Page 1

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

3

WES+ Installation and

Operation Manual

Page 2

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Contents

System Units

Unit Diagrams

WES+ Units

Fire Point

Detector – Heat

Detector – Smoke

Base Station

Link

Interface

Basic System

Health and Safety

Manual Handing, Storage and Transportation

Service and Maintenance

Damaged Units

Installation procedure

System operation

Raising the alarm

Manual activation

Automatic activation

Silencing the alarm

Resetting a call point

LED Indications

Unit Alive Indication

Amber LED Indication

Red LED Indication

Silent Tests

Initiating a silent test

Inspection of other system units

Cancelling a Silent Test

Moving a unit on site

Removing a unit from the site

Advanced systems – Base Stations

Menu Overview

Alarm

System Warnings

Base Station Controls

4

5

5

5

5

5

5

5

5

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

9

9

9

9

9

9

10

10

11

11

12

Page 3

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

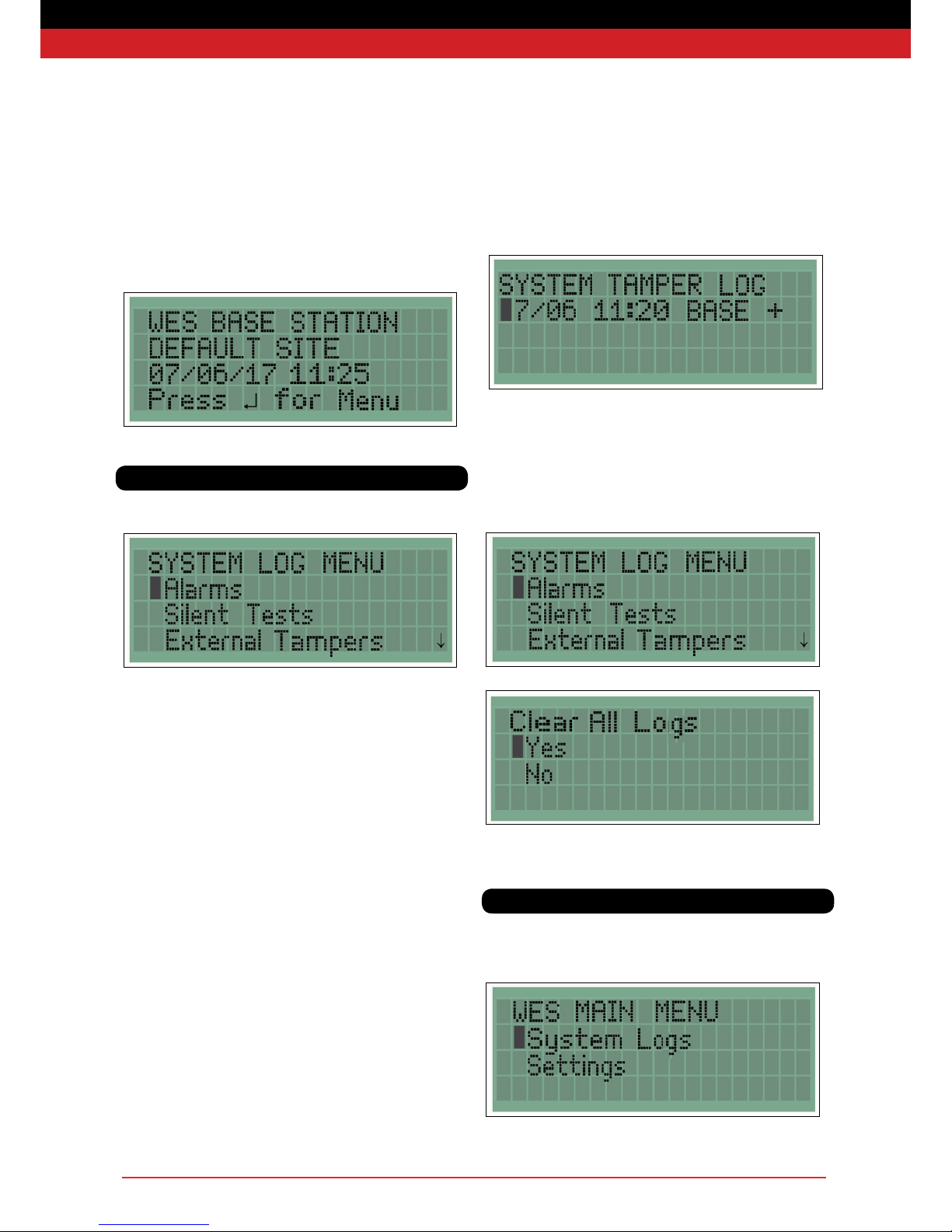

Home screen

System Logs

Settings

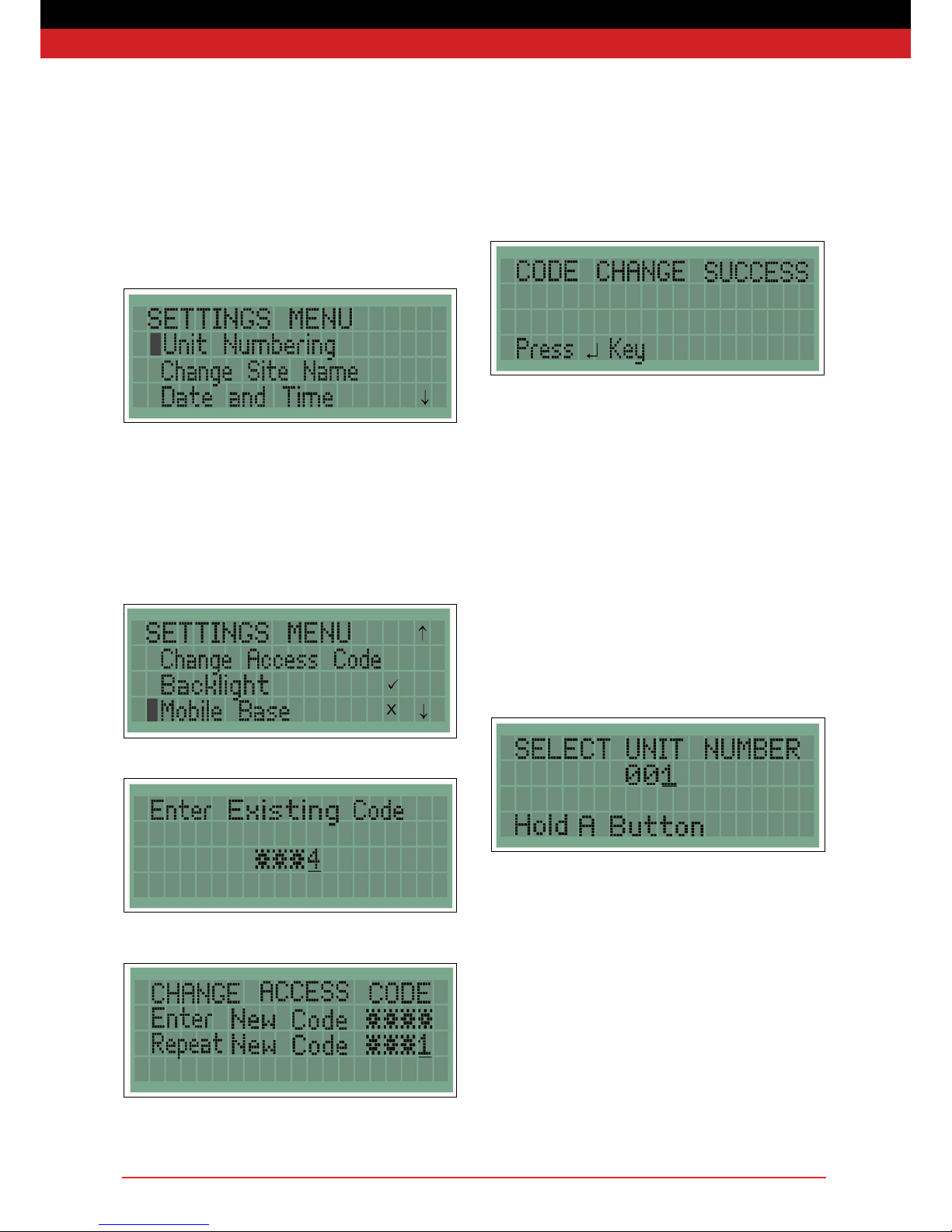

Change Access Code

Unit Numbering

Date and Time

Backlight

Mobile Base

SIM Card Installation - GSM Base Station

Communications

Change Site Name

User Phone Details

Test Phone Number

GSM Status

SIM Card Information

Text Message

Interface

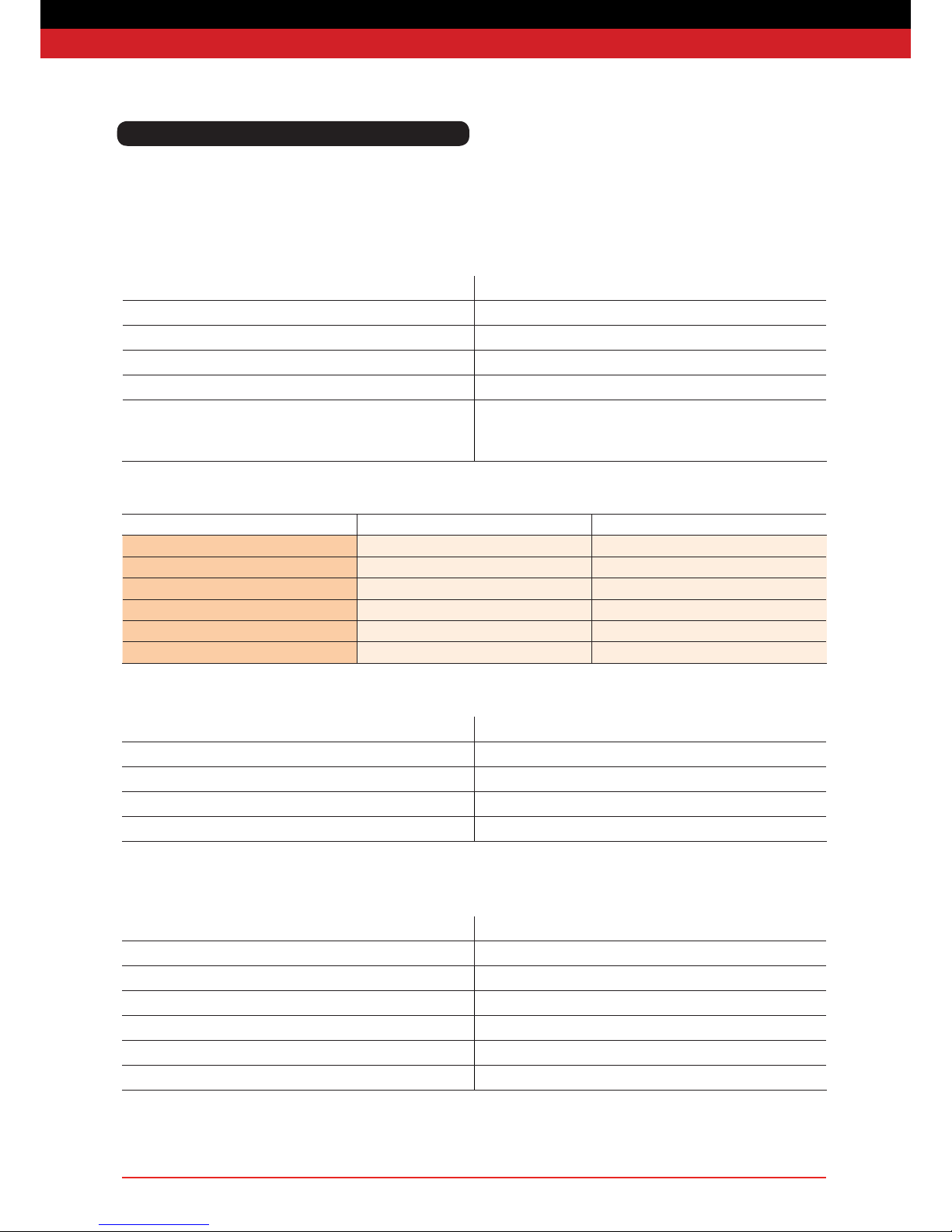

Fire Point Technical Data

Base Station Technical Data

Heat Detector Technical Data

Smoke Detector Technical Data

Link Technical Data

Interface Technical Data

