Page 1

63000

Series

BROAN MFG. CO., INC.

926 W. State St. Hartford, WI 53027

- 1 -

04306120

99042529A

Page 2

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended

by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the

warranty.

2. Before servicing or cleaning unit, switch

power off at service panel and lock service panel to prevent power from being

switched on accidentally. When the service disconnecting means cannot be

locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring

must be done by a qualified person(s) in

accordance with all applicable codes and

standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guidelines and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and

the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities.

6. Ducted fans must always be vented to

the outdoors.

7. Do not use this unit with any solid-state

speed control device.

8. To reduce the risk of fire, use only steel

ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

1. Keep fan, filters and grease laden surfaces clean.

2. Always turn hood ON when cooking at

high heat.

3. Use high range settings on range only

when necessary. Heat oil slowly on low

to medium setting.

4. Don’t leave range unattended when cooking.

5. Always use cookware and utensils appropriate for the type and amount of food

being prepared.

WARNING

TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting

lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go

out immediately, EV ACUA TE AND CALL

THE FIRE DEP ARTMENT.

2. NEVER PICK UP A FLAMING P AN - Y ou

may be burned.

3. DO NOT USE WATER, including wet

dishcloths or towels - violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. Y ou know you have a Class ABC ex-

tinguisher and you already know how

to operate it.

B. The fire is small and contained in the

area where it started.

C. The fire department is being called.

D. You can fight the fire with your back

to an exit.

* Based on “Kitchen Fire Safety Tips”

published by NFPA.

CAUTION

1. For general ventilating use only. Do not

use to exhaust hazardous or explosive

materials and vapors.

2. To avoid motor bearing damage and

noisy and/or unbalanced impellers, keep

drywall spray, construction dust, etc. off

power unit.

3. Y our hood motor has a thermal overload

which will automatically shut off the motor if it becomes overheated. The motor

will restart when it cools down. If the motor continues to shut off and restart, have

the hood serviced.

4. For best capture of cooking impurities,

the bottom of the hood should be a minimum of 24" and a maximum of 30" above

the cooking surface.

5. Two installers are recommended because of the large size and weight of this

hood.

