Page 1

INSTALLATION INSTRUCTIONS FOR

WRAPAROUND

KIT #295252 (CHROME) & KIT #295253 (BLACK)

ON FULLSIZE DODGE TRUCKS

NOTICE

Ramsey kits are designed for use with Ramsey Winches only.

Use or sales of kits for other winches or applications voids warranty.

WARNING

Ramsey offers mounting kits and winches for various vehicles. In crash tests on a limited number

of automotive manufacturer's vehicles, winches/mounting kits, which have been properly

mounted, have not interfered with air bag operation.

The user/customer, or their installer, must verify that the mounting kit does not interfere with the

factory air bag sensors, which must not be relocated or modified in any way.

The user/customer should follow the vehicle manufacturer's recommendations and those of a

qualified mechanic to determine if the winch/mounting kit might interfere with the air bag

operation. The user/customer should then determine the suitability of a winch/mounting kit on a

particular vehicle.

PLEASE BE ADVISED THAT THE VEHICLE'S AIR BAG SYSTEM MAY NOT OPERATE

PROPERLY IF THE WINCH/MOUNTING KIT IS NOT MOUNTED IN COMPLIANCE WITH THE

VEHICLE MANUFACTURER'S RECOMMENDATIONS.

DO NOT ATTACH TOW HOOK TO ANY PART OF MOUNTING KIT UNLESS INSTRUCTED TO

DO SO.

DO NOT SUBSTITUTE ATTACHING HARDWARE ITEMS (BOLTS, NUTS, OR WASHERS).

READ AND UNDERSTAND WINCH OWNER'S MANUAL BEFORE INSTALLATION AND

OPERATION OF WINCH. SEE WARNING AND CAUTION.

IMPORTANT NOTES!