Heat Detector Maintenance

Routine Inspection

Operational Test

Cleaning

Smoke Detector Maintenance

Routine Inspection

Operational Test

Cleaning

Contact Us

12

13

13

14

14

15

15

15

16

18

18

18

19

19

20

20

21

22

24

25

27

29

31

32

32

32

32

33

33

33

33

33

Page 4

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Unit Diagrams

System Units

Sounder and Strobe

LED indicators

Call Point

Heat Dectector

LED indicators

LCD Display

Navigation Pad

Smoke

Detector

Cable Gland

Fire Point

Detector Units

Link

Base Station

Detector Units

Interface

Antenna

Antenna

Antenna

LED indicators

Page 5

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Smoke detectors are silent but communicate with sounding units

automatically to raise the alarm if smoke is detected. NB: smoke

detectors are sensitive to dust and steam so are unsuitable for dusty

areas. If a detector has raised the alarm, its red LED indicator will ash

for 30 minutes or until the alarm is reset.

Smoke Detectors should be securely mounted to the ceiling and should

be regularly maintained (see Smoke Detector Maintenance section).

If proper maintenance is not carried out, there is a likelihood of

malfunction, including false alarms, which could disrupt operation on

site.

Smoke detectors may be identied by a reference ‘P’ on the detector

label (g.2)

Dust-resistant smoke detectors may be identied by a reference ‘DP’

on the detector label (g.3).

Note: Smoke detectors are intended for internal use in enclosed

spaces. Detectors will not function correctly if installed in open spaces

without ceilings, walls etc.

