Page 1

RMM2-E

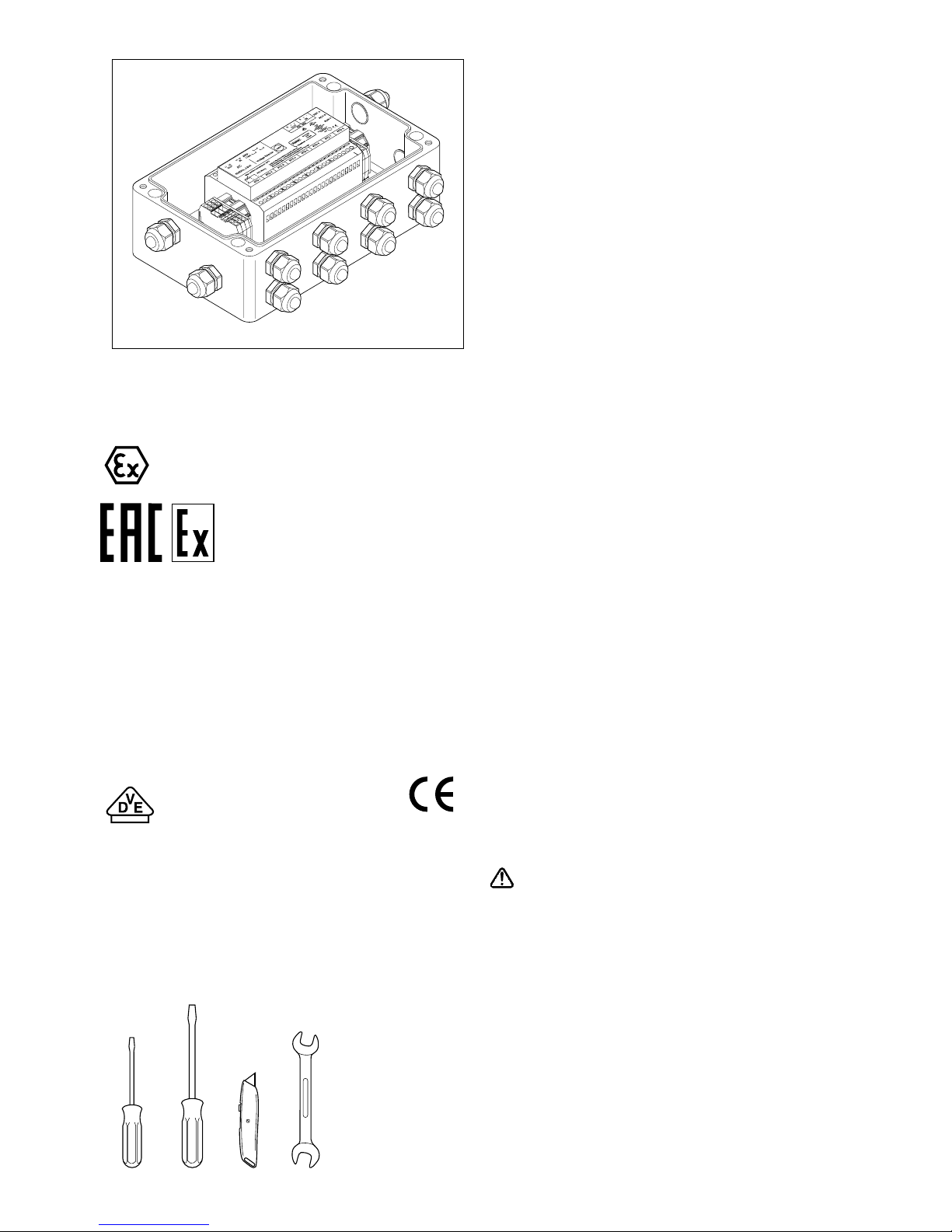

TRACE-HEATING REMOTE MONITORING MODULE

EXTERNES BEHEIZUNGS-ÜBERWACHUNGSMODUL

MODULE DE SURVEILLANCE À DISTANCE POUR TRAÇAGE ÉLECTRIQUE

МОДУЛЬ ДИСТАНЦИОННОГО КОНТРОЛЯ ЭЛЕКТРООБОГРЕВА

Page 2

C | nVent.com

INSTALLATION INSTRUCTIONS

Description

The nVent RAYCHEM Remote Monitoring

Module (RMM2-E) is part of the RAYCHEM NGC

control and monitoring system. The RMM2-E

accepts inputs from up to 8 RTDs (3 wire Pt 100

temperature sensors) measuring pipe or ambient

temperature in a trace heating system.

Up to 16 RMM2-E units communicate with a

RAYCHEM NGC-30 or NGC-40 controller using

a single RS-485 cable.

For technical assistance, call your local nVent

representative or the nVent service center listed

on the last page.

Parts (supplied)

RMM2-E without enclosure

• RMM2-E Trace-heating Remote Monitoring

Module

• Replacement fuses

• Jumper for voltage selection

• Label

Hazardous Area Unit (RMM2-EX-E)

• RMM2-EX-E Trace-heating Remote

Monitoring Module

• Exn R II T6 glassfibre-reinforced polyester

enclosure

• 12 Ex e M20 glands for power cable

(6 to 12 mm cable diameter) with mushroom

stopping plugs

• Replacement fuses

• Jumper for voltage selection

WARNING:

This component is an electrical device. It must be

installed correctly to ensure proper operation and

to prevent frozen pipes, shock or fire. Read and

carefully follow all the installation instructions.

Approvals

RMM2-EX-E:

Hazardous Areas

II 3 G/D T=70°C EExn R II T6

(Ta –20°C to +60°C)

Baseefa03ATEX0739

TC RU C-BE.ИМ43.B.01764

2Ex nR II T6 Gc IP66

Ta -55°C…+60°C

ООО “ТехИмпорт”

Special conditions for safe use:

All unused entry holes must be sealed using the

scheduled cable gland and stopping plug.

Consider the effects of direct heating on the

exterior of the enclosure and the impact this may

have on the internal temperature rise.

Non-Hazardous Areas

RTD and RS-485 circuitry

are isolated from power

mains circuitry by protective

separation.

Tools Required

• 7 mm flat-blade screwdriver

• 3 mm flat-blade screwdriver

• wire stripper/cutter

• 27 mm spanner (for M20 glands)

Page 3

nVent.com | 3

Specifications

Supply voltage (nominal): 115/230 Vac, ±10%, jumper selectable, 50/60 Hz

Power consumption: 2,5 VA

Ambient operating range: –40°C to +60°C

–20°C to +60°C (Exn enclosure and glands)

Relative humidity: 5 to 95%, noncondensing

Temperature sensors: 3-wire RTD (Pt 100)

Temperature coefficient: per IEC 751-1983 (100 Ω at 0°C)

Sensor connections: Can be extended with a 3-core shielded cable of 20 Ω max. per

conductor (e.g., 150 m with 3 x 1.5 mm2 cable)

RS-485 connections: Shielded, single twisted pair, max. 1200 m

Replaceable fuse: F 200 mA/250 V, Wickmann part number 19370-034-K (FAST BLOW)

Installation materials (not supplied)

Fasteners

4 screws for 6.5 mm holes for mounting enclosures

Pt 100 temperature sensors (RTDs)

MONI-PT100-NH Temperature sensor for non-hazardous areas with M20 cable gland

MONI-PT100-EXE Temperature sensor for hazardous areas

Remote Monitoring Module (RMM2-E)

1

Fuse (200 mA, 250V)

2

Terminals for power input with provision for

daisy chaining

3

Voltage selector jumpers

4

Terminals for RS-485 bus

5

LEDs which indicate communications

activity

6

LED which indicates power to the

RMM2-Eunit

7

Rotary switch (16 position) to assign

RS-485address

8

Terminals for RTD lead wires

9

Shorting block to select RS-485

terminationmode

60 mm

42 mm

15

mm

75

mm

125 mm

0

Install per nVent RMM2 Instructions Manual nVent Montage- und

Betriebsanleitung beachten Suivre attentivement les intructions

d’installation de nVent

60 mm

42 mm

15

mm

1

2

3 4

5

6

7

8

9

Page 4

C | nVent.com

Overview of Installation Procedure for the RMM2-EX-E

A. Mount RMM2-EX-E enclosure and install cables.

B. Connect power and earth wiring and select voltage operating range.

C. Connect RTD cables to the RMM2-EX-E.

D. Select RS-485 address for the RMM2-EX-E and connect the RS-485 bus cables.

Note: Installation to be performed by suitable trained personnel.

