact

Rayence Customer Service team, even if they appear to be working properly.

Do not place your battery near a heat source. Excessive heating can damage the

detector or the battery and could cause the detector or the battery to explode.

Do not dry a wet or damp battery with an appliance or heat source such as a

microwave oven, hair dryer, iron, or radiator.

Do not dispose of the detector or the battery in a fire. The detector or the battery may

explode when overheated.

CAUTION

Use only Rayence-approved batteries and recharge your battery (Model name:

RB37WHA) only with Rayence-approved char ger s (Model name: RC120WA) which are

specifically designed for your detector.

Use of a non-Rayence-approved battery or charger may present a risk of fire,

explosion, leakage, or other hazard. Rayence’s warranty does not cover damage to the

detector caused by non-Rayence-approved batteries and/or chargers.

Misuse or use of incompatible batteries and charging detectors could result in damage

to the detector and a possible risk of fire, explos ion, or leakage, leading to serious

injuries, damages to your detector, or other serious hazard.

Check the battery status frequently to avoid battery empty. When the low battery LED

of detector is turned on, change the battery or charge the battery using cable.

Recommendations to equipment manufacturers and battery assemblers

The following r epre sent s a typi cal, but non-exhaustive, list of good advice to be

provided by the manufacturer of secondary cells and batteries to equipment

manufacturers and battery assemblers.

Do not dismantle, open or shred cells. Batteries should be dismantled only by trained

personnel. Multicell battery cases should be designed so that they can be opened only

CAUTION

with the aid of a tool.

Do not short-circuit a cell or battery. Do not store cells or batteries haphazardly in a box

or drawer where they may short-circuit each other or be short-circuited by conductive

materials.

Do not remove a cell or battery from its original packaging until required for use.

1417WGC/WCC 17

PART II. Service Manual

Do not subject cell s or batter ie s to mechanic al sho ck.

In the event of a cell leaking, do not allow the liquid to come into contact with the skin

Equipment should be designed to prohibit the incorrect insertion of cells or batteries

Do not mix cells of different manufacture, capacity, size or type within a battery.

Seek medical advi ce im med iat ely if a cell or battery has been swallowed.

Consult the cell/battery manufacturer on the maximum number of cells, which may be

A dedicated charger should be provided for each equipment. Complete charging

Keep cells and batteries clean and dry.

Wipe the cell or battery terminals with a clean dry cloth if they become dirty.

Secondary cells and batteries need to be charged before use. Always refer to the cell

Do not maintain secondary cells and batteries on charge when not in use.

After ext ended peri ods of stor age, it may be necessary to charge and discharge the

Secondary cells and batteries give their best performance when they are operated at

Retain the original cell and battery literature for future reference.

When disposing of secondary cells or batteries, keep cells or batteries of different

Contact the Rayence Customer Service team to destroy a battery.

Do not expose cells or batteries to heat or fire. Avoid storage in direct sunlight.

or eyes. If contact has been made, wash the affected area with copious amounts of

water and seek medical advice.

and should have clear polarity marks. Always observe the polarity marks on the cell,

battery and equipment and ensure correct use.

assembled in a battery and on the safest way in which cells may be connected.

instructions should be provided for all secondary cells and batteries offered for sale.

or battery manufacturer’s instructions and use the correct charging procedure.

cells or batteries several times to obtain maximum performance.

normal room temperature.

electrochemical systems separate from each other.

1417WGC/WCC 18

PART II. Service Manual

Recommendations to the end-users

The following represents a typical, but not exhaustive list of good advice to be provided

by the equipment manufacturer to the end-user.

Do not dismantle, open or shred secondary cells or batteries.

Do not expose cells or batterie s to heat or fire. Avoid storage in direct sunlight.

Do not short-circuit a cell or a battery. Do not store cells or batteries haphazardly in a

box or drawer where they may short-circuit each other or be short-circuited by other

metal objects.

Do not remove a cell or battery from its original packaging until required for use.

Do not subject cell s or batter ie s to mechanic al sho ck.

In the event of a cell leaking, do not allow the liquid to come in contact with the skin or

eyes. If contact has been made, wash the affected area with copious amounts of water

and seek medical advice.

Do not use any charger other than that specifically provided for use with the

equipment.

Observe the plus (+) and minus (–) marks on the cell, battery and equipment and

ensure correct use.

Do not use any cell or battery which is not designed for use with the equipment.

Do not mix cells of different manufacture, capacity, size or type within a device.

Keep cells and batteries out of the reach of children.

CAUTION

Seek medical advi ce im mediately if a cell or a battery has been swallowed.

Always purchase the correct cell or battery for the equipment.

Keep cells and batteries clean and dry.

Wipe the cell or battery terminals with a clean dry cloth if they become dirty.

Secondary cells and batteries need to be charged before use. Always use the correct

charger and refer to the manufacturer’s instructions or equipment manual for proper

charging instructions.

Do not leave a battery on prolonged charge when not in use.

After ext ended peri ods of storage, it may be necessary to charge and discharge the

cells or batteries several times to obtain maximum performance.

Secondary cells and batteries give their best performance when they are operated at

normal room temperature (20 °C ± 5 °C).

Retain the original product literature for future reference.

Use only the cell or battery in the application for which it was intended.

When possible, remove the battery from the equipment when not in use.

Dispose of properly.

Contact the Rayence Customer Service team to destroy a battery.

1417WGC/WCC 19

PART II. Service Manual

1.5 Safety Information

Preparation

Be sure to connect the cables to the proper connectors. Otherwise, the detector may

malfunction or may be damaged.

The power supply provided by Rayence is designed for the detector from Rayence. Please

contact Rayence, if any other type of power supply is needed to be used.

Be sure to fully charge the battery before use. Charge the battery on the day of examination

or on the previous day.

