Page 1

INSTALLATION INSTRUCTIONS

FOR REPLACEMENT

MINI ROCKER SWITCH KIT

#256128

FOR ATV WINCH WITH

REMOTE MOUNTED

MANUAL SWITCH

Page 2

2

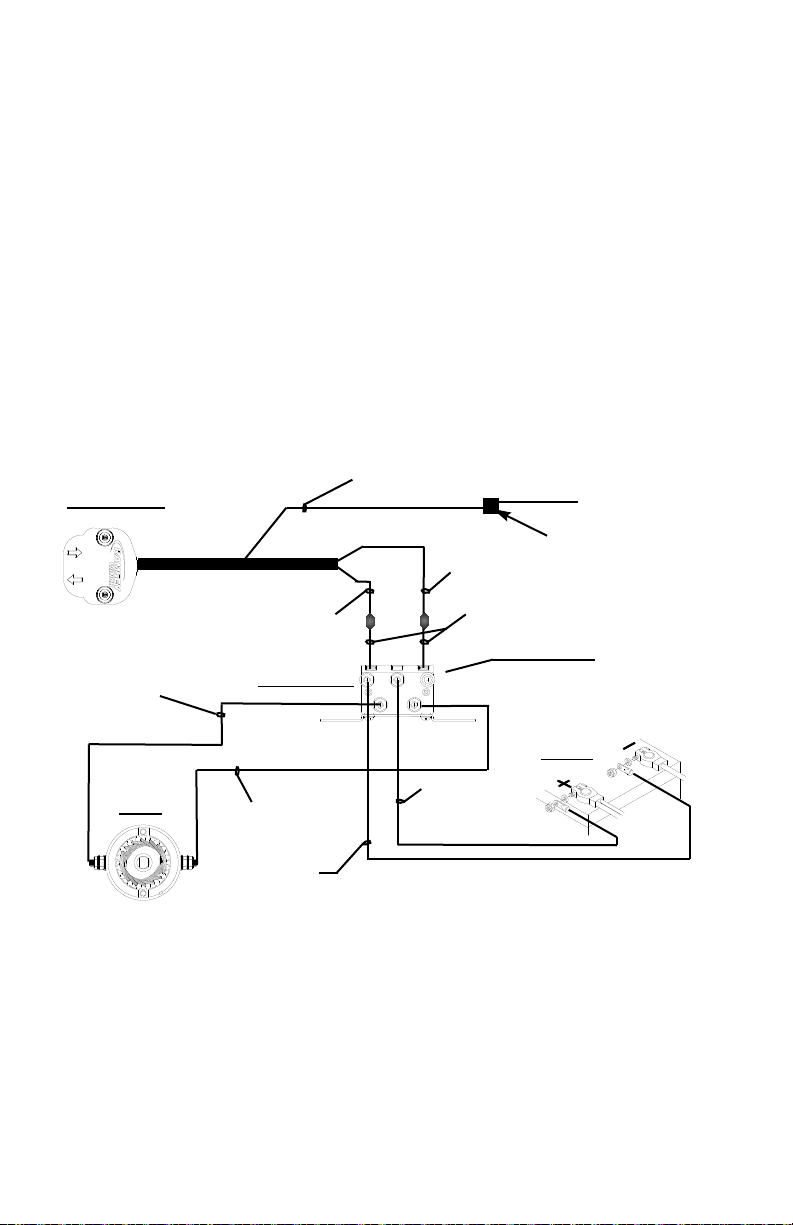

SOLENOID ASS’Y

.

BLACK W/ YELLOW

STRIPE MOTOR

LEAD

RED

BATTERY LEAD

BLACK

BATTERY LEAD

BATTERY

BLACK WIRE

BLACK MOTOR

LEAD

GREEN WIRE

RED WIRE

ROCKER SWITCH

#1

MOTOR

#2

NOTE:

TORQUE SOLENOID

TERMINAL NUTS TO

35-40 IN-LBS.

E

A

C

B

TO ATV IGNITION

SPLICE

Electrical Schematic

Before Beginning Installation

1. Locate Remote Mounted Switch and

Solenoid and disconnect all wiring to

battery and winch. Switch and Solenoid can

be removed and discarded.

2. Disconnect negative (-) battery cable

from battery. Turn off vehicle ignition.

3. Disengage winch clutch.

4. Remove hood or cowling as necessary for

easier access to installation area.

