RANDELL 2031F Installation Manual

Randell Manufacturing, Inc.

This manual provides information on installation, operating, maintenance,

troubleshooting & replacement parts for

2000 SERIES

REACH-INS

NOTIFY CARRIER OF DAMAGE AT ONCE.

It is the responsibility of the consignee to inspect the container upon receipt of same

and to determine the possibility of any damage, including concealed damage. Randell

suggests that if you are suspicious of damage to make a notation on the deliv ery

receipt. It will be the responsibility of the consignee to file a claim with the carrier. We

recommend that you do so at once.

520 S. Coldwater Road Weidman, Ml 48893-9683

Phone 1-800-621-8560 Fax 1-800-634-5369 www.randell.com

TABLE OF CONTENTS

Page 2 .............................................................................…………...Congratulations

Page 3 . ................................................... . …………………Factory Correspondence

Page 4 ....................................................…………………. Serial Number Location

Page 5 .....................................................…………………........ Unit Specifications

Page 8 ................................................………………….. Randell Limited Warranty

Page 11 ...................................................………………................... Unit Installation

Page 15 ........................................................……………................... Unit Operation.

Page 15 ................................................…………………...Preventative Maintenance

Page 17 ..........................................................……………................ Troubleshooting

Page 26 .........................................................……………....................... Part Figures

Page 43 ..................................……………………… Appendix A Heated Reach-ins

Congratulations on your recent purchase of Randell food service equipment, and welcome

to the growing family of satisfied Randell customers.

Our reputation for superior products is the result of consistent quality craftsmanship.

From the earliest stages of product design, to successive steps in fabrication and

assembly, rigid standards of excellence are maintained by our staff of designers,

engineers, and skilled employees.

Only the finest heavy-duty materials and parts are used in the production of Randell

brand equipment. This means that each unit, given proper maintenance, will provide

years of trouble free service to its owner.

In addition, all Randell food service equipment is backed by one

of the best warranties in the food service industry and by our

professional staff of service technicians.

2

Retain this manual for future reference.

Notice: Due to a continuous program of product improvement, Randell Manufacturing

reserves the right to make changes in design and specifications without prior

notice.

Notice: Please read the entire manual carefully before

installation.

If certain recommended procedures are not followed, warranty

claims will be denied.

Model Number ______________________

Serial Number ______________________

Installation Date ______________________

Randell Manufacturing

Service and Parts Hot Line

1-800-621-8560

3

RANDELL MANUFACTURING

SERIAL NUMBER LOCATION

FOR THE

2000 SERIES

This is a sample of a serial number tag.

The serial number tag on the 2000 series is located inside the refrigerated base on

the far left side of the unit.

4

Unit Specifications

For The

2000 Series

2000 SERIES

MODEL L D H DOORS CUBIC

FEET

2010 30" 33.5" 81.25" 1 24 3/11.75'

2010D 30" 33.5" 81.25" (2)1/2 SIZE 12/10 4/15.25"***

2010DR 30" 33.5" 81.25" (2)1/2 SIZE 12/10 4/15.25"***

201 OF 30" 33.5" 81.25" 1 24 3/11.75'

2010FP 30" 35.75" 81.25" 2 24 3/17.5 1/2 2180* 115/60/1 9.3 5-15P 425

2010FPR 30" 35.75" 81.25" 2 24 3/17.5 1/2 2180* 115/60/1 5 N/A 425

2010FR 30" 33.5" 81.25" 1 24 3/11.75' 1/4 2180* 115/60/1 5 N/A 345

2010P 30" 35.75" 81.25" 2 24 3/11.75' 1/3 1740* 115/60/1 8.6 5-15P 395

2010PR 30" 35.75" 81.25" 2 24 3/11.75' 1/4 1740* 115/60/1 2 N/A 345

2010R 30" 33.5" 81.25" 1 24 3/11.75' 1/4 1740* 115/60/1 2 N/A 345

2011 30" 33.5" 81.25" 1 24 3/11.75' 1/4 1740* 115/60/1 6.9 5-15P 395

2011F 30" 33.5" 81.25" 1 24 3/11.75'

2011FR 30" 33.5" 81.25" 1 24 3/11.75'

