Page 1

PNEUMATIC SCISSORS

USE MANUAL

FP862

MT

Page 2

2

EN

THE COMPANY

ACKNOWLEDGMENT

Rasor®Elettromeccanica S.r.l. was established in Milan in 1946 by the two promoting partners

Spinelli and Ciminaghi. For more than sixty years it has been producing automatic cutting

systems, cutting units for textile applications and electric and pneumatic cutters.

Initially considered as a point of reference for cutting systems in the

textile applications, the Rasor

®

products are nowadays widely used in

other fields: chemical, automotive, nautical and sport sectors and in

furniture manufacturing.

Rasor

®

can rely on the professional continuity of three generations,

thanks to the precious sup port of the promoting partner, to his passion, dedication and

great experience of seventy years.

The main characteristicofRasor

®

is thateach workingphase, starting from the manufacturing

of the product up to its packing and delivery is carried out in Rasor

®

premises by qualified

operators who have professionaly grown up following the spirit of the company and of its

founders. This ensures the high quality which Rasor

®

has always considered as essential

since the beginning of its activity.

Following the innovative spirit mentioned above, our company is constantly focused on the

improvement of the product quality, on the study and development of new materials and

technologies.

Dear Customer,

thank you for choosing a Rasor

®

Elettromeccanica S.r.l. product.

Rasor

®

has been a reference point in the field of cutting systems in the textile, clothing,

furniture, tailoring, sport, chemical, automotive, nautical and insulating material sectors for

years. Its prod u ction has been always synonymous with reliability attested by m any of

satisfied cust omers.

Rasor

®

quality system supervises all the company activities in order to provide the Customer

with a service that meets its needs and expectations in terms of product quality, delivery

reliability and stock of finished products.

All the parts o f t he devi ces have been plan ned and pro duced to gua rantee an optimum

performance. In order to keep the high quality level and the long reliabilty of the Rasor

®

products, it is recommended to use only original spare parts and to contact the head

office for any mainte nance work.

Page 3

EN

3

1. GENERAL SAFETY RULES

This manual is an integral part of pneumatic scissors FP862MT and must be

carefully read before using it since it gives important indications with regards

to its safe installation, use and maintenance. Keep it with care.

Before using pneumatic scissors FP862MT, read carefully the following general

safety rules.

• PACKAGING.

After taking off the packaging make sure that the machine is intact. In case

of dou bt do not use it and conta ct an au th oriz ed service centre. D o not leave

pieces of packag ing (plastic bags, foam polystyrene, bo xes, etc.) within the

reach of children or disabled persons since they are potential sources of danger.

•AVOIDDANGEROUSENVIRONMENTS.

•KEEPCHILDRENAWAY.

Unauthorized persons, in particular children, mu st be kept awa y from the

working area.

• KEEP THE WORK ING AREA ALWAYS IN ORDER.

The workplace must always be kept in order and well lightened.

•

ALWAYS USE PNEUMATIC SCISSORS FP862MT PROPERLY.

Use the scissors only to carry out the works they have been designed for; do

not use them improperly.

•OBSERVETHEUSEOFTHETOOLS.

Do not cut excessively thick materials and always check blade conditions.

•

AVOID ACCIDENTAL STARTINGS.

Before connecting pneumatic scissors FP862MT, make sure that everything

is installed properly.

• CLOTHI NG.

Do not use large clothes or accessories that might get stuck in the moving

parts.

• GOGGLES AND PROTECTIVE METAL MESH GLOVES.

Always us e goggles, pro tective m eta l mesh glov es approved by Ra so r

®

during

use and maintenance opera tions (according to UNI EN 388 :2004 standard).

•SPAREPARTS.

During maintenance and replacement operations use only original spare parts.

Blade maintenance must be only performed by Rasor

®

technicians.

• INSTALLATION.

Any installationthat is not in conformitywith these specificationscould jeopardize

your safety and cancels the warranty.

Page 4

4

EN

The original configuration of the pneumatic scissors must not be changed at all.

On receiving the machine make sure the supply corresponds to what has been ordered.

In case of non-compliance immediately inform Rasor

®

.

Also make sure the scissors have not been damaged during transport.

