Rayence RY1012WGB User Manual

1012WGB User manual

© Copyright 2014, Rayence Co. Ltd.

All pages of this document contain proprietary and confidential

information of Rayence Corporation and are intended for exclusive use

by Rayence Corporation personnel or customers. Copying, disclosure to

others or other use is prohibited without the express written

authorization from Rayence Corporation. Please report any violations of

requirement to Rayence Corporation.

This is used to emphasize essential information. Be sure to read this

information to avoid incorrect operation.

This indicates hazardous situation which, if not heeded, may result in

minor or moderate injury to you or others, or may result in machine

damage.

This indicates a potentially hazardous situation which, if not heeded, could

result in death or serious injury to you or others.

Federal Law restricts this device to sale by or the order of a radiologist or

any other practitioners licensed by the law of the state in which that

person practices to use or order the use of the device.

Attention

For improvement of product performance, supplementation, or follow-up of information; the

contents of this manual are subject to change without separate prior notice.

Please note that our company has neither responsibility for any accidents nor obligation to

do free repair service for any damage of the equipment due to user's mistake, which resulted

from failure to follow the contents in this manual. Make sure to be familiar with the safety

precautions and usage procedures. Also note that the product may slightly differ from the

contents of this manual depending on specification.

The following marks are used for the effective use of the product in this manual.

Attention, consult accompanying documents.

Contents

1. Introduction...................................................................................... 1

(1) Overview .......................................................................................... 1

(2) Product features .............................................................................. 1

(3) Product component ........................................................................ 2

(4) Components Description ............................................................... 4

(5) Warning ............................................................................................ 9

(6) Caution ........................................................................................... 11

2. Notes for Using the Detector ........................................................ 13

(1) Handling ......................................................................................... 13

(2) Handle Assembly .......................................................................... 13

(3) Before Exposure............................................................................ 14

(4) During Exposure ........................................................................... 14

(5) Disinfection and Cleaning ............................................................ 14

(6) Others ............................................................................................. 14

3. Technical Features ........................................................................ 15

(1) Mechanical Features ..................................................................... 15

(2) Electrical Features ........................................................................ 15

(3) Environmental requirement ......................................................... 18

(4) PC Requirements .......................................................................... 19

4. Installation ..................................................................................... 20

(1) Program setup ............................................................................... 20

(2) Connection (Manual Trigger) ....................................................... 21

(3) Connection (Auto Trigger) ............................................................ 29

(4) IP set up ......................................................................................... 34

(5) Checking Connection ................................................................... 35

5. Calibration ...................................................................................... 36

(1) General Principle ........................................................................... 36

(2) Calibration ...................................................................................... 38

6. Image Acquisition Test.................................................................. 43

(1) Get Image ....................................................................................... 43

(2) View Images ................................................................................... 44

7. Operation ........................................................................................ 49

(1) Recommend ................................................................................... 49

(2) Switching power on / off ............................................................... 49

(3) Storage ........................................................................................... 49

8. Radio Frequency compliance ........................................................ 50

(1) FCC Notice (U.S.A) ........................................................................ 50

(2) IC Notice (CANADA) ...................................................................... 52

(3) R&TTE Notice (European Union) ................................................. 53

9. Maintenance .................................................................................. 54

(1) Maintenance ................................................................................... 54

(2) Cleaning ......................................................................................... 54

(3) Inspection ...................................................................................... 55

(4) Marking and labeling symbols ..................................................... 56

Appendix .............................................................................................. 58

1. Introduction

(1) Overview

The 1012WGB is a digital X-ray flat panel detector that can

generate images of NDT. This X-ray imaging system consists of

a scintillator directly coupled to an a-Si TFT sensor. It makes

high-resolution, high-sensitive digital images.