2011R 30" 33.5" 81.25" 1 24 3/11.75' 1/4 1740* 115/60/1 2 N/A 345

2135 35" 34.5" 84" 1 31 N/A 1/3 2300* 115/60/1 8.6 5-15P 850

2135R 35" 34.5" 84" 1 31 N/A 1/3 2300* 115/60/1 2 N/A 800

2235 35" 34.5" 84" 1 31 N/A 3/4 2180* 115/60/1 12 5-20P 880

2235R 35" 34.5" 84" 1 31 N/A 1/2 2180* 115/60/1 5 N/A 830

*Based on 90F ambient +20F evaporator for refrigerators and -10F for freezers

** Condensing units specified for remote units are recommendations only.

***lncludes bottom of each section as one shelf.

Note: All remote reach-ins come standard on 6" legs in lieu of casters.

SHELVES

QTY/SQ. FT

5

HP** BTU/HR VOLT AMP NEMA SHIP

WT

1/4

1/2

1/2

1/2

1/2

1/2

1740* 115/60/1 6.9 5-15P 395

2180* 115/60/1 10.4 5-20P 495

2180* 115/60/1 7 N/A 445

2180* 115/60/1 9.3 5-15P 425

2180* 115/60/1 9.3 5-15P 425

2180* 115/60/1 5 N/A 345

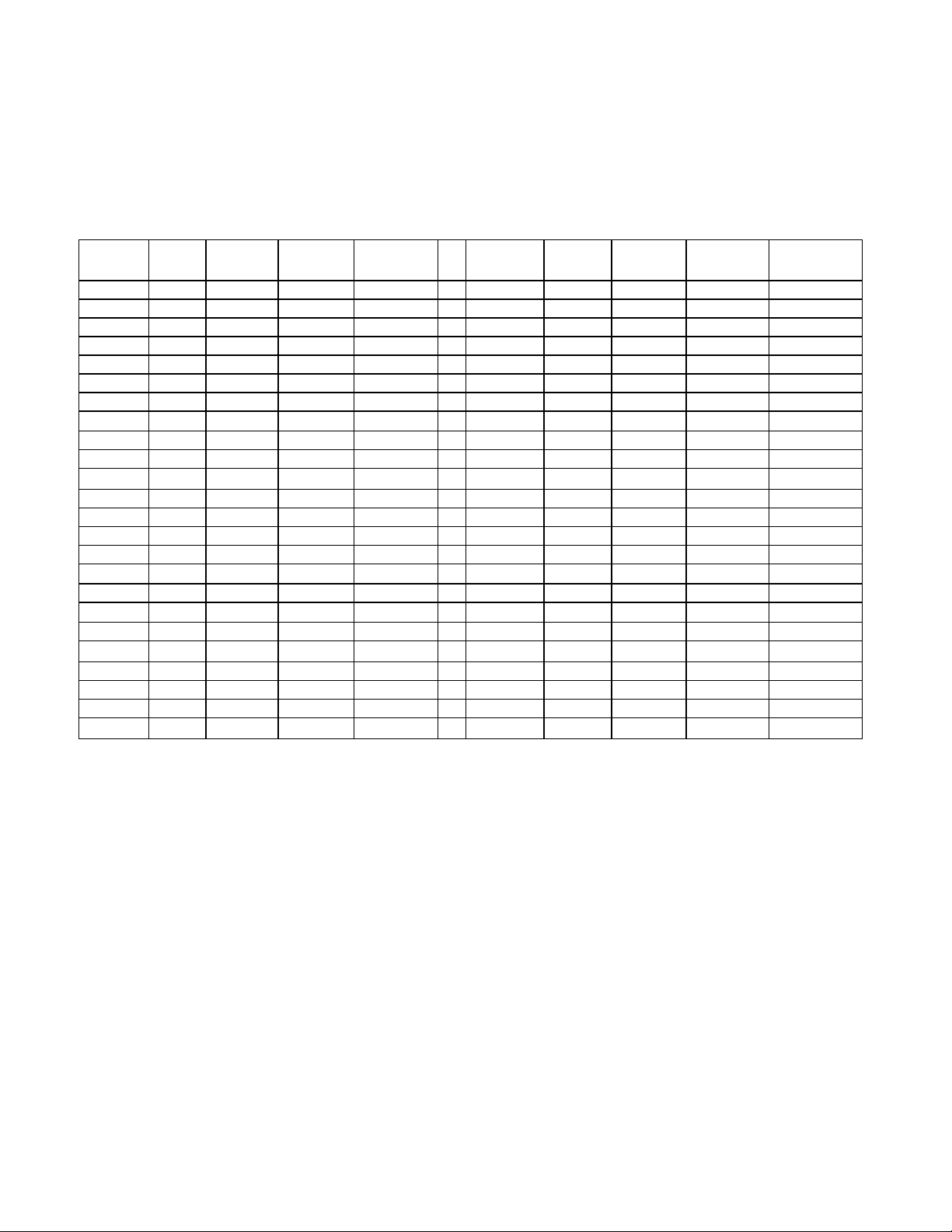

2000 SERIES

MODEL L D H DOORS

CUBIC

FEET

SHELVES

QTY/SQ FT.

HP

BTU/HR VOLT AMP

NEMA

SHIP

WT

2020 55" 33.5" 81.25" 2 47 6/26' 1/3 2300* 115/60/1 8.6 5-15P 595

2020D 55" 33.5" 81.25" (2)full size 47 8/26' 3/4 4020* 115/60/1 15.4 5-20P 690

2020DR 55" 33.5" 81.25" (2)full size 47 8/26' 3/4 4020* 115/60/1 7 N/A 640

2020F 55" 33.5" 81.25" 2 47 6/26' 3/4 4020* 115/60/1 15.4 5-15P 620

2020FP 55" 35.75" 81.25" 4 47 6/26' 3/4 4020* 115/60/1 15.4 5-15P 620

2020FPR 55" 35.75" 81.25" 4 47 6/26' 3/4 4020* 115/60/1 7 N/A 570

2020FR 55" 33.5" 81.25" 2 47 6/26' 3/4 4020* 115/60/1 7 N/A 570

2020P 55" 35.75" 81.25" 4 47 6/26' 1/2 2300* 115/60/1 11.7 5-15P 595

2020PR 55" 35.75" 81.25" 4 47 6/26' 1/3 2300* 115/60/1 3 N/A 545

