Rangemaster RM60000 SERIES Installation Instructions And User Manual

RM60000 SERIES

RANGE HOOD

INSTALLATION INSTRUCTIONS

AND USER MANUAL

HB0026

!

INTENDED FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEA VE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGE 10.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

NuTone,Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, ON L5T 1H9 (1-888-882-7626)

!

V05527 rev. D

WARNING WARNING

!

!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service disconnecting means

to prevent po w er from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be

done by qualified personnel in accordance with

all applicable codes and standards, including

fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer’s

guidelines and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any additional solid-state

speed control device.

8. To reduce the risk of fire, use only steel ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or

when cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware

appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid,

cookie sheet or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS.

IF THE FLAMES DO NOT GO OUT IMMEDIATELY,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN – You may

be burned.

3. DO NOT USE WATER, including wet dishcloths or

towels – This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and

you know how to operate it.

B. The fire is small and contained in the area

where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and

vapors.

2. To avoid motor bearing damage and noisy

and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

3. Your hood motor has a thermal overload which

will automatically shut off the motor if it

becomes overheated. The motor will restart when

it will be cooled down. If the motor continues

to shut off and restart, have the hood serviced.

4. For best capture of cooking impurities, the bottom of

the hood should be at a minimum of 24” and at a

maximum of 30” above the cooking surface.

5. To reduce the risk of fire and to properly

exhaust air, be sure to duct air outside – Do not

exhaust air into spaces within walls or ceilings

or into attics, crawl spaces or garage.

6. This product is equipped with a thermostat which

may start blower automatically. To reduce the

risk of injury and to prevent power from being

switched on accidentally, switch power off at service

panel and lock or tag service panel.

7.

To reduce the risk of fire and electrical shock, the

Rangemaster RM60000 Series hood must be

installed with blower models RM325H, RM326H,

331H, 332H, 335 or 336 only. Other blowers cannot

be substituted. (Blowers sold separately).

8. Use with approved cord-connection kit only.

9. Please read specification label on product for

further information and requirements.

- 2 -

TABLE OF CONTENTS

1.0 SELECT BLOWER OPTION AND INSTALL DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.0 MEASURE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.0 PREPARE THE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.0 INSTALL BACKSPLASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5.0 INSTALL WOOD MOUNTING STRIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.0 INSTALL THE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7.0 INSTALL TRANSITION TO ROUGH-IN PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

8.0 INSTALL THE ROUGH-IN PLATE TO THE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

9.0 CONNECT THE WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10.0 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

