Page 1

®

Assembly, Safety and Operation Manual

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

22114H-GB (rev.2)

Ransomes Gang Mower

Sportcutter Mk11, Magna Mk13

Product codes: LBMA171 Sportcutter Gang unit on pneumatic wheels

LBMA172 Sportcutter Gang unit on steel wheels

LJBA003 Sportcutter 3-unit on pneumatic wheels

LJBA004 Sportcutter 3-unit on steel wheels

LJBA011 Sportcutter Mounted 3-unit on pneumatic wheels

LJBA005 Sportcutter 5-unit on pneumatic wheels

LJBA006 Sportcutter 5-unit on steel wheels

LBMA174 Magna Gang unit on pneumatic wheels

LBMA173 Magna Gang unit on steel wheels.

LJBA015 Magna 3-unit on pneumatic wheels

LJBA016 Magna 3-unit on steel wheels

LJBA023 Magna Mounted 3-unit on pneumatic wheels

LJBA017 Magna 5-unit on pneumatic wheels

LJBA018 Magna 5-unit on steel wheels

GB

United

Kingdom

RJL 1C April 2013

Page 2

© 2009, Ransomes Jacobsen Limited. All Rights Reserved

Page 3

en-3

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

1 CONTENTS

CONTENTS PAGE

2 INTRODUCTION

2.1 IMPORTANT .............................................................................................................2

2.2 PRODUCT IDENTIFICATION ...................................................................................2

3 SAFETY INSTRUCTIONS

3.1 OPERATING INSTRUCTIONS .................................................................................3

3.2 SAFETY SIGNS ........................................................................................................3

3.3 STARTING THE ENGINE .........................................................................................3

3.4 DRIVING THE MACHINE ..........................................................................................3

3.5 TRANSPORTING ......................................................................................................3

3.6 LEAVING THE DRIVING POSITION ........................................................................4

3.7 SLOPES ....................................................................................................................4

3.8 BLOCKED CUTTING CYLINDERS ..........................................................................4

3.9 ADJUSTMENTS, LUBRICATION AND MAINTENANCE .........................................4

4 SPECIFICATIONS

4.1 CONFORMITY CERTIFICATES ...............................................................................6

5 DECALS AND UNIT SPECIFICATION

5.1 SAFETY DECALS .....................................................................................................8

5.2 COMPONENTS FOR TRAILED UNITS ....................................................................8

5.3 DIMENSIONS AND CUTTING PEFORMANCE .......................................................9

5.4 WEIGHTS ..................................................................................................................9

6 ASSEMBLY

6.1 SINGLE UNIT GANG MOWER ................................................................................10

6.2 3-UNIT GANG MOWER ...........................................................................................11

6.3 3-UNIT MOUNTED GANG MOWER ........................................................................12

6.4 5-UNIT GANG MOWER ...........................................................................................15

6.5 7-UNIT GANG MOWER ...........................................................................................16

6.6 9-UNIT GANG MOWER ...........................................................................................17

6.7 COUPLING GANG MOWERS TO POWER UNITS .................................................19

7 LUBRICATION

7.1 GEAR CASE, REAR ROLL, DRAWBAR ................................................................20

7.2 LUBRICATION CHART ...........................................................................................20

8 OPERATION

8.1 OPERATING PROCEDURE ....................................................................................21

8.2 DAILY INSPECTION ................................................................................................22

8.3 OPERATING THE GANG MOWERS .......................................................................22

9 MAINTENANCE

9.1 MAINTENANCE AND ADJUSTMENT .....................................................................23

10 TRANSPORTING

10.1 TRANSPORTING THE UNITS .................................................................................24

11 GUARANTEE/SALES & SERVICE .........................................................................25

Page 4

en-4

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

2 INTRODUCTION

Kg

Kw

Kg

Kg

West Road

Ransomes Europark

Ipswich IP3 9TT

England

A

B

CD

E

F

G

H

J

2.1 IMPORTANT

IMPORTANT: This is a precision machine and the service obtained from it depends on the way it is

operated and maintained.

This SAFETY AND OPERATORS MANUAL should be regarded as part of the machine. Suppliers of

both new and second-hand machines are advised to retain documentary evidence that this manual was

provided with the machine.

This machine is designed solely for use in customary grass cutting operations. Use in any other way is

considered as contrary to the intended use. Compliance with and strict adherence to the conditions of

operation, service and repair as specifi ed by the manufacturer, also constitute essential elements of the

intended use.

Before attempting to operate this machine, ALL operators MUST read through this manual and make

themselves thoroughly conversant with Safety Instructions, controls, lubrication and maintenance.

Accident prevention regulations, all other generally recognized regulations on safety and occupational

medicine, and all road traffi c regulations shall be observed at all times.

Any arbitrary modifi cations carried out on this machine may relieve the manufacturer of liability for any

resulting damage or injury.

2006/42/EC

These are the Original instructions verifi ed by Ransomes Jacobsen Limited.

A Maximum front axle load in Kg (for machines

being driven on the highway)

B Gross weight (mass) in Kg

C Maximum rear axle load in Kg (for machines

being driven on the highway)

D Power in Kw

E Date code

F Machine type (Designation)

G Product code

H Product name

J Serial number

2.2 PRODUCT IDENTIFICATION

Page 5

en-5

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

3 SAFETY INSTRUCTIONS

This safety symbol indicates important safety

messages in this manual. When you see this

symbol, be alert to the possibility of injury, carefully

read the message that follows, and inform other

operators.

3.1 OPERATING INSTRUCTIONS

• Ensure that the instructions in this book

are read and fully understood.

• No person should be allowed to operate

this machine unless they are fully

acquainted with all the controls and the

safety procedures.

• Never allow children or people unfamiliar

with these instructions to use this

machine. Local regulations may restrict

the age of the operator.

3.2 SAFETY SIGNS

• It is essential all safety labels are kept

legible, if they are missing or illegible

they must be replaced. If any part of

the machine is replaced and it originally

carried a safety label, a new label must

be affi xed to the replacement part.

New safety labels are obtainable from

Ransomes dealers.

3.3 STARTING THE ENGINE

• Before starting the engine check that the

brakes are applied, drives are in neutral,

guards are in position and intact, and

bystanders are clear of the machine.

• Do not run the engine in a building

without adequate ventilation.

3.4 DRIVING THE MACHINE

• Before moving the machine, check to

ensure that all parts are in good working

order, paying particular attention to

brakes, tyres, steering and the security of

cutting blades.

• Replace faulty silencers, mow only in

daylight or good artifi cial light

• Always observe the Highway Code both

on and off the roads. Keep alert and

aware at all times. Watch out for traffi c

when crossing or near roadways.

• Stop the blades rotating before crossing

surfaces other than grass.

• Remember that some people are deaf

or blind and that children and animals

can be unpredictable.

• Keep travelling speeds low enough for

an emergency stop to be effective and

safe at all times, in any conditions.

• Remove or avoid obstructions in the

area to be cut, thus reducing the

possibility of injury to yourself and/or

bystanders.

• When reversing, take special care to

ensure that the area behind is clear of

obstructions and/or bystanders. DO

NOT carry passengers.

• Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people or their

property.

• When the machine is to be parked,

stored or left unattended, lower the

cutting means unless the transport

locks are being used.

• While mowing, always wear substantial

footwear and long trousers. Do not

operate the equipment when barefoot

or wearing open sandals.

• Check the grass catcher frequently for

wear or deterioration. After striking a

foreign object. Inspect. the lawnmower

for damage and make repairs before

restarting and operating the equipment.

• If the machine starts to vibrate

abnormally, check immediately.

3.5 TRANSPORTING

• Ensure that the cutting units are

securely fastened in the transport

position. Do not transport with cutting

mechanism rotating.

• Drive the machine with due

consideration of road and surface

conditions, inclines and local

undulations.

• Sudden decelerating or braking can

cause the rear wheels to lift.

• Remember that the stability of the rear

of the machine is reduced as the fuel is

used.

Page 6

en-6

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

3 SAFETY INSTRUCTIONS

3.6 LEAVING THE DRIVING POSITION

• Park the machine on level ground.

• Before leaving the driving position, stop

the engine and make sure all moving

parts are stationary. Apply brakes and

disengage all drives. Remove the starter

key.

3.7 SLOPES

TAKE EXTRA CARE WHEN WORKING ON

SLOPES

• Local undulations and sinkage will

change the general slope. Avoid ground

conditions which can cause the machine

to slide.

• Keep machine speeds low on slopes and

during tight turns.

• Sudden decelerating or braking can

cause the rear wheels to lift. Remember

there is no such thing as a “safe” slope.

• Travel on grass slopes requires particular

care.

DO NOT USE ON SLOPES GREATER THAN 15°

IMPORTANT: When working on any slope set the

weight transfer, if fi tted to its maximum (+) setting.

3.8 BLOCKED CUTTING CYLINDERS

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Release blockages with care. Keep all

parts of the body away from the cutting

edge. Beware of energy in the drive which

can cause rotation when the blockage is

released.

• Keep other people away from the cutting

units as rotation of one cylinder can cause

the others to rotate.

3.9 ADJUSTMENTS, LUBRICATION AND

MAINTENANCE

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Read all the appropriate servicing

instructions.

• Use only the replacement parts supplied by

the original manufacturer.

• When adjusting the cutting cylinders take

care not to get hands and feet trapped when

rotating cylinders.

• Make sure that other people are not touching

any cutting units, as rotation of one cylinder

can cause the others to rotate.

• To reduce the fi re hazard, keep the engine,

silencer and battery compartments free of

grass, leaves or excessive grease.