Battery slowly discharges even when not in use. The battery may have expired if it

discharges immediately after being fully charged. You can purchase an optional battery to

replace an exhausted one.

The battery charger provided by Rayence is designed for the dedicated battery.

When the detector will not be used for some time, remove the battery.

Handling

Handle the detector carefully, as it may become damaged if it is hit, dropped, or receives a

strong jolt.

Be sure to use the detector on a flat place so it will not bend. Otherwise, the detector may

be damaged.

1417WGC/WCC 20

PART II. Service Manual

Be sure to check the detector daily and confirm that it works properly. Sudden heating of

the room in cold areas will cause condensation to form on the detector. In this case, wait

until condensation disappears before performing exposure. If the detector is used with

condensation formed on it, problems may occur in the quality of the detector. When an airconditioner is going to be used, be sure to raise/lower the temperature gradually so that a

difference in temperature in the room and in the detector does not occur, to prevent forming

of condensation. Follow the recommended proper Room temp.

Do not use the detector near devices generating a strong magnetic field. Doing so may

produce image noise or artifacts.

Keep the connectors free from being in contact with the patient.

Connectors are intended to be connected to an external device and must follow IEC

standards.

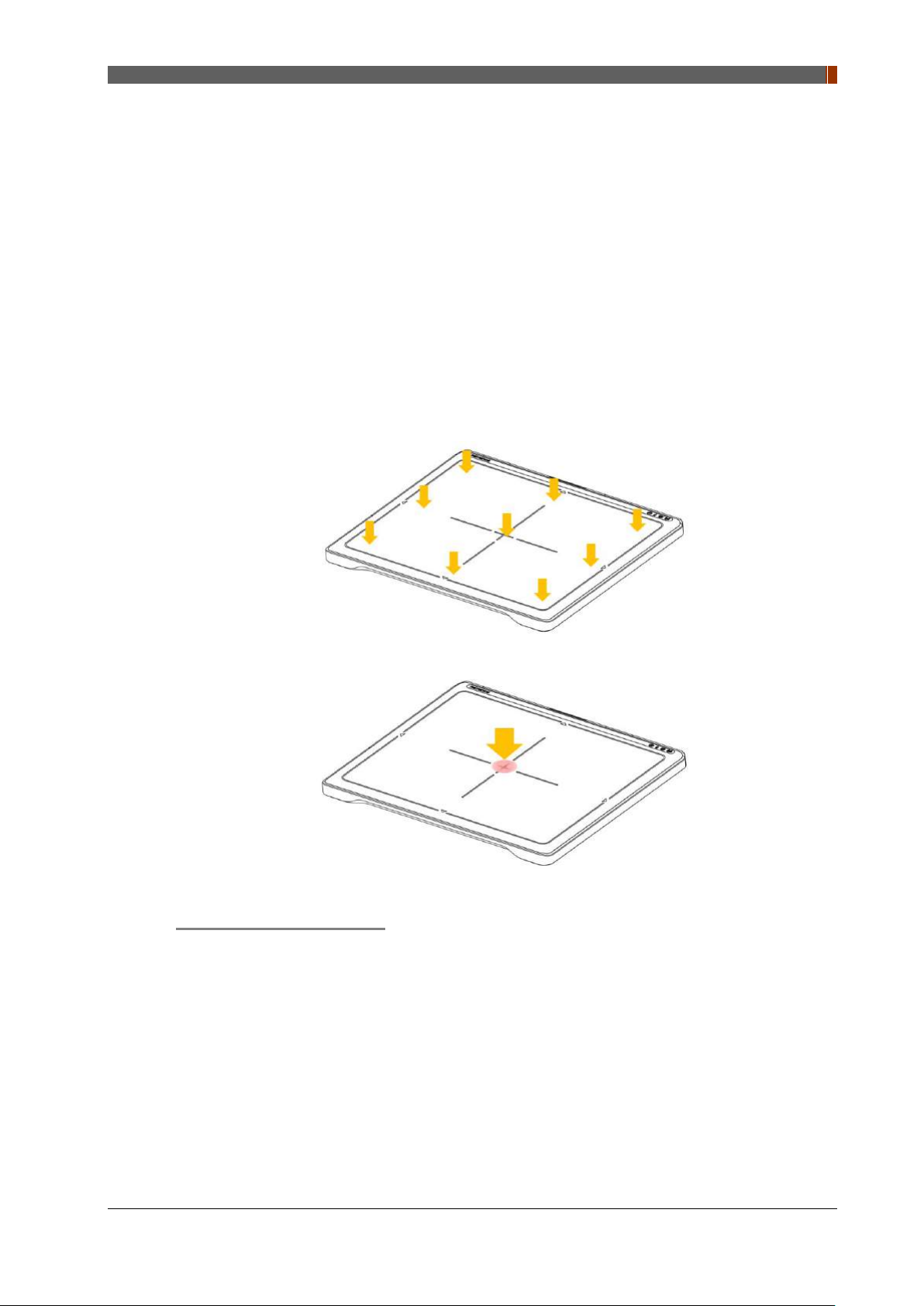

Do not apply excessive weight to the detector. Otherwise, the detector may be damaged.

Overall Pressure: 300kg(661lb) over the whole area of detector window.

Partial Pressure: 150kg(330lb) on an area 40 mm i n d iameter.

Disinfection and Cleaning

Do not spray disinfectants or detergents on the detector.

When cleaning the detector, be sure to turn off the power, and unplug the power cable from

the AC outlet.

Do not use any flammable chemicals such as thinner, benzene for cleaning. Otherwise, fire

or electric shock may result.

Wear waterproof gloves to protect your hands from direct contact with disinfectants or

detergents.

