Page 1

GLX490 RM GALAXY HOOD GLASS

Instructions Manual

www.rangemaster.co.uk

Page 2

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS.....................................................................................................................3

CHARACTERISTICS.............................................................................................................................................................4

INSTALLATION...................................................................................................................................................................... 6

USE........................................................................................................................................................................................9

MAINTENANCE...................................................................................................................................................................11

EN

2

2

Page 3

RECOMMENDATIONS AND SUGGESTIONS

The Instructions for Use apply to several versions of this appliance. Accord-

ingly, you may find descriptions of individual features that do not apply to your

specific appliance.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting from incorrect or improper installation.

• Check that the mains voltage corresponds to that indicated on the rating plate

fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

• Connect the extractor to the exhaust flue through a pipe of minimum diameter

120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes

(boilers, fireplaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas

burning appliances), a sufficient degree of aeration must be guaranteed in the

room in order to prevent the backflow of exhaust gas. The kitchen must have

an opening communicating directly with the open air in order to guarantee the

entry of clean air.

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has been designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making

sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can

burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out

any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

The symbol on the product or on its packaging indicates that this product may not be

treated as household waste. Instead it shall be handed over to the appl icable collection point

for the recycling of electrical and electronic equipment. By ensuring this product is disposed

of correctly, you will help prevent potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this

product. For more detailed information about recycling of this product, please contact your

local city office, your household waste disposal service or the shop wh ere you purchased t he

product.