• Replace worn or damaged parts for safety.

• When working underneath lifted parts or

machines, make sure adequate support Is

provided.

• Do not dismantle the machine without

releasing or restraining forces which can

cause parts to move suddenly.

• Do not alter engine speed above maximum

quoted in Engine Specifi cation. Do not

change the engine governor settings or

overspeed the engine. Operating the engine

at excessive speed may increase the hazard

of personal injury.

• When refuelling, STOP THE ENGINE, DO

NOT SMOKE. Add fuel before starting the

engine, never add fuel while the engine is

running.

• Use a funnel when pouring fuel from a can

into the tank.

• Do not fi ll the fuel tank beyond the bottom of

the fi ller neck.

• Replace all fuel tank and container caps

securely.

• Store fuel in containers specifi cally designed

for this purpose.

• Refuel outdoors only and do not smoke while

refuelling.

• If fuel is spilled, do not attempt to start the

engine but move the machine away from

the area of spillage and avoid creating any

source of ignition until fuel vapours have

dissipated.

• Allow the engine to cool before storing in any

enclosure.

• Never store the equipment with fuel in the

tank inside a building where fumes may

reach an open fl ame or spark.

• If the fuel tank has to be drained, this should

be done outdoors.

• Do not spill fuel onto hot components.

• When servicing batteries, DO NOT SMOKE,

and keep naked lights away.

• Do not place any metal objects across the

terminals.

Page 7

en-7

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

Hydraulic Fluid escaping under pressure

can penetrate skin and do serious

damage. Immediate medical assistance

must be sought.

WARNING

Batteries produce explosive gases and

contain corrosive acid and supply levels

of electrical current high enough to cause

burns.

WARNING

DO NOT USE ON SLOPES GREATER THAN

WARNING

3 SAFETY INSTRUCTIONS

DANGER - Indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING - Indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION - Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor

or moderate injury and property damage. It may

also be used to alert against unsafe practices.

IMPORTANT: Transport speed is for highway

use only. Never select transport speed on

grass areas or uneven or unsurfaced roads or

tracks.

Page 8

en-8

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

4.1 CONFORMITY CERTIFICATES

4 CERTIFICATION

Business name and full address of the m anufacturer ƒ Ɍɴɪɝɨɜɫɤɨ ɢɦɟ ɢ ɩɴɥɟɧ ɚɞɪɟɫ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ ƒ

Obchodní jméno a plná adresa v ýrobce ƒ Producentens firmanavn og ful de adresse ƒ Bedrijfsnaam en volledig adres v an de fabrikant ƒ Tootja ärinimi ja täielik aadress ƒ

Valmistajan toiminimi ja täydellinen osoite ƒ Nom commercial et adresse complète du fabricant ƒ Firmenname und vollständige Adresse des Herstellers ƒ ǼʌȦȞȣȝȓĮ țĮȚ

IJĮȤȣįȡȠȝȚțȒ įȚİȪșȣȞıȘțĮIJĮıțİȣĮıIJȒ ƒ A gyártó üzleti neve és teljes címe ƒ Ragione sociale e indirizzo completo del fabbr icante ƒ UzƼƝmuma nosaukums un pilna

ražotƗja adrese ƒ Verslo pavadinimas ir pi lnas gamintojo adresas ƒ Isem kummerƛjali u indirizz sƫiƫ tal-fabbrikant ƒ Nazwa firmy i pełny adres producent a ƒ Nome da

empresa e endereço completo do f abricante ƒ Denumirea comercialăúi adresa completă a producătorului ƒ Obchodný názov a úplná adresa výr obcu ƒ Naziv podjetja in

polni naslov proizv ajalca ƒ Nombre de la empresa y dirección c ompleta del fabricante ƒ Tillverkarens företagsnamn och kompletta adress ƒ Fyrirtækisheiti og fullt

heimilisfang framleiðanda ƒ Firmanav n og full adresse for produsenten

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

Product Code ƒ Ʉɨɞ ɧɚ ɩɪɨɞɭɤɬɚ ƒ Kód výrobku ƒ Produktkode ƒ Productcode ƒ Toote kood ƒ Tuot ekoodi ƒ Code produit ƒ Produktcode ƒ ȀȦįȚțȩȢ ʌȡȠȧ ȩȞIJȠȢ ƒ Termékkód ƒ

Codice prodotto ƒ Produkta kods ƒ Produkto k odas ƒ Kodiƛi tal-Prodott ƒ Kod produktu ƒ Código do Produto ƒ Cod pr

odus ƒ Kód výrobku ƒ Oznaka proizv oda ƒ Código de

producto ƒ Produktkod ƒ Vörunúmer ƒ Produktkode

LBMA171, LBMA172, LBMA173, LBMA174

Machine Name ƒ ɇɚɢɦɟɧɨɜɚɧɢɟ ɧɚ ɦɚɲɢɧɚɬɚ ƒ Název stroj e ƒ Maskinnavn ƒ Machinenaam ƒ Masina nimi ƒ Laitteen nimi ƒ Nom de la machine ƒ Maschinenbezeichnung ƒ

ȅȞȠȝĮıȓĮ ȝȘȤĮȞ ȒȝĮIJȠȢ ƒ Gépnév ƒ Denominazione della m acchina ƒ IekƗrtas nosaukums ƒ Mašinos pavadinimas ƒ Isem tal-Magna ƒ Nazwa urządzenia ƒ Nome da

Máquina ƒ Numele echipam entului ƒ Názov stroja ƒ Naziv stroj a ƒ Nombre de la máquina ƒ Maskinens namn ƒ Heiti tækis ƒ Maskinnavn

Ransomes Sportcutter Mk11

Ransomes Magna Mk13

Designation ƒ ɉɪɟɞɧɚɡɧɚɱɟɧɢɟ ƒ Oznaþení ƒ Bet egnelse ƒ Benaming ƒ Nimetus ƒ Tyyppimerkint ä ƒ Pažymơjimas ƒ

Bezeichnung ƒ ȋĮȡĮțIJȘȡȚıȝȩȢ ƒ Megnevezés ƒ Funzione ƒ ApzƯmƝjums ƒ Lithuanian ƒ Denom inazzjoni ƒ O

znaczenie ƒ

Designação ƒ SpecificaĠie ƒ Oznaþenie ƒ Namen stroja ƒ Descripción ƒ Beteckning ƒ Merking ƒ Konstruksjon

Towed Reel Mower

Serial Number ƒ ɋɟɪɢɟɧ ɧɨɦ ɟɪ ƒ Sériové þíslo ƒ Serienummer ƒ Serienummer ƒ Seeri anumber ƒ Valmistusnumero ƒ Numéro de série ƒ Seriennum mer ƒ ȈİȚȡȚĮțȩȢ ĮȡȚșȝȩȢ ƒ

Sorozatszám ƒ Numero di serie ƒ SƝrijas numurs ƒ Serijos numeris ƒ Numru Serjali ƒ Num er seryjny ƒ Número de Série ƒ Număr de serie ƒ Sériov é þíslo ƒ Serijska številka ƒ

Número de serie ƒ Serienumm er ƒ Raðnúmer ƒ Serienummer

LW000299 - LW999999

LX000299 - LX999999

LY000299 - LY999999

LZ000299 - LZ999999

Engine ƒ Ⱦɜɢɝɚɬɟɥ ƒ Motor ƒ Motor ƒ Motor ƒ Mootor ƒ Moottori ƒ Moteur ƒ Motor ƒȂȘȤĮȞȒƒ Modul név ƒ Motore ƒ DzinƝjs ƒ V

ariklis ƒ Saƫƫa Netta Installata ƒ Silnik ƒ Motor ƒ

Motor ƒ Motor ƒ Motor ƒ Motor ƒ Motor ƒ Vél ƒ Motor

Not Applicable

Net Installed Power ƒ ɇɟɬɧɚ ɢɧɫɬɚɥɢɪɚɧɚ ɦɨɳɧɨɫɬ ƒ ýistý i nstalovaný výkon ƒ Installeret nettoeffekt ƒ Netto geïnstalleerd vermogen ƒ I nstalleeritud netovõimsus ƒ

Asennettu nettoteho ƒ Puissance nominal e nette ƒ Installierte Nettoleistungƒ ȀĮșĮȡȒ İȖțĮIJİıIJȘȝȑȞ Ș ȚıȤȪȢ ƒ Nettó beépített teljesítmény ƒ Potenza netta installata ƒ

ParedzƝtƗ tƯkla jauda ƒ Grynoji galia ƒ Wisa’ tal-Qtugƫƒ Moc zai nstalowana netto ƒ Potência instalada ƒ Puterea instalată netăƒýistý inštalovaný výkon ƒ Neto v grajena moþ

ƒ Potencia instalada neta ƒ Nettoeffekt ƒ Nettóafl vélar ƒ Netto installert kraft

Not Applicable

Cutting Width ƒ ɒɢɪɨɱɢɧɚ ɧɚ ɪɹɡɚɧɟ ƒ ŠíĜka Ĝezu ƒ Skær ebredde ƒ Maaibreedte ƒ Lõikelaius ƒ Leikkuuleveys ƒ Largeur de coupe ƒ Schnitt breite ƒ ȂȒțȠȢ ȝȚıȚȞȑȗĮȢ ƒ Vágási

szélesség ƒ Lar ghezza di taglio ƒ G

riešanas platums ƒ Pjovi mo plotis ƒ Tikkonforma mad-Di rettivi ƒ SzerokoĞü ciĊcia ƒ Largura de Cort e ƒ LăĠimea de tăiere ƒ Šírka záberu ƒ

