Page 1

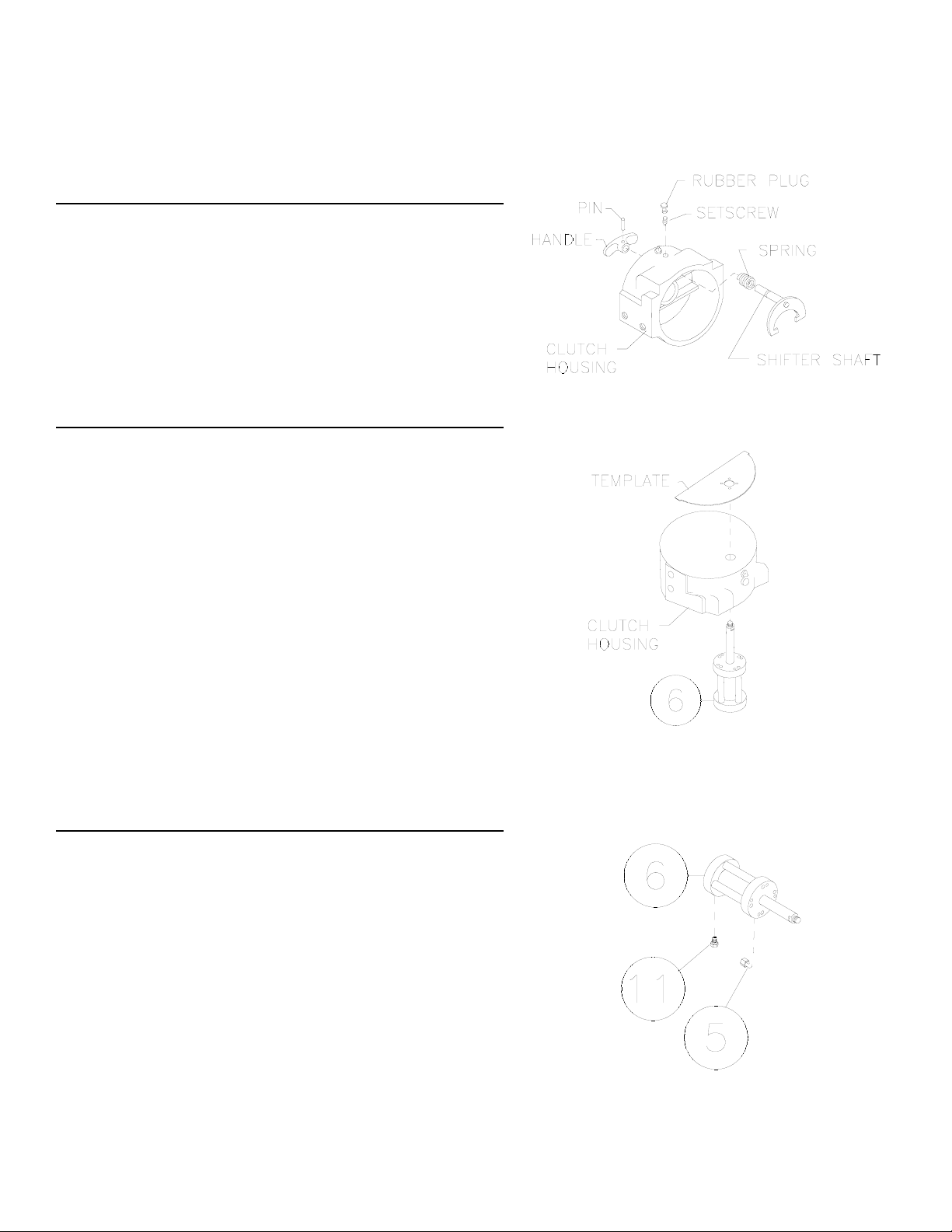

STEP 1

Remove winch assembly from mounting angle or

frame. Remove clutch housing assembly from winch.

Remove rubber plug and setscrew from clutch housing, discard rubber plug and setscrew. Drive pin from

handle and remove handle, spring and shifter shaft

from clutch housing. Discard spring, shifter shaft,

handle and pin.

