Page 1

Page 2

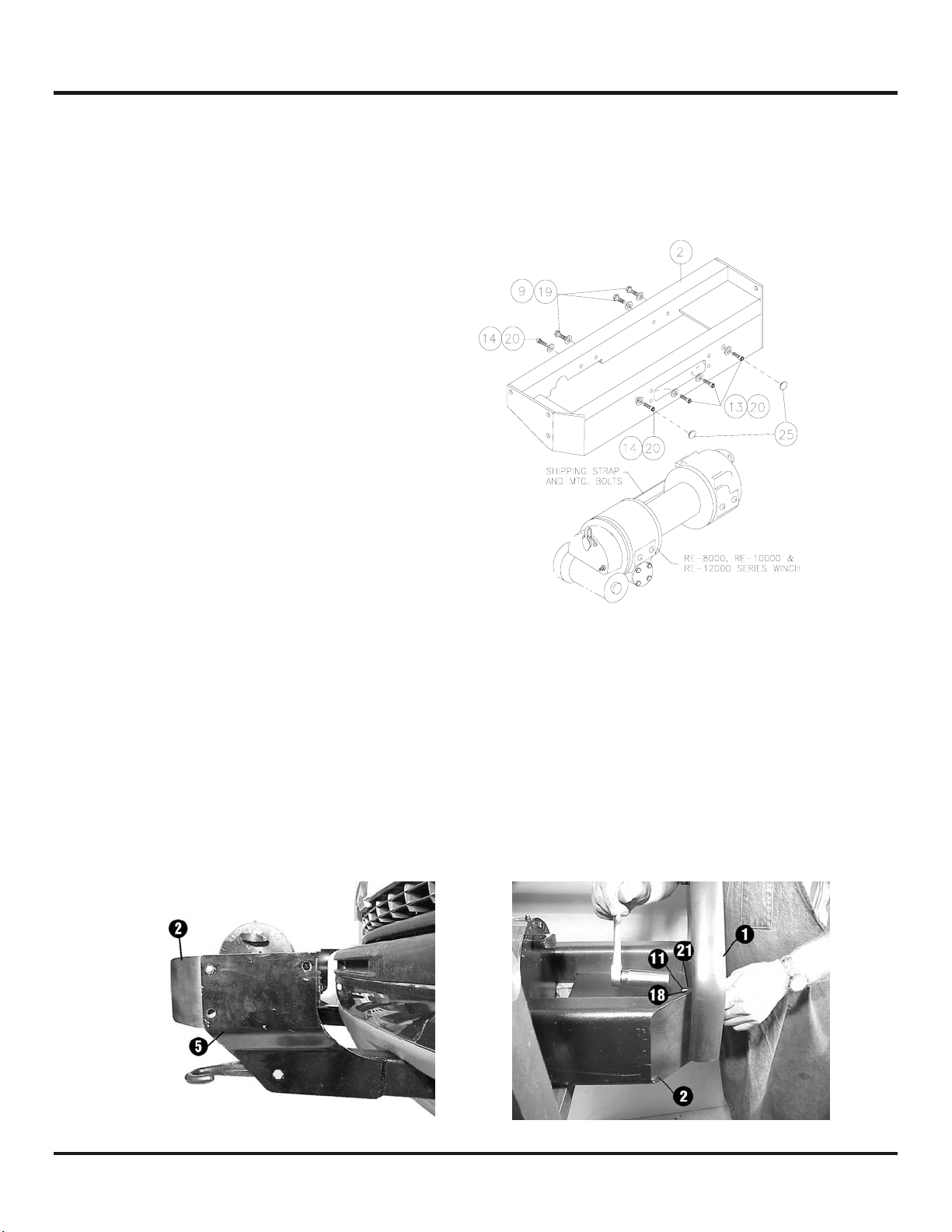

Step 1

Note: It is not necessary to remove or modify the vehicle bumper to install this mounting kit.

Remove the three M12 bolts that secure the vehicle tow hook. They are located on either side and on the bottom of

the tow hook (Figure 1). Remove the tow hook and set it aside.

Figure 1

Step 2

Install left hand bracket #5. Bracket is inserted through the existing

tow hook access in the air dam (Figure 3). Install ½-13 NC x 1-1/4

hex head bolt #12, lockwasher #22, & flat washer #23 through

bottom hole in frame (see Figure 2) and into captive nut in bracket #5.

Step 3

Insert ½-13NC x 4-1/2” hex bolt #10 through hole in frame (this is

where the tow hook was unbolted in step 1) and through bracket

#5 at location shown in Figure 3. Secure using lockwasher #22

& nut #17.

Place vehicle tow hook into the front section of bracket #5 (See

Figure 5), and secure using existing tow hook mounting hardware

removed in step 1 at sides and bottom of tow hook.

