Page 1

GENERAL NOTES: DO’S AND DON’TS:

TOOLS REQUIRED

nVent RAYCHEM TraceTek

TT-PTB-1000

(part # 486437-000)

Ohmmeter

(>20 M ohm)

nVent RAYCHEM TraceTek

TT-MAPPING CAP-MC

(part # P000000871)

Extran Vent RAYCHEM

TraceTek TT-MLC-MC-BLK

(part # 133332-000)

Extra TT-MET-MC

(part # 571293-000)

nVent RAYCHEM TraceTek

TT-Kellems-Grip-Large

(part # P000001291)

nVent RAYCHEM TraceTek

TT-ULTRA-TORCH

(part # 390067-000)

TT5000-HS (for fuel leaks) TT5001-HS (for solvent leaks)

TraceTek Sensing Cable for Underground Leak Detection

Installation Instructions

DESCRIPTION

These instructions explain the proper procedures for installing and testing

nVent RAYCHEM TraceTek TT500X-HS sensing cables. (TT500X-HS refers

to either TT5000-HS or TT5001-HS). TT500X-HS sensing cables are primarily

intended for use in underground (fuel or solvent) pipeline applications. TT500XHS sensing cables ignore water but will detect and locate (fuel or solvent) spills

and leaks. (See the data sheet for specific performance characteristics.)

Important Notes

When used to monitor underground fuel pipelines, TT500X-HS sensing cables

are typically installed within slotted conduit that is routed alongside the main

pipeline. TT500X-HS sensing cable is designed for use within slotted PVC

conduit and is constructed with an outer layer of polyethylene fibers to provide

extra pulling strength and low friction during the installation process. The

sensor cable core is standard TT5000 (for fuel) or TT5001 (for solvent) with

well documented response times, numerous third party qualifications and years

of successful applications.

• TT5000-HS sensing cable is identified by the all white color of the outer jacket.

• TT5001-HS sensing cable is identified by a purple TRACER in the white

outer jacket.

Portable Test Box, battery powered instrument

specifically designed for testing and trouble

shooting TraceTek systems

Can be used as an alternative and supplement to

the PTB 1000

Used to simulate leaks at connector points during

commissioning and mapping process

Leader cable. Used with the ohmmeter to make

connections to the sensor cable for resistance

measurements

End termination. Used during installation or trouble

shooting to temporarily isolate a sub-section of

sensor cable for resistance measurements.

Large Kellems Grip used in cable pulling when rope

overbraid loop not available.

Flameless heating tool (Ultratorch 200) or suitable

heat gun with concentrator tip

REQUIRED MATERIALS

Conduit cleaning tool Used in proofing installed sections of conduit.

Conduit end caps Used to cover exposed conduit end to maintain

Heat shrink tubing

segments

conduit cleanliness.

Used as environmental seal over all mated male/

female (pin/socket) connections

OPTIONAL MATERIALS

nVent RAYCHEM TraceTek

TT-MBC-MC-TW

(part # P000001206)

nVent RAYCHEM TraceTek

TT-MJC-XX-MC-BLK

nVent RAYCHEM TraceTek

TT5000–HUV–CK–

MC–M/F

(part # P000001207)

Branch connector designed for rugged outdoor

applications used to connect and branch "T" lines

Jumper cable is available in various pre-cut and

terminated lengths

Connector kit used during field connection of

TT500X-HS bulk cable

DO:

• Store the cable in its original container in a clean, dry area until ready to install.

• Schedule the sensor cable installation as late as possible in the construction

schedule to avoid risk of damage or contamination by other contractors or

construction tasks.

• Remove cable from the pipe if any thread cutting, welding, soldering or similar pipe

fitting work will be performed.

DON’T:

• Drag the cable through water, paint, solvents, oil or other contaminants.

• Install damaged or contaminated sensing cable.

• Exceed the maximum pulling force of 100 kg (220 lb).

• Use the cable as a rope for lifting or securing any object.

• Allow tools or heavy objects to fall on cable.