2020R 55" 33.5" 81.25" 2 47 6/26' 1/3 2300* 115/60/1 3 N/A 545

2021 55" 33.5" 81.25" 2 47 6/26' 1/3 2300* 115/60/1 8.6 5-15P 595

2021F 55" 33.5" 81.25" 2 47 6/26' 3/4 4020* 115/60/1 15.4 5-15P 620

2021FR 55" 33.5" 81.25" 2 47 6/26' 3/4 4020* 115/60/1 7 N/A 570

2021 R 55" 33.5" 81.25" 2 47 6/26' 3/4 2300* 115/60/1 3 N/A 545

2022 55" 31.5" 81.25" 2 47 6/26' 1/3 2300* 115/60/1 8.6 5-15P 605

2022P 55" 31.75" 81.25" 4 47 6/26' 1/2 2300* 115/60/1 11.7 5-15P 605

2022PR 55" 31.75" 81.25" 4 47 6/26' 1/3 2300* 115/60/1 3 N/A 555

2022R 55" 31.5" 81.25" 2 47 6/26' 1/3 2300* 115/60/1 3 N/A 555

2168 68" 34.5" 84" 2 66 N/A 1/2 2180* 115/60/1 11.7 5-20P 1275

2168R 68" 34.5" 84" 2 66 N/A 1/2 2180* 115/60/1 3 N/A 1205

2268 68" 34.5" 84" 2 66 N/A 1 4900* 115/60/1 9.7 14-20P

2268R 68" 34.5" 84" 2 66 N/A ****

**** **** **** N/A 1260

1310

*Based on 90F ambient +20F evaporator for refrigerators and -10F for freezers

** Condensing units specified for remote units are recommendations only.

***Includes bottom of each section as one shelf.

****Consult factory for recommended condensing unit specifications.

Note: All remote reach-ins come standard on 6" legs in lieu of casters.

6

MODEL L D H DOORS

2030 83" 33.5" 81.25"

2030F 83" 33.5" 81.25"

2030FR 83" 33.5" 81.25"

2030P 83" 35.75" 81.25"

2030PR 83" 35.75" 81.25"

2030R 83" 33.5" 81.25"

2031 83" 33.5" 81.25"

2031 R 83" 33.5" 81.25"

*Based on 90F ambient +20F evaporator for refrigerators and -10F for freezers

** Condensing units specified for remote units are recommendations only.

Note: All remote reach-ins come standard on 6" legs in lieu of casters.