(2) Product features

Based on a-Si TFT active matrix

Compact (18mm thickness) and light weight

High resolution : Min. 2.5 lp/mm, Max 3.9 lp/mm

14/16-bit digital output

Easy integration

1

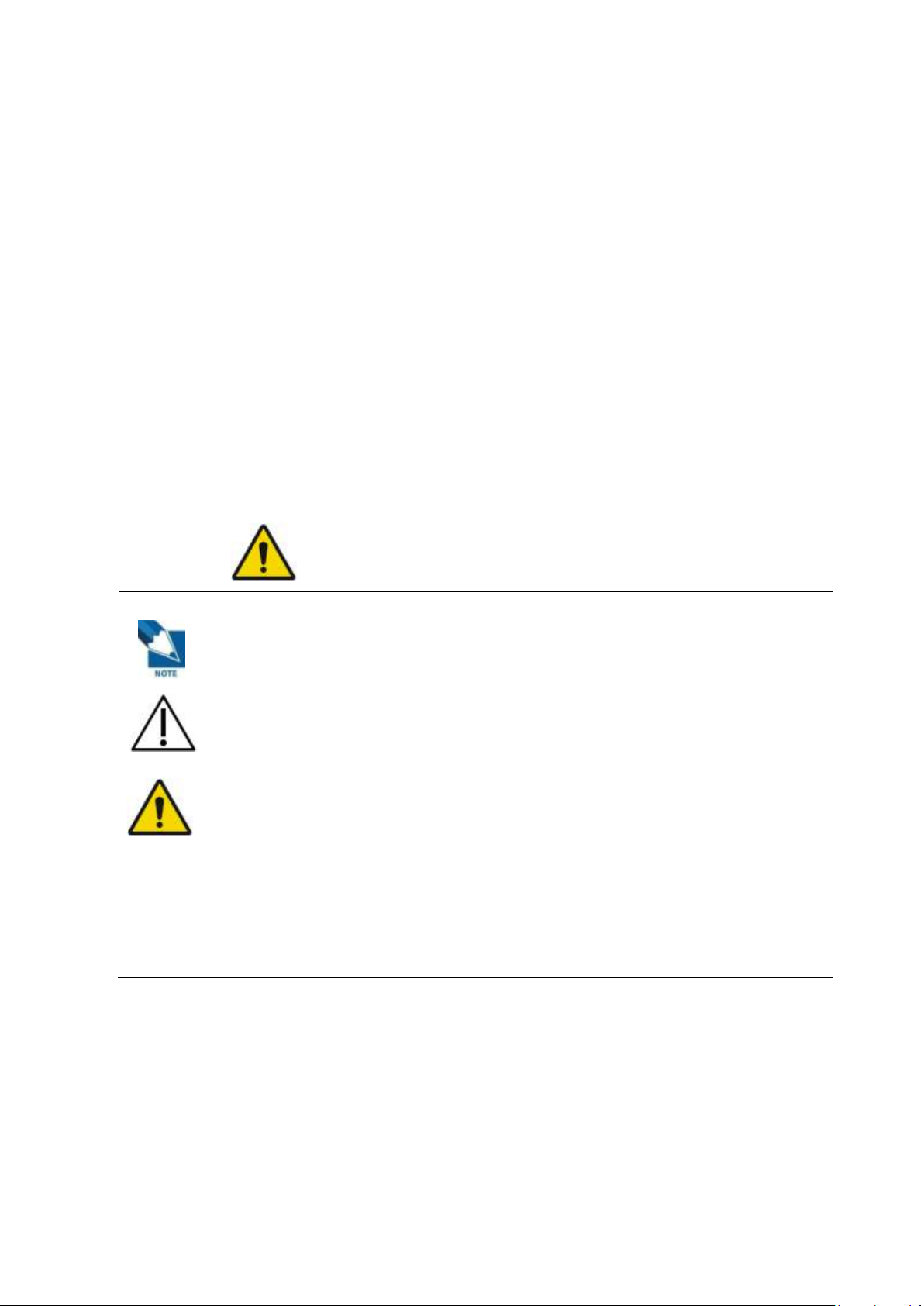