1. RIGHT AND LEFT HAND DIRECTIONS AS IF SEATED BEHIND STEERING WHEEL.

2. ALL FASTENING HARDWARE MUST BE LOOSELY ASSEMBLED UNTIL DIRECTED TO TIGHTEN.

RAMSEY WINCH COMPANY

P.O. BOX 581510

TULSA, OKLAHOMA 74158

KI-913275-0999-G

Page 2

STEP 1

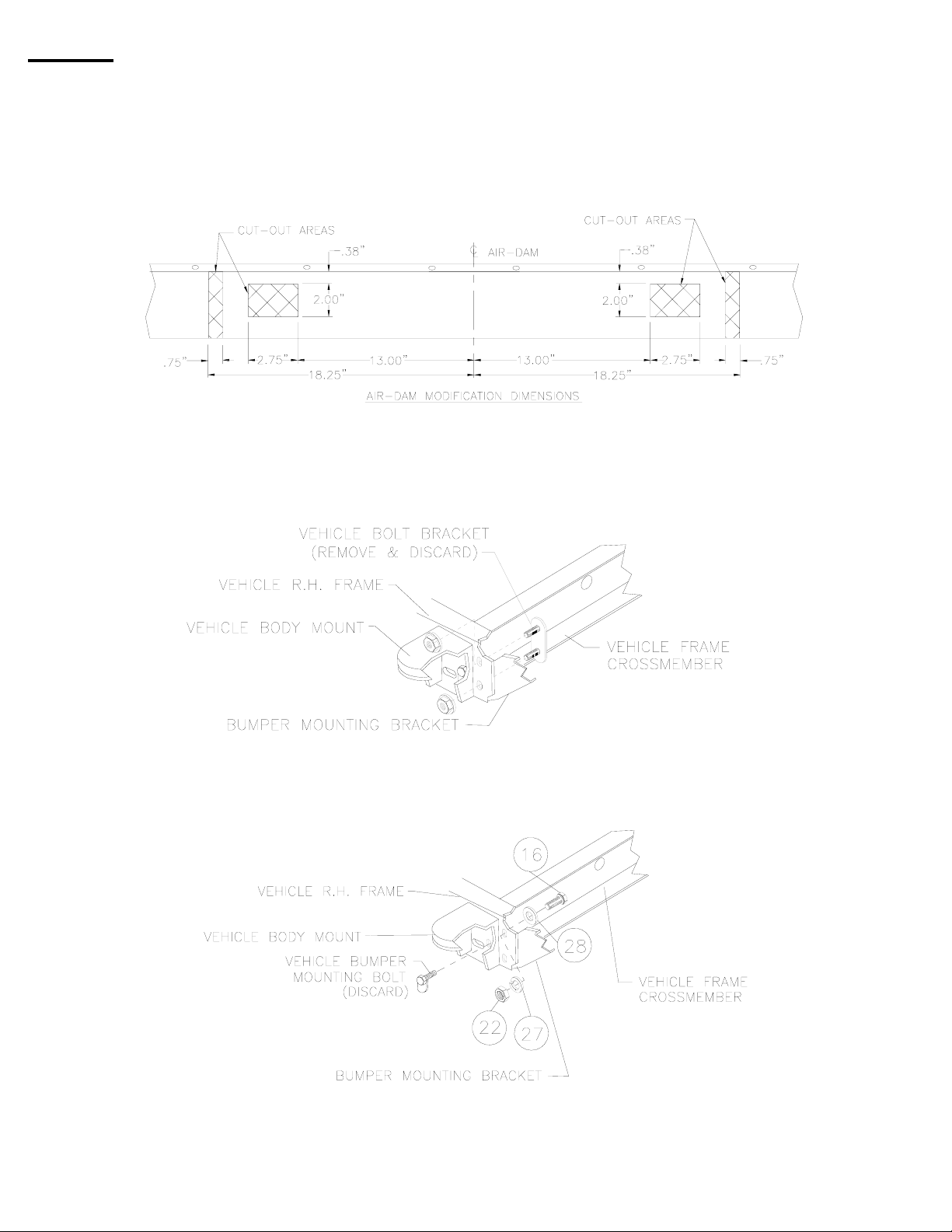

1. Vehicles equipped with factory tow hooks do not use spacer plate #31 (Refer to Step 2, Paragraph 4). If

vehicle is equipped with a lower air-dam, it must be modified to the diagram below or removed. The

notches and holes must be added for clearance of brackets #2, & #3 and braces #4 & #5 installed in a

later step.

NOTE: It is not necessary to remove the air-dam to add the notches and holes. It is easier to make the

cutouts with the air dam in place.

NOTE: IF YOU ARE INSTALLING A PRO-8000 OR PRO-9000 SERIES WINCH ON A 1998 OR 1999

VEHICLE ONLY, PLEASE GO TO PAGE 8 OF INSTRUCTIONS.

2. Remove vehicle bolt bracket from R.H. side of vehicle frame and discard bracket and nuts.

3. Install (1) 7/16-14NC x 1-1/2 lg. capscrew #16 with flatwasher #28, lockwasher #27, and nut #22 in

upper hole to hold vehicle bumper in place. Tighten capscrew to proper torque value (see TORQUE

VALUE CHART). Next, remove vehicle bumper mounting bolt and nut from vehicle frame and discard.

4. Repeat for L.H. side of vehicle.

1

KI-913275-0999-G

Page 3

5. NOTE: INSTRUCTIONS ON THIS PAGE APPLY ONLY TO PRO-8000 OR PRO-9000 SERIES

WINCHES ON A 1994-1997 VEHICLE. For all other winches, go to page 3.

a. If you are mounting a Pro-8000 or Pro-9000 series winch on a 1998 or 1999 vehicle, please use the

alternate instructions on page 8.

b. If you are mounting a Pro-8000 or Pro-9000 series winch on a 1994–1997 vehicle use the instructions

on this page.

