RASOR GRT12DT Use Manual

USE MANUAL

Enfocus Software - Customer Support

English

CUTTING UNIT

MOD. GRT12DT

ED.1-04/13

COMPANY

Enfocus Software - Customer Support

Rasor® Elettromeccanica S.r.l. was established in Milan in 1946 by the two promoting partners

Spinelli and Ciminaghi. For more than sixty years it has been producing automatic cutting

systems, cutting units for textile applications and electric and pneumatic cutters.

EN

18

Initially considered as a point of reference for cutting systems in the

textile applications, the Rasor

other fields: chemical, automotive, nautical and sport sectors and in

furniture manufacturing.

®

Rasor

can rely on the professional continuity of three generations,

®

products are nowadays widely used in

thanks to the precious support of the promoting partner, to his passion,

dedication and great experience of seventy years.

The main characteristic of Rasor

of the product up to its packing and delivery is carried out in Rasor

operators who have professionaly grown up following the spirit of the company and of its

founders. This ensures the high quality which Rasor

®

is that each working phase, starting from the manufacturing

®

has always considered as essential

®

premises by qualified

since the beginning of its activity.

Following the innovative spirit mentioned above, our company is constantly focused on the

improvement of the product quality, on the study and development of new materials and

technologies.

AKNOLEDGEMENT

Dear Customer,

thank you for choosing a Rasor

®

has been a reference point in the field of cutting systems in the textile, clothing,

Rasor

®

Elettromeccanica S.r.l. product.

furniture, tailoring, sport, chemical, automotive, nautical and insulating material sectors for

years. Its production has been always synonymous with reliability attested by many of

satisfied customers.

®

quality system supervises all the company activities in order to provide the Customer

Rasor

with a service that meets its needs and expectations in terms of product quality, delivery

reliability and stock of finished products.

All the parts of the devices have been planned and produced to guarantee an optimum

performance. In order to keep the high quality level and the long reliabilty of the Rasor

products, it is recommended to use only original spare parts and to contact the head

office for any maintenance work.

®

1. GENERAL SAFETY RULES

Enfocus Software - Customer Support

This manual is an integral part of cutting unit GRT12DT and must be carefully

read before using it since it gives important indications with regards to its safe

installation, use and maintenance. Keep it with care.

Before using cutting unit GRT12DT, read carefully the following general safety

rules.

• PACKAGING.

After taking off the packaging make sure that the cutting unit is intact. In

case of doubt do not use it and contact an authorized service centre. Do not

leave pieces of packaging (plastic bags, foam polystyrene, boxes, etc.) within

the reach of children or disabled persons since they are potential sources of

danger.

• AVOID DANGEROUS ENVIRONMENTS.

Prevent the cutting unit GRT12DT components from coming in contact with

damp or wet surfaces.

• KEEP CHILDREN AWAY.

Unauthorized persons, in particular children, must be kept away from the

working area.

•FEED CABLE.

Prevent the feed cable from coming in contact with hot objects, pointed

surfaces or sharp edges. Never pull the feed cable of the machine. It must

never be replaced by the user. If necessary contact professionally qualified

staff.

• KEEP THE WORKING AREA ALWAYS IN ORDER.

The workplace must always be kept in order and well lightened; liquids or oil

traces must not be present.

• ALWAYS USE CUTTING UNITS GRT12DT PROPERLY.

Use the cutting units only to carry out the works they have been designed

for; do not use them improperly.

• OBSERVE THE USE OF THE TOOLS.

Do not cut excessively thick materials and always check blade conditions.

• AVOID ACCIDENTAL STARTINGS.

Before connecting cu tting unit GRT12DT, make sure that eve rything is ins talled

properly.

• CLOTHING.

Do not use large clothes or accessories that might get stuck in the moving

parts.

• GOGGLES AND PROTECTIVE METAL MESH GLOVES.

Always use goggles, protective metal mesh gloves approved by Rasor

use and maintenance operations (according to UNI EN 388:2004 standard).

•SPARE PARTS.

During maintenance and replacement operations use only original spare parts.

Blade maintenance must be only performed by Rasor

®

technicians.

• INSTALLATION.

Any installation that is not in conformity with these

specifications could jeopardize your safety and cancels the

warranty.

®

during

EN

19

Informative letter

Enfocus Software - Customer Support

The installer and the maintenance man must know the content of this manual. Although

the main features of the machine described in this manual are not subject to change,

®

Rasor

Elettromeccanica S.r.l. reserves the right to modify the components, details

and accessories it deems necessary to improve the machine or to meet manufacturing

or commercial requirements at any time and without being obliged to update this

manual immediately.

EN

20

WARNING

ALL RIGHTS ARE RESERVED ACCORDING TO THE

INTERNATIONAL COPYRIGHT CONVENTIONS,

The reproduction of any part of this manual, in any form, is forbidden without

the prior written authorization of Rasor

The content of this guide can be modified without prior notice. Great care has

been taken in collecting and checking the documentation contained in this

manual to make it as complete and comprehensible as possible.

Nothing contained in this manual can be considered as a warranty, either

expressed or implied - including, not in a restrictive way, the suitability warranty

for any special purpose. Nothing contained in this manual can be interpreted as a

modification or confirmation of the terms of any purchase contract.

®

Elettromeccanica S.r.l. machines have not been conceived to work in areas at risk of

Rasor

explosions and at high risk of fire and they cannot cut wet or damp materials. Moreover, they

cannot work in case of rain.

In case of damage or malfunction, cutting unit GRT12DT must not be used until the Customer

Care Technical Service has repaired them.

®

Elettromeccanica S.r.l.

Customer Care Technical Service

For any information, please contact

®

RASOR

ELETTROMECCANICA S.r.l.