1417WGC/WCC 21

PART II. Service Manual

1.6 Label and Location of Attachment

Refer to the back of the device for details.

1.7 Summary of usability specifications

Medical purposes

Provision and reading of disease and injury diagnostic images

Patient groups

No patient population exists who uses or is in contact with the device.

Patient population for the X-ray images read is not specified.

Parts of body or organizations to which the device is mounted or that interact

with the device

Detector contacts the body surface of a patient and an operator.

Significant physical and performance characteristics

Refer to 2.4 Part Specifications in this manual

Operating principles

Flat panel detector is a system that can acquire, save, process and transfer digital images

of an area of interest taken with X-ray. X-ray beam entering the X-ray imaging sensor is

converted into visible light by scintillation layer of the sensor. The amorphous silicon (a-Si)

and Photo Diode on TFT Array of the sensor further converts visible light into electric signal.

Electric signals are amplified and converted to digital signals to form image data.

Obtained image data is transferred to the computer via Ethernet or Wi-Fi interface and

visually displayed on the monitor screen.

Intended user profile

No special training is required to use this device. The intended users of this device are as

follows.

A professional in good health with specialist knowledge/ qualifications who has fully understood

the content of this document. (Such as a doctor or radiological technologist)

1417WGC/WCC 22

PART II. Service Manual

2. Product Introduction and Specification

2.1 Product Features

The 1417WGC/WCC are wireless digital flat panel detectors that has been designed for a

faster, more streamlined approach to digital radiography systems.

The 1417WGC/WCC detector contains a built-in Access Point (AP) enabling images to be

directly sent to a Wi-Fi connected computer within seconds. Built-in image memory storage

permits taking images where a computer connection is not available and also prevents lost

images should there be an interruption of power. Whether an image was taken with the detector

in the portrait or landscape position, the auto image rotation function allows images to be

displayed in the correct orientation.

These features, coupled with an auto-trigger signal sensing technology that allows the detectors

to be used without generator integration, makes the 1417WGC/WCC the ideal flat panel

detector solutions for both fixed and portable applications.