11.0 INSTALL THE OPTIONAL SOFFIT CHIMNEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

12.0 INSTALL BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

13.0 INSTALL LIGHT BULBS AND WARMING LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

14.0 INSTALL FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

15.0 USE AND CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

16.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

17.0 SERVICE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

18.0 WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

- 3 -

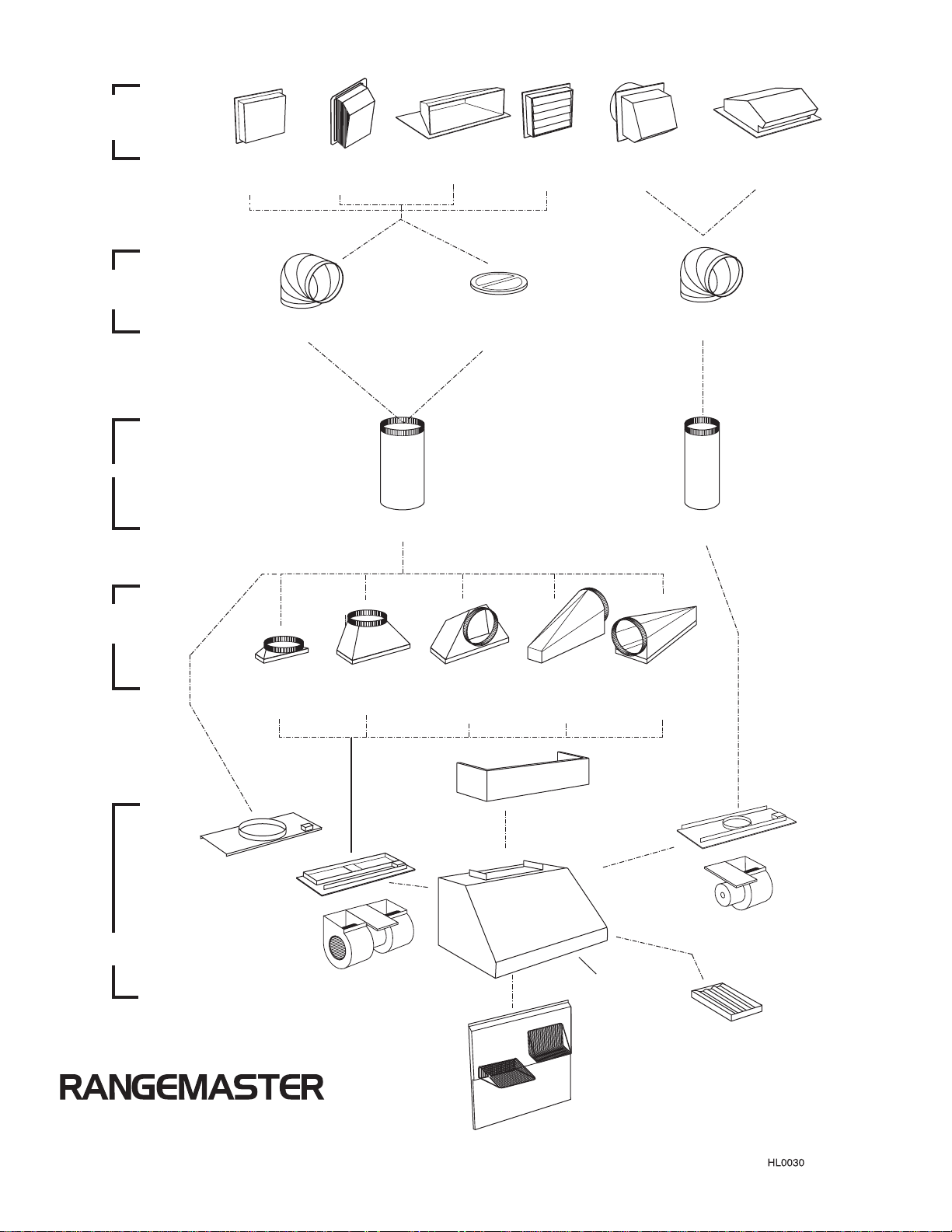

Wall & Roof

Caps, Ext.

Blowers

Elbows &

In-Line

Dampers

Ductwork

MODEL 331H

(600 cfm) OR

332H (900 cfm)

(Exterior Blower)

MODEL 418

(10” Rd. Adjustable Elbow)

MODEL 335

(1200 cfm) OR

336 (1500 cfm)

(Exterior Blower)

MODEL 437

(High Capacity

Roof Cap)

MODEL 421

(10” Rd. Vert.

In-Line Damper)

MODEL 441

(10” Rd.

Wall Cap)

MODEL 647

(7” Rd.

Wall Cap)

MODEL 415

(7” Rd. Adjustable Elbow)

MODEL 634

OR 644

(Roof Cap)

Choose 1 of

5 Discharge

Transitions

Choose 1 of 3

Blower Systems

MODEL 427

(4

to 10” Rd., 6”

high - lateral)

ROUGH-IN KIT

MODEL 332KR

(Use with all

Exterior Blower

models: 331H,

332H, 335, 336)

(10” Rd. Duct - 2 ft. sections)

MODEL 423

1

/2”x 181/2”

MODEL RM326H

BLOWER / ROUGH-IN KIT

(1200 cfm Interior Blower &

1

/2”x 181/2”to

(4

10” Rd. - vertical)

Rough-in Plate)

MODEL 410

MODEL 424

1

(4

/2”x 181/2”to

10” Rd. - horiz.

front / rear)

MODEL 454

1

(4

/2”x 181/2”to

10” Rd. -

horiz. / right)

OPTIONAL SOFFIT

CHIMNEY

RMN SERIES

MODEL 407

(7” Rd. Duct - 2 ft. sections)

MODEL 453

1

/2”x 181/2”to

(4

10” Rd. - horiz. /

left)

RM60000

SERIES

HOOD

(Canopy with

blower controls

& lighting.

Required for all

installations.)

MODEL RM325H

BLOWER / ROUGH-IN KIT

(600 cfm Interior Blower &

Rough-in Plate)

OPTIONAL

BAFFLE

FILTERS

RBF SERIES

B R O A N - N U T O N E

B Y

RM60000 SERIES

RANGE HOOD SYSTEM

- 4 -

RMP SERIES BACKSPLASH

(Stainless Steel wall covering

with warming shelves. Optional)

