Rangemaster RMDD4804, RMDD3604, RMDD3004EX, RMDD3604EX, RMDD4804EX Instructions Manual

®

Downdraft Ventilators

MODEL WIDTH

RMDD3004 30"

RMDD3604 36"

RMDD4804 48"

RMDD3004EX 30"

RMDD3604EX 36"

RMDD4804EX 48"

WARNING -To reduce the risk of burns or ignition of clothing by reaching across burners, the downdraft remote control MUST

be mounted in the countertop - at least 4" from the burners. See "INSTALL COOKTOP" section on page 8.

BLOWER

500 cfm interior

500 cfm interior

500 cfm interior

Models 331 H, 332H, 335, or 336 Exterior (purchase separately)

Models 331 H, 332H, 335, or 336 Exterior (purchase separately)

Models 331 H, 332H, 335, or 336 Exterior (purchase separately)

WARNING

TO REDUCE THE RiSK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

Ifyou have questions, contact the manufacturer at the address

or telephone number in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuet burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer's guideline and safety standards such as those

published bythe National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code au-

thorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fire, use only metal ductwork.

8. Do not install this product with the activating switch directly

behind a burner or element. Minimum distance between the

switch and the edge of the burner should be 4 inches.

9. Loose-fitting or hanging clothing should never be worn when

operating this appliance. They may be ignited by burners/

elements on cooktop.

10.Children should not be left alone or unattended in the area

where this appliance is in use.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings.

Boitovers cause smoking and greasy spitlovers that may

ignite. Heat oils slowly on tow or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

Page 1

WARNING

TO REDUCE THE RiSK OF INJURY TO PERSONS iN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWINGa:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immedi

atety, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels

- a violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

aBased on "Kitchen Firesafety Tips" published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

3. Clean filters and grease-laden surfaces frequently.

4. Do not repair or replace any part of this appliance unless

specifically recommended in this manual. All other servicing

should be done by a qualified technician.

5. Please read specification label on product for further informa-

tion and requirements.

NOTE"

Model RMDDRBK Remote Up/Down

Control sold separately.

INSTALLER:

Save this manual for Electrical

Inspector and Homeowner to use.

PLANNING

®

Downdraft Ventilators

Page 2

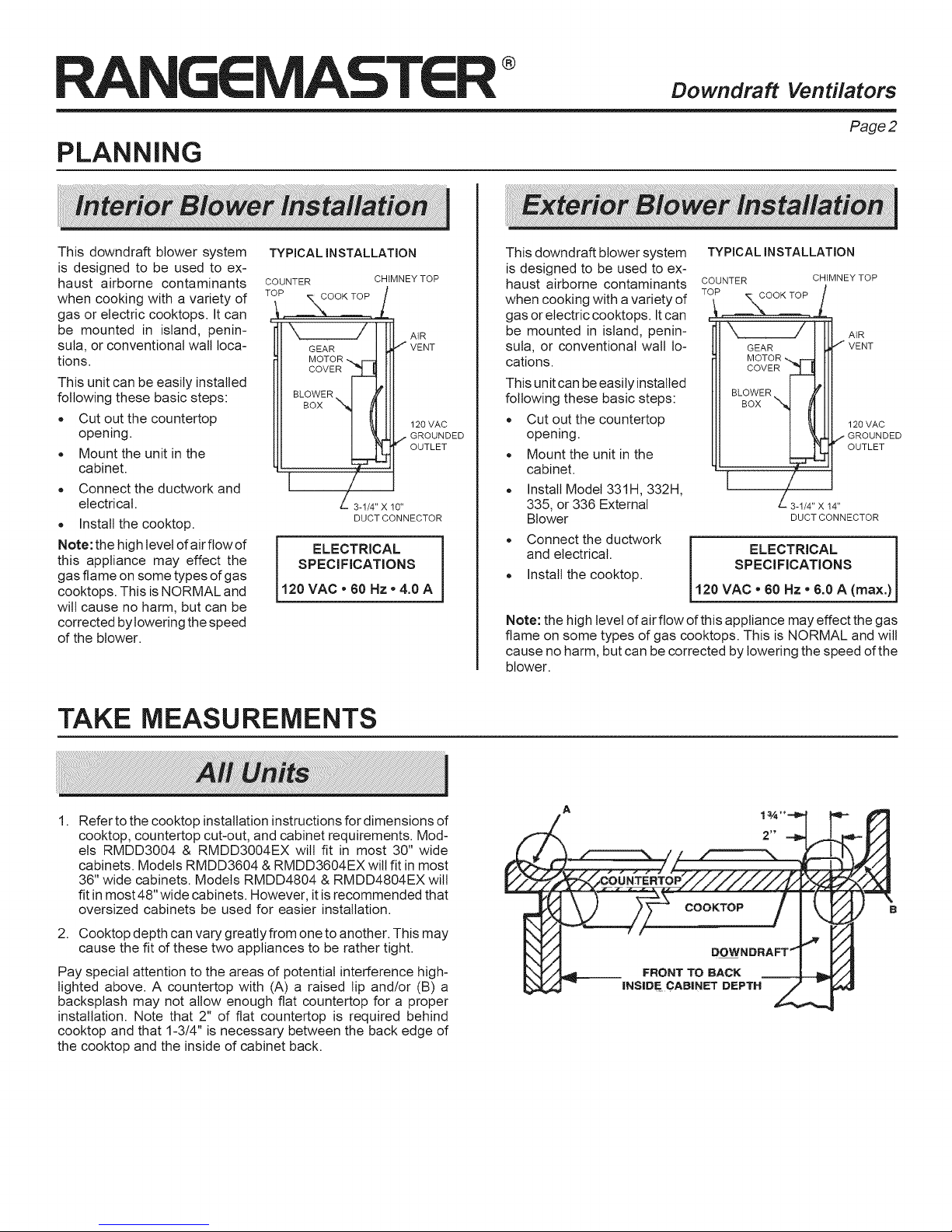

This downdraft blower system

is designed to be used to ex-

haust airborne contaminants

when cooking with a variety of

gas or electric cooktops. It can

be mounted in island, penin-

sula, or conventional wall loca-

tions.

This unit can be easily installed

following these basic steps:

• Cut out the countertop

opening.

Mount the unit in the

cabinet.

Connect the ductwork and

electrical.

Install the cooktop.

Note: the high level of air flow of

this appliance may effect the

gas flame on some types of gas

cooktops. This is NORMAL and

wilt cause no harm, but can be

corrected by lowering the speed

of the blower.

TYPICAL INSTALLATION

COUNTER CHIMNEY TOP

TOP

'e\\DO OK TOP

AtR

VENT

120 VAC

GROUNDED

OUTLET

X-1/4" X 10"

DUCT CONNECTOR

ELECTRICAL

SPECIFICATIONS

120 VAC * 60 Hz * 4.0 A

This downdraft blower system

is designed to be used to ex-

haust airborne contaminants

when cooking with avariety of

gas or electric cooktops. It can

be mounted in island, penin-

sula, or conventional wall lo-

cations.

