Page 1

Installation and Service KI-1480B

DAX60 60-Watt Power

Amplifier

DAX120 120-Watt Power

Amplifier

Rauland-Borg Corporation

Issued: 07/08/98

Page 1 of 18

Page 2

Copyright 1998 by Rauland-Borg Corporation, all rights reserved.

This document contains user’s information on technology that is proprietary to Rauland-Borg

Corporation. Permitted transmittal, receipt, or possession of this document does not express license or

imply any rights to use, sell, design or manufacture this information. No reproduction, publication, or

disclosure of this information, in whole or in part, shall be made without prior written authorization from

an officer of Rauland-Borg Corporation.

©

Rauland-Borg Corporation

Rauland-Borg Corporation

3450 West Oakton Street

Skokie, Illinois 60076-2958

(847) 679-0900

www.rauland.com

Page 3

Table of Contents

GENERAL INFORMATION.............................................................................................................................................. 4

ESCRIPTION

D

EVISION HISTORY

R

RAWINGS

D

ACKING LIST/UNPACKING PROCEDURE

P

NSTALLATION

I

..................................................................................................................................................................... 4

............................................................................................................................................................. 4

IAGRAMS, AND OTHER GRAPHICS

, D

.................................................................................................................. 5

.............................................................................................................................. 5

................................................................................................................................................................... 5

Rack-Mounting .............................................................................................................................................................6

Turret-Mounting (DAX6O only) .................................................................................................................................... 6

Input Connections......................................................................................................................................................... 7

Output Connections....................................................................................................................................................... 7

Selecting Balanced or Unbalanced Output Connections................................................................................................. 7

Grounding the Center Tap............................................................................................................................................. 8

Split-Center-Tap Operation........................................................................................................................................... 8

Auxiliary DC Power Supply........................................................................................................................................... 8

OWER CONNECTION

P

.......................................................................................................................................................... 9

Converting the Amplifiers to 240 VAC........................................................................................................................... 9

ETTING THE "INPUT LEVEL

S

EPLACING THE FUSE

R

NITIAL TROUBLESHOOTING

I

......................................................................................................................................................... 9

ONTROL

” C

.............................................................................................................................. 9

...............................................................................................................................................10

SERVICE INFORMATION ...............................................................................................................................................11

Locat in g the Tes t Po ints...............................................................................................................................................11

Measuring DC Voltages...............................................................................................................................................11

Measuring AC Voltag es................................................................................................................................................12

Locating the Driver and Power Transistors..................................................................................................................12

Removing and Replacing Transistors............................................................................................................................13

Testing Transistors.......................................................................................................................................................14

DAX6O Circuit Description .........................................................................................................................................14

DAX12O Circuit Description........................................................................................................................................14

APPENDIX A: LIMITED WARRANTY/SERVICE POLICY..........................................................................................17

IMITED WARRANTY

L

ERVICE POLICY

S

.........................................................................................................................................................17

................................................................................................................................................................18

Page 4

Description

The Rauland DAX Series amplifiers are designed for use with Rauland's

institutional program and communication Systems. They offer high-quality sound

and dependability. They can be driven to their rated power output by an input

signal as low as 0.3 volts. Their transformer-isolated, 25-volt balanced output

matches the output of Rauland's communication panels; they also have a 70.7-volt

balanced output. Their outputs can operate with a split center tap with Rauland's

Telecenter® 5000 and Responder® 3000 systems. The amplifiers are listed by

Underwriters Laboratories.

NKI1480B DAX60 and DAX120 Amplif ier s

General Information

—Installation

1

The DAX amplifiers offer helpful power connections for related equipment: three

120-VAC three-pin grounded outlets, and a floating auxiliary DC power output (28

VDC, 1.2 A) that can be used for Rauland's Director Series control panels,

preamplifiers, graphic equalizer, and other equipment.

The amplifiers come with black-enamel face panels. Optional brushed-chr o me

dress panels-the RP2525 (DAX6O) and RP2700 (DAX12O)—are available.

Revision History

This manual has been reformatted. No substantial changes were made during the

reformatting process.

