Page 1

Pi Cruiser Assembly Instructions

Tools needed

• A PH #1 screwdriver is required for most assembly. Included in the kit

• A small plier to hold the nuts

• A smaller screwdriver (PH #00) is required for attaching the ultrasonic sensor to the

mounting plate

Page 2

Caster Wheel Assembly

• Identify the bottom plate

o Attach the two caster wheels to the bottom plate using eight M3 x 8 screws and

nuts. You may have to hold the nuts using a plier while using the screw driver.

o Attach two 20-mm hexagonal standoffs (female-female) for the line sensor array

using two M3 x 8 screws.

Page 3

Line Sensor Assembly

o Connect five wires to the line sensor as shown. One for power, one for ground

and three are signal wires from each sensor.

o Notice the line sensor assembly can be mounted in one of the two sides (servo

wheel side or caster wheel side) depending upon your need.

o Attach the line sensor array using two screw M3 x 8 screws.

Route the wires through the slot.

Set aside this subassembly for now.

Page 4

Servos

• Locate the chassis

o Position a servo motor on the slot as shown. Notice how the servo wires are

oriented. Make sure servo motor tab is outside the chassis.

o Secure the servo using four M3 x 10 screws and nuts. To make assembly easy,

start with the lower screw and then go to the upper screw. Do not tighten the

screws until all the screws are in place and the servo is secured properly. Once all

the screws are in, tighten it. If the nuts spin, you may need to use a plier to hold

the nut as you tighten the screw.

o Secure the second servo exactly as the first servo. Do not flip the servo. Make

sure the wires are oriented in the same direction as the first servo.

Page 5

o Attach the wheels to the servo using two small black screws that come with

servos.

Page 6

Brackets

• Locate the two brackets. They are in a bag with rotating flanges.

o Keep the brackets on top of the chassis lining up with the holes and using two M3

x 8 screws secure the brackets

Page 7

Install the Battery

• Place two weather strips or similar material in the slot designed for battery.

• Route the battery power wire through the slot (along with the servo wires). The battery

charger cable can be secured to the underside of the chassis.

Page 8

• Place the battery in the compartment in a way that the battery wires come out of the open

side of the compartment and are close to the slot on the right. Refer to the photo.

• Close underside of the chassis using the plate. Make sure the eight holes on the plate are

aligned with the screw posts on the chassis. Place all the screws. Don’t tighten them

until all the screws are in place.

Page 9

• Turn your chassis and place it on a flat surface. Your chassis supported by two servo

wheel and casters must be stand even and sturdy.