(3) Product component

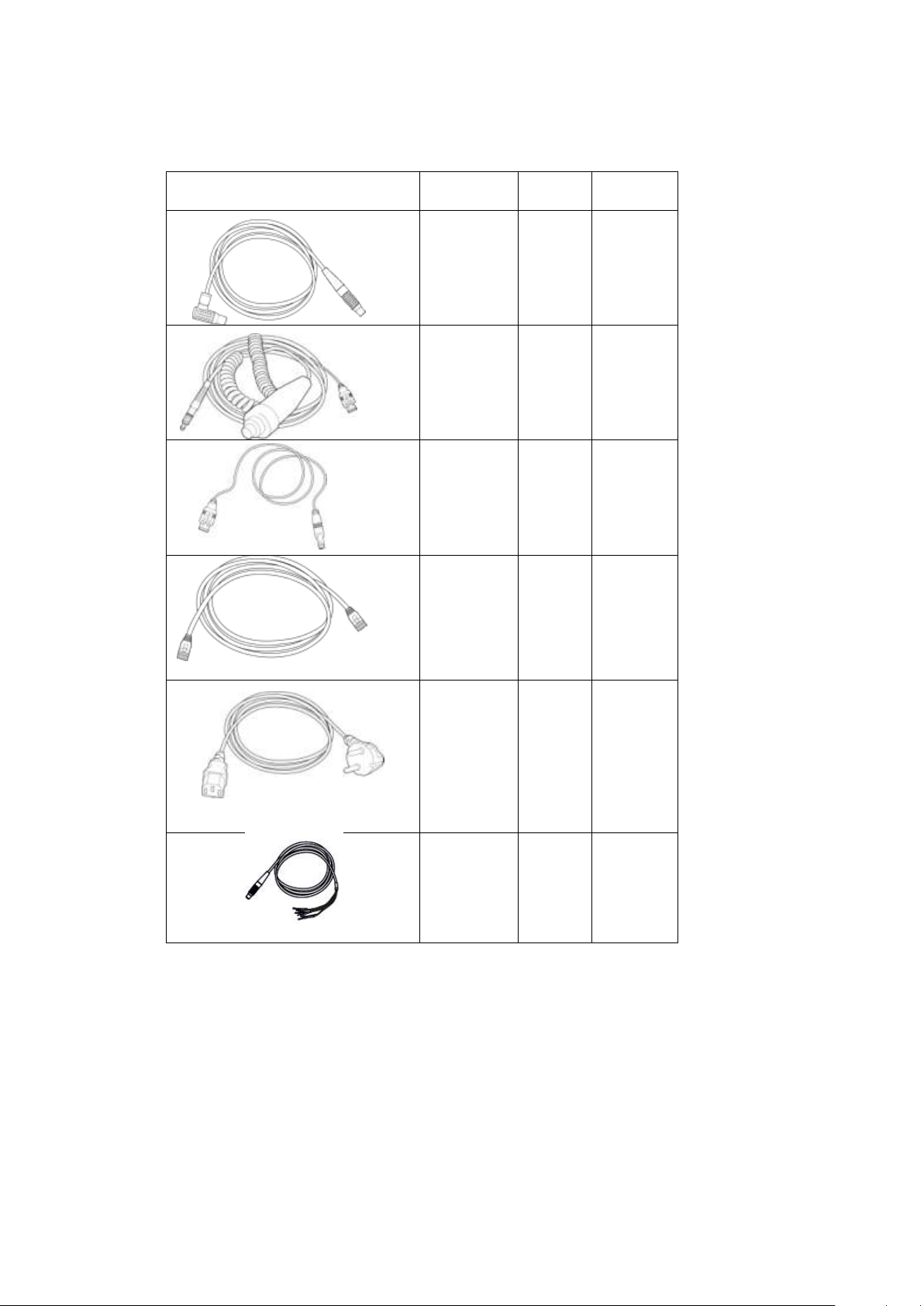

Photo

Item

Quantity

Detector

1

Handle

1 Battery pack

2

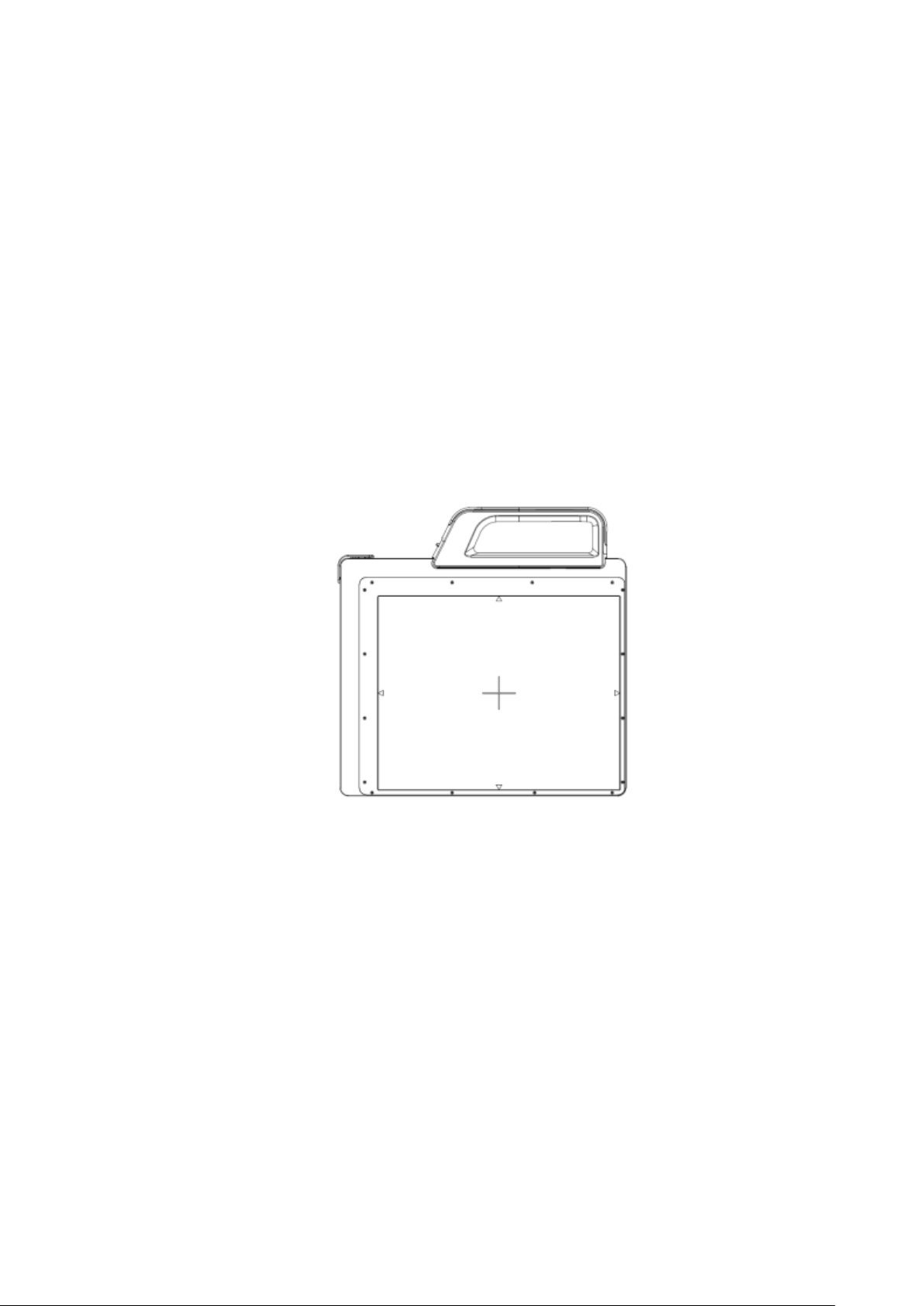

Battery charger

1

Charger