Base Station

Base stations include a buzzer, an LCD display, a navigation pad, and

if the GSM model has been selected, a modem to allow SMS

message sending. Base stations are not essential to a WES+ system,

but they provide centralised functionality and additional information

which is extremely useful on larger or complex sites.

Base Stations should be securely mounted. It is possible to use base

stations as mobile units (see Mobile Base section).

Link

Link units are used solely to relay WES+ radio messages on large or

complex sites if there is no need for additional call points. Link units

should be securely wall mounted.

Interface

Interface units allow external outputs to be triggered in the event of an

alarm. They can also take an input from an external trigger and set off

the alarm on the WES+ system.

P

WES+ units have three indicator LEDs, plus two push buttons, labelled

A and B.

All units should be securely xed using the two integrated mounting

points. We recommend that you use M4 x 50mm pan head screws

and wall plugs or other xings suitable for the particular wall/ceiling

material.

The tamper switch on the rear of each unit must be in contact with the

wall or ceiling for the unit to function correctly.

All WES+ units relay all WES+ radio messages for the relevant site.

Fire Point

Fire Point units include a manual call point used to raise the alarm

when necessary and a loud alarm sounder (with optional strobe light).

Fire Points should be securely mounted approximately 1.4 metres

above the oor.

Detector - Heat

Heat detectors automatically raise the alarm if the temperature rises

above a safe level. Heat detectors are silent, but communicate with re

points and base stations to raise an audible alarm. If a detector has

raised the alarm, its red LED indicator will ash for 30 minutes or until

the alarm is reset.

Heat detectors should be securely mounted to the ceiling and regularly

maintained (see Heat Detector Maintenance section). If proper

maintenance is not carried out, there is a likelihood of malfunction,

including false alarms, which could disrupt operation on site.

Heat detectors may be identied by a reference ‘A2’ on the detector

label (g.1)

WES+ Units Detector - Smoke

Fig 3

DP

Fig 2

Fig 1

A2

Note: Heat detectors are intended for internal use in enclosed spaces.

Detectors will not function correctly if installed in open spaces without

ceilings, walls etc.

Page 6

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

A basic system is made up of a minimum of three WES+ units. Fire

points are essential to all systems as these provide the audible

evacuation alarm.

Health and Safety

As with all site practices, working safely must be a priority when

installing the WES+ systems. It is important to observe appropriate

health and safety legislation on site, including national regulatory

obligations, as well as any local site- or client-specic requirements.

Prior to installation of WES+ equipment, an appropriate risk

assessment must be carried out and all reasonable efforts to remove

risk put in place. The following notes are intended as general guidance

only. Consideration must be given to design criteria, site conditions

other trades operating in the area during installation.

Prolonged or repeated exposure to loud noise such as re alarm

sirens may potentially lead to hearing damage. Ensure that protective

measures are taken that are appropriate to the exposure levels

expected on site.

WES+ units are not ATEX rated and have not been tested for use in

explosive atmospheres. These are not recommended for use in ATEX

applications.

Manual Handling, Storage and

Transportation

Whilst WES+ units are lightweight and designed to be easily handled

on-site, it is important that appropriate manual handling practices are

followed. Particular care should be taken when carrying units at height

or when ascending/descending elevated platforms, scaffolding and

ladders.

Units are stored and transported in boxes of 8. Refer to Product

Datasheets for full details of unit weights. Unopened boxes should be

stacked no more than 10 high, on a solid, stable surface. Individual

unboxed units should not be stacked on top of one another.

To avoid damage or injury during transit, ensure units are packaged

securely and restricted from moving around.

Service and Maintenance

Under normal conditions, WES+ units will function for up to three years

without the need for routine maintenance. A full range of servicing

options are available for aged units. Contact the WES+ Helpline for

details.

Basic System

It is essential that testing, repairs and servicing are carried out by

WES+ Engineers or approved, qualied partners. Modifying any part

of the unit can prevent correct functionality, even if the unit appears to

be working.

Damaged Units

Should a unit be dropped or impacted during installation, operation or

decommissioning, it should be inspected for signs of damage. Even if

no external damage is visible, the internal components may have been

affected. Test the unit for operation and if in doubt, remove the unit

from the network and contact Ramtech Technical Service.

Installation procedure

Note: WES+ units are only compatible with other WES+ units. It is not

possible to create a network using other version of the WES product

e.g. WES1, WES3. Ensure that all units intended to be used on site

are the WES+ units.

Installing WES+ on your site is easy. You will need to activate each unit

and add the units to the group so that they can communicate with each

other.

1- Activate units

DO NOT OPEN ANY UNIT AS THIS WILL INVALIDATE THE

WARRANTY

To activate a unit, hold down ‘A’ and press ‘B’ three times in quick

succession. All three LEDs will briey illuminate and then the amber

LED will ash.

Note: This operation activates the unit – no radio connection is

established at this point

2 - Start a new site group

Take two activated WES+ units

.

Press and hold ‘A’ on both units. The amber LEDs will illuminate

followed by the green LEDs to indicate that the units have been

successfully paired and a site group created. Release the ‘A’ buttons.

If the red LED illuminates, pairing has failed. Follow the ‘Removing a

unit from the site’ section to clear the two units and then repeat step

1 - Activate Units.

Page 7

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Note: The system must include a least one Fire Point in order to

generate an audible alarm. Where a system comprises Detectors only,

no audible alert will be transmitted on site.

3- Add units to an existing site group

Take a WES+ unit which is part of the existing site group and an

un-paired, activated WES+ unit.

Press and hold A on two units, the amber LEDs will illuminate followed

by the green LEDs to indicate successful pairing.

Release the ‘A’ buttons.

The activated unit has now been added to the existing site group and

can communicate with all other WES+ units on that site group.

If the red LED illuminates, pairing has failed. Follow the ‘Removing a

unit from the site’ section to clear the two units and then repeat step

1 - Activate Units.

4– Position units

Once activated and paired, WES+ units can be installed on site.

Ensure any applicable national guidelines or Standards regarding

locating units on site are adhered to e.g. BS5389-1 in the UK.

Wherever possible, avoid positioning the unit directly adjacent to metal

frames, electric cables and similar equipment that may interfere with

the signal strength.

5– Securely x the units in place

Each WES+ unit must be securely xed in place to ensure correct

operation.

• Detector units are ceiling mounted and intended for indoor use

only. Installation of detectors may involve working at height and

or on elevated platforms. Ensure a risk assessment has been

carried out and all reasonable safety precautions are in place

before commencing work.

• Fire points must be securely xed, with the antenna upright,

to a robust vertical surface such as a wall or trolley. Where the

existing surface is unsuitable for direct xing, the Fire Point can

be mounted to backing board or pattressing such as plywood or

similar sheet material.

Each unit should be securely mounted using its two integrated

mounting points with M4 x 50mm pan head screws and wall plugs or

other xings selected for the particular wall or ceiling type. Ensure that

all xing points are secure and that the back tamper is fully depressed

after installation.

Note: WES+ units must be securely xed in place for correct operation

The tamper switch on the rear of the unit must be in contact with the

wall or ceiling.