• Exceed 3300 ft (1000 m) of individual sensor cable circuit length when using a SIM

alarm module.

• Testthecablewithfuel. • Usetiewraporwiretosecurethecable.

Page 2

Installation

1

2A

Prepare the conduit and pull rope.

• Verify that major construction is complete.

• Verify conduit and pull rope has been installed

properly. Reference TraceTek document

H58175 for general information.

Note that conduit dimensions and related parts can vary

between projects.

Conduit Cleaning:

• Even if the conduit was proofed with a conduit cleaning

tool during the conduit installation process, it is

recommended to clean and check clearance of the

conduit immediately before installing cable in order to

avoid damaging the cable.

• Attach a rope section with a rag tied to the eye splice in

advance of the sizing tool.

2B

• Verify that the pull rope is free of knots and splices

and that there is 6 feet of extra rope at both ends of

each section.

• Two people are needed to manage the pull rope. One

person is on each end of the end pull rope, and each

person must be able to communicate with the other in

case of problems during the pull.

• The person feeding the pull rope into conduit needs to

maintain slack at all times.

• Pull the sizing tool from one end of the conduit

section to the other.

• Verify that the sizing tool pulls freely through

each section of conduit. Pull with a slow steady

motion. Do not use excessive force on the pull

rope, as this could damage the conduit.

• As you pull, coil the pull rope by hand and keep the

pull rope out of the dirt by placing it on cardboard or

plastic sheeting.

• If the pull rope becomes stuck, do not increase

pull force-instead pull the rope in opposite

direction for a short distance, then try repulling

in original direction with normal force.

• Shake the rag attached to the sizing tool free of excess

debris. Remove the rope section containing the rag

from the sizing tool. Replace the rag with a clean rag if

necessary, and then attach the rope section with the rag to

the eye splice in advance of the sizing tool.

• Reverse the pulling direction to bring the sizing tool

through the conduit in the opposite direction, and return the

original pull rope back into the conduit. Remove the sizing

tool and rope section with rag from the pull rope.

• Verify conduit ends are marked for example, with different

color conduit endcaps or tape to indicate direction

(towards or away) relative to TraceTek alarm module.

• Arrange excess pull rope by coiling around the riser pipe

and taping in place.

• Cover conduit ends to maintain cleanliness within conduit.

Use a plastic bag taped in place, or stuff a clean rag into

conduit end.

2 | nVent.com

Page 3

3A

3B

Install sensing cable in accordance with the leak detection

layout plan.

Planning the cable pull:

• Verify that each end is terminated in a rope overbraid

loop. Identify which end of the cable (Pin or Socket) is

on the outside of the reel by examining the label near the

overbraid loop.

• Attach the pull rope to the rope overbraid loop only

after planning the direction of the cable pull based

on which cable end is on the outside of the reel.

Note the PIN connector end of cable is always

oriented towards the TraceTek alarm module.

• If PIN connector end is on the outside of reel, pull cable

into conduit towards the TraceTek alarm module.

• If SOCKET connector end is on the outside of reel, pull cable

into conduit away from the TraceTek alarm module.

Common mistakes include pulling the cable into the wrong

conduit, and pulling the wrong end of cable into the conduit.

Before pulling the cable into any conduit, verify that correct

conduit is being used. Good conduit installations will use a

strategy to mark conduits. Check with project supervisors

if any doubt exists as to how the conduit is labeled. Errors

in conduit identification and cable orientation can result in

compromised cable quality.