adapter

1

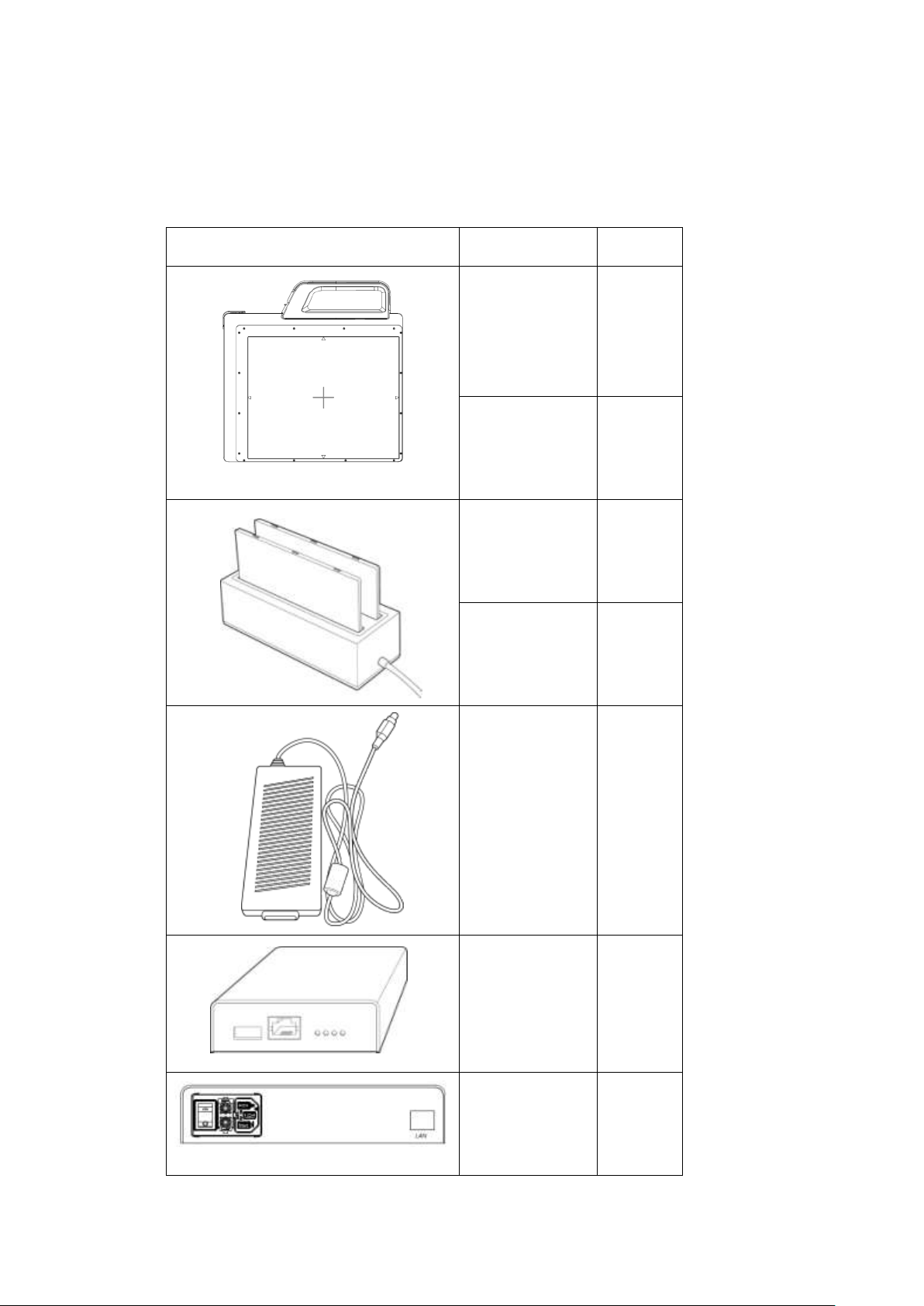

AGI

1

Power supply

box

1

Industrial Image Processing Unit

2

Cable

Item

Length

Quantity

Link cable

6m

1

PInterface

cable

8m

1

USB

cable(A to

B)

