RAMTRON FM18L08-70-S, FM18L08-70-P Datasheet

Preliminary

FM18L08

256Kb 2.7-3.6V Bytewide FRAM Memory

Features

256K bit Ferroelectric Nonvolatile RAM

• Organized as 32,768 x 8 bits

• 10 year data retention at 85° C

• Unlimited read/write cycles

• NoDelay™ write

• Advanced high-reliability ferroelectric process

Superior to Battery -backed SRAM

• No battery concerns

• Monolithic reliability

• True surface mount solution, no rework steps

• Superior for moisture, shock, and vibration

• Resistant to negative voltage undershoots

Description

The FM18L08 is a 256-kilobit nonvolatile memory

employing an advanced ferroelectric process. A

ferroelectric random access memory or FRAM is

nonvolatile but operates in other respects as a RAM.

It provides data retention for 10 years while

eliminating the reliability concerns, functional

disadvantages and system design complexities of

battery -backed SRAM. Fast-write time and practically

unlimited read/write endurance make it superior to

other types of nonvolatile memory and a good

substitute for ordinary SRAM.

In-system operation of the FM18L08 is very similar to

other RAM based devices. Memory read- and writecycles require equal times. The FRAM memory,

however, is nonvolatile due to its unique ferroelectric

memory process. Unlike BBSRAM, the FM18L08 is a

truly monolithic nonvolatile memory. It provides the

same functional benefits of a fast write without the

serious disadvantages associated with modules and

batteries or hybrid memory solutions.

These capabilities make the FM18L08 ideal for

nonvolatile memory applications requiring frequent or

rapid writes in a bytewide environment. The

availability of a true surface-mount package improves

the manufacturability of new designs, while the DIP

package facilitates simple design retrofits. The

FM18L08 offers guaranteed operation over an

industrial temperature range of -40°C to +85°C.

SRAM & EEPROM Compatible

• JEDEC 32Kx8 SRAM & EEPROM pinout

• 70 ns access time

• 130 ns cycle time

• Equal access & cycle time for reads and writes

Low Power Operation

• 2.7V to 3.6V operation

• 15 mA active current

• 15 µA standby current

Industry Standard Configuration

• Industrial temperature -40° C to +85° C

• 28-pin SOP or DIP

Pin Configuration

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

VSS DQ3

Ordering Information

FM18L08-70-S 70 ns access, 28-pin SOP

FM18L08-70-P 70 ns access, 28-pin DIP

VDD

WE

A13

A8

A9

A11

OE

A10

CE

DQ7

DQ6

DQ5

DQ4

This data sheet contains specifications for a product under development. Ramtron International Corporation

Characterization is not complete; specifications may change without notice. 1850 Ramtron Drive, Colorado Springs, CO 80921