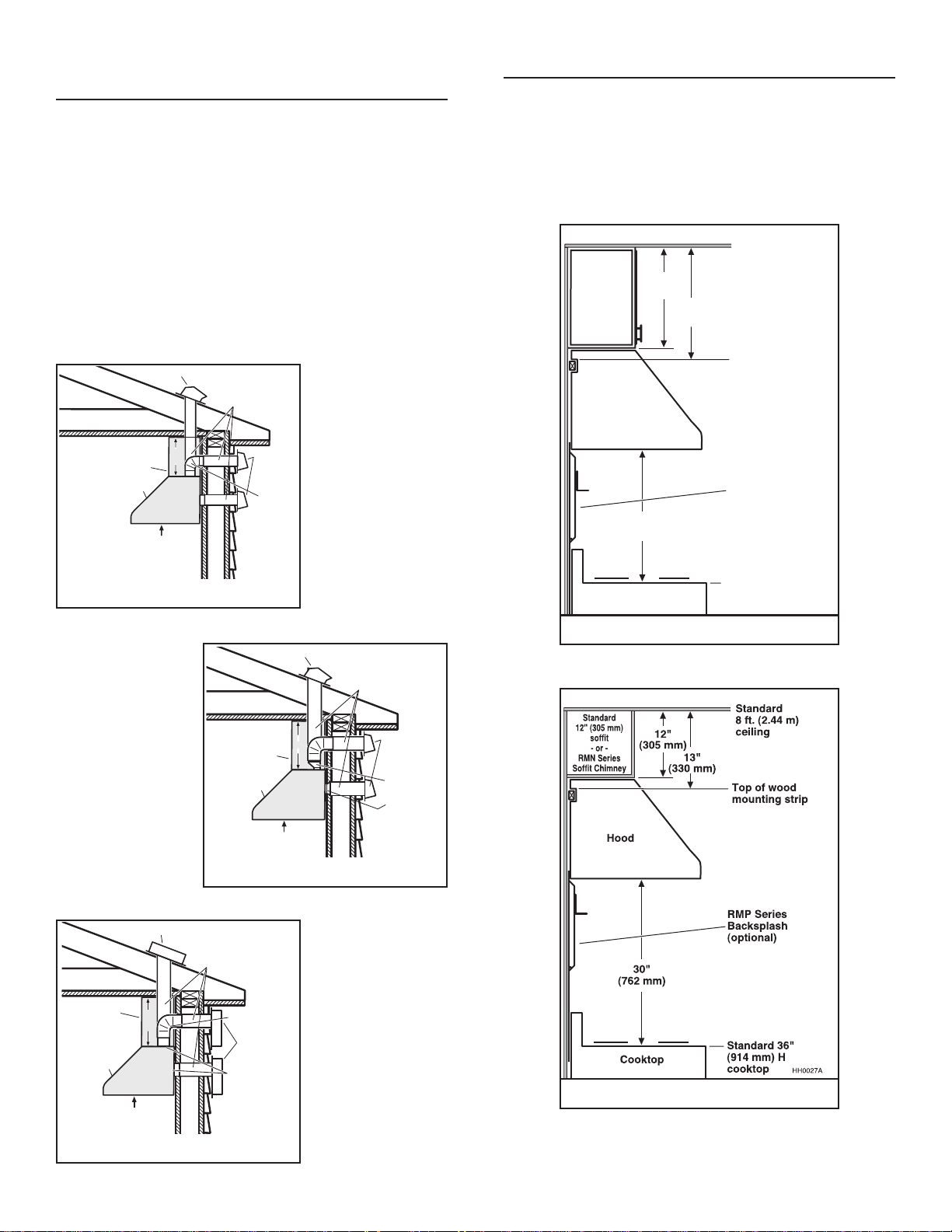

1. SELECT BLOWER OPTION

7" (178 mm)

ROUND DUCT

ROOF CAP

7" (178 mm)

ROUND

ELBOW

24" TO 30" (609 to 762 mm)

ABOVE COOKING SURFACE

WALL CAP

HOOD

DECORATIVE

FLUE

or SOFFIT

12"

(305 mm)

HH0024A

18"

(457 mm)

Standard 18"

(457 mm) H

over-cooktop

cabinet

24"

(610 mm)

Cooktop

19"

(483 mm)

Top of wood

mounting strip

Hood

RMP Series

Backsplash

(optional)

Standard

8 ft. (2.44 m)

ceiling

Standard 36"

(914 mm)

H cooktop

HH0028A

AND INSTALL DUCTWORK

2. MEASURE INSTALLATION

Either an interior or exterior blower may be used with this hood.

The RM60000 Series hood must be installed with blower models

RM325H, RM326H, 331H, 332H, 335 or 336 only. Other blowers

cannot be substituted. (Blowers sold separately).

NOTES:1. The 331H, 332H, 335 or 336 exterior blower MUST

BE installed with the rough-in kit model 332KR (sold

separately).

2. In addition to the blower models listed above, this hood

is also compatible with older internal blower versions

325H and 326H. However, discard the installation

instructions included with those blowers and contact

our technical suppport to obtain replacement instruction.

Plan where and how the ductwork will be located.

Install proper-sized ductwork, transition(s), elbow(s), and roof or

wall cap for the type of blower you are using.

Dimensions for the most common installations are shown

below.

Adjust your measurements for various heights of ceilings, soffits,

cabinets or cooktops. For proper operation, the hood must be a

minimum of 24" and a maximum of 30" above the cooktop.

Minimum distance

between the hood

and the cooktop

MODEL RM325H SINGLE BLOWER

TYPICAL DUCTWORK

DECORATIVE

FLUE

or SOFFIT

HOOD

24" TO 30" (609 to 762 mm)

ABOVE COOKING SURFACE

HH0025A

EXTERIOR BLOWER

DECORATIVE

FLUE

or SOFFIT

(305 mm)

HOOD

HH0026A

24" TO 30" (609 to 762 mm)

ABOVE COOKING SURFACE

MODEL 331H, 332H, 335 OR 336 EXT.

12"

BLOWER TYPICAL DUCTWORK

MODEL RM326H DUAL BLOWER

10" (254 mm)

ROUND DUCT

10" (254 mm)

ROUND ELBOW

EXTERIOR

BLOWER

332KR

ROUGH-IN KIT

(see page 4)

ROOF CAP

10" (254 mm)

ROUND DUCT

12"

(305 mm)

TYPICAL DUCTWORK

WALL CAP

4-1/2" x 18-1/2"

to 10"

(114 x 470 to

254 mm) ROUND

TRANSITION

(see page 4)