Page 4 of 18 (Jul-98)

Page 5

NKI1480B DAX60 and DAX120 Amplif ier s

—Installation

Drawings, Diagrams, and Other Graphics

This document includes the following drawings, diagrams, and/or supplemental

graphics:

Transistor Replacement Drawing—Exploded (IL0253)

9

Packing List/Unpacking Procedure

Although the amplifier was thoroughly checked at the factory, we recommend that

you inspect the amplifier, the enclosed parts, and the shipping container for signs of

improper handling during shipment. In case of damage, immediately place a claim

with the dealer, the distributor from whom you purchased the unit, or—if the unit

was shipped directly to you—with the carrier.

The following parts are included with the amplifier:

Installation

The amplifier should be rack-mounted where there is adequate ventilation, a

moderate temperature, an AC power outlet, and provisions for grounding.

The rack should have the standard 19-inch width and a vertical space of at least 5

1/4 inches (DAX6O) or 7 inches (DAX12O). It is recommended that additional

space be left above and below the amplifier to prevent hum from being introduced

into adjacent equipment (such as preamplifiers), to provide additional ventilation,

Quantity Part Part Number

4

4 Rack-mounting screws for untapped holes (10

4

Rack-mounting screws for tapped holes (10-32

x ½ hex-head, SEMS, unslotted, machine)

x ½ pan-head, slotted, thread-forming)

#10 Tinnerman “U” type speed nuts for

untapped rack holes

WA202

WA102

AB1889

Page 5 of 18 (Jul-98)

Page 6

NKI1480B DAX60 and DAX120 Amplif ier s

and to allow easier access for ser vi cing. All owi ng an inch of space behind the

amplifier for connections, the rack requires a total depth of seven inches. A cooling

fan is recommended when the rack is enclosed and any of the following conditions

exists:

The combined rated output power of all the equipment exceeds 250 watts

9

or

RMS;

—Installation

The input from the AC power line exceeds 500 watts;

9

Restricted air f low in the rack may cr eat e extreme heat .

9

or

Important:

Failure to observe the preceding precaut ions cou ld result in overheat ing t hat co uld

damage the equipment or create a fire hazard.

Rack-Mounting

The DAX Series amplifiers are designed to be mounted into a standard 19-inch

rack. #10 "U" nuts (AB1889) and two kinds of mounting screws are supplied with

each amplifier.

1. If the rack's holes are

(WA102). Push the #10 "U" nuts, their flat side facing outward, onto the

proper holes in the rack. (you may have to leave the "U" nuts off if the holes

are extruded).

2. I f th e rack's holes are

untapped

tapped

, select the #10 thread-forming screws

, select the #10 machine screws (WA202).

Turret-Mounting (DAX6O only)

The rack-mounting procedures can be used to install the DAX6O in a Rauland

Control Turret. However, if the turret’s internal rails are used

oriented with its front panel facing the rear of the turret, an optional MK1O

Mounting Kit will be needed. This special-order kit must be installed by factorytrained personnel.

Important:

Do not connect AC power to the amplifier until all of the necessary input and

9

output connections have been completed.

Do not disconnect the third wire on the power plug. This wire grounds the

9

amplifier's chassis to prevent a possibl e shock hazard. If an adapter is used to

connect the plug to a two-prong socket, make sure that the amplifier’s chassis

is connected to a proven earth ground.

Page 6 of 18 (Jul-98)

and

the amplifier is

Page 7

NKI1480B DAX60 and DAX120 Amplif ier s

—Installation

Input Connections

The input is unbalanced. The input screw terminals are labeled "COM" (-) and

"INPUT" (+), r especti vel y. The t erminal st r ip is located on the lo wer ri ght corner,

as viewed from the rear of the chassis. The signal source should deliver at least 300

millivolts into a 13-kilohm load.

To prevent coupling, route the input cables as far from the speaker cables as

possible.

Output Connections

The output screw terminals are located on the upper right corner, as viewed from

the rear of the chassis. The following illustration shows how the output

transformer's split windings are connected with a factory-installed link for most

applications (for applications with the link removed, see "Split-Center-Tap

Operation," below).

Figure 1

The output impedances are as follows:

DAX60 70.7V = 83.3 ohms 25V = 10.4 ohms

DAX120 70.7V = 41.6 ohms 25V = 5.2 ohms

Selecting Balanced or Unbalanced Output

Connections

The balanced outputs for 70.7 volts and 25 volts are for speakers designed for

constant-voltage lines. Each speaker must have a line-matching transformer, and

the speakers must be connected in parallel. The impedance taps on the primaries of

the line-matching transformers indicate how much power will be taken from the

line. Speakers can be added as required until the total wattage absorbed by all of

the transformers is equal to the rated power output of the amplifier. However, it is

good practice to allow an amplifier a headroom of 10% to 20%. For a 60-watt

Page 7 of 18 (Jul-98)

Page 8

NKI1480B DAX60 and DAX120 Amplif ier s

amplifier, the maximum speaker load should be approximately 50 watts; for a 120watt amplifier, the maximum speaker load should be approximately 100 watts.