Customer Care Technical Service

WARNING

Informativeletter

WARNING

The installer and the maintenance man must know the content of this manual. Although

the m a i n featu r e s of the mach ine described in t h i s m a nual are not subject to cha n ge ,

Rasor

®

Elettromeccanica S.r.l. reserves the right to m odify the components, details

and accessories it deems n ecessary to improve t he machine or to meet manufacturing

or commercial requirements at any tim e and without being obliged to update this

manual imm ediate ly.

ALL RIGHTS ARE RESERVED ACCORDING TO THE

INTE R NATIONALCOPYRIGHTCONV E NTIONS,

The reproduction of any part of this manual, in any form, is forbidden without

the prior written authorization of Rasor

®

Elettromeccanica S.r.l.

The content of this guide can be modified without prior notice. Great care has

been taken in collecting and checking th e documentation contained in this

manual to make it as complete and comprehensible as possible.

Nothing con ta in ed in this man u al can be con si dered a s a w arranty, eit he r

expressed or implied - including, not i n a restrictive way, the suitability warranty

for any special purpose. Nothing contained in t his manual can be interpreted as a

modification or confirmation of the term s of a ny purchase contract.

Rasor

®

Ele tt r om e cc an i ca S .r.l. machi nes have not been conce ived to work in areas at ri sk of

explosions and at high risk of fire.

In case of damage or malfunction, pneumatic scissors FP862MT must not be used until the

Customer Care Technical Service has repaired them.

For any information, please contact

RASOR

®

ELETTROMECCANICAS.r.l.