INSTALLATION WITH STANDARD 18’’ HIGH

OVER-COOKTOP CABINET

Maximum distance

between the hood

and the cooktop

INSTALLATION WITH 12’’ SOFFIT OR

OPTIONAL SOFFIT CHIMNEY RMN SERIES

- 5 -

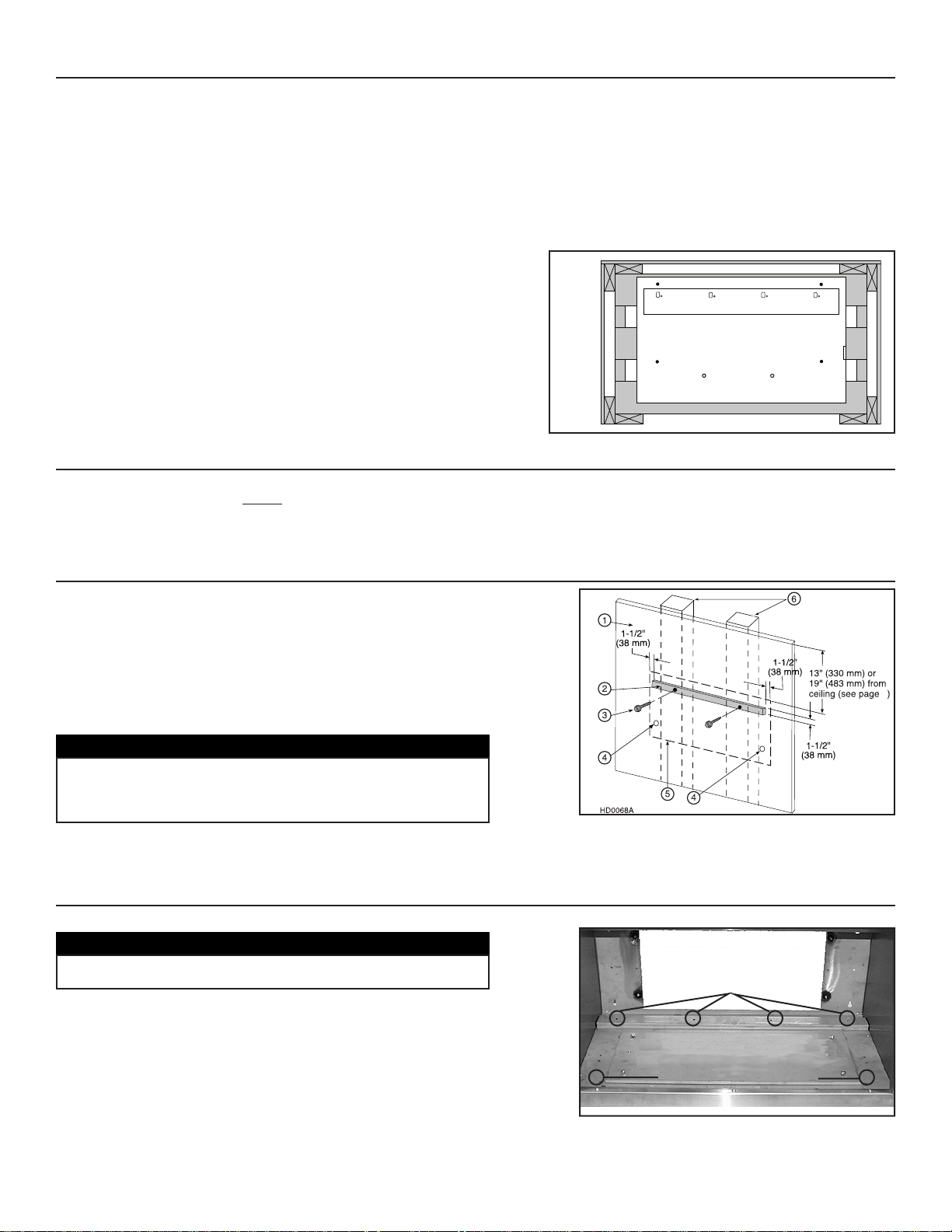

3. PREPARE THE INSTALLATION

Remove the installation kit from inside the hood.

Make sure that the following items are included:

-Wood strip

-Installation manual

-Accessories including:

.Filters (Quantity varies depending on range hood width)

.Bag of parts including:

Screws

Wall anchors (2), Washers 3/16" ID X 3/4" OD (2)

#10-2" flat head (4),Screws #8-3/4" (8), Nuts #10-32 (4)

Using a Phillips #2 or a Robertson #2 screwdriver, unscrew the hood

3

4

from the bottom of crate. Refer to figure beside to locate all 4 screws.

Discard these screws and remove hood from wood pallet.

1

HR0002

2

4. INSTALL BACKSPLASH

(OPTIONAL)

Backsplash must be installed before the hood shell because the hood shell covers the backsplash top mounting screws. In order to be

able to install the backsplash, make sure you have at least 18” (457 mm) clearance between bottom of hood and range control panel or

cooktop. (Refer to instructions included with backsplash.)

RMP Series

5. INSTALL WOOD MOUNTING STRIP

Measure and mark a level line on wall above cooktop location for the wood

mounting strip (see illustration below and under step 2). Use #10 - 2” flat

head screws to secure the mounting strip to the drywall. Make sure to

hit the wall studs. (See figure beside.)

5

CAUTION

Due to the weight of this hood, ensure that the wood strip is

attached to all of the available wall studs (2 studs minimum for

the 30” hood, more as hood width increases); not into the drywall

alone.

6. INSTALL THE HOOD

Rest the back cavity of the hood on the wood mounting strip.

CAUTION

Hold the hood until it is completely secured to the wood

mounting strip.

Secure hood to wood strip with (4) screws #8 - 3/4” (for 30” and 36”

width hoods) or (6) screws (for 42” width and wider hoods) provided at

locations shown. Drill (2) 3/16” size holes into the drywall for wall

anchors through the existing holes in the inside hood back in the locations shown. Then install the two wall anchors and attach the hood to

these anchors with the remaining #8 - 3/4” screws and the (2) washers

provided.

- 6 -

1. Drywall

2. Wood Mounting Strip

3. Flat Head Screw

Top of hood (inside view)

Mounting Screw Locations

Back of hood (inside view)

Wall Anchor Locations

HD0064

4. Wall Anchor Location

5. Outline of the Back of the Hood

6. Wall Studs

7. INSTALL TRANSITION TO ROUGH-IN PLATE

!

Model 423, 424, 427, 453, or 454

Attach transition (if required) to blower rough-in plate.

Use duct tape to make all joints secure and air-tight.

NOTE: Model RM325H blower plate connects directly to 7" round ductwork

without a transition.

Exterior blower models utilize a model 332KR rough-in plate

which connects directly to 10” round ductwork without a transition.

8. INSTALL THE ROUGH-IN PLATE TO THE HOOD

HD0049

Run power cable to installation location. Refer to the instructions

included with the selected blower or rough-in kit (sold separately) for

details on installing the rough-in plate. Install the rough-in plate so that

the wiring box is located on the right side as you are facing the hood.