For unbalanced operation, place a jumper between one of the speaker terminals

and “GND." Do not ground the center tap when you use unbalanced operation.

—Installation

Grounding the Center Tap

If required by the installation, the center-tap terminals may be jumpered to the

"GND” terminal when the balanced speaker output is used. The "GND" terminal is

next to the negative "AUX POWER" terminal on the DAX6O; on the DAX12O,

the "GND" terminal is next to the "COM" input terminal. When the two center-tap

terminals are linked together, either one of them may be connected to the "GND"

terminal.

Important:

Do not install a jumper between "GROUND" and "CT" with the

speaker connection: connecting both points to "GROUND" would create a short

circuit across the output tr an s forme r

unbalanced

Split-Center-Tap Operation

The amplifier output transformer can be configured for split-center-tap operation

with symmetrical output voltages on both sides of the center tap. This is intended

for special applicat ions wi th Rauland syst em s such as th e T elecent er® 5000 and the

Responder® 3000. When a DAX amplifier is used with the TC5OOO or the

NCS3OOO, (a) no more than 50 watts of power may be drawn through the system,

and (b) a TC5007 Transformer Module is required (see KI-1486).

If the installation requires an isolated, split-center-tapped output, remove the

supplied link from the two "CT" terminals; this will separate the two halves of the

output windings (see "OUTPUT CONNECTIONS," above, and the attached

KMO7BO).

Important:

There is a large capacitor inside the TC5OOO and the NCS3OOO that provides a

low AC impedance across the center taps. The split windings are not designed to

be used independently.

Auxiliary DC Power Supply

The 28-VDC terminals (on the right side of the DAX6O; below the output

transformer of the DAX12O) can provide up to 1.2 Amperes to preamplifiers,

Director Series control panels, and other auxiliary devices requiring DC power.

Since this supply is floating, it can also be used for devices requiring an isolated

Page 8 of 18 (Jul-98)

Page 9

NKI1480B DAX60 and DAX120 Amplif ier s

power source, such as Rauland's Model 6430 Pink-Noise Source and Model 6431

1/3-Octave Equalizer. Do not mix floating and grounded accessories.

Power Connection

Plug the power cord into a 120-V, 60-Hz, three-wire grounded outlet that can

provide at least 935 watts (DAX6O) or 11O5 watts (DAX12O). Although the

amplifier circuits by themselves consume no more than 175 watts (DAX6O) or 345

watts (DAX120), connecting another device to the DC output could consume

another 40 watts of power, and a total load of 720 watts could be connected to the

three AC sockets. Check the local regulations before installing permanent AC lines

and plugging in the equipment.

—Installation

Converting the Amplifiers to 240 VAC

If operation from a 240-VAC power source is desired, remove the front cover and

locate the "120V/240V" switch inside the amplifier, on the right. Use a small

screwdriver to slide the switch to the "240V" side. Re-secure the front cover.

Replace the fuse with a fast- b low, 240-volt fuse with half the current rating of the

supplied fuse; the new value would be 1.25 Amps for the DAX6O, 2.5 Amps for

the DAX12O (see "REPLACING THE FUSE," below). Repl ace th e plug on the

power cord with one approved for 240-VAC operation.

Important:

When the amplifier is connected to a 240-volt supply, its three "120 VAC"

convenience outlets will supply 240 volts. Accordingly, they should not be used

when the amplifier is connected to 240 volts

Setting the "Input Level” Control

The input-level control, marked "LEVEL" on the rear chassis below the output

transformer, can be adjusted with a 1/4-inch flat-blade screwdriver: turning the

control clockwise will increase the output level. This control should be set so that

the maximum possible input signal will not cause the output to clip. After this

control has been adjusted by the installer, it should be left alone.