Širina reza ƒ Anchura de corte ƒ Klippbredd ƒ Skurðbreidd ƒ Klippebredde

76 cm to 625 cm

DECLARATION OF CONFORMITY ƒ ȾȿɄɅȺɊȺɐɂə ɁȺ ɋɔɈɌȼȿɌɋɌȼɂȿ ƒ PROHLÁŠENÍ O SHODċƒ

OVERENSSTEMMELSESERKLÆRING ƒ CONFORMITEITSVERKLARING ƒ VASTAVUSDEKLARATSIOON ƒ

VAATIMUSTENMUKAISUUSVAKUUTUS ƒ DECLARATION DE CONFORMITE ƒ KONFORMITÄTSERKLÄRUNG ƒ ǻǾȁȍȈǾ

ȈȊȂȂȅȇĭȍȈǾȈ ƒ MEGFELELėSÉGI NYILATKOZAT ƒ DICHIARAZIONE DI CONFORMITÀ ƒ ATBILSTƮBAS DEKLARƖCIJA ƒ

ATITIKTIES DEKLARACIJA ƒ DIKJARAZZJONI TAL-KONFORMITÀ ƒ DEKLARACJA ZGODNOĝCI ƒ DECLARAÇÃO DE

CONFORMIDADE ƒ DECLARAğIE DE CONFORMITATE ƒ VYHLÁSENIE O ZHODE ƒ IZJAVA O SKLADNOSTI ƒ DECLARACIÓN

DE CONFORMIDAD ƒ DEKLARATION OM ÖVERENSSTÄMMELSE ƒ SAMRÆMISYFIRLÝSING ƒ KONFORMITETSERKLÆRING

Conforms to Directiv es ƒ ȼ ɫɴɨɬɜɟɬɫɬɜɢɟ ɫ ɞɢɪɟɤɬɢɜɢɬɟ ƒ SplĖuje podmínky smČrnic ƒ Er i overensstemmelse med direkti ver ƒ Voldoet aan de richtlijnen ƒ Vastab

direktiivi dele ƒ Direktiivien mukainen ƒ Conforme aux directives ƒ Ent spricht Richtlinien ƒ ǹțȠȜȠȣșȒıIJİ ʌ ȚıIJȐ IJȚȢ ȅįȘȖȓİȢ ƒ Megf elel az irányelveknek ƒ Conform e alle

Direttive ƒ Atbilst direktƯvƗm ƒ Atitinka direktyvǐ rei kalavimus ƒ Valutazzjoni tal-Konformità ƒ Dyrektywy związane ƒ Cumpre as Directivas ƒ Respectă Di rectivele ƒ Je v

súlade so sme rnicami ƒ Skladnost z di rektivami ƒ Cumple con las Directivas ƒ Uppfyller direktiv ƒ Samræmist tilskipunum ƒ I samsvar med direktiv

2006/42/EC

Conformity Assessment ƒ Ɉ ɰɟɧɤɚ ɡɚ ɫɴɨɬɜɟɬɫɬɜɢɟ ƒ Hodnocení plnČní podmínek ƒ Over ensstemmelsesvurdering ƒ

Conformiteitsbeoordel ing ƒ Vastavushindamine ƒ Vaatim ustenmukaisuuden arviointi ƒ Ev aluation de conformité ƒ

Konformitätsbeurtei lung ƒ ǻȚĮʌȓıIJȦıȘ ȈȣȝȝȩȡijȦıȘȢ ƒ M egfelelĘség-értékelés ƒ Valutazione della conf ormità ƒ

AtbilstƯbas novƝrtƝjums ƒ Atitikties Ƴvertinimas ƒ Livell tal-Qawwa tal-ƪoss Imkejjel ƒ Ocena zgodnoĞci

ƒ

Avaliação de Confor midade ƒ Evaluarea conformit ăĠii ƒ Vyhodnotenie zhodnosti ƒ Ocena skladnosti ƒ

Evaluación de conf ormidad ƒ Bedömning av överensstämm else ƒ Samræmismat ƒ Konformitetsvurdering

2006/42/EC Annex VIII

Measured Sound Power Level ƒ ɂɡɦɟɪɟɧɨ ɧɢɜɨ ɧɚ ɡɜɭ ɤɨɜɚ ɦɨɳɧɨɫɬ ƒ NamČĜený akustický výkon ƒ Målte lydstyrkeniv eau ƒ Gemeten geluidsniveau ƒ Mõõdetud

helivõimsuse tase ƒ Mi tattu äänitehotaso ƒ Niveau de puissance sonore mesuré ƒ Gemessener Schall druckpegel ƒ ȈIJĮșȝȚıȝȑȞȠ İʌȓʌİįȠ ȘȤȘIJȚțȒȢ ȚıȤȪȠȢ ƒ Mért

hangteljesítményszint ƒ Livello di potenza sonora misurato ƒ IzmƝrƯtais skaƼas jaudas lƯmenis ƒ Išm atuotas garso stiprumo lygis ƒ Livell tal-Qawwa tal-ƪoss Iggarantit ƒ Moc

akustyczna mierzona ƒ Nível sonoro medido ƒ Nivelul măsurat al puterii acustice ƒ Nameraná hladina akusti ckého výkonu ƒ Izmerjena raven zv oþne moþi ƒ Nivel de

potencia sonora medido ƒ Uppmätt ljudeffektsnivå ƒ Mælt hl jóðaflsstig ƒ Målt lydeffektnivå

Not Applicable

Guaranteed Sound Power Level ƒ Ƚɚɪɚɧɬɢɪɚɧɨ ɧɢɜɨ ɧɚ ɡɜɭɤɨɜɚ ɦɨɳɧɨɫɬ ƒ Garantovaný akustický výkon ƒ Gar anteret lydstyrkeniveau ƒ Gegarandeerd geluidsniv eau ƒ

Garanteeritud heliv õimsuse tase ƒ Taattu äänitehotaso ƒ Ni

veau de puissance sonore garanti ƒ Garanti erter Schalldruckpegel ƒ ǼȖȖȣȘȝȑȞȠ İʌȓʌİįȠ ȘȤȘIJȚțȒȢ Ț ıȤȪȠȢ ƒ

Szavatolt hangtel jesítményszint ƒ Livello di pot enza sonora garantito ƒ GarantƝtais skaƼas jaudas lƯmenis ƒ Garantuotas garso stiprumo l ygis ƒ Livell tal-Qawwa tal-ƪoss

Iggarantit ƒ Moc akustyczna gwarantowana ƒ Nível sonoro farantido ƒ Niv elul garantat al puterii acustice ƒ Garant ovaná hladina akustického výkonu ƒ Zajamþena rav en

zvoþne moþi ƒ Niv el de potencia sonora garantizado ƒ Garanterad ljudeff ektsnivå ƒ Hljóðaflsstig sem ábyr gð er tekin á ƒ Garanter lydeffektniv å

Not Applicable

Conformity Assessment Procedure ( Noise) ƒ Ɉɰɟɧɤɚ ɡɚ ɫɴɨɬɜɟɬɫɬɜɢɟ ɧɚ ɩɪɨɰɟɞɭɪɚɬɚ (ɒɭɦ) ƒ

Postup hodnocení plnČní podmínek (hluk ) ƒ Procedure for overensstemmelsesvurderi ng (Støj) ƒ

Procedure van de conform iteitsbeoordeling (geluid) ƒ Vastavushi ndamismenetlus (müra) ƒ

Vaatimustenmukaisuuden arv iointimenettely (Melu) ƒ P rocédure d’évaluation de conformité ( bruit) ƒ

Konformitätsbeurtei lungsverfahren (Geräusch) ƒ ǻȚĮįȚțĮıȓ Į ǹȟȚȠȜȩȖȘıȘȢ ȈȣȝȝȩȡijȦıȘȢ (ĬȩȡȣȕȠȢ) ƒ

MegfelelĘség-értékelési el járás (Zaj) ƒ Procedura di valutazione del la conformità (rumore) ƒ

AtbilstƯbas novƝrtƝjuma procednjra (troksnis) ƒ Atitikties Ƴvertinimo procednjra (garsas) ƒ

Proƛedura tal-Valutazzjoni tal-Konformità (ƪoss) ƒ P

rocedura oceny zgodnoĞci (poziom hałasu) ƒ

Processo de avaliação de confor midade (nível sonoro) Procedura de evaluar e a conformităĠii (zgomot) ƒ

Postup vyhodnocovania z hodnosti (hluk) ƒ Postopek za ugotavljanje skladnosti (hrup) ƒ

Procedimiento de ev aluación de conformidad (ruido) ƒ Procedur f ör bedömning av överensstämmel se (buller)

ƒ Samræmismatsaðf erð (hávaði) ƒ Prosedyre for konformi tetsvurdering (støy)

Not Applicable

UK Notified Body f or 2000/14/EC ƒ ɇɨɬɢɮɢɰɢɪɚɧ ɨɪɝɚɧ ɜ Ɉɛɟɞɢɧɟɧɨɬɨ ɤɪɚɥɫɬɜɨ ɡɚ 2000/14/ ȿɈ ƒ ÚĜad certifikovaný podle smČrnice þ. 2000/ 14/EC ƒ Det britiske

bemyndigede organ for 2001/14/EF ƒ Engels adviesorgaan voor 2000/14/EG ƒ Ühendkuningri igi teavitatud asutus direktii vi 2000/14/EÜ mõistes ƒ Direktiiv in 2000/14/EY

mukainen ilmoi tettu tarkastuslaitos Isossa-Britanniassa ƒ Organisme notif ié concernant la directive 2000/14/CE ƒ Britische benannte Stelle für 2000/14/EG ƒ ȀȠȚȞȠʌȠȚȘȝȑȞȠȢ