Page 10

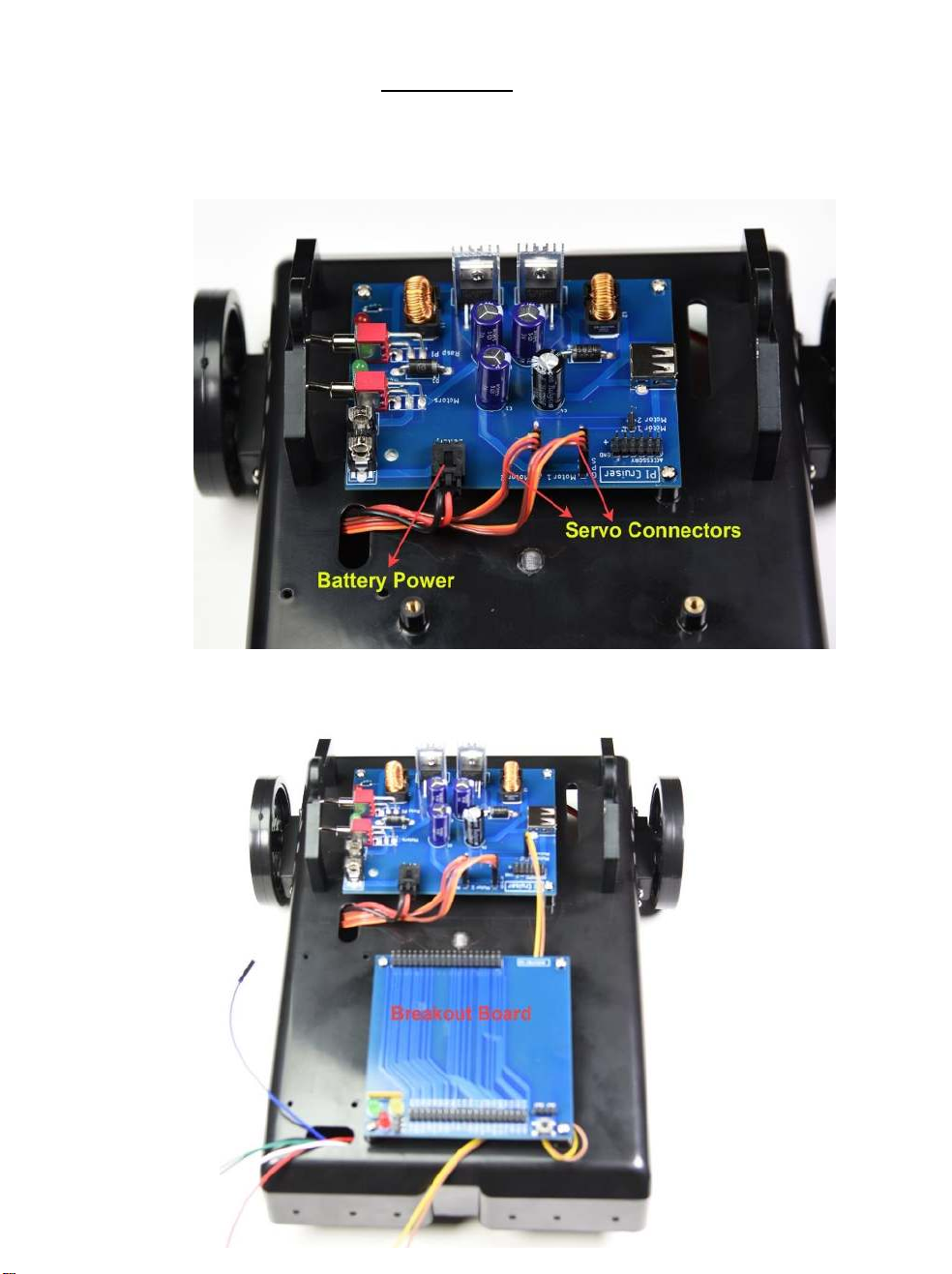

Electronics

• Mount the power board using three or four M3 x 8 screws on the top of the chassis as

shown. Be careful not to damage the electronic components while tightening the screws.

• Connect the servos to the Motor 1 ad Motor 2 ports.

• Connect battery power to the board

• Mount the break out board using four M3 x 8 screws on the top of the chassis as shown.

• Connect two female-female jumper wires to the power board

Page 11

• The servo motors can be attached to any of the two motor ports on the power board. We

will use M1 and M2 corresponding GPIO 13 and GPIO 18.

• Attach the mini-bread breakout board on the available space on the break bard.