Replacing the Fuse

A current surge during operation may cause the fuse to blow. To restore power to

the amplifier, first ascertain what th e problem is and correct it before replacing the

Page 9 of 18 (Jul-98)

Page 10

NKI1480B DAX60 and DAX120 Amplif ier s

fuse. Use a fast-blow fuse: 2.5 Amps for the DAX6O, 5 Amps for the DAX12O

(but only half of these values if the amplifier is operating from a 240-VAC line).

The fuse holder is on the rear of the amplifier, below the power transformer. You

will need a Phillips screwdriver to remove the center plug; you may find a scissorsnosed pliers helpful in removing the fuse. If the replacement f u ses conti nue to

blow, unplug the amplifier and consult a qualified service representative.

Initial Troubleshooting

Consult the following troubleshooting table when experiencing any difficulties:

Problem Possible Causes

Low volume or distorted sound.

—Installation

Check whether all the input and output

connections are properly made and fastened.

Turn the volume down to determine if the

speakers are being overdriven.

Make sure the power cord is plugged in to an

operating outlet.

Amplifier does not operate.

The 28-VDC output cycles off

and on, or remains off.

Examine the input and output lines for (1)

obvious shorts (among themselves and between

them and the chassis or surrounding equipment)

and/or (2) broken connections.

Replace th e fus e, if all else checks o u t.

Unplug the unit and contact your local

distrib u t o r (if all els e fai ls).

There are two circu i t breakers protecting t h i s

output. CB2 is a 1.6-Amp thermal breaker that

shuts down t h e circui t when the DC curren t

flow sign i fi can t l y exceeds t h e o u tput ’s 1. 2 ampere rating, then automatically resets. It will

continue cycling off and on until the problem is

corrected. If t h e am pli f i er rem ai n s off, CB l

(3.15 Amps) may have tripped. Check for a

short in the connections; then try manually

resetting CB1—by poking a small screwdriver

through the access hole in the front cover (at the

upper left corner of the DAX6O,or the lower

left corner of th e DAX12 O).

If the problem does not lie in the load or the

connections, one of the breakers may be

defective. Disconnect the load and call your

Rauland distributor.

Page 10 of 18 (Jul-98)

Page 11

NKI1480B DAX60 and DAX120 Amplif ier s

—Installation

2

Service Information

Do not attempt to service your amplifiers unless you are an authorized technician.

Important:

T

he information that fo llows is inte nded for qualified service technicians only

Locating the Test Points

Whenever possible, take the voltage readings on the large connector on the main

printed circuit board. You will have to remove the front cover to access it.

The DAX6O has a single 16-pin connector labeled "T” on the schematic; the pins

are numbered from bottom to top on the board.

The DAX12O has two 16-pin connectors: the top connector and the top half of the

bottom connector are referred to as "J1" on the schematic, and the rest of the

bottom connector is referred to as "J2" on the schematic. The pins are numbered 124 and 1-8, from top to bottom on the board.

Measuring DC Voltages

DC voltages are printed in rectangular boxes at various points on the schematic.

When measuring these voltages on the am pl ifier , use a DC met er with a resist ance

of 1 megohm per volt and proceed as follows:

Step 1

is present at the input terminals. Disconnect the speakers and connect a suitable

resistive load in t hei r place:

DAX6O: The load should have at least a 60-watt power rating and a value of 10.4

ohms across the 25-volt output or 83.3 ohms across the 70.7-volt output.

DAX12O: The load should have at least a 120-watt power rating and a value of 5.2

ohms across the 25-volt output or 41.6 ohms across the 70.7-volt output.

. Place the amplifier on a suitable work surface and make sure that no signal

Step 2

Step 3

at Connector “T-14." As you locate each DC voltage on the schematic, note the

number of the nearest "T" terminal in that leg of the circuit and, if possible, take the

readings between such a "T" term i nal and “T-1 4."

. Plug the amplifier into a 12Q-VAC, 60-Hz source.

. On the DAX6O: Connect the meter's negative lead to the amplifier common

Page 11 of 18 (Jul-98)

Page 12

NKI1480B DAX60 and DAX120 Amplif ier s

On the DAX12O: Connect the meter's negative lead to the amplifier common at

Connector "J1-13." As you locate each DC voltage on the schematic, note the

number of the nearest "J" terminal in that leg of the circuit and, if possible, take the

readings between such a “J” terminal and "J1- 13."

