Page 1

INSTALLATION INSTRUCTIONS

pp

Y

FOR WRAPAROUND KIT #295344

ON 1999-2004 FORD SUPER DUTY F-250/F550

& 2000-2004 FORD EXCURSION

Ramsey kits are designed for use with Ramsey Winches only.

Use or sales of kits for other winches or a

NOTICE

lications voids warranty.

WARNING

Ramsey offers mounting kits and winches for various vehicles. In crash tests on a limited number

of automotive manufacturer's vehicles, winches/mounting kits, which have been properly

mounted, have not interfered with air bag operation.

The user/customer, or their installer, must verify that the mounting kit does not interfere with the

factory air bag sensors, which must not be relocated or modified in any way.

The user/customer should follow the vehicle manufacturer's recommendations and those of a

qualified mechanic to determine if the winch/mounting kit might interfere with the air bag

operation. The user/customer should then determine the suitability of a winch/mounting kit on a

particular vehicle.

PLEASE BE ADVISED THAT THE VEHICLE'S AIR BAG SYSTEM MAY NOT OPERATE

PROPERLY IF THE WINCH/MOUNTING KIT IS NOT MOUNTED IN COMPLIANCE WITH THE

VEHICLE MANUFACTURER'S RECOMMENDATIONS.

DO NOT ATTACH TOW HOOK TO ANY PART OF MOUNTING KIT UNLESS INSTRUCTED TO

DO SO.

DO NOT SUBSTITUTE ATTACHING HARDWARE ITEMS (BOLTS, NUTS, OR WASHERS).

READ AND UNDERSTAND WINCH OWNER'S MANUAL BEFORE INSTALLATION AND OPERATION OF WINCH.

SEE WARNING AND CAUTION.

IMPORTANT NOTES!