This unit can be easily installed

following these basic steps:

Cut out the countertop

opening.

Mount the unit in the

cabinet.

,, Install Model 331H, 332H,

335, or 336 External

Blower

Connect the ductwork

and electrical.

Install the cooktop.

Note: the high level of airflow of this appliance may effect the gas

flame on some types of gas cooktops. This is NORMAL and will

cause no harm, but can be corrected by lowering the speed of the

blower.

TYPICAL INSTALLATION

COUNTER

TO _,_OOK TOP

CHIMNEY TOP

/

i

"\ f IIH.A'R

GEAR I _ VENT

MOTOR "_r"-_ fll

Jw°2 111

"I 111

I !1 II1 120VAC

i l.-'oyO 2fED

,24,,

DUCT CONNECTOR

ELECTRICAL

SPECIFICATIONS

120 VAC " 60 Hz" 6.0 A (max.)

TAKE MEASUREMENTS

1.

Refer to the cooktop installation instructions for dimensions of

cooktop, countertop cut-out, and cabinet requirements. Mod-

els RMDD3004 & RMDD3004EX wilt fit in most 30" wide

cabinets. Models RMDD3604 & RMDD3604EX will fit in most

36" wide cabinets. Models RMDD4804 & RMDD4804EX will

fit in most 48" wide cabinets. However, it is recommended that

oversized cabinets be used for easier installation.

2. Cooktop depth can vary greatly from one to another. This may

cause the fit of these two appliances to be rather tight.

Pay special attention to the areas of potential interference high-

lighted above. A countertop with (A) a raised lip and/or (B) a

backsplash may not allow enough flat countertop for a proper

installation. Note that 2" of flat countertop is required behind

cooktop and that 1-3/4" is necessary between the back edge of

the cooktop and the inside of cabinet back.

B

FRONT TO BACK

INSIDE CABINET DEPTH

®

TAKE

MEASUREMENTS (CONTINUED)

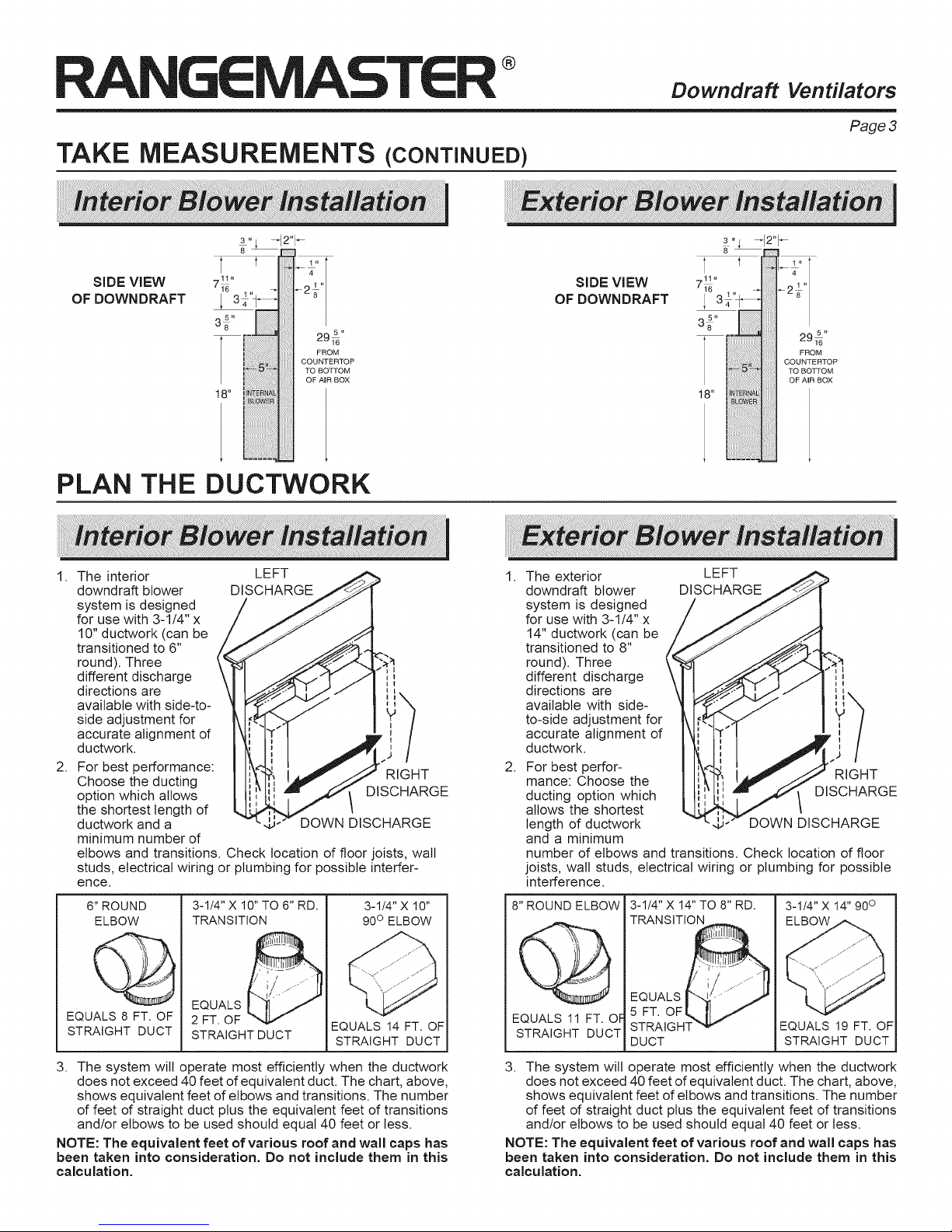

SIDE VIEW

OF DOWNDRAFT

PLAN THE

3,_ -12"1-

716 1,, _ _218 ''

FROM

COUNTERTOP

I !_ i TO BOTTOM

1 " i!iili _ _!:

2915,,

OF AIR BOX

DUCTWORK

SIDE VIEW

OF DOWNDRAFT

Downdraft

Ventilators

Page 3

295"

FROM

COUNTERTOP

TO BOTTOM

OF AIR BOX

1. The interior

downdraft blower

LEFT >

DISCHARGE

system is designed

for use with 3-1/4" x

10" ductwork (can be

transitioned to 6"

round). Three

different discharge

directions are

available with side-to-

side adjustment for

accurate alignment d

ductwork.

2,

For best performance:

Choose the ducting

'_ I_ r" JJ RIGHT

option which allows

the shortest length of

ductwork and a

J'" DOWN DISCHARGE

minimum number of

elbows and transitions. Check location of floor joists, wall

studs, electrical wiring or plumbing for possible interfer-

ence.

6" ROUND

ELBOW

EQUALS 8 FT. OF

STRAIGHT DUCT

3-1/4" X 10" TO 6" RD.

