Page 1

INSTRUCTION MANUAL

• For any further information please contact your local dealer or call:

For spare parts drawings refer to the section “ LIST OF COMPONENTS” enclosed to this manual.

GB

TRANSLATION FROM THE

ORIGINAL INSTRUCTIONS

G3.140R

GP3.140R

G3.140RS

GP3.140RS

1297-M007-1_R

1297-M007-1_R

Technical services: RAVAGLIOLI S.p.A. - Via 1° Maggio, 3 - 40037 Pontecchio Marconi - Bologna Italy

Phone (+39) 051 6781511 - Telex 510697 RAV I - Fax (+39) 051 846349 - e-mail: aftersales@ravaglioli.com

- Rev. n. 1 (02/2015)

Page 2

GB

Page 2 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

SUMMARY

SYMBOLS USED IN THE MANUAL AND ON

THE MACHINE __________________________ 5

1.0 GENERAL INTRODUCTION _________ 7

1.1 Introduction ___________________________7

2.0 INTENDED USE ____________________ 7

2.1 Staff training __________________________ 7

3.0 SAFETY DEVICES __________________ 8

3.1 Residual risks _________________________ 8

4.0 GENERAL SAFETY RULES _________ 8

5.0 PACKING AND MOBILIZATION FOR

TRANSPORT _______________________ 9

6.0 UNPACKING _______________________ 10

7.0 MOBILIZATION ____________________ 10

8.0 WORKING ENVIRONMENT

CONDITIONS ______________________ 10

8.1 Working area ________________________ 11

8.2 Lighting _____________________________ 11

9.0 MACHINE ASSEMBLY _____________ 11

9.1 Anchoring system ___________________ 11

9.2 Fixtures contained in the packing ___ 12

9.3 Assembly procedures ________________ 13

9.3.1 Fitting the mandrel on the flange _ 13

9.3.2 Fitting and removal of the

pneumatic mandrel on the

flange ___________________________ 13

9.3.3 Fitting of external data gauge

(standard for G3.140RS -

GP3.140RS versions) (optional for

G3.140R - GP3.140R versions) ___ 15

9.3.4 Fitting of professional external

data gauge (optional)____________ 16

9.3.5 Monitor fitting __________________ 17

9.3.6 Fitting the protection guard _____ 18

10.0 ELECTRICAL CONNECTION _______ 18

10.1 Electrical checks ____________________ 19

11.0 AIR CONNECTIONS _______________ 19

12.0 FITTING THE WHEEL ON THE

MANDREL _________________________ 20

12.1 Fitting of the wheel (G3.140R -

G3.140RS) ___________________________ 20

12.2 Fitting of the wheel (GP3.140R GP3.140RS) _________________________ 21

13.0 CONTROL PANEL _________________ 23

14.0 WHEEL BALANCING ______________ 23

14.1 Switching the machine on and off ___ 23

14.2 Balancing programs setting _________ 24

14.2.1 Programs rapid setting and

measurements through distancediameter caliper arm ____________ 24

14.2.2 Programs setting through

“Measurement being acquired”

screen page _____________________ 27

14.3 Indicative display of points where to

detect measures/to fit weight ________ 28

14.3.1 Weights positioning _____________ 28

14.4 Displaying the active/modifiable

field _________________________________ 28

14.5 Wheel balancing screen page

description __________________________ 29

14.5.1 Balancing mode _________________ 30

14.6 Use of machines with disabled

automatic gauge ____________________ 32

14.6.1 Manual setting of wheel

dimensions ______________________ 32

14.7 Standard balancing programs_______ 32

14.7.1 Static____________________________ 32

14.7.2 Static-1 __________________________ 33

14.7.3 Static-2 __________________________ 33

14.7.4 Dynamic_________________________ 33

14.7.5 ALU-S ___________________________ 33

14.7.6 ALU-S1 __________________________ 34

14.7.7 ALU-S2 __________________________ 34

14.7.8 ALU-1 ____________________________ 34

14.7.9 ALU-2 ____________________________ 34

14.7.10 ALU-3 __________________________ 35

14.7.11 ALU-4 __________________________ 35

14.8 Optional balancing programs _______ 35

14.8.1 ECO-WEIGHT mode ______________ 35

14.8.2 SPLIT mode _____________________ 37

14.8.3 Weights hidden behind spokes

mode ____________________________ 39

14.8.4 Matching mode __________________ 40

14.9 Special balancing programs _________ 43

14.9.1 Pax ______________________________ 43

14.10 Recalculation Function _____________ 43

14.11 Motorbike Mode wheel balancing ___ 44

15.0 USER MENU (OPTIONS AND

CALIBRATION) ____________________ 45

15.1 Options menu ________________________ 45

15.1.1 Lower weight limit ______________ 47

15.1.2 Setting adhesive weight

dimensions and static threshold

percentage ______________________ 47

15.1.3 User management _______________ 48

15.2 Machine calibration _________________ 49

15.2.1 Mandrel “Ø” calibration _________ 49

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 3

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 3 of 60

15.2.2 Weight measurement sensors calibration ______________________________ 49

15.2.3 Gauge calibration _______________ 50

16.0 ERROR SIGNALS __________________ 54

17.0 ROUTINE MAINTENANCE _________ 55

18.0 TECHNICAL DATA _________________ 56

18.1 Dimensions __________________________ 57

19.0 STORING __________________________ 58

20.0 SCRAPPING _______________________ 58

21.0 REGISTRATION PLATE DATA _____ 58

22.0 FUNCTIONAL DIAGRAMS _________ 58

Table A - Electrical and pneumatic

connection diagram ____________ 59

23.0 LIST OF COMPONENTS

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 4

GB

Page 4 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

2

3

4

5

6

7

8

9

10

11

11

12

13

14

15

16

17

18

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

KEY

1 – Weight holding bridge

2 – Pneumatic mandrel (only for GP3.140R - GP3.140RS models)

3 – Distance-diameter caliper

4 – Threaded mandrel (only for G3.140R - G3.140RS models)

5 – Protection guard

6 – Foot brake (only for G3.140R - G3.140RS models) / pneumatic mandrel open-close pedal (only for

GP3.140R - GP3.140RS models)

7 – Main switch

8 – External data gauge (standard for G3.140RS - GP3.140RS models ) (optional for G3.140R - GP3.140R

models)

9 – Fixed laser unit + led light (standard for G3.140RS - GP3.140RS models)

10 – Monitor

11 – Pusher ring

12 – Rapid ring nut (only for G3.140R - G3.140RS models)

13 – Locking sleeve (only for GP3.140R - GP3.140RS models)

14 – Cones

15 – Professional external data gauge (optional)

16 – Grippers for weight fitting

17 – Lateral guard

18 – Push-button panel with 7 keys

Fig. 1 - G3.140R - GP3.140R - G3.140RS - GP3.140RS

Page 5

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 5 of 60

SYMBOLS USED IN THE MANUAL AND ON THE MACHINE

Symbols Description

2167000

Read instruction manual.

FORBIDDEN!

Wear work gloves.

Wear work shoes.

2167000

Wear safety earcaps.

99990758

Shock hazard.

Caution: hanging loads.

Mandatory. Operations or jobs to

be performed compulsorily.

Danger! Be particularly careful.

Symbols Description

Move with fork lift truck or pallet

truck.

Lift from above.

1541000

General danger.

Wear safety goggles.

Technical assistance necessary.

Do not perform any intervention.

Warning. Be particularly careful

(possible material damages).

Note. Indication and/or useful

information.

Attention: never lift the machine

by means of the mandrel.

99990114

Arrow plate.

999912940

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 6

GB

Page 6 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

99990114

99990758

999912940

999914160

999914170

999910050

•

*

999916310

999920190

999920540

INFORMATION PLATE LOCATION TABLE

IF ONE OR MORE PLATES DISAPPEARS FROM THE MACHINE OR BECOMES DIFFICULT

TO READ, IT MUST BE REPLACED. QUOTE THE CODE NUMBER WHEN REORDERING.

99990114

99990758

999910050

999912940

999914160

999914170

999916310

999920190

999920540

•

*

Arrow plate

Electricity danger plate

Protection device use plate

Lifting plate

Voltage 230V 50/60 Hz 1 Ph plate

Voltage 115V 50/60 Hz 1 Ph plate

Skip label

New G3 logo plate

Laser point danger plate

Serial number plate

Manufacturer trademark nameplate

Code numbers of plates

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 7

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 7 of 60

SOME OF THE PICTURES PRESENT IN THIS MANUAL HAVE

BEEN OBTAINED FROM PICTURES

OF PROTOTYPES, THEREFORE

THE STANDARD PRODUCTION

MACHINES AND ACCESSORIES

CAN BE DIFFERENT IN SOME

COMPONENTS.

1.0 GENERAL INTRODUCTION

This manual is an integral part of the product and

must be retained for the whole operating life of the

machine.

Carefully study the warnings and instructions contained in this manual. It contains important instructions regarding FUNCTIONING, SAFE USE and

MAINTENANCE.

KEEP THE MANUAL IN A KNOWN,

EASILY ACCESSIBLE PLACE FOR

ALL ACCESSORY OPERATORS

TO CONSULT IT WHENEVER IN

DOUBT.