Note: Keep the Remote Monitoring Module clean and dry prior to installation to avoid damage to

internal components.

Note: When RMM2-E is used for DIN-rail installation in a local customised panel or enclosure,

must be added 10 earth terminals for earthing of RTD’s and power cables. Terminals should

accept wires from 0.2 to 4 mm

2

.

A. Mount Enclosure and Install Cables

1. Select a suitable location for the

RMM2-EX-E enclosure.

The enclosure is suitable for use in Zone 2 areas.

Do not mount in Zone 1 or Zone 0 areas. For

installations in Zone 1 areas, contact nVent.

Use the dimensions to locate mounting holes

for the enclosure. Mount the enclosure using

suitable screws (hole diameter 6 mm).

2. Install cables

Install power cable(s), RS-485 cable(s) and RTD

cables into enclosure using glands supplied.

Keep stopping plugs in unused entries.

0

91

160

110

260

240

6.5

Page 5

nVent.com | 5

B. Connect Power and Earth Wiring and

Select Voltage Operating Range

3. Select the voltage operating range

Connect the supplied wire jumpers to the

appropriate terminals to select input voltage.

The RMM2-E is supplied jumpered for 230 volts.

4. Connect wiring from power source to

designated terminals on RMM2-E.

Use only copper conductors. Connect power

cable wires to the terminals marked L1 and L2 on

the RMM2-E. If power is being daisy chained, be

sure to maintain polarity of L1 and L2 wiring for

incoming and outgoing wires.

The terminals accept stranded wires from

0.2 – 2,5 mm

2

. (0,2 - 4 mm2 solid wire)

5. Connect earth wiring.

Connect the earth wire(s) to the earth terminals

mounted on the DIN rail. The terminals accept 0,8

- 2,5 mm

2

solid or stranded wires.

Jumpered

for 115V

Jumpered

for 230V

0

2

0

3

Page 6

C | nVent.com

C. Connect RTD Cables to the RMM2-E

The RMM2-E has terminals for 8 three-wire, RTDs

(Pt 100 temperature sensors, to IEC 751); do not

use other types of RTDs. Select RTDs appropriate

for the usage:

MONI-PT100-NH Temperature sensor for

non-hazardous areas

MONI-PT100-EXE Temperature sensor for

hazardous areas

Install each RTD in accordance with the

installation instructions shipped with it, and run

the RTD lead wires to the RMM2-E.

Note: Resistance of lead wires from each RTD

must not exceed 20 Ω (e.g. 150 m with

3 x 1,5 mm

2

cable).

0

8

RMM2-E

terminal no.

1

2

3

4

5

6

7

8

Piping drawing

identification

Description or location

6. Connect lead wires from each RTD to the

selected RMM2-E terminal block

The RMM2-E has 8 terminal blocks to connect

lead wires from 8 RTDs. Each RTD connection

is numbered; the number identifies the RTD, and

determines the order in which the RAYCHEM

NGC system displays the RTD measurement.

Therefore, order the RTD connections in a manner

that makes the RAYCHEM NGC system display

most meaningful.

The RMM2-E cover shows the correct wiring

arrangement for the RTD wires. With RAYCHEM

RTDs, connect the two RTD lead wires of the

same colour to the terminals marked “-“ and

connect the RTD lead wire that is a different

colour to the + terminal.

7. If RTD-shield is not earthed elsewhere,

connect shield to earth terminal.

8. Record the location/identification for

eachRTD.

Because the RMM2-E terminal connection

number identifies the RTD in the RAYCHEM

NGC system, it is important to record the

location of each RTD. Use the space below to

record the connections, and label the RMM2-E

or its enclosure with this RTD identification

information.

Page 7

nVent.com | 7

D. Select RS-485 Address and Connect the

RS-485 Bus Cables

9. Select the RS-485 address for the

RMM2-Eunit.

Each RMM2-E connected to a RAYCHEM NGC

control and monitoring system must have a

unique address; if two RMM2-E’s are assigned the

same address, communication faults will result.

To ensure that you assign a unique address to

each RMM2-E unit, do the following:

• Review the RAYCHEM NGC system layout; if a

layout document does not exist, create one. If

it has not already been done, assign an RS-485

address to each RMM2-E (up to 16) connected

to the RAYCHEM NGC system.

• If you are adding one or more RMM2-E units to

an existing RAYCHEM NGC network, confirm

that the RS-485 addresses for existing RMM2-E

units correspond to the system layout. See

for details the programming guide of the

RAYCHEM NGC system.

By checking the RS-485 addresses on an existing

system, you can avoid potential conflicts that

would be confusing and time consuming to

troubleshoot otherwise.

Record the RS-485 address selected for the

Remote Monitoring Module you are currently

installing, and label the exterior of the enclosure

with the address assigned to the RMM2-E.

For reference, here are the 16 possible RS-485

addresses: (0 -15 HEXADECIMAL)

0 1 2 3 4 5 6 7

8 9 A B C D E F

10. Set the RS-485 address for the RMM2-E unit

using the rotary switch provided

Take of the lid and use a flat-blade screwdriver to

rotate the RS-485 address switch to the desired

position. The single character visible on the

switch indicates the RS-485 address assigned.

0

7

6

0

11. Connect the RS-485 bus

Note: Do not make connections to the RS-485

bus while it is connected to an operating

RAYCHEM NGC network. Damage and/or alarms

could result.

The RS-485 bus allows units with unique

addresses to be connected together along a

common bus. To add a new unit to the network,

simply connect the RS-485 bus from the last unit

to the new one, or insert the new unit between

two existing units on the bus. The order in which

units are attached to the RS-485 bus does not

matter. There are just two constraints on the

RS-485 network:

• Each RMM2-E must be assigned a unique

address

• The RS-485 bus must be a continuous string

from the first network device to the last

RMM2-E in the system.

Note: The RS-485 bus operates at 5 V, and

equipment connected to it could be damaged by

exposure to higher voltages. Take precautions to

avoid exposing the RS-485 wiring to discharge of

static electricity or other sources of high voltage

potential; in particular, avoid contact with the

power supply wiring.

Page 8

C | nVent.com

The RMM2-E has two sets of terminals for

connections to the RS-485 bus. One terminal

block allows the RMM2-E to connect to the

RS-485 bus, the second allows a continuation of

the bus to other RMM2-E units on the network.

Observe polarity, which is indicated on the

RMM2-E. Connect the incoming RS-485 bus to

the set of terminals marked “IN”, observing the

polarity noted on the cover of the RMM2-E; use

the terminal marked “S” for the shield of the

RS-485 cable. Connect the continuation

of the RS-485 bus to the set of terminals marked

“OUT” in the same manner (not required for the

last RMM2-E in the network).

Important: Do not connect the shield of the

RS-485 cables to the enclosure’s grounding

terminal. Connect the shield only to the RMM2-E

terminals provided. To avoid the potential

for spurious ground loops, the RS-485 cable

shield should be connected to ground only in

the RAYCHEM unit. For the last RMM2-E in the

network, terminate the RS-485 bus by removing

the shorting block on jumper location J17 from

2–3 and placing it across pins 1–2.

OR

NGC-30 via UIT2 NGC-40 via Bridge module

Page 9

nVent.com | 9

Page 10

C | nVent.com

MONTAGEANLEITUNG

Beschreibung

Das nVent RAYCHEM Überwachungsmodul

(RMM2-E) ist Teil des RAYCHEM NGC Steuer-,

Regel- und Überwachungssystems. An ein

RMM2-E können bis zu 8 WiderstandsTemperatursensoren (Pt 100- Sensor in 3-LeiterTechnik) angeschlossen werden, welche die

Temperaturen der beheizten Oberflächen oder

die Umgebungstemperaturen im Heizsystem

erfassen. Das Steuer- und Überwachungsgerät

RAYCHEM NGC-30 oder NGC-40 kann mit bis

zu 16 RMM2-E-Modulen über ein RS-485-Kabel

kommunizieren.

Wenden Sie sich für weitere technische

Unterstützung wenden Sie sich bitte an die für Sie

zuständige nVent-Vertretung.