(800) 545-FRAM, (719) 481-7000, Fax (719) 481-7058

www.ramtron.com

23 March 2001 1/11

Ramtron FM18L08

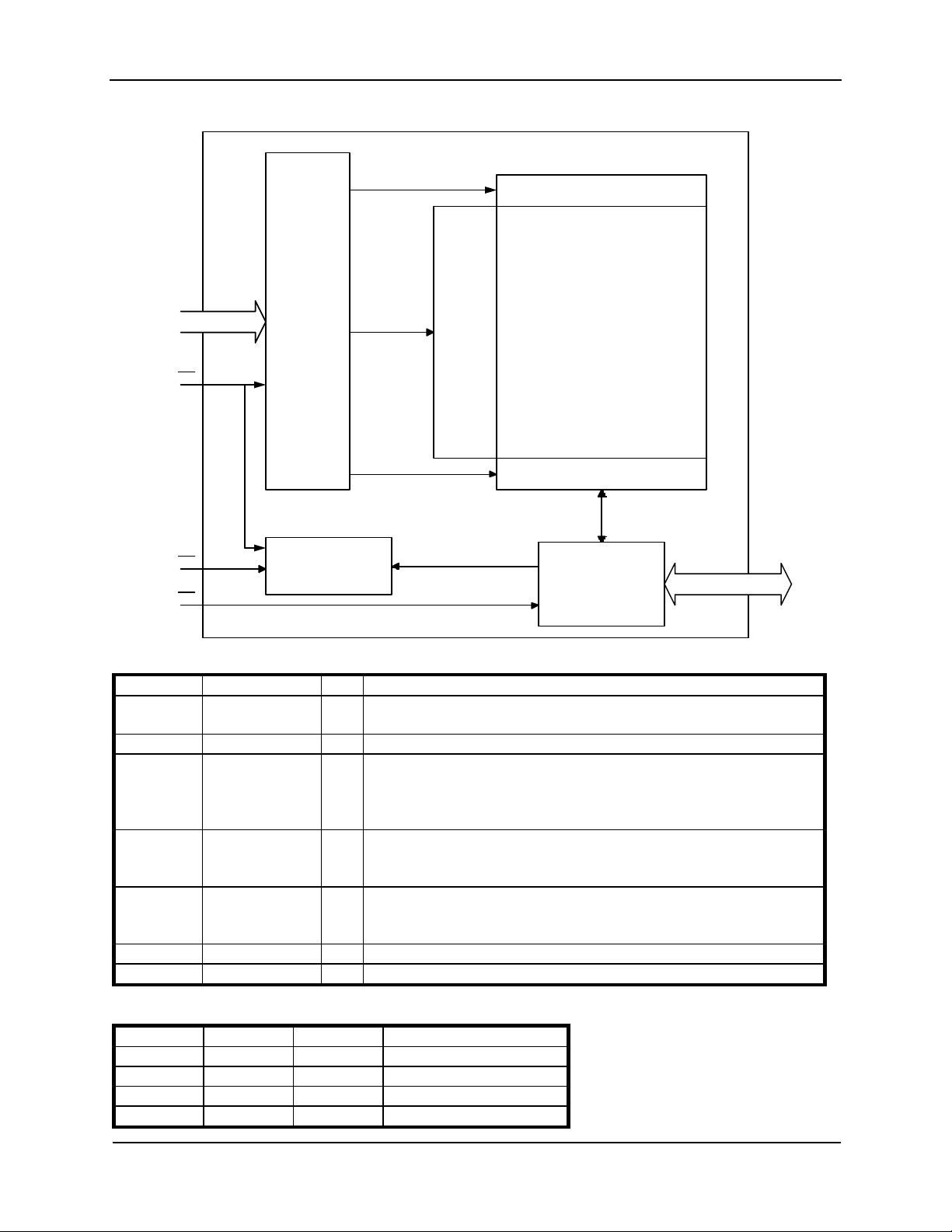

Figure 1. Block Diagram

CE

WE

OE

A0-A14

Address

Latch

Control

Logic

A10-A14

A0-A7

A8-A9

Row

Decoder

Block Decoder

32,768 x 8 FRAM Array

Column Decoder

I/O Latch

Bus Driver

DQ0-7

Pin Description

Pin Name Pin Number I/O Pin Description

A0-A14 1-10, 21, 23-26 I Address. The 15 address lines select one of 32,768 bytes in the FRAM

array. The address value will be latched on the falling edge of /CE.

DQ0-7 11-13, 15-19 I/O Data. 8-bit bi -directional data bus for accessing the FRAM array.

/CE 20 I Chip Enable. /CE selects the device when low. The falling edge of /CE

causes the address to be latched internally. Address changes that

occur after /CE goes low will be ignored until the next falling edge

occurs.

/OE 22 I Output Enable. When /OE is low the FM18L08 drives the data bus

when valid data is available. Taking /OE high causes the DQ pins to be

tri-stated.

/WE 27 I Write Enable. Taking /WE low causes the FM18L08 to write the

contents of the data bus to the address location latched by the falling

edge of /CE.