1.8m

1

LAN cable

10m

1

AC Power

cord

1.8m

1

cable

3m

1

Installation CD

o Manual

o Detector Library

Option

o Trigger cable

3

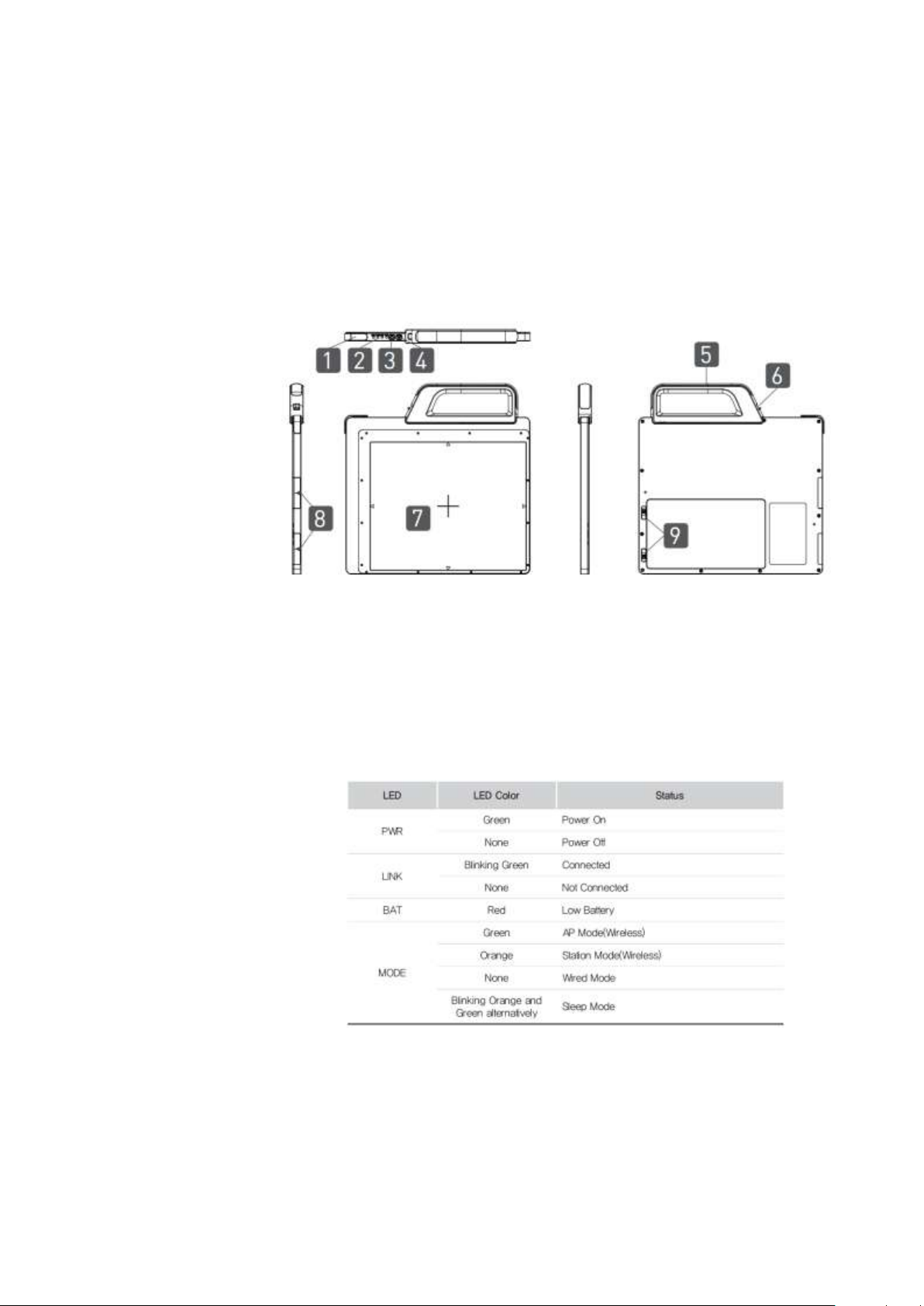

(4) Components Description

The detector is designed to capture radiographic images.

Captured images are transmitted to PC using the wired

connection.

(1) Detector

1. Link Cable Connector : This is a connector for Wire

communication and power supplying. Connect the detector to the

power supply using Link cable.

2. LED indicator: The LED indicates the state of detector.

3. Power Button : Power on / off switch (Press for over 3 seconds)

4. AP Mode Select Button : Button for changing mode

5. Handle : Hold this handle when carrying the sensor unit. It is

removable. (Horizon/Vertical)

4

6. Handle unlock-lever : This is an unlock-lever to remove handle.

7. CFRP(Carbon Fiber Reinforced Plastic) : The part of the patient’s

body to which an image is to be taken should be placed against this

plate.