1. RIGHT AND LEFT HAND DIRECTIONS AS IF SEATED BEHIND STEERING WHEEL.

2. ALL FASTENING HARDWARE MUST BE LOOSELY ASSEMBLED UNTIL DIRECTED TO TIGHTEN.

RAMSEY WINCH COMPAN

P.O. BOX 581510

TULSA, OKLAHOMA 74158

KI-913336-0204-L

Page 2

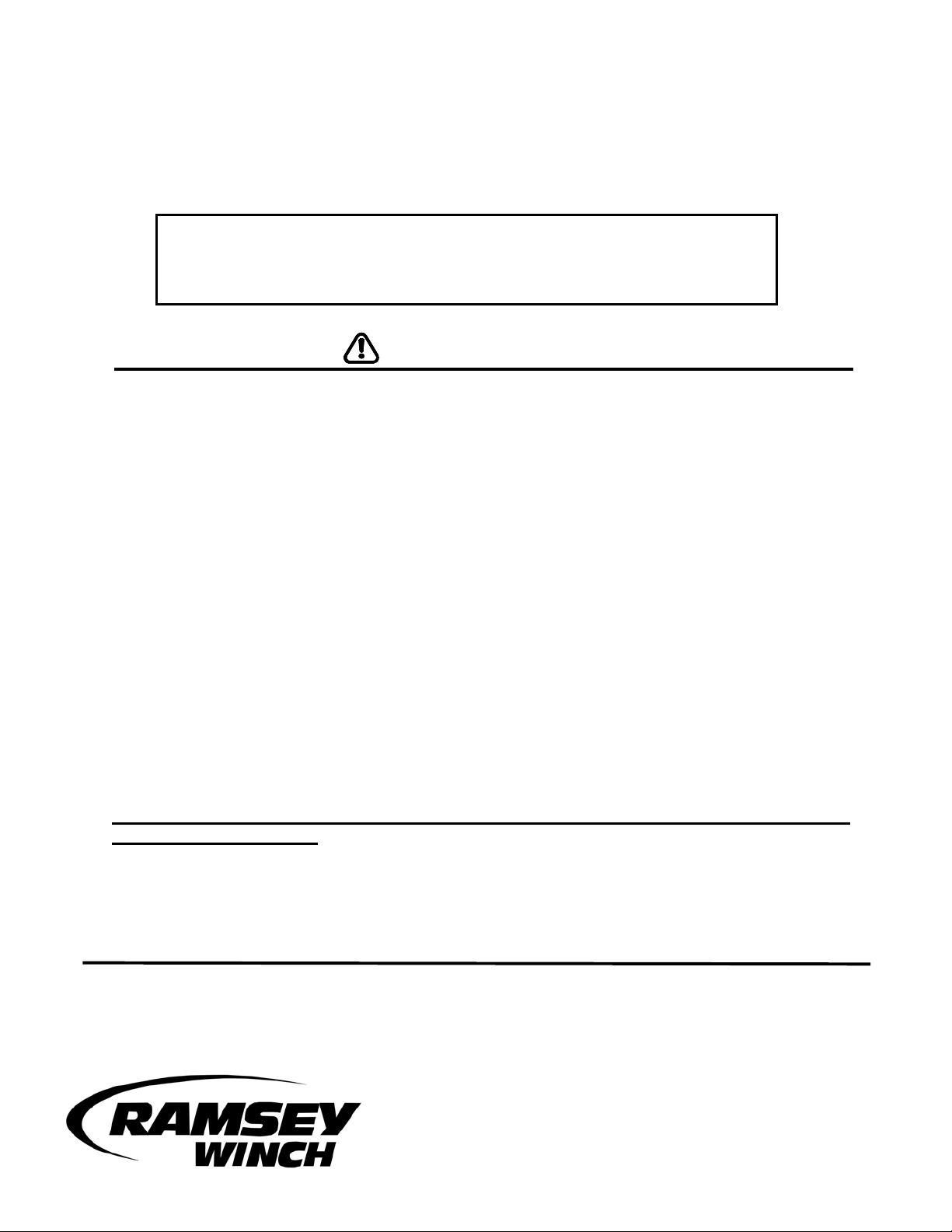

STEP 1

1. Unfasten plastic splashguard from radiator support bracket. Loosen, but do not remove, the

two bolts on the arms of the bumper support bracket as shown in Figure 1. Remove the bolt

attached to the vehicle frame. Repeat for other side of vehicle. Remove tow hooks and

vehicle bumper. Remove and discard shims hanging from front of vehicle frame, if so

equipped.

Figure 1

Figure 2

Figure 3

2. Next remove the two bolts on the left side of the blocker

bar as shown in Figure 2. Remove the three nuts on the

underside of the blocker bar as shown in Figure 3.

Repeat for other side of vehicle and remove blocker bar.

On some models, to remove the blocker bar, remove the

four bolts that hold the blocker bar to the bracket as

shown in Figure 3a.