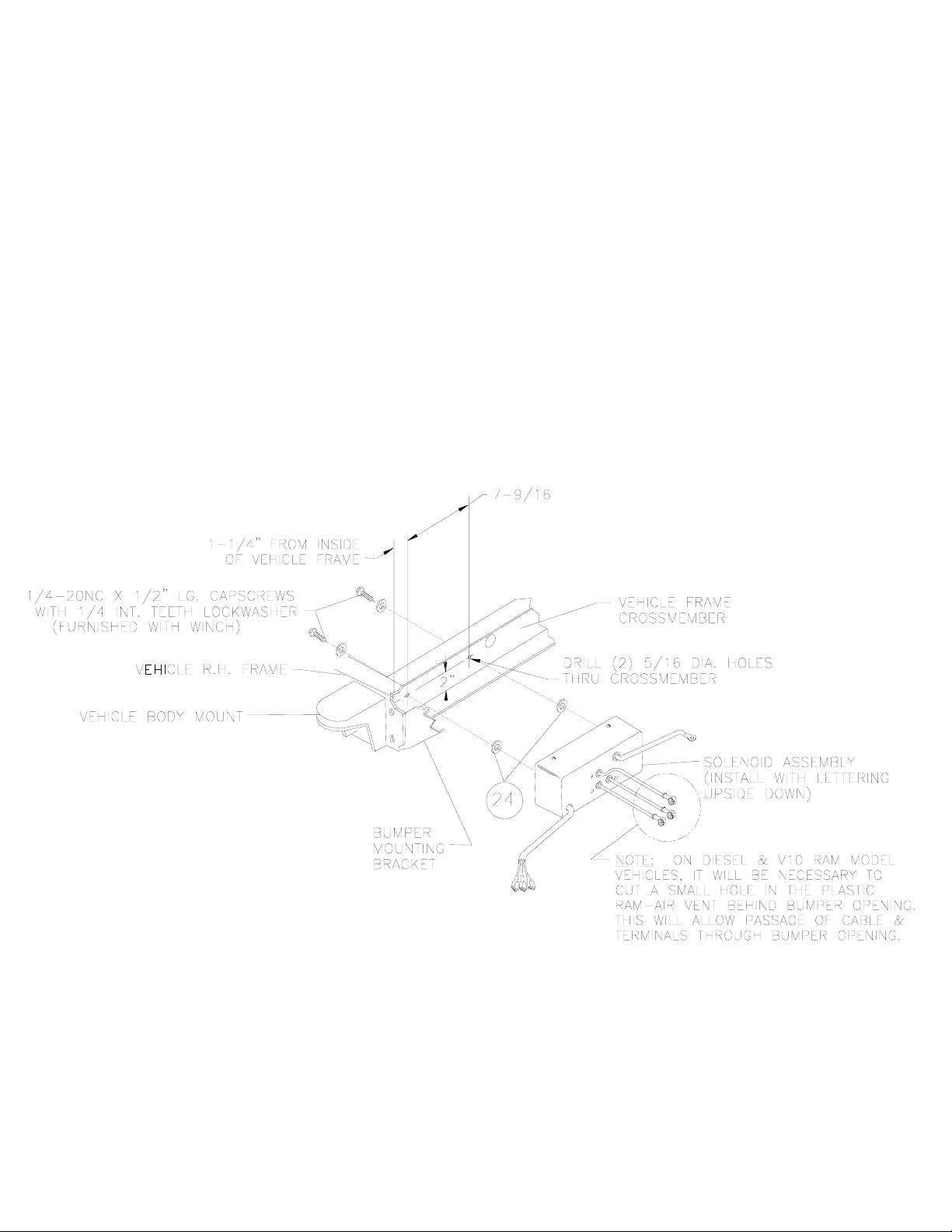

6. Mount solenoid assembly to the front side of the vehicle frame crossmember as follows:

a. Mark and centerpunch crossmember on the back (See diagram below for dimensions).

b. Drill (2) 5/16” dia. holes through the crossmember at the location shown below.

c. Attach solenoid assembly to crossmember using (2) ¼-20NC x ½” hex head capscrews with

lockwashers (furnished with winch).

d. Insert capscrews through lockwashers, then through back of vehicle crossmember, then through

flatwashers #24, and thread into captive nuts in bottom of solenoid assembly.

e. Tighten hardware securely.

NOTE: PLEASE READ INSTRUCTIONS ABOUT VEHICLE FRAME MOUNTING HOLE

CHANGE ON LAST 2 PAGES BEFORE YOU CONTINUE!