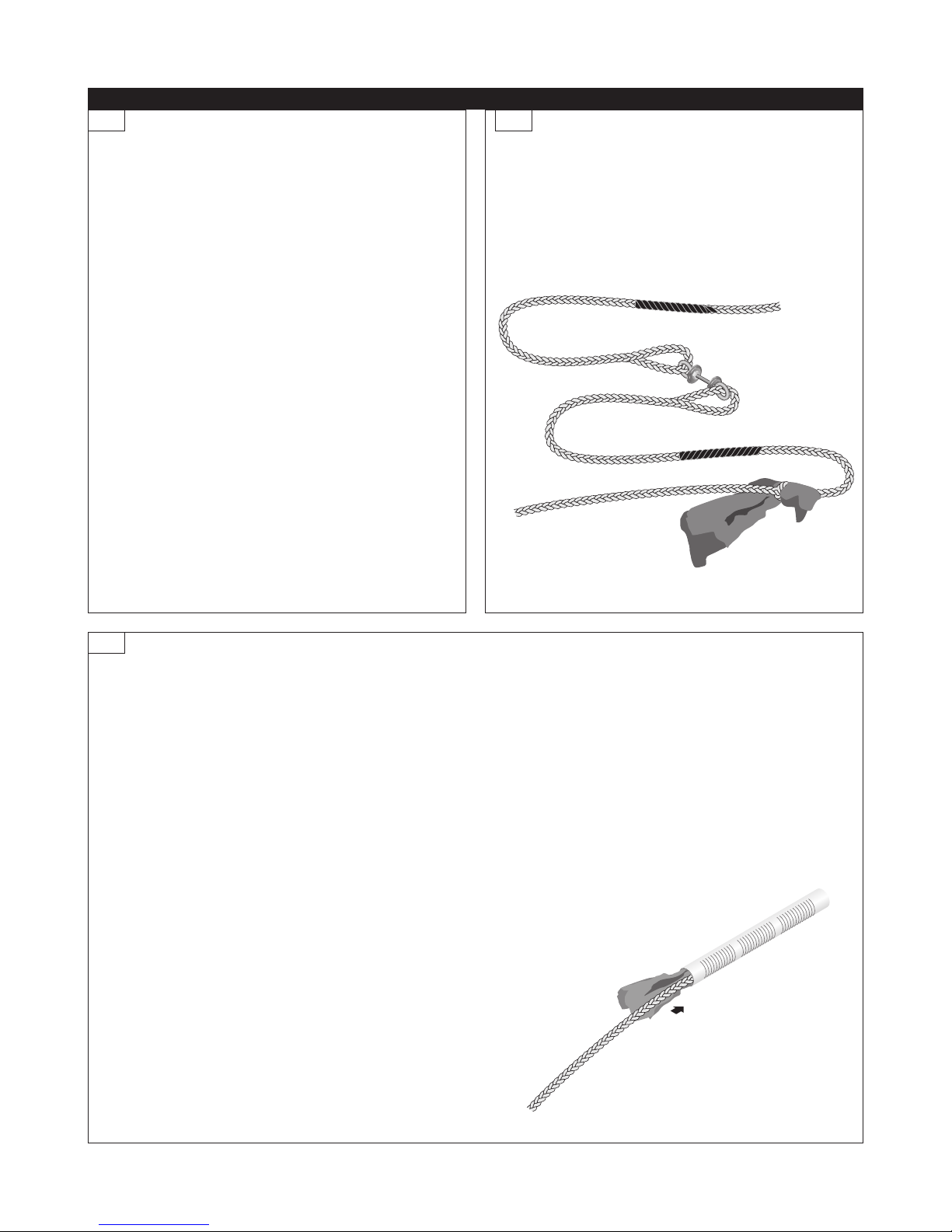

Attach the Kellems grip (if necessary):

• For TT500X-HS bulk cable, you may need to use a

Kellems grip to perform the cable pull when the rope

overbraid loop is not available.

• Make sure the end of the sensing cable has been

properly prepared.

• The end of TT500X-HS sensing cable should be sealed

with heat shrink tubing, and the end of the rope braid

should be taped to form a tapered end.

3C

• Insert the end of the rope braid as far as possible into

the cage end of the Kellems grip.

3D

• Tightly wrap electrical tape over last 1 inch of the

Kellems grip cage, and also over 1 inch of the rope

braid. Make a smooth transition with the tape. The tape

is necessary to prevent the Kellems grip cage from

releasing the cable in the event of a backwards pull.