EN

3

3

Page 4

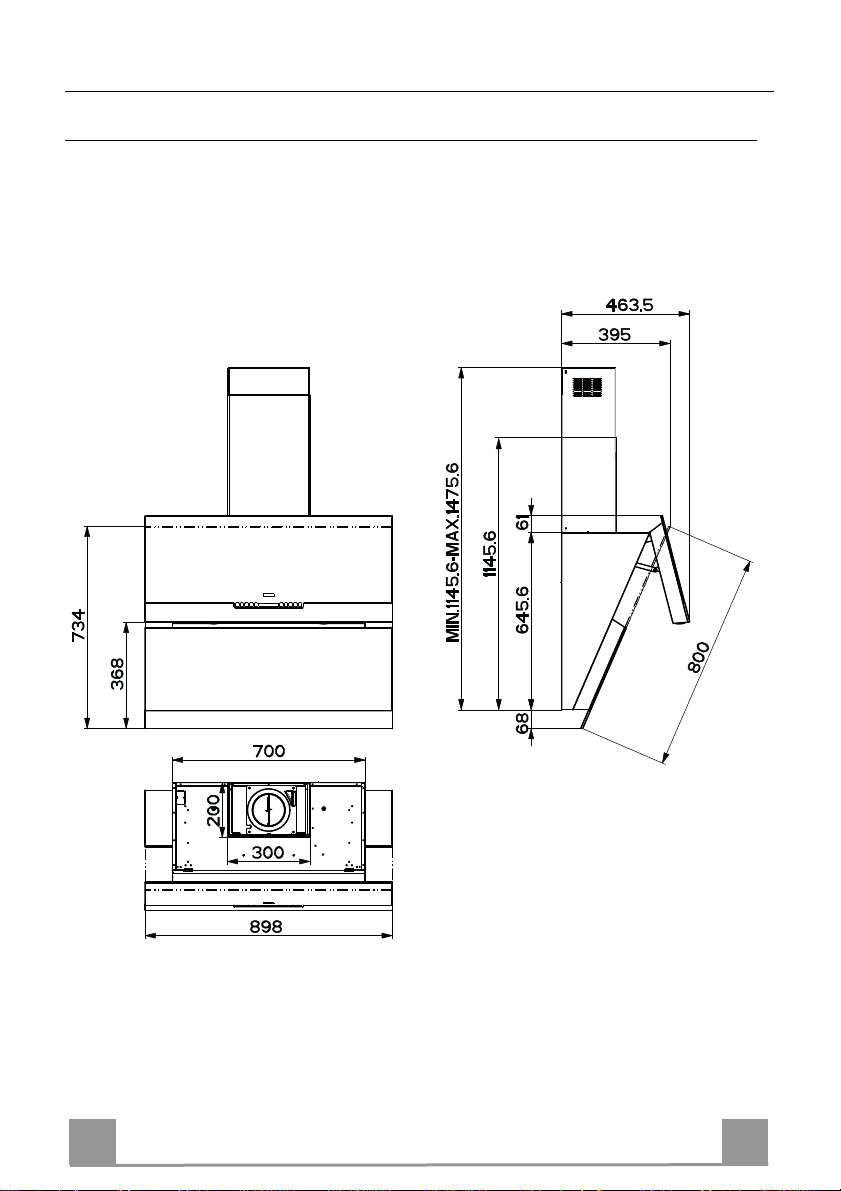

CHARACTERISTICS

Dimensions

EN

4

4

Page 5

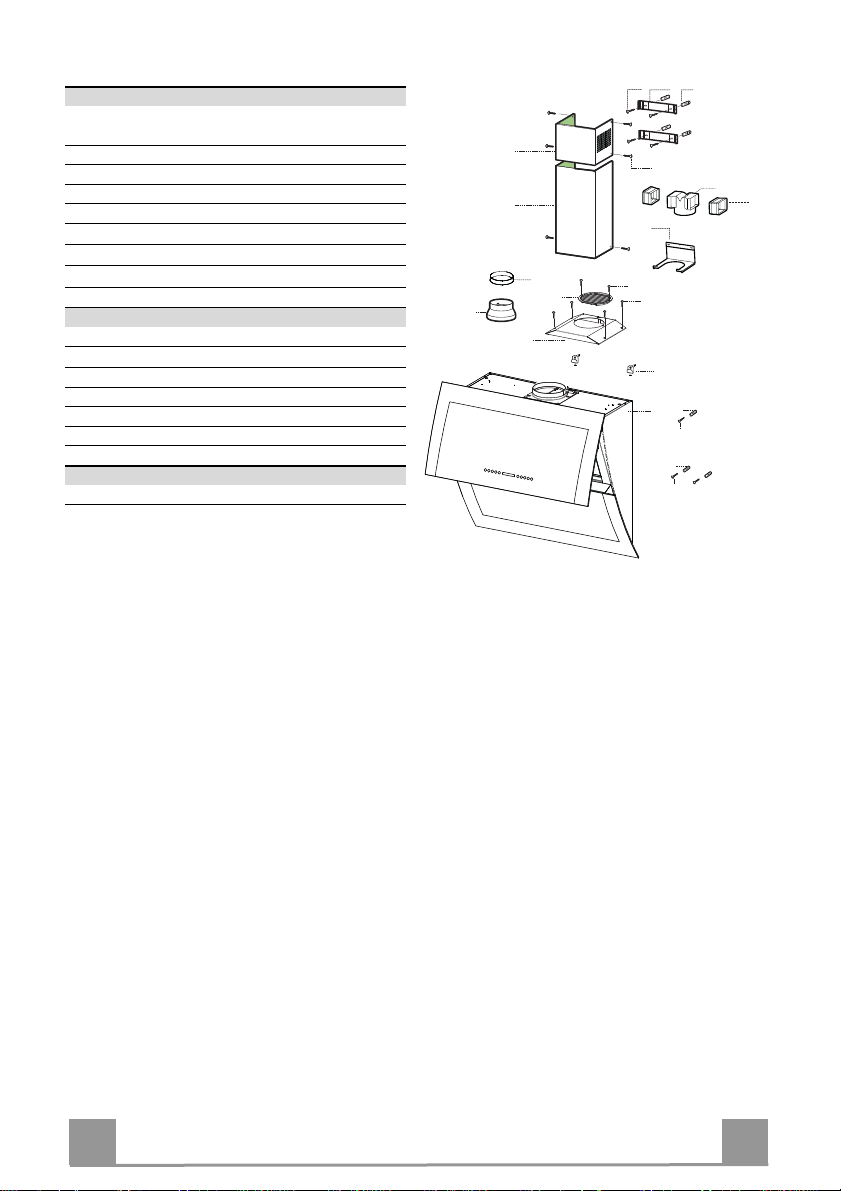

Components

Ref. Q.ty Product components

1 1 Cooker hood with control unit, lights,

blower unit, filters

2.1 1 Upper chimney

2.2 1 Lower chimney

8 1 Air outlet grid

9 1 Reducer flange Ø 150-120

10 1 Adapting ring ø 120-125 mm

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

16 1 Cover for recycling version

Ref. Q.ty Installation components

7.2.1 2 Fixing brackets for upper chimney

7.3 1 Air Outlet Connection Support

11 7 Plugs

11a 2 Plugs SB 12/10

12a 7 Screws 4,2 x 44,4

12c 10 Screws 2,9 x 6,5

12e 2 Screws 2,9 x 9,5

Q.ty Documentation

1 Instruction booklet

7.2.1 11

12a

2.1

2.2

10

9

8

16

12c

15

14.1

7.3

12d

12c

11a

11

1

12a

11

12a

EN

5

5

Page 6

INSTALLATION

Hood body mounting

• Firstly, it is necessary to adjust the two Vr-scre ws of

the 11a-brackets, at minimun (B).

• Hang the hood body on the two brackets 11a.

• Connect the hood to the mains supply by means of a

bipolar switch with at least 3 mm contact gap.

• Press the “A”-key for one second (see Part USE) to

open the upper panel.