6. Please read specification label on product for further information and requirements.

- 2 -

Page 3

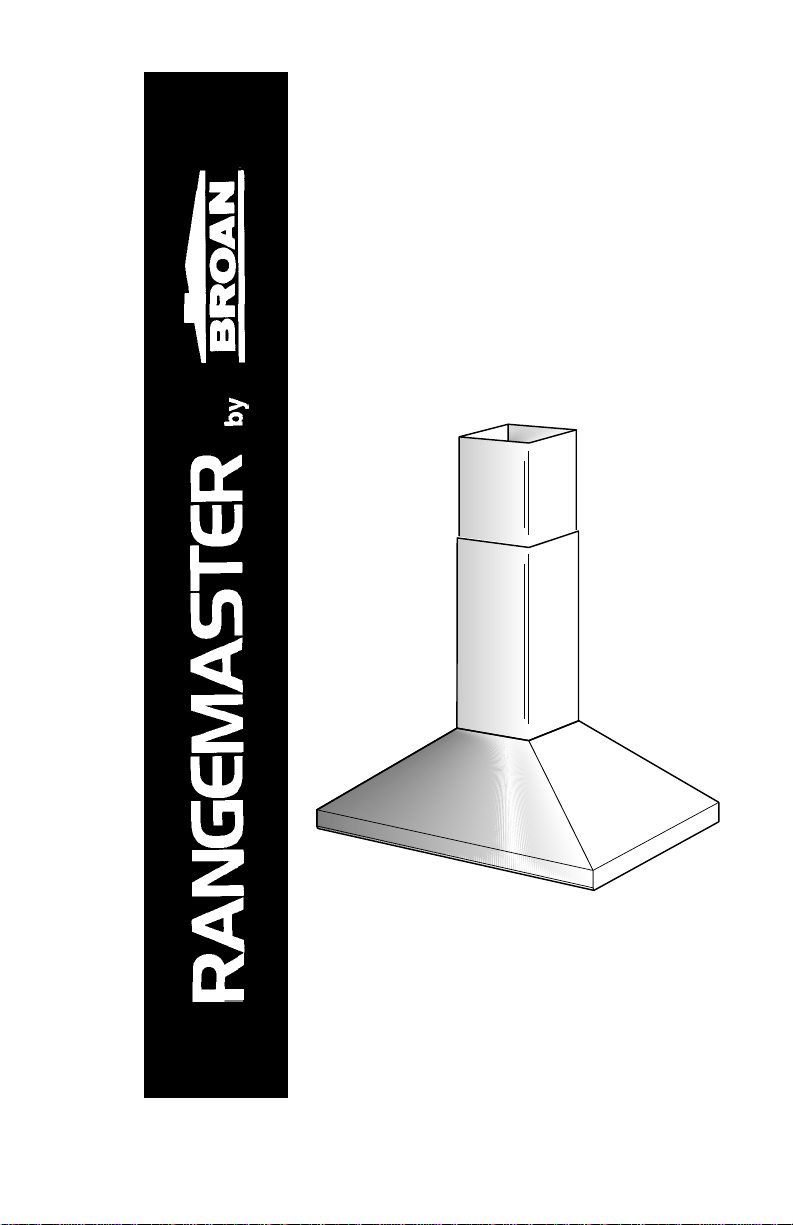

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only

steel ductwork.

1. Decide where the ductwork will run between

the hood and the outside.

2. A straight, short duct run will allow the hood

to perform most efficiently.

3. Long duct runs, elbows, and transitions will

reduce the performance of the hood. Use as

few of them as possible.

4. Install a roof or wall cap. Connect 8" round

steel ductwork to cap and work back towards

hood location. Use duct tape to seal the joints

between ductwork sections.