ViaV. Caldesi, 6; 20161, MILANO(MI)- ITALY

Phone: +39.02.66221231; F ax:+39.02.66221293

e-mail: info@rasor-cutter.com

web: www.rasor-cutters.com

Page 5

EN

5

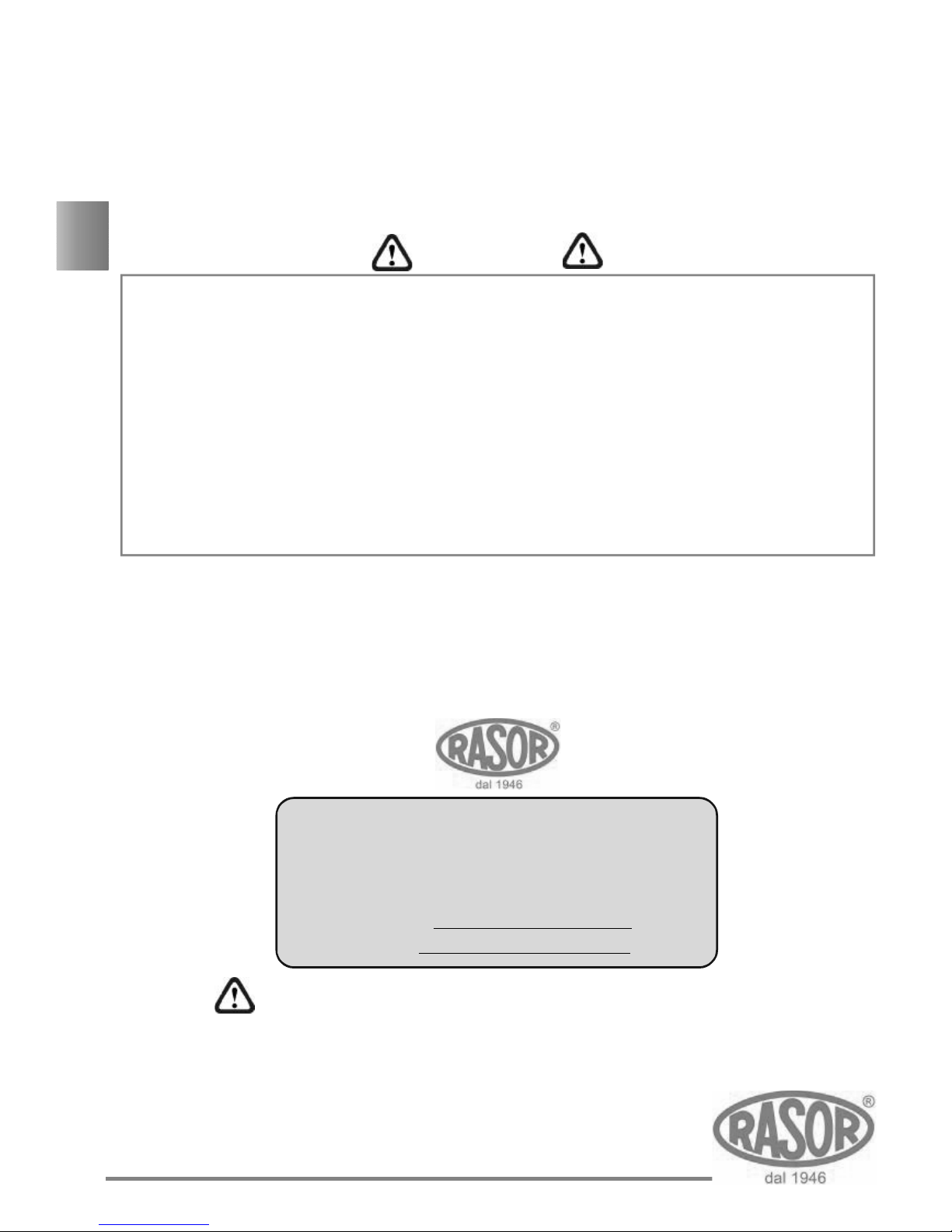

2. TRANSPORT AND PACKING

2

2

3. PLATE DATA

1

Serial number

Year of production

Model

Motor data

READ THE INSTRUCT ION MANUAL

USE METAL GL OVES

USE GOGGLES

SHEARIN G RIS

DO NOT REMOVE THE SAFETY

DEVICES

3

The pneumatic scissors are delivered in a cardboard box, inside which there are various

optionals. The code of the ordered product and its serial number are indicated outside the

package (see picture 1). The following accessories are contained in a bag inside the package:

1) Octagonal blade (8 sides);

2) Butterfly key for blade nut disassembly;

3) Drift for blade disassembly.

The manufacturer's identification and 2006/42/EC STANDARD conformity plate (see picture

below) is located on the front part of the pneumatic scissors.

The plate must not be removed at all, even if t h e machine is resold. Always refer to the serial

number (written on the plate itself) when contacting the manufacturer.

Several safety warnings are printed on a card which is applied to the scissors feeding cable;

such warnings must be s t rictly followed by everyone dealing with the machine. The company

is not to be held responsible for damage to property or accidents to people which might

occur if the above-mentioned warnings are not observed. In such a case, the operator is the

only person responsible.