—Installation

Measuring AC Voltages

AC voltages are printed without boxes at various points on the schematic. When

measuring these voltages on the amplifier, use an AC meter with a one-megohm

impedance and proceed as follows:

Step 1. Place the amplifier on a suitable work surface. Disconnect the speakers and

replace them with a suitable r esist i ve l oad:

DAX6O: The load should have at least a 60-watt power rating and a value of 10.4

ohms across the 25-volt output (or 83.3 ohms across the 70.7-volt output).

DAX12O: The load should have at least a 120-watt power rating and a value of 5.2

ohms across the 25-volt output or (41.6 ohms across the 70.7-volt output).

Step 2. Disconnect any input device and connect a one-kilohertz signal source in its

place. The source should be able to provide an amplitude of approximately 300

millivolts. Leave its output level turned down.

Step 3. Plug the amplifier into a 120-VAC, 60-Hz source. Turn the input-level

control fully clockwise, for maximum gain.

Step 4. Connect the test leads across the 25-V or 70.7-V outputs. Slowly increase

the output from the 1-KHz signal source until you obtain the rated output voltage

from the DAX. Check the input level required to obtain the rated output: a reading

of 300 millivolts or less is an indication that the amplifier gain is functioning

properly.

Step 5. On the DAX6O: Connect the meter’s negative lead to the amplifier common

at Connector "T-14." As you locate each AC voltage on the schematic, note the

number of the nearest "T" terminal in that leg of the circuit and, if possible, take the

readings between such a “T” terminal and "T-14."

On the DAX12O: Connect the meter's negative lead to the amplifier common at

Connector "J1-13." As you locate each AC voltage on the schematic, note the

number of the nearest "J" terminal in that leg of the circuit and, if possible, take the

readings between such a "J" terminal and "J1-13."

Locating the Driver and Power Transistors

On both amplifiers, driver transistors Q505 and Q506 are screwed to the "L"

bracket that is fastened t o the lar ge heat sink from i nsi de th e chassis. T he power

transistors (Q507-Q508 on the DAX6O, Q501-Q504 on the DAX12O) are fastened

directly to the large heat sink f r om the outside (t o access them, r em ove t he

protective cover). The transistors are numbered in ascending order, with the lowest

number at the bottom.

Page 12 of 18 (Jul-98)

Page 13

NKI1480B DAX60 and DAX120 Amplif ier s

—Installation

Removing and Replacing Transistors

Transistors are inherently long-lived devices that normally should not need

replacement. If, however, systematic troubleshooting indicates a problem, observe

these precautions when removing and replacing tr ansi stor s:

(1) Transistors can be damaged by excessive heat, so use a small soldering iron

when removing or replacing a transistor with solder connections.

(2) Transistors come with a wi de variety of cases and leads. T o avoid a costly

mistake, make a careful sketch of the lead connections before removing a transistor

from a printed circuit board or tie points.

(3) Before installing a power transistor (Q507-Q508 on the DAX6O, Q501Q504 on the DAX12O), obtain an appropriate Silpad® insulator. If a mica insulator

is used instead, coat both sides of it with silicone grease (Dow-Corning DC4 or an

equivalent). Fit the insulator between the transistor and the heat sink, as shown

below.

Figure 2

After installing a power transistor, check for a short circuit:

Step 1. On the DAX12O, isolate the circuit common from the chassis by

disconnecting the wire between the negative side of C503 (the large electrolytic

capacitor nearest the auxiliary 120-VAC outlets) and the star connector at the right

end of the amplifier (as viewed from the front). This capacitor is not grounded to

the chassis in the DAX6O.

Step 2. Use an ohmmeter to check for a short between the transistor case and the

heat sink. If there is a low-resistance r eadi ng, check t he i nsul at or, th e screws, et c. ,

as possible causes.

Page 13 of 18 (Jul-98)

Page 14

NKI1480B DAX60 and DAX120 Amplif ier s

Step 3. After obtaining a high-resistance reading (at least 100 kilohms) between

each transistor case and the heat sink, re-establish the connection between the

negative side of C503 and the standard connector (DAXI2O only).

—Installation

Testing Transistors

The best way to test a transistor is to use a transistor tester. However, if one is not

available, use an ohmmeter. Most failures result in a short or an open circuit

between the collector and the emitter.

Connect the ohmmeter leads to the collector and the emitter, then use the low ohm

range to read the resistance. If the reading in this range remains the same when the

leads are reversed, the transistor i s short ed. If the readings are “i nf in ite" for both

connections, the transistor is open.