Lieferumfang

RMM2-E (ohne Zusatzgehäuse, für den NichtEx-Bereich)

• RMM2-E Externes Beheizungs-Überwachungs-

modul

• Ersatzsicherungen

• Brücken (Jumper) für Spannungswahl

• Aufkleber

RMM2-EX-E (mit Zusatzgehäuse, für

Ex-Bereiche)

• RMM2-EX-E Externes Beheizungs-

Überwachungs modul

• EExn R II T6 glasfaserverstärktes

Polyester-Gehäuse

• 12 Stück M20 Kabelverschraubungen in

Eex e-Ausführung mit Blindstopfen

(für Netzkabel, RS-485-Leitung

und Sensorleitungen, 6-12 mm

Leitungsdurchmesser)

• Ersatzsicherungen

• Brücken (Jumper) für Spannungswahl

WARNUNG:

Bei diesem Gerät handelt es sich um eine

elektrische Vorrichtung. Für den einwandfreien

Betrieb und zur Vermeidung gefrorener

Rohrleitungen, elektrischer Schläge oder

Brände muss das Gerät fachgerecht installiert

werden. Lesen Sie alle Installationsanweisungen

sorgfältig durch und befolgen Sie diese.

Zulassungen

RMM2-EX-E:

Ex-Bereiche:

II 3 G/D T=70°C EExn R II T6

(Ta –20°C to +60°C)

Baseefa03ATEX0739

TC RU C-BE.ИМ43.B.01764

2Ex nR II T6 Gc IP66

Ta -55°C…+60°C

ООО “ТехИмпорт”

Besondere Bedingungen für den

sicherenEinsatz:

Alle nicht verwendeten Öffnungen müssen

mithilfe der vorgesehenen Kabelverschraubung

und des Blindstopfens verschlossen werden.

Auch ein potenzieller Temperaturanstieg

im Gehäuseinneren aufgrund direkter

Wärmeeinwirkung auf die Gehäuseaußenseite

muss berücksichtigt werden.

Non-Hazardous Areas

Die Sensor- und RS-485

Stromkreise sind von den

Netzstromkreisen durch

Schutzvorrichtungen getrennt.

Erforderliches Werkzeug

• 3 mm Schlitz-Schraubendreher

• 7 mm Längsschlitz-schraubendreher

• Abisolierzange/Cutter

• 27 mm Maulschlüssel

(für M20 Verschraubungen)

Page 11

nVent.com | 11

Technische Daten

Betriebsspannung: AC 115/230 V, +/- 10%, 50/60 Hz, mit Brücke (Jumper)

wählbar 50/60 Hz

Eigenverbrauch / Nennleistung: 2,5 VA

Einsatztemperaturbereich: –40°C bis +60°C

–20°C bis +60°C (Exn-Gehäuse und Blindstopfen)

Relative Luftfeuchtigkeit: 5 bis 95 %, nicht kondensierend

Temperatursensoren: Pt 100-Temperatursensor in 3-Leiter-Technik

Temperaturkoeffizient: gemäß IEC 751-1983 (100 Ω bei 0°C)

Sensoranschlüsse: Können mit einem 3-adrigen geschirmten Kabel von max.

20 Ω pro Leiter (z.B. 150 m mit einem 3 x 1,5 mm2 -Kabel)

verlängert werden

RS-485-Anschlüsse: Geschirmte, verdrillte 2-Ader-Leitung, max. 1200 m

Ersatzsicherung: F 200 mA/250 V, Wickmann-Ersatzteilnummer

19370-034-K (flink)

Installationsmaterial (im Lieferumfang nicht enthalten)

Halterungen

4 Schrauben für 6,5-mm-Bohrungen zur Gehäusemontage

Pt 100-Temperatursensoren

MONI-PT100-NH Temperatursensor für Nicht-Ex-Bereich mit M20-

Kabelverschraubung

MONI-PT100-EXE Temperaturesensor für Ex-Bereiche (EEx e II T6, Zone1) mit

M20-Kabelverschraubung

Abmessungen (nominal)

1

Sicherung (F 200 mA, AC 250 V)

2

Netzanschlussklemmen mit Möglichkeit für

Daisy-Chaining

3

Brücken (Jumper) zur Netzspannungswahl

4

Anschlussklemmen RS-485-Bus

5

Gelbe LED, Datenübertragung

6

Grüne LED, Netzspannungsanzeige

7

Drehknopfschalter, Adresseneinstellung

16 Positionen

8

Anschlussklemmen für Sensorleitung

(Pt 100 in 3-Leiter-Technik)

9

Brücke (Jumper) RS-485-Netzwerkabschluss

60 mm

42 mm

15

mm

75

mm

125 mm

0

Install per nVent RMM2 Instructions Manual nVent Montage- und

Betriebsanleitung beachten Suivre attentivement les intructions

d’installation de nVent

60 mm

42 mm

15

mm

2

3 4

5

6

7

8

9

Page 12

C | nVent.com

Installationsverfahren RMM2-EX-E

A. Montieren Sie das RMM2-EX-E-Gehäuse, und verlegen Sie die Kabel.

B. Schließen Sie das Netzkabel und den Erdungsleiter an und stellen Sie den

Betriebsspannunsgbereich ein.

C. Schließen Sie die Pt 100-Sensorleitung am RMM2-EX-E an.

D. Legen Sie die RS-485-Adresse für das RMM2-EX-E fest, und schließen Sie die RS-485-Kabel an.

Anmerkung: Die Installation muss von fachgeschultem Personal vorgenommen werden.

Anmerkung: Bewahren Sie das RMM2-EX-E zur Vermeidung von Schäden an der geräteinternen

Elektronik vor der Installation sauber und trocken auf.

Anmerkung: Soll ein RMM2-E auf einer DIN-Schiene im Schaltschrank oder Anschlusskasten installiert

werden, so müssen ggf. zusätzlich 10 Erdungsklemmen (0,2 bis 4 mm

2

) für die Pt-100-

Sensoren und die Netzkabel installiert werden.

A. Gehäusemontage und Kabelinstallation

1. Wählen Sie einen geeigneten Montageort für

RMM2-EX-E-Gehäuse

Das Gehäuse eignet sich für den Betrieb in Zone2-Bereichen. Montieren Sie das Gehäuse nicht in

Bereichen der Zone 1 oder Zone 0. Wenden Sie

sich für Installationen in Bereichen der Zone 1

annVent.

Beziehen Sie sich auf die Abmessungen, um die

Stellen für die Löcher zur Montage des Gehäuse

zu ermitteln. Befestigen Sie das Gehäuse mit

geeigneten Schrauben (Lochdurchmesser 6 mm).

2. Kabelinstallation.

Führen Sie das/die Netzkabel, RS-485Kabel sowie die Sensorkabel über die

Kabelverschraubungen in das Gehäuse ein.

Nehmen Sie die Blindstopfen von den nicht

benötigten Eingängen nicht ab.

0

91

160

110

260

240

6.5

Page 13

nVent.com | 13

Brücken-

anordnung

für 115 V

Brücken-

anordnung

für 230 V

B. Schließen Sie das Netzkabel und den

Erdungsleiter an, und stellen Sie den

Betriebsspannunsgbereich ein

3. Einstellung des Betriebsspannungsbereich

Stecken Sie für die Festlegung der

Eingangsspannung die mitgelieferten

Brücken (Jumper) auf den entsprechenden

Anschlussklemmen auf.

Bei der Auslieferung des RMM2-E sind die

Brücken (Jumper) für AC 230 V angeordnet.

4. Anschließen der Netzleitung

Verwenden Sie ausschließlich Kupferleiter.

Schließen Sie die Leiter des Netzkabels an die

mit L1 und L2 gekennzeichneten Anschlussklemmen an. Achten Sie bei Anwendung des

Daisy Chain Verfahrens auf die Beibehaltung

der „Polarität“ der Verdrahtung L1 und L2 für die

ein- und ausgehenden Leiter.

Die Anschlussklemmen sind für mehrdrähtige

Leiter von 0,2 mm

2

– 2,5 mm2 Leiterquerschnitt

oder eindrähtige Leiter von 0,2 mm

2

– 4 mm2

Leiterquerschnitt geeignet.

5. Anschließen der Erdleiter

Schließen Sie den/die Erdungsdrähte an den auf

der DIN-Schiene angebrachten Erdungsklemmen

an. Die Anschlussklemmen sind für ein- oder

mehrdrähtige Leiter einem Querschnitt von 0,8

mm

2

bis 2,5 mm2 ausgelegt.