THE MANUFACTURER DISCLAIMS

ALL RESPONSIBILITY FOR ANY

DAMAGE OCCURRED WHEN THE

INDICATIONS GIVEN IN THIS

MANUAL ARE NOT RESPECTED:

AS A MATTER OF FACT, THE NONCOMPLIANCE WITH SUCH INDICATIONS MIGHT LEAD TO EVEN

SERIOUS DANGERS.

1.1 Introduction

Thank you for preferring this wheel balancer. We feel

sure you will not regret your decision.

This machine has been designed for use in professional workshops and stands out for its reliability

and easy, safe and rapid operation. With just a small

degree of maintenance and care, this wheel balancer

will give you many years of trouble-free service and

lots of satisfaction.

2.0 INTENDED USE

The machines models G3.140R - GP3.140R G3.140RS - GP3.140RS, and relative versions,

are wheel balancers for car and light transport,

projected to be used exclusively to cancel out, or at

least reduce to acceptable limits the vibrations of the

wheels, by fitting counterweights of suitable size and

in specific positions to the same wheels that are not

correctly balanced.

DANGER: THIS MACHINE MUST

BE USED STRICTLY FOR THE

INTENDED PURPOSE IT WAS DESIGNED FOR (AS INDICATED IN

THIS MANUAL).

THE MANUFACTURER CANNOT

BE HELD RESPONSIBLE FOR ANY

DAMAGE CAUSED BY IMPROPER,

ERRONEOUS, OR UNACCEPTABLE

USE.

AN INTENSIVE USE OF THE EQUIPMENT IN INDUSTRIAL ENVIRONMENT IS NOT RECOMMENDED.

2.1 Staff training

The machine may be operated only by suitably

trained and authorized personnel.

Given the complexity of the operations necessary to

manage the machine and to carry out the operations

safely and efficiently, the personnel must be trained

in such a way that they learn all the information

necessary to operate the machine as intended by the

manufacturer.

A CAREFUL READING OF THIS

INSTRUCTION MANUAL FOR

USE AND MAINTENANCE AND A

SHORT PERIOD OF TRAINING

WITH SKILLED PERSONNEL CAN

BE AN ENOUGH PREVENTIVE

PREPARATION.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 8

GB

Page 8 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

3.0 SAFETY DEVICES

• Master switch positioned on the rear of the machine

Its function is to disconnect machine electric supply.

• Protection guard

Its function is to protect the operator from possible

projections of materials on the wheel during its spin.

Wheel spinning is normally prevented if the wheel

protection guard is raised (open). When the

protection guard is open, this interrupts the circuit that triggers the motor and automatic start

is prevented, including in the case of an error.

Press stop key to stop wheel rotation in

emergency conditions.

3.1 Residual risks

The machine was subjected to a complete analysis of

risks according to reference standard EN ISO 12100.

Risks are as reduced as possible in relation with technology and product functionality.

Possible residual risks have been emphasized through

pictorial representations and warnings which placing is

indicated in “ PLATE POSITIONING TABLE” at page 6.

4.0 GENERAL SAFETY RULES

• Any tampering with or modification to the machine

not previously authorized by the manufacturer exempts the latter from all responsibility for damage

caused by or derived from said actions.

• Removing of or tampering with the safety devices or

with the warning signals placed on the machine leads

to serious dangers and represents a transgression of

European safety rules.

• Use of the machine is only permitted in places free

from explosion or fire hazard and in dry places

under cover.

• Original spare parts and accessories should be used.

THE MANUFACTURER DENIES

ANY RESPONSIBILITY IN CASE

OF DAMAGES CAUSED BY UNAUTHORIZED MODIFICATIONS OR

BY THE USE OF NON ORIGINAL

COMPONENTS OR EQUIPMENT.

• Installation must be conducted only by qualified

personnel exactly according to the instructions that

are given below.

• Ensure that there are no dangerous situations during the machine operating manoeuvres. Immediately

stop the machine if it miss-functions and contact the

assistance service of an authorized dealer.

• In emergency situations and before carrying out any

maintenance or repairs, disconnect all supplies to

the machine by using the main switch, placed on the

machine itself, and unplugging the power supply.

• The machine electrical supply system must be

equipped with an appropriate earthing, to which

the yellow-green machine protection wire must be

connected.

• Ensure that the work area around the machine is free

of potentially dangerous objects and that there is no

oil since this could damage the tyre. Oil on the floor

is also a potential danger for the operator.

• UNDER NO CIRCUMSTANCES must the machine be

used to spin anything but vehicle wheels. Bad locking

can cause rotating parts to come loose, with potential

damage to the machine and anything in the vicinity

and injury to the operator.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 9

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 9 of 60

Fig. 2

5.0 PACKING AND MOBILIZATION

FOR TRANSPORT

HAVE THE MACHINE HANDLED BY SKILLED

PERSONNEL ONLY.

THE LIFTING EQUIPMENT MUST WITHSTAND

A MINIMUM RATED LOAD EQUAL TO THE

WEIGHT OF THE PACKED MACHINE (SEE

PARAGRAPH “TECHNICAL SPECIFICATIONS”).

The machine is packed completely assembled. The

machine is inside a carton box which size is mm

1040x950x1090.

Movement must be by pallet-lift or fork-lift trolley.

The fork lifting points are indicated on the packing.

OPERATORS MUST WEAR SUITABLE WORK CLOTHES, PROTECTIVE GLASSES AND GLOVES,

AGAINST THE DANGER FROM

THE SPRAYING OF DANGEROUS

DUST, AND POSSIBLY LOWER

BACK SUPPORTS FOR THE LIFTING OF HEAVY PARTS. DANGLING

OBJECTS LIKE BRACELETS MUST

NOT BE WORN, AND LONG HAIR

MUST BE TIED UP. FOOTWEAR

SHOULD BE ADEQUATE FOR THE

TYPE OF OPERATIONS TO BE CARRIED OUT.

• The machine handles and operating grips must be

kept clean and free from oil.

• The workshop must be kept clean and dry. Make sure

that the working premises are properly lit.

The machine can be operated by a single operator.

Unauthorized personnel must remain outside the

working area, as shown in Fig. 3.

Avoid any hazardous situations. Do not use airoperated or electrical equipment when the shop is

damp or the floor slippery and do not expose such

tools to atmospheric agents.

• When operating and servicing this machine, carefully

follow all applicable safety and accident-prevention

precautions.

The machine must not be operated by professionally

unskilled persons.

WHEN USING THE MODELS WITH

WHEEL PNEUMATIC CLAMPING,

DURING MANDREL OPENING/

CLOSING OPERATIONS, BE EXTREMELY CAREFUL AND KEEP

YOUR HANDS OR OTHER PARTS

OF YOUR BODY AWAY FROM THE

MOVING MANDREL.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 10

GB

Page 10 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

7.0 MOBILIZATION

THE LIFTING EQUIPMENT MUST WITHSTAND

A MINIMUM RATED LOAD EQUAL TO THE

WEIGHT OF THE MACHINE (SEE PARAGRAPH

TECHNICAL SPECIFICATIONS). DO NOT ALLOW THE LIFTED MACHINE TO SWING.

NEVER LIFT THE MACHINE BY MEANS OF THE

MANDREL.

If the machine has to be moved from its normal work

post, the movement must be conducted following the

instructions listed below.

• Protect the exposed corners with suitable material

(Pluribol/cardboard).

• Do not use metallic cables for lifting.

• Make sure the electrical supply (and, for GP3.140R

- GP3.140RS models, the pneumatic supply) of the

machine is not connected.

• Place again the machine onto the original pallet with

whom it was delivered.

• Use transpallet or fork-lift for handling.

8.0 WORKING ENVIRONMENT CONDI-

TIONS

The machine must be operated under proper conditions as follows:

• temperature: 0° + 45° C

• relative humidity: 30 - 90% (dew-free)

• atmospheric pressure: 860 - 1060 hPa (mbar).

The use of the machine in ambient conditions other

than those specified above is only allowed after prior

agreement with and approval of the manufacturer.

6.0 UNPACKING

DURING UNPACKING, ALWAYS

WEAR GLOVES TO PREVENT ANY

INJURY CAUSED BY CONTACT

WITH PACKAGING MATERIAL

(NAILS, ETC.).

The cardboard box is supported with plastic strapping.

Cut the strapping with suitable scissors. Use a small

knife to cut along the lateral axis of the box and open

it like a fan.

It is also possible to unnail the cardboard box from

the pallet it is fixed to. After removing the packing, and

in the case of the machine packed fully assembled,

check that the machine is complete and that there is

no visible damage.

If in doubt do not use the machine and refer to professionally qualified personnel (to the seller).

The packing (plastic bags, expanded polystyrene, nails,

screws, timber, etc.) should not be left within reach of

children since it is potentially dangerous. These materials should be deposited in the relevant collection

points if they are pollutants or non biodegradable.