ROOF CAP

HOOD

24" TO 30" ABOVE

COOKING SURFACE

8" ROUND

DUCT

8" ROUND

ELBOW

DECORATIVE

FLUE

EAVE

VENT

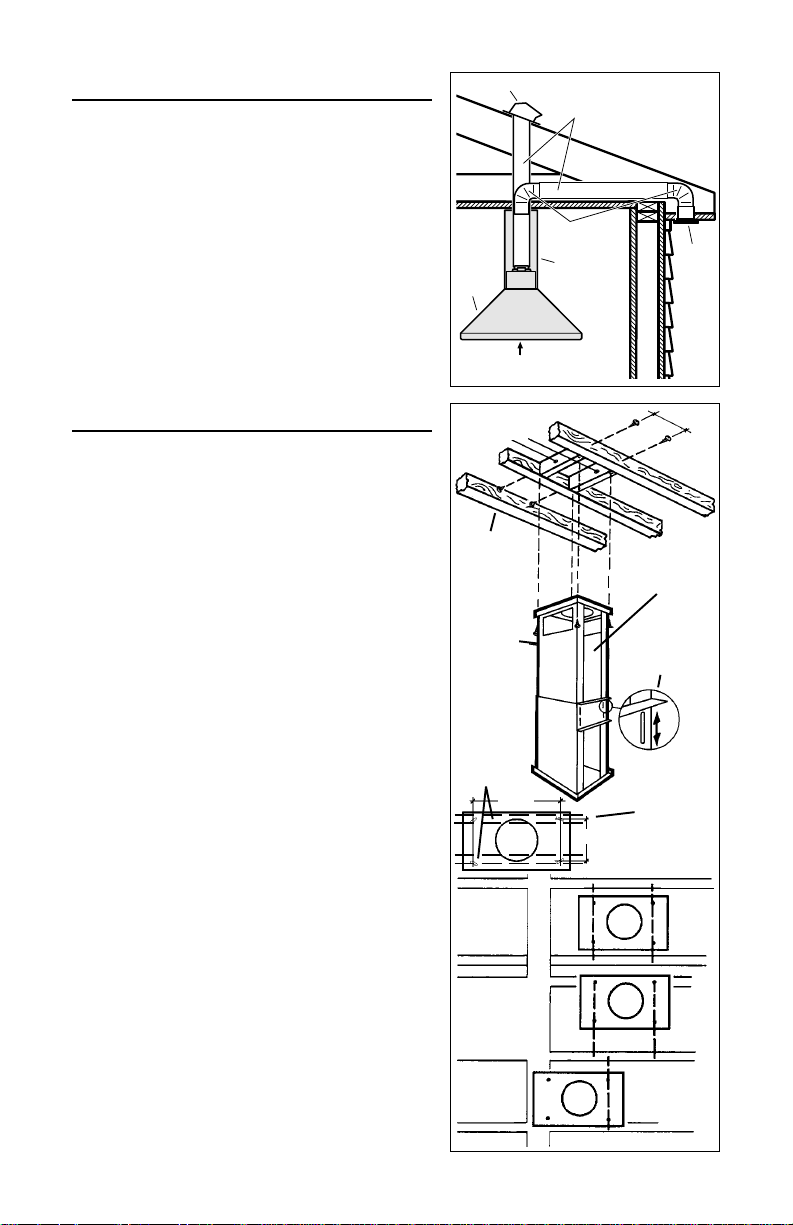

INSTALL SUPPORT SYSTEM

1. At hood location, install 2 X 4 cross framing

between ceiling joists using dimensions

shown.

2. Finish the ceiling surface. Be sure to mark

the location of the ceiling joists and cross

framing.

3. Position upper half of support frame so that

the support frame opening is on the short

side of the hood.

4. Secure the upper half of support frame to

joists and cross framing with four screws provided. Make sure screws are driven into center of joists and framing for maximum

strength.

5. Adjust the overall height of the support frame.

Loosen and re-tighten the screws in the

height adjustment slots as necessary. Note

that the hood height is 10¼” and that the

bottom of the hood must be 24” min. and 30”

max. above the cooktop.

CROSS

FRAMING

CEILING

JOISTS

UPPER

HALF OF

SUPPORT

FRAME

CROSS

FRAMING

93/16”

713/16”

3

/16”

9

SUPPORT

FRAME

OPENING

HEIGHT

ADJUSTMENT

SLOTS

TOP VIEW

OF

SUPPORT

FRAME

- 3 -

TYPICAL

SUPPORT

FRAME

MOUNTINGS

Page 4

CONNECT DECORATIVE FLUE

1. Secure the upper decorative flue section

to the upper support frame.

2. Temporarily hang the lower decorative flue

section from the support frame.

UPPER

DECORATIVE

FLUE

SECTION

LOWER

DECORATIVE

FLUE

SECTION

INSTALL DUCT CONNECTOR

1. Secure the duct connector to the top of the

hood using four (4) screws, supplied.

MOUNT HOOD TO SUPPORT

FRAME

1. Insert four (4) bolts through the top of the

hood - from the inside.

2. Use four (4) nuts to secure hood to support

frame as shown.

- 4 -

DUCT

CONNECTOR

NUT

BOLT

Page 5

WIRING

Note: This range hood must be properly

grounded. The unit should be installed by a

qualified electrician in accordance with all

applicable national and local electrical

codes.

1. Remove the wiring box cover. Remove a

knockout from the wiring box.

2. Feed 6" of power cable through the knockout opening and secure cable to the wiring

box with an appropriate connector.

3. Make electrical connections. Connect white

to white, black to black and green to green.

4. Replace wiring box cover and screws. Make

sure that wires are not pinched between

cover and box.

CONNECT DUCTWORK

1. Use 8" round steel duct to connect the duct

collar on the hood to the ductwork above.

2. Use duct tape to make all joints secure and

air tight.

3. Slide the lower decorative flue section

downward, until it fits properly around hood.

4. Secure decorative flue to hood with screws

provided.

8”

ROUND

STEEL

DUCT

WIRING BOX

COVER

LOWER

DECORATIVE

FLUE

SECTION

- 5 -

Page 6

MAINTENANCE

Grease Filters

The grease filters should be cleaned frequently.

Use a warm detergent solution. Grease filters

are dishwasher safe.

Remove filters by pushing filters towards the

back of hood and rotating filters downward.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will help

preserve its fine appearance.

Cleaning tips:

• Hot water with soap or detergent is all that is usually needed.

• Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to

avoid water marks.

• For discolorations or deposits that persist, use a non-scratching household cleanser

or stainless steel polishing powder with a little water and a soft cloth.

• For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleaser and water. Rub lightly in direction of polishing lines or "grain" of the stainless finish. Avoid using too much pressure which may mar the surface.