5. Locate and mark mounting location for

Solenoid Assembly.

6. Locate accessory wire from vehicle ignition

switch that is powered only when ignition is

ON. Use this wire when splicing to Red wire

on Rocker switch.

7. Make sure locations are close enough for

wiring connections to be made without making alterations to wire lengths.

CAUTION: DO NOT CONNECT NEGATIVE BATTERY

CABLE OR ENGAGE CLUTCH UNTIL INSTALLATION

IS COMPLETE

. WINCH COULD BEGIN SPOOLING

CABLE UNEXPECTEDLY CAUSING INJURY OR

DAMAGE TO WINCH

.

IN

OUT

WIRE CONNECTORS

Page 3

Solenoid Mounting: Choose a mounting

location that will remain protected and dry

(The best location will usually be where the

Solenoid for the Remote Switch was located.) Solenoid must be mounted within 24” of

winch motor. Solenoid should be mounted

on a flat surface.

Installing the Solenoid

1. Use Solenoid Assembly as a guide to

mark and drill (2) 7/32” holes in location

determined for solenoid OR if there is no

good place to drill holes for mounting,

use the tube clamps (item #1-16).

2. Use (2) 3/4” long #10 screws (item #1-

5), (2) #10 flat washers (item #1-8),

and (2) #10 zinc locknuts (item #1-10)

to mount solenoid. Tighten to 60 in-lbs

(7 Nm) torque.

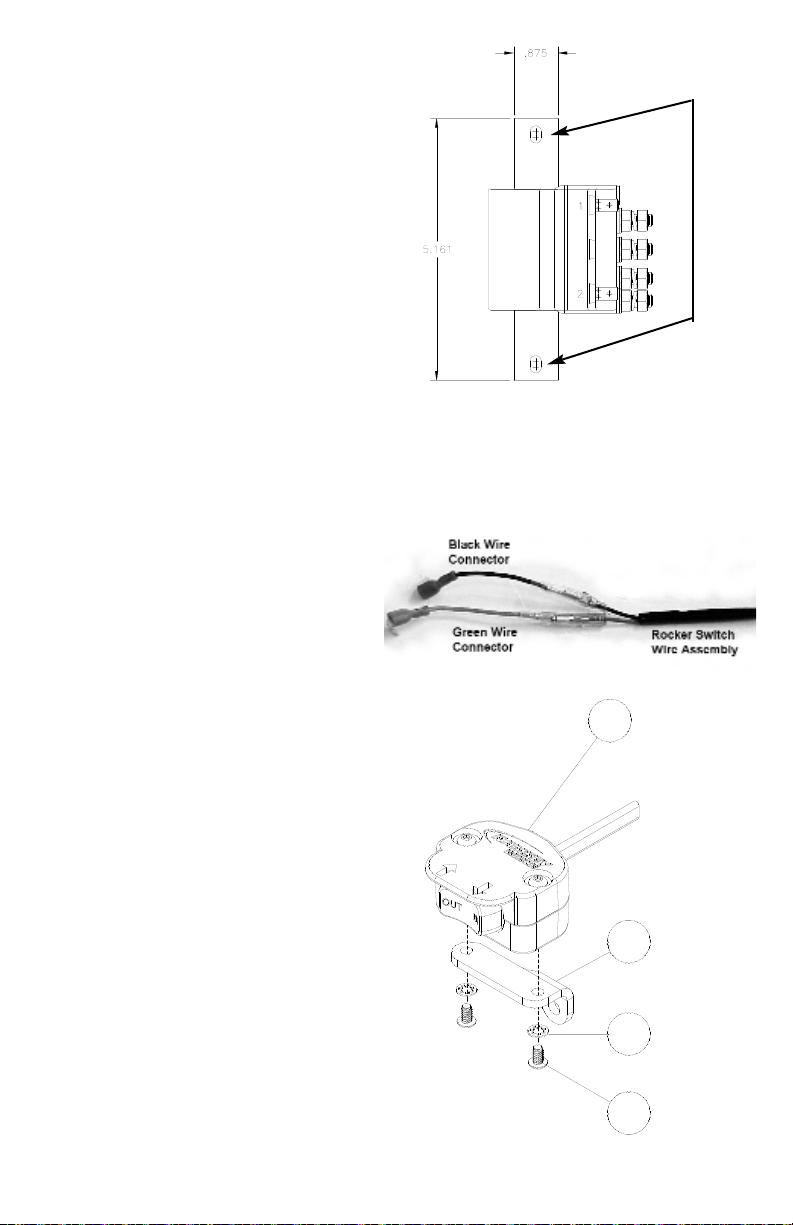

Installing the Rocker Switch

For clarification, see wiring schematic on

page 2.