THE BOX CONTAINING THE FIXTURES IS CONTAINED IN THE

WRAPPING. DO NOT THROW IT

AWAY WITH THE PACKING.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 11

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 11 of 60

600

600

600

X

b

a

1

X

X

c

8.1 Working area

Fig. 4

a = 306

b = 580

c = 55

USE THE MACHINE INDOORS OR IN A ROOFED

AREA. PLACE OF INSTALLATION MUST BE

DRY, ADEQUATELY LIT AND IN COMPLIANCE

WITH APPLICABLE SAFETY REGULATIONS.

The location of the machine requires a usable space

as indicated in Fig. 3. The positioning of the machine

must be according to the distances shown. From the

control position the operator is able to observe all the

machine and surrounding area. He must prevent unauthorized personnel or objects that could be dangerous

from entering the area.

The machine must be fixed on a flat floor surface,

preferably of cement or tiled. Avoid yielding or irregular surfaces.

The base floor must be able to support the loads transmitted during operation.

This surface must have a strength of at least 500 kg/m².

The depth of the solid floor must be sufficient to guarantee that the anchoring bolts hold.

8.2 Lighting

The machine does not require its own lighting for

normal working operations. However, it must be used

in an adequately lit environment.

In case of poor lighting use lamps having total power

800/1200 Watt.

IF IT IS INSTALLED, EACH TIME

THE ROD OF THE GAUGE IS EXTRACTED FROM ITS HOUSING,

THE LED LIGHT (FIG. 1 REF. 9)

TURNS ON MAKING THE INSIDE

OF THE WHEEL WHERE THE OPERATOR MUST WORK BRIGHTER.

9.0 MACHINE ASSEMBLY

After having freed the various components from the

packing check that they are complete, and that there

are no anomalies, then comply with the following instructions for the assembly of the components making

use of the attached series of illustrations.

9.1 Anchoring system

The packed machine is fixed to a pallet by support feet.

Such feet also fix the machine to the ground through

anchor small blocks as shown in Fig. 4 ref._1.

IN CASE OF WHEEL WEIGHING

MORE THAN 30 KG, IT IS COMPULSORY TO FIX TO THE GROUND

BY MEANS OF SCREW ANCHORS.

The holes in the solid floor must be about 10 cm deep

with a diameter of 8 MA.

The bolts (Fig. 4 ref. 1) must be inserted in the prearranged holes and fully tightened (tightening torque:

about 22 Nm) until reaching the system full seal.

Fig. 3

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 12

GB

Page 12 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1300A004

999072

129571492

GAR111

GAR101

GAR108

129590710

A

Fig. 5

9.2 Fixtures contained in the packing

The packing case contains also the fixtures box.

Check that all the parts listed below are there (see

Fig. 5).

For G3.140R model

Code Description N.

GAR101 Rapid ring nut + pusher ring 1

GAR111 Cones + protection cup 1

129571492 Gauge 1

1300A004 Weight pliers 1

999072 Carriages counterweight 1

For GP3.140R model

Code Description N.

GAR108 Rapid ring nut + pusher ring 1

GAR111 Cones + protection cup 1

129571492 Gauge 1

1300A004 Weight pliers 1

999072 Carriages counterweight 1

For G3.140RS model

Code Description N.

GAR101 Rapid ring nut + pusher ring 1

GAR111 Cones + protection cup 1

129571492 Gauge 1

1300A004 Weight pliers 1

999072 Carriages counterweight 1

129590710 External data gauge 1

For GP3.140RS model

Code Description N.

GAR108 Rapid ring nut + pusher ring 1

GAR111 Cones + protection cup 1

129571492 Gauge 1

1300A004 Weight pliers 1

999072 Carriages counterweight 1

129590710 External data gauge 1

THE GRIP-RING (FIG. 5 REF. A)

MUST BE MOUNTED WITH THE

TEETH OR DISCHARGE SIDE

TOWARDS THE RING-NUT OR

SLEEVE (SEE FIG. 5).

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 13

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 13 of 60

1

2

Fig. 6

Fig. 7

Fig. 8

9.3 Assembly procedures

9.3.1 Fitting the mandrel on the flange

Only for G3.140R - G3.140RS models

Screw the mandrel with an Allen wrench (Fig. 6 ref. 1)

on the flange (Fig. 6 ref. 2).

9.3.2 Fitting and removal of the pneumatic

mandrel on the flange

Only for GP3.140R - GP3.140RS models

FITTING

1. After making power and air connections switch on

the machine (the pneumatic mandrel always opens

when the machine is switched on). Switch the machine off. Fit the internal mandrel on the flange

and tighten it with the wrench provided (Fig. 7

and Fig. 8).

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 14

GB

Page 14 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

2. Press the brake's pedal and, at the same time, tighten

the internal mandrel as far as it will go using the

wrench provided (Fig. 9).

Fig. 9

3. Fit the external mandrel and tighten it manually

(Fig. 10).

Fig. 10

4. Close the pneumatic mandrel by means of the pedal

to access the key socket (Fig.(Fig. 11).

Fig. 11

5. Press the brake pedal and at the same time block

the external mandrel using the wrench supplied

(Fig. 12).

Fig. 12

REMOVAL

• Close the pneumatic mandrel by means of the pedal

to access the key socket (Fig. 11).

• Press the brake pedal and at the same time release

the external mandrel by using the wrench provided

(Fig. 12).

• Remove the external mandrel, open the pneumatic

mandrel by means of the pedal provided and loosen

the internal mandrel using the special wrench

(Fig. 9).

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 15

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 15 of 60

1

2

3

1

2

2

3

4

5

6

1

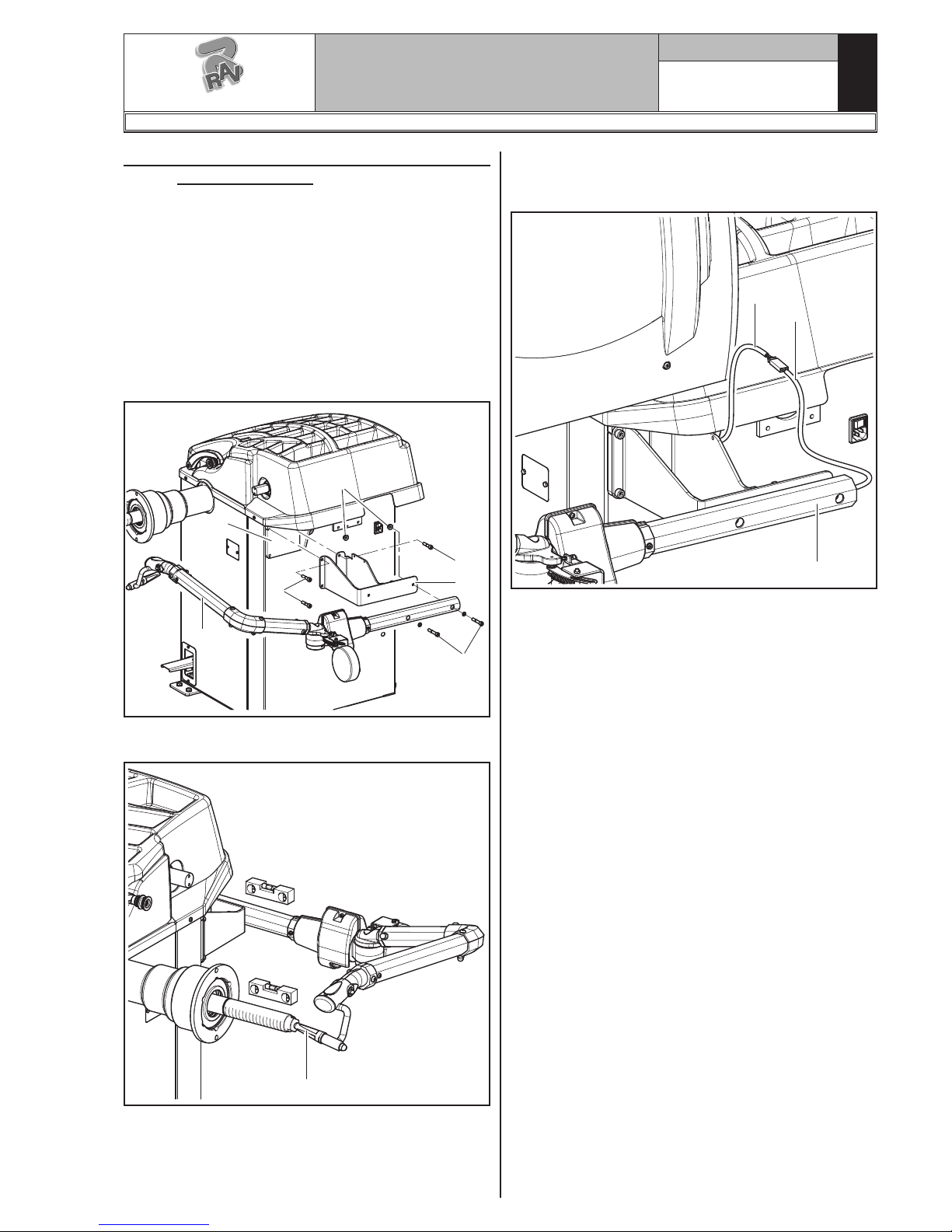

9.3.3 Fitting of external data gauge (standard

for G3.140RS - GP3.140RS versions)

(optional for G3.140R - GP3.140R versions)

1. Unscrew the fastening screws of the equalizer's

support (Fig. 13 ref. 1), being very careful about

holding the same support.