1

Figure 2

Figure 3

KI-913358-0200-A

Page 3

Step 4

Repeat Step 1 through Step 3 for right hand side of vehicle. Tighten hardware to the appropriate

torque value (See Torque Value Chart on page 5).

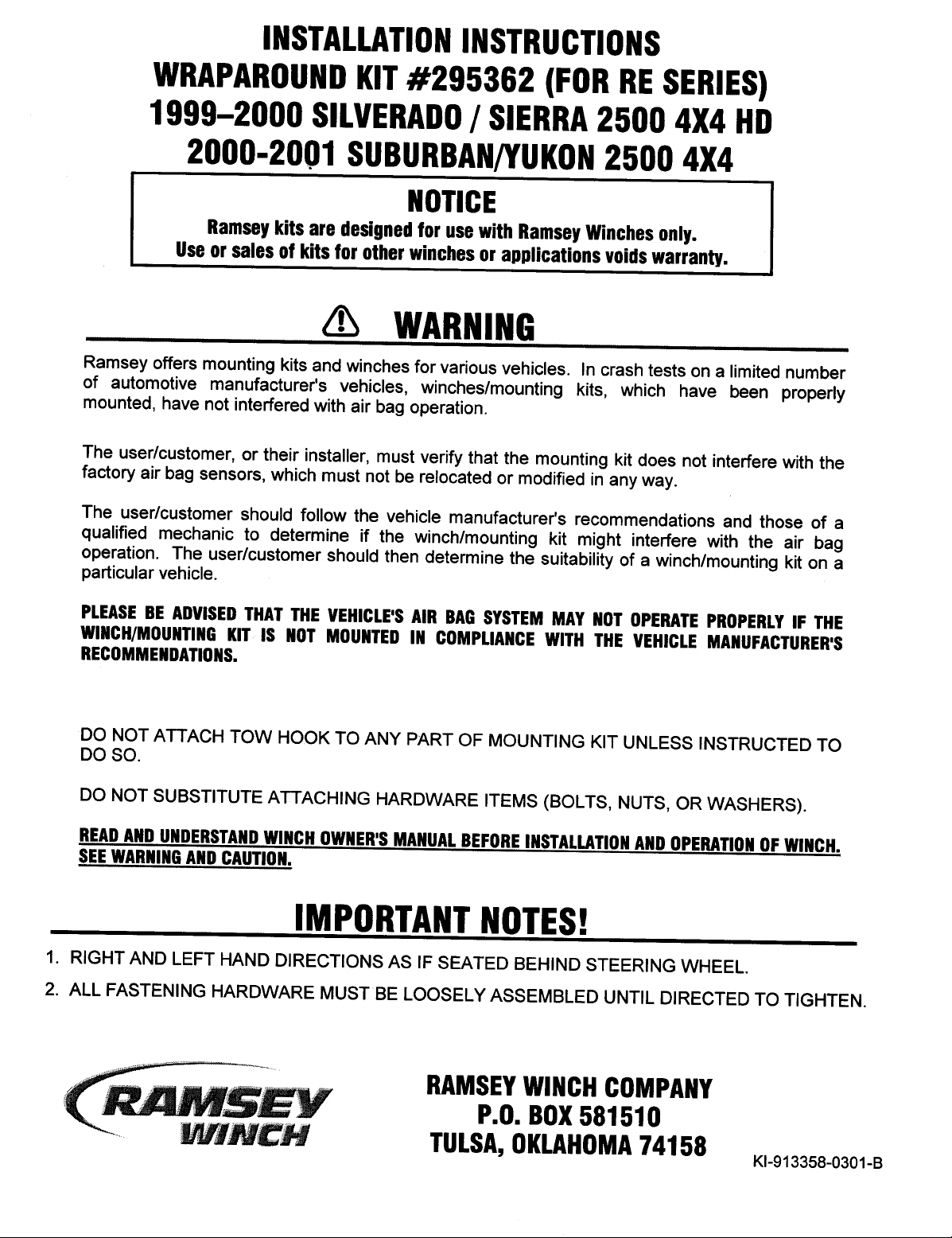

Step 5

Remove shipping strap and mounting bolts from

winch assembly and discard. Place frame assembly

#2 over top of winch and secure. Use (3) 3/8-16NC

x 1” hex head capscrews #9 with lockwashers #19

and (1) 3/8-16NC x ¾” socket head capscrew #14

with 9/16” high collar lockwasher #20 to attach

winch to rear angle of frame assembly (Figure 4). DO

NOT TIGHTEN.

Attach winch to front angle of frame assembly using

(3) 3/8-16NC x 1” socket head capscrews #13 with

high collar lockwashers (9/16 OD) #20 and (1) 3/816NC x ¾” socket head capscrew #14 with 9/16”

high collar lockwasher #20 as shown in Figure 4.