0

2

0

3

Page 14

C | nVent.com

C. Anschluss der Pt 100-Sensorleitungen

an das RMM2-E

Am RMM2-E befinden sich Anschlussklemmen

für 8 Pt-100-Temperatursensoren in 3-LeiterTechnik (gem. IEC 751). Verwenden Sie keine

anderen Sensortypen.

Wählen Sie die Pt-100-Sensoren je nach

Einsatzbereich aus:

MONI-PT100-NH Temperatursensor für Nicht-

Ex-Bereiche

MONI-PT100-EXE Temperatursensor für

Ex-Bereiche

Installieren Sie alle Pt-100-Sensoren gemäß der

dazugehörigen Montageanleitung und verlegen

Sie die Pt-100-Sensorleitungen für den Anschluss

an das RMM2-E.

Anmerkung: Der Widerstand der Adern an

allen Pt-100-Sensorleitungen darf 20 Ω nicht

übersteigen (z. B. 150 m mit 3 x 1,5-mm

2

-Kabel).

0

8

RMM2-E Anschluss-terminal

no.

1

2

3

4

5

6

7

8

Piping drawing

kennzeichnung

RohrverlegungsBeschreibung oder Montageort

6. Schließen Sie die Adern der Pt-100-Leitungen

an den entsprechenden Anschlussblock des

RMM2-E an.

Das RMM2-E verfügt über 8 Anschlussblöcke

für die Adern von 8 Pt-100-Sensorleitungen.

Jeder Sensoranschluss ist nummeriert.

DieNummer kennzeichnet den Sensor und

legt die Reihenfolge fest, in der das RAYCHEM

NGC-System die Sensormessungen anzeigt.

OrdnenSie die Sensoren beim Anschließen daher

so an, dass die Messwerte am RAYCHEM NGCSystem in einer möglichst sinnvollen Reihenfolge

angezeigt werden.

Auf dem Deckel des RMM2-E ist die

korrekte Verdrahtungsanordnung für die

Sensorleitungen dargestellt. Bei RAYCHEMTemperatursensoren schließen Sie die beiden

gleichfarbigen Sensorleitungsadern an die

mit „-“ gekennzeichneten Anschlussklemmen

und die andersfarbige Ader an die mit „+“

gekennzeichnete Anschlussklemme an.

7. Falls die Abschirmung des Sensors nicht

anderweitig geerdet ist, schließen Sie die

Abschirmung an die Erdungsklemme an.

8. Notieren Sie den Montageort/

die Kennzeichnung für alle Pt-100Sensorleitungen.

Da die Pt-100-Temperatursensoren im

RAYCHEM NGC-System mit der Nummer der

RMM2-E-Anschlussklemme gekennzeichnet

werden, ist es wichtig, die Anschlüsse der

einzelnen Pt-100-Sensoren zu notieren. Dafür

steht die nachfolgende Tabelle zur Verfügung.

Bringen Sie diese Informationen zu den Pt-100Temperatursensoren am RMM2-E oder dessen

Gehäuse an.

Page 15

nVent.com | 15

D. Festlegung der RS-485-Adresse und

Anschluss der RS-485-Bus-Kabel

9. Festlegung der RS-485-Adresse

Jedes an einer RAYCHEM NGC System Steuerund Überwachungseinheit angeschlossene

RMM2-E muss eine unverwechselbare

Adresse aufweisen; wenn zwei RMM2-E mit

der gleichen Adresse zugeordnet werden, sind

Kommunikationsfehler die Folge. Verfahren Sie

folgendermaßen, um sicherzustellen, dassSie

jedem RMM2-E eine eindeutige Adresse

zuordnen:

• Überprüfen Sie den Auslegungsplan des

RAYCHEM-Systems oder erstellen Sie einen

solchen, falls keiner vorliegt. Ordnen Sie, sofern

noch nicht erfolgt, jedem an das RAYCHEM

NGC-System angeschlossenen RMM2-E

(bis zu 16) eine RS-485-Adresse zu.

• Prüfen Sie, wenn Sie ein bestehendes

RAYCHEM NGC-Netzwerk um eine oder

mehrere RMM2-E-Module ergänzen, ob

die RS-485-Adresse der vorhandenen

RMM2-E-Module mit der Systemauslegung

übereinstimmt. Ausführliche Informationen

dazu finden Sie im Programmierhandbuch des

RAYCHEM NGC-Systems.

Durch die Überprüfung der RS-485-Adressen

in einem bestehenden System können

potentielle Konflikte vermieden werden, die

sich als verwirrend und zeitaufwendig bei einer

nachträglichen Fehlerortung erweisen würden.

Notieren Sie die RS-485-Adresse, die

dem zu installierenden RAYCHEM

Fernüberwachungsmodul zugeordnet wurde,

und kennzeichnen Sie die Gehäuseaußenseite

anhand eines Aufklebers mit der dem RMM2-E

zugeordneten Adresse. Als Referenz: es sind nur

16 RS-485-Adressen möglich.

(0 -15 HEXADEZIMAL)

0 1 2 3 4 5 6 7

8 9 A B C D E F

10. Stellen Sie die RS-485-Adresse mit dem

Drehschalter ein.

Nehmen Sie den Deckel ab, und drehen Sie

den RS-485-Adressenschalter mit einem

Schlitzschraubendreher auf die entsprechende

Position. Die Ziffer bzw. der Buchstabe gibt die

zugeordnete RS-485-Adresse an.

0

7

6

0

11. Anschluss RS-485-Kabel

Anmerkung: Nehmen Sie keine Anschlüsse an ein

sich im Betrieb befindliches System vor, da dies

zu Schäden und/oder Fehlalarmen führen kann.

Der RS-485-Bus lässt den Anschluss mehrerer

RMM2-E mit unterschiedlichen Adressen an einer

Busleitung zu. Soll das System um ein RMM2-E

erweitert werden, so verbinden Sie das letzte

RMM2-E-Modul mit dem neuen RMM2-E-Modul.

Die Reihenfolge, in der die Module an dem

RS-485-Bus angeschlossen werden, spielt keine

Rolle. In einem RS-485-Netzwerk gibt es lediglich

zwei Einschränkungen:

• Jedem RMM2-E muss eine eindeutige Adresse

zugeordnet sein.

• Der RS-485-Bus muss vom RAYCHEM System

bis zum letzten RMM2-E innerhalb des

Systems einen durchgehenden Pfad bilden.

Anmerkung: Am RS-485-Bus liegt eine Spannung

von 5 Volt an; andere daran angeschlossene

Vorrichtungen könnten aufgrund der Spannung

beschädigt werden. Treffen Sie entsprechende

Vorbeugungsmaßnahmen, um die RS-485Verdrahtung vor der Entladung statischer

Elektrizität oder vor Hochspannungspotentialen

zu schützen. Vermeiden Sie insbesondere

jeglichen Kontakt mit der Netzstromverkabelung.

Page 16

C | nVent.com

Das RMM2-E weist zwei Anschlussklemmblöcke

für den Anschluss der RS-485-Leiter auf.

Aneinem Block kann das RMM2-E an dem

RS-485-Bus-Leiter angeschlossen werden, der

andere Block ermöglicht die Weiterleitung des

Bus-Leiters an andere RMM2-E-Module innerhalb

des Netzwerks. Sie die auf dem RMM2-E

angegebene Polarität.

Schließen Sie die eingehenden RS-485-Leiter

unter Einhaltung der auf dem Deckel des

RMM2-E angegebenen Polarität an die mit „IN“

gekennzeichneten Anschlussklemmen und die

Abschirmung des RS-485-Kabels an der mit „S“

gekennzeichneten Anschlussklemme an.

Schließen Sie die abgehende Leitung des

RS-485-Bus-Leiters auf die gleiche Weise an den

mit „OUT“ gekennzeichneten Anschlussklemmen

an (nicht erforderlich, wenn es sich um das letzte

RMM2-E innerhalb eines Netzwerks handelt).