8. Shock sensor : Detector has built-in 2 Shock sensors. It detects

and records impact and mishandling of fragile

9. Battery unlock-lever : This is an unlock-lever to remove battery.

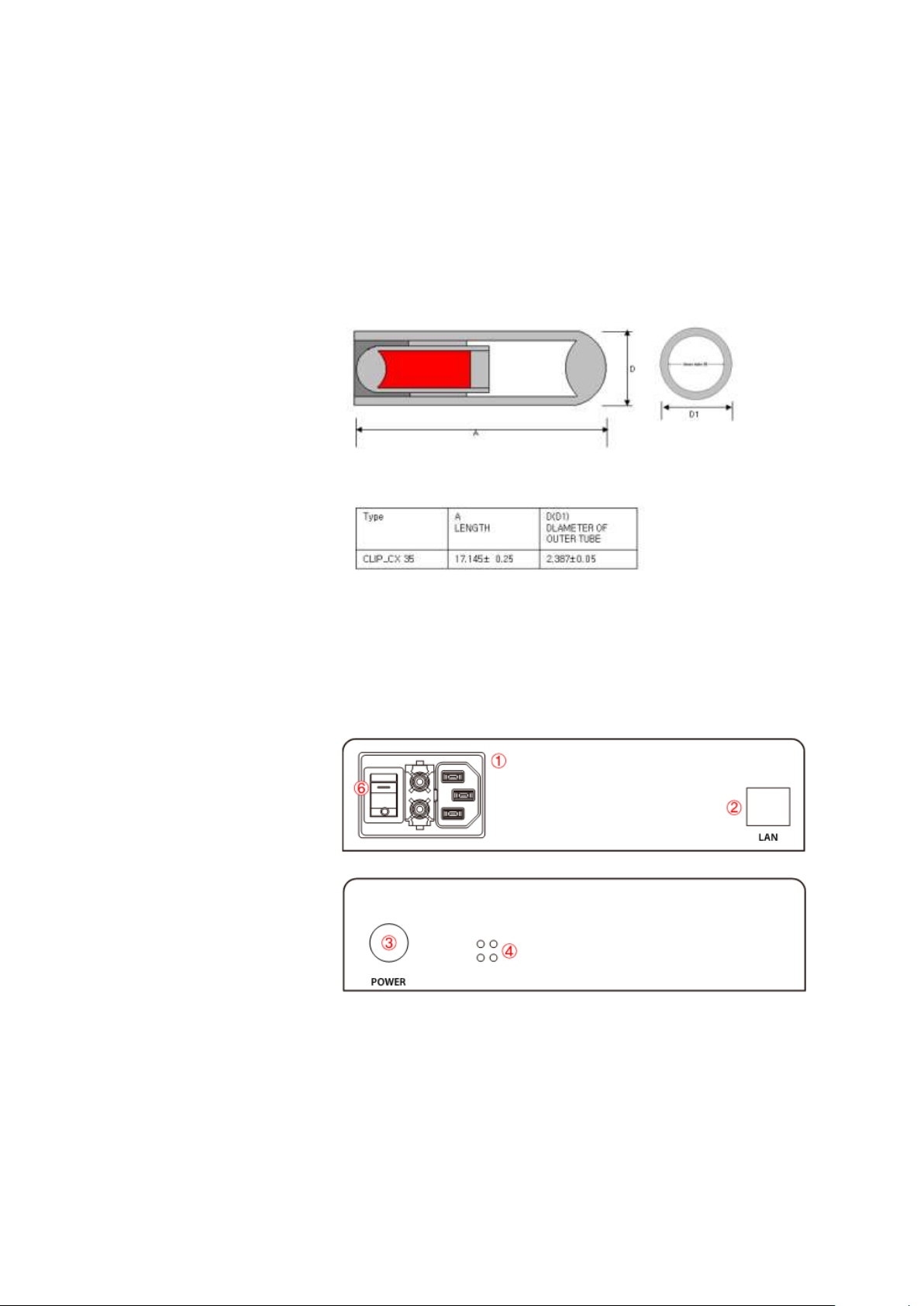

(2) Power supply

1. Power plug connector: Connect with AC power supply cord

2. LAN connector : Ethernet port for transmitting the image/command

between detector and PC

3. Link cable connector: Power connector for detector operating

4. LED indicator: Four LEDs to display the status

※ Changeable part: Fuse T3.15 AL 250V

5

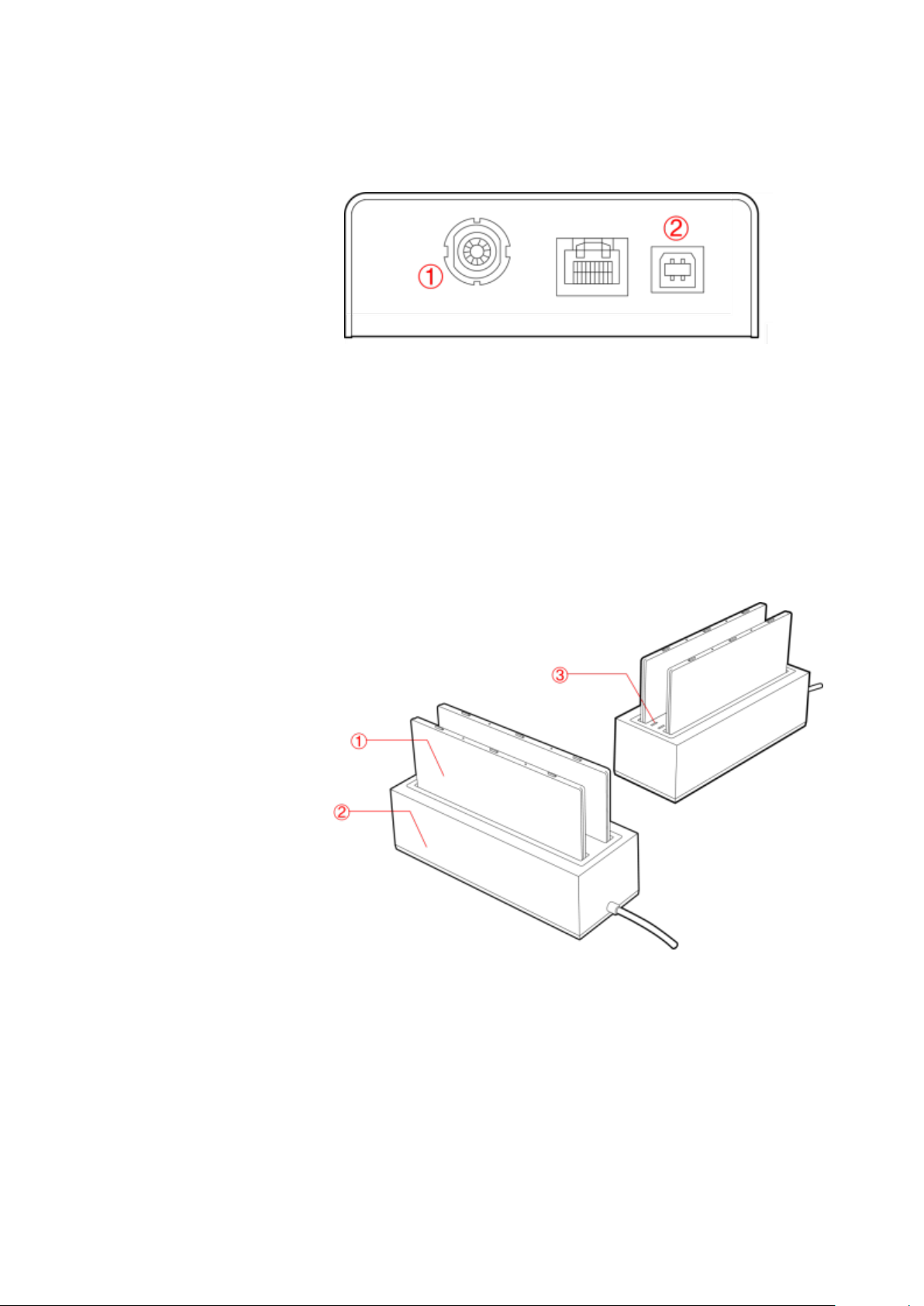

(3) AGI

<AGI is needed on only Manual Trigger Mode>

1. Trigger connector: This is a connector for synchronization

between detector and generator. Connect the AGI to the generator

using P-interface cable..

2. USB connector: This is a connector for communication between

AGI and PC. Connect the AGI to the PC using USB cable

(4) Battery & Charger

1. Battery : Lithium ion battery. The number of times being acquired

image is 960 images(@ cycle time : 15s). The batteries last 2.5

hours and are rechargeable.

2. Charger : Two port cradle type.

3. LED indicator :

i. Orange on : charging

ii. Green on : Charging is completed.

6

※Wireless Module and Wireless Antenna

Wireless antennas:

The module adopts the latest 802.11n Dual-Band technology.

DUT does not support simultaneous transmission.

The transmitter of the module is powered by host equipment (Detector).

The antennas are 2 printed-dipole and correlated antennas.

Does not support beamforming.

※Wireless module:

The end product will use the in original certified transmitter module and will keep the original

authorization condition except the change in antenna of the module during the final end

product assembly.

Data transmission is always initiated by software, which is the passed down through the

MAC, through the digital and analog baseband, and finally to the RF chip. Several special

packets are initiated by the MAC. These are the only ways the digital baseband portion will

turn on the RF transmitter, which it then turns off at the end of the packet. Therefore, the

transmitter will be on only while one of the aforementioned packets is being transmitted. In