MT

1

FP862MT

MT

1400

Page 6

6

EN

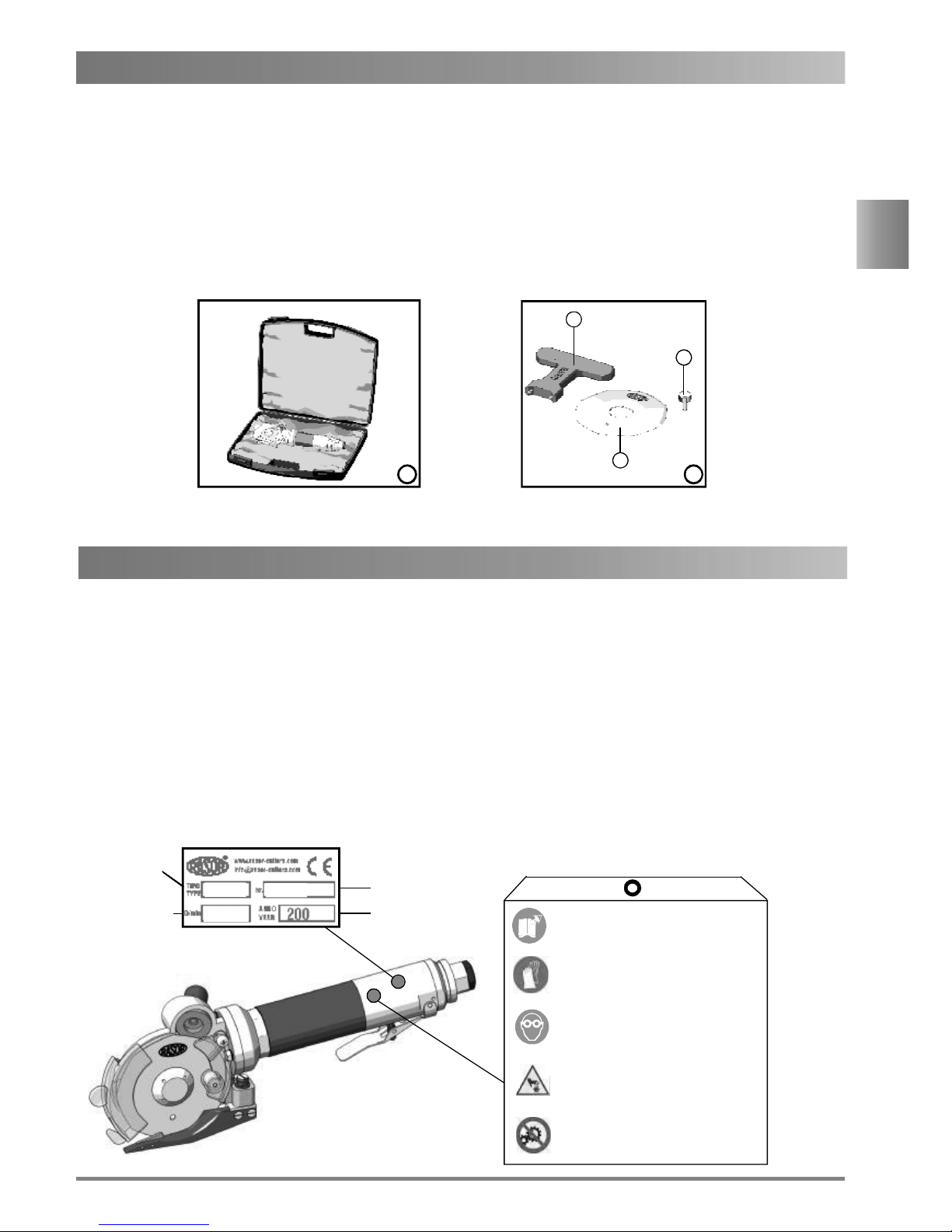

4. PRODUCT DESCRIPTION

2

1

3

13

15

5

9

7

8

10

14

6

11

12

4

The fixture described in this manual is a pneumatic scissor model FP862MT which has been

designed to cut composite materials such as Kevlar, fiberglass or carbon fibre. It is extremely

versatile, light and precise in the cutting operation, suitable also for v

ery difficult cuttings.

One special feature of pneumatic scissors FP862MT is their ability to sharpen the blade in

each moment without disassembling it by means of a grinding wheel mounted on the

scissors head. After carrying out this operation, it is possible to start cutting again. The

pneumatic scissors are provided with a threaded connection to the pneumatic circuits. The

turbine, p erfectly b alanced, w ith a hig h number of revol utions and totall y free of maintenance,

reduces the vibrations and the noise to the minimum.

The pneumatic scissors can be used also outdoor and to cut dam p or wet materials and

therefore particularly recommended in tannery, dyeworks, etc.

The pneumatic scissors FP862MT are extremely light (they weight only 1 Kg) and handy

and allow carrying out quick and precise cuts, even with curve profiles. The use of compressed

air as source of energy allows working continuously without problems of heating or

motor overload. The mechanical parts are made up of steel and high resistant bronze and

require a lubrication after many working hours.

1

1/4" gas connection for the air

connector

9 Sharpening button

2

Safet device to enable the control

lever

10 Front guard of the blade (movable)

3 Controllever 11 Rearguard of the blade(fixed)

4 Supporting foot 12 M otor support

5 Polygonal blade 13 Silencer

6 Greaser 14 Reference drift

7 Pneumatic motor 15 Counterblade

8Sharpener

Device components

Page 7

EN

7

7. FIELD OF APPLICATION

6. NOISE LEVEL

5. TECHNICAL FEATURES

The technical data are only indicative and they can be changed without notice.