6– Test the system

After installation of the units, it is essential to perform a silent alarm

test to conrm proper operation of the system. It is also best practice

to conduct a full Silent Test on a weekly basis. This test should also

be performed following any signicant change to the site environment

(new structure, wall or construction equipment installed) that may affect

the network signal.

To perform the test:

1. Go to any unit in the system

2. Check it is ashing its Green LED at the rate of once every 4

seconds

3. Press and hold B until the Amber LED illuminates, then release B

.

4. Check that the Green LED is now on.

5. Walk the site and conrm that the green LED is lit on every

installed WES+ unit.

6. A ashing Green LED means the unit has failed the test.

7. Units ashing Red then Amber and units still occasionally ashing

the green LED have failed the test. Refer to ‘Fault LED

Indication’ section to troubleshoot the problem.

8. At the end of the test, press and hold the B button on any WES+

unit to end the test.

Note : Following initial installation, wait for a minimum of 60 minutes

before starting the rst silent test. During this time, the WES+ units will

self-calibrate to adjust for background radio noise which may impact

the accuracy of the silent test.

Page 8

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Manual activation

To raise the alarm, press any call point in the system. The call point will

latch into the pressed position and a mechanical yellow and black

striped ag will be displayed in the call point window as below.

Automatic activation

Smoke detection units will automatically raise the alarm if sufcient

smoke is detected.

Heat detection units will automatically raise the alarm if the

temperature rises above the threshold. The red ‘Alarm’ LED will only

ash on the unit(s) which raised the alarm.

Silencing the alarm

Note: it is vital to conrm that there is no re hazard before silencing

the alarm.

Do not attempt to open the unit or deactivate by removing the battery.

The alarm must be silenced either by using the reset key or at the

Base Station.

The re alarm will automatically silence 30 minutes after activation.

The re alarm can be manually cancelled from a call point that has

been pressed using the reset key provided. If necessary, a call point on

a nearer re point can be pressed and then reset to cancel the alarm.

Please wait for 5 seconds between pressing and resetting a call point.

After the alarm has cleared the system has a short (2 minute) re-arm

period during which the sirens will sound intermittently, and the amber

warning LEDs ash in groups of 5, following which the system is

re-armed and ready for use.

During the re-arm period, the alarm cannot be reactivated. It is

therefore vital to conrm that there is no re hazard before silencing

the alarm.

Any re point units with activated call points will periodically beep after

the re-arm period has ended as a reminder that the call points need to

be mechanically reset using the key before they can be used to raise

a re alarm.

1) Insert reset key with tab to the right as shown below.

2) Push key in as far as possible

3) Turn key anti-clockwise until a loud mechanical click is heard.

4) Remove the key

Ensure the call point is fully reset before removing the key. Partially

resetting a latched call point after the re alarm has been cancelled

can retrigger the re alarm.

Unit Alive Indication

Active units with no faults will ash their green LED once every 4

seconds to indicate that the unit is operational

Amber LED Indication

Each WES+ unit monitors itself for a number of faults. These are

indicated via the amber LED, which will ash in grouped patterns with

longer than usual gaps in between them.

Units displaying one of these patterns require further investigation and

should not be relied upon as part of the re alarm and detection system

until the fault has been corrected. Use the below chart to determine the

nature of the issue.

Group Flash 1 - Low Battery

Group Flash 2 - Low signal

Group Flash 3 - No signal

Group Flash 4 - Tamper

Group Flash 5 - Re-arm

Red LED Indication

If a detector has raised the alarm, its red LED indicator will ash during

a re alarm.

Raising the alarm Resetting a call point

System Operation

LED Indications

Page 9

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

It is recommended that the re system is tested weekly or whenever

a signicant change has been made to the installation or the building

under construction. WES+ is equipped with a silent test function that

allows you to test the radio link between units without activating an

audible re alarm. You can therefore ensure each unit in the system

has a robust radio link with sufcient capacity to allow for

environmental uctuations without disturbing the site.

Initiating a silent test

Press and hold the B button on any error free unit for more than 1

second to initiate a silent test. The amber LED will illuminate for up to

30 seconds to indicate that the unit has begun a test. The Silent Test

message is propagated by radio around the system.

The test result is indicated as follows:

Pass Green LED solid illumination

Radio OK, other fault

detected

Red LED ashes followed by Amber LED

group ashes to indicate fault (see ‘Amber

LED Indication’).

No Radio Signal Amber LED group ashes to indicate fault

(see ‘Amber LED indication’).

Inspection of other system units

After a silent test has been initiated, all other units should be inspected.

The test result can be determined by examining the LEDs on each unit:

Pass Green LED solid illumination

Radio OK, other fault

detected

Red LED ashes followed by Amber LED

group ashes to indicate fault (see above).

No Radio Signal Alive Indication or Red LED ashes

followed by Amber LED group ashes to

indicate fault (see above).

Cancelling a silent test

The silent test can be cancelled from any unit, except those which are

indicating the Alive Indication, by pressing and holding the B button for

more than 1 second.

The silent test will automatically cancel 20 minutes after activation.

The unit will detect that it has been removed from its installed position

and then reinstalled. Check that after reinstallation the unit is not

displaying any fault warnings on its amber LED.

After moving a unit, we recommend that you conduct a silent test

to check that the movement has not adversely affected radio

communication.

Before shipping a unit or moving it to another site it must rst be

deactivated, in order to:

• prevent accidental triggering

• preserve battery unit life

• clear site information which would prevent it forming or joining

another site

First, remove the unit to be deactivated from the wall/ceiling and

ensure the back tamper button is not pressed.

Hold down ‘A’ and then press ‘B’ three times in quick succession. All

three LEDs will briey illuminate and then extinguish and remain off.

Note: units cannot be deactivated during a re alarm.

Silent Tests Moving a unit on site

Removing the unit from the site

Page 10

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

One or more base station units can be added to a basic system to

provide additional system monitoring information. Base stations include

details about which units have raised re alarms, any units with current

fault warnings and historical event logs. The base station also allows

an authorised user to silence a re alarm using an access code.

Optional GSM functionality allows up to six users to receive text

messages in the event of a re or other system warnings occurring.

To conserve battery power, the LCD display and backlight turn off after

a short period of inactivity. Pressing any of the navigation buttons will

activate the display. If there are no current warnings or re alarms

across the system, the base station will display the home screen which

shows the site name and the date and time.

Pressing enter ( ) goes to the main menu to allow settings to be

changed or logs to be viewed.

Advanced systems - Base Stations

Menu overview

Main Menu

Settings

System Logs

Settings Menu*

Unit Numbering

Communications

Date and Time

Change Access

Code

Backlight

Mobile Base

Change Language

Communication

Menu**

Change Site

Name

User Phone

Details

GSM Status

SIM Card

Information

System Log

Menu

Alarms

Silent Tests

External

Tampers

Internal

Tampers

DT Head

Tampers

Low Signals

Low Batteries

Flat Batteries

Latched Units

Unit Removed

Clear All

Logs*

Change

Language

English

Deutsche

Français

User Phone

Details

Edit User Name

Edit Phone

Number

SMS Notications

Test Phone

Number

* Acces Code Required

** Only for GSM Base Stations

Page 11

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

At the end of the re-arming period the base station will return to the

home screen unless any system warnings have been received during

the re alarm or re-arm period

System Warnings

The base station will indicate warnings from itself or any other system

unit. When a warning is received the LCD will ash and the unit will

beep periodically.