• Remove the metal filters.

• In order to align the hood it is necessary to adjust the

Vr-screws from inside the hood.

• Fasten the safety screw 11.

• Fit again the metal filters into their seats and close the

upper panel by pressing “L”-key for one second (see

Part USE).

• Disconnect the hood from the mains supply.

Attention: t he upper pane l stops if any barrier occurs in its

way during the panel opening or closing. To open the panel

it is enough to remove the barrier and pres s the key once

again.

A

L

11a

Vr

(B)

11

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to

the chimney using either a flexible or rigid pipe ø 150

or 125 mm, the choice of which is left to the installer.

• To install a ø 125 mm air exhaust connection, insert

the reducer flange 9 on the hood body air outlet and

the adapting ring ø120-125 10 on the reducer flange.

• Fix the pipe in position using sufficient pipe clamps

(not supplied).

• Remove any activated charcoal filters.

EN

ø 150

ø 125

9

10

6

6

Page 7

RECYCLING VERSION AIR OUTLET

16

12c

12d

8

ø 150

15

14.1

7.3

To install the hood in recycling version, the optional charcoal

filter kit must be purchased.

• Remove the chimney angle bracket.

• Screw the filter cover onto the air outlet, using four screws 12c

(2.9 x 12.5).

• Fix the air outlet grid 8 on the recirculation air outlet using the

2 screws 12d (2,9 x 9,5) provided.

RECIRCULATION VERSION AIR OUTLET

• Insert the connection extension pieces laterally 14.1 in connection 15.

• Insert the Connector 15 into the Support bracket 7.3 and fix it

with a screw.

• Make sure that the outlet of the extension pieces 14.1 is horizontally and vertically aligned with the chimney outlets.

• Connect the air outlet connection 15 to the hood body outlet

using either a flexible or rigid pipe ø 150 mm, the choice of

which is left to the installer.

• Ensure that the activated charcoal filters have been inserted.

ELECTRICAL CONNECTION

• Connect the hood to the mains supply.

• Open the upper panel by pressing the A-key (See Part “USE” )

for at least 2 seconds.

• Remove the metal filters (See Part “MAINTENANCE”) and

make sure that the connector piece of the supply cable is correctly inside the hood socket.

EN

7

7

Page 8

Flue assembly

Upper exhaust flue

• Slightly widen the two sides of the upper flue and

hook them behind the brackets 7.2.1, making sure

that they are well seated.

• Secure the sides to the brackets using the 4 screws

12c (2,9 x 9,5) supplied.

• Make sure that the outlet of the extensions pieces is

aligned with the chimney outlets.

Lower exhaust flue

• Slightly widen the two sides of the flue and hook

them between the upper flue and the wall, making sure that they are well seated.

• Fix the lower part laterally to the hood body using

the 2 screws 12c (2,9 x 9,5) supplied.

12c

2.1

2

2.2

12c

12c

EN

8

8

Page 9

USE

A

B

C

E

D

Key Function Display

A Upper panel closed: when pressed for about one sec-

ond it opens the upper panel. It switches the motor on

at the latest selected speed.

Upper panel open: when shortly pressed it switches

the motor on/off.

B Decreases the suction speed. Number of lit LEDS decreases.

C Increases the suction speed. Number of lit LEDS increases.

D Functioning only when the upper panel is open. This

speed has been timed at 10 minutes. After that ti me

the system activates automatically the late st selected

speed. The function is suitable for cooking conditions

when vapours and smells are of the utmost emission.

E Functioning on ly when the upper panel is open. By

pressing this key it is possible to set up the motor to a

suction speed at 100 m

F Functioning only when the motor is on. By pressing

this key it is possible to set the delayed shutdown of

the motor and the lighting to 30 minutes.

G By pressing this key for about 2 seconds it is possible

to reset the filter saturation alarm.

H By pressing this key the intensity of the lighting sys-

tem can be modified up to five levels.

I Upper panel closed: when pressed for about 1 second

it opens the upper panel and sets the lights at the

maximum intensity.

Upper panel open: when shortly pressed it switches

the lights on/off.

L Upper panel closed: when pressed for about one sec-

ond it opens the upper panel and switches the motor

on at the third speed and the lights at the maximum

intensity.

Upper panel open: when pressed for about 1 second it

switches off motor and lights resetting every activated

function, and closes the upper panel.

3

/h .

Keyboard lock: it is possible to jam the keyboard when, for example, cleaning the glass. The

motor and lights are switched off, and upper panel can be open or closed.

By pressing the F-key (Delay) for about 5 seconds the keyboard block can be activated or deactivated. This function is confirmed by a Beep and by moving motor LEDS on display.

EN

Control panel

F

G

H

Indicates the selected speed.

I flashes and all the LEDS on the display

are lit.