Figure 3a

1

Page 3

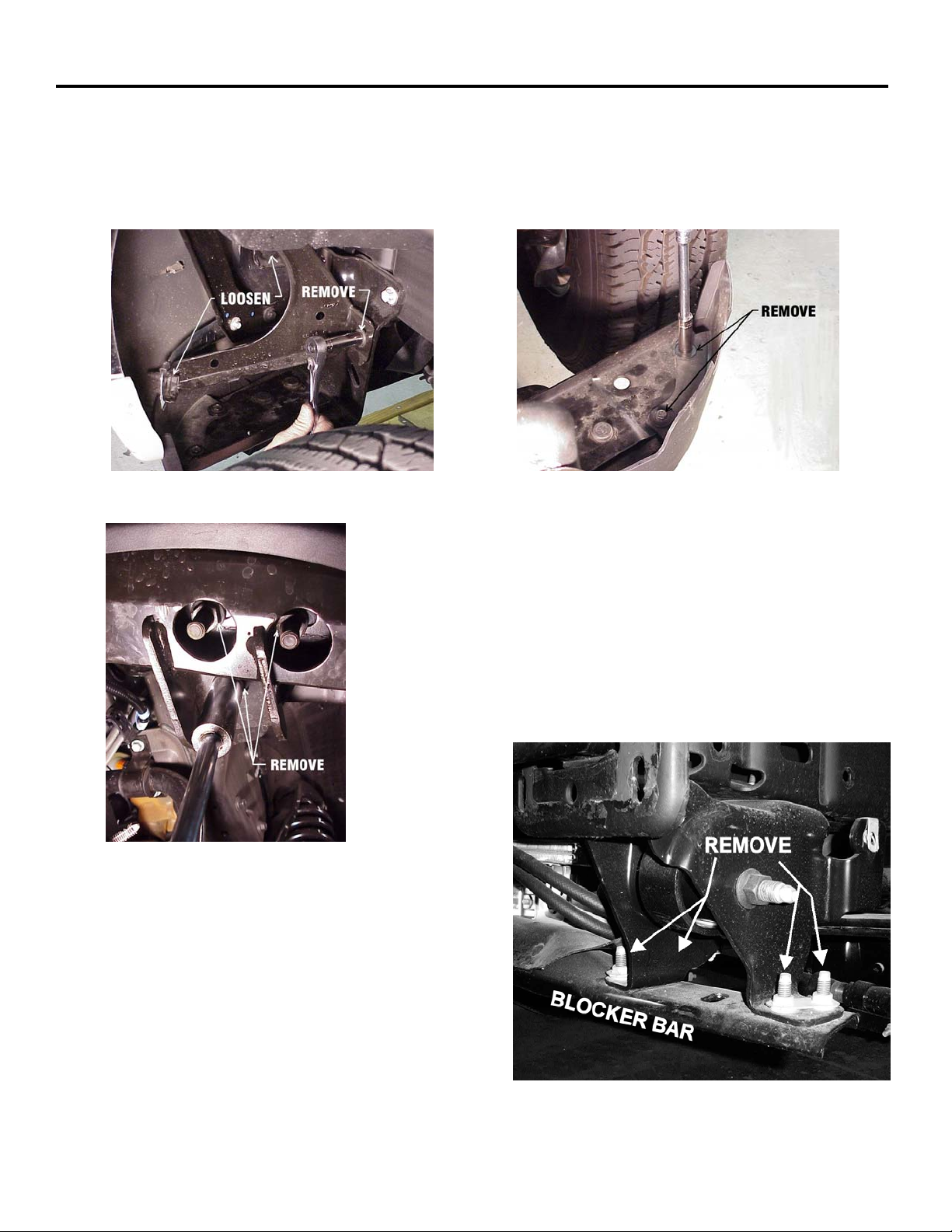

STEP 1

3. Loosen, but do not remove, the two top bolts on the blocker bar mounting bracket as shown in

Figure 4. Loosen, but do not remove, the two bolts on the under side of the blocker bar

mounting bracket. Repeat for other side of vehicle.

Figure 4

Figure 5

2

Page 4

STEP 2

Enlarge rectangular cutout in bumper bracket by 3/4 at top and 1/4” at bottom". See REAR VIEW

OF BUMPER below.

Attach nut plate (item #4) to inside of each bracket assembly (items #7 & #8) using (2) 1/2-13NC x 11/4 lg. capscrews with lockwashers and flatwashers, each side. While holding bumper in place,

install end of R.H. and L.H. bracket assemblies through bumper and bumper brackets and into ends

of R.H. and L.H. vehicle frame. Secure brackets to front of frame using (3) 1/2-13NC x 1-1/2 lg.

capscrews with lockwashers, nuts, and nut strips (item #1), each side. DO NOT TIGHTEN

HARDWARE COMPLETELY.

3

Page 5

STEP 2

Remove shipping strap and mounting bolts from winch assembly and discard. Place frame assembly

(item #5) over top of winch and secure. Use (3) 3/8-16NC x 1" lg. hx.hd. capscrews with lockwashers

and (1) 3/8-16NC x 3/4 lg. soc.hd. capscrew with high collar lockwasher (9/16 O.D.) to attach winch

to rear angle of frame assembly DO NOT TIGHTEN.

Attach winch to front channel of frame assembly, using (3) 3/8-16NC x 1 lg. soc.hd. capscrews with

high collar lockwashers (9/16 O.D.) and (1) 3/8-16NC x 3/4 lg. soc.hd. capscrew with high collar

lockwasher (9/16 O.D.), as shown below. NOTE: The (2) outer-most capscrews are inserted through

holes in face of channel and threaded into winch. The (2) inner-most holes are placed through

channel at fairlead opening and threaded into winch. Tighten front hardware to proper torque

value then tighten back hardware (see TORQUE VALUE CHART). Snap hole plugs (item #31) into

outer-most holes in front of frame assembly.

4

Page 6

STEP 2

Place frame assembly (item #5), including winch, between bracket assemblies (item #7 & #8) and

R.H. & L.H. side plates (items #2) to the outboard sides of bracket assemblies. Use (3) 1/2-13NC x

1-1/2 lg. and (1) 1/2-13NC x 1-1/4 lg. carriage bolts with lockwashers and nuts (each side), as

shown, to attach side plates and brackets to frame assembly. DO NOT TIGHTEN HARDWARE

Install (2) tube assemblies (item #6) between side plates (items #2), placing shims (item #32)

between side plates and ends of tube. Attach light tube assemblies (item #9) to side plates, as

shown. Use (2) 3/8-16NC x 3/4 carriage bolts with lockwashers and nuts, each side.

5

Page 7

STEP 2

Remove bumper bracket bolts from bumper (4) each side. This allows bumper to move forward to

provide access to lower bracket bolts. Use (3) 1/2-13NC x 1-1/2lg. capscrews with lockwashers

through bottom of vehicle frame and into nut and nut strip attached to bracket assemblies, each side.

Tighten all hardware to full torque.

Reattach bumper to bumper brackets and tighten to full torque. Drill (2) 9/16 DIA. holes through

bumper brackets, as shown below. Use bracket assembly (item #5&6) as a template. Install (2) 1/213NC x 1-1/2lg. capscrews with flatwashers, lockwashers and nuts, each side. Reattach vehicle tow

hooks to inside of bracket assembly (item #5&6) using M12 x 1.75 x 65 mm capscrews in place of

the factory hardware. Reattach splash guard. Reattach blocker bar (see step 1). Tighten to full

torque.