DAX6O Circuit Description

Refer to the attached schematic, KC1546, to trace the circuit descriptions that

follow.

Input and Preamplifier Circuits: Resistor Ri and Capacitors Cl and C507 reject

Radio Frequency Interference (RFI). RV1 is the input LEVEL control

(potentiometer), which controls the signal level that is applied to the DAX's

preamplifier circuits. Capacitors C2 and C8 govern the low-frequency response of

the input signal, to protect horn-type speakers. Transistor Qi is a common-emitter

amplifier that provides the preamplifier gain. It is also a common-base inverter for

the feedback entering its emitter.

Power-Amplifier Circuits: Transistor Q2 is a high-voltage-gain amplifier that drives

Transistors Q3 and Q4. The latter are phase splitters that form a unity-gain

configuration. Diode D503 is a negative-temperature-coefficient device mounted

on the heat sink. This diode controls the DC bias for the drive and the output

transistors. Transistors Q505 and Q506 are current amplifiers (drivers) that supply

high base current to the output transistors, Q507 and Q508. The latter are push-pull

power amplifiers that drive the output transformer. Capacitor C506 blocks DC from

the output transformer and limits the low-frequency output to protect horn-type

speakers.

Protective Circuits: T her e ar e sever al pr ot ecti ons against excessive cur r ent .

Resistors R16 and R19 are current limiters; if a short occurs across the audio

output, each resistor will drop 10 VDC. An excessive current surge will cause the

fuse to open. In the 28-VDC supply, a short circuit on the DC output or a DC load

that draws significantl y m ore curr ent than 1.2 Amperes will cause ther m al Br eaker

CB2 to open within 70 seconds. It will try to reset within 15 seconds, then continue

opening and closing until the short or the excessive load is removed, at which time

it will remain closed for normal operation. A more serious problem will cause CB1

to open; it must be reset manually.

DAX12O Circuit Description

Refer to KC1547 (attached) to trace the circuit descriptions that follow.

Page 14 of 18 (Jul-98)

Page 15

NKI1480B DAX60 and DAX120 Amplif ier s

—Installation

Input and preamplifier circuits: Resistor R1 and Capacitors Cl and C507 filter

Radio Frequency Interference (RFI). RV1 is the input LEVEL control

(potentiometer), which controls the signal that is applied to the preamplifier

circuits. Capacitors C2 and C9 govern the low-frequency response of the input

signal, to protect horn-type speakers. Transistor Qi is a common-emitter amplifier

that provides the preamplifier gain. It is also a common-base inverter for the

feedback entering its emitter. Q2 is an emitter follower.

Power-amplifier circuits: Transistor Q3 is a high-voltage-gain amplifier that drives

Transistors Q5 and Q6. The latter, operating as phase splitters in a unity-gain

configuration, provide the drive for Transistors Q505 and Q506. Q505 and Q506

are the drivers for the output transistors (Q501-Q504). Diode D503 is a negativetemperature-coefficient device mounted on the heat sink. This diode controls the

DC bias for the driver and output transistors. Transistors Q501 through Q504 are

push-pull power amplifiers that drive the output transformer. Capacitor C505

blocks DC from the output transformer and limits he low-frequency output to

protect horn-type speakers.

Protective circuits: There ar e sever al pr otect ions agai nst excessi ve cur r ent.

Transistors Q4 and Q7 are current limiters. If a short occurs across the audio

output, the following sequence of events will occur: (1) the DC voltage across

Resistors R29 and R32 will drop; (2) this drop will drive Transistors Q4 and Q7

into conduction; (3) the output of Q4 and Q7 will limit the drive to Transistors Q5

and Q6; and (4) the reduced output from Q5 and Q6 to the power transistors will

reduce the overall gain (and, thereby, the total power) of the amplifier. An

excessive current surge will cause the fuse to open. In the 28-VDC supply, a short

circuit on the DC output or a DC load that draws significantly more current than

1.2 Amperes will cause Thermal Breaker CB2 to open within 70 seconds. It will try

to reset within 15 seconds, then continue opening and closing until the short or the

excessive load is removed, at which time it will remain closed for normal

operation. A more serious problem will cause CB1 to open; it must be reset

manually.