2

KI-913275-0999-G

Page 4

STEP 2

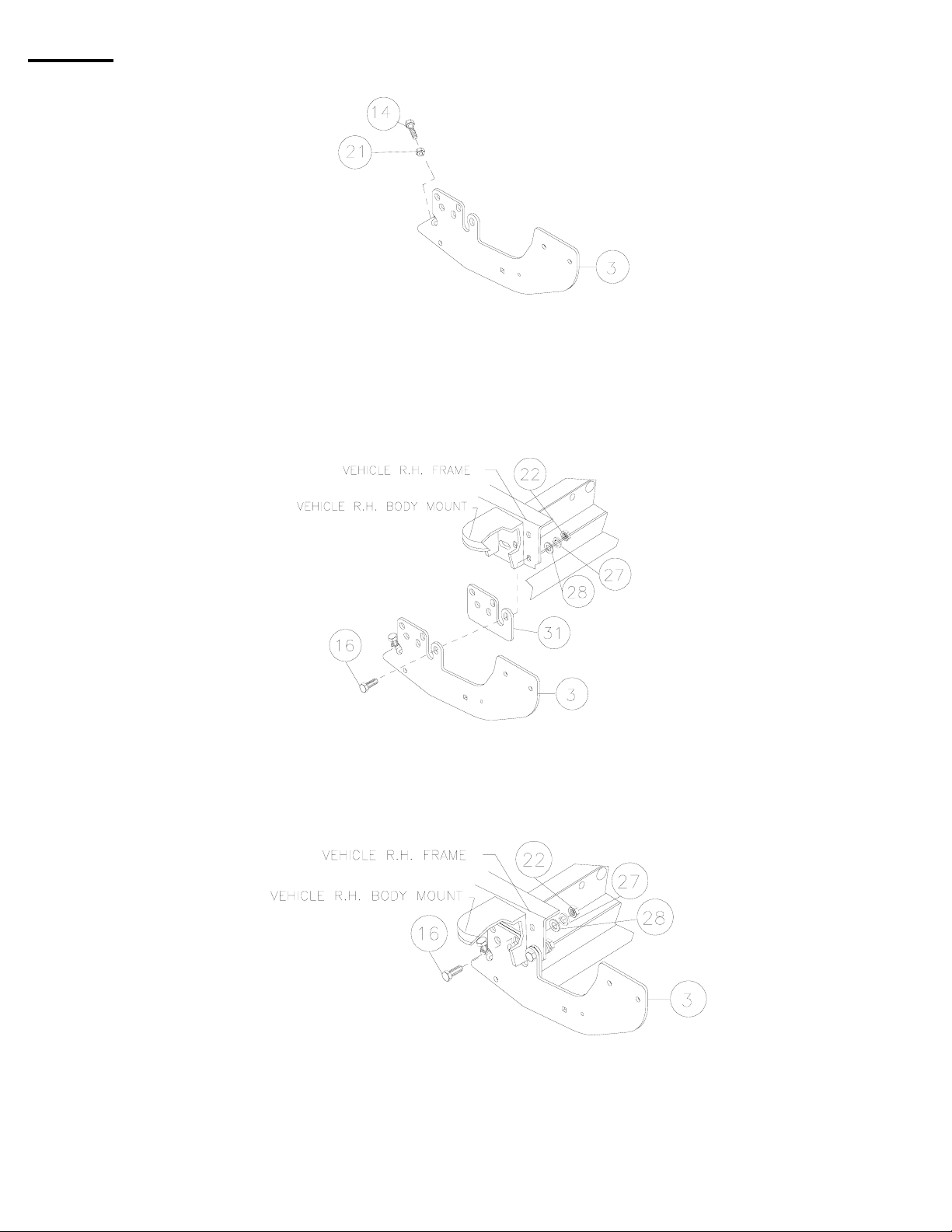

2. Thread (1) 3/8-16NC x 1-1/2 capscrew #14 through lock nut #21 and through nut welded to bottom of

bracket #3.

3. If vehicle is not equipped with tow hooks, this kit requires spacer plate #31 to be used.

4. Mount R.H. bracket #3 as shown, adding spacer plate #31 (if required). Using (1) 7/16-14NC x 1-1/2 lg.

hx. hd. capscrew #16, insert through front hole of bracket, then through spacer plate #31 (if required) or

tow hook and then through bumper mounting bracket and frame. Attach with flatwasher #28, lockwasher

#27 and nut #22 as shown. DO NOT TIGHTEN.

5. For the middle hole, insert (1) 7/16-14NC x 1-1/2 lg. hx hd capscrew #16, insert through bracket #3, then

through spacer plate #31 (if required) or tow hook and then through bumper mounting bracket and

frame. Attach with flatwasher #28, lockwasher #27 and nut #22 as shown. DO NOT TIGHTEN.