2 in

(50 mm)

Tape over here.

nVent.com | 3

Page 4

4

Pulling the cable:

• TT500X-HS sensing cable is sensitive to pressure from

such things as pinches or tight corners. Cable stress,

binding and kinking can result in cable damage and

potential false leak detection signals. Take care during

installation to maintain cable integrity in order to promote

a successful project.

• Two people are needed to manage the pull rope. One person is on each end of the end pull rope, and each person

must be able to communicate with the other in case of

problems during the pull.

• Before pulling the cable into the conduit, identify the

correct pull rope. If there is more than one section of pull

rope at this access point, the person feeding the cable can

lightly tug the pull rope, while the person on the pulling

end conrms they feel the tension.

(A common mistake results from the wrong rope end being pulled, and the other end of the pull rope disappearing

into the conduit).

Note: Be careful not to lose the rope into the access point

conduit. It can be time consuming and expensive to recover a

pull rope lost into the conduit.

• Conrm the pull rope moves easily. Slow and steady

pulling is recommended to promote an easier installation which results in reduced stress on the cable. The

person feeding the cable into the conduit needs to provide

continual slack to reduce stress on the cable. The person

feeding the cable must be able to communicate problems

(such as snags or twisted cable) to the person pulling,

before the sensing cable is subjected to excessive stress.

• As you pull, coil the pull rope by hand and keep the

pull rope out of the dirt by placing it on cardboard or

plastic sheeting.

• If the pull rope becomes stuck, do not increase pull

force-instead pull the rope in opposite direction for a

short distance, then try repulling in original direction

with normal force.

• Finish the cable pull by extending the TT500X-HS-MC

(with factory installed connectors) or TT5000-HS-HYBHSE (with factory installed end termination) cable at least

1 foot beyond top of the access point conduit riser.

• For TT500X-HS (bulk sensing cable without connectors)

cable, extend at least 2 feet beyond top of the access

point conduit riser. The extra length is necessary due to

connectorization requirements.

• Secure excess pull rope by coiling around the riser pipe

and taping in place.

• Cover conduit ends to maintain cleanliness within conduit.

Use a plastic bag taped in place, or stuff a clean rag into

conduit end.

Sensing Cable Test Procedure

5 5A

Expose the sealed end of the cable, see illustrations A,

B and C below

• For connectorized cable (TT500X-HS-MC), remove the

heat shrink tubing from the sealed end, then remove the

attached end termination to access the connectorized

cable end.

• Test each length of connectorized sensing cable after

pulling into conduit and before attaching it to cable

already installed. Confirm that the sensing cable is clean

and intact by following the Sensing Cable Test Procedure,

described later in this document.

Connectorization procedure for bulk cable

• Bulk (unconnectorized) cable is usually connectorized

after pulling into conduit. Use connector kit TT5000–

HUV–CK–MC–M/F for TT500X-HS sensing cable. Refer

to TraceTek document H54830 for detailed instructions

regarding connectorization procedures. If bulk cable is

cut and connectors will not be immediately installed, use

shrink tubing or carefully tape the cable ends to protect

cable integrity (water/physical damage). If water enters

cable ends, the cable will be compromised and may have

to be replaced.

• Grasp rope braid about 1 in. (25 mm) behind the taped

end near the looped end of the pull rope. Feel for the

sealed end of the sensor cable beneath the rope braid.

Bend the rope braid to a 90 degree angle and locate

sealed end of the sensor cable.

5B

• Spread the rope braid fibers apart to expose the sealed

end of the sensor cable.

4 | nVent.com

Page 5

65C

WARNING:

CAUTION:

• Grasp the sealed end and pull about 12 inches (30 cm) of

sensor cable out while holding the rope braid in place.

• Tape the rope braid to sensor cable to prevent the rope

from springing back.

Tape

7

Complete the system

1. Install other TraceTek components (such as Modular

Branching Connectors, Weighted Lengths, and Modular

Jumper Cables) as called for in the system layout.

Complete the sensing circuit.