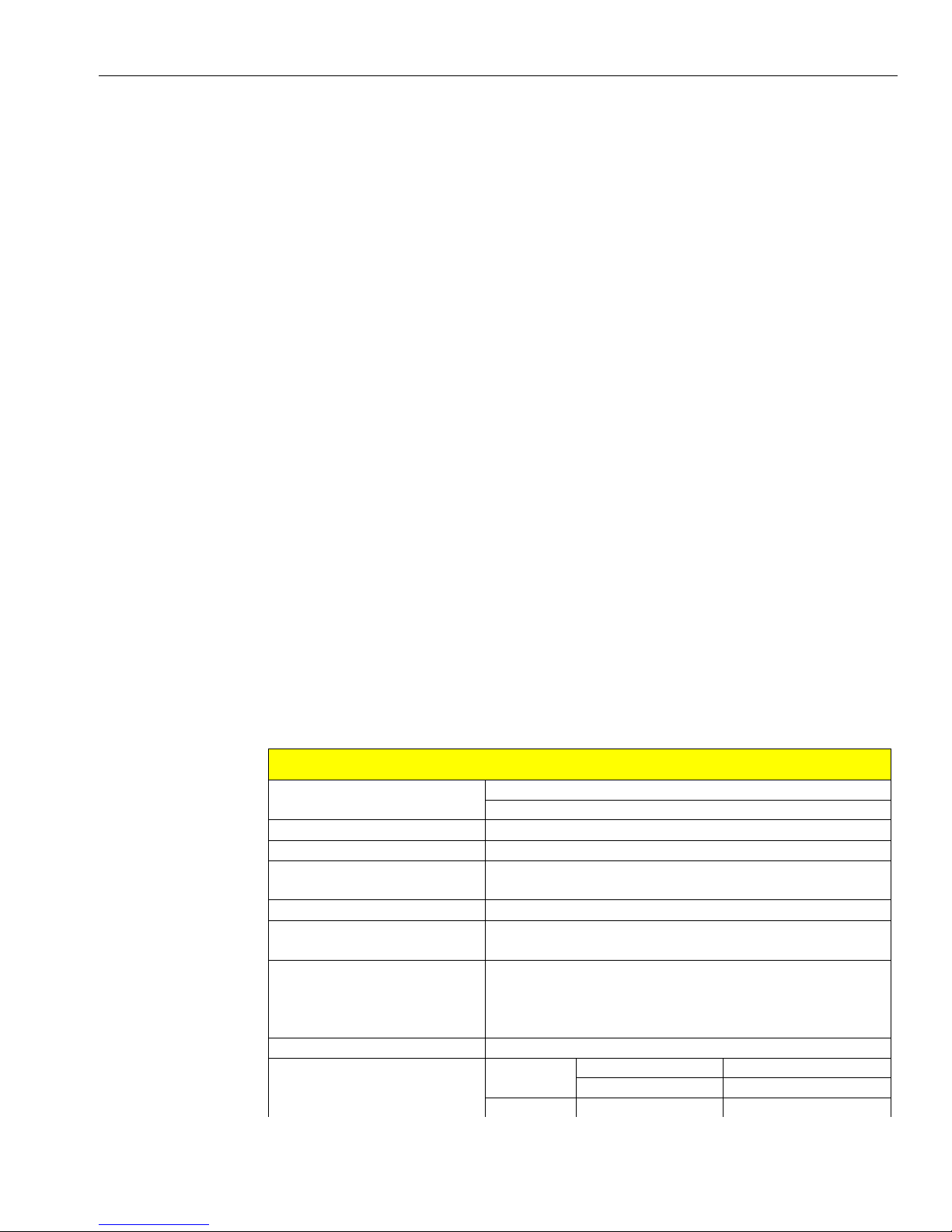

Rated Power Outpu t

Frequency Response

Harmonic Distortion

Noise Level

Input Impedance

Input Sensitivity for Rated

Power Outpu t

Power Requi remen ts

Auxiliary DC Output

AC Power Consumption

(28 VDC Auxiliary Output

Disconnected)

Page 15 of 18 (Jul-98)

Specifications

DAX6O: 60 watts RMS

DAX12O: 120 watts RMS

+-1.5 dB from 40 Hz to 15 kHz at -3 dB from RPO.