3

KI-913275-0999-G

Page 5

6. Place 1/2” nut extender #10 through hole in vehicle frame just below bumper strut. NOTE: It is necessary

to temporarily loosen strut-mounting hardware and shift strut clear until extender is attached. Install (1)

1/20--13NC x 1-1/2" lg. capscrew #17 with lockwasher #29 through bracket #3, as shown in VIEW A-A,

and thread into nut of nut extender (each side).

7. Shift vehicle bumper strut back into place and reinstall bumper strut mounting hardware.

Repeat 2-7 for L.H. bracket

After brackets are mounted to vehicle frame, tighten adjuster screw firmly against bottom of vehicle frame,

and tighten lock nuts against brackets.

STEP 3

1. You will need assistance for this step.

2. Have someone hold the winch mounting channel #6 between brackets #2 & #3.

3. Position R.H. side plate #7 to outside of bracket #3 as shown below.

4. Insert (2) 3/8-16NC x 1-1/2 lg. carriage bolts #13 through side plates, mounting bracket and winch

mounting channel as shown below. Secure using 3/8” lockwasher #26 and 3/8” nut #20 for each

carriage bolt.

5. Repeat for L.H. side.

6. Finally, insert 3/8-16NC x 1-1/2 lg carriage bolt #13 through rear hole of side plate and into mounting

bracket as shown below. Secure using 3/8” lockwasher #26 and 3/8” nut #20.

7. Repeat for L.H. side.

DO NOT TIGHTEN HARDWARE

4

KI-913275-0999-G

Page 6

STEP 4

1. Install lower grille tube #8 between side plates #7, placing shims #32 between side plates and ends of tubes. Use 3/8-16NC x

3/4 lg. button hd. capscrews #18 to secure each end of tube to side plates. TIGHTEN HARDWARE SECURELY.

2. Install upper grille tube #8 between side plates #7, placing shims #32 between side plates and ends of tubes. Use 3/8-16NC x

3/4 lg. button hd. capscrews #18 to secure each end of tube to side plates. TIGHTEN HARDWARE SECURELY

3. Attach light tube #9 to side plate as shown. Use (2) 3/8-16NC x 1” carriage bolts #12, with lock washers #26, and nuts #20.

Note: On chrome kit #295253 use plated hardware at this location.

3. Secure fairlead to front of winch mounting channel as shown below using capscrews, lockwashers, and nuts furnished with

winch.

4. Attach license tag brackets #1 to bottom, L.H. side of mounting frame using (2) 1/4-20NC x 3/4 lg. capscrews #11, and

flatwashers #25. Insert capscrews through flatwashers, license-mounting bracket, then through bottom of mounting channel

as shown below. Secure using lockwasher #23 and nut #19.

5

KI-913275-0999-G

Page 7

STEP 5

2. Attach R.H. & L.H. brace #4& #5 to bottom of winch mounting channel #6, as shown below. Use (1) 3/8-16NC X

1-1/2” capscrew #14 each side. Insert capscrew through flatwasher (included with winch), brace, winch mounting

channel, and thread into front feet of winch as shown below.

3. Secure back feet of winch using remaining winch mounting hardware furnished with winch.

4. Attach remaining end of braces to brackets #2 & #3 using (1) 3/8-16NC x 1 lg. hx.hd. capscrew #15 with

lockwasher #26 and nut #20, (each side) as shown below .

5. Square mounting frame, side plates and brackets with front of vehicle by tightening adjuster screw until kit is level

(refer to VIEW A-A, pg. 3). Tighten lock nuts #21 against brackets

1. Tighten all hardware to proper torque value (see TORQUE VALUE CHART).

4. Refer to winch Owner's Manual Installation Instructions for electrical connections.

a. Route free end of red and black battery cables up to battery and secure to terminals using spacers #33, as shown

below.

b. BE SURE BATTERY CABLES ARE NOT DRAWN TAUT ACROSS ANY SURFACES WHICH COULD POSSIBLY

DAMAGE THEM. Use cable ties #30 and loom #34 to secure cable and wires to a location of the installer's

discretion, behind vehicle grille.

c. Plug remote switch into receptacle of black solenoid cover of winch. Run winch forward and reverse to check

connections. Snap appropriate "IN" and "OUT" disc into proper thumb cavity, after determining winch-operating

direction. DO NOT LEAVE SWITCH PLUGGED IN WHEN WINCH IS NOT IN USE.