Wichtiger Hinweis: Schließen Sie die

Abschirmungen der RS-485-Kabel nicht an den

Erdungsanschlüssen des Gehäuses an. Schließen

Sie die Abschirmungen ausschließlich an den

dafür vorgesehenen RMM2-E-Anschlussklemmen

an. Zur Vermeidung fehlerträchtiger

Erdungsschleifenpotentiale sollte die

Abschirmung des RS-485-Kabels ausschließlich

innerhalb des RAYCHEM NGC System geerdet

werden. Versehen Sie den RS-485-Bus des letzten

RMM2-E innerhalb des Netzwerks mit einem

Endabschluss, indem Sie die Kurzschlussbrücke

J17 von 2-3 abziehen und auf die Kontaktstifte

1-2 stecken.

NGC-30 via UIT2 NGC-40 via Bridge module

ODER

Page 17

nVent.com | 17

Page 18

C | nVent.com

NOTICE D’INSTALLATION

Description

Le module de surveillance à distance nVent

RAYCHEM (RMM2-E) est un des éléments du

système RAYCHEM NGC, qui assure la régulation

et la surveillance des applications de traçage

électrique. Chaque module RMM2-E peut être

connecté à un maximum de huit sondes de

températures RTD (PT-100 à 3 fils) qui mesurent

la température ambiante ou la température de

tuyauterie. Un régulateur central RAYCHEM

NGC-30 ou NGC-40 peut communiquer avec un

maximum de 16 unités RMM2-E par un simple

câble RS-485. Pour obtenir une assistance

technique, contactez votre représentant nVent ou

le centre technique nVent dont les coordonnées

sont renseignées en dernière page.

Pièces fournies

RMM2-E sans boîtier

• RMM2-E Module de surveillance à distance

pour traçage électrique

• Fusibles de réserve

• Cavalier pour sélection de la tension

• Étiquette

Module pour zone explosible

(MONI-RMM2-EX-E)

• RMM2-EX-E Module de surveillance à distance

pour traçage électrique

• Boîtier polyester renforcé de fibre de verre

EExn R II T6Presse-étoupes 12 EEx e M20 pour

câble d’alimentation (diamètre câble de 6 à

12 mm) avec bouchons d’arrêt en forme de

champignon

• Fusibles de réserve

• Cavalier pour séle

AVERTISSEMENT:

Ce composant est un dispositif électrique. Il

doit être installé correctement pour assurer

un fonctionnement adéquat et éviter tout

gel des tuyaux, décharge ou incendie. Lire et

suivre scrupuleusement toutes les instructions

d’installation.

Agréments

RMM2-EX-E:

Zones explosibles

II 3 G/D T=70°C EExn R II T6

(Ta –20°C to +60°C)

Baseefa03ATEX0739

TC RU C-BE.ИМ43.B.01764

2Ex nR II T6 Gc IP66

Ta -55°C…+60°C

ООО “ТехИмпорт”

Conditions spéciales pour une utilisation sûre :

Tous les trous d’entrée non utilisés doivent être

obstrués à l’aide des presse-étoupes et des

bouchons d’arrêt prévus à cet effet.

Tenir compte de l’effet d’un chauffage direct au

niveau de l’extérieur du boîtier et de l’impact que

ceci pourrait avoir en termes d’augmentation de

la température interne.

Zones non explosibles

L’ensemble des circuits RTD etRS-485

sont isolés de l’ensembledes circuits

du réseauélectrique par une

séparationde protection.

Outillage

• Tournevis plat 7 mm

• Tournevis plat 3 mm

• Pince à dénuder/cutter

• Clé plate de 27 mm (pour presse-étoupe de

20mm)

Page 19

nVent.com | 19

Caractéristiques techniques

Tension d’alimentation (nominale) : 115/230 Vac, ±10%, sélection par cavalier, 50/60 Hz

Consommation électrique : 2,5 VA

Température de service : –40°C à +60°C (module RMM2-E)

–20°C à +60°C (boîtier et presse-étoupes Exn)

Humidité relative : 5 à 95 %, sans condensation

Sondes de température : RTD 3 fils (Pt 100)

Coefficient de température : Selon IEC 751-1983 (100 Ω à 0°C)

Raccords sonde : La sonde peut être prolongée par un câble blindé à

3 conducteurs de 20 Ω chacun (par ex.150 m avec 3 câbles

de 1,5 mm

2

)

Connexions RS-485 Blindage, paire forsadée simple, max. 1200 m

Fusibles : F 200 mA/250 V, référence Wickmann 19370-034-K

(FAST BLOW)

Matériel d’installation (non fourni)

Attaches

Fixation des boîtiers : 4 vis pour trous de 6,5 mm

Sondes de température Pt100 (RTD)

MONI-PT100-NH Sonde de température pour zones non explosibles avec

presse-étoupe M20

MONI-PT100-EXE Sonde de température pour zones explosibles (EEx e II T6,

zone1) avec presse-étoupe M20

Module de surveillance à distance (RMM2-E)

1

Fusible (200 mA, 250V)

2

Bornes pour alimentation avec possibilité de

connexion en série

3

Cavaliers de sélection de tension

4

Bornes pour bus RS-485

5

Diodes indiquant que le module est en

communication

6

Diode indiquant que l’unité RMM2-E est

soustension

7

Commutateur à 16 positions permettant

l’adressage RS-485

8

Bornes pour câbles d’alimentation RTD

9

Bloc permettant de sélectionner le mode de

terminaison RS-485

60 mm

42 mm

15

mm

75

mm

125 mm

0

Install per nVent RMM2 Instructions Manual nVent Montage- und

Betriebsanleitung beachten Suivre attentivement les intructions

d’installation de nVent

60 mm

42 mm

15

mm

1

2

3 4

5

6

7

8

9

Page 20

C | nVent.com

Procédure d’installation du module RMM2-EX-E

A. Monter le boîtier RMM2-EX-E, installer les câbles et les raccorder selon schéma.

B. Raccorder au secteur et à la terre, et sélectionner la tension de service.

C. Connecter les câbles de sonde RTD au RMM2-EX-E.

D. Sélectionner l’adresse RS-485 du RMM2-EX-E et raccorder les câbles du bus RS-485.

Remarque: L’installation doit être confiée à du personnel expérimenté.

Remarque: Pour éviter d’endommager les éléments internes du module, le conserver à l’abri

de l’humidité et de la saleté jusqu’à son installation.

Remarque: Lorsque le RMM2-EX-E est installé sur des rails DIN dans des tableaux ou boîtiers

sur mesure, il faut y ajouter 10 bornes de mise à la terre des RTD et des câbles

d’alimentation. Les bornes sont conçues pour des câbles de 0,2 à 4 mm

2

.

A. Monter le boîtier et installer les câbles

1. Choisir l’emplacement adéquat pour le boîtier

RMM2-Ex-E.

Le boîtier convient pour des utilisations en

Zone 2. Ne pas le placer en Zone 1 ou en

Zone 0. Pour des installations en Zone 1,

contacter nVent. À l’aide des dimensions figurant

sur le schéma, repérer l’endroit des perforations

pour fixer le boîtier.

Fixer le boîtier au moyen de vis appropriées

(diamètre du perçage : 6 mm).

2. Installer les câbles

Brancher les câbles d’alimentation, RS-485

et RTD dans le boîtier au moyen des presseétoupes fournis. Laisser les bouchons sur les

entrées inutilisées.

0

91

160

110

260

240

6.5

Page 21

nVent.com | 21

B. Raccorder au secteur et à la terre, et

sélectionner la tension de service

3. Sélectionner la tension de service

Placer les cavaliers sur les bornes adéquates

pour déterminer la tension d’entrée. À la livraison,

le module RMM2-E est configuré pour

230 V.

4. Raccorder les câbles d’alimentation aux

bornes du RMM2-E prévues à cet effet.

N’utiliser que des conducteurs en cuivre.

Rac-corder les câbles d’alimentation aux

bornes identifiées par L1 et L2. S’il s’agit d’une

alimentation en série, veiller à respecter la

polarité du câblage de L1 et L2 pour les câbles

entrants et sortants. Les bornes sont conçues

pour des câbles torsadés de 0,2 à -2,5 mm²

(conducteurs à âme pleine de 0,2 à 4 mm²).

5. Mise à la terre.

Raccorder les câbles de mise à la terre aux

bornes correspondantes situées sur le rail DIN.

Les bornes sont conçues pour des câbles pleins

ou torsadés de 0,8 à 2,5 mm².