2. Unscrew the 3 screws (Fig. 13 ref. 2) to the gauge

bracket (Fig. 13 ref. 3) and in the special inserts

placed on the rear side of the frame.

Lock the gauge arm (Fig. 13 ref. 4) by screwing

the 2 screws provided (Fig. 13 ref. 5). Lock these

screws with the nuts (Fig. 13 ref. 6) so that the

mandrel and the gauge arm are levelled out (see

Fig. 14).

Fig. 13

3. Also make sure the gauge tip (Fig. 14 ref. 1) is

positioned at the centre of the mandrel.

Fig. 14

4. Connect connector (Fig. 15 ref. 1) of the cable coming from inside the machine to connector (Fig. 15

ref. 2) of the cable coming from the gauge arm. Fit

the section of the cable with the connectors inside

the arm (Fig. 15 ref. 3).

5. Fasten the cable with clamps.

6. Enable the external data gauge and carry out the

device's calibration.

Fig. 15

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 16

GB

Page 16 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

2

4

5

2

3

6

1

2

3

1

9.3.4 Fitting of professional external data

gauge (optional)

1. Unscrew the fastening screws of the equalizer's

support (Fig. 16 ref. 1), being very careful about

holding the same support.

2. Unscrew the 3 screws (Fig. 16 ref. 2) to the gauge

bracket (Fig. 16 ref. 3) and in the special inserts

placed on the rear side of the frame.

Lock the gauge arm (Fig. 16 ref. 4) by screwing

the 2 screws provided (Fig. 16 ref. 5). Lock these

screws with the nuts (Fig. 16 ref. 6) so that the

mandrel and the gauge arm are levelled out (see

Fig. 17).

Fig. 16

3. Also make sure the gauge tip (Fig. 17 ref. 1) is

positioned at the centre of the mandrel.

Fig. 17

4. Connect connector (Fig. 18 ref. 1) of the cable com-

ing from inside the machine to connector (Fig. 18

ref. 2) of the cable coming from the gauge arm. Fit

the section of the cable with the connectors inside

the arm (Fig. 18 ref. 3).

Fig. 18

5. Fasten the cable with clamps.

6. Enable the external data gauge and carry out the

device's calibration.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 17

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 17 of 60

1

90°

3

4

5

2

1

2

3

3

4

4

1

2

3

3

4

4

9.3.5 Monitor fitting

1. Unscrew the nuts (Fig. 19 ref. 1) and the washers

(Fig. 19 ref. 2) from the screws (Fig. 19 ref. 3).

Fit the support tube (Fig. 19 ref. 4) rotated through

90°, paying attention to the monitor and keyboard

cables (Fig. 19 ref. 5) inside it. Then screw the

previously unscrewed nuts and washers again.

Fig. 19

2. Connect the plugs on the power supply sockets and

monitor signal. Connect the wiring of the keyboard.

3. Fix the monitor (Fig. 20 ref. 1) to the support

(Fig. 20 ref. 2) with the screws (Fig. 20 ref. 3)

and the washers (Fig. 20 ref. 4) supplied.

Fig. 20

4. Mount the guard (Fig. 21 ref. 1) to the support

(Fig. 21 ref. 2) with the 6 screws (Fig. 21 ref. 3)

and the washers (Fig. 21 ref. 4) supplied.

Fig. 21

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 18

GB

Page 18 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

2

3

4

4

Fig. 22

9.3.6 Fitting the protection guard

1. Mount the protection guard (Fig. 22 ref. 1) to the

support (Fig. 22 ref. 2) using the screws (Fig. 22

ref. 3), interposing the Belleville washers (Fig. 22

ref. 4).

2. Tighten the screws (Fig. 22 ref. 3) in order to make

the guard (Fig. 22 ref. 1) lift or lower without

bumping against the limit switch. Carry out the

adjustment so that it's possible to manually guide

the guard both during closing and opening.

DURING GUARD'S ASSEMBLY,

PAY ATTENTION TO THE MICRO

PLACED INSIDE THE MACHINE.

10.0 ELECTRICAL CONNECTION

EVEN THE TINIEST PROCEDURE

OF AN ELECTRICAL NATURE

MUST BE CARRIED OUT BY PROFESSIONALLY QUALIFIED STAFF.

BEFORE CONNECTING THE MACHINE MAKE SURE THAT:

• THE MAIN POWER RATING CORRESPONDS TO THE MACHINE

RATING AS SHOWN ON THE

MACHINE PLATE;

• ALL MAIN POWER COMPONENTS ARE IN GOOD CONDITION;

• THE ELECTRICAL SYSTEM

IS PROPERLY GROUNDED

(GROUND WIRE MUST BE THE

SAME CROSS-SECTION AREA

AS THE LARGEST POWER SUPPLY CABLES OR GREATER);

• MAKE SURE THAT THE ELECTRICAL SYSTEM FEATURES A

CUTOUT WITH DIFFERENTIAL

PROTECTION SET AT 30 mA.

Connect the machine up to the mains by means of the

3-pole plug provided (230 V single-phase) through the

wall socket.

If the plug provided is not suitable for the wall socket,

fit a plug that complies with local and applicable regulations. This operation must be performed by expert

and professional personnel.

FIT A TYPE-APPROVED (AS REPORTED BEFORE) PLUG TO THE

MACHINE CABLE (THE GROUND

WIRE IS YELLOW/GREEN AND

MUST NEVER BE CONNECTED TO

THE PHASE LEADS). MAKE SURE

THAT THE ELECTRICAL SYSTEM

IS COMPATIBLE WITH THE RATED

POWER ABSORPTION SPECIFIED

IN THIS MANUAL AND APT TO

ENSURE THAT VOLTAGE DROP

UNDER FULL LOAD WILL NOT

EXCEED 4% OF RATED VOLTAGE

(10% UPON START-UP).

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 19

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 19 of 60

1

Fig. 24

FAILURE TO OBSERVE THE ABOVE

INSTRUCTIONS WILL IMMEDIATELY INVALIDATE THE WARRANTY.

10.1 Electrical checks

BEFORE STARTING UP THE

WHEEL-BALANCER, BE SURE TO

BECOME FAMILIAR WITH THE LOCATION AND OPERATION OF ALL

CONTROLS AND CHECK THEIR

PROPER OPERATION (SEE PAR.

“CONTROLS”).

CARRY OUT A DAILY CHECK OF

MAINTAINED-TYPE CONTROLS

CORRECT FUNCTIONING, BEFORE

STARTING MACHINE OPERATION.

Once the plug/socket connection has been made, turn

on the machine using the master switch (Fig. 23

ref. 1).

11.0 AIR CONNECTIONS

Only for GP3.140R - GP3.140RS models

IN CASE OF A CHANCE SUPPLY FAILURE, AND/OR BEFORE

ANY PNEUMATIC CONNECTIONS,

MOVE THE CONTROLS TO THE

NEUTRAL POSITION.

Connect the wheel balancer to the centralised compressed-air system by means of the connection on the

back of the machine (see Fig. 24).

The air system supplying the machine must be able

to supply filtered and de-humidified air at a pressure

between 8 and 10 bar. It must feature an on-off valve

upstream of the machine.

Fig. 23

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 20

GB

Page 20 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

2

3

4

1

2

1

2

3

4. Fit the protection cap (Fig. 26 ref. 1) in the locknut

(Fig. 26 ref. 2) and fasten against the wheel.

Fig. 25

Fig. 26

Fig. 27

Some aluminium wheels, with very high centring, must

be fitted with the cone outside the wheel.

5. Clean the mandrel (Fig. 27 ref. 1) before fitting

the wheel.

6. Fit the wheel (Fig. 27 ref. 3) with the inside of the

rim towards the wheel balancer, until the wheel is

up against the support flange (Fig. 27 ref. 2).

12.0 FITTING THE WHEEL ON THE

MANDREL

To achieve perfect balancing, the wheel must be carefully and properly fitted on the mandrel. Imperfect

centring will inevitably cause unbalances.

MOST IMPORTANT IS THAT ORIGINAL CONES AND ACCESSORIES

ARE USED MADE SPECIFICALLY

FOR USE ON THE WHEEL BALANCER.

Wheel fitting using the cones provided is illustrated below. For alternative fittings, using optional accessories,

refer to the special instructions provided separately.

12.1 Fitting of the wheel (G3.140R - G3.140RS)

1. Remove any type of foreign body from the wheel

(Fig. 25 ref. 3): pre-existing weights, stones and

mud, and make sure the mandrel (Fig. 25 ref. 1)

and the rim centring area are clean before fitting

the wheel on the mandrel.

2. Carefully choose the cone (Fig. 25 ref. 2) most suit-

able for the wheel to be balanced. These accessories

must be selected according to the shape of the rim.

Position the wheel (Fig. 25 ref. 3), fitting the cone

(Fig. 25 ref. 2) on the mandrel (Fig. 25 ref. 1): be

careful (otherwise this could seize) until this rests

against the support flange (Fig. 25 ref. 4).