TRANSITION

EQUALS _

2 FT. OF

STRAIGHT DUCT

3-1/4" X 10"

90° ELBOW

EQUALS 14 FT. OF

STRAIGHT DUCT

1,

The exterior

downdraft blower

system is designed

LEFT .I" ,.

DISCHARGE _>_ _'

for use with 3-1/4" x

14" ductwork (can be

transitioned to 8"

round). Three

different discharge

directions are

available with side-

to-side adjustment for

accurate alignment of

ductwork.

2,

For best perfor-

mance: Choose the

ducting option which

allows the shortest

',

length of ductwork

and a minimum

number of elbows and transitions. Check location of floor

joists, wall studs, electrical wiring or plumbing for possible

interference.

8" ROUND ELBOW

EQUALS 11 FT. OF

STRAIGHT DUCT

3-1/4" X 14" TO 8" RD.

TRANSITION

DUCT

3-1/4" X 14" 90°

EQUALS 19 FT. OF

STRAIGHT DUCT

3. The system will operate most efficiently when the ductwork

does not exceed 40 feet of equivalent duct. The chart, above,

shows equivalent feet of elbows and transitions. The number

of feet d straight duct plus the equivalent feet of transitions

and/or elbows to be used should equal 40 feet or less.

NOTE: The equivalent feet of various roof and wall caps has

been taken into consideration. Do not include them in this

calculation.

3. The system will operate most efficiently when the ductwork

does not exceed 40 feet of equivalent duct. The chart, above,

shows equivalent feet of elbows and transitions. The number

of feet of straight duct plus the equivalent feet of transitions

and/or elbows to be used should equal 40 feet or tess.

NOTE: The equivalent feet of various roof and wall caps has

been taken into consideration. Do not include them in this

calculation.

®

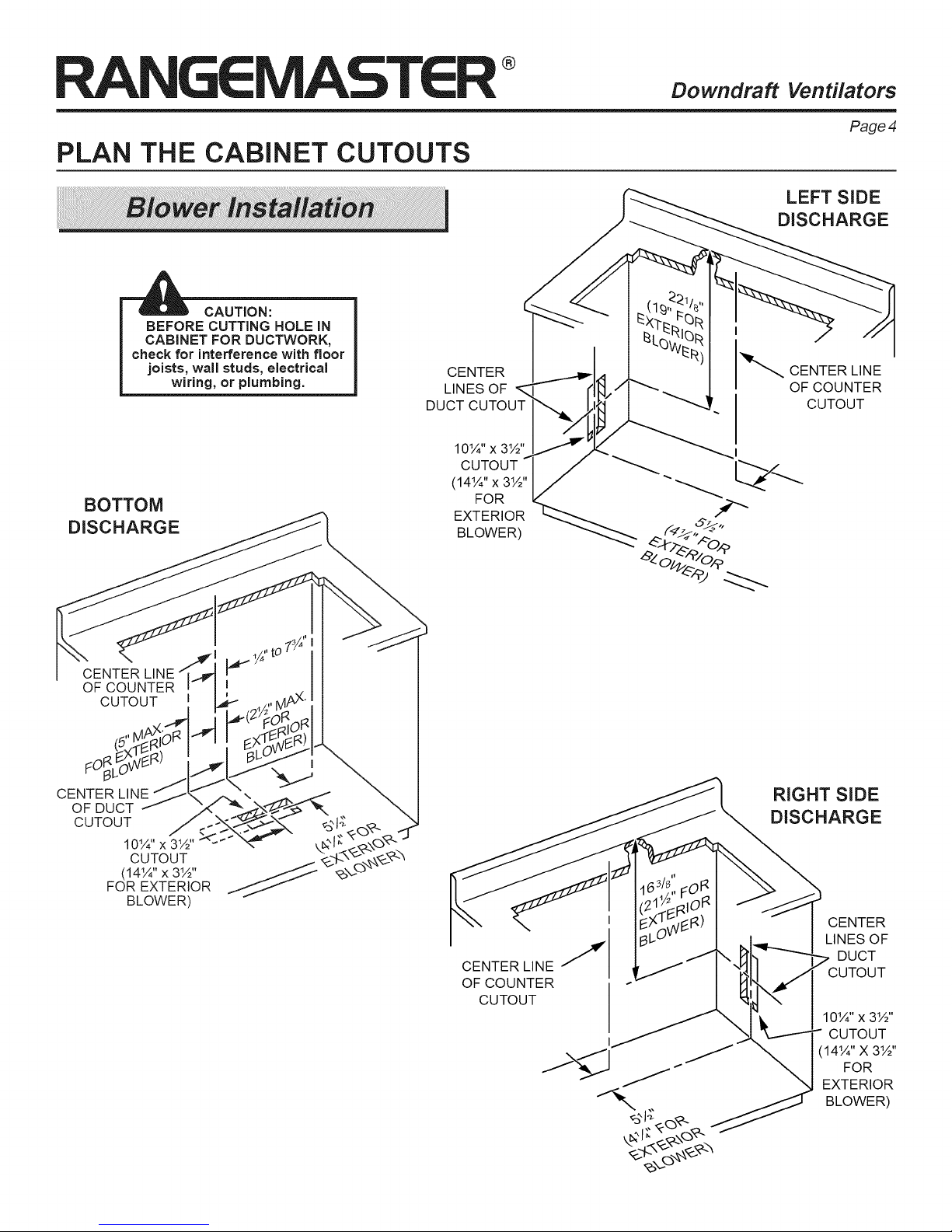

PLAN

'_ CAUTION:

BOTTOM

DISCHARGE

THE CABINET CUTOUTS

BEFORE CUTTING HOLE IN

CABINET FOR DUCTWORK,

check for interference with floor

joists, wall studs, electrical

wiring, or plumbing.

CENTER

LINES OF

DUCT CUTOUT

10¼" x 3½"

CUTOUT

(14¼" x 3½"

FOR

EXTERIOR

BLOWER)

Downdraft

_...CENTER LINE

Ventilators

Page 4

LEFT SiDE

DISCHARGE

OF COUNTER

CUTOUT

OF COUNTER

CUTOUT

FO_L

CENTER LINE

OF DUCT

CUTOUT

10¼" x 3½"

CUTOUT

(14¼" x 3½"

FOR EXTERIOR

BLOWER)

CENTER LINE J

OF COUNTER

CUTOUT

j%_l j-J

RIGHT SiDE

DISCHARGE

CENTER

LINES OF

DUCT

CUTOUT

10¼" x 3½"

CUTOUT

(14¼" X 3½"

FOR

EXTERIOR

BLOWER)

®

PLAN THE WIRING

1. The Interior Downdraft Blower system draws 4 AMPS and

requires a 120 VAC, 60 Hz circuit.

2. The unit has a 18 in. tong power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit's power cord to reach.

IMPORTANT - LOCATION OF ELECTRICAL OUTLET:

If Model RMDD3004 is being installed in a 30" wide

cabinet...

or Model RMDD3604 is being installed in a 36" wide

cabinet...

or Model RMDD4804 is being installed in a 48" wide

cabinet...

...the outlet cannot be located on the back wall

of cabinet.