For ducting through back of hood, remove existing plate from inside

back of hood and attach to inside top of hood to cover hole. Secure to

threaded studs with same (4) nuts.

For ducting through top of hood, existing plate remains in place on

inside back of hood.

Connect ducting to transition or rough-in plate as you are installing the

rough-in plate. Use duct tape to make all joints secure and air-tight.

1

3

1

HD0063

1. Locknuts

2. Plate on top of hood

3. Rough-in plate on back of hood

4. Wiring Cover

2

1

4

1

9. CONNECT THE WIRING

WARNING

Risk of electrical shock. Electrical wiring must be done by qualified personnel in accordance with all applicable codes and

standards. Before connecting wires, switch power off at service panel and lock service disconnecting means to prevent power

from being switched on accidentally.

Remove wiring cover from rough-in plate and set aside.

Remove appropriate knockout from rough-in plate. As you are installing the rough-in plate, feed 6” of power cable through knockout

opening and attach cable to wiring box with appropriate connector.

Connect BLACK to BLACK, WHITE to WHITE and GREEN or bare wire under GREEN ground screw.

Reinstall wiring cover.

- 7 -

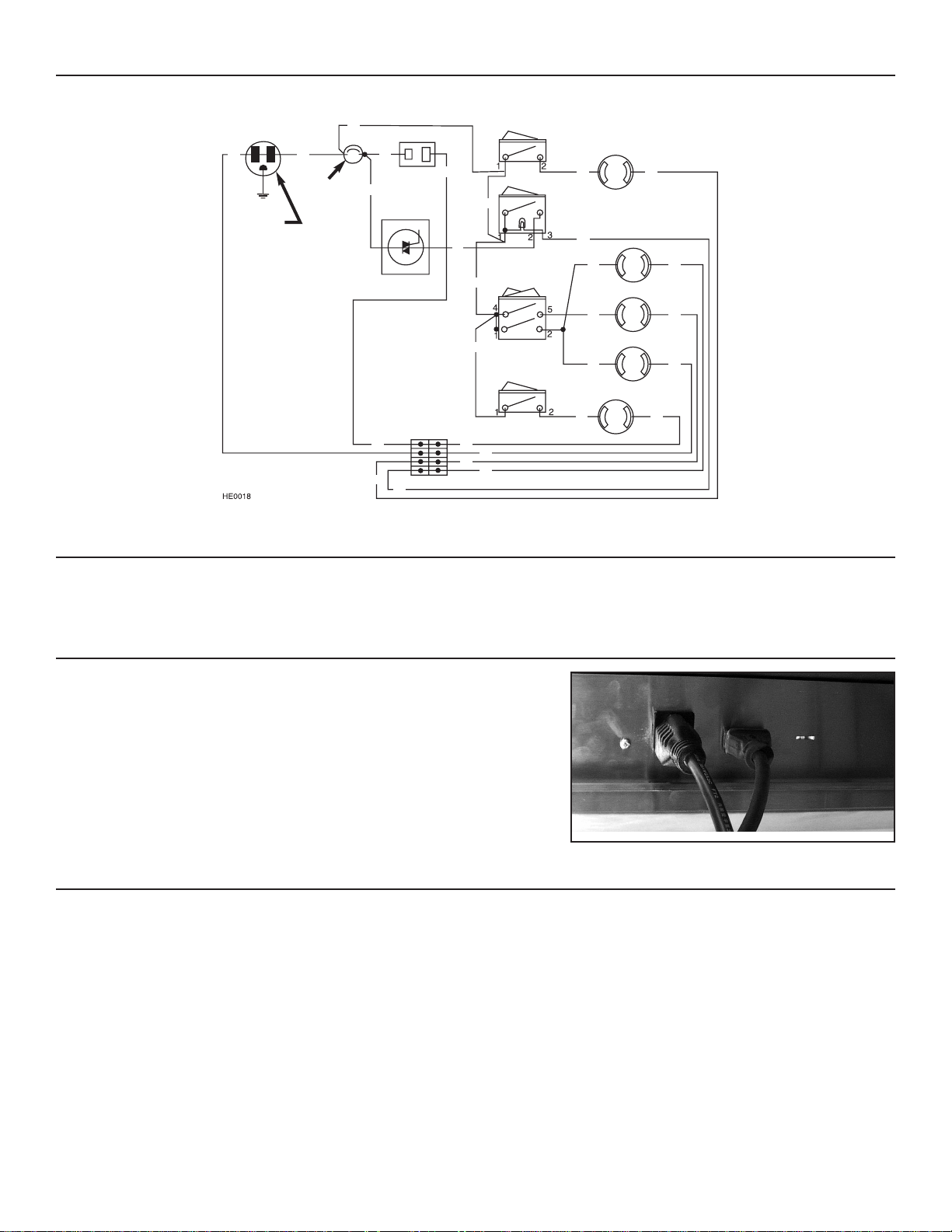

10. WIRING DIAGRAM

120V 60HZIN

W

G

NEMA

5-15P PLUG

B

HS

THERMOSTAT

B

TO FAN MOTOR

B

B

SPEED

CONTROL

RIGHT HEAT LAMP SWITCH

W

B

FAN SWITCH

B

LIGHTS SWITCH

B

RIGHT HEAT LAMP SOCKET

B

W

B

CENTER LIGHT SOCKET

B

W

RIGHT LIGHT

SOCKET

W

W

B

TERMINAL BLOCK

W

W

W

W

W

11. INSTALL THE OPTIONAL SOFFIT CHIMNEY

(OPTIONAL)

Refer to the instructions included with the soffit chimney.