Note: All components of the system have male or female

metal connectors or both. The male connectors are oriented

toward the instrument panel. As new sections of cable are

added to the main leg or branch, each newly added section

should end with an open female connector. The end of each

branch or main leg is terminated with a male end termination.

2. Test the sensing circuit (or portions of it) to confirm that

the sensing cable is clean and intact. Follow the Sensing

Cable Test Procedure.

3. Locate the unlabeled heat shrink tubing segment (delivered

along with the TT500X-HS connectorized cable, or as part

of the TT5000–HUV–CK–MC–M/F connector kit.) Install

the heat shrink tube as environmental seal over all mated

male/female (pin/socket) connections.

• Center the unlabeled shrink tube over the pin/socket

connection. Heat shrink the tube over the connection,

beginning in the center and shrinking towards the ends

until the tube fully conforms to the shape of the connection

and adhesive flows from each end of the tube.

CAUTION: Burn Hazard. Do not get hot adhesive on

your bare skin. The hot adhesive will burn your skin.

• Avoid overheating the thin wall unlabeled shrink tubing.

The thin wall tubing requires less heat than the SCT cable

shrink tubing.

• Let the entire connector area cool before handling the cable.

Note: Do not leave connector open to environment. If

the connector becomes wet or contaminated, it will need

to be replaced.

Prior to installing a new length of sensor cable, slide the

unlabeled shrink tube (from connector kit) onto the cable.

Connect the sensing cable to the cable circuit (lengths of

sensing cable connected in series) previously installed.

• Mark the connector position on the layout plan.

• Install TraceTek mapping tag (TT-TAG).

• Note: As an extra precaution on large installations,

periodically test the entire cable circuit to confirm that all

installed sensing cable is still clean and intact.

• Unplug the end termination and connect it to the next

length of sensing cable to be installed.

Repeat the installation sequence for each length of cable.

Note: When arranging any TT500X-HS cables do not use a

bend radius less than 2 in. (51 mm).

Note: If a heat-shrinkable tube must be removed (for

example, for cable testing), refer to Oversleeve Removal

Instructions (H54258).

4. Connect the sensing circuit to the TraceTek alarm module

and activate the system as soon as is practical. Use the

alarm module to monitor for events during the final stages

of construction.

Unlabeled heat-shrinkable tube

SCT

SCT

Adhesive visible at

ends of tubing

FIRE HAZARD. Heat guns and flameless heating

tools can cause fire or explosion in hazardous

areas. Be sure there are no flammable materials

or vapors in the area before using these tools.

Follow all site safety guidelines when working in

hazardous areas.

Component approvals and performance are based

on the use of specified parts only.

HEALTH HAZARD. Overheating heat-shrinkable

tubing will produce fumes that may cause

irritation. Use adequate ventilation and avoid

charring or burning. Consult MSDS RAY3122 for

further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258

.

nVent.com | 5

Page 6

8

Take precautions if installation is incomplete at end of

work day.

At the end of the work day:

• Ensure that there are no exposed connectors. Each

sensing cable should be connected to a Modular

Leader Cable (TT-MLC-MC), Modular End Termination

(TT-MET-MC), and/or other sensing cables; check both

ends of the cable.

• Test and record the condition of installed sensing cable

following the Sensing Cable Test Procedure.

• If practical, connect the installed sensing cable

to the TraceTek alarm module. Test the system

and put it in operation following the alarm module

installation instructions.

At the beginning of the next work day:

• Check that the installed sensing cable is clean and intact

following the Sensing Cable Test Procedure. Compare

the results with those obtained at the end of the previous

work day. If necessary, investigate and correct problems

before proceeding.

Modular

leader cable

Modular end

termination

TRACETEK

6 | nVent.com

Page 7

Sensing Cable Test Procedure

Method with nVent RAYCHEM TraceTek Portable Test Box

(TT-PTB-1000)

1. Ensure the end termination is connected to the sensing cable.

If checking several lengths of sensing cable in series (a cable

string), ensure they are all connected.

2. Connect the PTB to the sensing cable(s) using its

adapter, as illustrated.