1417WGC/WCC 23

PART II. Service Manual

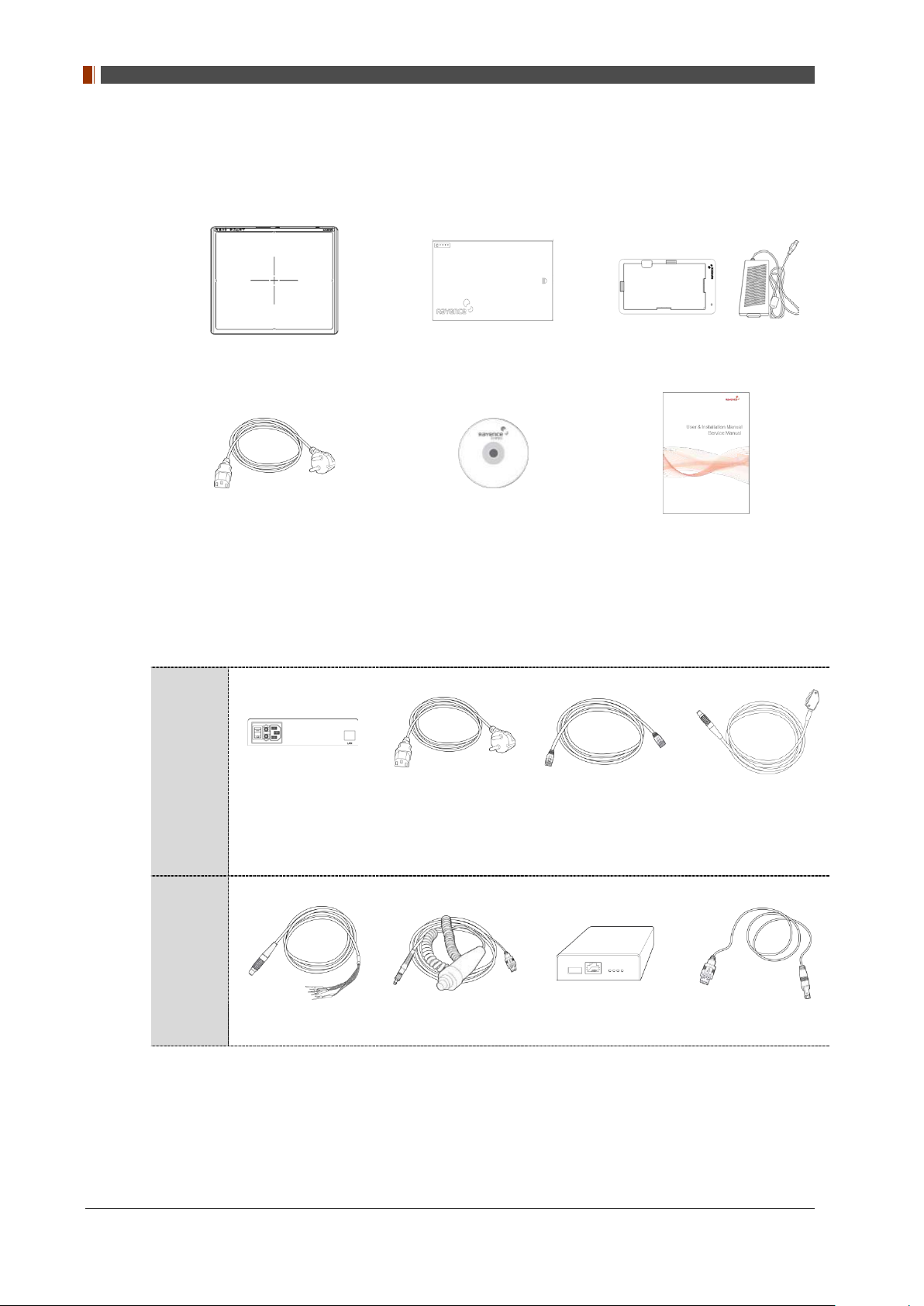

2.2 Product Components

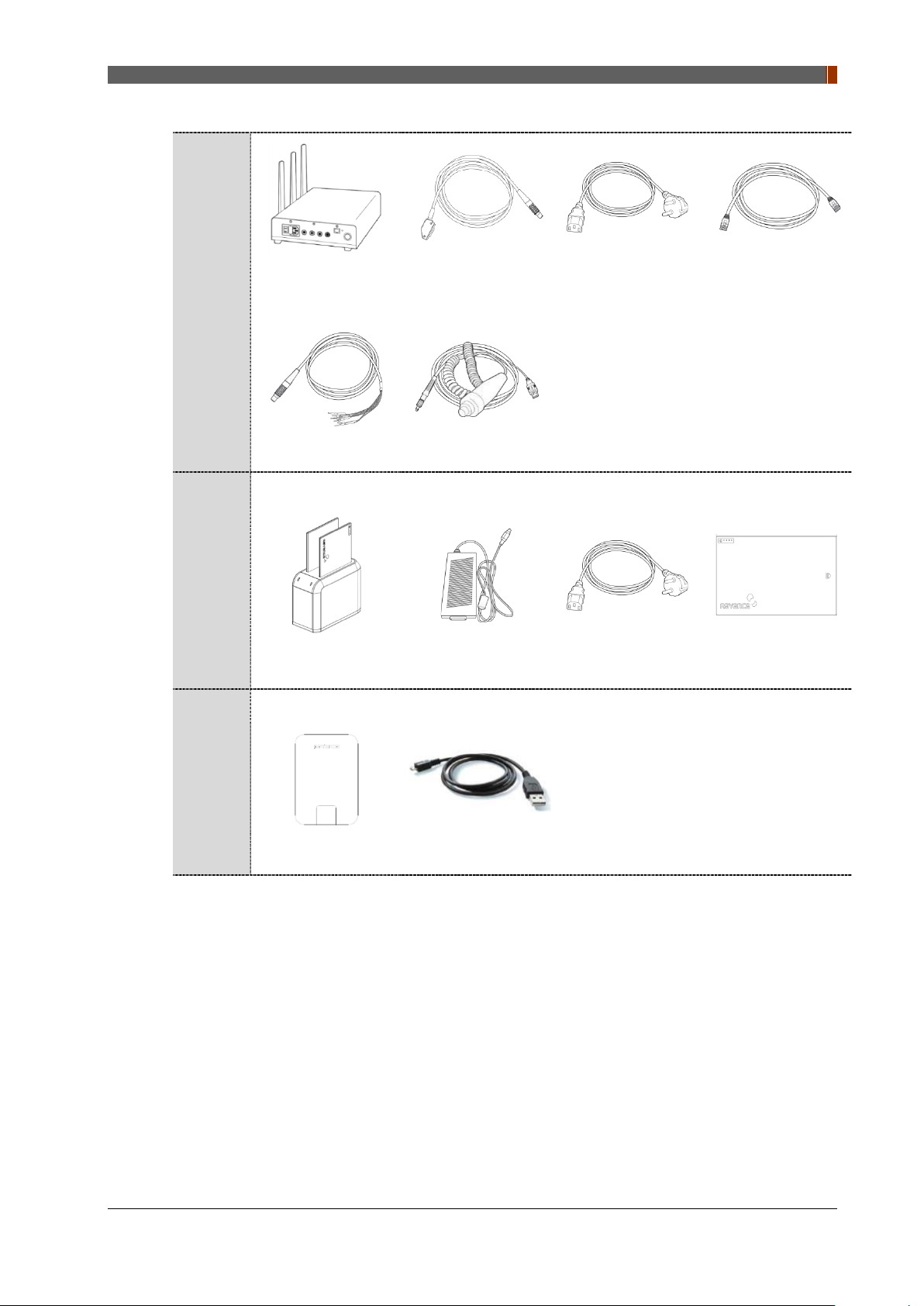

2.2.1 Basic Components

Detector 1EA Battery 2EA

AC power cord 1EA

(110V or 220V 1.8m)

2.2.2 Optional Components

Power

supply

package

Charger Adaptor 1EA &

Mobile charger adaptor 1EA

Installation CD 1EA Manual 1EA

AGI

package

Power supply1EA

Trigger Cable 1EA

AC power cord 1EA

(110V or 220V 1.8m)

P-interface Cable

1EA

LAN cable 1EA

(CAT 6, 10m)

(straight-through)

AGI Box 1EA USB Cable 1EA

Link Cable 1EA

(7, 9m)

1417WGC/WCC 24

PART II. Service Manual

Interface

box

package

Battery

Charger

Package

RAP001A

Trigger Cable 1EA

Battery Charger 1EA

Link Cable 1EA

P-interface Cable

Battery Charger

adapter 1EA

(7, 9m)

1EA

AC power cord 1EA

(110V or 220V 1.8m)

LAN cable 1EA

(CAT 6, 10m)

(straight-through)

AC power cord 1EA

(110V or 220V 1.8m)