RMN Series

12. INSTALL BLOWER

Refer to instructions included with blower.

Once the blower is installed, plug the blower unit into the female receptacle

and the power supply onto the male connector inside the hood. DO

NOT plug the two cords into each other.

LEFT

HEAT LAMP SWITCH

W

W

LEFT LIGHT SOCKET

B

LEFT HEAT LAMP SOCKET

B

W

W

HE0003

13. INSTALL LIGHT BULBS AND WARMING LAMPS

Install (2) heat lamp bulbs. Use BR40 size, 250W Max., infrared bulbs only (purchase separately).

Install (3) halogen light bulbs. Use PAR20 50W Size (purchase separately).

- 8 -

2

1

3

4

HD0024

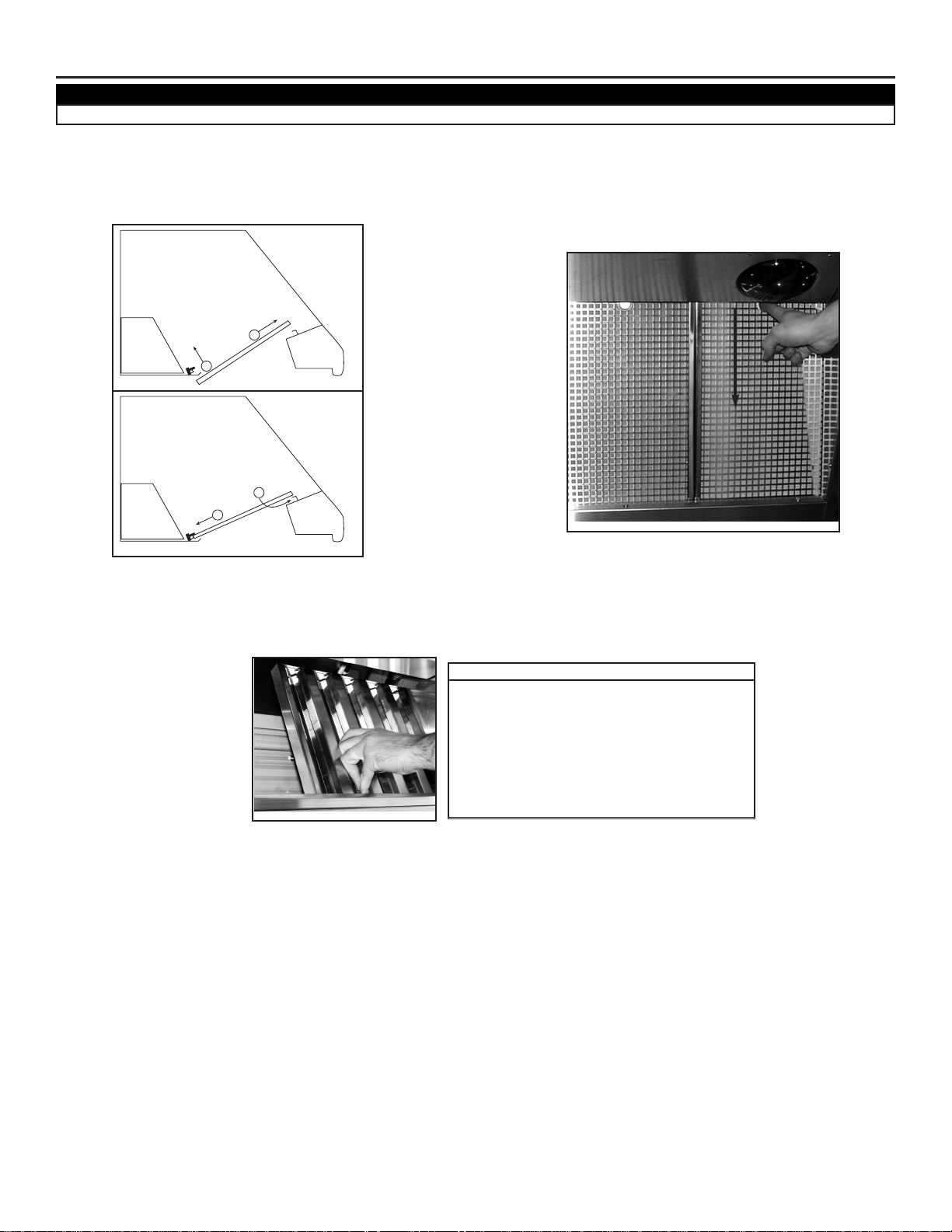

14. INSTALL FILTERS

CAUTION

Remove protective plastic film covering filters before installing them.

It is recommended to install side filters first and finish with center one(s).

1. Insert upper end of filter into the hood (finger sized cup side).

2. Raise lower end toward the inside of hood.

3. Position rear part of filter into channel and pull.

4. Using finger sized cup, pull on the upper end of filter and slide it under the front inner retaining piece.

HD0065

Replacement filters are available from your dealer. See label inside hood for size and part number.

Baffle Filters

Baffle filters are available as an option. To order them, refer to the table below to find the right filter kit number for your hood. To install

them, refer to instruction sheet included with baffle filter kit.

HD0011

BAFFLE FILTER (TYPICAL)

KIT #

RBF6030

RBF6036

RBF6042

RBF6048

RBF6054

RBF6060

RBF6066

RBF6072

HOOD WIDTH

30”

36”

42”

48”

54”

60”

66”

72”

- 9 -

15. USE AND CARE

!

!

16. OPERATION

Grease Filters

The grease filters should be cleaned frequently. Use a warm

detergent solution. Grease filters are dishwasher safe. Wash

more often if our cooking style generates greater grease - like

frying foods or wok cooking.