3. Fit the wheel with the inner side of the rim towards

the wheel balancer and against the cone.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 21

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 21 of 60

3

1

2

Fig. 28

7. Fit the cone (Fig. 28 ref. 3) with the narrowest part

turned towards the wheel

8. Fit the grip-ring (Fig. 28 ref. 1) in the nut (Fig. 28

ref. 2) and fasten the cone (Fig. 28 ref. 3).

12.2 Fitting of the wheel (GP3.140R -

GP3.140RS)

1. Remove any type of foreign body from the wheel

(Fig. 30 ref. 3): pre-existing weights, stones and

mud, and make sure the mandrel (Fig. 30 ref. 1)

and the rim centring area are clean before fitting

the wheel on the mandrel.

2. Carefully choose the cone (Fig. 30 ref. 2) most suit-

able for the wheel to be balanced. These accessories

must be selected according to the shape of the rim.

Position the wheel (Fig. 30 ref. 3), fitting the cone

(Fig. 30 ref. 2) on the mandrel (Fig. 30 ref. 1): be

careful (otherwise this could seize) until this rests

against the support flange (Fig. 30 ref. 4).

3. Fit the wheel with the inner side of the rim towards

the wheel balancer and against the cone.

Fig. 29

Open/close

the pneumatic

mandrel

Brake the wheel

Open the pneumatic mandrel by means of the special

pedal, see Fig. 29.

THE GRIP-RING (FIG. 28 REF. 1)

MUST BE MOUNTED WITH THE

TEETH SIDE TOWARDS THE RINGNUT (FIG. 28 REF. 2).

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 22

GB

Page 22 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1 2

3

1

2

1

2

3

1

2

3

4

Fig. 30

4. Fit the protection cap (Fig. 31 ref. 1) in the bush

(Fig. 31 ref. 2) and bring everything against the

wheel.

Lift the control pedal to close the mandrel and then

clamp the wheel.

Some aluminium wheels, with very high centring, must

be fitted with the cone outside the wheel.

5. Clean the mandrel (Fig. 32 ref. 1) before fitting

the wheel.

6. Fit the wheel (Fig. 32 ref. 3) with the inside of the

rim towards the wheel balancer, until the wheel is

up against the support flange (Fig. 32 ref. 2).

Fig. 31

Fig. 32

7. Fit the cone (Fig. 33 ref. 3) with the narrowest part

turned towards the wheel

8. Fit the grip-ring (Fig. 33 ref. 1) in the bush (Fig. 33

ref. 2) and bring everything against the wheel.

Fig. 33

THE GRIP-RING (FIG. 33 REF. 1)

MUST BE MOUNTED WITH THE

DISCHARGE SIDE TOWARDS THE

SLEEVE (FIG. 33 REF. 2).

Close the pneumatic mandrel by lifting the appropriate

control pedal.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 23

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 23 of 60

7

2

3

4

5

6

8

9

1

Fig. 34

KEY

1 – Monitor

2 – Function push button (red)

3 – Function push button (yellow)

4 – Function push button (grey)

5 – Function push button (blue)

6 – Function push button (green)

7 – Previous page push button

8 – Next page/print push button

9 – Push-button panel (push-button panel with 7 keys)

14.0 WHEEL BALANCING

14.1 Switching the machine on and off

Press the "ON" switch (Fig. 23 ref. 1), located in the

rear part of the equipment.

IN THE CASE OF PNEUMATIC

MODELS, ON STARTING, THE

PNEUMATIC MANDREL IS ALWAYS OPENED. ALWAYS KEEP

YOUR HANDS AND OTHER PARTS

OF THE BODY AWAY FROM THE

MOVING MANDREL.

ALSO TAKE CARE IF A WHEEL

IS ALREADY FITTED ON THE

MANDREL, AS THIS COULD BE

FORCED OFF THE SHAFT DURING THE OPENING OF THE MANDREL ITSELF.

Wait a few seconds until the complete loading of the operational program. The equipment is ready to operate

when the main screen “Home” appears on the monitor..

Fig. 35

1 2 34 5A B C

DURING MANDREL OPENING/

CLOSING OPERATIONS, BE CAREFUL TO KEEP YOUR HANDS AND

OTHER PARTS OF THE BODY

AWAY FROM THE MANDREL.

13.0 CONTROL PANEL

The wheel balancers are equipped with a control panel

equipped with a keyboard to interact/operate the controls presented in graphical form on the monitor.

On the monitor are displayed all the instructions for the

correct wheel balancing, for example indicating where

the operator shall fit adhesive or clip weights and the

balancing mode and/or option used, as well as correct

wheel rotation for inner/outer weights positioning.

KEY

A – Displaying operations/information area

B – Colours for identification of the buttons to be

used

C – Function icons

1 – Programs and measurements acquisition but-

tons

2 – Wheel spin push-button

3 – Go to next page

4 – Pneumatic mandrel opening/closing (only

for GP3.140R - GP3.140RS models)

(generally used in case of emergency)

5 – User management (if enabled)

(user management is not enabled on ma-

chine delivery)

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 24

GB

Page 24 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

2

1

At the bottom of the main screen and each screen

described below, there will be coloured rectangles

(Fig. 35 ref. B) located above the icons of identification function (Fig. 35 ref. C). These functions are

activated by pressing the appropriate coloured button on the keypad (Fig. 34 ref. 9). Press the button

(Fig. 35 ref. 3) to display a second page where you

can access the "Technical assistance" menu and the

"Run-out" menu (see Fig. 36).

Fig. 36

KEY

1 – User menu

2 – Run-out menu (visible only if the machine is fit

or if the Run-out device is enabled)

3 – Return to previous page

Fig. 38

1 23

Fig. 37

In order to turn off the machine, simply press the "OFF"

switch (Fig. 23 ref. 1).

WHEN THE EQUIPMENT IS

TURNED OFF LOSES ALL THE

MEASUREMENTS AND THE

STORED DATA (SIZE, SPINS, USERS, ETC ...). AT RESTARTING,

PRESSING THE BUTTON (IN

THE CASE HAVE NOT YET BEEN

STORED ON THE NEW MEASURES

AFTER THE SWITCHING ON), THE

MACHINE DOES NOT PERFORM

ANY OPERATION.

14.2 Balancing programs setting

The setting of the balancing programs can be performed in two ways:

- through the gauge arm (rapid setting);

- through “Measurement being acquired” screen, ap-

pearing when the button is pressed (Fig. 35

ref. 1).

The setting modes are completely different even if

they allow to reach the same result (but with different

times).

14.2.1 Programs rapid setting and measurements through distance-diameter

caliper arm

The use of the distance-diameter caliper arm allows

the rapid automatic wheel balancing program and the

measures entry. From page “Home”:

- bring into contact the weights fitting gripper with the

inner part of the rim (1 contact only) to select the

program "STATIC" (see Fig. 37).

REPEATEDLY BRINGING THE

GAUGE'S ARM (FIG. 38 REF. 1) IN

CONTACT WITH THE MANDREL

(FIG. 38 REF. 2), THE PROGRAM

WILL CYCLE FROM "STATIC" TO

"STATIC 1" TO "2 STATIC" THEN

RETURNING TO THE BEGINNING.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 25

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 25 of 60

Fig. 39

Width

automatic

measurement

Width

automatic

measurement

1

Fig. 40

Fig. 41

1

- After entering all the required measures, you can spin

the wheel by pressing the button and closing

the protective guard.

• Measuring procedure of electronic RUN-OUT with

the distance-diameter caliper arm.

The electronic RUN-OUT measuring device is useful

to check if the rim has some imperfections.

To access the screen to choose the rim control mode,

proceed as follows:

- from the "Home" page, press the button

(Fig. 40 re. 1) and then the button (see

Fig. 41 ref. 1).

GAR304

GAR306

- Bring into contact the weights fitting gripper with the

inner part of the rim (2 contact points) (see Fig. 37)

to select “ALU-S” program.

REPEATEDLY BRINGING THE

GAUGE'S ARM (FIG. 38 REF. 1) IN

CONTACT WITH THE MANDREL

(FIG. 38 REF. 2), THE PROGRAM

WILL CYCLE FROM "ALU-S" TO

"ALU-S1" TO "ALU-S2" THEN RETURNING TO THE BEGINNING.

WHENEVER THE DISTANCE-DIAMETER CALIPER AND/OR THE

EXTERNAL DATA GAUGE (GAR306

OR GAR304, SEE FIG. 39) (IF ANY)

IS KEPT IN POSITION FOR A FEW

SECONDS AGAINST THE RIM

(UNTIL THE MACHINE MAKES AN

APPROPRIATE SOUND NOTIFICATION), THE POSITION IS STORED

AND THE VALUES MEASURED IN

THE PRE-ARRANGED FIELDS IN

THE SELECTED WHEEL BALANCING PROGRAM ARE LOADED.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 26

GB

Page 26 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

- On the monitor you will see the screen below where

there are buttons to select the type of flaw detection.

1 – Rim inner right lateral fault detection (ena-

bled only with GAR303)

2 – Rim inner left lateral fault detection (enabled

only with GAR303)

3 – Rim inner lateral fault detection

4 – Tyre fault detection (enabled only with

GAR303)

5 – Wheel spin push-button

1 2 3 4 5

Fig. 42

Tyre fault detection (lateral inner side).