3 69 9/39' 1/2 2180* 115/60/1 11.7 5-15P 800

3 69 9/39' 1 4900* 115/60/1 9.7 5-15P 840

3 69 9/39' *** *** *** *** N/A 790

6 69 9/39' 1/2 2180* 115/60/1 11.7 5-15P 800

6 69 9/39' 1/2 2180* 115/60/1 4 N/A 750

3 69 9/39' 1/2 2180* 115/60/1 2 N/A 750

3 69 9/39' 1/2 2180* 115/60/1 11.7 5-15P 800

3 69 9/39' 1/2 2180* 115/60/1 2 N/A 750

***Consult factory for recommended condensing unit specifications.

CUBIC

FEET

2000 SERIES

SHELVES

QTY/SQ FT

7

HP** BTU/HR* VOLT AMP NEMA

SHIP

WT

Randell Manufacturing, Inc.

Warranty Policies

Parts Warranty

Randell warrants all component parts of manufactured new equipment to be free of defects

in material or workmanship, and that the equipment meets or exceeds reasonable industry

standards of performance for a period of one year from the date of shipment from any

Randell factory, assembly plant or warehouse facility.

Note: Warranties are effective from date of shipment, with a thirty day window to allow

for shipment, installation and set up. In the event equipment was shipped to a site

other than the final installation site, Randell will warranty for a period of three

months following installation, with proof of starting date, up to a maximum of eighteen

months from date of purchase.

Component parts warranty does not cover glass breakage or gasket replacement. Randell

covers all shipping cost related to component part warranty sent at regular ground rates

(UPS, USPS).

Freight or postage incurred for any express or specialty methods of shipping are the

responsibility of the customer.

Labor Coverage

In the unlikely event a Randell manufactured unit fails due to defects in materials or

workmanship within the first ninety days, Randell agrees to pay reasonable labor

incurred. During the first ninety days work authorizations are not required for in

warranty repairs. However, repair times are limited to certain flex rate schedules and

hours will be deducted from service invoices if they exceed allowed times without prior

approval and a work authorization number. Warranties are effective from date of

shipment, with a 30 day window to allow for shipment, installation and setup.

Where equipment is shipped to any site other than final installation Randell will honor

the labor warranty for a period of ninety days following installation with proof of

starting date, up to a maximum of nine months from date of purchase. Travel time is

limited to one hour each direction or two hours per invoice. Any travel time exceeding

two hours will be the responsibility of the customer.

Note: Temperature adjustments are not covered under warranty, due to the wide range

of ambient conditions.

8

Five Year Extended Compressor Warranty

United States installations only:

Randell will pay for the replacement compressor only. Freight, labor, refrigerant,

handling and all other miscellaneous charges are the responsibility of the customer.

Randell will fulfill its warranty obligation by using one of the four methods provided

below, which will be selected by the Randell in house service technician:

1. Provide reimbursement to servicing customer for the cost of the locally obtained

replacement compressor in exchange for the return of the defective compressor

returned to Randell freight prepaid. Randell does limit the amount of reimbursement

allowed and does require a copy of the local supply house bill for replacement

compressor.

Customer should not pay servicing agent up front for compressor.

2. Provide repair at the manufacturing facility by requiring that the defective unit

be sent back to Randell freight prepaid. Perform repair at the expense of Randell

and ship the item back to job location freight collect.

3. Furnish a replacement compressor freight collect in exchange for the return of the

defective compressor sent back freight prepaid.

4. Furnish complete condensing unit or replacement package

freight collect in exchange for the return of the defective compressor sent back

freight prepaid, (decisions based on whether or not to send complete condensing unit

will be made by Randell in-house service technician).

Export Warranty

Our export warranties will cover all non electrical parts for the period of one year

from the date of shipment to be free of defects in material or workmanship. Electrical

parts are also covered if ordered and operated on 60 Hz. Electrical components, ordered

and operated on 50 Hz, are warranted for the first 90 days from shipment only. Service

labor is covered for the first 90 days with authorization from factory prior to service.

Warranty is automatically initiated 60 days from ship date. Inbound costs on any factory

supplied items would be the responsibility of the customer. Adherence to recommended

equipment maintenance procedures, according to the owners manual provided with each

unit, is required for this warranty to remain in effect, and can have a substantial

effect on extending the service life of your equipment. Equipment abuse voids any

warranty. Extended warranties are not available for parts, labor or compressors on units

shipped outside the United States.