Battery 2EA

Sharing

Package

IrDA module 1EA

Micro USB cable

1EA

1417WGC/WCC 25

PART II. Service Manual

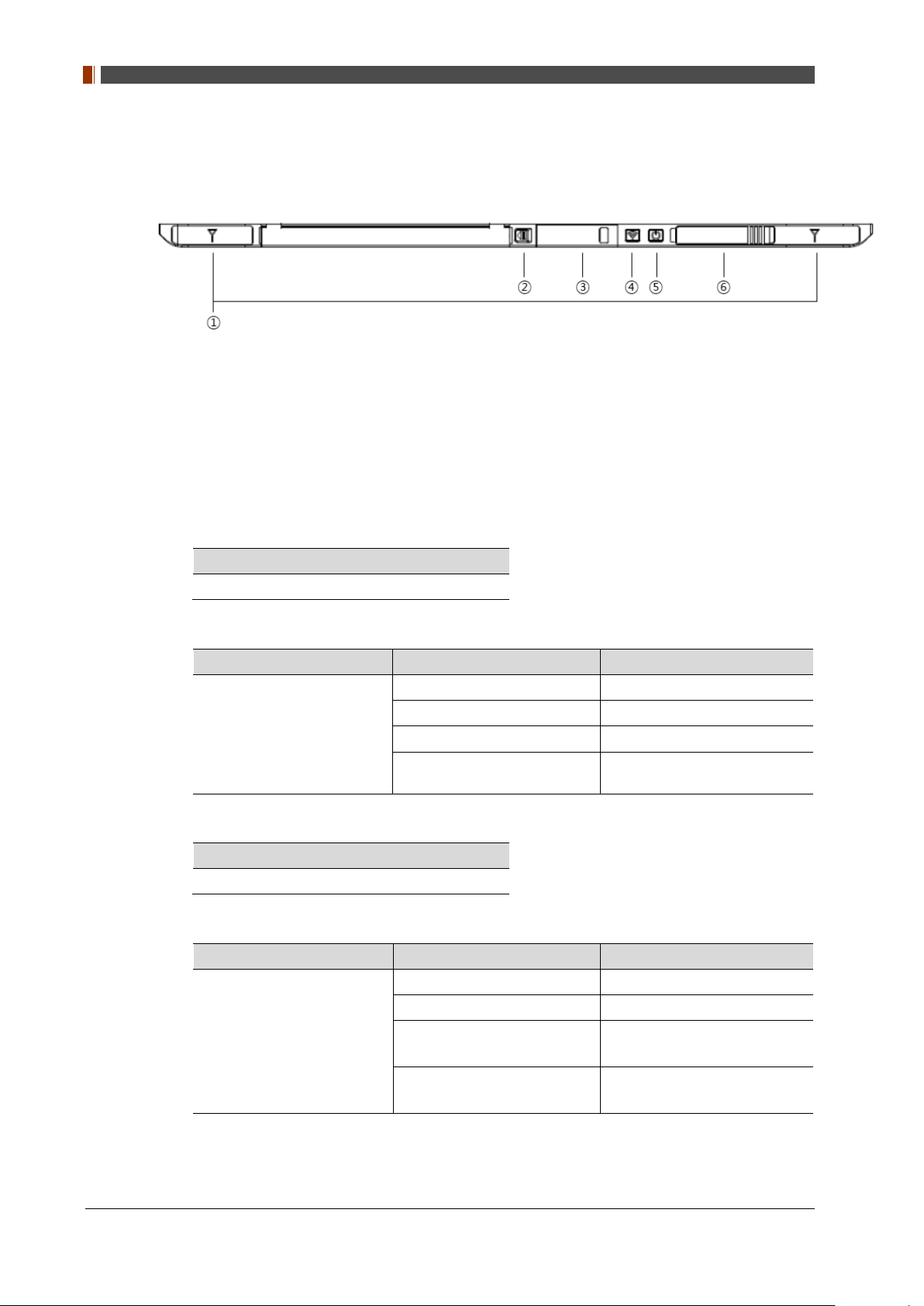

2.3 Part Names and Functions

2.3.1 Detector

1. Wireless Antenna

2. Battery Unlock button

This is an unlock button to remove battery

3. IrDA & OLED window

IrDA module can communicate with infrared ray and inform the product status.

4. Mode select button & LED indicator

Mode Change

Press the 1 second

Indication the status of detector

Name of LED Status of LED Status of product

Mode

5. Power button & LED indicator

Power On / Off

Press over than 3 seconds

Indicating the status of detector

Name of LED Status of LED Status of product

Power

Orange on Station mode(wireless)

Green on AP mode(wireless)

Off Wired mode

Blinking Orange and Green

alternatively

Green Power on

Blinking green Power booting

Red

Orange

(Battery remain 0~7%)

(Battery remain 7~15%)

Sleep mode

Low battery

Low battery

1417WGC/WCC 26

6. Link cable connector

Use for data transfer and charging battery while wired mode is in use (Connect between

detector and power supply.)