• DO NOT allow deposits to remain for long periods of time.

• DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

• DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

remain in contact with stainless steel for extended periods. Many of these compounds contain chemicals which may be harmful. Rinse with water after exposure

and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

GREASE FILTERS

OPERATION

Controls

The hood is operated using the slide controls

under the front edge of the hood.

The light switch turns the halogen lights on

and off.

The blower on / off switch turns the blower on

to the running speed set by the blower speed

control. The blower must be turned on and off

using this switch.

The blower speed control changes the running speed of the blower. It is infinitely adjustable from low to high speed.

The pilot lamp lights up whenever the blower

is on.

- 6 -

LIGHT

SWITCH

BLOWER

SPEED

CONTROL

BLOWER

ON / OFF

SWITCH

PILOT

LAMP

Page 7

HALOGEN BULBS

This range hood requires four (4) halogen bulbs

(Type T4, 12V, 20W).

To change bulbs:

1. Open the light lens by grasping the tab on

the lens and rotating lens downward.

2. Remove the bulb by pulling sideward (Do not

rotate). CAUTION: BULB MAY BE HOT!

3. Do not touch replacement bulb with bare

hands! Push bulb securely into lamp socket

and snap lens closed.

LIGHT LENS

TAB

- 7 -

Page 8

WARRANTY

BROAN ONE YEAR LIMITED WARRANTY

Broan warrants to the original consumer purchaser of its products that such

products will be free from defects in materials or workmanship for a period of

one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A P ARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without

charge, any product or part which is found to be defective under normal use

and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES. This warranty does not cover (a) normal maintenance and

service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan), faulty

installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty . Some states do not allow limitation on how long

an implied warranty lasts, so the above limitation may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN’S OPTION,

SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER

THIS WARRANTY. BROAN SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other

rights, which vary from state to state. This warranty supersedes all prior warranties.

T o qualify for warranty service, you must (a) notify Broan at the address stated

below or telephone: 1-800-637-1453, (b) give the model number and part

identification and (c) describe the nature of any defect in the product or part.

At the time of requesting warranty service, you must present evidence of the

original purchase date.

BROAN MFG. CO., INC., 926 West State Street Hartford, WI 53027

- 8 -

Page 9

SERVICE PARTS

63000 SERIES RANGE HOOD

KEY NO. P ART NO. DESCRIPTION

6 B02000191 Filter Spring

9 B08087485 Grease Filter

14 B02300730 Motor Capacitor

19 B03295005 Terminal Box

26 B02300722 Halogen Lamp Bulb

30 B03292291 Switch Cover

48 B02310094 Motor

49 B03295000 Blower Wheel

53 B03202007 Rubber Washer

57 BE3300527 Damper Flap

68 B02011064 Right Blower Housing

69 B02011063 Left Blower Housing

86 B08088242 Duct Connector

99 BE3334373 Filter Channel

113 B03202433 Nameplate

115 BE3495228 Wiring Box

116 BE3334252 Wiring Box Cover

118 BE3407823 Decorative Flue Bottom

119 BE3407816 Decorative Flue Top

124 B03109013 Support Frame Bottom

125 B03109014 Support Frame Top

144 B03292287 Wire Clamp

147 BR2300134 Terminal Block

165 B03292161 Control Board Box

166 B08086101 Control Board

167 B03292162 Control Board Box Cover

168 B03292163 Capacitor Box Cover

208 B02300729 Transformer

223 B03292294 Switch Button

474 B02300719 Halogen Lamp Housing

477 B03295006 Terminal Cover

* B06001772 Blower Assembly (Includes Key Nos. 48, 49,

53, 68, 69)

* B06106298 Control Board Assembly w/ Circuit Board

(Includes Key Nos. 144, 147, 165, 166, 167,

168)

* B06106297 Switch Assembly (Includes Key Nos. 222, 223,

224, 225, 226, 228, 229, 230)

* B06106294 Motor Capacitor Assembly w/ Wires

(Includes Key No. 14 & Wires)

* B080810199 Duct Connector Assembly

(Includes Key Nos. 57 & 86)

- 9 -

Page 10

SERVICE PARTS

63000 SERIES RANGE HOOD

- 10 -

Loading...

Loading...