0

2

0

3

Cavaliers

pour 115 V

Cavaliers

pour 230 V

Page 22

C | nVent.com

C. Connecter les câbles RTD au RMM2-E

Le RMM2-E possède 8 bornes pour RTD à trois

fils (sondes de température Pt 100, selon IEC

751-1983) ; ne pas utiliser d’autres types de

RTD. Sélectionner les RTD en fonction de

l’application :

MONI-PT100-NH Sonde de température pour

zones non explosibles

MONI-PT100-EXE Sonde de température pour

zones explosibles (EEx e II

T6, zone1)

Installer chaque RTD suivant les instructions

fournies et tirer le câblage jusqu’au RMM2-E.

Remarque : La résistance des câbles en provenance de chaque RTD doit être inférieure à

20 Ω (par ex. 150 m avec câble à 3 fils de

1,5mm²).

0

8

RMM2-E

borne n°

1

2

3

4

5

6

7

8

Identification de la

canalisdation sur plan

Description ou

emplacement

6. Brancher les câbles de chaque RTD sur la

borne appropriée du RMM2-E

Le RMM2-E possède 8 bornes permettant de connecter les câbles de 8 RTD. Chaque connexion

RTD porte un numéro qui identifie le RTD et

détermine l’ordre dans lequel le RAYCHEM NGC

system affiche les mesures RTD.

En conséquence, l’ordre des connexions RTD

doit se faire de sorte que l’affichage du système

RAYCHEM NGC soit le plus logique possible.

Le couvercle du RMM2-E indique le schéma de

câblage correct des câbles RTD. Avec des RTD

RAYCHEM, brancher les deux câbles RTD de

même couleur aux bornes marquées « – » et

connecter le câble RTD d’une couleur différente à

la borne « + ».

7. Si le blindage RTD n’est pas mis à la terre

ailleurs, le relier à la borne de terre.

8. Noter l’emplacement/l’identification de

chaque RTD.

Il est important de noter précisément

l’emplacement de chaque RTD, étant donné

que le numéro de la borne RMM2-E identifie

la sonde dans le système RAYCHEM.

L’espace sous les connexions est destiné à les

identifier. Une étiquette d’identification des RTD

doit être apposée sur le RMM2-E ou sur son

boîtier.

Page 23

nVent.com | 23

D. Sélectionner l’adresse RS-485 du

RMM2-E et raccorder les câbles bus

RS-485

9. Sélectionner l’adresse RS-485 pour l’unité

RMM2-E.

Chaque RMM2-E connecté à une centrale

système RAYCHEM NGC doit posséder une

adresse unique. L’attribution d’une même

adresse à deux RMM2-E provoque des erreurs

de communication. Pour s’assurer d’un

adressage correct de chaque RMM2-E, suivre les

instructions suivantes :

• Vérifier le plan du système RAYCHEM ; si

celui-ci n’existe pas, le créer. Si cela n’a pas

encore été fait, attribuer une adresse RS-485

à chaque RMM2-E (jusqu’à 16) connecté à

la centrale système RAYCHEM NGC. Pour

enregistrer les adressages RS-485, utiliser

le formulaire du manuel d’installation d’un

système RAYCHEM NGC. Plus d’information,

la guide de programmation du système

RAYCHEM.

• En cas d’ajout d’un ou plusieurs modules

RMM2-E dans un réseau système RAYCHEM

NGC existant, vérifier que les adresses RS-485

des modules existants correspondent au plan.

Cette vérification s’effectue sur l’écran du

système RAYCHEM NGC. Lorsque le système

RAYCHEM NGC affiche une température, il

identifie la sonde RTD par deux éléments:

un préfixe qui indique l’adresse RMM2-E

et un suffixe qui correspond à la borne sur

laquelle la sonde est connectée. Par exemple,

RTD3-7indique que la sonde est connectée à

l’adresse 3 du RMM2-E, sur la borne 7.

La vérification des adresses RS-485 d’un système

existant permet d’éviter les éventuels conflits

et la confusion ou les pertes de temps qui en

résulteraient.

Noter l’adresse RS-485 du module en cours

d’installation, et apposer sur le boîtier une

étiquette mentionnant l’adresse attribuée au

RMM2-E.

Pour référence, voici les 16 adresses RS-485

possibles : (0 -15 HEXADÉCIMAL)

0 1 2 3 4 5 6 7

8 9 A B C D E F

10. Sélectionner l’adresse RS-485 de l’unité

RMM2-E au moyen du commutateur

Retirer le couvercle et, au moyen d’un tournevis,

positionner le sélecteur sur l’adresse RS-485

souhaitée. Le seul chiffre visible dans l’encoche

du sélecteur indique l’adresse sélectionnée.

0

7

6

0

11. Connecter le bus RS-485

Remarque : Ne rien raccorder au bus RS-485

tant qu’il est connecté à la unité RAYCHEM NGC

sous tension pour éviter des dégâts et/ou des

déclenchements d’alarmes.

Le bus RS-485 permet de rassembler sur un bus

commun plusieurs unités possédant chacune

une adresse unique. Pour ajouter une unité au

réseau, il suffit de connecter le bus RS-485 de

la dernière unité à celle nouvellement installée,

ou d’insérer la nouvelle unité entre deux unités

existantes. L’ordre dans lequel les unités sont

reliées au bus RS-485 n’a pas d’importance.

Leréseau RS-485 n’impose que deux contraintes :

• Chaque RMM2-E doit posséder une adresse

unique

• Le bus RS-485 doit constituer une chaîne

continue du du système RAYCHEM au dernier

RMM2-E du système.

Remarque : Le bus RS-485 fonctionne avec

une tension de 5 V. Une tension supérieure

endommagerait les équipements qui y

sont connectés. Prendre les précautions

nécessaires pour que le câblage RS-485 soit

à l’abri des décharges d’électricité statique ou

de toute source de haute tension. Éviter plus

particulièrement tout contact avec les câbles

d’alimentation.

Page 24

C | nVent.com

En zone Ex, il est indispensable de mettre

hors tension le boîter RMM2-E-Ex avant toute

modification d’adresse ou de raccordement d’une

ou plusieurs nouvelles sondes.

Le RMM2-E possède deux borniers de connexion

au bus RS-485. Le premier permet de raccorder

le RMM2-E au bus RS-485, le second permet de

prolonger le bus vers d’autres unités RMM2-E

du réseau. Respecter la polarité mentionnée sur

leRMM2-E.

Raccorder le bus RS-485 entrant au bornier

« IN », en respectant la polarité renseignée sur

le couvercle du RMM2-E ; utiliser la borne « S »

pour le blindage du câble RS-485. Connecter

de la même manière le prolongement du bus

RS-485 au bornier « OUT » (pas pour le RMM2-E

terminant le réseau).

Important : Ne pas connecter le blindage des

câbles RS-485 au bornier de mise à la terre du

boîtier. Ne connecter le blindage qu’aux bornes

RMM2-E prévues. Pour éviter des boucles de

terre parasites, le blindage du câble RS-485 doit

exclusivement être mis à la terre au niveau de

l’unité RAYCHEM. Terminer le bus RS-485 du

dernier RMM2-E du réseau en enlevant le pontage

J17 des broches 2-3 et en le plaçant sur les

broches 1-2.

OU

NGC-30 par le UIT2 NGC-40 par le Bridge module

Page 25

nVent.com | 25

Page 26

C | nVent.com

ИНСТРУКЦИЯ ПО МОНТАЖУ

Описание

Модуль дистанционного контроля

электрообогрева nVent RAYCHEM (RMM2-E)

является частью системы контроля и

управления электрообогревом RAYCHEM

NGC. Каждый модуль RMM2-E может

принимать сигналы от 8 датчиков

температуры Pt 100. До 16 модулей RMM2-E

соединяются с контроллером RAYCHEM NGC30 или NGC-40 с помощью одного кабеля

RS-485.

За технической помощью обращайтесь

в местное представительство nVent или

сервисный центр компании, список которых

приведён на обратной стороне обложки

данного руководства.