5. Place end of wire rope through fairlead and attach clevis hook. Use clevis pin and cotter pin (furnished with winch).

REFER TO WINCH OWNER'S MANUAL FOR SAFE OPERATIONS.

6

KI-913275-0999-G

Page 8

PARTS LIST FOR KIT #295252 (CHROME) & #295253 (BLACK)

ITEM #

1 2 312332 BRACKET-LICENSE MTG.

2 1 395164 BRACKET ASSEMBLY-R.H.

3 1 395165 BRACKET ASSEMBLY-L.H.

4 1 395166 BRACE-R.H.

5 1 395167 BRACE-L.H.

6 1 395170 CHANNEL ASSEMBLY-WINCH MTG.

7 2 395270 SIDE PLATE ASSEMBLY-R.H. & L.H. (BLACK)

2 395271 SIDE PLATE ASSEMBLY-R.H. & L.H. (CHROME)

8 2 395272 TUBE ASSEMBLY (BLACK)

2 395273 TUBE ASSEMBLY (CHROME)

9 2 395280 LIGHT TUBE (BLACK)

2 395281 LIGHT TUBE (CHROME)

10 2 408269 NUT EXTENDER - 1/2"

11 2 414048 CAPSCREW 1/4-20NC X 3/4 LG. HX.HD. BLACK

12 4 414220 CARRIAGE BOLT 3/8-16NC X 1 LG. GR.5 BLACK

4 414227 CARRIAGE BOLT 3/8-16NC X 1 LG. GR.5 PLATED

13 6 414222 CARRIAGE BOLT 3/8-16NC X 1-1/2 GR.5 BLACK

6 414219 CARRIAGE BOLT 3/8-16NC X 1-1/2 GR.5 PLATED

14 4 414292 CAPSCREW 3/8-16NC X 1-1/2 GR.8 BLACK

15 2 414321 CAPSCREW 3/8-16NC X 1 LG. HX.HD.GR.5 BLACK

16 6 414479 CAPSCREW 7/16-14NCX1-1/2LG.HX.HD.GR.5 BLACK

17 2 414548 CAPSCREW 1/2-13NC X 1-1/2 LG. HX. HD. GR 5 PLATED

18 4 414937 CAPSCREW 3/8-16NC X 3/4 LG. HX. BUTTON HD. BLACK

4 414938 CAPSCREW 3/8-16NC X 3/4 LG. HX. BUTTON HD. PLATED

19 2 418020 NUT 1/4-20NC HX. REG. BLACK

20 12 418033 NUT 3/8-16NC HX. REG. BLACK

4 418035 NUT 3/8-16NC HX. REG. PLATED

21 2 418044 NUT-LOCK 3/8-16NC PLATED

22 6 418047 NUT 7/16-14NC HX. REG. BLACK

23 2 418147 LOCKWASHER 1/4 MED.SECT. BLACK

24 2 418153 WASHER 1/4 SAE FLAT PLATED

25 2 418158 WASHER-1/4 SAE FLAT, BLACK

26 12 418175 LOCKWASHER 3/8 MED.SECT. BLACK

4 418177 LOCKWASHER 3/8 MED.SECT. PLATED

27 6 418196 LOCKWASHER 7/16 MED.SECT. BLACK

28 6 418208 WASHER 7/16 USS FLAT, BLACK

29 2 418218 LOCKWASHER ½ MED. SECT. PLATED

30 4 440138 CABLE TIES

31 2 474087 SPACER PLATE

32 4 488011 SHIM

33 2 418518 SPACER

QTY. PART # DESCRIPTION

34 1 690504 LOOM

TORQUE VALUE CHART

SIZE TORQUE FT./LB. NM

1/4-20 5 7

5/16-18 18 24

3/8-16 34 46

7/16-14 50 68

1/2-13 87 118

7

KI-913275-0999-G

Page 9

SOLENOID MOUNTING FOR PRO-8000/PRO-9000 SERIES WINCHES ON 1998-1999

VEHICLES ONLY

1. It will be necessary to remove bumper in order to drill mounting holes for solenoid assembly at the

required location.

