Rayburn 212SFW, 200SFW User Manual

Installation Instructions for

Rayburn Cookmaster 200SFW

and Rayburn Cookmaster

Plus 212SFW Solid Fuel Cooker

REMEMBER, when replacing a part on this

appliance, use only spare parts that you can be

assured conform to the safety and performance

specification that we require. Do not use

reconditioned or copy parts that have not been

authorised by AGA.

The Rayburn Cookmaster 200SFW is intended to be

used for cooking only. The Rayburn Cookmaster Plus

212SFW is intended to supply heating for cooking and

domestic hot water.

The Rayburn Cookmaster 200SFW has been tested

using Taybrite manufactured smokeless fuel only. The

nominal heat output of this appliance is 4.4 kW.

The Rayburn Cookmaster Plus 212SFW has been

tested using Taybrite manufactured smokeless fuel and

wood logs. The nominal heat output of this appliance is

6 kW. This provides about 2 kW to hot water and 4 kW

to the appliance. Other fuels may give a slightly

different result.

Weight of Rayburn Cookmaster Plus 212SFW - 300 Kgs.

Weight of Rayburn Cookmaster 200SFW - 240 Kgs.

There is no requirement for an electrical power supply.

The mean flue gas temperature of the Rayburn

Cookmaster 200SFW directly downstream of the flue

spigot at nominal heat output is 131ºC.

The mean flue gas temperature of the Rayburn

Cookmaster Plus 212SFW directly downstream of the

flue spigot at nominal heat output is 210ºC.

PERFORMANCE

1

08/06 EINS 514406

raywarranty@aga-web.co.uk

Consumer Protection

As responsible manufacturers we take care to make sure that our

products are designed and constructed to meet the required safety

standard when properly installed and used.

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING

WARRANTY. Any alteration that is not approved by Aga could

invalidate the approval of the appliance, operation of the warranty

and could affect your statutory rights.

All local regulations including those referring to National and

European standards need to be complied with when installing

the appliance.

Important

This appliance may contain some of the materials that are

indicated. It is the Users/Installers responsibility to ensure that the

necessary personal protective clothing is worn when handling,

where applicable, the pertinent parts that contain any of the listed

materials that could be interpreted as being injurious to health and

safety, see below for information.

Firebricks, Fuel beds, Artificial Fuels - when handling use

disposable gloves.

Fire Cement - when handling use disposable gloves.

Glues and Sealants - exercise caution - if these are still in liquid

form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Kerosene/Gas Oil -

may be harmful if inhaled, may be irritating to skin, eyes, nose and

throat. When handling avoid inhaling and contact with skin or

eyes. Use disposable gloves, face-masks and eye protection.

After handling wash hands and other exposed parts. When

disposing of the product, reduce dust with water spray, ensure that

parts are securely wrapped.

WARNING

THE ASHPIT DOOR AND FIREBOX DOORS MUST

BE LOCKED CLOSED AT ALL TIMES DURING

NORMAL USE, EXCEPT WHEN LIGHTING OR RE-

FUELLING

DESN 510179 D

Better than you ever imagined

The cooker fully meets the requirements of BS: 1252

and is fully approved by the HETAS Ltd Approval

Scheme.

Air for combustion within the firebox and the rate of

burning is determined by the manually operated

spinwheel control on the ashpit door and flue damper.

With normal usage in 24 hours continuous burning the

Rayburn Cookmaster Plus 212SFW has an

approximate output of 100 gallons of hot water. To

provide 2 or 3 hot baths at intervals and normal

household requirements, the following conditions must

be fulfiled:-

Rayburn Cookmaster Plus 212SFW - It is

recommended that a 140 litre (30 galls) indirect hot

water storage cylinder of the double feed type, (e.g.

manufactured by Albion Cylinders) complying with BS

1566 Part 1: DF Type 8 should be lagged and fixed

vertically as near as possible to the cooker.

The maximum water pressure is 1.75 bar.

The water capacity of the boiler is 7 litres.

The 28mm minimum diameter primary flow and return

pipes must not exceed 10m in length and pipes longer

than 5m must be lagged.

Ensure that the flow pipe has an open vent and rises

continuously from the boiler to the cylinder to ensure

good gravity circulation.