STEP 2

Add holes to existing clutch housing:

Use the air cylinder as a guide for hole layout locations. This is accomplished by aligning the air cylinder (item #6) to the thru hole inside the clutch housing. Lower clutch housing (open end first) over the

air cylinder shaft. The end of the air cylinder shaft

should protrude through the closed end of the clutch

housing. Take template from page 5 and cut-out 1/2”

dia. hole. Lay template over clutch housing and air

cylinder shaft. Align the edges with the mounting

pads and clutch housing. Use a center punch at the

center locations of the four 5/32” (.156) diameter

holes to mark housing. Remove template and air

cylinder. Use 5/32” (.156) diameter drill to drill thru

housing at (4) center punched locations.

STEP 3

Air cylinder Sub-up:

Apply thread sealant to threads of elbow fitting (item

#5) and threads of breather vent (item #11). Attach

elbow fitting (item #5) to port at shaft end of air cylinder (item #6), pay attention to position the end of the

elbow fitting 180 degrees from the shaft, as shown.

Attach the breather vent (item #11) to the port at the

other end of the air cylinder.

1

912585-0905-B

Installation Instructions for Air Shifter Kit #256103

Page 2

STEP 4

Air cylinder to clutch housing sub-up:

Insert shaft of air cylinder through hole in shim (item #13),

then insert shaft of air cylinder (item #6) into hole of clutch

housing, as shown. Line up holes of air cylinder and shim

to holes drilled previously in clutch housing. Pay attention

to allow flat portion of shim to be at the top to provide

clearance between the letters on the clutch housing and

the air cylinder. Install the bottom 2 socket hd. capscrews

(item #2) with lockwashers (item #4) from inside of the

clutch housing and torque to 28 in.lbs. each, so that the

shim will remain tight against the air cylinder and not allow

it to pivot. Install the top 2 remaining capscrews and lockwashers and torque to 28 in.lbs. each. Place spring (item

#14) over shaft and place yoke (item #1) over threads at

end of air cylinder shaft. While holding the air cylinder

shaft at the wrench flats tighten down the flex locking nut

(item #3), torque to 170 in.lbs.

STEP 5

Clutch housing assembly to winch:

Apply grease to keys and end of shaft. Place clutch housing over end of drum shaft. Pull jaw clutch upward, toward

clutch housing, enough to allow yoke, in clutch housing, to

fit properly in groove around jaw clutch. Air may have to

be applied to force housing down onto drum. Reinstall

winch into mounting frame.