Warnings are displayed in the format: date, time, unit number and type,

warning type. Some warnings, for example EXT, will self-clear if the

fault is resolved.

When an alarm has been raised by a re point or detector, the base

station will ash the LCD display, beep and display ALARM ALARM

ALARM together with which units raised the alarm. The newest event

will be at the top of the list.

Units are identied by unit number and unit type. F indicates a re

point, I an Interface and D a detector. For example, the above shows

that a Fire Point with the number 001 was activated at 08:53 on the

8th October.

An alarm can be silenced in three ways:

i) Resetting a call point

ii) Waiting 30 minutes after the last activation

iii) Using your access code to silence the alarm from the base station

To silence the alarm from the base station, press enter during the re

alarm. This will take you to the Silence Alarm screen.

Select ‘Yes’, and enter your access code when requested. During

the re-arming period the following message will be displayed for two

minutes.

Alarm

Page 12

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

It is not possible to exit the warning screen until all warnings have

either been resolved or acknowledged by an authorised user.

To acknowledge a warning, select it with the navigation pad and press

enter. You will need to enter your access code for the rst warning you

acknowledge.

Base Station Controls

The navigation pad, shown below, is used to move between menus,

change characters and select entries.

Menu items can be selected using the up and down arrows and then

pressing enter (middle arrow button).

Change characters using the up and down arrows while the character

is highlighted.

WES Warning Code Guide

Warning Code Warning Description Self-Cleaning SMS setting

BAT Low Battery Unit NNN has a low battery No 5

DET Detector Tamper Detector unit NNN has had its detector head

removed

Yes 3

EXT External Tamper Unit NNN has been removed from the wall/

ceiling

Yes 4

FLT Flat Unit NNN has turned off, its battery is at No 8

INT Internal Tamper Unit NNN has been opened up and potentially

tampered with or damaged

No 2

LAT Latched The call point on unit NNN is still latched in

after the alarm has been reset

Yes 10

REM Removed Unit NNN has been deactivated and removed

from the re alarm system

No 9

SIG Low Signal Unit NNN has a low radio signal Yes 6

TST Silent Test Unit NNN initiated a Silent Test Yes 7

Scroll through characters by holding down the up or down arrows.

Move to the next character or eld using the right arrow.

Use the left arrow button to move to a previous character.

To exit a menu, move to the left-most character and press the left

arrow key again.

Home Screen

Pressing enter on the home screen opens the main menu, giving

access to the System Log Menu and the Settings Menu. The settings

are only available to authorised users with an access code.

If the base station has not yet been paired, it will display ‘Unpaired’

instead of the site name.

Page 13

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Once a unit has been added to a site group, the site name will be

displayed. Note: by default, this is ‘DEFAULT SITE’. Please ensure you

change it to reect the location of your site, as this will be used in text

message alerts to identify the site where an alarm has been activated.

The following logs are accessible from the System Log menu:

• Fire Alarms

• Silent Tests

• External Tampers

• Internal Tampers

• DT Head Tampers

• Low Signals

• Low Batteries

• Flat Batteries

• Latched Units

• Unit Removed

All logs are in the same format with the most recent event at the top

of list.

Each log entry starts with the date and time the event was logged,

followed by the unit number and type and then a + or – symbol to

indicate the raising (+) or clearing (-) of an event. If there is a down

arrow in the bottom right corner, there are further log entries which can

be displayed by pressing the down arrow on the navigation pad.

The below example shows the External Tamper Log where unit BASE

had an External Tamper cleared at 11:20 on 23rd September.

Exit the log display using the left arrow key on the navigation pad.

Logs can be cleared by either deactivating the unit (see ‘Removing a

unit from the site’) or using the Clear All Logs option at the end of the

System Log Menu. This can only be performed by an authorised user

as it requires the access code.

System Logs

Settings

The Settings menu can be accessed from the Main Menu by selecting

Settings with the directional pad then pressing Enter.

Page 14

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

All settings are protected from unauthorised change by an access

code. By default, this is set to 1234. The access code can be reset

by deactivating and then activating the base station. All site specic

information will be cleared upon activation.

Change Access Code

We recommend that you change the default 1234 access code to a

secure code specic to site.

To change the access code, navigate down the Settings Menu until the

Change Access Code option is highlighted as shown. Press Enter to

select.

The existing Access Code will then be requested, as shown below.

The new Access Code then needs to be entered twice.

Conrmation of the Access Code change will be displayed.

Unit Numbering

By default, every WES+ unit is numbered 001 when activated. This unit

number can be changed so that you can assign unique identication

numbers to individual units or create groups of units with the same

number to enable you to pinpoint where an alarm has been triggered

or other fault identied.

This is done using the Unit Numbering feature, and any number

between 001 and 999 may be used.

Units must be either freshly activated or already paired to a unit on

the same site as the base station before renumbering.

To number a unit from a different site network, you will rst need to

deactivate and reactivate the site to remove the information specic to

the original site.

Select the number you wish to assign to a particular WES+ unit using

the navigation pad. Once the correct number is displayed, press and

hold the A buttons on both the base station and the unit you are

numbering. The amber LEDs on both units will illuminate and then the

green LEDs will ash to conrm successful renumbering.

To exit the Unit Numbering screen, press the left arrow when at the left

most digit of the unit number.

Page 15

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

In advanced systems, pairing units creates a clone of the installed

unit by replicating both the site code and unit number. Pairing in an

advanced system is performed in exactly the same way as pairing in a

basic system (see Basic System – Installation Procedure – Add other

units to an existing site group).

The process copies the unit number from a unit already installed on the

site to a freshly activated unit. This allows multiple units to be grouped

with the same number, if you require particular areas of a site to be

assigned a number according to a re plan or map on site .

Unit Numbering LED indications

When the A button is held down on two units, both will begin by

illuminating the amber LED followed by a conrmation LED pattern.

The following table indicates the meaning of the various LED patterns.

One of the units needs to be the Base Station

LED pattern Description

● Red

● Amber

● Green

Pairing started

● Red

● Amber

● Green

Pairing success. The two units are on the same

site and have the same unit number.

● Red

● Amber

● Green

Pairing failed. The units are already part of two

different existing sites. The units need to be

deactivated and reactivated to allow pairing to

succeed.

● Red

● Amber

● Green

Cloning failed. The two units are already part of

the same site but have different unit numbers. No

information has been changed on either unit.

● Red

● Amber

● Green

Unit numbering success. The unit has successfully

joined the same site as the base station and has

the unit number selected in the Unit Numbering

Screen.

A unit whose amber LED fails to illuminate will not pair. This may be

due to an internal tamper.