The water draw-off pipes to the taps must be dead-leg

connection from the vent/expansion pipe.

A towel rail of not more than 0.5m

2

heating surface may

be heated providing the flow and return pipes are not

more than 5m each in length, and provided the cylinder

and towel rail are lagged. When the hot water storage

cylinder is very closely coupled to the boiler, a towel rail

is advisable as a heat leak, and lagging should not be

applied. A radiator is not recommended.

To obtain the boiler outputs the fire must be idled

overnight, and daytime cooking take place.

All installations must be fitted with a drain tap at the

lowest point of the system.

IMPORTANT NOTE: THESE INSTRUCTIONS MUST

BE STRICTLY OBSERVED. IF THEY ARE

DISREGARDED (E.G. AN UNLAGGED OR OVERSIZE CYLINDER), CONSUMPTION OF FUEL MAY BE

EXCESSIVE, AND THE COOKER DAMAGED BY

OVERFIRING.

In some circumstances it may be possible to overheat

the appliance and the water inside will boil. This will be

evident by the sound of a knocking noise coming from

the appliance and pipes around the house. If this occurs

close off all air controls and manually start the central

heating pump if fitted. Opening the oven doors and

hotplate covers will help to release heat from the

appliance. Be aware that steam and boiling water will

be expended from any open vent from the heating

system probably in the roof space at the expansion

tank.

Rayburn Cookmaster Plus 212SFW - Unscrew the

sheet metal cover plate on the side of the cooker and

remove the insulating material from behind it.

Joint the flow and return connections to the boiler,

replace the insulating material and screw on the cover

plate and collar.

The boiler is now ready for connection to the hot water

cylinder.