Комплект поставки

Модуль RMM2-E без защитного корпуса

• Модуль дистанционного контроля

электрообогрева RMM2-E

• Сменные предохранители

• Перемычка для выбора напряжения

• Маркировочная табличка

Модуль в защитном корпусе

для взрывоопасных зон (RMM2-EX-E)

• Модуль дистанционного контроля

электрообогрева RMM2-EX-E

• Защитный корпус из армированного

полиэфирного стеклопластика, Exn R II T6

• 12 сальников M20 для силового кабеля

(Ø 6–12 мм) с грибовидными заглушками

• Сменные предохранители

• Перемычка для выбора напряжения

ПРЕДУПРЕЖДЕНИЕ:

Данный модуль является электрическим

устройством. Для обеспечения правильной

работы и предотвращения замерзания

труб, поражения электрическим током

и возгорания необходимо осуществить

правильный монтаж модуля. Прочтите

все инструкции по монтажу и строго

придерживайтесь их в ходе монтажа.

Сертификация

RMM2-EX-E:

Взрывоопасные зоны

II 3 G/D T=70°C EExn R II T6

(Ta –20°C до +60°C)

Baseefa03ATEX0739

TC RU C-BE.ИМ43.B.01764

2Ex nR II T6 Gc IP66

Ta -55°C…+60°C

ООО “ТехИмпорт”

Специальные условия для безопасного

использования:

Все неиспользуемые отверстия должны

быть закрыты с помощью соответствующего

кабельного сальника и заглушки. Следует

принять во внимание эффекты прямого

нагрева корпуса снаружи и влияние, которое

это может оказать на повышение внутренней

температуры.

Невзрывоопасные зоны

Датчики температуры и сеть RS-485

изолированы от питающей сети с

помо-щью защитных разделителей

Инструменты для монтажа

• Отвёртка с плоским лезвием на 7 мм

• Отвёртка с плоским лезвием на 3 мм

• Нож для обрезки

• Гаечный ключ на 24 мм

(для сальников M20)

Page 27

nVent.com | 27

Технические характеристики

Номинальное напряжение 115/230 В перем. тока (уст. перемычкой), ±10%, 50/60 Гц

Энергопотребление 2,5 ВА

Допустимая температура –40...+60°С (модуль RMM2)

окр. среды –20...+60°С (корпус Exn и кабельные сальники)

Относительная влажность 5–95%, без конденсации влаги

Датчики температуры 3-проводные термометры сопротивления (Pt 100)

Темп. коэффициент В соотв. IEC 751-1983 (100 Ом при 0°С)

Подключение датчиков Кабель датчика; может быть удлинен 3-жильным экраниро ванным кабелем с макс. сопротивлением 20 Ом на жилу

Подключение к сети RS-485 Экранированный кабель типа «витая пара», макс. длина 1200 м

Сменный предохранитель F 200 мA/250 В,

№ по каталогу Wickmann 19370-034-K (FAST BLOW)

Комплектующие для монтажа (не входят в комплект)

Крепеж

4 винта для отверстий Ø 6,5 мм для крепления защитного корпуса

Датчики температуры Pt 100 (RTD)

MONI-PT100-NH Датчик температуры для невзрывоопасных зон

с кабельным сальником M20

MONI-PT100-EXE Датчик температуры для взрывоопасных зон

(EEx e II T6, класс 1) с кабельным сальником M20

Модуль дистанционного контроля Moni-RMM2

1

Предохранитель (200 мА, 250 В)

2

Клеммы питания (с возможностью

последовательного подключения к

питанию)

3

Перемычки выбора питания

4

Разъёмы интерфейса RS-485

5

Индикатор передачи данных

6

Индикатор питания

7

Переключатель для выбора

адреса RS-485 (16 позиций)

8

Клеммы для подключения датчиков

температуры

9

Блок перемычек для указания

последнего модуля RMM2 в сети RS-485

60 mm

42 mm

15

mm

75

mm

125 mm

0

Install per nVent RMM2 Instructions Manual nVent Montage- und

Betriebsanleitung beachten Suivre attentivement les intructions

d’installation de nVent

60 mm

42 mm

15

mm

1

2

3 4

5

6

7

8

9

9

Page 28

C | nVent.com

Основные этапы процедуры монтажа модуля RMM2-EX-E

A. Монтаж защитного корпуса RMM2-EX-E и ввод кабелей в корпус.

B. Подключение кабелей, заземления и выбор напряжения питания.

C. Подключение кабелей датчиков температуры к модулю RMM2-EX-E.

D. Выбор адреса RS-485 модуля RMM2-EX-E и подключение к сети RS-485.

E. Инициализация или обновление списка обнаруженного устройством управления RAYCHEM

200N оборудования и настройка каждого датчика температуры (с панели управления

устройства управления RAYCHEM 200N).

Примечание: Монтаж должен производиться соответствующим образом

обученным персоналом.

Примечание: Чтобы не повредить внутренние компоненты, модуль дистанционного

контроля до монтажа должен храниться в чистом и сухом месте.

Примечание: При монтаже модуля RMM2-E на DIN-рейку по месту в слокальной панели

или корпусе необходимо добавить 10 клемм заземления для заземления

датчиков температуры и силовых кабелей. Клеммы должны быть рассчитаны

на кабели диаметром от 0,2 до 4 мм

2

.

A. Монтаж защитного корпуса RMM2 и

кабелей

1. Выбор подходящего места для корпуса

RMM2-EX-E.

Защитный корпус рассчитан на

использование во взрывоопасных зонах

класса 2 и НЕ ПРЕДНАЗНАЧЕН для

использования во взрывоопасных зонах

класса 1 и класса 0. Для использования

модулей RMM2 во взрывоопасных зонах

класса 1, свяжитесь с nVent. Для разметки

монтажных отверстий на корпусе следует

воспользоваться приведенными на чертеже

размерами. Смонтируйте защитный корпус,

используя подходящие винты (диаметр

монтажных отверстий 6 мм).

2. Монтаж кабелей.

Подключите силовой(ые) кабель(и), кабель(и)

RS-485 и кабели датчиков температуры

с помощью поставляемых в комплекте

кабельных сальников. В неиспользуемых

кабельных вводах следует оставить

заглушки.

0

91

160

110

260

240

6.5

Page 29

nVent.com | 29

B. Подключение кабелей, заземления и

выбор напряжения питания

3. Выбор напряжения питания.

Выставите входящие в комплект поставки

перемычки в положение, соответствующее

напряжению питания.

По умолчанию выставлено напряжение 230 В.

4. Подключение питания к соответствующим

клеммам на модуле RMM2.

Для подвода питания используйте только

медные проводники. Подключите силовой

кабель к клеммам на модуле RMM2,

помеченным L1 и L2. Если используется

последовательное подключение питания

к модулям RMM2, убедитесь в соблюдении

полярности кабелей, подключённых к

клеммам L1 и L2. Клеммы рассчитаны на

кабели с многопроволочными жилами

сечением 0,2–2,5 мм

2

или цельными жилами

сечением 0,2–4 мм

2

.

5. Подключение заземления.

Подключите провод(а) заземления к

зажимам заземления, смонтированным на

DIN-рейке. Клеммы рассчитаны на кабели с

многопроволочными или цельными жилами

сечением 0,8–2,5 мм

2

.

0

2

0

3

Перемычки

выставлены

на 115 В

Перемычкa

выставлена

на 230 В

Page 30

C | nVent.com

0

8

C. Подключение кабелей датчиков

температуры к модулю RMM2-E

Модуль RMM2-E имеет клеммы для

подключения восьми 3-проводных датчиков

температуры (датчики температуры Pt 100,

соотв. IEC 751; не используйте датчики

температуры других типов). Необходимо

выбрать подходящий датчик температуры с

учетом условий его работы:

MONI-PT100-NH Датчик температуры

для невзрывоопасных зон

MONI-PT100-EXE Датчик температуры

для взрывоопасных зон

(EEx e II T6, класс 1)

Каждый датчик температуры необходимо

устанавливать в соответствии с

инструкциями по монтажу, поставляемыми

вместе с ними, и проложить провода от

датчиков к модулю RMM2-E.

Примечание: Сопротивление провода от

каждого датчика температуры не должно

превышать 20 Ом (например, кабель длиной

150 м с сечением каждой жилы 1,5 мм

2

).

6. Подключение кабелей от каждого из

датчиков температуры к выбранному

блоку клемм на модуле RMM2-E.

На модуле RMM2-E предусмотрено 8 блоков

клемм для присоединения проводов от 8

датчиков температуры. Каждый из блоков

имеет номер, который определяет порядок

вывода показаний датчиков системой

RAYCHEM NGC. Поэтому подключение

проводов от датчиков температуры к

клеммным блокам модуля RMM2-E следует

организовать таким образом, чтобы система

RAYCHEM NGC выводила сначала наиболее

значимые данные. На крышке модуля RMM2-E

показана схема правильного подключения

проводов от датчиков температуры. При

использовании датчиков температуры

RAYCHEM два провода одного цвета следует

подсоединить к клеммам со знаком «–», а

оставшийся провод другого цвета — к клемме

со знаком «+».