ȅȡȖĮȞȚıȝȩȢ ǾȞȦȝȑȞȠȣ ǺĮıȚȜİȓȠȣ ȖȚĮ 2000/14/ǼȀ ƒ 2000/14/EK – egyesült ki rályságbeli bejelentett szervezet ƒ Or ganismo Notificato in GB per 2000/14/CE ƒ 2000/ 14/EK

AK reƧistrƝtƗ organizƗcija ƒ JK notifikuotosios Ƴstaigos 2000/14/EC ƒ Korp Notifikat tar-Renju Unit gƫal 2000/14/KE ƒ Dopuszczona jednostka badawcza w Wielkiej Brytanii

wg 2000/14/WE ƒ Entidade noti ficada no Reino Unido para 2000/14/CE ƒ Organism noti ficat în Marea Britanie pentru 2000/14/CE ƒ Notifikovaný orgán Spojeného

kráĐovstva pre smernic u 2000/14/ES ƒ Britanski priglašeni organ za 2000/14/ES ƒ Cuerpo not ificado en el Reino Unido para 2000/14/CE ƒ Anmäl t organ för 2000/14/EG i

Storbritannien ƒ Tilkynntur aðili í Bretlandi fyrir 2000/14/EC ƒ Britisk teknisk for 2000/ 14/EF

Not Applicable

Page 9

en-9

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

4 CERTIFICATION

Operator Ear Noise Level ƒ Ɉɩɟɪɚɬɨɪ ɧɚ ɧɢɜɨɬɨ ɧɚ ɞɨɥɨɜɢɦ ɨɬ ɭɯɨɬɨ ɲ ɭɦ ƒ

Hladina hluku v obl asti uší operátora ƒ Støjniveau i fø rers ørehøjde ƒ

Geluidsniveau oor bestuurder ƒ Müratase operaatori kõrvas ƒ

Melutaso käyttäjän korv an kohdalla ƒ Niveau de bruit à hauteur des oreilles de l’opérateur ƒ

Schallpegel am Bediener ohr ƒ ǼʌȓʌİįȠ șȠȡȪȕȠȣ ıİ ȜİȚ IJȠȣȡȖȓĮ ƒ

A kezelĘ fülénél mért zajszint ƒ Livello di potenza sonora all’orecchi o dell’operatore ƒ

TrokšƼa lƯmenis pie operatora auss ƒ Dirbanþiojo su mašina patiriamo triukšmo lygis ƒ

Livell tal-ƪoss fil-Widna tal-Oper atur ƒ Dopuszczalny poziom hałasu dla operatora ƒ

Nível sonoro nos ouvidos do operador ƒ Nivelul zgomotului la urechea oper atorului ƒ

Hladina hluku pôsobiaca na sluch operátora ƒ Rav en hrupa pri ušesu upravljavca ƒ

Nivel sonoro en el oído del operador ƒ Ljudnivå vid förarens öra ƒ Háv aðastig fyrir stjórnanda ƒ Støyniv å ved operatørens øre

Not Applicable

Harmonised standards used ƒ ɂɡɩɨɥɡɜɚɧɢ ɯɚɪɦɨɧɢɡɢɪɚɧɢ ɫɬɚɧɞɚɪɬɢ ƒ Použité harm onizované normy ƒ Brugte harmoniserede standarder ƒ Gebr uikte geharmoniseerde

standaards ƒ Kasutatud ühtlustatud standardid ƒ Käyt etyt yhdenmukaistetut standardit ƒ Normes harmonisées utilisées ƒ Angewandte harmonisierte Normen ƒ

ǼȞĮȡȝȠȞȚıȝ ȑȞĮ ʌȡȩIJȣʌĮ ʌȠȣ ȤȡȘıȚȝȠʌȠȚ ȒșȘțĮȞ ƒ Harmonizált szabv ányok ƒ Standard armonizzati applicati ƒ Izmantotie saskaƼotie standarti ƒ Panaudoti suderinti

standartai ƒ Standards armoniz zati uĪati ƒ Normy spójne powiązane ƒ Normas harmoni zadas usadas ƒ Standardele armonizate utilizate ƒ Použité harmonizované normy ƒ

Upor

abljeni usklajeni standardi ƒ Estándares armonizados utilizados ƒ Harmoniserade standarder som anv änds

BS EN 836-1997

Technical standards and specific ations used ƒ ɂɡɩɨɥɡɜɚɧɢ ɬɟɯɧɢɱɟɫɤɢ ɫɬɚɧɞɚɪɬɢ ɢ ɫɩɟɰɢɮɢɤɚɰɢɢ ƒ

Použité technické norm y a specifikace ƒ Brugte tekniske standarder og specifi kationer ƒ

Gebruikte technische standaards en specif icaties ƒ Kasutatud tehnilised standardid ja spetsifikatsioonid ƒ

Käytetyt tekniset standardit ja eritelmät ƒ Spécifications et normes techniques utilisées ƒ

Angewandte technische Normen und Spezif ikationen ƒ ȉİȤȞȚțȐ ʌȡȩIJȣʌĮ țĮȚ ʌȡ ȠįȚĮȖȡĮijȑȢ ʌȠȣ ȤȡȘıȚȝȠʌȠȚȒșȘțĮȞ ƒ MĦszaki szabványok és specifi kációk ƒ Standard

tecnici e specifiche applicati ƒ

Izmantotie tehniski e standarti un specifikƗcijas ƒ Panaudoti techniniai standartai ir techninơ informacija ƒ

Standards u speƛifikazzjonijiet tekniƛi uĪati ƒ Normy i specyfikacj e techniczne powiązane ƒ

Normas técnicas e especificaç ões usadas ƒ Standardele tehnice úi specificaĠiile utilizate ƒ

Použité technické norm y a špecifikácie ƒ Uporabljeni tehniþni standardi in specifikacije ƒ

Estándares y especificaciones técni cas utilizadas ƒ Tekniska standarder och specifikationer som anv änds ƒ Samræmdir staðlar sem notaðir eru ƒ Benyttede harmoniserte

standarder

Not Applicable

The place and date of the declar ation ƒ Ɇɹɫɬɨ ɢ ɞɚɬɚ ɧɚ ɞɟɤɥɚɪɚɰɢɹɬɚ ƒ Místo a datum prohlášení ƒ Sted og dat o for erklæringen ƒ Plaats en datum van de v erklaring ƒ

Deklaratsiooni väl jastamise koht ja kuupäev ƒ Vakuutuksen paikka j a päivämäärä ƒ Lieu et date de la déclarati on ƒ Ort und Datum der Erklärung ƒ ȉȩʌȠȢ țĮȚ ȘȝİȡȠȝȘȞȓĮ

įȒȜȦıȘȢ ƒ A nyilatkoz at kelte (hely és idĘ) ƒ Luogo e data della dichiarazi one ƒ Dek

larƗcijas viet a un datums ƒ Deklaracijos vieta ir data ƒ I l-post u d-data tad-dikjarazzjoni ƒ

Miejsce i data wystawienia deklaracj i ƒ Local e data da declaração ƒ Locul úi data declaraĠiei ƒ Miesto a dátum vyhlásenia ƒ Kraj in datum izjave ƒ Lugar y fecha de la

declaración ƒ Plats och datum för deklarationen ƒ Tæknistaðlar og tækni lýsingar sem notaðar eru ƒ Benyttede tekniske standarder og spesifi kasjoner ƒ Staður og dagsetning

yfirlýsingar ƒ S ted og dato for erklæringen

Ransomes Jacobsen Limited

West Roa d, Ransomes Europa rk,

Ipswich, England, IP3 9TT

1st September.2004

Signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentati on and is authorised to compile the technical file, and who is

established in the Community.

ɉɨɞɩɢɫ ɧɚ ɱɨɜɟɤɚ, ɭɩɴɥɧɨɦɨɳɟɧ ɞɚ ɫɴɫɬɚɜɢ ɞɟɤɥɚɪɚɰɢɹɬɚ ɨɬ ɢɦɟɬɨ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ, ɤɨɣɬɨ ɩɨɞɞɴɪɠɚɳ

ɬɟɯɧɢɱɟɫɤɚɬɚ ɞɨɤɭɦɟɧɬɚɰɢɹ ɢ ɟ ɨɬɨɪɢɡɢɪɚɧ ɞɚ ɢɡɝɨɬɜɢ ɬɟɯɧɢɱɟɫɤɢɹ ɮɚɣɥ ɢ ɟ ɪɟɝɢɫɬɪɢɪɚɧ ɜ ɨɛɳɧɨɫɬɬɚ.

Podpis osoby oprávnČné sestavit prohlášení jménem výrobce, držet technickou dokumentaci a osoby oprávnČné

sestavit technické soubory a založené v rámci Evropského spoleþenství.

Underskrift af personen, der har fuldmagt til at udarbejde erklæringen på vegne af producenten, der er indehaver

af dokumentationen og er bemyndiget til at udarbejde den tekniske journal, og som er baseret i nærom rådet.

Handtekening van de persoon die bevoegd is de verklaring namens de fabrikant te tekenen, de technische

documentatie bewaart en bevoegd is om het technische bestand samen te stellen, en die is gevestigd in het Woongebied.

Ühenduse registrisse kantud isiku allkiri, kes on volitatud tootja nimel deklaratsiooni koostama, kes omab tehnilist

dokumentatsiooni ja kellel on õigus koostada tehniline toimik.