THE BOILER

2

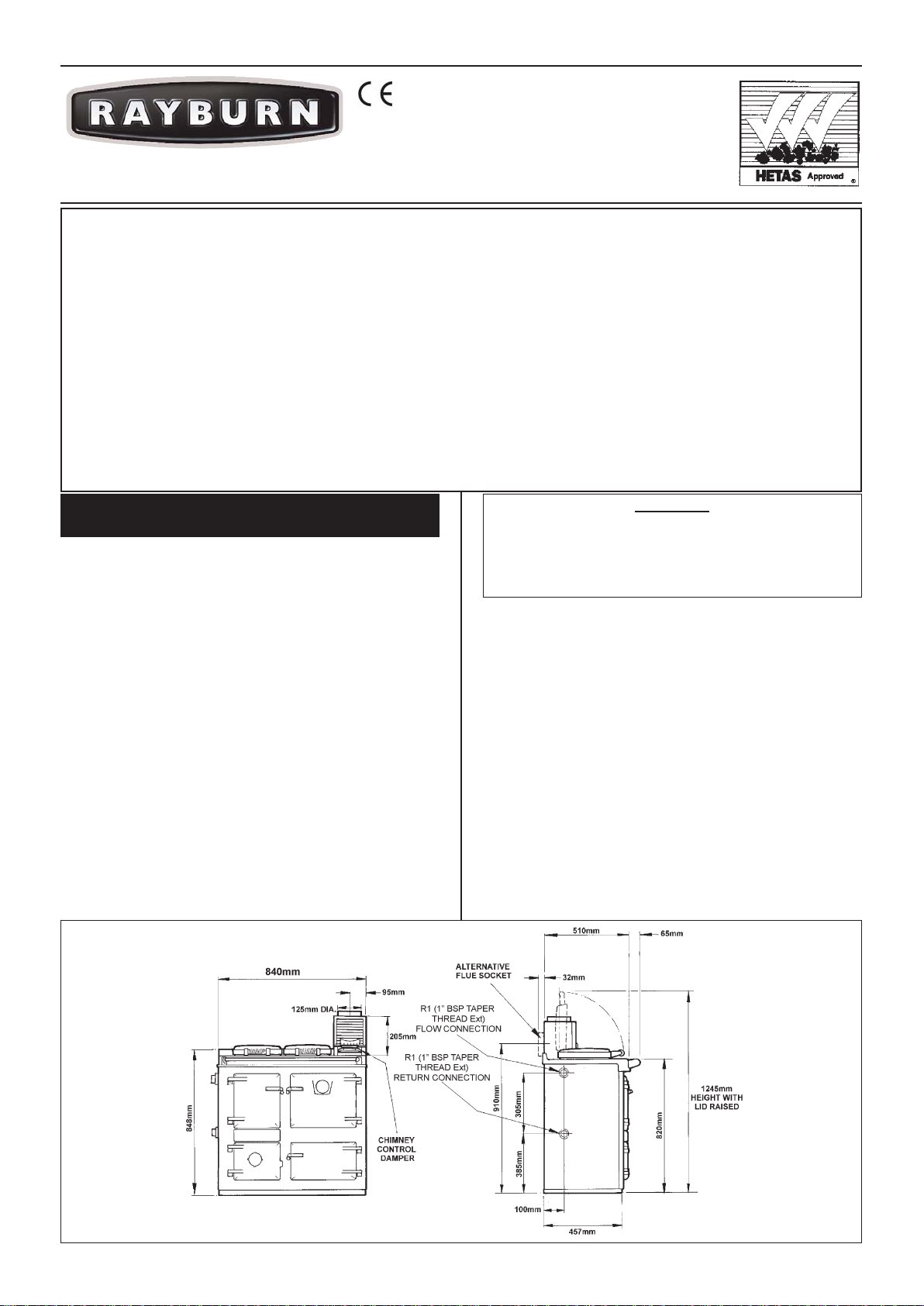

Fig. 1

HOT WATER SYSTEM

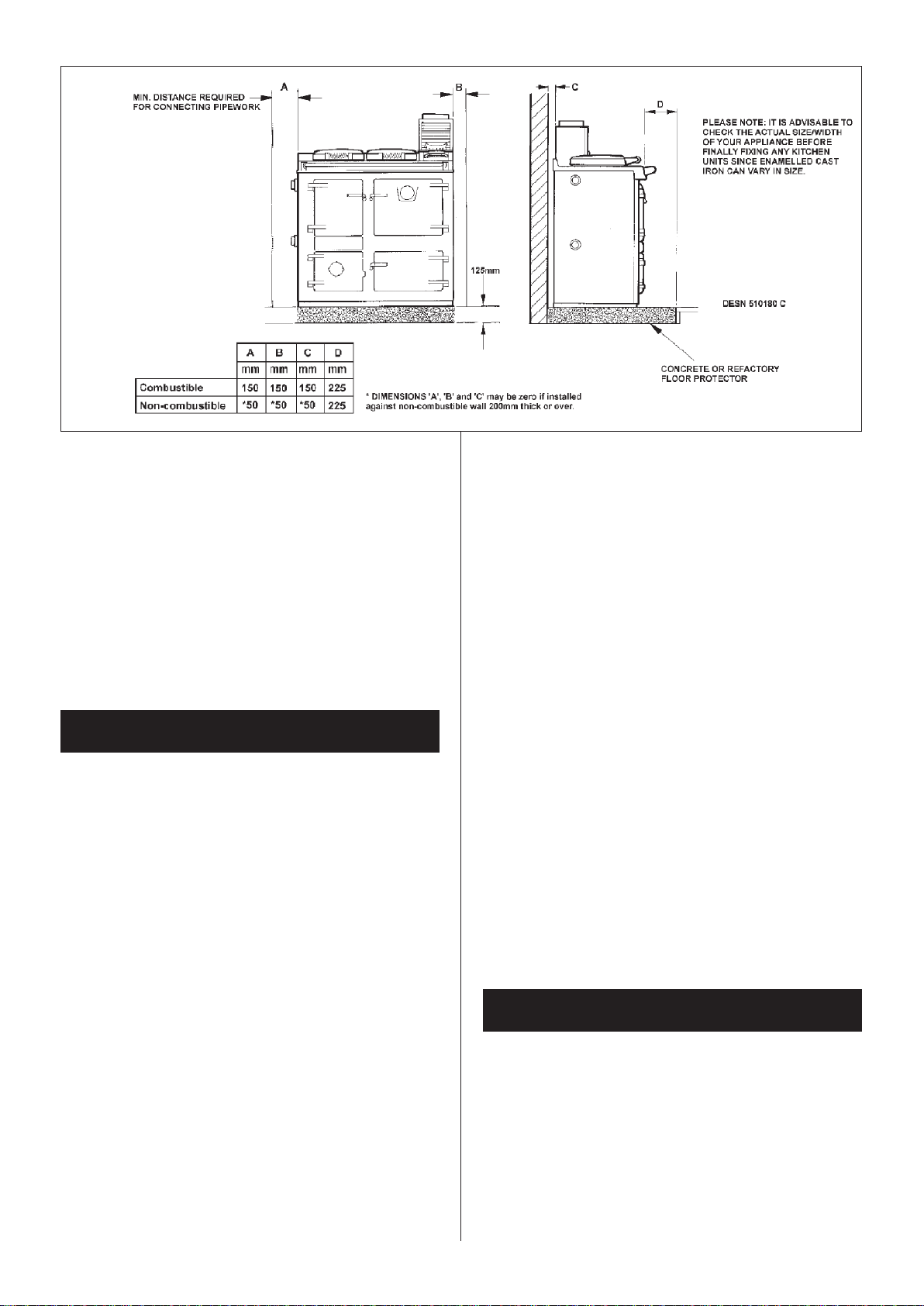

Minimum clearance to

combustible materials

150mm.

IMPORTANT: LIFT OUT THE HOTPLATE AND

CEMENT SEAL THE JOINT BETWEEN THE BOILER

FACE AND ITS LOCATING FACE ON THE FIREBOX

SIDES WITH FIRE CEMENT. RENEW ANY

BRICKWORK CEMENTED JOINTS THAT MAY HAVE

OPENED IN TRANSIT.

The non-combustible hearth must be solid and level

and together with the walls adjacent to the cooker and

chimney, conform to current Building Regulations.

The cooker and chimney flue installation should be in

accordance with the relevant recommendations of

BS8303, BS. 6461 Part 1 and BS. 7566 Parts 1 to 4.

Rayburn Cookmaster Plus 212SFW - The boiler

installation section must also be in accordance with the

byelaws of the local Water Undertaking and any

relevant requirements of the Local Authority.

When the cooker is installed in a recess it must be

‘freestanding’ and not built-in solid at the sides.

Where the cooker is to stand in a recess or against

a wall which is to be tiled, in no circumstances

should the tiles overlap the cooker top plate.

Ensure that any combustible material e.g. kitchen

furniture is spaced away from the cooker to the

recommended distances. See Fig. 1. The work surface

however, may be fitted to the top plate on both sides.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL

USAGE

Some parts of the cooker have been coated with a light

covering of protective oil, this may cause smoke/smell

to be emitted, and is normal and not a fault with the

appliance, it is therefore advisable to open doors and or