Inthese cases, the width of the downdraft covers nearly the

entire width of the back walt of the cabinet. So you must

either:

• mount the electrical box to a side wall or cabinet floor

- at least 12 inches from the back wall.

• mount the electrical box to a wall stud behind the

cabinet - where it will not be covered by the downdraft.

Then provide a clearance hole in the back wall of the

cabinet.

I

Downdraft

1. The Exterior Downdraft Blower system draws 6 AMPS and

requires a 120 VAC, 60 Hz circuit.

2. The unit has a 18 in. tong power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit's power cord to reach.

IMPORTANT - LOCATION OF ELECTRICAL OUTLET:

If Model RMDD3004EX is being installed in a 30" wide

cabinet...

or Model RMDD3604EX is being installed in a 36"

wide cabinet...

or Model RMDD4804EX is being installed in a 48"

wide cabinet...

...the outlet cannot be located on the back wall

of cabinet.

Inthese cases, the width of the downdraft covers nearly the

entire width of the back walt of the cabinet. So you must

either:

• mount the electrical box to a side wall or cabinet floor

- at least 12 inches from the back wall.

• mount the electrical box to a wall stud behind the

cabinet -where itwill not be covered by the downdraft.

Then provide a clearance hole in the back wall of the

cabinet.

Ventilators

Page 5

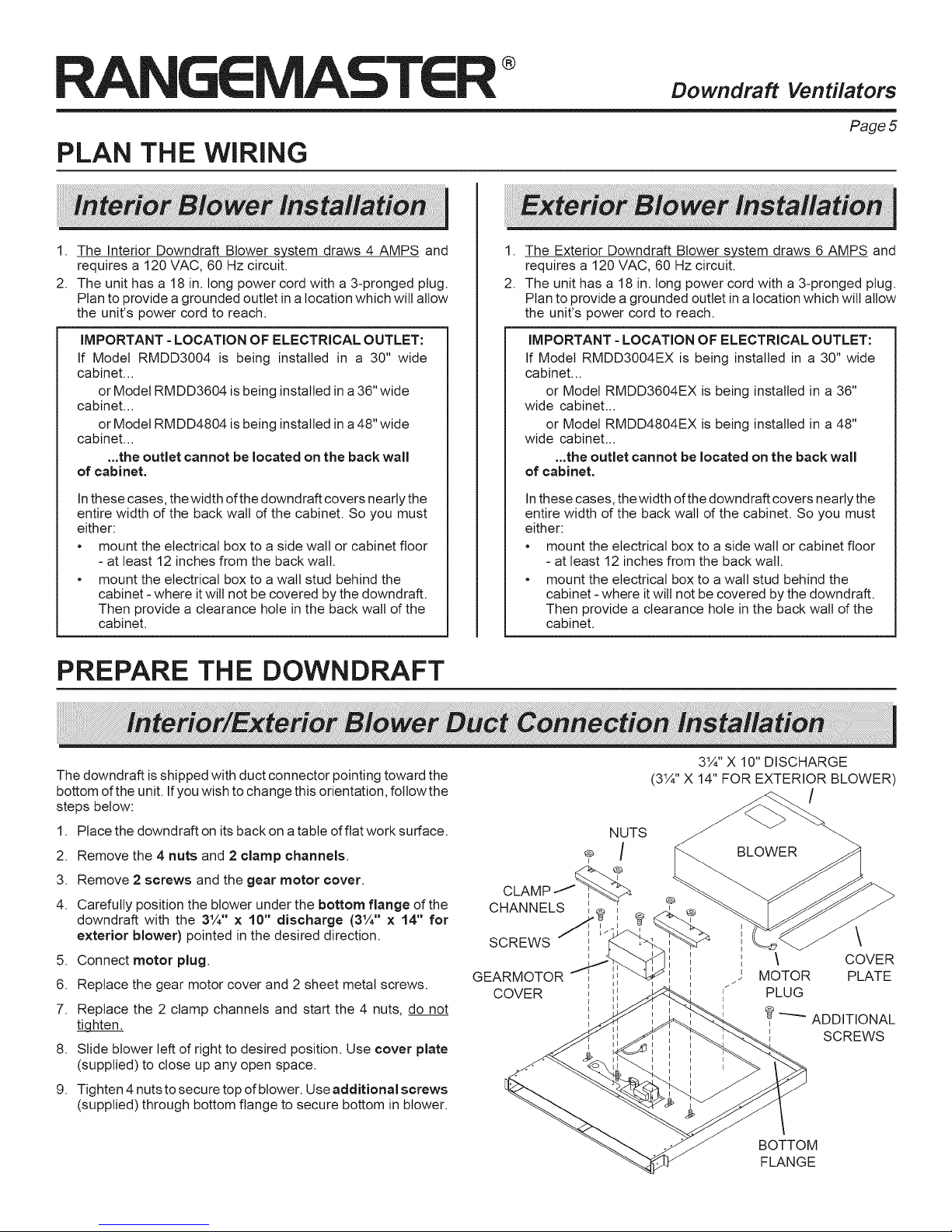

PREPARE THE DOWNDRAFT

The downdraft isshipped with duct connector pointing toward the

bottom of the unit. Ifyou wish to change this orientation, follow the

steps below:

1. Place the downdraft on its back on a table of fiat work surface.

2. Remove the 4 nuts and 2 clamp channels.

3. Remove 2 screws and the gear motor cover.

4. Carefully position the blower under the bottom flange of the

downdraft with the 3¼" x 10" discharge (3¼" x 14" for

exterior blower) pointed in the desired direction.

5. Connect motor plug.

6. Replace the gear motor cover and 2 sheet metal screws.

7. Replace the 2 clamp channels and start the 4 nuts, do not

_hten.

8. Slide blower left of right to desired position. Use cover plate

(supplied) to close up any open space.

9. Tighten 4 nuts to secure top of blower. Useadditional screws

(supplied) through bottom flange to secure bottom in blower.

CHANNELS I_

SCREWS _ I-

GEARMOTOR

COVER I ii

3¼"XI0"DISCHARGE

(3¼" X 14" FOR EXTERIOR BLOWER)