Sen henkilön allekirjoitus, jolla on valmistajan valtuutus vakuutuksen laadintaan, jolla on hallussaan tekniset

asiakirjat, joka on valtuutettu laatimaan tekniset asiakirjat ja joka on sijoittautunut yhteisöön.

Signature de la personne habilitée à rédiger la déclaration au nom du fabricant, à détenir la documentation

technique, à compiler les fichiers techniques et qui est implantée dans la Comm unauté.

Unterschrift der Person, die berechtigt ist, die Erklärung im Nam en des Herstellers abzugeben, die die

technischen Unterlagen aufbewahrt und berechtigt ist, die technischen Unterlagen zusammenzustellen,

und die in der Gemeinschaft niedergelassen ist.

ȊʌȠȖȡĮijȒ ĮIJȩȝȠȣ İȟȠȣıȚȠįȠIJȘȝȑȞȠȣ ȖȚĮ IJȘȞ ıȪȞIJĮȟȘ IJȘȢ įȒȜȦıȘȢ İț ȝȑȡȠȣȢ IJȠȣ țĮIJĮıțİȣĮıIJȒ, Ƞ ȠʌȠȓȠȢ

țĮIJȑȤİȚ IJȘȞ IJİȤȞȚțȒ ȑțșİıȘ țĮȚ ȑȤİȚ IJȘȞ İȟȠȣıȚȠįȩIJȘıȘ ȞĮ IJĮȟȚȞȠȝȒıİȚIJȠȞ IJİȤȞȚțȩ ijȐțİȜȠ țĮȚ Ƞ ȠʌȠȓȠȢ İȓȞĮȚ įȚȠȡȚıȝȑȞȠȢ ıIJȘȞ ȀȠȚȞȩIJȘIJĮ.

A gyártó nevében meghatalmazott személy, akinek jogában áll módosítani a a nyilatkozatot, a mĦszaki

dokumentációt Ęrzi, engedéllyel rendelkezik a mĦszaki fájl összeállításához, és aki a közösségben letelepedett személy.

Firma della persona autorizzata a redigere la dichiarazione a nome del fabbricante, in possesso Della

documentazione tecnica ed autorizzata a costituire il fascicolo tecnico, che deve essere stabilita nella Comunità.

TƗs personas paraksts, kura ir pilnvarota deklarƗcijas sastƗdƯšanai ražotƗja vƗrdƗ, kurai ir tehniskƗ

dokumentƗcija, kura ir pilnvarota sagatavot tehnisko reƧistru un kura ir apstiprinƗta KopienƗ.

Asmuo, kuris yra gana žinomas, kuriam gamintojas suteikơƳgaliojimus sudaryti šią deklaraciją, ir kur is ją

pasirašơ, turi visą techninĊ informaciją ir yra Ƴgaliotas sudaryti techninơs informacijos dokum entą.

Il-firma tal-persuna awtorizzata li tfassal id-dikjarazzjoni f’isem il-fabbrikant, gƫandha d-dokumentazzjoni

teknika u hija awtorizzata li tikkompila l-fajl tekniku u li hija stabbilita fil-Komunità.

Podpis osoby upowaĪnionej do sporządzenia deklaracji w imieniu producenta, przechowującej dokumentacjĊ

techniczną, upowaĪnioną do stworzenia dokumentacji technicznej oraz wyznaczonej ds. wspólnotowych.

Assinatura da pessoa com poderes para emitir a declaração em nome do fabricante, que possui a docum entação

técnica, que está autorizada a compilar o processo técnico e que está estabelecida na Comunidade.

Semnătura persoanei împuternicite să elaboreze declaraĠia în numele producătorului, care deĠine documentaĠia

tehnică, e

ste autorizată să compileze dosarul tehnic úi este stabilită în Comunitate.

Podpis osoby poverenej vystavením vyhlásenia v mene výrobcu, ktorá má technickú dokumentáciu a je

oprávnená spracovaĢ technické podklady a ktorá je umiestnená v Spoloþenstve.

Podpis osebe, pooblašþene za izdelavo izjave v imenu proizvajalca, ki ima tehniþno dokumentacijo in lahko

sestavlja spis tehniþne dokumentacije, ter ima sedež v Skupnosti.

Firma de la persona responsable de la declaración en nombre del fabricante, que posee la documentación técnica

y está autorizada para recopilar el archivo técnico y que está establecido en la Comunidad.

Undertecknas av den som bemyndigad att upprätta deklarationen å tillverkarens vägnar, innehar den tekniska

dokumentationen och är bemyndigad att samm anställa den tekniska informationen och som är etablerad i

gemenskapen. Undirskrift aðilans sem hefur umboð til að gera yfirlýsinguna fyrir hönd framleiðandans, hefur undir höndum

tæknigögnin og hefur leyfi til að taka saman t ækniskýrsluna, og er viðurkenndur innan evrópska efnahagssvæðisins.

Signaturen til personen som har fullmakt t il å utferdige erklæringen på vegne av produsenten, er i besittelse av den

tekniske dokumentasjonen, har autorisasjon til å utarbeide den tekniske filen og som har til hold i EU.

Tim Lansdell

Technical Director

1st January 2013

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

Certificate Num ber ƒ ɇɨɦɟɪ ɧɚ ɫɟɪɬɢɮɢɤɚɬ ƒ ýíslo osvČdþení ƒ Certifikatnummer ƒ Certificaatnum mer ƒ Sertifikaadi number ƒ Hyv äksyntänumero ƒ Numéro de certific at ƒ

Bescheinigungsnummer ƒ ǹȡȚșȝȩȢ ȆȚıIJȠʌȠȚȘIJ ȚțȠȪ ƒ Hitelesítési szám ƒ Numero del certif icato ƒ SertifikƗta numurs ƒ Sertifikato numeris ƒ Num ru taƛ-ƚertifikat ƒ Numer

certyfikatu ƒ Número do Certif icado ƒ Număr certificat ƒýíslo osvedþenia ƒ Številka certifikata ƒ Número de certificado ƒ Certifikatsnummer ƒ Númer skírteinis ƒ

Sertifikatnum mer

4129431 (Rev.2)

Page 10

en-10

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

5.1 SAFETY DECALS AND INSTRUCTION

DECALS

A903489 Keep a Safe Distance from the

Machine.

A903494 Caution Rotating Blades.

5 DECALS AND UNIT SPECIFICATIONS

5.2 COMPONENTS FOR TRAILED UNITS

Single unit Gang Mower

Cutting unit

Short draw bar (A)

Unit frame (C)

3-Unit Gang Mower

3 Cutting units

3 Short draw bars (A)

3 Unit frames (C)

2 Extension wings (D)

5-Unit Gang Mower

5 Cutting units

3 Short drawbars (A)

1 Long drawbar (B)

5 Unit frames (C)

2 Extensions wings (D)

1 Twin coupling frame (E)

7-Unit Gang Mower

7 Cutting units

4 Short drawbars (A)

2 Extension wings (D)

2 Twin coupling frames (E)

1 Single point 7 unit drawbar (F)

7 Unit frames (C)

9-Unit Gang Mower

9 Cutting units

6 Short drawbars (A)

2 Long drawbars (C)

9 Unit frames (B)

4 Extension Wings (D)

1 Twin coupling frame (E)

1 Expac 9 unit yoke (G)

Page 11

en-11

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

5.3 DIMENSIONS AND CUTTING

PERFORMANCE

5 DECALS AND UNIT SPECIFICATIONS

5.4 WEIGHT

Mounted Gang Mower:

Frame: 176 kg

Individual Cutting Unit:

Sportcutter Mk 11: 115 kg

Magna Mk 13: 125 kg

Model

Gang Mowers

Mounted

Gang

Mower

Number

of Cutting

Units

13 5 7 9 3

Width of

Cut

76 cm

(2ft 6in)

2.1 m

(7ft 0in)

3.5 m

(11ft 6in)

3.27 m

(16ft 0in)

6.25 m

(20ft 6in)

2.1 m

(7ft 0in)

Overall

Width

1.22 m

(4ft 0in)

2.59 m

(8ft 6in)

3.96 m

(13ft 0in)

5.33 m

(17ft 6in)

6.70 m

(22ft oin)

2.59 m

(8ft 6in)

Overall

Length

81 cm

(2ft 8in)

2.59 m

(8ft 6In)

3.88 m

(12ft 9in)

3.27 m

(10ft 9in)

4.64 m

(15ft 3in)

2.59 m

(8ft 6in)

Transport

Width

-- - - -

2.43 m

(8ft 1in)

Hectares

(Acres)

Cut per

hour

8 kph

(5 mph)

0.40

(1.0)

1.20

(3.0)

2.00

(5.0)

2.80

(7.0)

3.60

(9.0)

1.20

(3.0)

10 kph

(7 mph)

0.50

(1.4)

1.50

(4.2)

2.50

(7.0)

3.50

(9.8)

4.5

(12.6)

1.50

(4.2)

16 kph

(10 mph)

0.80

(2.0)

2.40

(6.0)

4.00

(10.0)

5.60

(14.0)

7.20

(18.0)

2.40

(6.0)

Dr

awbar

Pull

Initial

Pull

100 kg

(220 lb)

300 kg

(660 lb)

500 kg

(1100 lb)

700 kg

(1540 lb)

900 kg

(1980 lb)

300 kg

(660 lb)

In work

50 kg

(110 lb)

150 kg

(330 lb)

250 kg

(550 lb)

350 kg

(770 lb)

450 kg

(990 lb)

150 kg

(330 lb)

Page 12

en-12

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6 ASSEMBLY

6.1 ASSEMBLY—SINGLE UNIT GANG MOWER

1. (Fig. 1). Unscrew the pivot bolt (A) from

the centre of the unit frame. Insert the

lifting lever (B), spring fi rst, into the rear

of the unit frame. The cranked handle can

face right or left. Check that the spring is

pointing downwards and hang ing free,

then insert the pivot bolt (A), through the

hole in the lever and tighten. Do not overtighten as the lever must be free to move.