3. Verify that the sensing cable is intact; follow the operating

instructions printed inside the lid of the PTB itself. If a cable

or connection is broken, the PTB illuminates its LED indicating

“cable break,” and displays a “1” in the leftmost position of its

LCD display. If the cable string is intact, the PTB measures the

system length.

• If the cable string is not intact, apply this test procedure to

segments of the system to identify the open connection or

damaged modular length.

• Note: If a heat-shrink tube must be removed to

access a connector, refer to Oversleeve Removal

Instructions (H54258).

4. Check the condition of the sensing cable(s), again following

the PTB operating instructions. If the sensing cables are clean

and free of contamination, the current measured should be

0 µA. If the reading exceeds 10 µA, use the PTB to locate the

liquid or contamination and take appropriate corrective action.

Method with Ohmmeter

1. Ensure the end termination is connected to the sensing cable.

If checking several lengths of sensing cable in series (a cable

string), ensure they are all connected.

2. Connect a Modular Leader Cable (TT-MLC-MC) to the

sensing cable.

3. Verify that the sensing cable is intact:

• Loop 1: Measure the resistance between the yellow and black

wires of the leader cable as illustrated.

• Loop 2: Measure the resistance between the red and green

wires of the leader cable.

The readings should roughly equal a multiple of the length of

sensing cable:

4.0 times the length of sensing cable (in feet), or 13.1 times

the length of sensing cable (in meters).

Example: 4.0 x 50 ft of cable = 200 Ω

13.1 x 15 m of cable = 197 Ω

In addition, the resistance of the two loops should be within

5 percent of each other.

If the cable string is not intact, apply this test procedure

to individual segments of the system to identify the open

connection or damaged modular length.

Note: If a heat-shrink tube must be removed to access a

connector, refer to Oversleeve Removal Instructions (H54258).

4. Check the condition of the sensing cable. Measure the

resistance between the black and green wires of the

leader cable.

If the reading is below 20 megohms, apply this test procedure

to individual segments of the system to identify the modular

sensing cable length(s) affected, locate the damage or

contamination, and take appropriate corrective action.

Testing a

cable string

Testing an

individual

length of

cable

Testing a

cable string

Ohm

meter

Testing an

individual

length of

cable

To red

To green

End termination

PTB

TRACETEK

TRACETEK

End termination

TT-MLC-MC

End termination

To yellow

To black

End termination

End

termination

End

termination

nVent.com | 7

Page 8

Complete System Connections and Layout

to cover each connection.

AC

AC

RS+

AC

AC

SHLD

RS–

RS+

AC

AC

RED

GRN

YEL

BLK

GND

TTSIM-1

Leak Location Module

RATING: 24Vac

±

10%

50/60 Hz

3VA

Do not exceed 240 m Max.

Pull Box

A. TT500X-HS is available in bulkform, cut to length in the field

and joined using connector kits–or it can be obtained in

standard or custom cut lengths with connectors attached in

the factory. Each cable has a female metal connector on one

end and a male metal connector on the opposite end. Cable

sections plug together like extension cords.

B. (Optional) A branch connector (TT-MBC-MC-TW) is used

to connect and branch “T” lines. The branch connector

has one male connector and two female connectors. For

mapping purposes, the cable connected to the center leg of

the branch connector will be counted first, then the distance

measurements will continue from the second female

connector and continue along the rest of the system. A dead

band of 16 ft (5 m) is inserted at the beginning of each branch

to avoid any location ambiguity.

C. (Optional) It is permissible to have multiple sub-branches as

needed to fully trace the pipe system.

D. Install an end termination (TT-MET-MC) at the end of the main

line and each branch line. (Note: A good check on the system

design and bill of materials is that the total number of end

terminations installed in the system should equal the number

of branch connectors plus one).

E. (Optional) Install jumper cables (TT-MJC-xx-MC-BLK) as

needed if they are to connect sensing cable sections in

separate areas. Jumper cable is available in various pre-cut

and terminated lengths and is also available in bulk form

for long distance runs between the sensor cable and alarm

module location.