Via V. Caldesi, 6; 20161, MILANO (MI) - ITALY

Tel: +39.02.66221231; Fax: +39.02.66221293

e-mail: info@rasor-cutters.com

web: www.rasor-cutters.com

WARNING

The original configuration of the cutting unit must not be changed at all.

On receiving the machine make sure the supply corresponds to what has been ordered.

In case of non-compliance immediately inform Rasor

®

.

Also make sure the cutting unit has not been damaged during transport.

2. TRANSPORT AND PACKING

Enfocus Software - Customer Support

The cutting unit is delivered in a cardboard box, inside which there are various options. The

code of the ordered product and its serial number are indicated outside the package (see

picture 1). The following accessories are contained in a bag inside the package:

1) Poligonal blade;

2) Butterfly wrench for blade nut disassembly;

3) Drift for blade disassembly.

1

3

2

EN

21

1

2

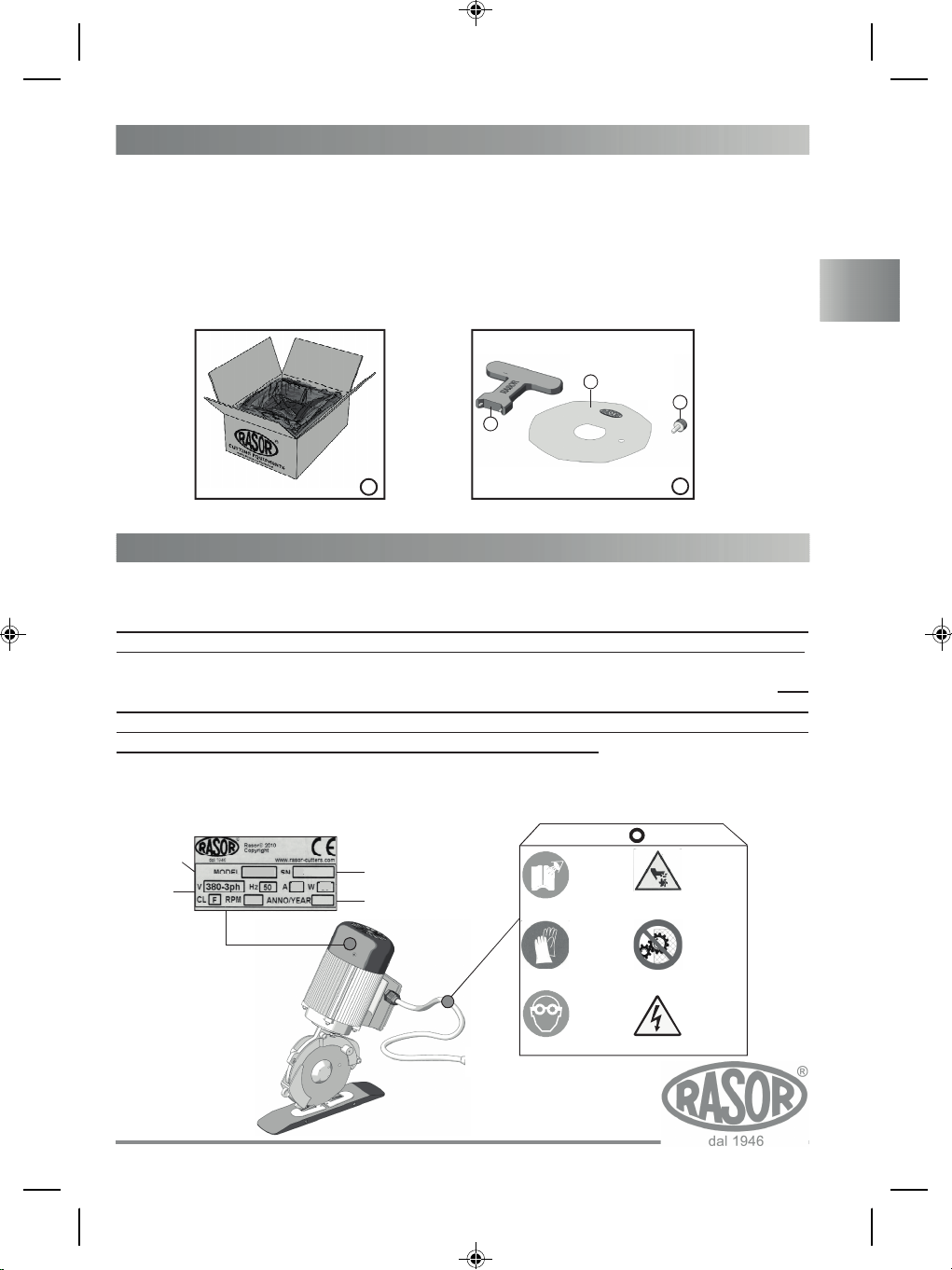

3. PLATE DATA

The manufacturer's identification and EC STANDARD 2006/42/EC conformity plate (see picture

below) is located on the front part of the cutting unit.

The plate must not be removed at all, even if the machine is resold. Always refer to

the serial number written on the plate itself when contacting the manufacturer.

Several safety warnings are printed on a card which is applied to the cutting unit feeding

cable; such warnings must be strictly followed by everyone dealing with the machine. The

company is not to be held responsible for damage to property or accidents to

people which might occur if the above-mentioned warnings are not observed. In

such a case, the operator is the only person responsible.

Model

Electric data

GRT12DT

12

M

0,52

400 2___

180

Serial number

Year of production

READ

THE

INSTRUCTION

MANUAL

USE

METAL

GLOVES

USE

GOOGLES

SHEARING

RISK

DO NOT

REMOVE

THE SAFET Y

DEVICES

HIGH

VOLTAGE

Loading...

Loading...