The date and time can be updated in the Date and Time screen

using the navigation pad and pressing enter to save. The Date and

Time is in Co-ordinated Universal Time (UTC) and will not

automatically change for British Summer Time.

Back Light

The LCD backlight can be disabled by pressing enter when the

Backlight option is highlighted. A tick indicates that the backlight is

enabled and a cross indicates it is disabled. By default the backlight is

enabled.

Mobile Base

It may be desirable for the base station to be used without being xed

to a wall, for example, if you need to keep it in the site ofce during the

day but move it to a security hut at night.

The Base Station unit can be made mobile by pressing enter on the

Mobile base option. A tick indicates that the Mobile Base option has

been enabled.

Unit Cloning Date and Time

Page 16

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Reassemble of the Lid

1. Reattach the facia (19-way ribbon) to the PCB and reconnect the

battery connector.

2. Position the lid so that it is higher. (Fig1.)

3. Slide in place, ensuring that it aligned with the screws. (Fig 2)

4. Ensure that there are no trapped wires in between the lid and the

base

5. Screw down the lid using the T20 screwdriver with a maximum of

2Nm Torque.

Fig. 1

Direction is iindicated by the

orange arrow

Fig. 2

Starting point of the lid with screws.

Highlighted in Orange

Sim Card installation - GSM Base Station

Before installation the following parts and tools are required:

• Sim Card

• T20 Torx Screwdriver

Please ensure that you are in an ESO protected area before

undertaking the installation of the Sim card into the WES+

Base Station

The unit must be switched off and in Transit mode

Removal of the Lid

1. Using the T20 Torx screwdriver, remove all four screws from the

base station lid. (Fig. 1)

2. Slide the lid upwards to ensure that the tamper leaver does not

short circuit. (Fig. 2)

3. Carefully lift the lid, and disconnect the fascia (19 way ribbon)

from the PCB. Disconnect the battery connector.

4. Turn the lid over. Take the sim card and insert into the sim slot

as shown below. Make sure that the sim card connections are

facing down.

5. Now you are ready to reattach the fascia (19-way ribbon) to the

PCB, and reattach the lid.

Fig. 1

Removal of screws -

highlighted in Orange

Fig. 2

Sllide the lid upwards.

You can now switch on the unit.

Hold down the ‘A” button and press the ‘B’ button 3 times, to set up.

When you switch the unit on, you will see the following screen

Next press the menu button.

From the next menu WES+ Main Menu select Settings.

You will be asked to enter an access code (see overleaf). The default

code is 1234 unless your change it.

Reassemble of the Lid

1. Reattach the facia (19-way ribbon) to the PCB and reconnect the

battery connector.

2. Position the lid so that it is higher. (Fig1.)

3. Slide in place, ensuring that it aligned with the screws. (Fig 2)

4. Ensure that there are no trapped wires in between the lid and the

base

5. Screw down the lid using the T20 screwdriver with a maximum of

2Nm Torque.

Fig. 1

Direction is iindicated by the

orange arrow

Fig. 2

Starting point of the lid with screws.

Highlighted in Orange

Sim Card installation - GSM Base Station

Fig. 1

Removal of screws -

highlighted in Orange

Fig. 2

Sllide the lid upwards.

You can now switch on the unit.

Hold down the ‘A” button and press the ‘B’ button 3 times, to set up.

When you switch the unit on, you will see the following screen

Next press the menu button.

From the next menu WES+ Main Menu select Settings.

You will be asked to enter an access code (see overleaf). The default

code is 1234 unless your change it.

Page 17

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Now select Communication from the Menu.

On the next menu select GSM-Status. Wait a short time for the unit

to nd a signal. If the unit fails to nd a signal - go back to the

beginning and start the process again.

In case of any problem with the sim card, cello tape the reaming

packaging to the back of your unit (as shown below).

Your unit is now ready to use.

Final Testing

Step

No.

Action Pass criteria Notes

1. Hold unit at on workbench.

Hold button “A” and press ‘B’

three times in quick succession

Red, Amber and Green LEDs simultameously ash

three times.

Amber LED then ashes in groups of 3

Brings unit out of “Transit’ mode.

If amber LED ashes in groups of 4 then

ensure back tamper is held down rmly

and wait for 10 seconds or until ashes

are in groups of three.

2. Hold “A” button down on both

units. Release buttons when

LEDs units illuminate green.

Amber LEDs on both units illuminate, then turn to

green.

This pairs the units with the re point to

test the radio communication and

conrms that the internal tamper is not

active.

3. Intermittent ashing green LED Green LED ashes once every four seconds Indicates no fault warnings are active.

4. Press the manual call point on

captive test re point

Check that unit sounds and strobe ashes, or display

and captive re point strobe ashes

Alarm has been raised by the unit and

a message has been sent via radio to

captive re point.

5 Reset manual call point Amber LED will ash in groups of 5, within 5 seconds

of call point reset.

Units in re-arm mode

6. Stand unit up (to release back

tamper), then hold ‘A:’ and press

“B” three in quick succession.

Red, Amber and Green LEDs simultaneously illuminate and then extinguish

Unit in transit mode

SIG Low Signal Unit NNN has a low radio signal Yes

TST Silent Test Unit NNN initiated a Silent Test Yes

Page 18

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Base Stations with the optional SMS text alerts feature enabled

have a Communications menu which is used to set up text message

alerts, users and associated telephone numbers.

The communication menu has four options as shown below.

Change Site Name

The site name appears on the Home Screen and is included in every

text message so that you can quickly identify the source of the alarm

or warning. The site name should be changed to a uniquely

recognisable site location.

The site name is edited using the navigation pad and conrmed by

pressing enter.

Communications

User Phone Details

The user phone details allows up to six users’ names and telephone

numbers to be entered and the type of warning each user will

receive to be selected. Text message on a re alarm is set for each

user and cannot be altered. Only one text message is sent during each

re alarm although multiple units (re points and detectors) may be

activated during the re.

Once edited, USER X is replaced by the name of the user entered.

A user is selected using the navigation pad and pressing enter, the

user menu then appears.

Select Edit User Name and enter the name of this user with the

navigation pad.

Page 19

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Press enter to conrm and then edit the phone number in the same

way.

The telephone number must be in international format with a

+ and then the country code.

For the UK the country code is +44. E.g. a mobile telephone number of

07806123456 would be entered as +447806123456, the starting 0 of

the telephone number is dropped.

The SMS Notications Menu can be used to select which events the

user is interested in. A tick will result in a message being sent for that

particular event

The notications are shown below, NNN is the unit number of the unit

with a fault warning.

1

Alarm

A re alarm has been raised on the

site, initiated by unit number NNN

2.

internal tamper

Unit NNN has been opened up

and potentially tampered with or

damaged

3. detector tamper

Detector unit NNN has had its

detector head removed

4. external tamper

Unit NNN has been removed from

the wall/ceiling

5.

low battery

Unit NNN has low battery

6.

low signal

Unit NNN has a low radio signal

7.

silent test Unit NNN has initiated a silent test

8.

at battery

Unit NNN has turned off, its battery

is at

9. removed

Unit NNN has been deactivated and

removed from the re alarm system

10.

latched

The call point on unit NNN is still

latched in after the alarm has been

reset

Test Phone Number

The nal option in the user menu is to test the phone number.