2. Remove nuts and unscrew bolts (C) from

the unit frame stirrups. Position frame

over unit and lock the spring on to the

end of the arm which points forward from

the front axle of the cutting unit (Fig. 2),

then lower the frame on to the unit so

that the stirrups fi t over the axle correctly.

Screw in and tighten bolts (C). Do not

over-tighten as too much pressure will

distort the stirrup and cause jamming.

3. Fit the lifting link (D) to the lifting lever

and lug (E), on the rear of the cutting unit

bottom block. The two nuts on the main

body of the link should be pointing away

from the cutting cylinder. The fi xed short

loop at one end of the link should be

bolted to the lever, the sliding long loop

should be attached to the cutting unit. Do

not overtighten the bolts. When correctly

coupled the link should be free to pivot

either end, and be free to slide in and out.

4. Remove hitchpin (F) and with the

lubricating nipples on top insert the

drawbar into the front of the unit frame.

The slot must fi t over the distance piece

which is already in position. Insert the

linchpin and secure with spring clip.

Fig 1

Fig 2

Page 13

en-13

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6 ASSEMBLY

6.2 ASSEMBLY—3-UNIT GANG MOWER

Assemble each cutting unit as single unit mower

instruction. Refer to page 10.

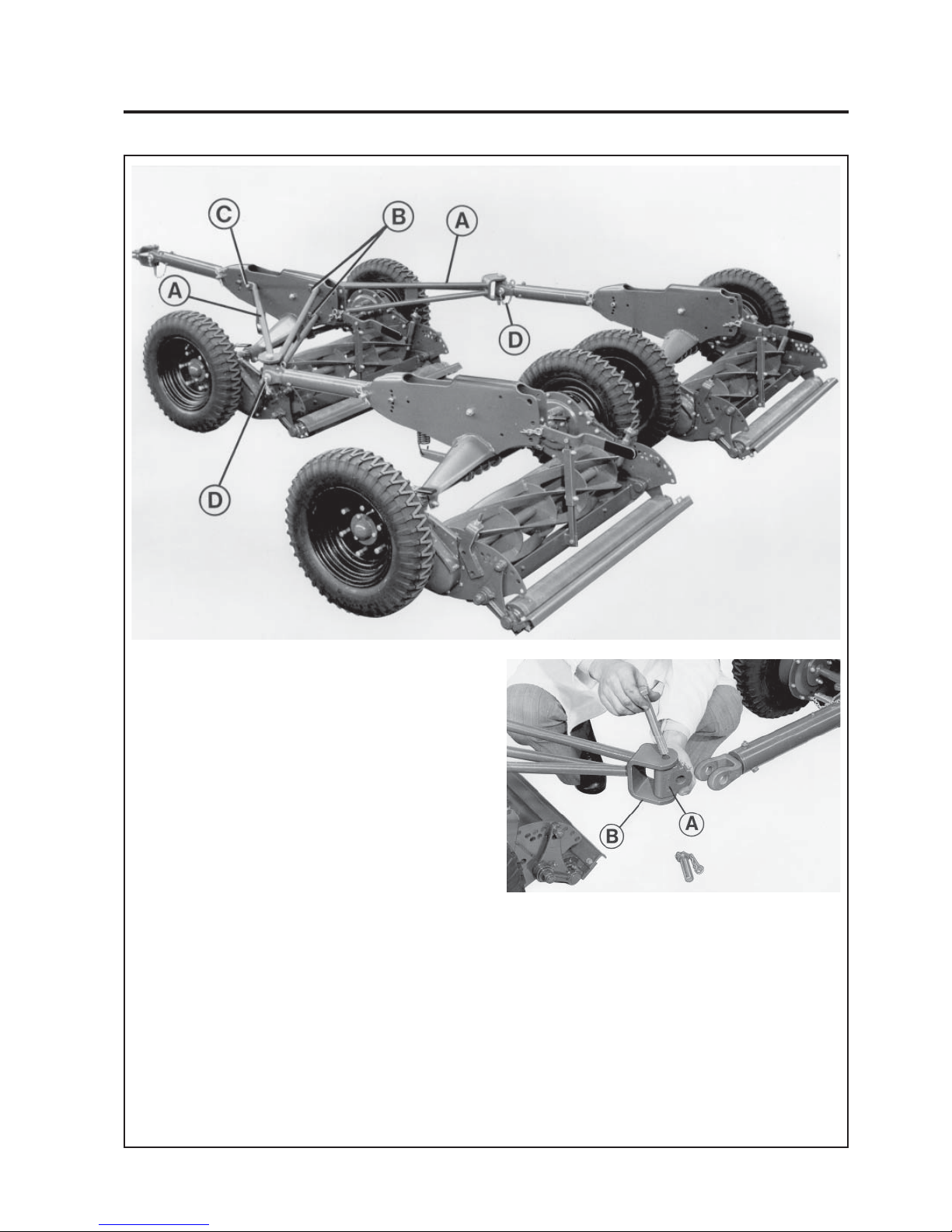

1. (Fig. 3). To one of the cutting units bolt

on the extension wings (A) one each side

of the unit frame. Two long bolts (B) are

used at the rear which go through the

lugs of the extension wings and the unit

frame. Two short bolts (C) are used to

secure the front of the extension wings.

All must be tightened securely.

2. (Fig. 4). From two of the short drawbars

take the universal couplings (A) and bolt

these into the towing points (B) on the

extension wings, ensuring that the bolts

are not overtightened as this will cause

distortion. The universal coupling must

be free to swivel. The lubricating nipples

must point upwards.

3. (Fig. 3). Couple the two rear units to

the towing point on the extension wings

ensuring that the chains (D) hang below

the drawbars.

Fig 4

Fig 3

Page 14

en-14

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6 ASSEMBLY

Fig 7Fig 6

Fig 5

Page 15

en-15

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6.3 ASSEMBLY—3-UNIT MOUNTED GANG

MOWER

1. (Fig. 5). Arrange the cutting units so that

the front two are in line alongside each

other, and the rear unit central. Attach the

hook end of the six diagonal stays (D) into

the lugs (A) on the stops of the cutting

units axle (B).

2 Fit stone guards to Sportcutter Units (Fig.

6) and on Magna Units (Fig. 7). The rear

of stone guard to be fi tted before clamping

front of guard to main axle.

3. (Fig. 5). Remove the six screws (C) from

the hinge brackets of the main frame. Lift

main frame over units and slide hinge

brackets over the centre of the axles,

insert screws and tighten.

Put end of diagonal stays (D) into lugs

forward of the main frame. Retain with

plain washers and split pins provided.

Remove lever pivot bolts (E) from main

frames, fi t the lifting levers (F) spring fi rst,

and replace pivot bolts. Hook springs (G)

on to arm protruding from front of cutting

unit axle.

Fit the lifting link (H) to the lifting lever

(F) and lug (I) on the rear of the cutting

unit bottom block. The two nuts on the

main body of the link should be pointing

away from the cutting cylinder. The fi xed

short loop at one end of the link should be

bolted to the lever, the sliding long loop

should be attached to the cutting unit. Do

not overtighten the bolts. When correctly

coupled the link should be free to pivot

either end and be free to slide in and out.

Remove bolts (K) from lugs on the rear

diagonal tubes of the main frame and

fi t the short ends of the lifting chain (J).

Check that chain is not twisted.

4. (Fig. 8). Slide the ball joint of the two

bottom tractor arms over the end of the

lifting spindle (A) using the upper point

for Ford and British Leyland tractors, and

the lower ones for Massey Ferguson and

David Brown tractors. Insert the retaining

pins supplied with the tractor.

6 ASSEMBLY

Fig 8

Fig 9

Page 16

en-16

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6 CONTROLS

Swing up the lifting frame and couple the

top link (B). The top hole and distance

piece is used with Ford and British

Leyland tractors. The top link on Massey

Ferguson and David Brown trac tors is

fi tted to the lower hole without a distance

piece.

5. (Fig. 9). Reverse tractor to gang mower

and hitch up the draught eye (A) inserting

the pin from the top.

6. (Fig. 5). Place long end of the lifting chain

over the pulley (L) and secure to lugs (M)

on main frame. Check that the spring (N)

is in position on the chain. It should be

positioned between the short chains 15

cm (6”) from the central ring.

7. (Fig. 9). Set tractor drawbar using tractor

hy draulics until centre of lifting spindle

is 32 cm (12.5cm) from the ground, as

illustrated. Move tractor forward a little to

apply a load to the draught eye and check

that the swivel arms (B) are midway in

the guide plate, when the outfi t is on

level ground. The swivel arm must not

foul the top or bottom of the guide plates

as in work this will result in poor ground

following and bending of components.

Adjust length of the top link so that the

lifting frame is vertical. Lock top link.

Page 17

en-17

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6.4 ASSEMBLY—5-UNIT GANG MOWER

1. Assemble three cutting units with unit

frames and short drawbars, and two

cutting units with unit frames only. Refer

to page 10.