From the screen page Fig. 42 press the button

(Fig. 42 ref. 3). The screen page below is displayed.

Place the distance-diameter caliper grippers (Fig. 43

ref. 1) on the inner side of the rim, as shown in

Fig._43.

Press the green button on the monitor

(Fig. 42 ref. 5) to start the rim analysis procedure.

The circle starts to spin at low speed (30 rpm) and

at the end of the measurement the eccentricity graph

appears, as shown in the Fig._44.

Fig. 43

Fig. 44

1 23

6

1 – Fundamental sine wave(fuchsia-coloured-

graph)

2 – Graph of detected eccentricity (red)

3 – Slider that indicates the current position of

the rim ("12 o'clock") (green)

4 – Value in mm of the highest peak of imperfec-

tion detected on the rim

5 – Value in mm of imperfection of the rim at the

current position

6 – Value in mm of the lowest peak of imperfec-

tion detected on the rim

7 – Graph deleting button

8 – Run-out mode carried out where the data is

displayed in the graph

The red graph (Fig. 44 ref. 2) represents exactly the

geometric shape of the rim. The more the circle is

round and linear, the more the graph is flat, unlike the

more the circle has deficiencies, the more the graph

is large.

You can follow the eccentricity in the graph by manually turning the rim, the green-coloured-slider (Fig. 44

ref. 3), indicates the position of the rim in "12 o'clock"

position.

4

57

8

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 27

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 27 of 60

14.2.2 Programs setting through “Measurement being acquired” screen page

From the “Home” page, press the (Fig. 35

ref. 1) button to display the "Measurement being ac-

quired" screen below:

- Press the button to display the following programs selection screen page:

PRESS THE BUTTON

(Fig. 35 ref. 1) TO DISABLE AU-

TOMATIC FUNCTION OF THE

DISTANCE-DIAMETER CALIPER

ARM WHEEL BALANCING SELECTION, DESCRIBED IN PAR. 14.2.1.

TO BE ABLE TO REUSE THE

AUTOMATIC FUNCTION TO SELECT THE WHEEL BALANCING

PROGRAM WITH GAUGE ARM, IT

IS NECESSARY TO RETURN TO

"HOME" PAGE, BY PRESSING THE

BUTTON .

The selection of the wheel balancing program is possible in 2 ways:

- with highlighted program (blue colour) by pressing the

or until you see the desired program.

With this mode only the 11 standard programs can

be selected (DYN, ALU-S, ALU-S1, ALU-S2, STAT,

STAT-1, STAT-2, ALU-1, ALU-2, ALU-3, ALU-4).

IF THE PROGRAM NAME IS NOT

HIGHLIGHTED (BLUE), PRESS

THE BUTTON REPEATEDLY

UNTIL THE ABOVE CONDITION IS

REACHED.

Use the arrows and/or to select the

wished mode (blue). In this mode you can select the

11 standard programs (listed above) and special

programs (PAX360, PAX420, PAX460, PAX700).

AFTER YOU HAVE SELECTED THE

DESIRED PROGRAM, USE THE

DISTANCE-DIAMETER CALIPER

AND/OR THE EXTERNAL DATA

GAUGE (GAR306 OR GAR304) (IF

ANY) TO DETECT THE MEASURES

REQUIRED BY THE PROGRAM.

WHENEVER THE DISTANCE-DIAMETER CALIPER AND/OR THE

EXTERNAL DATA GAUGE (GAR306

OR GAR304, SEE FIG. 39) (IF ANY)

IS KEPT IN POSITION FOR A FEW

SECONDS AGAINST THE RIM

(UNTIL THE MACHINE MAKES AN

APPROPRIATE SOUND NOTIFICATION), THE POSITION IS STORED

AND THE VALUES MEASURED IN

THE PRE-ARRANGED FIELDS IN

THE SELECTED WHEEL BALANCING PROGRAM ARE LOADED.

- After entering all the required measures, you can spin

the wheel by pressing the button and closing

the protective guard.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 28

GB

Page 28 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

Fig. 45

2

516 5 34

7

KEY

1 – 1st weight fitting point distance

2 – Rim diameter

3 – Balancing mode

4 – Point at which to take the measure/adhesive

weight fitting

5 – Point at which to take the measure/clip weight

fitting

6 – Last unbalance detected by the machine

7 – Rim width

14.3 Indicative display of points where to

detect measures/to fit weight

IT IS VERY IMPORTANT TO REMEMBER THE POINTS SELECTED

FOR MEASUREMENT INSIDE THE

RIM SINCE DURING THE WEIGHTS

FITTING WITH FIXED LASER YOU

WILL NOT HAVE ANY OTHER

REFERENCE EXCEPT FOR THE

CROSS LINE ON THE RIM, GENERATED BY THE LASER ITSELF.

THE POSITIONING IN DEPTH WILL

BE AT THE DISCRETION OF THE

OPERATOR.

Depending on the type of program selected,the machine

shows on the monitor the guideline points where to

take measures and, consequently, where you must

apply weights (Fig. 45 ref. 4-5).

THE MORE THE POINTS CHOSEN

FOR THE PROBING ARE DISTANT

FROM EACH OTHER THE MORE

THE BALANCING WILL BE EFFECTIVE.

14.3.1 Weights positioning

The monitor displays when it is absolutely necessary

that the weight is applied at "12 o'clock" position. Pay

particular attention to the content of the weights iden-

tification icons since if the following words are

displayed, then the icon corresponding weight has to

be applied at "12 o'clock" position (typical of ALU-S1,

ALU-S2 programs).

IF ALL MEASURES REQUIRED BY

THE PROGRAM HAVE NOT BEEN

TAKEN/INSERTED, THE MACHINE

DOES NOT ALLOW THE WHEEL

SPIN TO DETECT THE UNBALANCE.

14.4 Displaying the active/modifiable field

During the various phases of measures detection, the

active field turns blue.

Pressing the buttons or you can change

the value and/or program inside the active field. To

change the selected active field, simply press the button

until the desired field is coloured blue.

THE SELECTION OF THE ACTIVE

FIELD IS DONE BY HIGHLIGHTING THE FIELDS IN A CLOCKWISE

DIRECTION.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 29

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 29 of 60

14.5 Wheel balancing screen page description

After executing the spin of the wheel, the monitor displays a series of important information that helps the

operator in his operations and subsequent choices.

2P163 P2

29783

1 a b

d 5 c 4

KEY

1 – Measures used by the program to perform the

spin and detect the values in P1 - P2

P1 – Weight to be fitted on rim outer side

P2 – Weight to be fitted on rim inner side

2 – Wheel placed to fit the weight on wheel outer

side (arrows both green)

3 – Wheel not placed to fit the weight on wheel

inner side (blue/black arrows)

4 – Wheel balancing suggestions

4a – SPLIT Program (Clip weights program) or

MATCHING Program

4b – SPOKES Program (program with adhesive

weights)

4c – ECO-WEIGHT Program with weight value to

be fitted (if the value is of blue, the machine

advises not to use it)

4d – STATIC Program

5 – N° user (if selected)

6 – Arrows indicating the weight fitting point with

distance-diameter caliper arm

7 – Wheel repositioning button for weights fitting

8 – Display the actual weight

9 – By pressing the button you will see the

following page where you can select one of the

programs suggested by the machine.

Fig. 46

NORMALLY DURING THE DETECTION OF MEASUREMENTS, THE

1ST ACTIVE FIELD WILL BE THE

ONE FOR THE SELECTION OF THE

PROGRAM.

THERE IS A CASE, HOWEVER, IN

WHICH THE 1ST ACTIVE FIELD

WILL BE THE RIM WIDTH.

THIS CASE WILL OCCUR ONLY IF

FROM "HOME" PAGE IS DETECTED

ONLY ONE MEASUREMENT INSIDE THE RIM. THE PROGRAM

WILL AUTOMATICALLY SET TO

"STATIC" BUT IT WILL MAKE IT

POSSIBLE (IN CASE OF ABSENCE

OF EXTERNAL DATA GAUGE) TO

MANUALLY ENTER RIM WIDTH

AND TO QUICKLY SWITCH TO THE

PROGRAM "DYNAMIC".

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 30

GB

Page 30 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

SPLIT program

or MATCHING

SPOKES Program

ECO-WEIGHT

Program

14.5.1 Balancing mode

The machine has the ability to perform the wheel bal-

ancing (weights fitting) in 3 different ways:

- using the distance-diameter caliper arm with weights

fitting grippers;

- using the laser at “6 o'clock”;

- weights fitting at “6 o'clock” (without the use of lasers).

• Weights fitting with distance-diameter caliper

arm.

1. Place the adhesive weight on the arm grippers.

Fit the adhesive weight in the

pliers of the gauge rod

2. Pull out the gauge until the arrows (Fig. 46 ref._6)

both turn green.

3. Rotate the gauge arm until the weight touches

the rim.

Fit weight on the position where

pliers touches the wheel

4. Bring the distance-diameter caliper arm into rest-

ing position.

5. Press the button to change the weight fit-

ting side.

6. Proceed in the same way as described in points

1-2-3.