Примечание: При несоблюдении полярности

проводов от датчиков температуры

система RAYCHEM NGC будет показывать

неправильную температуру.

7. Если экранирующая оплетка кабеля

датчика температуры не заземлена

где-либо, подсоедините ее к зажиму

заземления.

8. Запишите место и обозначение каждого из

датчиков температуры.

Поскольку номер блока клемм, к которому

присоединён датчик температуры,

определяет адрес датчика в системе

RAYCHEM NGC, необходимо зарегистрировать

местонахождение каждого датчика

температуры. В приведённую ниже

форму нужно занести соответствующую

информацию и наклеить эту этикетку на

модуль RMM2-E или его защитный корпус.

Номер блока

клемммодуля

Обозначение

датчика по схеме

Описание или

местонахождение

1

2

3

4

5

6

7

8

Page 31

nVent.com | 31

D. Выбор адреса RS-485 модуля RMM2 и

подключение к сети RS-485

9. Выбор адреса RS-485 модуля RMM2-E.

Каждому модулю RMM2-E, подключенному

к системе RAYCHEM NGC, должен быть

присвоен уникальный адрес; если

одинаковый адрес будет присвоен двум

модулям RMM2-E, это приведет к ошибкам

0

7

6

0

связи. Чтобы убедиться, что каждому

модулю RMM2-E присвоен уникальный адрес,

необходимо:

• Проверить схему конфигурации системы

RAYCHEM NGC; если таковая отсутствует,

необходимо ее составить. Если этого

не было сделано ранее, выберите адрес

RS-485 каждому из модулей RMM2-E (до

16 модулей), подсоединенных к системе

RAYCHEM NGC.

• При подключении одного или нескольких

модулей дистанционного контроля к

существующей сети RAYCHEM NGC

необходимо убедиться в том, что адреса

RS-485 ранее подключенных модулей

соответствуют конфигурации системы.

Более подробная информация приведена

в инструкции по программированию

системы RAYCHEM NGC.

Проверка адресов RS-485 существующей

системы позволяет избежать возможных

конфликтов, обнаружение и устранение

которых иным способом может быть

сложным и может отнять много времени.

Запишите установленный адрес RS-485 и

наклейте этикетку с адресом модуля на

внешнюю сторону защитного корпуса модуля

RMM2. Ниже приведены 16 возможных

адресов RS-485 (шестнадцатиричные 0–15):

0 1 2 3 4 5 6 7

8 9 A B C D E F

10. Установка адреса RS-485 модуля RMM2-E

с помощью переключателя на модуле.

Снимите крышку и с помощью плоской

отвёртки поверните переключатель адреса

RS-485 в нужное положение. Единственный

видимый на переключателе символ

показывает присвоенный модулю адрес

RS-485.

11. Подключение к сети RS-485

Примечание: Не следует производить

подключения к сети RS-485, если она

подключена к работающей сети RAYCHEM

NGC, так как это может привести к неполадке

и/или срабатыванию сигнализации.

Сеть RS-485 позволяет подсоединять

модули RMM2-E с уникальными адресами.

Для добавления в сеть нового модуля

нужно просто подключить его через

интерфейс RS-485 к последнему модулю

в сети или подключить его между двумя

существующими модулями в сети. Порядок

подключения модулей к сети RS-485 не имеет

значения.

Для сети RS-485 существуют лишь два

ограничения:

• Каждому модулю RMM2-E должен быть

присвоен уникальный адрес;

• Сеть RS-485 должна представлять собой

непрерывную цепочку от первого до

последнего модуля RMM2-E в системе.

Примечание: Сеть RS-485 работает от

напряжения 5 В, поэтому оборудование,

подсоединённое к ней, может быть

повреждено при воздействии более высоких

напряжений. Необходимо принять меры

предосторожности, чтобы исключить

воздействие разрядов статического

электричества или высокого напряжения из

других источников сеть RS-485. В частности,

следует избегать ее контакта с линиями

подвода питания.

Page 32

C | nVent.com

или

NGC-30 через модуль UIT2 NGC-40 через модуль Bridge

На модуле RMM2-E предусмотрено два

разъёма интерфейса RS-485. Один разъем

служит для связи модуля RMM2-E с сетью

RS-485, а второй — для последующего

подключения сети RS-485 к другим модулям

RMM2. Необходимо соблюдать полярность,

указанную на модуле RMM2-E. Входящий

кабель RS-485 присоединяется к разъёму с

маркировкой “IN” с соблюдением полярности,

указанной на модуле RMM2-E. Экранирующая

оплетка кабеля RS-485 присоединяется

к выводу с маркировкой «S». Исходящий

кабель RS-485 присоединяется к разъёму с

маркировкой “OUT” аналогичным образом

(исходящий кабель на последнем модуле

RMM2-E в сети не требуется).

Предупреждение: Нельзя присоединять

экранирующую кабеля RS-485 к

выводу заземления на корпусе, она

должна присоединяться к специально

предусмотренному выводу на

модуле. Во избежание образования

“паразитных”контуров заземления,

экранирующая оплетка кабеля RS-485

должна быть подсоединена к выводу

заземления только на устройстве RAYCHEM.

На последнем модуле RMM2-E в сети

необходимо указать конец сети RS-485 путем

перестановки перемычки J17 из положения

2–3 в положение 1–2.

Page 33

nVent.com | 33

Page 34

C | nVent.com

Page 35

nVent.com | 35

Page 36

©2018 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its aliates. All other trademarks are the property of their respective owners.

nVent reserves the right to change specications without notice.

Raychem-IM-INSTALL061-RMM2E-ML-1811

nVent.com

België / Belgique

Tel. +32 16 21 35 02

Fax +32 16 21 36 04

salesbelux@nvent.com

Bulgaria

Tel. +359 5686 6886

Fax +359 5686 6886

salesee@nvent.com

Česká Republika

Tel. +420 602 232 969

czechinfo@nvent.com

Denmark

Tel. +45 70 11 04 00

salesdk@nvent.com

Deutschland

Tel. 0800 1818205

Fax 0800 1818204

salesde@nvent.com

España

Tel. +34 911 59 30 60

Fax +34 900 98 32 64

ntm-sales-es@nvent.com

France

Tél. 0800 906045

Fax 0800 906003

salesfr@nvent.com

Hrvatska

Tel. +385 1 605 01 88

Fax +385 1 605 01 88

salesee@nvent.com

Italia

Tel. +39 02 577 61 51

Fax +39 02 577 61 55 28

salesit@nvent.com

Lietuva/Latvija/Eesti

Tel. +370 5 2136633

Fax +370 5 2330084

info.baltic@nvent.com

Magyarország

Tel. +36 1 253 7617

Fax +36 1 253 7618

saleshu@nvent.com

Nederland

Tel. 0800 0224978

Fax 0800 0224993

salesnl@nvent.com

Norge

Tel. +47 66 81 79 90

salesno@nvent.com

Österreich

Tel. 0800 29 74 10

Fax 0800 29 74 09

salesat@nvent.com

Polska

Tel. +48 22 331 29 50

Fax +48 22 331 29 51

salespl@nvent.com

Republic of Kazakhstan

Tel. +7 7122 32 09 68

Fax +7 7122 32 55 54

saleskz@nvent.com

Россия

Тел. +7 495 926 18 85

Факс +97 495 926 18 86

salesru@nvent.com

Serbia and Montenegro

Tel. +381 230 401 770

Fax +381 230 401 770

salesee@nvent.com

Schweiz / Suisse

Tel. +41 (41) 766 30 80

Fax +41 (41) 766 30 81

infoBaar@nvent.com

Suomi

Puh. 0800 11 67 99

salesfi@nvent.com

Sverige

Tel. +46 31 335 58 00

salesse@nvent.com

Türkiye

Tel. +90 560 977 6467

Fax +32 16 21 36 04

ntm-sales-tr@nvent.com

United Kingdom

Tel. 0800 969 013

Fax 0800 968 624

salesthermalUK@nvent.com

Loading...

Loading...