8sidebladeØ86mm,inH.S.S.steel

5sidebladeØ86mm,inH.S.S.steel

8 side blade Ø 86 mm, in H.S.S. steel treated

with titanium

8 side blade Ø 86 mm, in H.S.S. steel covered

with Teflon

5 side blade Ø 86 mm, in H.S.S. steel covered

with Teflon

8sidebladeØ86mm,inintegralhardmetal

(Widia)

Features o f the available blades

86THSS

86THSSTN

86TMD

86PHSSTN

86THSSTF

86PHSS

The maximum acoustic pressure level emitted by

pneumatic scissors FP862MT is about 60 dB

(A).

Noise tests have been carried out in compliance with Standard ISO 11202. The device noise

levels, measured at different distances (without any sound wave filtering system), vary in

the extent of few db (A). The noise level has beeen detected with the silencer supplied

with the fixture assembled on the exhaust. The silencer must never be removed.

NOTE

It is advisable for pneumatic scissors FP862MT owners to verify the compliance with the

standard concerning safety of workers: refer to the Local Law. The use of ear

protecting devicesiscompulsory.

Pneumatic scissors FP862MT have been designed, manufactured and assembled to cut every

kind of fabrics or materials, with the exception of metal, plastic or wood, by means of rotary

pentagonal or octagonal blades.

This equipment must not work:

-inareaspronetoexplosions;

- in presence of fine dust or corrosive gases;

- to cut plastic, metal and wooden materials.

It is forbidden to use pneumatic scissors FP862MT for purposes different from the

above-mentioned ones.

86 mm with hard-metal counterblade

1400 rev./min

about 20 mm

400 W with max. pressure

max. 6 bar

1100 g

2000 g

9 litres/sec.

LUX 200

< 2,5 m/s

2

0 ~ 55°C

10 ~ 95% without condensate

Cutting working depth

Power

Weight

Pneumatic scissors FP862MT features

Blade diameter

Blade speed

Working pressure

Temperature

Humidity

Weight with pa ckage

Air consumption

Minimum light for working operations

Vibra tions at the start up

Page 8

8

EN

8. USE WARNINGS

We recommend following the indications below in order to always work in safety conditions.

All the operations must be carried out complying strictly with the safety rules of the

country where the machine is to be installed.

It is STRICTLY FORBIDDEN to smoke during the installation or adjustment operations of

the pneumatic scissors.

The Customer undertakes to comply with and make his staff observe all the rules and

regulations in force concerning safety, prevention of accidents and health in the work

place. Therefore, the Customer assumes the responsibility to strictly follow all the rules and

regulations in force, as well as the special provisions in force in sport and public installations

the Customer declares to know after receiving all the relative necessary information.

The pneumatic scissors work also without their safety protective device and

when the protection guard is lifted. This protective device must NEVER be

removed.

Always check the resistance of the material to be cut and the kind of blade which is being

used.

The Customer shall equip his own personnel with all the individual safety protections for

the execution of the works, as well as with the ones which might be prescribed by the

Manufacturer due to specific danger conditions of the plant or of the area where the

personnel must work.

Only one operator must use the pneumatic scissors always standing behind the guide

handle. Do not make any adjustment while the blade is working.

Always pay attention to the position of the air pipe to prevent it from being cut or

damaged by the blade.

It is allowed to assemble pneumatic scissors FP862MT on machines O.E.M. on condition

that their original structure is not modified. Otherwise, the intervention must be certified

by Rasor®.

The pneumatic scissors FP862MT are equipped with double safety push button with a

lever and a ratchet on the handle: the ratchet prevents the start push button from being

enabled accidentally

, the lever operates the scissors. Never remove the ratchet.

Page 9

EN

9

9. RESIDUAL RISKS

10. USE

4

3

5

6

B

A

Thecuttingbladecanworkevenwhentheprotectivedeviceisdisassembled.

Even though the pneumatic scissors are safe, operators must pay attention to preserve their

and other people’s safety.

To use the pneumatic scissors manually, proceed as follows:

1) Lay the material to be cut on the table;

2) Connect the air hose to the quick connection “A” (not supplied) (see picture 3);

3) Adjust the pressure gauge (optional) on 6 bar;

4) Put the material on the cutting foot (see picture 4);

5) Push the startin g lever after moving the safety device (see picture 5);

6) Push the pneumatic scissors in the desired direction, being careful to keep the material

in front of them as stretched as possible and preventing it from curling in the front

part of the scissors.