Note: The (2) outer-most capscrews are inserted

through holes in face of mounting frame and threaded

into winch. The (2) inner-most capscrews are placed

through fairlead opening and threaded into winch.

Tighten front hardware to appropriate torque

value, then tighten back hardware (See Torque

Value Chart on page 5). Snap hole plugs #25 into outer-most holes in front of frame assembly.

Figure 4

Step 6

NOTE: YOU WILL NEED ASSISTANCE FOR THIS STEP.

Have someone hold the winch and mounting frame #2 between the left and right brackets. Position

left-hand side plate assembly #1 at the outside of the winch mounting frame (Figure 5). Insert (3) 1/213NC x 1-1/2” carriage bolts #11 through the holes in side plate #1, through frame mounting bracket

#5, and through the mounting frame. Secure using (1) lockwasher #21 and nut #18 for each carriage

bolt. Do not tighten completely. Repeat for the right hand side plate.

Figure 5

2

KI-913358-0200-A

Page 4

Step 7

Install upper tube assembly #3 between side plates #1.

Insert (1) shim #26 between tube and side plate at each

end. Secure using (1) 3/8-16NC x 3/4” hex socket button

head capscrew #15 through side plate and into threaded

hole in each end of tube (Figure 6). Repeat for other tube.

TIGHTEN ALL HARDWARE COMPLETELY. Start at the upper

tube assembly and work down to the lower bracket

assemblies tightening all hardware to the appropriate torque

value. (See Torque Value Chart on page 5).

Step 8

Attach left-hand light tube assembly #6 to left-hand side

plate #1 (Figure 7). Insert (2) 3/8-16 NC x 1” plated carriage

bolts #7 through light tube assembly and into side plate as

shown. Secure using (2) lockwashers #19 and (2) nuts #16.

Tighten to torque value listed in Torque Value Chart on page 5.

Repeat for right-hand side.

Figure 6

Figure 7

Step 9

Install fairlead as shown below. Note that top holes in channel (Figure 8) align with bottom holes on

roller fairlead. Secure using capscrews, lockwashers, and nuts furnished with winch.

Figure 8

3

KI-913358-0200-A

Page 5

4

KI-913358-0200-A

Page 6

PARTS LIST

Item # Part # Qty. Description

1 265085 2 Side plate assembly (left & right)

2 395230 1 Winch mounting frame assembly

3 395272 2 Upper tube assembly

4 395415 1 Bracket assembly (right)

5 395416 1 Bracket assembly (left)

6 395417 2 Light tube assembly (left & right)

7 414220 4 Carriage bolt – 3/8-16NC x 1” lg. Gr. 5, F/B

8 414320 2 Capscrew – 3/8-16NC x 1-1/4” lg. Gr. 5, F/B

9 414321 3 Bolt – 3/8-16NC x 1” lg. Hex Head, Gr. 5, F/B

10 414519 2 Bolt – 1/2-13NC x 4-1/2” lg. Hex Head, Gr. 5, F/B

11 414560 6 Carriage bolt – 1/2-13NC x 1-1/2” long, Gr. 5, F/B

12 414578 2 Carriage bolt – 1/2-13NC x 1-1/4” long, Hex Head, Gr. 5, Z/P

13 414919 3 Screw – 3/8-16NC x 1” long, Hex Socket Head, F/B

14 414936 2 Capscrew – 3/8-16NC x 3/4” long, Hex Socket Head, F/B

15 414937 4 Capscrew – 3/8-16NC x 3/4” long, Hex Socket Button Head, F/B

16 418033 6 Nut – 3/8-16NC F/B

17 418069 2 Nut – 1/2-13NC Hex, Reg., Z/P

18 418072 6 Nut – 1/2-13NC Hex, Reg., F/B

19 418175 9 Lockwasher – 3/8” med. sect. F/B

20 418188 5 Lockwasher – 3/8” Hi-collar, F/B

21 418216 6 Lockwasher - 1/2” med. sect., F/B

22 418218 4 Lockwasher – 1/2” med. sect. Z/P

23 418223 2 Washer – 1/2 USS, flat, Z/P

24 440138 4 Cable tie

25 472027 2 Plug, 5/8” – plastic, F/B

26 488011 4 Shim

27 690504 1 Loom

28 312525 2 License mounting bracket

29 414036 4 Capscrew ¼-20NC x ½” Hex Head Gr. 5, F/B

30 416279 2 Screw ¼-20NC x ¾” Hex Head Self Tapping, F/B

31 418020 4 Nut ¼-20NC Hex Reg. F/B

32 418147 6 Lockwasher ¼ Med. Sect. F/B

TORQUE VALUE CHART

SIZE TORQUE – FT. LBS. TORQUE - Nm

3/8-16 34 46

1/2-13 87 118

M12 60 90

5

KI-913358-0200-A

Page 7

6

KI-913358-0200-A

Loading...

Loading...