/

NUTS

\

\ COVER

MOTOR PLATE

PLUG

_ ADDITIONAL

SCREWS

BOTTOM

FLANGE

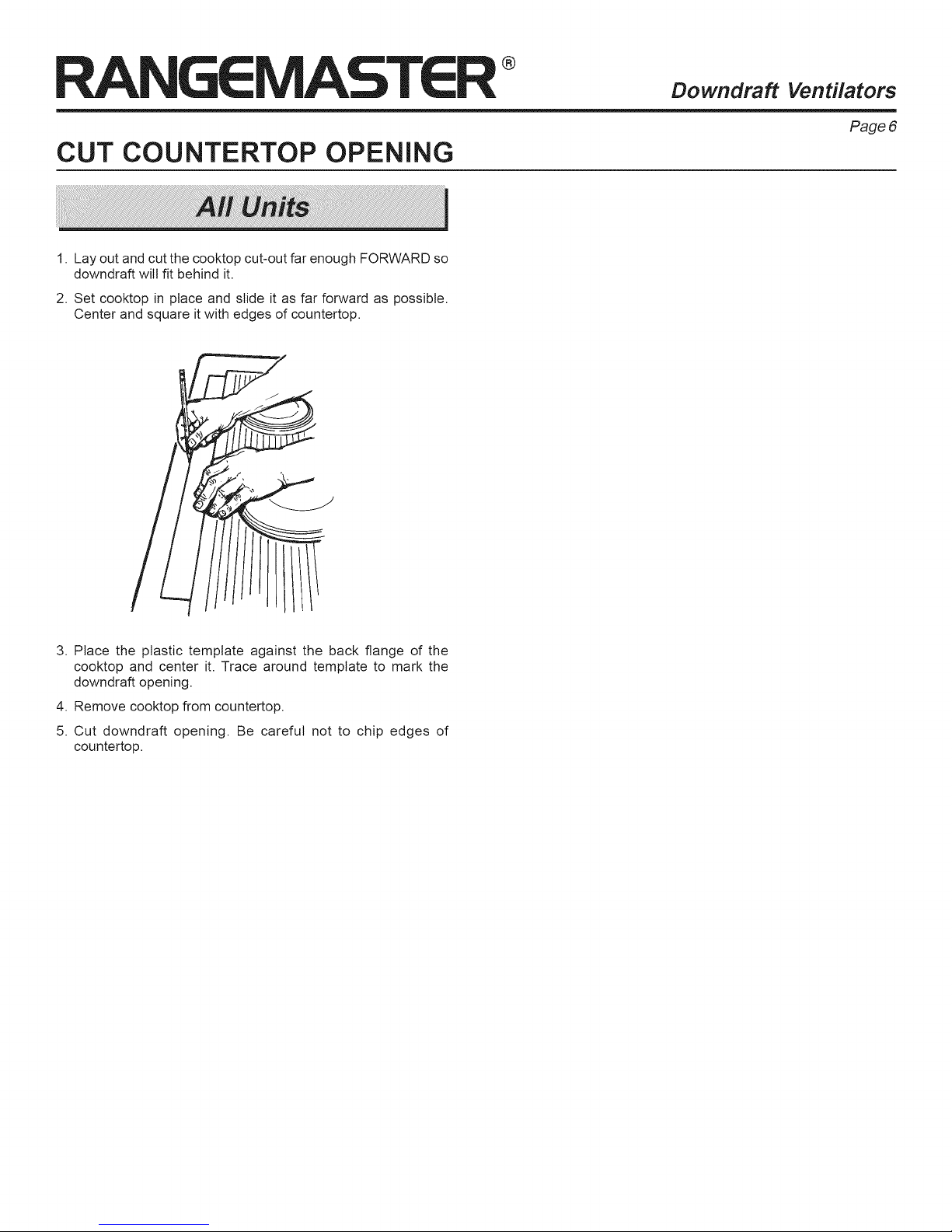

CUT COUNTERTOP OPENING

1. Lay out and cut the cooktop cut-out far enough FORWARD so

downdraft will fit behind it.

2. Set cooktop in place and slide it as far forward as possible.

Center and square it with edges of countertop.

®

Downdraft Ventilators

Page 6

3. Place the plastic template against the back flange of the

cooktop and center it. Trace around template to mark the

downdraft opening.

4. Remove cooktop from countertop.

5. Cut downdraft opening. Be careful not to chip edges of

countertop.

®

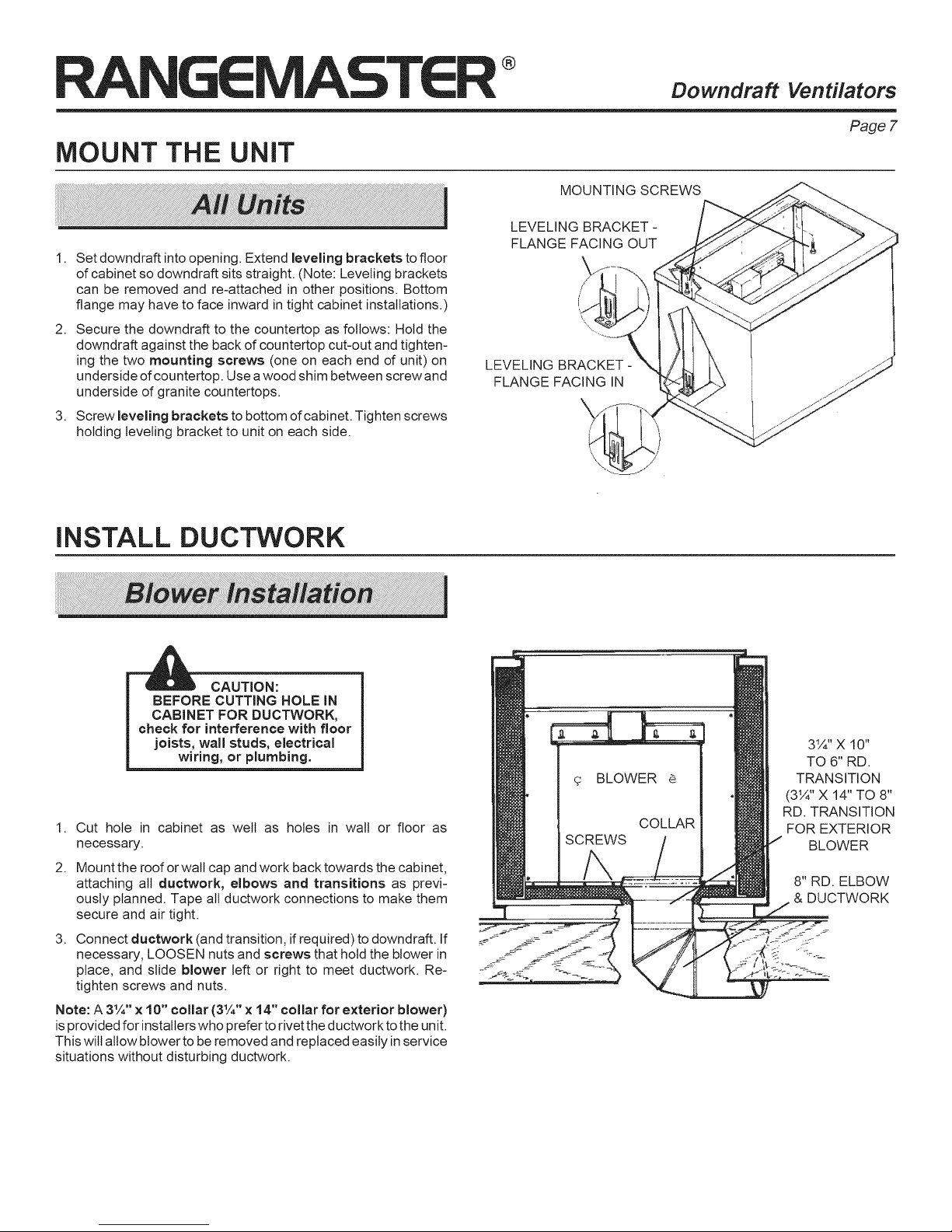

MOUNT THE UNIT

1,

Set downdraft into opening. Extend leveling brackets to floor

of cabinet so downdraft sits straight. (Note: Leveling brackets

can be removed and re-attached in other positions. Bottom

flange may have to face inward in tight cabinet installations.)