9

Freight Damage

Any and all freight damage that occurs to a Randell piece of equipment as a result of

carrier handling is not considered warranty, and is not covered under warranty

guidelines. Any freight damage incurred during shipping needs to have a freight claim

filed by the receiver with the shipping carrier (note all damages on freight bill at

time of delivery). Internal or concealed damage may fall under Randell's responsibility

dependent upon the circumstances surrounding each specific incident and are at the

discretion of the Randell in-house service technician.

Gasket Coverage

Randell does not cover gaskets under warranty. Gaskets are a maintenance type component

that are subject to daily wear and tear and are the responsibility of the owner of the

equipment. Because of the unlimited number of customer related circumstances that can

cause gasket failure all gasket replacement issues are considered non-warranty. Randell

recommends thorough cleaning of gaskets on a weekly basis with a mild dish soap and warm

water. With proper care Randell gaskets can last up to two years, at which time we

recommend replacement of all gaskets on the equipment for the best possible performance.

NOTICE: FOOD LOSS IS NOT COVERED UNDER WARRANTY

10

Unit Installation

A. Receiving Shipment

Upon arrival, examine the exterior of the shipping crate for signs of abuse. It is

advisable that the shipping crate be partially removed, in order to examine the cabinet

for any possible concealed damages which might have occurred during shipment. If no

damages are evident, replace the crate in order to protect the unit during storage and

local delivery. If the unit is damaged, it should be noted on the delivery slip or bill

of lading and signed to that effect. A claim must be filed immediately against the

carrier indicating the extent and estimated cost of damage occurred.

B. Electrical Supply

The wiring should be done by a qualified electrician in accordance with local electrical

codes. A properly wired, and grounded outlet will assure proper operation. Please

consult the data plate attached to the compressor to ascertain the correct electrical

requirements. Supply voltage and amperage requirements are located on the serial number

tag located inside the far left door.

Note: It is important that a voltage reading be made at the

compressor motor electrical connections, while the unit is in operation, to verify

that the correct voltage required by the compressor is being supplied. Low or high

voltage can detrimentally affect operation and thereby void its warranty.

Note: It is important that your unit has its own dedicated line. Condensing units are

designed to operate with a voltage fluctuation of plus or minus 10% of the voltage

indicated on the unit data plate. Burn out of a condensing unit due to exceeding

voltage limits will void the warranty.

C. Door Inspection

1. Check doors/drawers to ensure that they are sealing properly.

2. Check doors for proper alignment (see figure D. page 14).

3. Check doors to ensure that they open and shut freely.

11

D. Locating Your New Unit

2021

FR 47 35 570 2215

2010DR

12/10

35

445 1215

2021

R 47 35 545 2190

2010F

24 35

425 1265

2022

47 35

605 2250

201

0FP 24 35 425 1265

2022P

47 35

605 2250

2010FPR

24 35

425 1265

2022PR

47 35

555 2200

2010FR

24 35

345 1185

2022

R 47 35 555 2200

2010P

24 35

395 1235

2030

69 35

800 3215

201

0PR 24 35 345 1185

2030FR

69 35

790 3205

2011

24 35

395 1235

2030P

69 35

800 3215

2011F 24 35

425 1265

2030R

69 35

750 3165

2011R 24 35

345 1185

2031

69 35

800 3215

2020

47 35 595 2240

2031

R 69 35 750 3165

2020D

47 35

690 2335

2135

31 35

850 1935

2020DR

47 35

640 2285

2168

66 35

1275

3585

2020FP

47 35

620 2265

2235

31 35

880 1965

2020FR

47 35

570 2215

2268

66 35

1310

3620

2020PR

47 35

545 2190

2268R

66 35

1260

3570

2020R

47 35

545 2190

2010

24 35

395 1235

2021

47 35

595 2240

The following conditions should be considered when selecting a location for your

unit:

1. Floor load - The area on which the unit will rest must be free of vibration and

suitably strong enough to support the combined weights of the unit plus the maximum

product load weight, which are provided in the table below:

MODEL

2030F 69 35 840 3255

2030PR 69 35 750 3165

2135R 31 35 800 1885

2168R 66 35 1205 3515

2235R 31 35 830 1915

CUBIC

FT

FACTOR

WEIGHT

POUNDS

TOTAL

CAPACITY

MODEL

2010R 24 35 345 1185

2011FR 24 35 345 1185

2020F 47 35 620 2265

2020FPR 47 35 570 2215

2020P 47 35 595 2240

CUBIC

FT

FACTOR

WEIGHT

POUNDS

CAPACITY

TOTAL

2010D 12/10 35 495 1265

2. Clearance - There must be a combined total of at least 3" clearance on all sides of

the unit.