2. YOU WILL NEED ASSISTANCE FOR THIS STEP.

3. Remove vehicle bumper mounting bolt and nut from R.H. side of vehicle frame and discard.

4. Remove vehicle bumper strut mounting hardware and save for later use. Shift strut down until it clears

the vehicle body mount.

5. Repeat 3 & 4 for L.H. side.

6. Have someone hold the vehicle bumper while you remove the vehicle bolt bracket and nuts from R.H.

side of vehicle frame and discard.

7. Repeat for L.H. side of vehicle.

8

KI-913275-0999-G

Page 10

8. See Detail A for proper location to drill holes, then follow steps below for mounting solenoid assembly.

9. Mount solenoid assembly to the front side of the vehicle frame crossmember as follows:

a. Mark and center punch crossmember (see diagram below for dimensions).

b. Drill (2) 5/16” dia. holes through the crossmember at the location shown below.

c. Attach solenoid assembly to crossmember using (2) ¼-20NC x ½” hex head capscrews with

lockwashers (furnished with winch).

d. Insert capscrews through lockwashers, then through back of vehicle crossmember, then through

flatwashers #24, and thread into captive nuts in bottom of solenoid assembly. Tighten hardware

securely.

10. Re-install vehicle bumper as follows:

a. Secure bumper with (1) 7/16-14NC x 1-1/2” capscrew #16, with flatwasher #28, lockwasher #27,

and nut #22 in upper hole (each side).

b. Align bumper with headlamps, maintaining a ¾” gap between top of bumper and bottom of

headlamps on each side. Tighten hardware to proper torque. (See torque value chart).

PLEASE CHECK VEHICLE FRAME MOUNTING HOLE CHANGE ON NEXT PAGE BEFORE

PROCEEDING FURTHER.

9

KI-913275-0999-G

Page 11

VEHICLE FRAME MOUNTING HOLE CHANGE

Beginning with vehicles manufactured in January 1999, Chrysler has modified the vehicle frames of the full

size Dodge Ram truck by moving the location of the horizontal slot and adding a hole. Look carefully at the

diagram below to determine which hole configuration is on your vehicle frame. If your frame looks like the

“old hole pattern”, disregard the rest of the instructions in this section and return to Step 2 on page 3. If

your frame looks like the “new hole pattern”, use the instructions in this section for mounting the left and

right bracket assemblies. All other instructions are unchanged.

2. Thread (1) 3/8-16NC x 1-1/2 capscrew #14 through lock nut #21 and through nut welded to bracket #3.

3. If vehicle is not equipped with tow hooks, this kit requires spacer plate #31 (Refer to Paragraph 4) to be

used.

4. Mount R.H. bracket #3 as shown, adding spacer plate #31(if required). Using (1) 7/16-14NC x 1-1/2 lg.

hx.hd. capscrew #16, insert through front hole of bracket, then through spacer plate #31 (if required) or

tow hook and then through bumper mounting bracket and winch mounting channel. Attach with

flatwasher #28, lockwasher #27 and nut #22 as shown. DO NOT TIGHTEN.

10

KI-913275-0999-G

Page 12

5. For the middle hole, insert (1) 7/16-14NC x 1-1/2 lg. hx hd capscrew #16, insert through bracket, then

through spacer plate #31 (if required) or tow hook and then through bumper mounting bracket and winch

mounting channel. Attach with flatwasher #28, lockwasher #27 and nut #22 as shown. DO NOT

TIGHTEN.

6. Place ½” nut extender #10 through hole in vehicle frame, just below bumper strut. NOTE: If you have not

already done so, it is necessary to temporarily loosen strut-mounting hardware and shift strut clear until

extender is attached. Install (1) 1/2-13NC x 1-1/2" lg. capscrew #17 with lockwasher #29 through

bracket, as shown in VIEW A-A, and thread into nut of nut extender (each side).

7. Shift vehicle bumper strut back into place and reinstall bumper strut mounting hardware.

Repeat 2-7 for L.H. bracket

After brackets are mounted to vehicle frame, tighten adjuster screw firmly against bottom of vehicle frame,

and tighten lock nuts against brackets.

Return to Step 3 on page 4.

11

KI-913275-0999-G

Loading...

Loading...