2. (Fig. 10). Place the two units without

drawbars side by side. Remove the hinge

plates (A) from the twin coupling frame

(B). Bolt an extension wing (C) and a

hinge plate to each unit. The extension

wings are fi tted to the outer sides of the

unit frames and the hinge plates on the

inner sides. Long bolts (D) are used

on the two rear positions to secure the

extension wing and hinge plate to the unit

frame. Two short bolts (E) are used to

secure the front of the extension wing and

hinge plate.

3. (Fig. 11). Locate the twin coupling frame

on to the hinge plates between the two

front units and secure with clips.

4 (Fig. 10). With the lubricating nipples on

top insert the long drawbar (J) into the

front of the twin coupling frame. The slot

fi ts over a distance piece which is already

in position. Insert the pin (K) and secure

with the spring clips.

5. (Fig. 10). From the three short drawbars

remove the universal couplings (F). Bolt

two couplings into the towing points on

the extension wings and the other into the

towing point at the rear of the twin coupling

frame. Couple the three rear units to the

towing points on the extension wings

and centre of the twin coupling frame,

ensuring that the chains (L) hang below

the drawbars.

Ensure that the bolts are not overtightened

as this will cause distortion.

The coupling must be free to swivel.

Lubricating nipples must point upwards.

6 ASSEMBLY

Fig 11

Fig 10

Page 18

en-18

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6.5 ASSEMBLY—7-UNIT GANG MOWER

1. Assemble four cutting units with unit

frames and short drawbar and three

cutting units with unit frames only. Refer

to page 10.

2. Place the three units without drawbars

side by side.

3 (Fig. 12). Remove hinge plates (A) from

the coupling frames.

4. Bolt an extension wing (B) and a hinge

plate (A) to the outer units. The extension

wings are fi tted to the outer sides of the

unit frames and the hinge plates on the

inner sides. Long bolts (C) are used

on the two rear positions to secure the

extension wing and hinge plate to the unit

frame.

Two short bolts (D) are used to secure

the front of the extension wing and hinge

plate.

5 Bolt hinge plates on both sides of the

centre unit frame with long bolts at the

rear and short bolts at the front and

tighten securely.

6. Locate the twin coupling frames on to the

hinge plates between the three front units

and secure with clips. From the four short

drawbars remove the universal couplings.

Bolt two couplings into the towing points

on the extension wings and the other one

into the towing point at the rear of the twin

coupling frames. Couple the four rear units

to the towing point on the extension wings

and centre of the twin coupling frames,

ensuring that the chains hang below the

drawbars. Ensure that the bolts are not

overtightened, as this will cause distortion.

The coupling must be free to swivel. The

lubricating nipples must point upwards.

7. (Fig. 13). Fit the seven unit drawbar (A)

into the front of the twin coupling frame

using the pins provided and ensuring

that the lubricating nipples are pointing

upwards. From the short drawbars remove

the universal couplings (E) (Fig. 12). Bolt

these couplings into the towing hitches on

the extension wings and the towing points

at the rear of the twin coupling frames.

Ensure that the bolts are not overtightened

as this will cause distortion. The couplings

must be free to swivel. The lubricating

nipples must point upwards.

6 ASSEMBLY

Fig 12

Fig 13

Page 19

en-19

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6 ASSEMBLY

Fig 14

Page 20

en-20

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6.6 ASSEMBLY—9-UNIT GANG MOWER

Assemble fi ve cutting units with unit frames and

and short drawbars, two cutting units

with unit frames and long drawbars, two

cutting units with unit frames only. Refer

to page 10.

2. (Fig. 14). To two of the units fi tted

with unit frames and long drawbars fi t

extension wings (A) to both sides using

long bolts to secure the rear and short

bolts at the front.

3. Position the two units without drawbars

side by side. Remove the hinge plates

(B) from the twin coupling frame and bolt

these to the inner sides of the unit frame

using long bolts at the rear and short

bolts at the front. Locate twin coupling

frame (C) on to the hinge plates and

secure with clips. Fit short drawbar to

front of twin coupling frame. Remove

hitch pin and with the lubricating nipples

on top insert the drawbar into the front

of the unit frame. The slot must fi t over

the distance piece which is already in

position. Insert the hitch pin and secure

with spring clip.

4. (Fig. 15). Fit centre tube (A) of the yoke

to the main tube (B). Check that the stand

(C) and hook (D) are pointing downwards

and secure with the bolts, nuts and

washers provided. Next fi t the two outer

members (E) to the front of the centre

tube and to the outer face of the brackets

on the end of the main tube (Fig. 16).

Tighten all bolts securely. Fit wheels (F)

to the main tube.

5. Remove the universal couplings from all

drawbars and bolt these to the towing

points on the yoke, twin coupling frames

and extension wings.

Ensure that the bolts are not

overtightened as this will cause distortion.

Universal couplings must be free to

swivel. Lubricating nipples must point

upwards.

(a) Couple the two units fi tted with twin coup-

ling frame to the towing hitch at the centre

of the yoke.

(b) Couple one unit fi tted with a short drawbar

to the towing point at the rear of the twin

coupling frame.

(c) Couple two units fi tted with long drawbars

to the towing points at each end of the

yoke.

(d) Couple four units fi tted with short drawbars

to the towing points on the extension

wings.

Ensure when securing drawbars to towing

hitches that the chain attached to the hitch

pins hang below the drawbars.

6 ASSEMBLY

Fig 16

Fig 15

Page 21

en-21

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

6.7 COUPLING THE GANG MOWERS

TO A TRACTOR

(Fig. 17). The tractor drawbar must be fi xed. If it

is a swivelling type, a bracket (A) must be fi tted to

prevent it from tipping up or down. Stabilisers must

be fi tted to the lower links of the tractor to prevent

movement from side to side. Bolt the tractor hitch

(B) to the tractor drawbar and tighten securely.

TRACTOR TOWING HITCH FOR 1, 3, 5 AND 7

UNIT TRAILED GANG MOWER (Fig. 17)

With the lubricating nipples on top insert the

univers al coupling (C) and secure with bolt. If the

space between the two plates is too wide for the

universal coupling fi t plain washers (D) as required.

The long bolt which holds the universal coupling

between the plates should be inserted from the top.

It must not be overtightened as this will squeeze

in the plates. The universal coupling must be free

to swivel. Couple the drawbar to the universal

coupling with the hitch pin and clip. The chain at

this point must hang freely underneath the drawbar

to prevent damage.

TRACTOR TOWING HITCH FOR 9 UNIT

TRAILED GANG MOWER

The tractor loop (A, Fig. 18) is bolted to the centre

of the tractor drawbar. The yoke ~s supported

by the adjustable stand (A, Fig. 19). The tractor

can then be reversed so that the tractor loop is

beneath the hook on the yoke. The foot rest is then

retracted allowing the hook to locate in the tractor

loop. A safety catch (B) must be raised and held in

position by the drop pin.

ALIGNMENT AND ADJUSTMENTS

(Fig. 20). With the tractor on level ground and the

drawbar set at 15” from the ground check that the

top of the unit frame is horizontal. If it is not it can

be adjusted by withdrawing the bolts from the front

of the unit frame (A). This will allow the front of the

unit frame to be raised or lowered to give correct

level. The bolt should be replaced in the nearest

hole but check that the distance piece inside the

unit frame is in position before securing.

Adjust the rear roller of the cutting unit to give the

height of cut you require, then check the position

of the lifting link (B). The sliding part of the link

should be in a mid way position, i.e. half the link

shoud be outside the square main body and half

inside, ensur ing maximum fl oat of the cutting unit

over ground undulations. The lifting lever can be

moved to any one of three positions to give this

adjustment. The lever is secured by a pin (C) which

should be placed into the nearest hole when the

link is in its correct position.

If the height of cut is altered you must check the

position of the lifting link and adjust as necessary.

The chain (D) at this point should be over the lever.

The outfi t as far as assembly and alignment is con-

cerned is now ready for use but before putting it

into work it must be serviced.

Fig 17

Fig 18

Fig 19

Fig 20

6 ASSEMBLY

Page 22

en-22

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

7.1 LUBRICATION

GEAR CASE

Machines are despatched without oil in the

gearcases which must be fi lled to the correct level

before use. (Fig. 21). Correct lubrication of the gear

box is essential for long life and good performance.

Each gear box—there is one on the left and one on

the right of the cutting unit—must be provided with

oil up to the level of the oil level plug (A). Remove

this plug to check oil level. If necessary remove

fi lter plug (B) and top up until oil appears from level

plug hole. Replace the oil level plug ensuring that

the fi bre washer is in position. Never top up without

removing level plug. The correct grade of oil for

gear boxes is SAE 140. If the unit is used with

other manufacturers frame work which tilts the unit

on end the gear box should be lubricated with non

tracking grease to prevent leakage. Check level

monthly.

REAR ROLL

(Fig. 22). There are two lubricating nipples (A) in

the rear roller carriages which must be lubricated

weekly using oil in the lubricating gun.

DRAWBAR

Each drawbar and universal coupling has four

nipples

(B and C), which should be lubricated weekly.

Do not lubricate the sliding parts or attachment

points of the lifting links (D). Oil on these points will

collect dirt and grit which will accelerate wear.

Fig 21

Fig 22

7 LUBRICATION

7.2 LUBRICATION CHART

Gear Boxes Check and Top Up Monthly

SAE 140 Oil or

Retinax 'G' Semi Fluid

Grease

Rear Roll Carridges Lubricate Weekly Grease

Drawbar Lubricate Weekly Grease

Universal Joint Lubricate Weekly Grease

Page 23

en-23

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

8.1 OPERATING PROCEDURE

1. Under no circumstances should the engine be started without the operator seated on the tractor.

2. Do not operate tractor or attachments with loose, damaged or missing components. Whenever

possible mow when grass is dry

3. First mow in a test area to become thoroughly familiar with the operation of the tractor and control

levers.