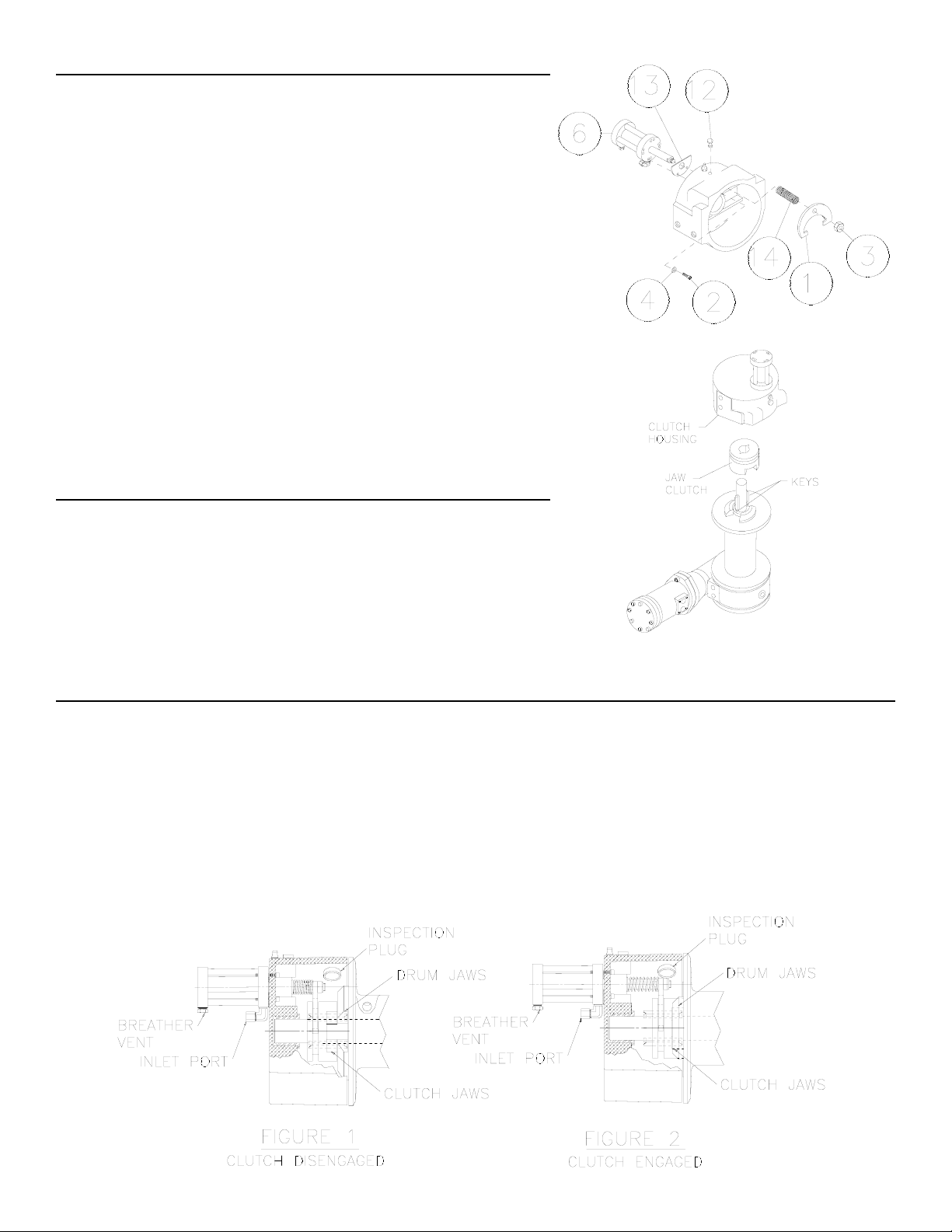

STEP 6

Verify clutch ENGAGED and DISENGAGED positions:

Hook up air to inlet port of air cylinder.

Apply air pressure (60-125 psi) to disengage clutch. Rotate drum by hand to verify free spool.

Remove inspection plug, rotate drum until clutch jaws line up with drum jaws. Remove air pressure

so clutch jaws rest against drum jaws (See FIGURE 1). Rotate drum and observe if clutch jaws

engage fully with drum jaws (See FIGURE 2). Repeat three times.

Replace inspection plug.

2

Page 3

STEP 7

Winch clutch operation and data tag modifications:

Clutch operations decal (item #9) must be affixed over clutch operation portion of data tag on winch.

Warning decal (item #10) must be affixed over warning portion of tag on winch.

The clutch is spring loaded for engagement when air pressure is removed from air shifter. Verify air

shifter control valve lever position for engaged position. The clutch engagement tag (item #7) must

be mounted as near as possible to air shifter control lever in the ENGAGED position.

The clutch is dis-engaged by applying 60-125 psi air pressure to air shifter. Verify air shifter control

valve lever position for dis-engaged position. The clutch dis-engaged tag (item #8) must be mounted

as near as possible to air shifter control lever in the DIS-ENGAGED position.

Ram-Lok®Air-Shifter Clutch Operations

The Ram-Lok

®

air-shifter clutch allows rapid unspooling of the cable, from cable drum, for hooking

onto the load. The clutch is operated by an air cylinder as follows:

TO DISENGAGE CLUTCH, run the winch in the reverse (reel out) direction until the load is off

the cable. Apply 60-125 PSI to inlet port fitting of air cylinder.

TO ENGAGE CLUTCH, remove air pressure from air cylinder. Run the winch in reverse until

the cable drum starts turning. The plastic plug in top of clutch housing may be removed, for

inspection of clutch to assure total engagement. After the clutch is fully engaged, the winch is

ready for winching in the cable.

3

Page 4

PARTS LIST FOR KIT #256103

ITEM NO.

QTY. PART NO. DESCRIPTION

1 1 370043 YOKE-SHIFTER

2 4 416198 SCREW #6-32 NC X 1 LG. HX.SOC.HD.

3 1 418044 NUT 3/8-16NC FLEX-LOK

4 4 418136 LOCKWASHER #6 MED.SECT.

5 1 432033 FITTING-ELBOW

6 1 433021 AIR CYLINDER

7 1 434385 TAG-CLUTCH ENGAGED

8 1 434386 TAG-CLUTCH DISENGAGED

9 1 434388 DECAL-CLUTCH AIR SHIFTER

10 1 434389 DECAL-AIR SHIFTER WARNING

11 1 456038 FITTING-VENT BREATHER

12 1 472012 PLUG-RUBBER

13 1 488012 SHIM-AIR SHIFTER

14 1 494053 SPRING

4

Page 5

Loading...

Loading...