windows to allow for ventilation. Lift the insulating lids to

prevent staining the linings.

Rayburn Cookmaster 200SFW: There is no

requirement for additional ventilation as this appliance

is rated at less than 5kW. Should another appliance be

used in the property and the total heat output is greater

than 5 kW, additional ventilation must be provided in

accordance with the Building Regulations.

Rayburn Cookmaster Plus 212SFW: Provision must

be made for additional ventilation. A permanent

unobstructed air vent having a minimum effective area

of 5.5 cm

2

must communicate to outside air or an

adjacent room which in turn has a permanent vent of at

least the same size to outside air.

If a flue draught stabiliser is fitted in the flue this vent

size must be increased to a minimum 23.5 cm

2

. If his

appliance us used with an additional appliance of a

similar type then the air supply must be adequate for

both appliances in accordance with the Building

Regulations.

Any air inlet grilles must be positioned so that they are

not liable to blockage.

It is not permissible to use an air extraction device in

the same room as the appliance, unless additional

ventilation is provided to prevent any adverse effect on

the flue.

Effect of Extractor Fan

Avoid if possible the installation of an extractor fan in

the same room as the appliance or the room where the

permanent air vent is located.

Compensating extra air inlets must be introduced

equivalent to the capacity of the fan wheel when fitted.

PREPARATION OF SITE

COOKER POSITION

AIR SUPPLY

3

Loading...

Loading...