Less than 3% from 60 Hz to 15 kHz

84 dB with LEVEL control at maximum setting 90dB

with LEVEL control at minimum setting

13 kilohms

0.3 V

DAX6O: 105-130 VAC, 60 Hz, 935 watts

(including the AC and DC outputs)

DAX12O: 105-130 VAC, 60 Hz, 1105 watts (including

the AC and DC outputs)

Supplies 1.2 Amperes at 28 VDC

DAX60 DAX120

No Signal 12 Watts 12 Watts

1/3 RPO 105 Watts 210 Watts

Page 16

NKI1480B DAX60 and DAX120 Amplif ier s

Full RPO 175 Watts 345 Watts

AC Power Consumption

(28 VDC Auxiliary Output

Fully Loaded)

AC Convenience O u tl ets

Operating Temperature

Line Protecti o n

28 VDC Protection

No Signal 50 Watts 50 Watts

1/3 RPO 145 Watts 250 Watts

Full RPO 215 Watts 385 Watts

720 watts maximum

0

0

F to 1300F (-17.8-00C to 54.40C)

Fast-blow fuse: 2.5A (DAX6O), 5A (DAX12O)

1.6-Amp thermal breaker, auto reset;

3.15-Amp breaker, manually reset

DAX6O: 19" W, 5-1/4" H, 6-1/2" D (48.3 cm x 13.3 cm

Size

x 16.5 cm)

DAX12O: 19" W, 6-3/4" H, 6-1/2" D (48.3 cm x 17.2

cm x 16.5 cm)

Unit Weight

DAX6O: 23 lb. (10.42 kg)

DAX12O: 27lb (12.23 kg)

—Installation

DAX60 DAX120

Page 16 of 18 (Jul-98)

Page 17

NKI1480B DAX60 and DAX120 Amplif ier s

Warranty/Service Policy

Limited Warranty

—Installation

A

Appendix A: Limited

This warranty supersedes any warranty or guarantee that may appear on any printed

material packed with any product or any warranty or guarantee previously issued

by Rauland-Borg Corporation.

Rauland-Borg Corporation warrants equipment manufactured by it to be free from

defects in material and workmanship arising from normal usage for a period of one

year from date of shipment by Rauland-Borg.

Our obligation under this warranty is limited to repairing any such defect and/or

replacing any such defective part, provided the unit and/or the defective part is

returned to us, transportation prepaid, within one year after date of original

shipment by Rauland-Borg and found by our inspection to be defective in materials

and workmanship. The obligation of Rauland-Borg Corporation is limited to the

above and does not include either the cost or the furnishing of any labor in

connection with the repair of any such defect and/or replacement of any such

defective part unless accompl ished at Rauland- Bor g, nor does it include

responsibility for any transportation expense.

This warranty is extended only to the original purchaser chaser from Rauland-Borg

and is not transferable, and covers only equipment either installed by or under the

direct supervision of a factory-trained arid authorized Rauland distributor. This

warranty does not extend to any product which has been subject to misuse, neglect,

accident, improper repair, or alter at ion. Accessor ies not of our manuf acture used

with this equipment are not covered by this warranty.

All implied warranties, including but not limited to implied warranties of fitness

and merchantability, are limited in duration to a period ending one year from the

dale of shipment by' Rauland-Borg.

Page 17 of 18 (Jul-98)

Page 18

NKI1480B DAX60 and DAX120 Amplif ier s

All material returned to Rauland-Borg Corporation under this warranty must be

accompanied with informati on concerning the nature of the defect, the original date

of shipment, original invoice number, and, if a defective component, the model

number of the unit from which it was removed.

This warranty is in lieu of all other agreements arid warranties, general or special,

expressed or implied, and no representative or person is authorized to assume for us

any other liability in connection with the sale or use of our products.

Service Policy

The entire Rauland-Borg organization is interested in the proper maintenance of

your equipment for as long as you own it. Our national network of Rauland-Borg

distributors is at the service of all purchasers of our products.

Should you have a problem with your equipment, or require any advice or

assistance, contact your local Rauland-Borg distributor. If you are not able to locate

a local Rauland-Borg distributor, the information or action that you want can be

obtained by writing to our Sales Engineering Department, at the address shown

above.

—Installation

No end-user replaceable components are contained within this equipment. Refer

servicing to your local Rauland-Borg distributor.

Important:

Any attempt at self-service of this equipment may result in exposure to electrical

shock, or in extensive damage to the equipment and possible voiding of the

equipment warranty.

Page 18 of 18 (Jul-98)

Loading...

Loading...