3. Ventilation - The air cooled self contained unit requires a sufficient amount of cool

clean air. Avoid placing the unit near heat generating equipment such as ovens,

ranges, heaters, fryers, steam kettles, etc. and out of direct sunlight. Avoid

locating the unit in an unheated room or where the room temperature may drop below

55° F or above 90° F.

2021F 47 35 620 2265

12

E. Installation Checklist

After the final location of the unit has been determined refer to the following

checklist prior to start up:

1. Check all exposed refrigeration lines to ensure that they are not kinked, dented or

rubbing together.

2. Check that condenser and evaporator fans rotate freely without striking any

stationary members.

3. Unit must be properly leveled.

4. Plug in unit and turn on main on/off switch.

5. Turn on cold control located inside the base.

6. Refer to the front of this manual for serial number location. Please record this

information in your manual on page 3 now. It will be necessary when ordering

replacement parts or requesting warranty service.

7. Confirm that unit is holding temperature. Set controls to desired temperature for

your particular ambient and altitude (See figure A.).

8. Allow your unit to operate for approximately 2 hours before putting in food this

allows interior to cool down to storage temperature.

Note: All motors are oiled and sealed.

Note: All self-contained models are shipped from the factory with the service valves

open ready for operation.

13

Figure B - Temperature control adjustments

The control knob allows for temperature

adjustments, with in the cabinet only. Turning

the knob clockwise will result in increased

cooling. Keep the arrow on the knob pointed

within the green arc. Turning it clockwise

beyond the green can result in freeze-up, while

turning it counterclockwise beyond the green

will shut the compressor off. If your cabinet

temperature remains to warm and your

temperature control is at the maximum setting

you may need to adjust the pressure control.

Your units pressure control should be set at

the time of installation by a qualified

installation contractor. If minor adjustments

are needed at a later date, adjust control by

turning the right adjusting screw clockwise

(1/4 turn at a time) to a lower number for

colder temperature and counterclockwise to a

higher number for warmer temperature.

Note: Numbers are pounds of pressure not degrees F.

Note: Do not adjust the differential screw (Left screw).

Note: Temperature Controls located behind louver on top of unit.

14

Unit Operation

Randell has attempted to preset the cold control for an average interior temperature of

38°F at the factory but due to varying ambient conditions, including elevation, food

product as well as type of operation you may need to alter this temperature. Additional

adjustments can be made (within limits) by turning the control dial up or down until the

desired temperature is reached. The control dial is located on the evaporator housing

inside the base.

Your reach-in will maintain proper temperatures when utilized properly. It is strongly

recommended that the doors be kept closed as much as possible. This is especially

important in the summer and in kitchens exceeding 80° F.. Do not leave the covers open

for prolonged periods of time. Make sure doors close properly after each use.

Note: Even though your reach-in was designed for heavy use, excessive door openings

should be avoided, in order to maintain proper box temperature and eliminate

the possibility of coil freeze up.

Preventive Maintenance

Randell strongly suggests a preventive maintenance program which would include the

following Monthly procedures:

1. Cleaning of all condenser coils. Condenser coils are a critical component in the

life of the compressor and must remain clean to assure proper air flow and heat

transfer. Failure to maintain this heat transfer will affect unit performance and

eventually destroy the compressor. Clean the condenser coils with coil cleaner

and/or a vacuum cleaner and brush.

Note: Brush coil in direction of fins, normally vertically as to not damage or restrict

air flow from passing through condenser.

2. Clean all fan blades, both on the condensing unit and the evaporator assembly.

3. Lubricate door hinges with lithium grease.

4. Clean and disinfect drain lines and evaporator pan with a solution of warm water

and bleach.

5. Clean all gaskets on a weekly if not daily basis with a

solution of warm water and a mild detergent to extend gasket

life.

NOTE: DO NOT USE SHARP UTENSILS

15

Loading...

Loading...