VDD 28 I Supply Voltage.

VSS 14 I Ground.

Functional Truth Table

/CE /WE /OE Function

H X X Standby/Precharge

æ

X X Latch Address

L H L Read

L L X Write

23 March 2001 2/11

Ramtron FM18L08

Overview

The FM18L08 is a bytewide FRAM logically

organized as 32,768 x 8. It is accessed using an

industry standard parallel interface. The FM18L08 is

inherently nonvolatile via its unique ferroelectric

process. All data written to the part is immediately

nonvolatile with no delay. Functional operation of the

FRAM memory is similar to SRAM type devices. The

major operating difference between the FM18L08 and

an SRAM (besides nonvolatile storage) is that the

FM18L08 latches the address on the falling edge of

/CE.

Memory Operation

Users access 32,768 memory locations each with 8

data bits through a parallel interface. The access and

cycle time are the same for read and write memory

operations. Writes occur immediately at the end of the

access with no delay. Unlike an EEPROM, it is not

necessary to poll the device for a ready condition

since writes occur at bus speed. A pre-charge

operation, where /CE goes inactive, is a part of every

memory cycle. Thus unlike SRAM, the access and

cycle times are not equal.

Note that the FM18L08 contains a limited low voltage

write protection circuit. This will prevent access when

VDD is much lower than the specified operating

range. It is still the user’s responsibility to ensure that

VDD is within data sheet tolerances to prevent

incorrect operation.

The FM18L08 is designed to operate in a manner very

similar to other bytewide memory products. For users

familiar with SRAM, the performance is comparable

but the bytewide interface operates in a slightly

different manner as described below. For users

familiar with EEPROM, the obvious differences result

from the higher write performance of FRAM

technology including NoDelay writes and from

unlimited write endurance.

Read Operatio n

A read operation begins on the falling edge of /CE. At

this time, the address bits are latched and a memory

cycle is initiated. Once started, a full memory cycle

must be completed internally regardless of the state of

/CE. Data becomes available on the bus after the

access time has been satisfied.

After the address has been latched, the address value

may be changed upon satisfying the hold time

parameter. Unlike an SRAM, changing address values

23 March 2001 3/11

will have no effect on the memory operation after the

address is latched.

The FM18L08 will drive the data bus when /OE is

asserted to a low state. If /OE is asserted after the

memory access time has been satisfied, the data bus

will be driven with valid data. If /OE is asserted prior

to completion of the memory access, the data bus will

be driven when valid data is available. This feature

minimizes supply current in the system by eliminating

transients due to invalid data. When /OE is inactive

the data bus will remain tri-stated.

Write Operation

Writes operations require the same time as reads. The

FM18L08 supports both /CE- and /WE-controlled

write cycles. In all cases, the address is latched on the

falling edge of /CE.

In a /CE-controlled write, the /WE signal is asserted

prior to beginning the memory cycle. That is, /WE is

low when /CE falls. In this case, the device begins the

memory cycle as a write. The FM18L08 will not drive

the data bus regardless of the state of /OE.

In a /WE-controlled write, the memory cycle begins

on the falling edge of /CE. The /WE signal falls after

the falling edge of /CE. Therefore, the memory cycle

begins as a read. The data bus will be driven

according to the state of /OE until /WE falls. The

timing of both /CE- and /WE-controlled write cycles is

shown in the electrical specifications.

Write access to the array begins asynchronously

after the memory cycle is initiated. The write access

terminates on the rising edge of /WE or /CE,

whichever is first. Data set-up time, as shown in the

electrical specifications, indicates the in terval during

which data cannot change prior to the end of the write

access.

Unlike other truly nonvolatile memory technologies,

there is no write delay with FRAM. Since the read and

write access times of the underlying memory are the

same, the user experiences no delay through the bus.