IF THE GUARD AND REPOSITIONING FUNCTION ARE DISABLED,

ON BUTTON 7 YOU WILL SEE

THE ICON THAT WILL ALLOW THE WHEEL SPIN WITHOUT

RETURNING TO THE PREVIOUS

PAGE. THE POSITIONING OF THE

WHEEL FOR THE APPLICATION

OF THE WEIGHTS MUST BE DONE

MANUALLY.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 31

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 31 of 60

BEFORE REMOVING THE DIAMETER-DISTANCE CALIPER, PRESS

THE BRAKE PEDAL AND HOLD IT

DOWN UNTIL THE WEIGHT HAS

NOT BEEN APPLIED, ENSURING IN

THIS WAY THAT, DURING THESE

PHASES, THE WHEEL CAN NOT

ROTATE.

• Weights fitting with laser (at "6 hours").

ON DELIVERY THE MACHINE (IF

PRE-SET WITH FIXED LASER) IS

SET WITH THE CORRESPONDING

OPTION DESELECTED.

TO USE THIS MODE, IT IS NECESSARY THAT THE RELEVANT FUNC-

TION IS ENABLED

ON THE

MENU "OPTIONS" DESCRIBED IN

PAR. 15.1.

TO USE THIS WEIGHTS APPLICATION MODE THE OPERATOR

MUST REMEMBER THE PRECISE

POINT AT WHICH THE MEASUREMENT WAS TAKEN WITH THE DISTANCE-DIAMETER CALIPER ARM.

At the end of the spin, on the rim at "6 hours" is

displayed a laser beam (blade) indicating the axis

on which to apply the weight. The positioning of the

weight (s) in depth shall be at the discretion of the

operator, depending on where remembers taking

the measure.

BE SURE TO APPLY THE (INTERNAL OR EXTERNAL) WEIGHT AS

INDICATED BY THE 2 GREEN

ARROWS (Fig. 46 ref. 2 or 3) ON

THE CORRESPONDING MONITOR

SCREEN.

• Weights fitting at “6 o'clock” (without the use of

lasers).

TO USE THIS MODE, IT IS NECESSARY THAT THE RELEVANT FUNC-

TION IS ENABLED ON THE

MENU "OPTIONS" DESCRIBED IN

PAR. 15.1.

TO USE THIS WEIGHTS APPLICATION MODE THE OPERATOR

MUST REMEMBER THE PRECISE

POINT AT WHICH THE MEASUREMENT WAS TAKEN WITH THE DISTANCE-DIAMETER CALIPER ARM.

USING THIS MODE, THE MACHINE

ALLOWS YOU TO APPLY ANY ADHESIVE WEIGHTS THAT WOULD

BE APPLIED TO "12 HOURS" TO

"6 O'CLOCK". IF, AFTER YOU ENABLE THIS MODE, ON BALANCING

PROGRAM APPEARED AGAIN THE

ICON (ONLY IN THIS CASE)

THE ADHESIVE WEIGHT WILL BE

APPLIED TO "12 HOURS".

At the end of the spin, the wheel stops in place to

apply the weight at "6 o'clock". The positioning of

the weight (s) in depth shall be at the discretion of

the operator, depending on where remembers taking

the measure.

BE SURE TO APPLY THE WEIGHT

(INTERNAL OR EXTERNAL) AS

INDICATED BY THE 2 GREEN

ARROWS (Fig. 46 ref. 2 or 3) ON

THE CORRESPONDING MONITOR

SCREEN.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 32

GB

Page 32 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

14.6 Use of machines with disabled automatic gauge

The entry of diameter, width and distance measures

of the machine rim must be performed manually. The

reading of these measures can be made as follows:

- visual readout on caliper graduated scale (distance);

- values readout on rim (diameter and width);

- width value detection with manual caliper (width)

(see Fig. 47).

Fig. 47

MANUAL

CALIPER.

Width manual

detection

14.6.1 Manual setting of wheel dimensions

In case the operator wants to edit and/or manually

enter the wheel dimensions, proceed as follows:

- from the desired measurement mode screen, press

the button until highlighting with blue the field

to modify/edit;

- press the buttons or until reaching the

desired value;

- press button to shift to the next value.

After entering all the required measures, you can spin

the wheel by pressing the button and closing

the protective guard.

NOTE: In case the distance-diameter caliper was disa-

bled, the displayed page for detected unbalance

is as follows:

In this screen page,in addition to the information of

the detected unbalance, there are measurements in

mm where you must remove the gauge arm (Fig. 48

ref._1-2) to apply the weights inside the rim.

14.7 Standard balancing programs

14.7.1 Static

The STATIC program permits balancing wheels by fitting adhesive weights on the outer and inner sides of

the rim. Enter the measurements (see Par. 14.2.1 or

14.6.1) and proceed as described in Par. 14.5.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

Fig. 48

1 2

The procedure has now been completed.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 33

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 33 of 60

14.7.2 Static-1

The STATIC 1 function is a procedure that offsets wheel

vibrations using a single weight with clip on a single

plane positioned exactly at 12 o’ clock.

Enter the measurements (see Par. 14.2.1 or 14.6.1) and

proceed as described in Par. 14.5 "Dynamic balancing"

(only for wheel inner side).

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

14.7.3 Static-2

The STATIC 2 function is a procedure that offsets wheel

vibrations using a single adhesive weight on a single

plane positioned exactly at 12 o’ clock.

Enter the measurements (see Par. 14.2.1 or 14.6.1) and

proceed as described in Par. 14.5 "Dynamic balancing"

(only for wheel inner side).

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

14.7.4 Dynamic

The DYNAMIC program allows the wheels balancing

by fitting two clip adhesive weights: one on the outside

and one on the inside rim. Enter the measurements

(see Par. 14.2.1 or 14.6.1) and proceed as described

in Par. 14.5.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

The procedure has now been completed.

14.7.5 ALU-S

The ALU-S program permits balancing wheels by two

fitting adhesive weights on the outer and inner sides

of the rim. Enter the measurements (see Par. 14.2.1 or

14.6.1) and proceed as described in Par. 14.5.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 34

GB

Page 34 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

14.7.6 ALU-S1

The ALU-S1 function permits balancing wheels with

light alloy rims by fitting adhesive weights on the outer

side and weight with clip on inner side of wheel (at 12

o’ clock).

Enter the measurements (see Par. 14.2.1 or 14.6.1)

and proceed as described in Par. 14.5 (the inner weight

is with clip).

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

14.7.8 ALU-1

The ALU-1 function permits balancing wheels with light

alloy rims by fitting adhesive weights on the outer and

inner sides of the rim at 12 o’ clock.

Enter the measurements (see Par. 14.2.1 or 14.6.1)

and proceed as described in Par. 14.5.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

14.7.9 ALU-2

The ALU-2 function balances wheels with light alloy

rims by fitting adhesive weights on the outside and

inside of the rim. The position of the outer weight is

not visible but hidden inside. Enter the measurements

(see Par. 14.2.1 or 14.6.1) and proceed as for dynamic

unbalance.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

14.7.7 ALU-S2

The ALU-S2 function permits balancing wheels with

light alloy rims by fitting two adhesive weights: one on

the outer and one on inner sides of the rim (the inner

weight is at 12 o’ clock).

Enter the measurements (see Par. 14.2.1 or 14.6.1)

and proceed as described in Par. 14.5.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

The procedure has now been completed.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 35

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 35 of 60

14.7.10 ALU-3

The ALU-3 function is a procedure that uses mixed

weights to offset wheel unbalance: weight with clip on

inner side of wheel, adhesive weight on outer side, not

visible because inside the rim.

Enter the measurements (see Par. 14.2.1 or 14.6.1)

and proceed as for dynamic unbalance.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

14.7.11 ALU-4

The ALU-4 function is a procedure that uses mixed

weights to offset wheel unbalance: weight with clip

on inner side of wheel, adhesive weight on outer side.

Enter the measurements (see Par. 14.2.1 or 14.6.1)

and proceed as for dynamic unbalance.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The procedure has now been completed.

It is possible to fit a single weight at a predetermined

distance from the machine, so as to optimise the weight

consumption and reduce both the DYNAMIC and any

remaining STATIC unbalance as much as possible.

Unlike the standard STATIC procedure, the ECOWEIGHT procedure, though only using one weight,

also considerably reduces the DYNAMIC unbalance,

because the fitting distance of the weight on the rim

is also calculated.

From the ALU-S unbalance results page, if there is

considerable static unbalance, press the button

to display on the following monitor screen:

14.8 Optional balancing programs

14.8.1 ECO-WEIGHT mode

TO USE THE ECO-WEIGHT PROCEDURE IT IS NECESSARY THAT

THE DISTANCE-DIAMETER CALIPER ARM IS ENABLED IN THE

“OPTIONS” MENU DESCRIBED IN

PAR. 15.1.

THE ECO-WEIGHT PROCEDURE

CAN ONLY BE USED WITH THE

PROGRAM ALU-S.

This procedure represents a modern system for the

reset of the unbalance in order to reduce weights consumption. This procedure ensures a fastest execution

of the operations, thanks to a lesser number of spins

and repositioning.

After making the wheel spin in ALU-S mode, the monitor shows the total of 2 adhesive weights to precisely

correct STATIC and DYNAMIC unbalance.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 36

GB

Page 36 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

Press the brake pedal and fit the adhesive weight inside

pliers as shown in Fig. 50.