Note: the base station cannot check whether the text message has

arrived at the mobile telephone, just that it is delivered to the network.

It is important to conrm that the message has actually arrived at the

mobile telephone.

GSM Status

The status of the connection to a mobile telephone network can be

checked via the GSM Status option. Note that the modem is switched

off when not in use to conserve battery power, so this check can take a

few minutes to complete.

The screen will initially display…

…and then move to….

…then nally display…

Page 20

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

…to show whether the base station is able to send text messages. In

the above example it has connected to the Orange UK network and

has a signal strength of 14.

Signal strengths are:

0-9 Poor

10-14 OK

15-19 Good

>20 V. Good

Base Stations with ‘Poor’ signal strength should be relocated if

possible to improve signal strength for SMS messages.

SIM Card Information

The SIM card ID number can be read using the SIM Card Information

option.

Text Message

The text message begins with WES+ Base Station, followed by the

message type, site name, time and date as shown below.

WES Base Station Text Message:

Semt from DEFAULT SITE at 14-12: 57

on 29 July 2013

29 Jul

Note that the SMS messaging feature of WES+ is intended for

notication purposes only and is not to be relied upon as the sole

response to site alarms. Depending on network activity, text

messages may be received some time after the SMS message

has been generated.

Network Scan

The selection of a mobile telephone network can be undertaken

via the Network Scan option. Note this scan can take a few minutes to

complete. The screen will initially display...

...and then move to...

The network can be selected using the navigation pad and conrmed

by pressing enter.

In the above example giffgaff has been selected as the mobile telephone network

Page 21

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

The Interface has two auxiliary relay outputs and one auxiliary input.

These allow the WES+ system to be expanded to interact with external

devices.

Pictured right is the layout of the connections inside the Interface Unit

The Interface unit should be installed by a suitably qualied person.

DO NOT connect the Interface to mains current.

Interface

The input is unmonitored. The connection of automatic or manual re

detection devices and active re protection systems such as such as sprinklers, gas suppression systems etc. may require additional measures.

Cable disconnection or damage could result in the alarm not activating when required without any fault or warning indication.

All cable lengths must be less than 3 metres long.

Output

The outputs are rated for 24V at up to 2 Amps maximum.

Input

The input requires a “volt free” contact from a relay and should not be connected to power.

The input is unmonitored and connection of automatic or nanual re detection devices is not recommended.

Cable disconnection or damage could result in the alarm not activating when required without any fault or warning indication.

When NOT in Alarm

When in Alarm

Normanally Open (NO)

Normanally Open (NC)

Normanally Open (NO)

Normanally Open (NC)

Common (C)

Common (C)

Alarm NOT Triggered

Alarm Triggered

IN-IN+

IN-

IN+

Page 22

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Fire Point Technical Data

Model Numbers: W2-FPT-CSS-U, W2-FPT-CSS-N, W2-FPT-SRO-U, W2-FPT-SRO-N

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 128 (excl. antenna 81mm and USB 15mm)

Weight 1.7kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

IP Code: IP55C

Main Sound Frequencies & Patterns: 800Hz to 970Hz swept at 1Hz – UK

1200Hz falling to 500Hz over 1 sec, silence 10ms – Germany

554Hz for 100ms and 440Hz for 400ms – France

Minimum A-weighted sound at 1 metre

Position Horizontal Plane dB(A) Vertical Plane dB(A)

15 83.7 85.3

45 89.4 91.6

75 96.5 94.8

105 96.5 97.6

135 90.4 91.3

165 85.0 83.9

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

EN54-3 Voltage Range: 4.4-6.4V from internal battery

Power: 620μW average

Current Consumption: 120μA average

Battery type: Alkaline primary cells, 23Ah

Pack life: > 4 years

Estimated life (eld usage): > 5 years

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Page 23

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-FPT-CSS-R, W2-FPT-SRO-R

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 128 (excl. antenna 81mm)

Weight 1.1kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

IP Code: IP55C

Main Sound Frequencies & Patterns: 800Hz to 970Hz swept at 1Hz – UK

1200Hz falling to 500Hz over 1 sec, silence 10ms – Germany

554Hz for 100ms and 440Hz for 400ms – France

Minimum A-weighted sound at 1 metre

Position Horizontal Plane dB(A) Vertical Plane dB(A)

15 83.7 85.3

45 89.4 91.6

75 96.5 94.8

105 96.5 97.6

135 90.4 91.3

165 85.0 83.9

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

EN54-3 Voltage Range: 4.4-6.4V from internal battery

Power: 620μW average

Current Consumption: 120μA average

Battery type: Alkaline primary cells, 7.6Ah

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Fire Point Technical Data

Page 24

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Fire Pont Technical Data

Model Numbers: W2-BST-GSM-U, W2-BST-GSM-N, W2-BST-STD-U, W2-BST-STD-N

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 128 (excl. antenna 81mm and USB 15mm)

Weight 1.5kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

Power: 620μW average

Current Consumption: 120μA average

Battery type: Alkaline primary cells, 23Ah

Pack life: > 4 years

Estimated life (eld usage): > 5 years

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Transmit Band (Tx) Receive Band Power

E-GSM 900 880 to 915 MHz 925 to 960 MHz 2 Watts EGSM 900 radio section

DCS 1800 1710 to 1785 MHz 1805 to 1680 MHz 1 Watt GSM1800 radio section

Base Station Technical Data

Page 25

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-DET-HTD-U, W2-DET-HTD-N

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 118 (excl. antenna 81mm and USB 15mm)

Weight 1.6kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Heat Detector Class A2

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

Power: 2.7mW average

Current Consumption: 520μA average

Battery type: Alkaline primary cells, 23Ah

Pack life: > 4 years

Estimated life (eld usage): > 5 years

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Heat Detector Technical Data

Page 26

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-DET-HTD-R

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 118 (excl. antenna 81mm)

Weight 1.3kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Heat Detector Class A2

Supply Parameters

Operating Voltage Range: 4.0-6.4V from internal battery

Power: 1.3mW average

Current Consumption: 240 μA average

Battery type: Alkaline primary cells,15.2Ah

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Heat Detector Technical Data

Page 27

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-DET-SMD-U, W2-DET-SMD-N, W2-DET-SMP-U, W2-DET-SMP-N

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 108 (excl. antenna 81mm and USB 15mm)

Weight 1.6kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from iinternal battery

Power: 2.7mW average

Current Consumption: 520μA average

Battery type: Alkaline primary cells, 23Ah

Pack life: > 4 years

Estimated life (eld usage): > 5 years

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Smoke Detector Technical Data

Page 28

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-DET-SMD-R, W2-DET-SMP-R

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 108 (excl. antenna 81mm)

Weight 1.3kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

Power: 1.3mW average

Current Consumption: 240μ A average

Battery type: Alkaline primary cells,15.2Ah

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Smoke Detector Technical Data