NOTE

The thrust on the pneumatic scissors must be as uniform as possible. To carry out linear cuts

with precision (and to follow predetermined paths), we also recommend using the arrow

pointonthefrontprotection(seepoint“B”infigure6).

Page 10

10

EN

12. BLADE SHARPENING

11. AIR PRESSURE GAUGE (OPTIONAL)

8

1

2

7

5

1

2

3

4

6

7

8

The sharpener button can be used only if the

transparent guard is completely lowered.

WARNING

13. LUBRICATION

The blade must never be dirty with grease or oil.

9

WARNING

A

The pneumatic scissors must be necessarily fed with

lubricated air with a pressure of maximum 6 bar.

Rasor

®

offers, as optional, a reduction unit filter with

a pressure gauge already calibrated with the quantity

of oil to be delivered as optional.

The unit shown also in picture 7 is made up of:

1 - pressure reducer;

2 - valve to drain the condensate;

3 - drip-feed oiler unit;

4-oiltank;

5 - pressure gauge;

6-condensatetank;

7 - pipe fitting to connect the quick connection to

the network;

8 - pipe fitting to connect the quick connection to the scissor.

For the use and maintenance read the instruction sheet supplied with the filter.

After using the machine for some hours without

interruption, or if the machine cutting capacity

is redu ce d, it is necessa r y to shar pen the blade.

To carry out this operation, start the blade and

press sharpener “2” on the blade itself (by means

of push button “1”, as shown in picture 8) for 34 seconds. Repeat this operation 2-3 times.

Every 3-4 working hours, it is necessary to lubricate the

gear pair. In order to carry out this operation, remove

protective plug “A” located on the head of the pneumatic

scissors and fill it with the grease supplied. Screw plug

“A” again a few turns. Screw plug “A” a few turns every

2-3 working hours (see picture 9).

Page 11

EN

11

11

12

E

F

G

14. BLADE REPLACEMENT

10

2

1

3

C

B

A

D

If the blade is no more able to cut (even after repeating

the sharpening operation several times) it is necessary to

replace it. In order to carry out this operation, use butterfly

wrench “1” and drift “3” locking th e blade ( s h o wn in

picture 10).

In order to replace the blade, proceed as follows:

1) Usesomeprotectiveglovesincompliancewiththe

LocalLawoftheCountrywherethemachineisto

be used (use of personal protection devices);

2)Removefixedsafetyprotection“A”andthemovable

front safety protection “B” ,byunsc rewingrespectively

the cross screw “C” and the slotted screw “D” by

means of a screwdriver (not supplied by the

manufacturer ), as shown in pict ure 11.

3) Insert drift “3” (see picture 10) in hole “E” in order

to l ock the blade (the hole in the blade must

correspond to the hole in the structure).

4) Use butterfly wrench “1” in order to unscrew nut

“F” and remove blade “G” (see picture 12).

5) Replace the worn blade with the new one “2” , being

careful to center the blade on the gear, in the correct

position, and remember to assemble it with its sharp

side (the o ne with the writing Rasor) positione d

towards the external side of the pneumatic scissors.

6) Assemble all the components again and carry out

some cutting and sharpening tests.

1

IMPORTANT!

Never rotate the supporting foot beyond the

proper locking screw. This operation could

damage the springs and make the cutting quality

worse (see picture 13)

13

Page 12

12

EN

16. SPARE PARTS / EXPLODED VIEW

15. TROUBLESHOOTING

•

SOLUTION

Check the counterblade integrity

Check the kind of fabric

Sharpen the blade

Check the fabric thickness

Check the compatibility between blade and fabric

Make sure that the turbine turns correctly

Check the force of the steel foot springs

Reduce the feeding speed

Carry out the lubrication

Disassemble the blade and remove the material

residues

Check the silencer

Check the wear of the gear pair

Check the pneumatic circuit integrity

Adjust the working pressure at 6 bar

The scissors start slowly or work intermittently

•

PROBLEM

The fabric is not cut or itgets stuck between the

blade and the counterblade

The pneumatic scissors are noisy

CODE DESCRIPTION CODE DESCRIPTION CODE DESCRIPTION CODE DESCRIPTION

86THSS 8-SIDE BLADE 86 mm, H.S.S. STEEL FP 86108 THREADED RING NUT FP 86138MT COMPLETE MOTOR SUPPORT SW108900 SHARPENER BUSH