Fit the adhesive weight in the

pliers of the gauge rod

Fig. 50

Pull out the gauge rod until the arrows (Fig. 49 ref. 6)

turn green.

At the end of the procedure, the wheel balancing conditions can be checked by performing a trial spin.

The ECO-WEIGHT procedure has now been completed.

Fig. 51

Fit weight on the position where

pliers touches the wheel

1

2 3 4 56

KEY

1 – Only weight to be fitted

2 – Last program and last values used for the spin

3 – Residual dynamic unbalance value (if the value

is blue it is not to carry out ECO-WEIGHT

procedure)

4 – Static unbalance value (if the value is blue it

is not to carry out ECO-WEIGHT procedure)

5 – Residual dynamic unbalance value (if the value

is blue it is not to carry out ECO-WEIGHT

procedure)

6 – Arrows indicating the weight fitting point with

distance-diameter caliper arm

Press button to select such procedure and bring

automatically the wheel into weight fitting position.

Fig. 49

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 37

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 37 of 60

14.8.2 SPLIT mode

The Split procedure proves useful when the dynamic

unbalance of a wheel is fairly high and the weight to

be fitted is not available, for instance a 100 g weight.

It's possible then to correct the unbalance dividing

the amount of weight into two weights of smaller size.

The Split procedure eliminates errors by using the

“DYNAMIC” program, as for example by manually fitting two 50 g weights close to one another, instead of

only a 100 gr one.

For example:

100 g WEIGHT

TO BE FITTED TO CORRECT UNBAL-

ANCE

TWO SMALLER WEIGHTS (50g)

FITTED MANUALLY

IMMEDIATELY AFTER HAVING

SELECTED THE ECO-WEIGHT

PROCEDURE, YOU CAN KNOW

IN ADVANCE THE TWO DYNAMIC

UNBALANCES AND THE STATIC

RESIDUE IN ORDER TO DECIDE

WHETHER IT IS CONVENIENT TO

CONTINUE (SEE FIG. 49).

IF BOTH DYNAMIC UNBALANCES

AND STATIC RESIDUE ARE SHOWN

AS WHITE VALUES ON THE MONITOR, THIS MEANS THAT THE

PROGRAM HAS DECIDED THAT IT

IS BETTER TO CONTINUE. WHILE

IF, ON THE OTHER HAND, ONE OR

MORE VALUES ARE BLUE, THE

PROGRAM SUGGESTS USING THE

STANDARD ALU-S PROCEDURE.

PRESS BUTTON ONCE. THE

TWO RESIDUAL DYNAMIC UNBALANCES WILL BE DISPLAYED ON

MONITOR.

PRESS BUTTON ONCE

MORE. THE CALCULATED REAL

STATIC WEIGHT AND THE RESIDUAL STATIC WEIGHT WILL BE

DISPLAYED ON SCREEN.

IF YOU ARE NOT WISHING TO OPERATE WITH THE ECO-WEIGHT

PROCEDURE, PRESS BUTTON

, ONCE MORE. THE ALU-S

UNBALANCE VALUES WILL BE

DISPLAYED AGAIN.

WHILE IF YOU WISH TO OPERATE

WITH THE ECO-WEIGHT PROCE-

DURE, PRESS BUTTON FOR

A LONGER TIME (OR KEY )

TO GO BACK TO THE RESIDUAL

DYNAMIC/ECO-WEIGHT WEIGHT

DISPLAY SCREENS.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 38

GB

Page 38 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

TWO SMALLER WEIGHTS (55g)

USING SPLIT PROCEDURE

Proceed to “DYNAMIC” unbalance measurement displaying by performing a standard wheel spin.

Once detected the unbalance values, verify that the

machine displays the ability to use the "SPLIT" option

(Fig. 46 ref. 4a). Press button to shift to the

next screen page.

Press button to enter the “SPLIT” function.

On the monitor screen will be displayed where you

must enter the value of the weights to be fitted.

Press button to select the outer weight to edit.

Press buttons or to increase or decrease

the total weight to be fitted.

THE BLUE VALUE INDICATES

WHICH VALUE IS ACTIVE AND YOU

ARE EDITING.

THE HIGHER THE CHOSEN

WEIGHTS VALUE IS, THE MORE

THEY WILL BE SPACED.

After choosing the value of the weights to be fitted,

press button to position the wheel for the application of the 1st clip weight.

THE TWO GREEN ARROWS INDICATE THAT THE WHEEL IS PROPERLY POSITIONED FOR THE APPLICATION OF THE 1ST WEIGHT.

Fit the clip weight of the chosen value at 12 o’clock on

the outside of the wheel. Press again button to

position the wheel for the fitting of the 2nd clip weight.

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 39

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 39 of 60

Fit the clip weight of the chosen value at 12 o’clock

on the outside of the wheel. Press button to

highlight the value of the weights to be fitted on the

inside of the wheel.

Repeat the above steps for the weights to be fitted

inside the wheel.

At the end perform again a checking spin to see that

you have applied the weights correctly.

14.8.3 Weights hidden behind spokes mode

Adhesive correction weight positioning may not look attractive on some types of rims. In this case, the "weights

hidden behind spokes" mode can be used. This splits

any correction weight on the outer side into two parts

to be hidden behind the rim spokes. It can be used in

both ALU-S or STATIC modes.

Display the ALU-S or STATIC, unbalance measurements, by performing a standard wheel spin.

Press button to enter the relevant function.

On the monitor the next screen page will be displayed:

Once detected the unbalance values, verify that the

machine displays the ability to use the "spokes" options

(Fig. 46 ref. 4b).

Press button to shift to the next screen page.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 40

GB

Page 40 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

Bring any spoke upwards at "12 o'clock" position and

press the button to confirm and continue.

Lead to “12 hours” the 2nd spoke. The machine will

automatically calculate the total number of spokes. If

the value shown on the screen (A) is correct, press the

button .

The machine automatically calculates weight position

in two positions hidden behind the spokes. The monitor shows the amount of weight to be applied behind

the FIRST spoke and the rim will reach the position

to apply the FIRST weight.

Extract the gauge rod, and fit the FIRST weight in

the position shown by the machine, as explained in

Pa r. 14.5.1. Press the button to confirm that

they have applied the FIRST weight and to automatically position the wheel for the fitting of the 2nd weight.

The monitor shows the amount of weight to be applied

behind the SECOND spoke.

Pull out the gauge rod and fit the SECOND weight in

the position shown by the machine, as done for the

first weight.

Press the button to confirm that you have applied the SECOND weight and get back to the initial

situation of unbalance, before performing the "weights

hidden behind the spokes" procedure

Perform another test spin. The “weights hidden behind

spokes” procedure is completed.

Complete the operation by adding an additional weight

inside the rim as required by the selected mode (ALUS or STATIC).

14.8.4 Matching mode

The “Matching” procedure offsets strong unbalance,

reducing the weight quantity to be fitted on the wheel

to achieve balancing. This procedure permits reducing

unbalance as much as possible by offsetting the tyre

unbalance with that of the rim in any used program.

Proceed to unbalance measurement displaying by

performing a standard wheel spin.

THE MATCHING PROCEDURE CAN

BE CARRIED OUT ONLY IF THE

STATIC UNBALANCE IS > 30 G.

Press button to enter the relevant function.

On the monitor the next screen page will be displayed:

Once detected the unbalance values, verify that the

machine displays the ability to use the “matching” options (Fig. 46 ref. 4a).

Press button to shift to the next screen page.

A

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

1297-M007-1_R

Page 41

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 41 of 60

STEP 1. Move the slider on the flange to the "12 o'clock"

position. Make a reference mark, using chalk for instance, on the rim and tyre, in line with the arrow on

the flange, so as to be able to fit the rim back on in the

same position on the machine.

Press button to confirm that step 1 has been

completed.

On the display the next screen page will be displayed:

Make a reference mark on the rim and tyre, in line

with the arrow on the flange

Fit the wheel back on the wheel balancer, positioning

the reference mark on the rim in line with the arrow

on the flange.

Position the reference mark on the rim in line with

the arrow on the flange.

Position the tyre ref-

erence mark on the

opposite side to the

arrow on the flange.

After having fitted wheel back in position, close the

protection guard to make an automatic wheel spin.

At the end of the spin the monitor will display the following screen:

STEP 2. Remove the wheel from the wheel balancer.

Remove the tyre and turn it on the rim by 180°.

Press button to confirm that step 2 has been

completed.

On the display the next screen page will be displayed

suggesting to perform a spin of the wheel.

1297-M007-1_R

G3.140R - GP3.140R - G3.140RS - GP3.140RS

RAVAGLIOLI S.p.A.

Page 42

GB

Page 42 of 60

INSTRUCTION, USE AND

MAINTENANCE MANUAL

In this screen you will see the dynamic unbalance that

the wheel had before performing the operation (Fig. 52

ref. 1), the dynamic unbalance after having rotated

the tyre of 180 ° compared to the rim (Fig. 52 ref. 2)

and the unbalance which can be obtained following the

directions of the machine (Fig. 52 ref. 3).