6

Page 8

STEP 3

Attach license tag brackets (item #3) to bottom, R.H. side, of channel using (2) 1/4-20NC x 3/4 lg.

self tapping capscrews with lockwashers. Attach tag to brackets using (4) 1/4-20NC x 1/2 hx.hd.

capscrews with lockwashers and nuts. Tighten all hardware to proper torque value (see TORQUE

VALUE CHART).

Place (2) 3/8-16NC x 1-1/4 lg. capscrews through lower-most holes in frame assembly from inside of

channel. Secure fairlead to capscrews using (2) 3/8 lockwashers and nuts. Tighten hardware to

proper torque value (see TORQUE VALUE CHART).

Refer to winch Owner's Manual Installation Instructions for electrical connections. BE SURE

BATTERY CABLES ARE NOT DRAWN TAUT ACROSS ANY SURFACES WHICH COULD

POSSIBLY DAMAGE THEM. Push battery cables into loom #33 and slide loom up cable as close

as possible to winch mounting frame. Secure loom to cable using (1) cable tie #30 at each end of

loom. To improve appearance, wrap ends of loom with black electrical tape.

Plug remote switch into receptacle of black solenoid cover of winch. Run winch forward and reverse

to check connections. Snap appropriate "IN" and "OUT" disc into proper thumb cavity, after

determining winch operating direction. DO NOT LEAVE SWITCH PLUGGED IN WHEN WINCH IS

NOT IN USE.

Place end of wire rope through fairlead and attach clevis hook. Use clevis pin and cotter pin

(furnished with winch).

REFER TO WINCH OWNER'S MANUAL FOR SAFE OPERATIONS.

7

Page 9

PARTS LIST FOR KIT #295344 (BLACK)

ITEM NO. QTY. PART NUMBER DESCRIPTION

1 4 364165 NUT STRIP

2 2 265073 SIDE PLATE R.H. & L.H.-BLACK

3 2 312525 BRACKET-LICENSE

4 2 350666 PLATE-NUT

5 1 395230 FRAME ASSEMBLY-WINCH MTG

6 2 395272 TUBE ASSEMBLY (BLACK)

7 1 395380 BRACKET ASSEMBLY-R.H.

8 1 395381 BRACKET ASSEMBLY-L.H.

9 2 395386 LIGHT TUBE ASSEMBLY (BLACK)

10 4 414036 CAPSCREW 1/4-20NC X 1/2 LG. HX.HD. GR.5 BLACK

11 4 414220 CARRIAGE BOLT 3/8-16NC X 1 LG. GR.5 BLACK

12 2 414320 CAPSCREW 3/8-16NC X 1-1/4 LG. HX.HD. GR.5 BLACK

13 3 414321 CAPSCREW 3/8-16NC X 1 LG. HX.HD. GR.5 BLACK

14 14 414551 CAPSCREW 1/2-13NC X 1-1/2 LG. HX.HD. GR.5 BLACK

15 2 414559 CARRIAGE BOLT 1/2-13NC X 1-1/4 LG. GR.5 BLACK

16 6 414560 CARRIAGE BOLT 1/2-13NC X 1-1/2 LG. GR.5 BLACK

17 4 414578 CAPSCREW 1/2-13NC X 1-1/4 LG HX.HD. GR.5 PLATED

18 3 414919 CAPSCREW 3/8-16NC X 1 LG. HX.SOC.HD. GR.5 BLACK

19 2 414936 CAPSCREW 3/8-16NC X 3/4 LG. HX.SOC.HD. BLACK

20 4 414937 CAPSCREW 3/8-16NC X 3/4 LG. HX.SOC.BUTTON HD. BLK.

21 2 416279 SCREW 1/4-20NC X 3/4 LG. HX.HD. SELF-TAPPING, BLACK

22 4 418020 NUT 1/4-20NC HX. REG. BLACK

23 6 418033 NUT 3/8-16NC HX. REG.-BLACK

24 16 418072 NUT 1/2-13NC HX. REG.-BLACK

25 6 418147 LOCKWASHER 1/4 MED.SECT. BLACK

26 9 418175 LOCKWASHER 3/8 MED.SECT.-BLACK

27 5 418188 LOCKWASHER 3/8, HI-COLLAR

28 26 418216 LOCKWASHER 1/2 MED.SECT.-BLACK

29 4 418229 WASHER 1/2 FLAT

30 4 440138 CABLE TIES

31 2 472027 PLUG

32 4 488011 SHIM-PLASTIC

33 1 690504 LOOM

34 6 415311 CAPSCREW M12 X 1.75 X 50 MM HX HD GR8.8 Z/P

TORQUE VALUE CHART

SIZE TORQUE

FT./LB. NM

1/4-20 5 7

3/8-16 34 46

1/2-13 50 7

12mm 39 54

5

8

Loading...

Loading...