F. Install a leader cable (TT-MLC-MC-BLK) between the sensor

cable and the alarm module location. The factory standard

length of leader cable is 12 ft (4 m). It has a female metal

connector on one end and four tinned leads on the opposite

end for connection at the alarm module terminal block. In

some installations the distance between the alarm module

and the start of the sensor cable run will be much greater

than 12 feet. In those cases a simple solution is to purchase

a jumper cable of sufficient length, then cut off and discard

the male connector and any extra cable. Bulk jumper cable

and splicing kits are also available for lengths that exceed the

longest available standard jumper cable.

G. Use fastening straps to neatly coil and secure any excess

sensor cable, jumper cable, branch connectors, etc.

TRACETEK

TTSIM-1

(Sensor

interface

module)

TraceTek alarm module

(several models available;

TTDM-128 alarm and

locating module is shown)

CH23 CGN

SUN 12 04 08

RS-485 twisted pair

8910111289101112

TT500X-HS

in slotted pipe

Modular jumper cable

(TT-MJC-xx-MC-BLK)

in conduit

TT500X-HS

in slotted pipe

Modular end termination

TT500X-HS

in slotted pipe

Note:

• Drawing not to scale.

• Not shown: heat-shrinkable tube

(TT-MET-MC)

240 m Max.

between pull boxes

8 | nVent.com

Page 9

AC

AC

SHLD

RS–

RS+

AC

AC

SHLD

RS–

RS+

AC

AC

RED

GRN

YEL

BLK

GND

TTSIM-1

Leak Location Module

RATING: 24Vac

±10%

50/60 Hz

3VA

Network

Address

Initial Power-up and Test

Connect the cable to the alarm module and test the system.

• For direct buried long line underground leak detection

applications, TraceTek requires use of nVent RAYCHEM

TraceTek TTSIM-1. TTSIM-1 can be used as standalone unit or

in conjunction with TTDM-128.

• Apply power to the TraceTek instrument and look for a

“Normal” indication.

– On TTSIM-1, Normal Condition is indicated by a green LED

and a momentary ash of the RED LED every 5 seconds.

– On nVent RAYCHEM TraceTek TTDM-128 the alpha-numeric

display will indicate a channel number and display the words

SYSTEM NORMAL.

• If the Yellow LED is on in any of these instruments or the words

“Cable Break” or “Loop Break” is displayed, then the cable

system must be inspected for loose connections, missing end

terminations until the cable continuity is established and the

“Normal” condition is achieved.

• Leak testing can be done with a mapping cap (TT-MAPPING

CAP-MC) or by bending the sensor cable tightly between

fingers. The MAPPING CAP simulates a leak at the location

where it is installed in the system.

– For TTSIM-1 a red LED will indicate that the simulated LEAK

has been detected.

– For TTDM-128 a leak location will be displayed in feet or

meters (as selected) in addition to the red LED indication

• For larger piping systems with TTDM-128 or TTSIM-1,

the MAPPING CAP should be moved sequentially to each

accessible connector. Record the distance displayed on the

as-built drawings. This will become the basis for the System

Map.

• Create a System Map showing where sensing cables and alarm

modules have been installed. The System Map will include

the beginning and end of sensing cables, and location of any

connections. If using locating alarm modules, the System Map

should include distance readings at significant landmarks

(beginning and end of system, changes of direction, branches,

valves, low points, etc.).

Note: Do not use fuel to test the TT5000-HS cable. Do not use

solvent to test the TT5001-HS cable. The TT500X-HS cable is not

resettable after exposure. Leak testing should be done, by bending

sensor cable tightly between fingers, or with a mapping cap

(TT-MAPPING CAP-MC). The TT-MAPPING CAP-MC simulates a

leak at the location where it is installed in the system.