FP 86000CPL COMPLETE MOTOR UNIT FP 86110 COMPENSATOR RING FP 86140L FO OT FIXING SCREWS SW109000 E MERY SPRING Ø 6 mm

FP 86009 COUPLING FLANGE FP 86111 COMPENSATION BUSH FP 86140R TOOTHED WASHER SW109100 S HARPENER CAP WITH BEARING

FP 86010 PISTON GUIDE FP 86112 MOTOR FLANGE BEARING FP 86141MT STEEL MOVABLE FOOT SW109200 SHARPENER CAP FIXING SCREW

FP 86011 PISTON GUIDE O' RING FP 86113 FRONT F LANGE FP 86141MTCPL ROTATING FOOT SET SW109300 STEEL W ASHE R

FP 86012 PISTON GUIDE O' RING FP 86114 ROTOR FP 86146 COMPLETE CONTROL LEVER T102906 LEVER FIXING PIN

FP 86013 PISTON FP 86115 ROTOR BLADE FP 86147 MOVABLE FOOT FIXING SCREW T102909 RATCHET FOR LEVER SERIES 2002

FP 86013CPL COMPLETE PISTON WITH GUIDE FP 86116 POSITIONING PIN FP 86148 ROTATING SUPPORT WITH PIN T102910 RATCHET SPRING

FP 86117 REAR FLANGE FP 86150 COUPLING SHAFT T104500 FRONT PROTECTION FIXING SCR EW

FP 86118 REAR FLANGE BEARING FP 86150CPL COMPLETE COUPLING SHAFT T104501 PAIR OF CONVEX WASHERS

FP 86119 REAR FLANGE CAP FP 86151 LOW ER SPRING MT T104700 GREASER CAP

FP 86120 CYLINDER FP 86152 UPPER SPRING MT T104800 GREASER

FP 86120CPL COMPLETE TURBINE FP 86153 FIXING SCREW T105200 SUPPORT FIXING SCREW

FP 86121 O'RING GASKET FP 86154 STOP RING T105300 WASHER

FP 86122 MOTOR FRAME FP 86155 BRONZE ROTATING BUSH T105600 SHAVING WASHER

FP 86123 CONTROL HEAD FP 86156 COUNTERBLADE FIXING SCREW T105700 BEARING FIXING RING NUT

FP 8612301CPL COMPLETE CONTROL HEAD T105800 GEAR RING BEARING

FP 86017 VALVE

FP 86018 VALVE O' RING

FP 86019 STEEL BALL

FP 86020 SPRING

FP 86021 SILENCER HOUSING O'RING

FP 86022 SILENCER HOUSING

FP 86025 BRONZE SILENCER FILTER

FP 86026 REDUCTION UNIT O' RING

FP 86028 REDUCTION UNIT

FP 86101P3 GEAR WORM SCREW

FP 86126 HANDLE FOR HOOK T106000 LEFT SCREW FOR GEAR F I XING

FP 86101P3CPL COMPLETE GEAR PAIR

FP 86130 1/4" CONNECTOR WITH FILTER T106100 SUBBLADE RING

FP 86102 ELASTIC PIN FP 86135 REAR GUARD T106300 BLADE FIXING RING NUT

FP 86103 SHAFT FRONT BEARING FP 86135CPL REAR PROTECTION SET T107500 BLADE DISASSEMBLING WRENCH

FP 86104 SNAP RING FP 86136 4MA SCREW FOR GUARD FIXING T107600 BLADE LOCKING DRIFT

FP 86106 SHAFT REAR BEARING FP 86137 FRONT GUAR D T107900 LUBRICATING GREASE

FP 86107 JOINT FP 86137CPL FRONT PROTECTION SET

T1059P3 COMPLETE RING GEAR

SW104102 OILER RING

SW104103 OILER SPRING

SW1081MT HARD METAL COUNTERBLADE

SW108600 EMERY TYPE Ø 25 x9 x 6

SW1086CPL COMPLETE EMERY UNIT

SW108700 EMERY PIN

SW108800 EMERY SPRING Ø 11 mm

T865400 ANTI-FRICTION BUSH

ACCESSORIES

CODE DESCRIPTION CODE DESCRIPTION

P169

FLEXIBLE PIPE FITTING Ø 8 mm - 1/4"