other words, this device automatically discontinues transmission in case of either absence of

information to transmit or operational failure.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

FCC CAUTION

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment. This transmitter must not be colocated or operated in conjunction with any other antenna or transmitter.

When installing it in a mobile equipment

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment and meets the FCC radio frequency (RF) Exposure Guidelines in Supplement

C to OET65. This equipment has very low levels of RF energy that it deemed to comply

without maximum permissive exposure evaluation (MPE). But it is desirable that it should be

installed and operated keeping the radiator at least 20cm or more away from person’s body

(excluding extremities: hands, wrists, feet and ankles).

When you use the detector with wire mode, the wireless function is automatically off.

※5150~5250 MHz band is restricted to indoor operations only.

7

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause undesired

operation of the device.

Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisee aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioelectrique subi, meme si le brouillage est susceptible d'en compromettre le

fonctionnement.

Operations to just the specific band(s) : limited device Software program.

User cannot enable the other bands, because PC set up should be necessary.

(details for user manual_Ch.3 Installation and Calibration)

8

(5) Warning

Make sure

to observe

the following right

Environment of Use and Storage

Follow the specified process of operational instructions written in

this manual for the safety of the users

Does not use or store the instrument near any flammable

chemicals such as thinner, benzene, etc. Also, this instrument is

not a category AP or APG equipment. If chemicals are spilled or

evaporate, it may result in fire or electric shock through contact

with electric parts inside the instruments. Also, some

disinfectants are flammable. Be sure to take care when using

them.

Connection

Do not connect the instrument with anything other than specified.

Otherwise, it may result in fire or electric shock.