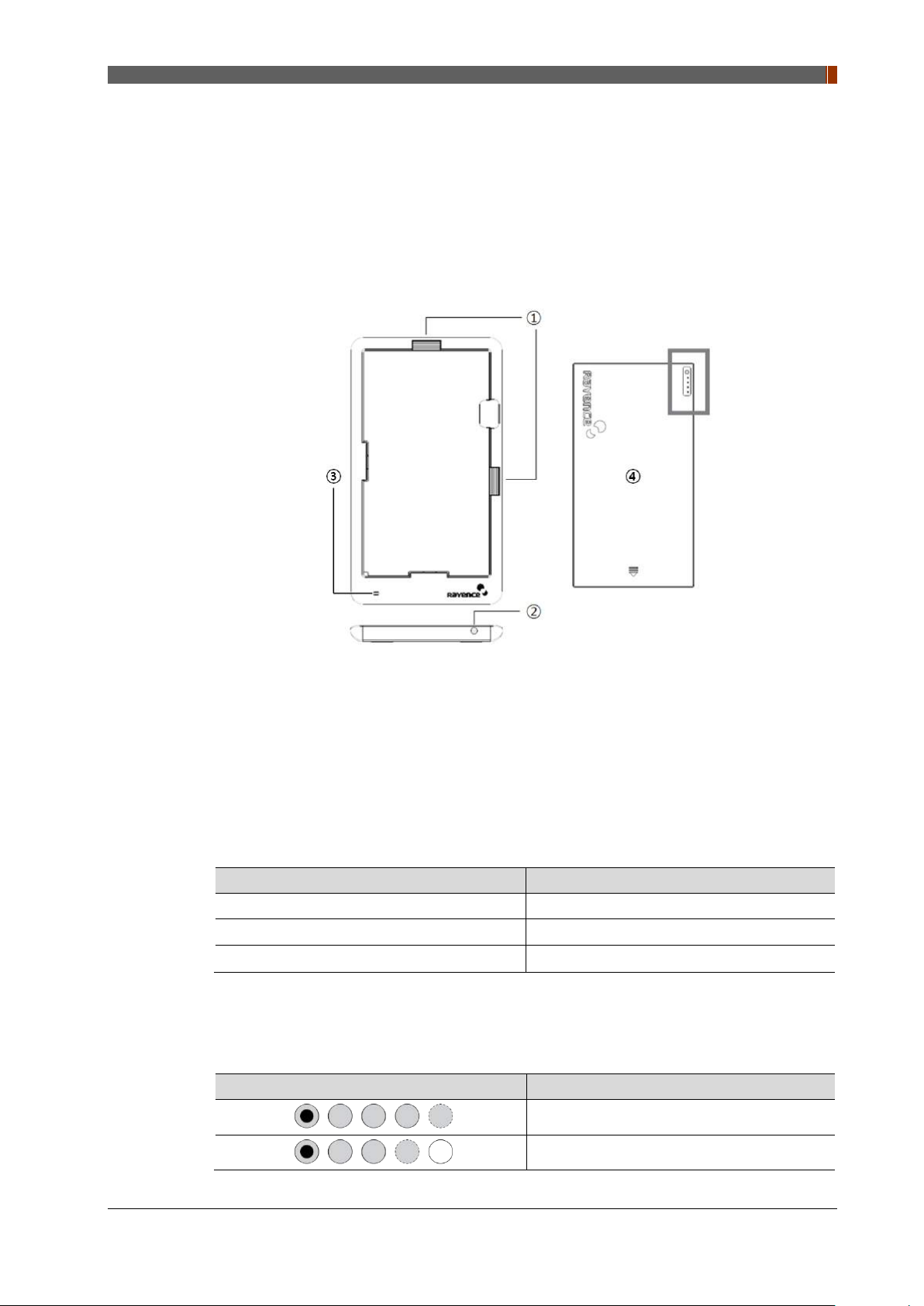

2.3.2 Battery & Mobile charger

PART II. Service Manual

1. Battery unlock level

This is an unlock-level to remove battery

2. Power connector

Connects to the mobile charger adapter

3. LED Indicator

Display battery charging status.

LED Color Battery Status

Green Fully charged

Orange Charging

Blinking orange and Green alternatively

4. Battery : Rechargeable Lithium Ion battery(Charging Time-3 hrs)

Error

• In the diagram above, the box shows where the remaining battery percentage is

displayed.