Note: To prevent damage to the reel and bottom blade never operate the reels when they are not

cutting grass. Excessive friction and heat will develop between the bottom blade and reel

and damage the cutting edge.

4. Study the area to determine the best and safest operating procedure. Consider the height of

the grass, type of terrain, and condition of the surface. Each condition will require certain

adjustments or precautions.

5. Never direct discharge of material toward bystanders, nor allow anyone near the machine while in

operation. The owner/operator is responsible for injuries infl icted to bystanders and/or damage to

their property.

6. Use discretion when mowing near gravel areas (roadway, parking areas, cart paths, etc.). Stones

discharged from the implement may cause serious injuries to bystanders and/or damage the

equipment.

7. Stop and inspect the equipment for damage immediately after striking an obstruction or if the

machine begins to vibrate abnormally. Have the equipment repaired before resuming operation.

To help prevent injury, always wear safety

glasses, leather work shoes or boots, a

hard hat and ear protection.

CAUTION

Pick up all debris you can f nd before

mowing. Enter a new area cautiously

Always operate at speeds that allow you to

have complete control of the tractor

CAUTION

Before you clean, adjust, or repair this

equipment, always disengage all drives,

lower implements to the ground, engage

parking brake, stop engine and remove key

from ignition switch to prevent injuries.

WARNING

8 OPERATION

Page 24

en-24

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

8.3 OPERATING THE GANG MOWERS

1. (Fig. 23). Engage the cutting unit drive by

pulling out and turning the gear selectors

(A) on each side of the cutting unit to a

vertical position and ensure that the cross

pin (B) is located in the vertical groove.

Both selectors must be in drive otherwise

overloading and also wheel slip will be

caused.

2. The correct towing speed is dependent

on ground conditions.

Average conditions 6—8 kph (4—5 mph).

Good, relatively smooth ground

conditions 9—11 kph (6—7 mph).

Speeds of up to 16 kph (10 mph) can be

used where ground conditions permit.

3. If the rear rolls bounce slow down. It is a

sign that you are going too fast.

4. The speed of the machine should be fast

enough to give a good grass throw from

the rear of the unit. This will ensure even

distribution of the cut grass behind the

machine and give a good appear ance

and also prevent grass being carried

round by the cutting cylinder and choking

it.

Fig 23

Fig 24

8 OPERATION

The daily inspection should be performed

only when the engine is off and all f uids

are cold. Lower implements to the ground,

engage parking brake, stop engine and

remove ignition key.

CAUTION

8.2 DAILY INSPECTION

1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardwear and missing or

damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and

tubes are in good condition.

2. Make sure all cutting units are adjusted to the same height of cut.

3. Check all tyres for proper infl ation.

5. Avoid rapid acceleration or violent

engagement of the tractor clutch. Pull

away gently to avoid shocks to the

transmission, this will help consid erably

towards obtaining long life and good service from your machine.

Page 25

en-25

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

9.1 MAINTENANCE

CUTTING CYLINDER ADJUSTMENT

(Fig. 24). Before use, check the cutting cylinder

adjustment, which must be set correctly and locked.

To do this, check the adjustment by revolving the

cutting cylinder manually and testing with thin paper,

newspaper will do. If the paper is not cut cleanly,

unlock the bottom block locks (A) by turning them

clockwise. Next turn the nut (B) on top of the bracket

clockwise a little at a time until the cutting cylinder

will cut paper cleanly. The cutting cylinder MUST

spin freely. Retighten the bottom block lock securely,

adjusting nut (B) as necessary to maintain correct

setting. The correct setting of the unit is essential for

good performance and long life.

HEIGHT OF CUT ADJUSTMENT

(Fig. 25). The machine is supplied to give a medium

cut. To alter the height of cut remove the bolts (A)

which secure the rear roll carriages and move the carriages up or down as required. Replace and securely

tighten the bolts.

Note The nuts (B) need not be slackened to do this.

Caution A machine should never be used with the

bottom blade pressing on the ground as the cutting

cylinder may be damaged by the bottom blade being

forced upwards, also the wear is greater and the

machine will be harder to work.

TYRE PRESSURE

The tyre pressure should be maintained at 1.05 kg/

cm

2

(15 psi).

SCRAPER

Scrapers are intended for use in wet, muddy conditions and should be adjusted so that they are just clear

of the rear roll. They must never be allowed to contact

the rear roll.

REMOVING THE CUTUING CYLINDER

(Fig. 30). The cutting cylinder can be removed without

dismantling the remainder of the machine. Remove

the small cover (A) and gasket from the main gear

cover. Take out the four screws securing the cylinder

housing (B) to the side frames. The cylinder can

now be lifted out by a steady upward pull applied

simultaneously to each end of the cylin der.

GENERAL MAINTENANCE AND STORAGE

After use, it is recommended that you clean off the

machine, brush or wipe oil on to the cutters. A few

turns in reverse when you are doing this will scrape oil

on to the edge of the bottom blade.

Fig 25

9 MAINTENANCE

If the machine is washed down use low pressure

only, otherwise water will be forced into the bearings

and housings and cause corrosion which will shorten

the working life.

Use only genuine parts supplied from your

approved Textron Turf Care and Specialty

Products Dealer, when maintaining and

repairing your equipment.

CAUTION

Page 26

en-26

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

10.1 TRANSPORTING

TRAILED GANG UNITS

1. When moving from site to site the cutting

cylin ders must be out of gear, but this

must not be done while the machine is in

motion.

2 (Fig. 26). When trailed gang mowers are

moved along paths or roads the rear rolls

must be raised clear of the ground by

locking the lifting lever in the top hole (A)

of the unit frame.

TRANSPORTING TRAILED GANG MOWERS IN

TRAILERS AND TRUCKS

(Fig. 27). All drawbars and coupling frames can

be quickly removed and the frame dismantled into

easily transportable units. The lifting levers must be

anchor ed in the bottom position (A) and the nose

of the rear unit pinned into the top lifting lever hole

(B) of the front unit. By this method a three unit or

fi ve unit mower can be coupled nose to tail and

winched up to a truck or trailer.

The unit fi tted with extension wings must be the

last of the series. When close packing fi ve unit and

seven unit mowers which include two unit frames

fi ted with one extension wing each, it is necessary

to use the trailing hitch (C). This should be fi tted to

the lifting hole (D) of the second last unit frame and

the nose of the last frame pinned through the hole

in the hitch (E). The lifting lever of the last frame

should be allowed to fl oat.

MOUNTED TRIPLE MOWER

For road transport the machine must be raised and

locked for safety to reduce the overall width of the

machine to comply with the Ministry of Transport

Regulations.

1. (Fig. 28). Remove locking pins (A) from

hole in brackets (B) at both sides of the

machine.

2. (Fig. 29). Attach check chains (A) to main

axle of outer cutting units.

3. Lift machine by operating tractor hydraulic

lift.

4. (Fig. 28). Replace locking pins (A) in

brackets (B) at both sides of the machine.

After transporting, the above procedure is reversed

Fig 26

10 TRANSPORTING

Fig 27

before putting the machine into work. It is necessary,

however, to drive the tractor forward to enable the

wing units to take up their working position before

replacing the locking pins.

Fig 28

Fig 29

Page 27

en-27

RANSOMES GANG MOWERS

SPORTCUTTER Mk11, MAGNA Mk13

SAFETY AND OPERATORS MANUAL

11 GUARANTEE / SALES & SERVICE

GUARANTEE

We GUARANTEE that should any defect in workmanship or material occur in the

goods within TWO YEARS or two thousand hours (on models equipped with hour

meters), or whichever occurs f rst.

Exception to this warranty will be Aeration products, which are covered for a period

of TWO-YEARS or f ve hundred hours (on models equipped with hour meters) or

whichever occurs f rst.

We will repair, or at our option, replace the defective part without making any charge

for labour or for materials, provided that the claim under this guarantee is made

through an authorised dealer and that the defective part shall, if we so request, be

returned to us or to the dealer.

This guarantee is in addition to, and does not exclude, any condition or warranty

implied by law, except that we accept no liability in respect of used/second-hand

goods, or in respect of defects which in our opinion are in any way or to any extent

attributable to misuse, lack of reasonable care or ordinary wear and tear, or to

the f tting of spares, replacements, or extra components which are not supplied

or approved by us for the purpose. The use of non-recommended oil or lubricant

nullif es the guarantee.

Damage through transport or normal wear does not come under the guarantee.

The warranty is extended to the original purchaser only and is not transferable to

subsequent owners. The warranty period begins on the date the product is delivered

to the end user (customer), unless otherwise agreed with the manufacturer. At the

end of the f rst year the owner must have the product serviced by an authorised

dealer to be eligible for the second year of warranty coverage.

SALES & SERVICE

A network of authorised Sales and Service dealers has been established and these

details are available from your supplier.

When service attention, or spares, are required for the machine, within or after

the guarantee period your supplier or any authorised dealer should be contacted.

Always quote the registered number of the machine.

If any damage is apparent when delivery is made, report the details at once to the

supplier of the machine.

Page 28

Page 29

Page 30

Europe & Rest of The World Except North & South America

Ransomes Jacobsen Limited

West Road, Ransomes Europark, Ipswich, IP3 9TT

English Company Registration No. 1070731

www.ransomesjacobsen.com

North & South America

Jacobsen, A Textron Company

11108 Quality Drive, Charlotte,

NC 28273, USA

www.Jacobsen.com

Loading...

Loading...