2,

Secure the downdraft to the countertop as follows: Hold the

downdraft against the back of countertop cut-out and tighten-

ing the two mounting screws (one on each end d unit) on

underside ofcountertop. Use a wood shim between screw and

underside of granite countertops.

3,

Screw leveling brackets to bottom of cabinet. Tighten screws

holding leveling bracket to unit on each side.

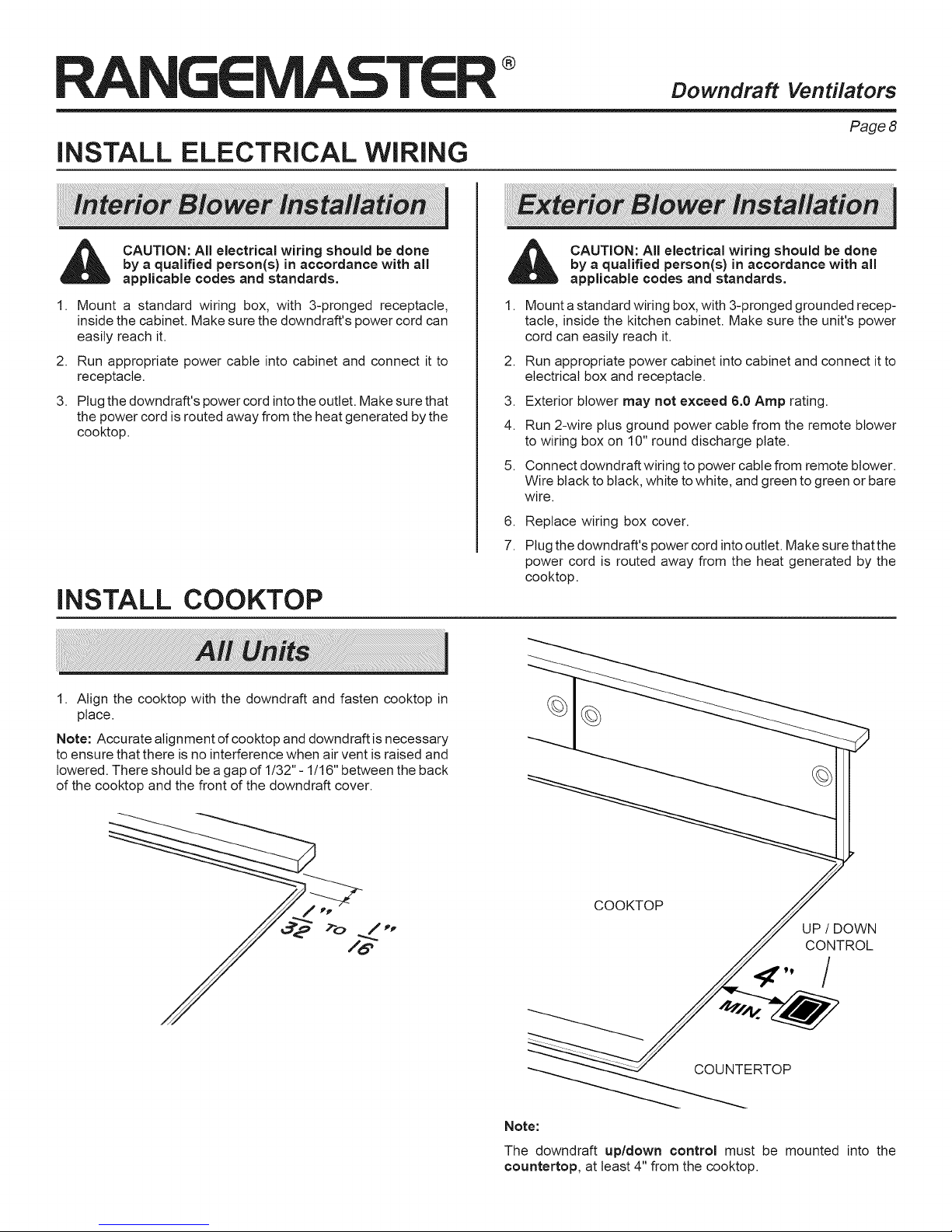

INSTALL DUCTWORK

MOUNTING SCREWS

LEVELING BRACKET-

FLANGE FACING OUT

LEVELING BRACKET-

FLANGE FACING IN

Downdraft

Ventilators

Page 7

--'_ CAUTION:

BEFORE CUTTING HOLE IN

CABINET FOR DUCTWORK,

check for interference with floor

joists, wall studs, electrical

wiring, or plumbing.

1. Cut hole in cabinet as welt as holes in wall or floor as

necessary.

2,

Mount the roof or wall cap and work back towards the cabinet,

attaching all ductwork, elbows and transitions as previ-

ously planned. Tape all ductwork connections to make them

secure and air tight.

3,

Connect ductwork (and transition, if required) to downdraft. If

necessary, LOOSEN nuts and screws that hold the blower in

place, and slide blower left or right to meet ductwork. Re-

tighten screws and nuts.

Note: A 3¼" x 10" collar (3¼" x 14" collar for exterior blower)

isprovided for installers who prefer to rivet the ductwork tothe unit.

This will allow blower to be removed and replaced easily in service

situations without disturbing ductwork.

3¼" X 10"

TO 6" RD.

TRANSITION

(3¼" X 14" TO 8"

RD. TRANSITION

FOR EXTERIOR

BLOWER

8" RD. ELBOW

DUCTWORK

®

iNSTALL

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1.

Mount a standard wiring box, with 3-pronged receptacle,

inside the cabinet. Make sure the downdraft's power cord can

easily reach it.

2.

Run appropriate power cable into cabinet and connect it to

receptacle.

3.

Plug the downdraft's power cord into the outlet. Make sure that

the power cord is routed away from the heat generated by the

cooktop.

ELECTRICAL WIRING

iNSTALL COOKTOP

Downdraft

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1.

Mount a standard wiring box, with 3-pronged grounded recep-

tacle, inside the kitchen cabinet. Make sure the unit's power

cord can easily reach it.

2.

Run appropriate power cabinet into cabinet and connect it to

electrical box and receptacle.

3.

Exterior blower may not exceed 6.0 Amp rating.

4.

Run 2-wire plus ground power cable from the remote blower

to wiring box on 10" round discharge plate.

5.

Connect downdraft wiring to power cable from remote blower.

Wire black to black, white to white, and green to green or bare

wire.

6.

Replace wiring box cover.

7.