GAS FEMALE

P171 MALE QUICK COUPLING - 1/4" GAS

P170 FEMALE QUICK COUP LING - 1/4" GAS

P173 AIR PIPE Ø 8x6 mm

Page 13

SW108600

SW108700

SW108800

SW108900

SW109200

FP86141MTCPL

FP86153

FP86141MT

FP86148

FP86151

FP86155

FP86154

FP86026

FP86130

FP86028

FP86011

FP86010

FP86018

FP86020

FP86019

FP86017

FP86025

FP86026

FP8612301CPL

FP8612301

FP86102

FP86101P3CPL

FP86101P3

FP86122

FP86022

FP86121

FP86021

FP86014

FP86103

FP86104

FP86150

FP86146

T104500

T104501

FP86137

FP86137CPL

SW109000

SW109100

SW1086CPL

FP86136

FP86135

SW104103

FP86135CPL

SW104102

FP86013

FP86012

FP86013CPL

FP86009

FP86110

FP86106

FP86107

FP86112

FP86113

FP86120

FP86115

FP86114

FP86116

FP86117

FP86118

FP86119

FP86120CPL

T102906

T102910

T 107500

T 10

7600

T 107900

AIR PIPE

P171

P170

ACCESSORIES

SW109300

T102909

T105200

T105300

FP86198

T105600

T106000

T1059P3

86THSS

T106300

T105700

T105800

T106100

FP86140R

FP86140L

FP86152

SW1081MT

FP86147

FP86156

T104800

T104700

FP86138MT

T865400

P17

3

Page 14

W ARRAN TY

Rasor®Elettromeccanica S.r.l. pneumatic scissors have a 12 month warranty from the date

indicated on the last page of this manual, except in case of different written agreements.

The warrantycovers all manufacturingandmaterialdefects.Replacementandrepairoperations

are covered only if carried out by our company and at our workshop.

In case of returned goods for repair under warranty, the Customer must send to

Rasor

®

always the complet e machine. Repairs under wa rran ty of single faulty comp o nents

are not accepted.

The material to be repaired must be sent CARRIAGE FREE.

Once the machine has been repaired, it will be sent CARRIAGE FORWARD to the customer.

The warranty covers neither technicians' intervention on site nor the machine disassembly

from the installation place.

If for practical reasons, one of our technicians is sent to the premises, the customer will be

charged the costs plus the travelling expenses.

The warranty does not include:

• failure caused by wrong use or assembly,

• failure caused by external agents,

• failure caused by lack of maintenance or neglicence;

• blades and components subject to wear.

WARRANTY FORFEIT URE:

• In case of arrearage or other breaches of contract,

• Whenever changes or repairs are carried out on our electric scissors without our

prior authorization,

• Whenever the serial number is tampered with or cancelled,

• Whenever the damage is caused by improper use, bad treatment, bumps, falls and

other causes not due to normal working conditions,

• Whenever the unit seems tampered with, dismantled or previou sly repaired by

unauthorized staff,

• In case the pneumatic scissors are used for purposes that are different from the

ones described in this manual.

All repair operations carried out under warranty do not interrupt its duration.

All disputes will be settled in the court of justice of Milan (Italy).

We thank you in advance for the attention you will pay to this manual and we invite you to

inform us of any change you deem necessary to improve it and make it more complete.

Page 15

RASOR ELETTROMECCANICA SRL

Via Vincenzo Caldesi 6

20161 Milan ∙ Italy

ph. +39 02 66 22 12 31

fax +39 02 66 22 12 93

info@rasor-cutters.com

www.rasor-cutters.com

FOLLOW US:

Loading...

Loading...