Page 12

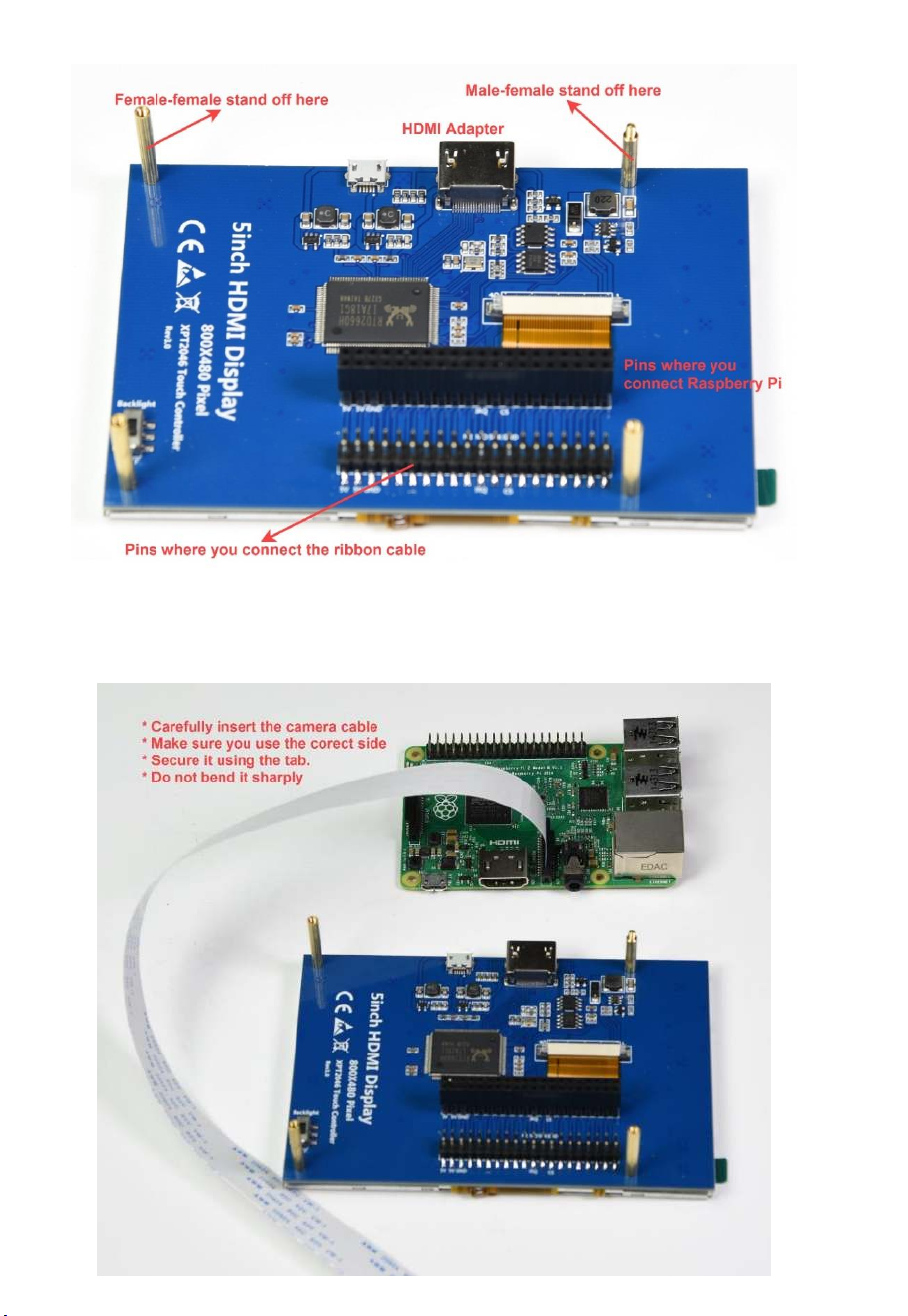

LCD Screen assembly

• Open the LCD screen and Raspberry Pi from their boxes. Keep the ribbon cable, the

acrylic LCD mount, and the SD card handy. Raspberry Pi not included in the kit.

o Turn over the LCD screen

Page 13

o Attach the three female-female standoffs and one female-male standoff

o Secure the camera cable on your Raspberry Pi properly. Make sure you use the

correct side.

o Route the camera cable as shown (to the left). Do not sharply bend the cable.

Page 14

o Carefully insert the 40-pins of Raspberry Pi onto the LCD screen. Make sure you

are doing it properly, so the HDMI adapter of the Pi and the LCD monitor are

aligned, and the standoff goes through the hole in the board.

o Attach the HDMI adapter connecting the monitor and the Pi.

o Secure the 5 mm standoff.

o Insert the SD card. Make sure you are inserting in the right direction. Forcing he

SD card may damage it.

o Attach the ribbon cable to the male headers on the LCD screen carefully as

shown. If you bend the pins, your screen won’t work.

Page 15

o Route the cable through the slot in the acrylic monitor mount.

o Secure the acrylic mount to the monitor using four M2 x 5 screws.

o Attach the rotating flanges to the brackets using two large thump screws.

o Secure the monitor assembly to the rotating mount using four M3 x 8 screws.

Page 16

Complete the assembly

o Attach the ribbon cable to the male headers on the breakout board. Make sure pins

are aligned before applying pressure. Insert the pins fully.

o Connect the power cable. DO NOT USE ANY OTHER CABLE. This is

a specially designed cable to provide power for Raspberry Pi and the LCD

monitor. Other power cables won’t work. Power cable goes from the USB port on

the power board the micro USB port on the Raspberry Pi board.

The assembly of your basic robot is now complete. If you haven’t already, attach

the two wires coming out of Motor 1 and Motor 2 ports from the power board to

GPIO 13 and GPIO 18 on the breakout board. You can now program your robot to

move. You can use the breadboard area to create your circuits.

Page 17

Ultrasonic sensor and LEDs Assembly

• Find the ultrasonic sensor, sensor plate, LED holders, two LEDs and keep them ready.

o Install the ultrasonic sensor in the mount using our M1.6 x 6 screws and nuts as

shown. These screws and nuts are very tiny so you can easily lose them. You

need the smaller screw driver for this step. You can accidentally drop the nut

or a screw and may never find it so watch out. Be careful not to damage the

electronic components on the back side of the ultrasonic sensor. This can happen

when you use a plier to hold the nut in pace.

o Attach two LEDs using the LED holder to the ultrasonic sensor mount. First insert

the LED holder from the front of the mount. Insert the LED from the back of the

mount with a slight push.

o Secure the ultrasonic sensor-LED assembly to the chassis using two M3 x 10

screws and nuts. You can mount this assembly in any of the three location on the

front side or back side. Depending upon where you mount, you may need to use

longer wires for the sensor and the LEDs.

Page 18

Camera Assembly (Camera not included in the kit)

• Raspberry Pi camera is very sensitive to static electricity. Make sure you ground yourself

before handling the camera.

o Mount the camera unit on the plate using four M2 x 5 screws and nuts. Handle

the camera gently and don’t apply too much pressure when you are securing.

Make sure the camera cable slot is facing down.

Page 19

o Secure the camera assembly to the chassis using two M3 x 10 screws and nuts.

Your robot is now ready for programming fun.

Page 20

Ultrasonic sensor - wiring diagram

Wiring line sensor array - wiring diagram

Loading...

Loading...