1. Install green Wire Connector (item #1-

14) to green wire on Rocker Switch (item

#2) and black Wire Connector (item #1-

15) to black wire on Rocker Switch, as

shown at right.

2. The Rocker Switch assembly (item #2)

will be assembled with the two halves of

the housing already attached. Install the

Mounting Bracket (item #1-2) using (2)

#6 screws (item #1-4) and shake-proof

washers (item #1-7). See figure at right.

Tighten securely. Do not overtighten.

3

Mounting Hole Pattern:

Two 7/32” holes spaced

4.5” apart

1-2

2

1-7

1-4

Page 4

4

3. Install (2) Handle Bar Clamps (item #1-

3) around ATV handle bars at a convenient location. Use a 3/4” long #10 screw

(item #1-5) and #10 locknut (item #1-

11) to secure them. See figures below.

Secure loosely, do not tighten.

4. Install the Mounting Arm (item #1-1) to

the Handle Bar Clamps using a 7/8” long

#10 screw (item #1-6), shake-proof

washer (item #1-9), and locknut (item

#1-11). Install the shake-proof washer

between the handle bar clamps and the

mounting arm. See figures below. Do not

tighten.

5. Install the Mounting Bracket (with rocker

switch attached) to the Mounting

Arm Bracket using a 3/4” long

#10 screw, shake-proof washer,

and locknut. Install the shake-proof

washer between the mounting arm

bracket and the mounting bracket.

6. Tighten all screws for the handle

bar clamps and mounting brackets

securely, positioning the rocker

switch as desired.

7. Route the Rocker Switch wire down the

handle bars to where the solenoid is

installed. Turn the handle bars fully right

and left to ensure enough slack in the

wire. Make sure wire is not drawn taut

across any surface that could damage it.

Use cable ties to anchor wire. Do not

connect wires to solenoid yet.

8. Push ATV Accessory wire and red wire

from switch into plastic splice (item #1-

12). Fold splice clip over itself and snap

closed.

NOTE:

LONGER SCREW

1-5

1-6

1-9

1-11

1-1

1-5

1-3

1-11

Page 5

5

Connect Wiring to Solenoid

C

AUTION: TIGHTEN NUTS ON TERMINAL STUDS

TO

35-40 IN-LBS. (3-4 NM) TORQUE. DO

NOT OVER

-

TIGHTEN.

For clarification, see wiring schematic on

page 2.

1. Connect Red Battery Lead (Item #3-3)

between “A” terminal on Solenoid and

positive (+) vehicle battery terminal.

2. Connect Black Motor Lead (item #3-1)

between #2 terminal on motor and C

terminal on solenoid. Connect Black

w/Yellow Stripe Motor Lead (item #3-2)

between #1 terminal on motor and B

terminal on solenoid.

3. Connect Black Battery Lead (item #3-4)

to “E” terminal on Solenoid and route to

negative (-) vehicle battery terminal but

do not connect.

4. Plug black wire from switch into right terminal (terminal above black with yellow

stripe motor lead). Plug Green wire from

switch into left terminal (terminal above

black motor lead).

Finish Installation

1. Confirm that winch clutch is disengaged.

2. Connect negative (-) battery cable to

vehicle battery. Connect Black Battery

Lead from winch to negative (-) vehicle

battery terminal.

3. With ignition switch OFF, press Rocker

switch to “OUT”—winch should not

operate. If the winch does operate with

the ignition off, confirm that proper

accessory wire from ignition was spliced.

4. Spool a few feet of cable out by hand.

Engage winch clutch. Turn ignition switch

ON and press Rocker switch to “OUT”—

winch should spool cable out. If winch

does not operate with ignition on, check

wiring against the schematic on page 1.

5. If winch spools cable IN instead of OUT,

turn off ignition and reverse black and

green wires on solenoid.