Battery Remain Indicator Battery Level

75~100 %

50~75 %

1417WGC/WCC 27

PART II. Service Manual

Battery Remain Indicator Battery Level

• Battery warranty period: 6 months

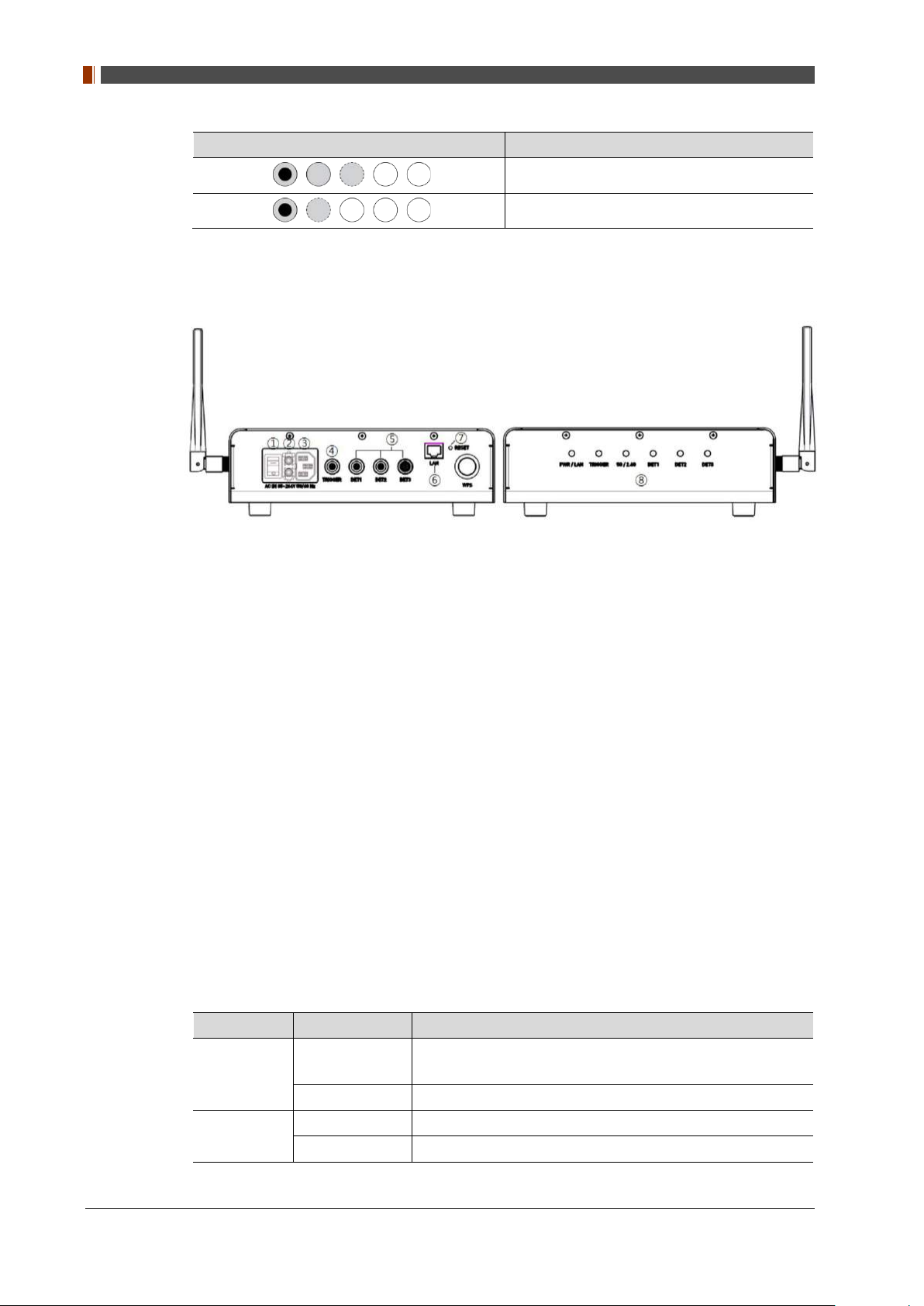

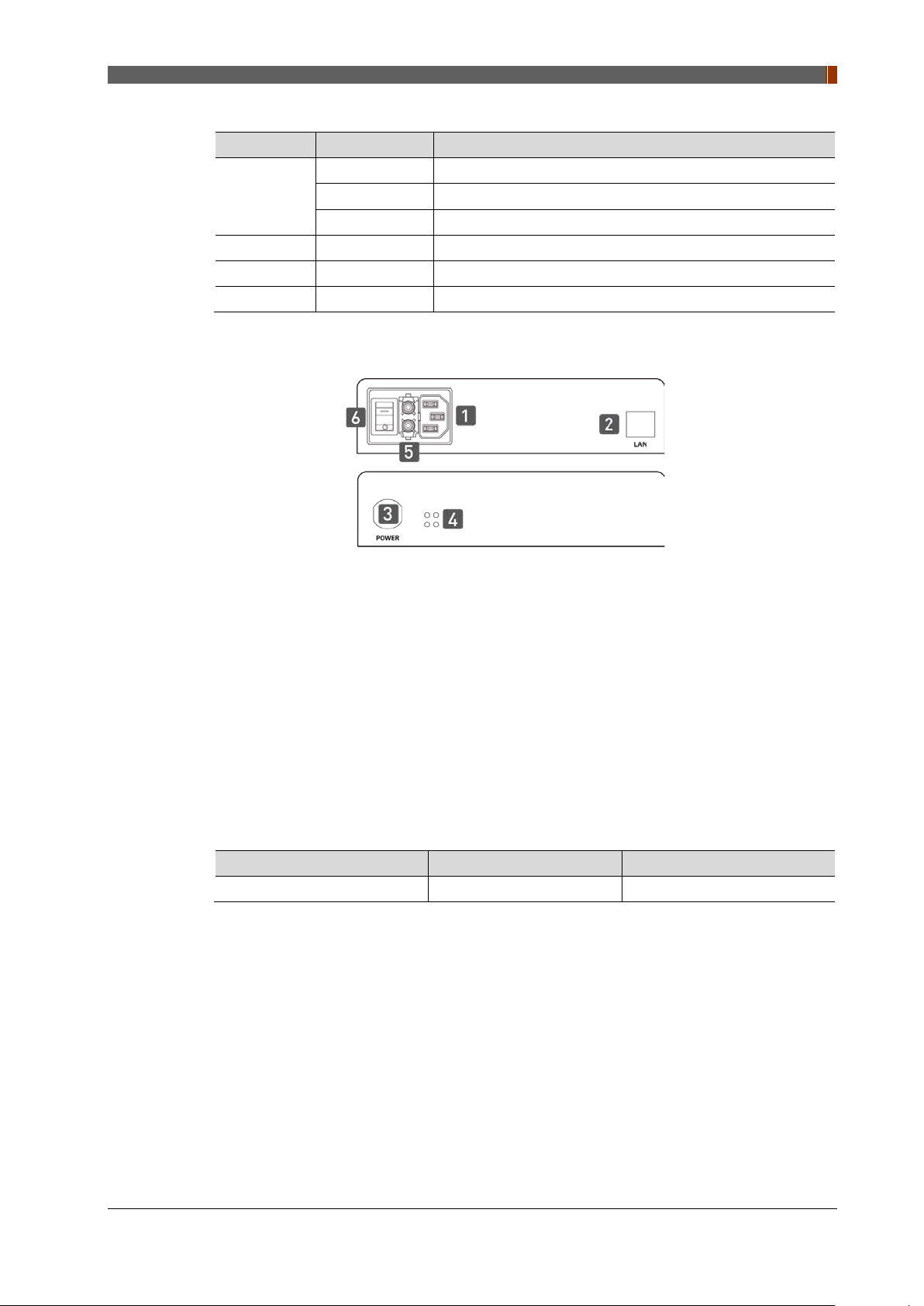

2.3.3 RAP001A (Optional)

25~50 %

0~25 %

1. Switch

Power On/Off switch

2. Fuse

T3.15 AL 250V

3. Power plug connector

Connects to the AC power cord

4. T rigger connector

This is a connector to synchronize the detector and generator. Connect the RAP001A to the

generator by using a P-interface cable or trigger cable.