By pressing the key the function is deactivated.

24–symbol appears and the LEDS on the

display go off cyclically, one by one.

By pressing the key the function is deactivated.

A flashing clock symbol appears.

By pressing the key the function is deactivated.

A drop symbol indicates that the metal

grease filters saturation alarm has been

activated, and the filters need to be

washed. The alarm is triggered after 100

working hours.

C indicates that the charcoal filter saturation alarm has been activated, and the filter

has to be replaced. The alarm s triggered

after 200 working hours.

L

I

9

9

Page 10

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control

powered by a 1.5 V carbon-zinc alkaline batteries of the

standard LR03-AAA type.

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper

manner.

Remote control (control panel)

T1

T2

T3

T4

T5

T6

T7

T1 Lighting Upper panel closed: opens the upper panel and sets the lights at the maximum inten-

Upper panel open: switches the lights on/off.

T2 Courtesy light Sets the lights at an intermediate intensity or switches the lights off (only when the

T3 Motor Upper panel closed: opens the upper panel, switches on the motor at the latest se-

Upper panel open: switches the motor on/off.

When pressed for about 2 Seconds:

upper panel closed: opens the upper panel and switches on the motor at the third

Upper panel open: switches off lights and motor and closes the upper panel.

T4 Decreases the speed at every short pressure.

When pressed for about 2 Seconds:

decreases the intensity of lights.

T5 Increases the speed at every short pressure.

When pressed for about 2 Seconds:

Increases the intensity of lights.

T6 Activates/deactivates the intensive speed.

T7 Delay / 24h Activates / deactivates the Delay-function.

When pressed for 2 seconds :

Activates/deactivates the 24H-function.

sity.

upper panel is open).

lected speed.

speed and the lights at the maximum intensity.

EN

1

10

Page 11

MAINTENANCE

Metal grease filters

Filters can be washed in the dish machine. They need to be

washed when Drop-sign appears on the display or in any case

every 2 months, or even more frequently in case of particularly

intensive use of the hood.

Alarm reset

• Press the G–key for at least 2 seconds.

Cleaning the filters

• Open the upper panel by pressing the A-key for 1 second (see

Part USE).

• Remove the filters one by one pushing them towards the back

side of the hood unit and simultaneously pulling downwards.

• Any kind of bending of the filters has to be avoided when

washing them. Before fitting them again into the hood make

sure that they are completely dry. (The colour of the filter surface may change throughout the time but this has no influence

to the filter efficiency).

• When fitting the filters into the hood pay attention that they are

mounted in correct position the handle facing outwards.

EN

1

11

Page 12

Charcoal filter (recycling version)

A

B

This filter cannot be washed or regenerated. It must be replaced when the C appears on the

display or at least once every 4 months. The filter saturation alarm has to be activated already

before.

Activation of the alarm signal

• In the recycling version hoods the filter saturation alarm must be activated during the installation or later.

• Switch off the hood and the lights.

• Press the E-key for about 5 seconds until the last two segments of the motor LEDS are lit on

the display.

• By releasing the E-key the clock icon starts to flash.

• Within 3 seconds press the D-key to activate/deactivate charcoal filter saturation alarm.

• C-symbol lit - charcoal filter saturation alarm ACTIVATED.

• C-symbol unlit - charcoal filter saturation alarm DEACTIVATED.

REPLACING THE CHARCOAL FILTER

Alarm reset

• Press the G-key for at least 2 seconds.

Replacing the filter

• Open the upper panel by pressing the A-key for about a second

(see Part USE).

• Remove the metal filters.

• Remove the saturated charcoal filter as indicated (A).

• Fit the new filters as indicated (B).

• Put the metal grease filters in their seats.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Extract the lamp from the lamp holder by pulling gently.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

EN

1

12

Page 13

Replacing the fuser

The hood panel opening and closing mechanism is controlled by a starter motor which is activated by a fuser.

This fuser works only on the starter motor. In case the

fuser gets damaged when the panel is closed it is be

necessary to manually unblock the panel. In this case

proceed as follows:

• Remove the cover placed up on the left side.

• Press the releasing lever with the screwdriver as

much as necessary to enable the manual opening of

the panel.

• After having completely opened the panel remove the

metal grease filters, as explained in the part concerning the filter cleaning.

• The fuser is placed up on the right side. Turn the

fuser holder as indicated. Replace the fuser with one

having the same features.

• Put the fuser holder and grease filters into their place

again. Make sure that the hood functions correctly. In

case the panel doesn’t work correctly it is necessary

to contact an authorized technician.

If the fuser gets damaged being the panel open, it is sufficient to simply remove the grease filters and replace

the fuser.

EN

1

13

Page 14

Page 15

Page 16

436004217_ver1

AGA RANGEMASTER LTD.

Loading...

Loading...