Page 6

6

PARTS LIST

ITEM

NO

. QTY. PART NO.DESCRIPTION

1 1 257560 HARDWARE KIT (see below)

2 1 282065 ROCKER SWITCH

3 1 299724 SOLENOID WIRING KIT (see below)

4 1 251234 SOLENOID ASSY

5 1 257522 HARDWARE KIT (Not pictured)

Hardware Kit, as shown on the opposite page, consists of the following components (Extra

parts included with kit but not used in this assembly may be discarded):

ITEM NO

. QTY. DESCRIPTION

1-1 1 Mounting Arm Bracket

1-2 1 Mounting Bracket

1-3 2 Handle Bar Clamp Bracket

1-4 2 Screw #6-32NC x 1/4” Socket Head Black

1-5 4 Screw #10-24NC x 3/4” Truss Cross Recess Black

1-6 1 Screw #10-24NC x 7/8” Truss Cross Recess Black

1-7 2 Washer #6 Shake Proof

1-8 1 Washer #10 Flat Zinc

1-9 2 Washer #10 Shake Proof

1-10 2 Locknut #10-24NC Hex Zinc

1-11 3 Locknut #10-24NC Hex Black

1-12 1 Wire Splice

1-13 1 Cable Ties (pkg. of 12) [not pictured]

1-14 1 Wire Connector (to green)

1-15 1 Wire Connector (to black)

1-16 2 Tube Clamps

Solenoid Wiring Kit, as shown on the opposite page, consists of the following components:

ITEM NO

. QTY. DESCRIPTION

3-1 1 37” Motor lead - black

3-2 1 37” Motor lead - black w/yellow stripe

3-3 1 97” Battery lead - red

3-4 1 97” Battery lead - black

Page 7

7

3-Solenoid

Wiring Kit

3

1

2

4

3

9

8

1

5

4

11

6

10

2

7

1-Hardware Kit

2-Rocker Switch

4-Solenoid

14

12

15

Page 8

RAMSEY WINCH COMPANY

P.O. BOX 581510

TULSA, OK 74158-1510 USA

PHONE: (918) 438-2760

FAX: (918) 438-6888

visit us at http://www.ramsey.com

913403-0108-B

Limited Lifetime Warranty

Ramsey Winch offers a limited lifetime warranty for each new

Ramsey ATV winch against manufacturing defects in workmanship and materials on all manufactured components.

Warranty registration cards for each winch must be submitted

at the time of purchase, or within 90 days. Online registration

of your winch is available at www.ramsey.com.

All Ramsey mounting kits and other accessories carry a 1- year

limited warranty against defects in materials and workmanship.

This warranty is void if winch is used in commercial/industrial

applications other than front mount self recovery.

Electrical components consisting of motors, solenoids, wiring,

wire connectors, and associated parts carr y a limited 1-year

warranty.

The obligation under this warranty, statutory or otherwise, is

limited to the replacement or repair at the manufacturers factory, or at a point designated by the manufacturer, of such par t as

shall appear to the manufacturer, upon inspection of such part,

to have been defective in material or workmanship. This

Warranty does not obligate Ramsey Winch Company to bear

the cost of transportation charges in connection with the

replacement or repair of defective parts, nor shall it apply to a

product upon which repairs or alterations have been made,

unless authorized by the manufacturer, or for equipment misused, neglected, or improperly installed.

Important notice: To the fullest extent permitted by applicable law, the following are hereby excluded and disclaimed:

1. All warranties of fitness for a particular purpose;

2. All warranties of merchantability;

3. All claims for consequential or incidental damages.

There are no warranties that extend beyond the descrip-

tion that appears on the face hereof.

Some states do not allow the above exclusions or dis-

claimers in consumer transactions and as such this disclaimer/exclusion may not apply to your particular case.

To the extent such warranties of fitness for a particular

purpose or merchantability are deemed to apply to this

product, they exist only for so long as the express limited

warranty elsewhere set forth is in existence.

Ramsey Winch Company makes no warranty in respect to

accessories, same being subject to the warranties of their

respective manufacturers.

Ramsey Winch Company, whose policy is one of continuous

product improvement, reserves the right to improve any product through changes in design or materials as it may deem

desirable without being obligated to incorporate such changes

in products of previous manufacture.

If field service at the request of the buyer is rendered and the

fault is found not to be with Ramsey Winch Company’s product, the buyer shall pay the time and expense of the field representative. Bills for service, labor or other expenses which have

been incurred by the buyer without express approval or authorization by Ramsey Winch Company will not be accepted.

This Warranty gives you specific legal rights and you may also

have other legal rights which vary from state to state.

Loading...

Loading...