5. Link connector 1~3

Use for data transfer and charging battery while detector is in use (Connect between

detector and RAP001A), Up to three detector can be connected

6. LAN connector

Ethernet port for transmitting an image/command between the detector and PC

7. Reset button

Reset all settings to default values

8. Indicating the status of RAP001A

LED LED Color Status

PWR/LAN

Red

Blinking Green Connected with PC LAN

Red Trigger READY DONE

TRIGGER

Green Trigger READY IN

Turned on while booting after connecting with power supply.

Turned off upo n the completion of booting.

1417WGC/WCC 28

LED LED Color Status

Red Frequency of 2.4GHz

5G/2.4G

DET1 Green Connected with detector of port1

DET2 Green Connected with detector of port2

DET3 Green Connected with detector of port3

Green Frequency of 5GHz

Yellow Frequency of 2.4GHz and 5GHz

2.3.4 Power Suppy (Optional)

PART II. Service Manual

1. Power Plug Connector

Connects to the AC power cord

2. LAN Connector

Ethernet port for transmitting an image/command between the detector and PC

3. Link Connector

Used for charging the battery while the detector is in use (Connect the detector and power

supply)

4. LED Indicator

Display status of the power supply.

Color Status Power Status

Green On Power on

5. Fuse

T3.15 AL 250V

6. Switch

Power On/Off switch

1417WGC/WCC 29

PART II. Service Manual

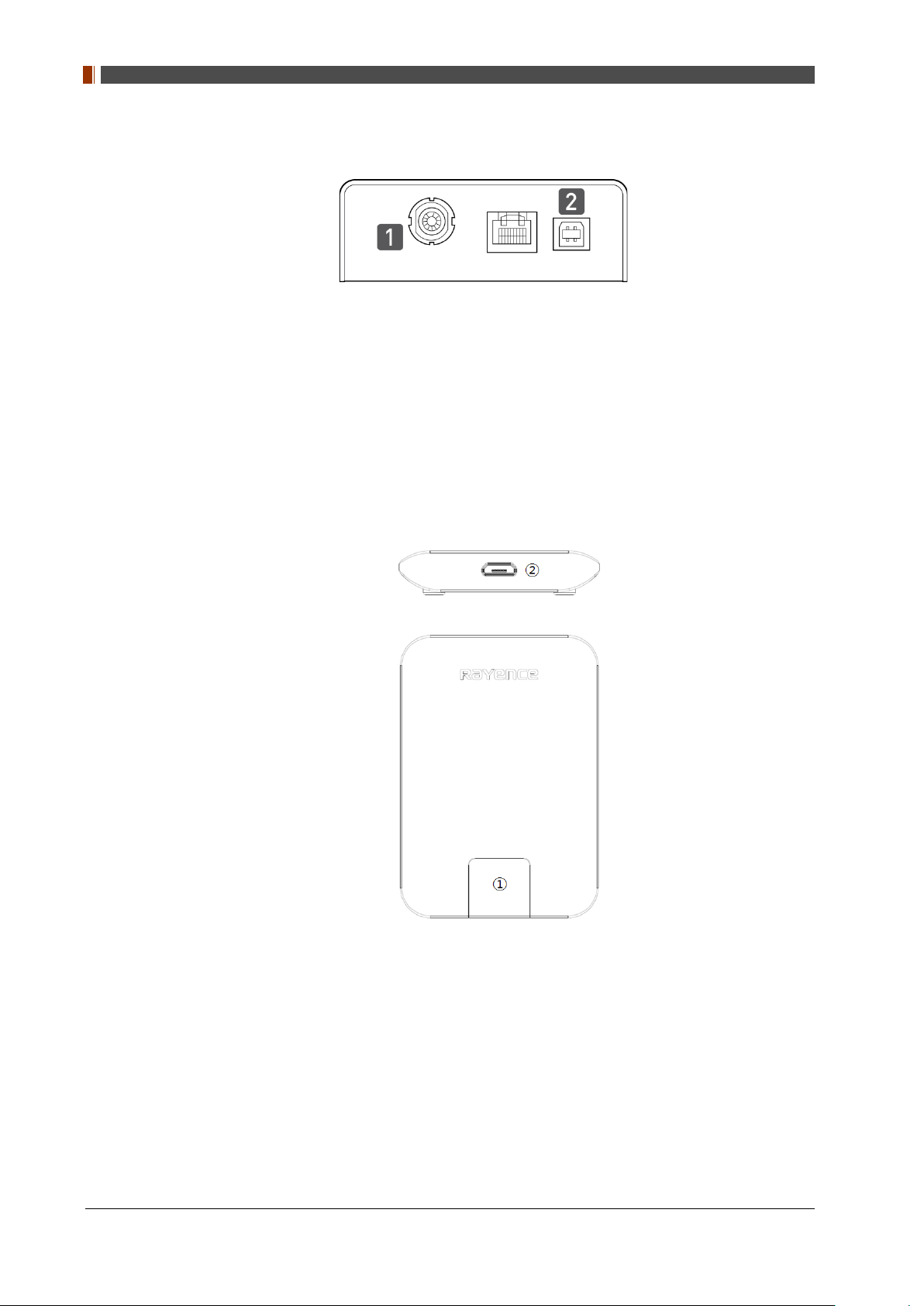

2.3.5 AGI Box (Optional)

7. T rigger Connector

This is a connector to synchronize the detector and generator. Connect the AGI to the

generator by using a P-interface cable or trigger cable.

8. USB Connector

This is a connector for communication between the AGI and PC. Connect the AGI to the PC

by using a USB cable.

2.3.6 IrDA module (Optional)

1. IrDA window

Window for communicating intrared with Detector

2. Micro USB connector

Connector for communication with IrDA and PC connect the PC through the Micro USB

cable.

1417WGC/WCC 30

Loading...

Loading...