Page 1

GB

Instruction Manual

Page 2

Page 3

RECOMMENDATIONS AND SUGGESTIONS

INSTALLATION

• The manufacturer will not be held liable for any damages

resulting from incorrect or improper installation.

• The minimum safety distance between the cooker top and the

extractor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated

on the rating plate fi xed to the inside of the hood.

• For Class I appliances, check that the domestic power supply

guarantees adequate earthing.

Connect the extractor to the exhaust fl ue through a pipe of

minimum diameter 120 mm. The route of the fl ue must be as

short as possible.

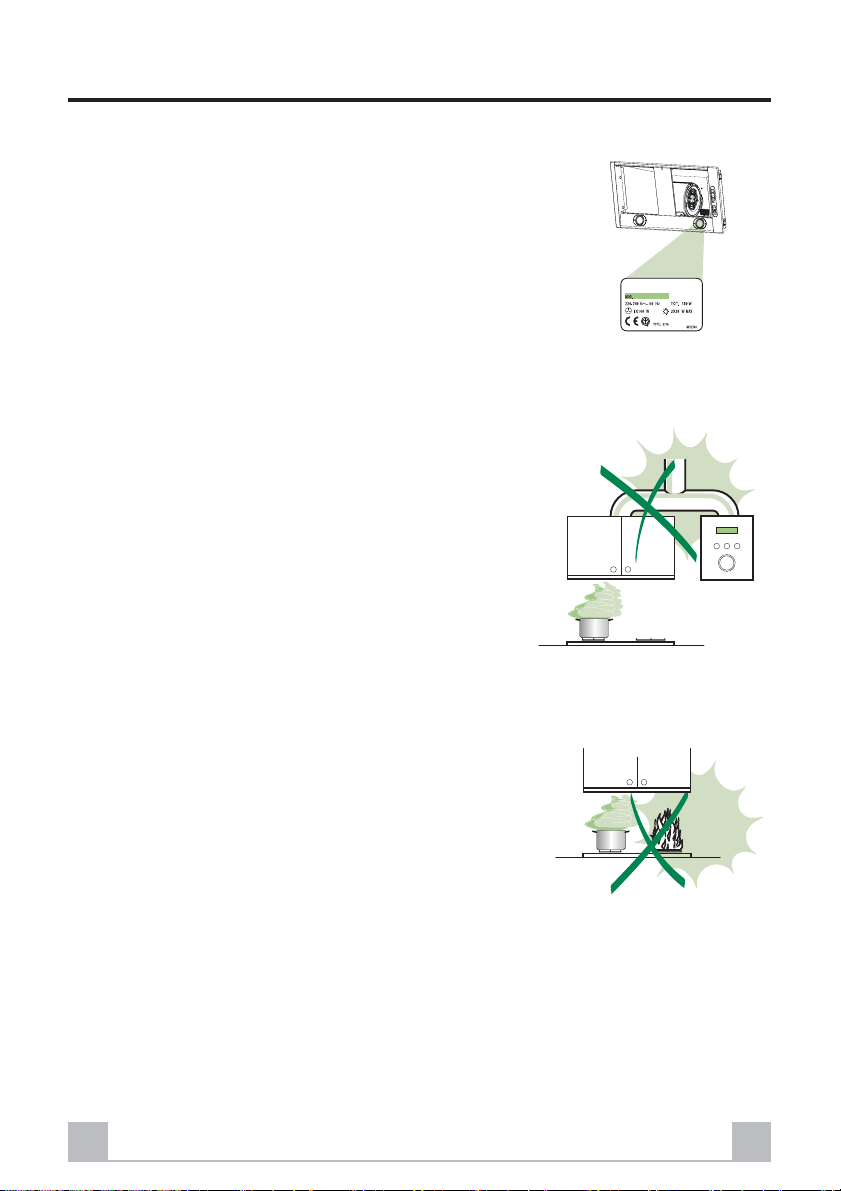

• Do not connect the extractor hood to exhaust ducts carrying

combustion fumes (boilers, fi replaces, etc.).

• If the extractor is used in conjunction with non-electrical

appliances (e.g. gas burning appliances), a suffi cient degree

of aeration must be guaranteed in the room in order to prevent the backfl ow of exhaust gas. The kitchen must have an

opening communicating directly with the open air in order

to guarantee the entry of clean air.

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has

ben designed.

• Never leave high naked fl ames under the hood when it is in

operation.

• Adjust the fl ame intensity to direct it onto the bottom of the

pan only, making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use:

overheated oil can burst into fl ames.

• The hood should not be used by children or persons not

instructed in its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply

before carrying out any maintenance work.

• Clean and/or replace the Filters after the specifi ed time pe-

riod.

• Clean the hood using a damp cloth and a neutral liquid detergent.

GB

12

Page 4

CHARACTERISTICS

Dimensions

ø150

L1

Hood Type 54 72

L 540 720

L1 512 692

9

12c

240

L

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light,

9 1 Reducer Flange ø 150-120 mm

Ref. Q.ty Installation Components

12c 2 Screws 2,9 x 6,5

Q.ty Documentation

1 Instruction Manual

1 Electric Diagram

Blower, Filters

370

240

175

400

GB

13

Page 5

INSTALLATION

Drilling the Support surface and Fitting the Hood

The Hood can be fi tted directly to the underside of the Wall units (min. 650 mm above the cooker

top) with snap-on side supports, which are set up for a support panel thickness of between 15 mm

and 30 mm.