Remove filters by pushing filters towards the back of hood and

rotating filters downward.

Blower Cleaning

Remove the filters in order to access the blower. Vacuum blower

to clean. Do not immerse in water. Refer to blower instruction

manual for more details.

Grease Rail

The grease rail should be cleaned frequently, especially if baffle

filters are used.

Remove filters, then, disassemble the grease rail from the hood

by removing its 3 retaining screws. See illustration below.

HD0069

Refer to

below. Once the grease rail is clean and dry, reassemble it to the

hood and reinstall filters.

stainless steel cleaning

in Hood Cleaning section

Hood Cleaning

Stainless steel cleaning:

Do:

- Regularly wash surfaces with clean cloth or rag soaked with

warm water and mild soap or liquid dish detergent.

- Always clean in the direction of original polish lines.

- Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

- You may also use a specialized household stainless steel

cleaner.

Don’t:

- Do not use any steel or stainless steel wool or any other scrapers

to remove stubborn dirt.

- Do not use any harsh or abrasive cleansers.

- Do not allow dirt to accumulate.

- Do not let plaster dust or any other construction residues

reach the hood. During construction/renovation, cover the

hood to make sure no dust sticks to stainless steel surface.

Avoid: when choosing a detergent

- Any cleaners that contain bleach will attack stainless steel.

- Any products containing : chloride, fluoride, iodide, bromide

will deteriorate surfaces rapidly.

- Any combustible products used for cleaning such as acetone,

alcohol, ether, benzol, etc., are highly explosive and should

not be used close to a range.

Enamel finish:

Clean with warm water and mild detergent only.

When discoloration occurs, use a good enamel polish such as

automotive polish. (DO NOT use rough abrasive cleaner or

porcelain cleaner.)

How to maintain its « BRIGHT LOOK »

Always turn ON your hood before you begin cooking in order to

establish an air flow in the kitchen. Let the blower run for a few

minutes to clear the air after you turn off the range.This will help

keep the whole kitchen cleaner and brighter.

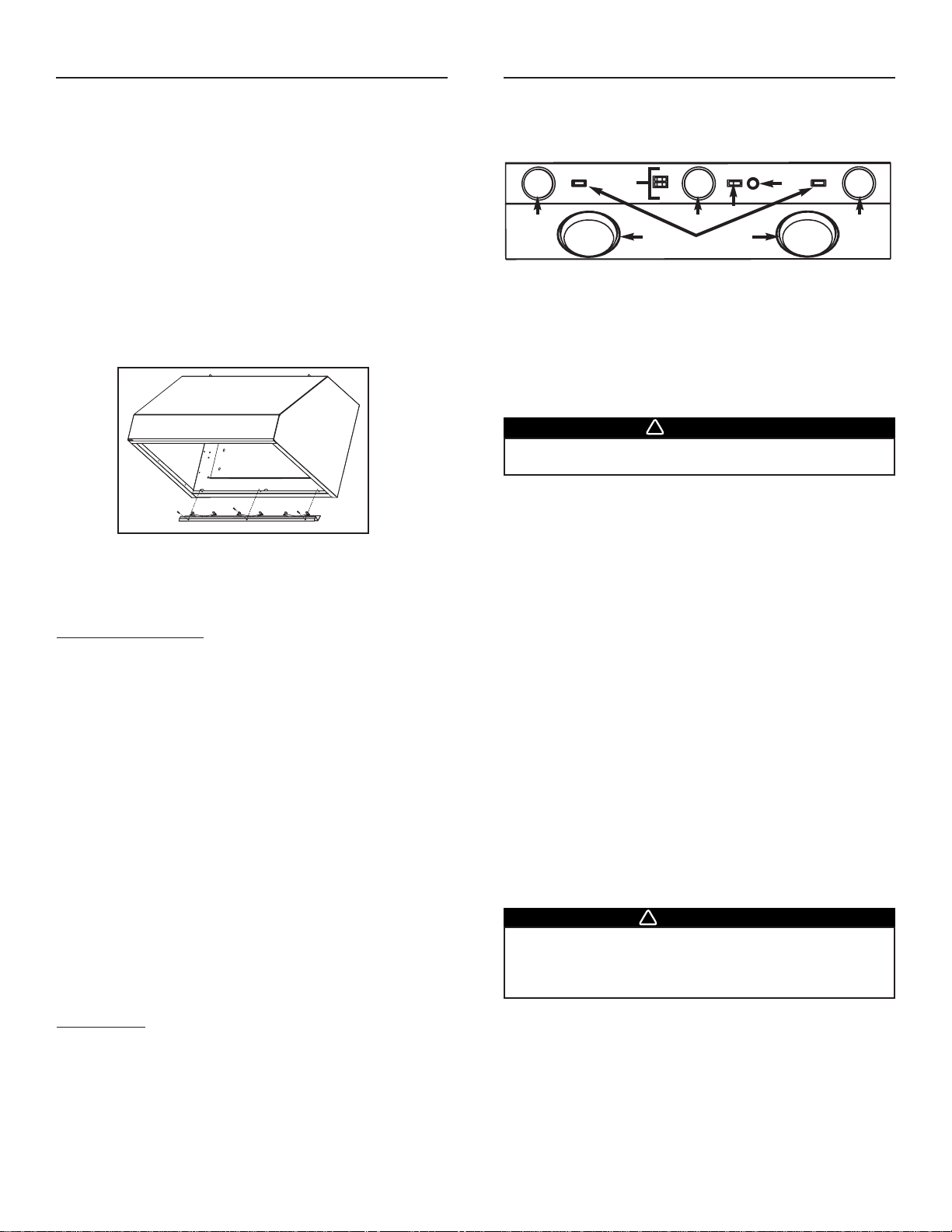

64

5

3 3

3

1

1

2

HC0004

1. Warming lamps

2. Warming lamp switches

3. Halogen lights

4. Halogen light switches

5. ON/OFF Blower switch

6. Blower speed control

Warming lamps (Infrared)

Each warming lamp (item 1 in picture above) is controlled with

is own ON/OFF switch (item 2 on picture above).