The entire memory operation occurs in a single bus

cycle. Therefore, any operation including read or write

can occur immediately following a write. Data polling,

a technique used with EEPROMs to determine if a

write is complete, is unnecessary.

Pre-charge Operation

The pre-charge operation is an internal condition

where the state of the memory is prepared for a new

Ramtron FM18L08

access. All memory cycles consist of a memory

access and a pre-charge. The pre-charge is user

initiated by taking the /CE signal high or inactive. It

must remain high for at least the minimum pre -charge

timing specification.

The user dictates the beginning of this operation

since a pre-charge will not begin until /CE rises.

However, the device has a maximum /CE low time

specification that must be satisfied.

Applications

As a true nonvolatile RAM, the FM18L08 fits into

many diverse applications. Clearly, its monolithic

nature and high performance make it superior to

battery -backed SRAM in most every application.

Unlimited endurance allows the FM18L08 to be used

in applications that could not take advantage of the

previous generation of RAM products. This

applications guide is intended to facilitate the

transition from BBSRAM to FRAM. It is divided into

two parts. First is a treatment of the advantages of

FRAM memory compared with battery-backed

SRAM. Second is a design guide, which highlights

the simple design considerations that should be

reviewed in both retrofit and new design situations.

FRAM Advantages

Although battery-backed SRAM is a mature and

established solution, it has numerous weaknesses.

These stem directly or indirectly from the presence of

the battery. FRAM uses an inherently nonvolatile

storage mechanism that requires no battery. It

therefore eliminates these weaknesses. The major

considerations in upgrading to FRAM are as follows.

Construction Issues

1. Cost

The cost of both the component and the

manufacturing overhead of battery -backed SRAM is

high. FRAM with its monolithic construction is

inherently a lower cost solution. In addition, there is

no ‘built-in’ rework step required for battery

attachment when using surface mount parts.

Therefore assembly is streamlined and more cost

effective. In the case of DIP battery -backed modules,

the user is constrained to through-hole assembly

techniques and a board wash using no water.

2. Humidity

A typical battery-backed SRAM module is qualified at

60º C, 90% Rh, no bias, and no pressure. This is

because the multi-component assemblies are

vulnerable to moisture, not to mention dirt. FRAM is

qualified using HAST – highly accelerated stress test.

This requires 120º C at 85% Rh, 24.4 psia at VDD.

3. System reliability

Data integrity must be in question when using a

battery -backed SRAM. They are inherently

vulnerable to shock and vibration. If the battery

contact comes loose, data will be lost. In addition a

negative voltage, even a momentary undershoot, on

any pin of a battery-backed SRAM can cause data

loss. The negative voltage causes current to be drawn

directly from the battery. These momentary short

circuits can greatly weaken a battery and reduce its

capacity over time. In general, there is no way to

monitor the lost battery capacity. Should an

undershoot occur in a battery backed system during a

power down, data can be lost immediately.

4. Space

Certain disadvantages of battery-backed SRAM, such

as susceptibility to shock, can be reduced by using

the old fashioned DIP module. However, this

alternative takes up board space, height, and dictates

through-hole assembly. FRAM offers a true surfacemount solution that uses 25% of the board space.

No multi-piece assemblies, no connectors, and no

modules. A real nonvolatile RAM is finally

available!

Direct Battery Issues

5. Field maintenance

Batteries, no matter how mature, are a built-in

maintenance problem. They eventually must be

replaced. Despite long life projections, it is impossible

to know if any individual battery will last considering

all of the factors that can degrade them.

6. Environmental

Lithium batteries are widely regarded as an

environmental problem. They are a potential fire

hazard and proper disposal can be a burden. In

addition, shipping of lithium batteries may be

restricted.

7. Style!

Backing up an SRAM with a battery is an oldfashioned approach. In many cases, such modules are

the only through-hole component in sight. FRAM is

the latest memory technology and it is changing the

way systems are designed.

23 March 2001 4/11

Loading...

Loading...