• Cut a fi tted opening in the bottom surface of the

wall unit, as shown.

• Remove the metal grease fi lters (see par. on

Maintenance).

• Disconnect the fi lter support by turning the

internal handles provided.

• Insert the hood until the side supports snap into

place.

• Lock in position by tightening the screws Vf

from underneath the hood.

Hood Type 54 72

L2 515 695

GB

375

L2

Vf

14

Page 6

• Replace the fi lter support

• Screw the fi lter support using the 2 screws 12c (2,9 x 6 ,5) pro-

vided.

• Replace the grease fi lters make sure that the handle is visible on

the outside.

12c

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the chimney using either a fl exible or rigid

pipe ø 150 or 120 mm, the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection,

insert the reducer fl ange 9 on the hood body

outlet.

• Fix the pipe in position using suffi cient pipe

clamps (not supplied).

• Remove any activated charcoal fi lters.

ø 150

ø 120

9

RECIRCULATION VERSION AIR OUTLET

• Drill a hole ø 120 or 150 mm in the shelf above the hood

and connect the hood canopy outlet to the top part of

the wall unit by means of a rigid or fl exible pipe of the

same diameter, the choice of which is at the discretion

of the installer.

• To install a ø 120 mm air exhaust connection, insert the

reducer fl ange 9 on the hood body outlet.

• Fix the pipe in position using suffi cient pipe clamps (not

supplied).

• Ensure that the activated charcoal fi lters have been

inserted.

9

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3

mm.

GB

150

120

15

Page 7

USE

Control Panel

The hood can be switched on pushing directly onto the requested speed without fi rstly having to

select 0/1 button.

L

T1

T2

T3

T4

S1

KEY LED FUNCTIONS

L 0/1 Light Turns lighting on and off.

T1 0/1 Motor on First speed.

T2 Speed on Second speed.

T3 Speed on Third speed.

T4 Speed Fixed Max. speed

Flashing Intensive speed.

Suitable for the strongest cooking vapours and odours.

S1 Led Fixed Indicates that the Metal grease fi lters saturation alarm

Flashing indicates that the activated charcoal odour fi lter satu-

When pressed for about 2 seconds the motor is switched off.

The function becomes active when the button is pushed

for about 2 seconds. After 10 minutes of functioning it

turns off automatically. This function can be interrupted

by means of pressing any of the buttons.

has been triggered, and the fi lters need to be washed.

The alarm is triggered after 100 working hours. (Reset;

check the Maintenance-paragraph)

ration alarm has been triggered, and the fi lter has to be

replaced; the metal grease fi lters must also be washed.

The activated charcoal odour fi lter is triggered after

200 working hours. (Activation and Reset; check the

Maintenance-paragraph)

GB

16

Page 8

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote

control powered by a 1.5 V carbon-zinc alkaline

batteries of the standard LR03-AAA type.

• Do not place the remote control near to heat

sources.

• Used batteries must be disposed of in the proper

manner.

MAINTENANCE

Grease fi lters

CLEANING METAL GREASE FILTERS

Alarm signal reset

• Switch of the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the

leds start to fl ash.

Cleaning the fi lters

• The fi lters are washable and must be cleaned

when led S1 fl ashes or at least every 2 months

of operation, or more frequently for particularly

heavy usage.

• Remove the fi lters one at a time, supporting

them with one hand and turning the safety

knobs (pull and turn).

• Wash the fi lters, taking care not to bend them.

Allow them to dry before refi tting.

• Replace them and fi x them using the safety

knobs provided (pull and turn).

GB

17

Page 9

Activated charcoal fi lter (Recirculation version)

REPLACING THE ACTIVATED CHARCOAL FILTER

• The fi lter is not washable and cannot be regene-

rated. It must be replaced when led S1 fl ashes

or at least every 4 months. The alarm signal

will only light up when the extractor motor is

switched on.

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the

leds start to fl ash.

Replacing the Filter

• Remove the grease fi lters.

• Remove the saturated activated charcoal fi lters

as shown (A).

• Fit new fi lters (B).

• Replace the grease fi lters.

Alarm signal activation

• In Recirculation version Hoods, the Filter saturation alarm can be enabled on installation or at a

later date.

• Turn the Lights and the suction Motor off.

• Disconnect the Hood using the Main switch or the double-pole switch on the mains power supply.

• Restore the connection by pressing and holding T1.

• Release the button. All fi ve LEDs are turned on

• Within 3 seconds press T1 until LEDs T1 and T4 fl ash in confi rmation:

LED fl ashes twice - Activated charcoal fi lter saturation alarm ENABLED

LED fl ashes once - Activated charcoal fi lter saturation alarm DISABLED

B

A

Lighting

LIGHT REPLACEMENT

50 W halogen light.

• Remove the 2 screws fi xing the light cover.

• Remove the lamp by gripping the protruding

part and turning to the left.

• Replace with a new lamp with the same characteristics, making sure that you insert the two

pins properly into their housings.

• Replace the cover and fi x it in position using

the two screws removed as above

GB

18

Loading...

Loading...