Page 29

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-LNK-NNN-U, W2-LNK-NNN-N

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 58 (excl. antenna 81mm and USB 15mm)

Weight 1.4kg

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

Power: 620μW average

Current Consumption: 120μA average

Battery type: Alkaline primary cells, 23Ah

Pack life: > 4 years

Estimated life (eld usage): > 5 years

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Link Technical Data

Page 30

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-LNK-NNN-R

Device Parameters

Dimensions (mm) HxWxD 235 x 161 x 58 (excl. antenna 81mm and USB 15mm)

Weight 800g

Operating Temperature: -25°C to +70°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from iinternal battery

Power: 600μW average

Current Consumption: 110μW average

Battery type: Alkaline primary cells, 7.6Ah

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Compatible with: other WES+ units

Protocol: proprietary

Link Technical Data

Page 31

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

Model Numbers: W2-INF-I2O-U-UK, W2-INF-I2O-N-UK

Device Parameters

Operating Temperature: -10°C to +55°C

Humidity: Relative Humidity >95% (25°C to 55°C)

Supply Parameters

Operating Voltage Range: 4.4-6.4V from internal battery

Power: 770μW average

Current Consumption: 150μW average

Battery type: Alkaline primary cells, 23Ah

RF Parameters

Operating frequency: 868.3MHz

Transmit power: 25mW max

Duty Cycle: <1%

Encryption: none

Channel spacing: single channel

Interface Technical Data

Page 32

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

The maintenance procedures described below should be conducted

with the following frequency:

One month after : Routine inspection

Installation Routine

Inspection every 3

months thereafter

Every 6 months : Operational Test

Every 12 months : Cleaning

All above frequencies of maintenance are dependent upon ambient

conditions. Best judgment should be used to ensure proper

maintenance.

Routine inspection

i) Ensure the detector head is secure and undamaged

ii) Check the heat entry apertures are in no way obstructed.

iii) Ensure the surface of the detector’s outer cover is clean. If there

are deposits due to the presence of oil vapour, dust etc, the detector

should be cleaned in accordance with the cleaning instructions

detailed later. It may be advisable to ensure that such cleaning is

conducted regularly in the future.

iv) Ensure no equipment which may generate excessive heat has

been installed in the vicinity of the detector since the last routine

inspection. If such equipment has been installed, you should notify

the Safety Ofcer or other competent authority that its presence

may cause false alarms.

Operational Test

The purpose of the Operational Test is to conrm the detector’s correct

operation in response to a heat condition.

i) Testing the detectors will trigger the site wide alarm. To avoid

unnecessary evacutation site personnel should be informed when

testing starts and when testing is complete.

ii) Test the detector with heat from a warm air gun designed for heat

detector testing (e.g. ‘No Climb - Solo’ heat sensor tester). =

Check that the detector gives an alarm condition within 10-20

seconds depending upon the detector grade and the applied air

temperature.

N.B. Hot air blowers sold for paint stripping, soldering pipes etc,

generate sufcient heat to damage the detector and should not be

used for testing heat detectors.

iii) After the detector has given the alarm condition, silence the system

from a re point or base station. It may be necessary to allow a

short time to elapse before resetting the detector, to allow any

residual heat from the test to disperse.

iv) Before proceeding to the next detector, ensure that the detector

just tested does not re-operate due to the presence of residual

heat.

Functional Test

The Functional Test checks the detector’s operation. These detectors

may be returned to Ramtech Electronics for Functional Testing.

Cleaning

Note: The detector head should NOT be disassembled.

i) Carefully remove the detector head from its base.

ii) Use a soft, lint-free cloth, moistened with alcohol for sticky depos

its, to clean the plastic casing.

iii) Using a soft bristle brush (e.g. an artist’s paint- brush) carefully

brush between the vanes and thermistor in a linear motion away

from the apertures on the plastic case.

iv) Ensure that no debris is left on or around the thermistor once

cleaning is complete.

v) If the unit needs further cleaning, or is damaged or corroded,

please return the complete detector to Ramtech Electronics for service.

Heat Detector Maintenance

Page 33

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

The maintenance procedures described below should be conducted

with the following frequency:

One month after : Routine inspection

installation and every 3

months thereafter

Every 6 months : Operational Test

Every 12 months : Cleaning

All above frequencies of maintenance are dependent upon ambient

conditions.

Routine inspection

i) Ensure the detector head is secure and undamaged

ii) Check the heat entry apertures are in no way obstructed.

iii) Ensure the surface of the detector’s outer cover is clean. If there

are deposits due to the presence of oil vapour, dust etc, the detector

should be cleaned in accordance with the cleaning instructions

detailed later. It may be advisable to ensure that such cleaning is

conducted regularly in the future.

iiv) Ensure no equipment which may generate excessive heat has

been installed in the vicinity of the detector since the last routine

inspection. If such equipment has been installed, you should notify

the Safety Ofcer or other competent authority that its presence

may cause false alarms.

Operational Test

The purpose of the Operational Test is to conrm the detector’s correct

operation in response to a heat condition.

v) Testing the detectors will trigger the site wide alarm. To avoid

unnecessary evacu T ation site personnel should be informed when

testing starts and when testing is complete.

vi) Introduce a discrete amount of smoke into the detector head, e.g.

using a ‘No Climb -Solo’ smoke test head. Check that the detector

gives an alarm condition within 15 seconds. Check the LED

indicator on the Detector illuminates and any remote indicator LED

tted also illuminates.

vii) Before proceeding to the next detector, ensure that the detector

just tested does not re-operate due to the presence of residual

heat.

Functional Test

The Functional Test checks the detector’s operation. These detectors

may be returned to Ramtech Electronics for Functional Testing.

Cleaning

Note : The detector head should NOT be disassembled.

i) Carefully remove the detector head from its base.

ii) Use a soft, lint-free cloth, moistened with alcohol for sticky depos

its, to clean the plastic casing.

iii) Using a soft bristle brush (e.g. an artist’s paint- brush) carefully

brush between the vanes and thermistor in a linear motion away

from the apertures on the plastic case.

iv) Ensure that no debris is left on or around the thermistor once

cleaning is complete.

v) If the unit needs further cleaning, or is damaged or corroded,

please return the complete detector to Ramtech Electronics for

service.

Further Information:

For further information please visit the WES+ website at

www.wesre.co.uk

Telephone +44 (0)115 822 3424

Email wes@ramtech.co.uk

Twitter @wesre

Website www.wesre.co.uk

Technical Support

Technical support is available over the phone by contacting the WES+

Helpline, and site visits can be arranged if required.

Smoke Detector Maintenance

Contact

Page 34

WES+ Installation and Operations Manual V2.3 Ramtech Electronics 2017

electronics

Tel: +44 (0)115 822 3424

Email: wes@ramtech.co.uk

Web: www.wesre.co.uk

Abbeyeld House, Abbeyeld Road, Nottingham NG7 2SZ UK

V2.3- 08-2017

Loading...

Loading...