To avoid the risk of electric shock, this equipment must only be

connected to a supply mains with protective earth.

Handling

Always be sure to keep checking the condition of the system to

ensure they are normal during the use of the instrument. If any

problem is found, take appropriate measures, such as stopping

the operation of the instrument, as required.

Never disassemble or modify the product as it may result in fire

or electric shock. Also, since the instrument incorporates parts

that may cause electric shocks and other hazardous parts,

touching them may cause death or serious injury.

Do not hit or drop the instrument. The instrument may be

damaged if it receives a strong jolt, which may result in fire or

electric shock if the instrument is used without it being repaired.

9

When Problem Occurs

Make sure

to observe

the following right.

Should any of the following occur, immediately turn OFF the

power of each instruments, unplug the power supply cord from

the AC outlet, and contact Rayence representative or distributor.

When there is smoke, odd smell or abnormal sound.

When liquid has been spilled into the instrument or a metal

object has entered through an opening.

When the instrument has been dropped and it is damaged.

Maintenance and Inspection

For safety reasons, be sure to turn OFF the power of each

instrument when the inspections indicated in this manual are

going to be performed. Otherwise, it may result in electric shock.

When the instrument is going to be cleaned, be sure to turn OFF

the power of each instrument, and unplug the power supply cord

from the AC outlet. Never use benzene, thinner or any other

flammable cleaning agents. Otherwise, fire or electric shock may

result.

The instrument must be repaired by a qualified engineer only. If it

is not repaired properly, it may cause fire, electric shock, or

accident.

10

(6) Caution

Environment of Use and Storage

Do not install the instrument in a location with the conditions

listed below. Otherwise, it may result in failure or malfunction, fall

or cause fire or injury.

Close to facilities where water is used.

Close to air-conditioner or ventilation equipment.

Close to heat source such as a heater.

Prone to vibration.

Insecure place.

Dusty environment.

Saline or sulfurous environment.

High temperature or humidity.

Freezing or condensation.

Do not place the storage case in a location with the conditions

listed below.

Where the cable of the sensor unit will be strongly pulled

when the sensor unit is put into the case, otherwise, the cable

may be damaged, resulting in fire or electric shock.

Where someone might get their foot caught in the cable of the

sensor unit is put in the case. Otherwise they could trip over,

resulting in injury

11

Handling

Wipe the CFRP plate of the sensor unit with ethanol or

glutaraldehyde solution

Turn off the power of each instrument for safety when they are

not going to be used.

Maintenance and Inspection

For safety reasons, be sure to inspect the instrument before

using it. In addition, carry out a regular inspection at least once a

year.

If the device does not work, do not disassemble yourself. Please

contact to the Rayence C/S team.

12

2. Notes for Using the Detector

Please confirm lever position. When the

handle is locked, the lever should be

same position with the right picture.

Insert the handle in

the same direction

If the

handle is

not locked,

the detector can be

dropped.

(1) Handling

Handle the instrument carefully, as it may be damaged if

something is hit against it, dropped, or receives a strong jolt.

(2) Handle Assembly

※ Insert the handle always in the same

13

(3) Before Exposure

Be sure to check the equipment daily and confirm that it works

properly.

Sudden heating of the room in cold areas will cause

condensation to form on the instrument. In this case, wait until

condensation disappears before performing exposure.

If the instrument is used with condensation formed on it,

problems may occur in the quality of the instrument. When an airconditioner is going to be used, be sure to raise/lower the

temperature gradually so that a difference in temperature in the

room and in the instrument does not occur, to prevent forming of

condensation.

(4) During Exposure

Do not use the detector near devices generating a strong

magnetic field. Doing so may produce image noise or artifacts.

Do not apply excessive weight to the sensor unit. Otherwise, the

sensor may be damaged.

(5) Disinfection and Cleaning

Do not spray the detector directly with disinfectants or detergents.

Do not use anything other than neutral detergent for cleaning the

cover of the instrument. Otherwise, the coating will be corroded.

(6) Others

Be sure to reconnect the cables to the proper connectors.

Otherwise, the instrument may malfunction or may be damaged.

14

3. Technical Features

Size

385 x 320 x 18 mm

Weight

3.2 kg (incl. Battery, not incl. handle)

Encapsulation Material

Mg

Window Material

Carbon fiber plate

Sensor Type

Amorphous Silicon with TFT (Single Panel)

X-ray Converter

Gd2O2S:Tb

Total Pixel Number

2560 × 2048 pixels

Total Pixel Area

325.1 x 260.1 mm

Effective Pixel Number

2520 × 2008 pixels

Effective Pixel Area

320 x 255 mm

Pixel Pitch

127 μm

Limiting Resolution

Max. 3.9 lp/mm

Energy Range

40 - 150 kV

A/D Conversion

14 / 16 bits

Preview Time

< 2.0 sec (wired)

< 5.0 sec (wireless)

Data Interface

Gigabit Ethernet

Wi-Fi (802.11a/g/n)

(1) Mechanical Features

(2) Electrical Features

Detector

Table 1: Product specification

Under RQA5 condition (70kVp, 21mmAl)

Preview time is not included post-processing time

15

Loading...

Loading...