TTSIM-1

TTDM-128

Manual leak testing

TRACETEK

TTSIM-1 Indications:

LEAK Red

CABLE BREAK Flashing yellow

SERVICE Flashing yellow

POWER LED Green

TTDM-128 Indications:

LEAK Red

CABLE BREAK Yellow

POWER LED Green

Text message in 4x20 display

nVent.com | 9

Page 10

Troubleshooting

Symptom Possible Cause and Correction

Green LED not visible on

TraceTek instrument

Leak alarm

(TTDM-128 message and red LED)

(TTSIM-1 Red LED ON)

Flashing yellow LED on TTSIM-1 Could be cable break or service indication. Refer to alarm module instructions for more information.

“SERVICE Req'd” message

(TTDM-128 Only)

Red LED fails to turn off after leak

is repaired, and leak alarm reset

attempted

Leak location seems inaccurate in

actual leak situation

Leak locations seem inaccurate or

unstable during mapping tests

System is not powered. Check power wiring. Check circuit breakers that may have been tripped.

On TTDM-128 check fuse and replace if necessary.

This is an indication of a LEAK event.

For leak locating modules (TTDM-128): Using leak distance indication and System Map as a guide,

investigate system condition, work to locate and repair leak.

For non-locating modules: Work to locate and repair the leak. (If your system is constructed with multiple

sensor cable segments, using an end termination (TT-MET-MC) to break the system into sections can help in

locating the leak. Work outward from the alarm module using the end termination to establish a temporary

end of the circuit, then sequentially move outward adding one cable segment at a time).

TT500X-HS cannot be reset like other TraceTek cables. Once the cable has been exposed to fuel (for

TT5000-HS) or solvent (for TT5001-HS) it must be replaced. Damaged cable must be cut out of the system

and replacement cable must be installed using factory standard lengths or sections of bulk cable and

connector kits.

In the event of a leak, examine the metal connectors on the sensing cable for possible corrosion. Also

examine the conduit and soil in the leak vicinity for residual contamination. Replace any damaged

components; thoroughly clean up all leaked liquid to eliminate the risk of another sensor cable alarm from

residual contamination.

Note: When the Service Req’d or SERVICE condition exists (Yellow LED), leak location accuracy is reduced

for a new leak.

For Cable break indication: Check for loose connectors, missing end terminations, broken jumper wires or

physical damage to the cable. Repair or replace cable if necessary. The TT-MET-MC end termination can be

used to isolate a damaged section by working outward from the instrument using the end termination to

establish a temporary end of the circuit then sequentially moving outward adding one cable segment at a

time.

This is an early warning message from the TTDM-128 panel indicating there is current leakage, but not yet to

the level that constitutes a leak. The TTDM-128 panel may display a location in square brackets. If a location

is displayed it should be investigated for possible sources of kinks or pinches. The square brackets indicate

that the leak signal is not strong enough for an accurate location calculation, and may include some error.

Examine cable for additional damage or leaks.

More than one leak may be present or the cable may be wetted in several locations. If the system is

monitored by a TTDM-128, check the event history to see if there is an earlier indication of a nearby leak or a

SERVICE NEEDED message. If necessary use the end termination to break the system into smaller segments

and work outward to isolate each leak location in multiple leak scenarios.

Make sure that the simulated leak produced by tightly bending the sensor cable or use of TT-MAPPING

CAP-MC is kept in place for at least 30 seconds. The location circuitry in the instruments require a steady

leak location in order to compute an accurate distance. Removing the simulated leak too quickly induces a

random error.

North America

Tel +1.800.545.6258

Fax +1.800.527.5703

thermal.info@nvent.com

©2018 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its aliates. All other trademarks are the property of their respective owners.

nVent reserves the right to change specications without notice.

RaychemTraceTek-IM-H58740-TT5000HS-EN-1805 PN P000001289

Europe, Middle East, Africa

Tel +32.16.213.511

Fax +32.16.213.604

thermal.info@nvent.com

Asia Pacific

Tel +86.21.2412.1688

Fax +86.21.5426.3167

cn.thermal.info@nvent.com

Latin America

Tel +1.713.868.4800

Fax +1.713.868.2333

thermal.info@nvent.com

nVent.com

Loading...

Loading...