Use only BR40 Size, 250W Max., Infrared bulbs.

(Purchase separately)

WARNING

Do not place highly flammable material on warming

shelves.

Cooktop Lighting (Halogen)

A double set of ON/OFF switches (item 4 on picture above)

control the halogen lights (item 3 on picture above).

The front rocker controls the center light. The rear rocker

controls both side lights. Select one, two, or three lights for

best cooktop lighting.

Use PAR 20, 50W halogen bulbs. (Purchase separately)

Blower

The blower is operated using two (2) controls.

Use the red, lighted ON/OFF switch (item 5 on picture above)

to start and stop the blower. When turned on, the blower will

operate at the previous setting of the speed control (item 6 on

picture above).

Turn the speed control knob clockwise to decrease blower

speed - counterclockwise to increase speed.

HEAT SENTRY™

Your hood is equipped with a HEAT SENTRY™ thermostat.

This thermostat is a device that will turn on or speed up the

blower if it senses excessive heat above the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up

to HIGH speed.

When the temperature level drops to normal, the blower will

return to its original setting.

WARNING

The HEAT SENTRY™ thermostat can start the blower even if

the hood is turned OFF. When this occurs, it is impossible

to turn the blower OFF with the switch. If you must stop

the blower, do it from the main electrical panel.

- 10 -

17. SERVICE PARTS

20

1

21

8

7

HL0031

13

12

14

19

17

11

16

3

4

6

18

20

22

5

15

7

9

10

22

KEY PART QTY (HOOD WIDTH)

NO. NUMBER DESCRIPTION 30” 36” 42” 48” 54” 60” 66” 72”

1 V03493 Rangemaster Logo 1 1 1 1 1 1 1 1

2 V02264 Socket Lamp 5 5 5 5 5 5 5 5

3 V02773 Male Connector 1 1 1 1 1 1 1 1

4 V02772 Female Connector 1 1 1 1 1 1 1 1

5 V03435 Thermostat 1 1 1 1 1 1 1 1

6 V03436 Thermostat Bracket 1 1 1 1 1 1 1 1

7 V02563 SPST Single Switch for Warming Lamps 2 2 2 2 2 2 2 2

8 V03502 SPST Double Switch for Halogen Lights 1 1 1 1 1 1 1 1

9 V03503 SPST Lighted Single Switch for Blower 1 1 1 1 1 1 1 1

10 V03504 Speed Control Button 1 1 1 1 1 1 1 1

11 V03501 Speed Controller 1 1 1 1 1 1 1 1

12 V03505 Terminal strip 1 1 1 1 1 1 1 1

‡

V03517 10” Power Cord 1 1 1 1 1 1 1 1

‡

V03519 10” Control Wire 1 1 1 1 1 1 1 1

‡

V03520 10” Lighted Switch Wire 1 1 1 1 1 1 1 1

13 V00673 Lock-Nut 8-32 2 2 2 2 2 2 2 2

14 V02512 Screw 8-32 x 1/2 Quadrex 2 2 2 2 2 2 2 2

15 V01869 Machine Screw 8-32 x 1/4 2 2 2 2 2 2 2 2

16 V01582 Lock nut 6-32 2 2 2 2 2 2 2 2

17 V05522 Sq. Perf. Grille Filter 9.5 x 15.25 x 0.355 3 - - - - - - 17 V05523 Sq. Perf. Grille Filter 11.61 x 15.25 x 0.355 - 3 - 4 - 5 2 17 V05524 Sq. Perf. Grille Filter 13.61 x 15.25 x 0.355 - - 3 - - - 3 17 V05525 Sq. Perf. Grille Filt. 17.525 x 15.25 x 0.355 - - - - 3 - - 4

18 V14763 Grease Rail 30” 1 - - - - - - 18 V14764 Grease Rail 36” - 1 - - - - - 18 V14765 Grease Rail 42” - - 1 - - - - 18 V14766 Grease Rail 48” - - - 1 - - - 18 V14767 Grease Rail 54” - - - - 1 - - 18 V14768 Grease Rail 60” - - - - - 1 - 18 V14769 Grease Rail 66” - - - - - - 1 18 V14770 Grease Rail 72” - - - - - - - 1

19 V05528 Filter Spring 5.265” x 0.350” 3 3 3 4 3 5 5 4

20 V05521 Sealing Extrusion 20.625” 2 2 2 2 2 2 2 2

21 V14744 Left Side Liner 1 1 1 1 1 1 1 1

22 V14745 Right Side Liner 1 1 1 1 1 1 1 1

‡

V05527 Installation Guide 1 1 1 1 1 1 1 1

‡

V12971 Parts Bag

‡

V02544 Halogen Lamp PAR20 50W 3 3 3 3 3 3 3 3

‡*

‡ Not shown.

* Purchase locally.

Screws #8 x 3/4” (8), Nuts #10-32 (4).

Wall anchors (2), Washers 3/16” ID x 3/4” OD (2))

Warming Lamp BR40, 250W max. 2 2 2 2 2 2 2 2

(Flat head screws #10 x 2” (4),

1 1111111

- 11 -

Loading...

Loading...