Plug the downdraft's power cord into outlet. Make sure that the

power cord is routed away from the heat generated by the

cooktop.

Ventilators

Page 8

1. Align the cooktop with the downdraft and fasten cooktop in

place.

Note: Accurate alignment d cooktop and downdraft is necessary

to ensure that there is no interference when air vent is raised and

lowered. There should be a gap of 1/32"- 1/16" between the back

of the cooktop and the front of the downdraft cover.

©

©

COOKTOP

UP / DOWN

CONTROL

-X- /

COUNTERTOP

Note:

The downdraft up/down control must be mounted into the

countertop, at least 4" from the cooktop.

®

Downdraft Ventilators

Page9

REMOTE

When to use the Remote UP/DOWN Control

The Remote UP/DOWN Control should be used when your

cooktop has a burner that is within 4 inches of the UP/DOWN

Button on the downdraft chimney.

The Remote UP/DOWN Control can be used for convenient UP/

DOWN operation of the downdraft chimney (even when a burner

is more than 4 inches from the UP/DOWN Button of the downdraft

chimney).

How to use the Remote UP/DOWN Control

Do not place the remote control where it wilt interfere with

cooking, where hot pans could be set, or where hot liquids could

be spilled on the control.

The Remote UP/DOWN Control disables the UP/DOWN function

of the UP/DOWN Button on the downdraft chimney.

Installation

1. Using the template at right, lay out the 3-hole pattern on the

counter top. Mark the centers of the three holes to be drilled.

2. Carefully drill the three holes through the counter top. Be

careful not to damage or chip the counter top surface when

drilling the holes.

3. Remove the control from the plastic bag. Line the control up

with the three holes and position the control so it is parallel

with the front d the counter top.

4. Remove the two nylon thumbnuts from the plastic bag and

thread onto the two studs on the control from below the

counter top. Hand tighten only.

WARNING: To reduce the risk of burns or ignition

of clothing by reaching across burners, the re-

mote control must be mounted at least 4" away

from any cook top burner.

5. Remove the blower, clamp channels, and gearmotor cover

from downdraft (see"Prepare the Downdraft" on page 5).

Remove the large panel to expose the downdraft's wiring.

UP/DOWN CONTROL INSTALLATION (OPTIONAL)

WIRING

BOX

.438

DIA.

HOLE

2.000

.250 DIA.

HOLES

DOTTED LiNE

--f-

.750

br

I

I .750

I

WIRING

BOX

6. At the lower right hand corner of downdraft, unplug the cable

from the left side of the wiring box.

DOWNDRAFT

CABINET

FLOOR

REMOTE

CABLE

LOWER

RIGHT

SIDE

OF

7. Remove remote cable from the plastic bag and plug into back of

control from below counter top. Route cable through cabinet to

lower right hand comer of downdraft and through the clearance

holes in the side of downdraft and wiring box. Plug cable intocircuit

board plug, as shown.

8. Stuff excess cable out of the way, secure the cable so it is not

damaged by itemsstoredinthe cabinet, and reassemble downdraft.

®

USE AND CARE

WARNING: Always disconnect electric

supply before cleaning and/or servicing unit.

Always turn the downdraft blower on before you begin cooking to

establish an air flow in the kitchen. Let the blower run for a few

minutes to clean the air after you turn the cooktop off. This will

keep the whole kitchen cleaner and brighter. The activating switch

is pressed and the air vent rises.

power

Downdraft

Cleaning

Use a mild detergent suitable for painted surfaces. DO NOT USE

ABRASIVE CLOTH, STEEL WOOL PADS, OR SCOURING

POWDERS. Vacuum blower to clean. Do not immerse blower in

water.

Wash the 2 aluminum/stainless steel grease filters in a mild

detergent solution or a dishwasher, Remove them from the air

vent by grasping the tab at the top of each filter,

Servicing

It may be necessary to remove the downdraft blower system from

the cabinet in order to service components such as the blower

motor or air vent mechanism.

Disconnect power to the cooktop and remove it first. Reverse the

steps under "MOUNT THE UNIT" to remove the downdraft from

the cabinet.

Ventilators

Page 10

BACKSIDE OF

REMOTE SWITCH

TEMPLATE

OPERATION

®

Downdraft Ventilators

Page 11

Turnthe_t bl_er OFF by pressingtheactivatingswitch

again.The air v_ntwillgo dckns_d the blowerwillsh!tOFF.

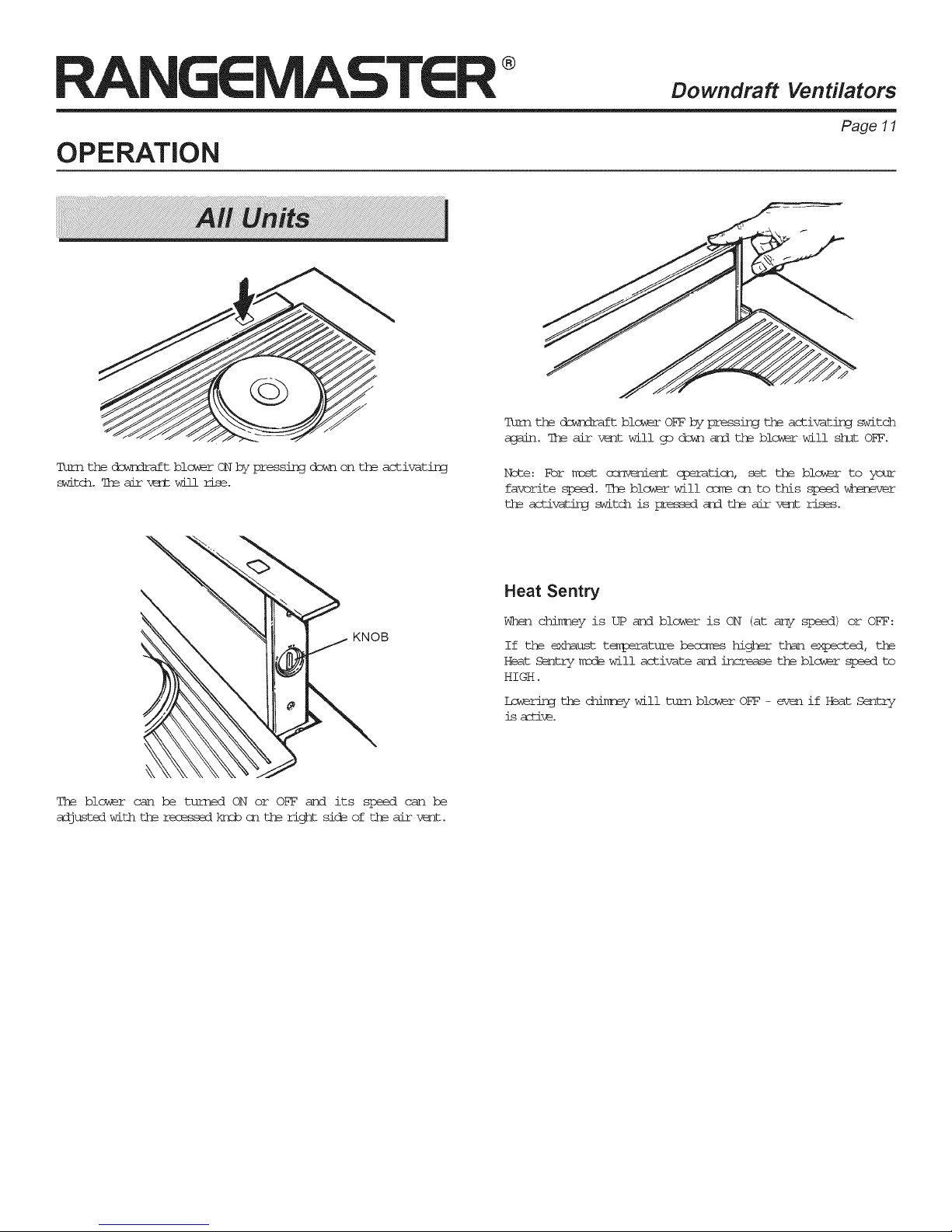

Turn the dowrlraft b!ower ON by pressing down on the activating

switch.7h_air-_ wil! rise.

KNOB

The b!ower can be turned ON or OFF and its speed can be

adjustedwithth_rec_sedkseben th_rightsic_ofth_air-w<r_t.

Note: For Kost corfqemier_cperation, set the blcwar to your

favorite speed. The blcwer wil! ccm_ cn to this slseeffwhenever

th_ activatirgswitch is pressed and th_ air vc_t rises.

Heat Sentry

When chimey is UP and blower is ON (atany speed)or OFF:

If the exhaust tem!3eratureheosm÷s higher than expected, the

Heat Sentry msde wil! activate and increase the b!ower s_ed to

HIGH.

Lc_rLngthechimc_ywil!turnbl__rOFF- evenifHeatSentry

isamid.

®

WARRANTY

BROAN ONE YEAR LIMITED WARRANTY

Broan warrants to the original consumer purchaser of

its products that such products will be free from defects

in materials or workmanship for a period of one year

from the date of original purchase. THERE ARE NO

OTHER WARRANTIES, EXPRESS OR IMPLIED, IN-

CLUDING, BUT NOT LIMITED TO, IMPLIED WARRAN-

TIES OR MERCHANT ABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

During this one-year period, Broan will, at its option,

repair or replace, without charge, any product or part

which is found to be defective under normal use and

service.

THIS WARRANTY DOES NOT EXTEND TO FLUO-

RESCENT LAMP STARTERS, TUBES, HALOGEN AND

INCANDESCENDT BULBS. This warranty does not

cover (a) normal maintenance and service or (b) any

products or parts which have been subject to misuse,

negligence, accident, improper maintenance or repair

(other than by Broan), faulty installation or installation

contrary to recommended installation instructions.

The duration of any implied warranty is limited to the

one-year period as specified for the express warranty.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

BROAN'S OBLIGATION TO REPAIR OR REPLACE, AT

BROAN'S OPTION, SHALL BE THE PURCHASER'S

SOLEAND EXCLUSIVE REMEDY UNDERTHIS WAR-

RANTY. BROAN SHALL NOT BE LIABLE FOR INCI-

DENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES

ARISING OUT OF OR IN CONNECTION WITH PROD-

UCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you

may also have other rights, which vary from state to

state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan

at the address or telephone number below, (b) give the

model number and part identification and (c) describe

the nature of any defect in the product or part. At the time

of requesting warranty service, you must present evi-

dence of the original purchase date.

Broan-NuTone LLC, 926 W. State Street,

Hartford, Wisconsin 53027 (1-800-637-1453)

Downdraft

Ventilators

Page 12

SERVICE PARTS

KEY 30N 36N 48N

NO. WIDTH WIDTH WIDTH DESCRIPTION

1 97015987 97015988 97015989 TOP COVER

2 99140195 99140195 99140195 FILTERSPRING

3 99230345 99230345 99230345 POP RIVET

4 97015970 97015971 97015972 CHIMNEYWELDMENT

5 97015874 97015874 97015874 ENDCAP RH

6 98009358 98009358 98009358 ENDCAP LR

7 97015973 97015973 97015973 MACHINEDCHIMNEYSLIDE

8 98010013 98010013 98010013 MACHINEDAIRBOXSLIDE

9 99160421 99160421 99160421 SCREWRHM8-32x .375

10 99160419 99160419 99160419 SCREW8-32x..500PHL

11 99271218 99271218 99271218 GROUNDWIRE

12 99150471 99150471 99150471 SCREW10-32x .500TYPCAPH

13 97015841 97015842 97015843 FILTER

14 99710032 99710032 99710032 SPACER

15 99111184 99111184 99111184 SLIDE STRIPS

16 97015974 97015975 97015976 AIRBOXWELDMENT

17 99271210 99271210 99271210 CORDSET

18 99400060 99400060 99400060 STRAINRELIEFBUSHING

19 99271295 99271295 99271295 WIRE HARNESS

20 99271292 99271292 99271292 POT ASSEMBLY

21 99271291 99271291 99271291 CONTROLBOARD

22 97015674 97015674 97015674 CRANK ASSEMBLY

23 97015977 97015977 97015977 GEAR MOTORBRACKET

24 99080513 99080542 99080542 GEAR MOTOR

26 98009802 98009801 98009800 FRONTAIRBOXBOTTOM

27 97015990 97015991 97015992 GEAR MOTORCOVER

INTERNALBLOWERMODELS

97015993 97015994 97015995 GEAR MOTORCOVER

EXTERNALBLOWERMODELS

28 98008158 98008158 98008158 AIRBOX OPENINGCOVER

29 98009773 98009773 98009773 AIRBOXCLAMP

30 99260488 99260488 99260488 WHIZNUT10-24

31 97015700 97015700 97015700 SCROLLBOXASSEMBLY

32 98008150 98008150 98008150 SCROLLBOXCOVER

33 98008157 98008157 98008157 CAPACITORCLAMP

34 98008167 98008167 98008167 EXT - SCROLLBOXWELDMENT

35 99080362 99080362 99080362 MOTORW/CAPACITOR

36 99020247 99020247 99020247 BLOWERWHEEL

37 99100484 99100484 99100484 MOTORMOUNTISOLATOR

38 99260477 99260477 99260477 WHIZNUT1/4-20

39 99030323 99030323 99030323 THERMOSTAT

40 97015903 97015903 97015903 ADAPTOR PLATE

41 98010005 98010005 98010005 OUTLETPLATE

42 99271304 99271304 99271304 WIRE HARNESS

43 99400042 99400042 99400042 STRAINRELIEFBUSHING

44 99271296 99271296 99271296 UP/DOWNBUTTONHARNESS

45 99271306 99271306 99271306 THERMOSTATWIREHARNESS

46 98010010 98010010 98010010 THERMOSTATMOUNTING

BRACKET

Loading...

Loading...